Chamfering machine for regular polygon-shaped steel plate

A regular polygon and chamfering machine technology, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problem that the processing efficiency of regular polygon steel plates is not high, which affects the processing cost and processing of regular polygon steel plates. Quality and other issues, to achieve the effect of saving manpower and material resources, high degree of automation, and improving chamfering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

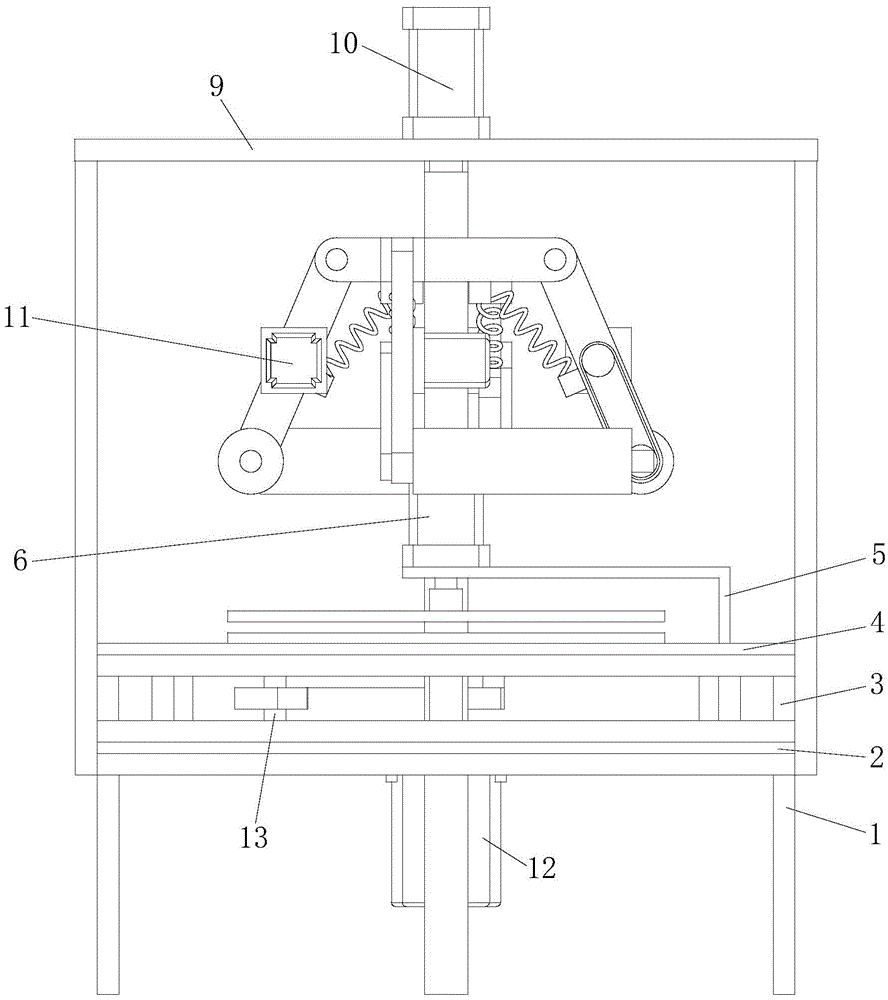

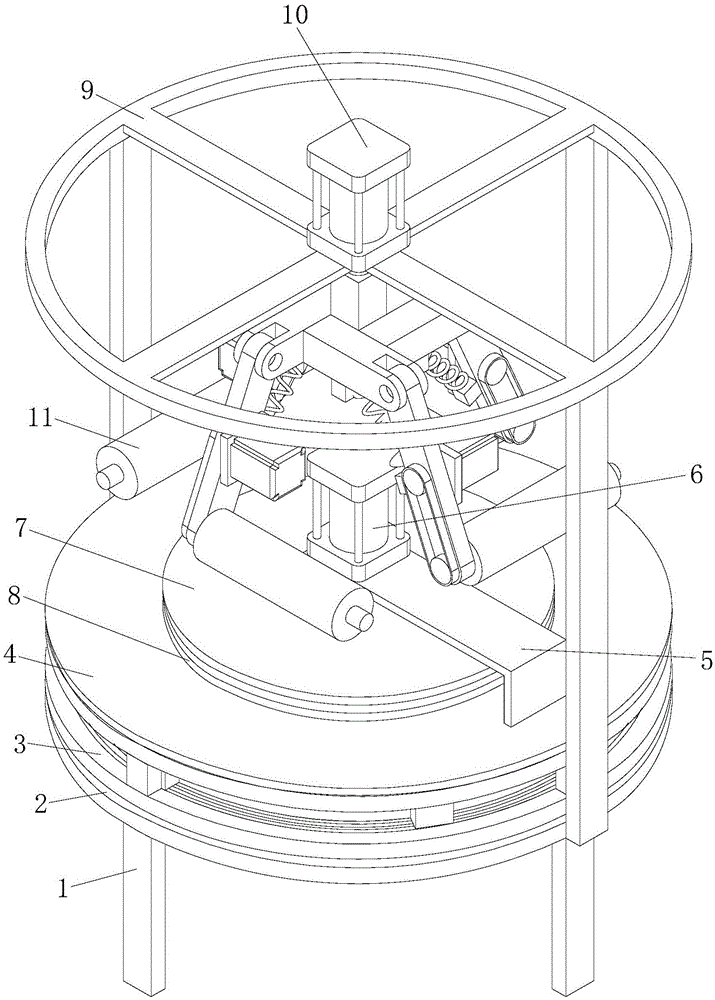

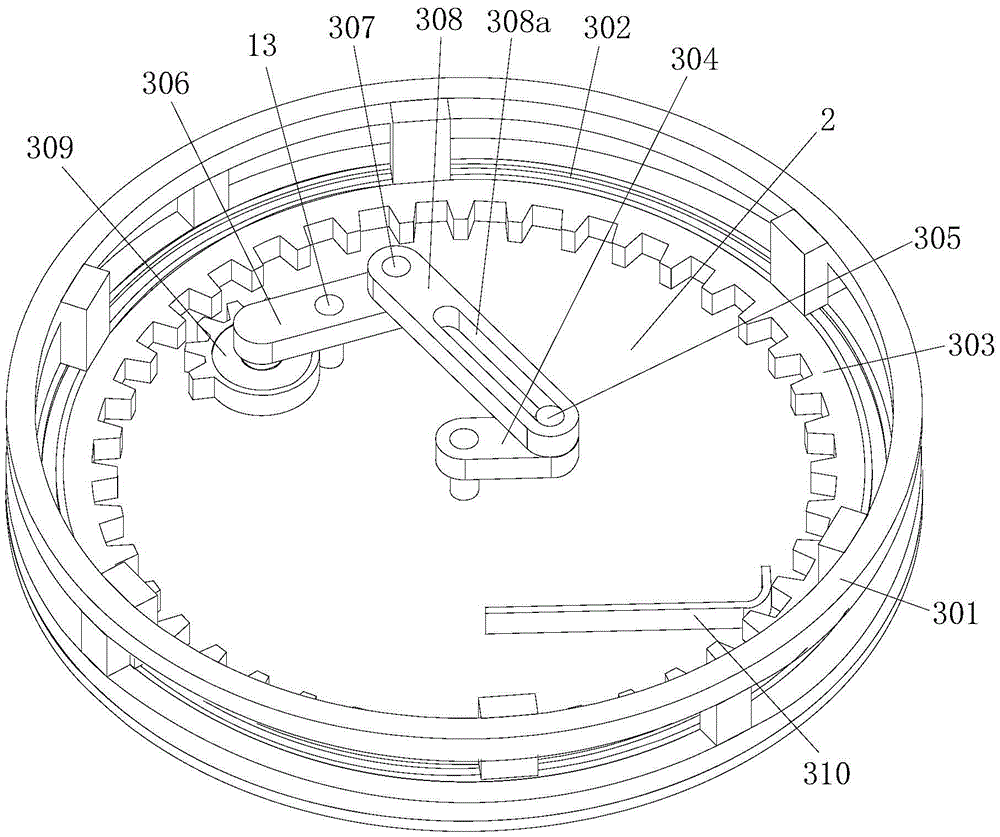

[0019] Such as Figure 1 to Figure 5 As shown, a chamfering machine for a regular polygonal steel plate includes a support frame 1, a lower mounting plate 2 is fixed on the upper end of the support frame 1, an intermittent drive device 3 is fixed on the upper end of the upper mounting plate 4, the intermittent The upper end of the driving device 3 is fixed with an upper mounting plate 4, the upper end of the upper mounting plate 4 has a fixed seat 5, the upper end of the fixed seat 5 is equipped with a No. 1 cylinder 6, and the lower end of the No. 1 air cylinder 6 is fixed with an upper press. Tight block 7, the top of desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com