Large gantry polar coordinate CNC gear compound chamfering machine tool

A polar coordinate and chamfering technology, which is applied in the field of large-scale gantry polar coordinate CNC gear compound chamfering machine tools, can solve the problems of not being able to meet the chamfering of the tooth direction, the profiling head is easy to wear, and affects the machining accuracy, etc., to achieve automatic tooth groove alignment Medium, avoid turning over and secondary clamping, high chamfering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

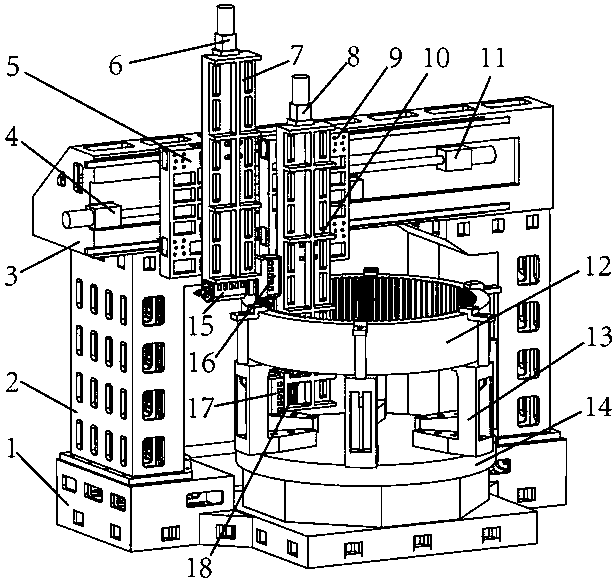

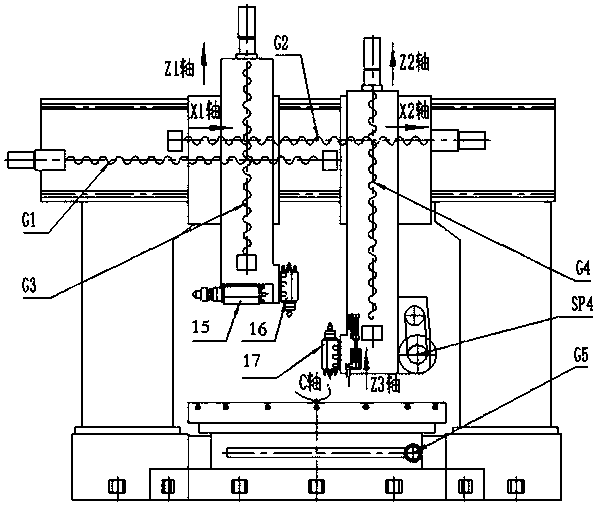

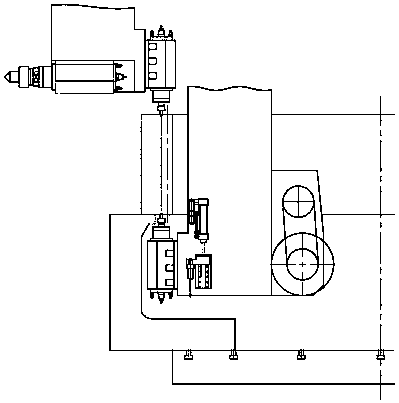

[0029] Below in conjunction with accompanying drawing, technical content of the present invention is described:

[0030]A large-scale gantry polar coordinate CNC gear compound chamfering machine tool, which is characterized in that it is based on the polar coordinate machining theory and the CNC envelope principle, and uses a high-speed rotating carbide milling cutter to realize both sides of the tooth profile of the inner / outer straight / helical gears Composite chamfering of the end face, chamfering on both sides of the tooth direction at the same time, and polishing the burrs on the root and corner of the tooth; the composite chamfering machine tool includes a bed 1, a column 2, a beam 3, a rotary table 14, and an X1 shaft diameter Axial feed system 4, X2 axis radial feed system 11, Z1 axial feed system 6, Z2 axial feed system 8, C-axis transmission worm gear pair G5, polishing wheel SP4, Z3 axis online measuring head system 18 and Chamfering spindle system, the chamfering sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com