Car mold platen groove chamfer cutter

A technology for automobile molds and pressure plate grooves, which is applied to milling cutters, manufacturing tools, milling machine equipment details, etc., and can solve problems such as unevenness, low efficiency, and aesthetic impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

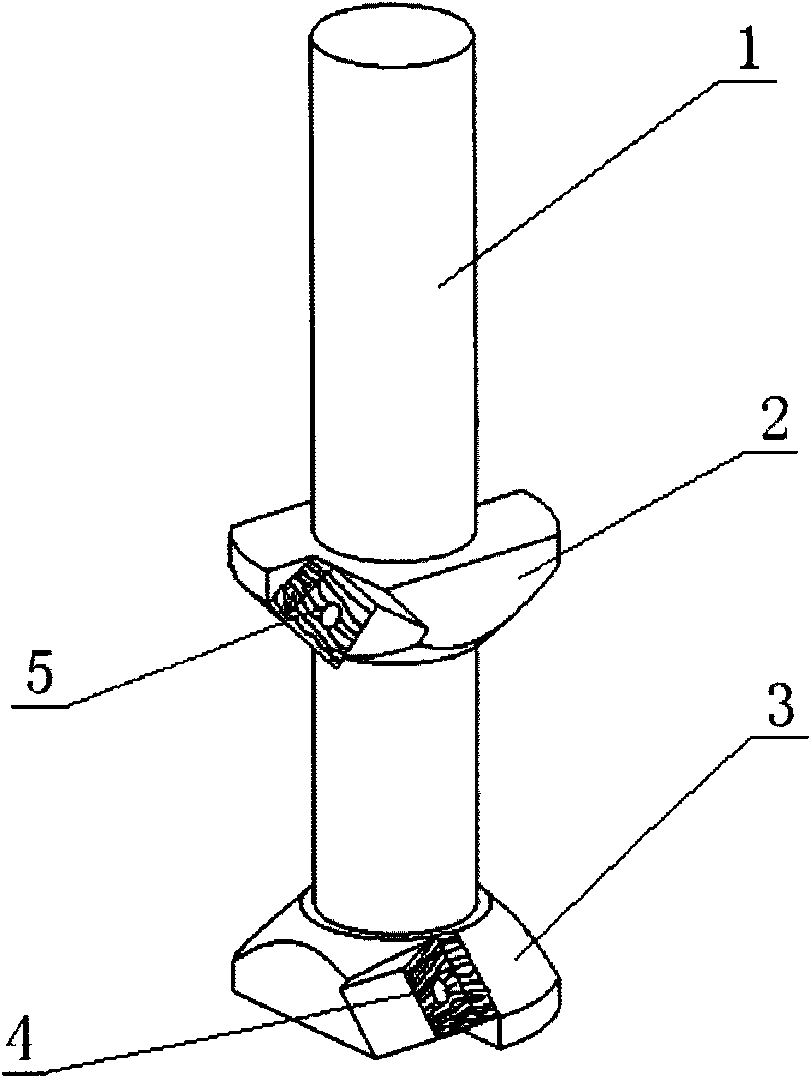

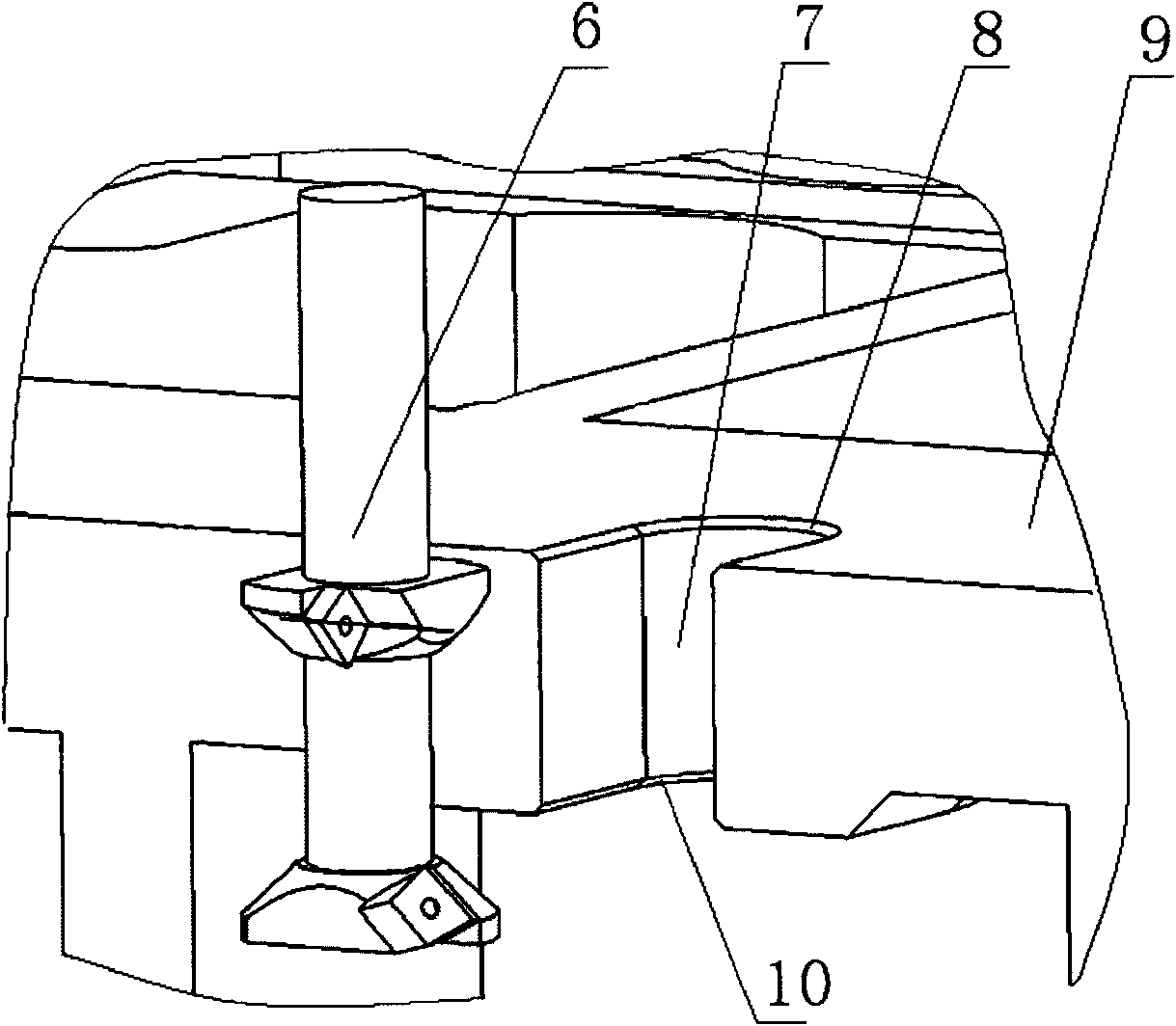

[0012] Such as figure 1 , figure 2 As shown, the chamfering knife for the pressure plate groove of the automobile mold includes a knife bar 1, a lower blade holder 3 at the lower end of the knife bar 1, an upper blade holder 2 in the middle of the knife bar 1, an upper blade 5 and a lower blade 4, and the upper blade 5 The number is two, the number of the lower blades 4 is two, the two upper blades 5 are fastened on the upper blade holder 2 by screws, and the two lower blades 4 are fastened on the lower blade holder 3 by screws , the height interval of the lower blade holder 3 and the upper blade holder 2 is adapted to the height interval of the upper chamfer 8 of the pressure plate groove and the lower chamfer 10 of the pressure plate groove, that is, it is adapted to the thickness of the pressure plate groove, and the thickness of the pressure plate groove is different. The height interval of the lower blade holder 3 and the upper blade holder is just different, in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com