Automatic chamfering machine for coil rod material head

A technology of chamfering machine and wire rod is applied in the field of chamfering machine to achieve the effect of saving feeding time, reducing labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

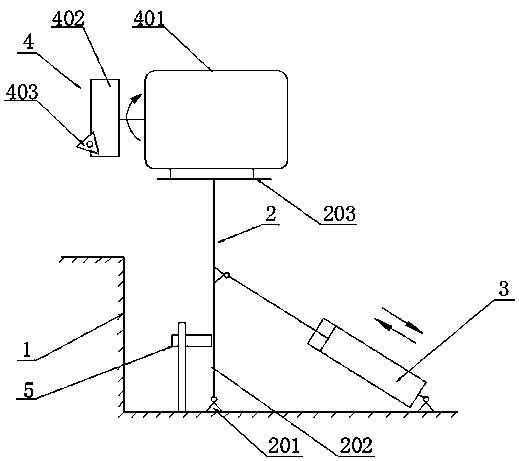

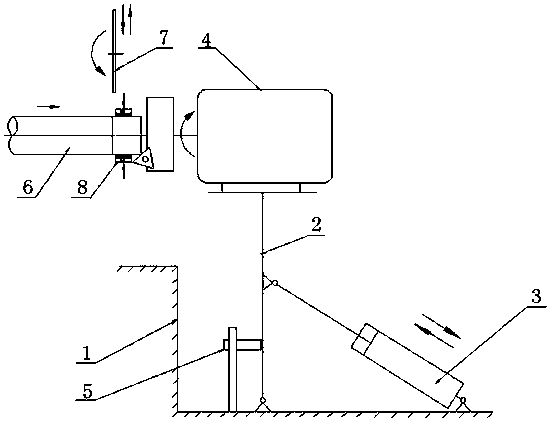

[0011] Such as figure 1 As shown, an automatic chamfering machine for round wire material head includes a frame 1, a support seat 2, a cylinder 3, a chamfering device 4 and a sensor 5; the frame 1 is welded by a plurality of square tubes, fixed on the On the discharge end of the horizontal material rack; the support seat 2 is composed of a bearing seat 201, a vertical rod 202, and a base plate 203. The rotating shaft is connected, the upper end of the vertical rod 202 is connected with the base plate 203, and the vertical rod 202 can rotate around the bearing seat 201; the working table of the frame 1 is provided with a cylinder seat, and the connection end of the cylinder 3 is hinged with the cylinder seat through a pin shaft, thereby realizing The cylinder 3 is hinged on the frame 1; the piston rod in the cylinder 3 is hinged with the middle section of the vertical rod 202 through a pin; the cylinder 3 is manually controlled by a manual valve; Structure; the reducer 401 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com