Production equipment and production process for chamfering pin

A technology of production equipment and production process, which is applied in the field of production equipment and production technology with chamfered pins, and can solve problems such as unreasonable production process of pins, low production efficiency of pins, and inability to meet the needs of actual production. , to achieve the effects of improving manufacturing efficiency, realizing automated manufacturing, and optimizing manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

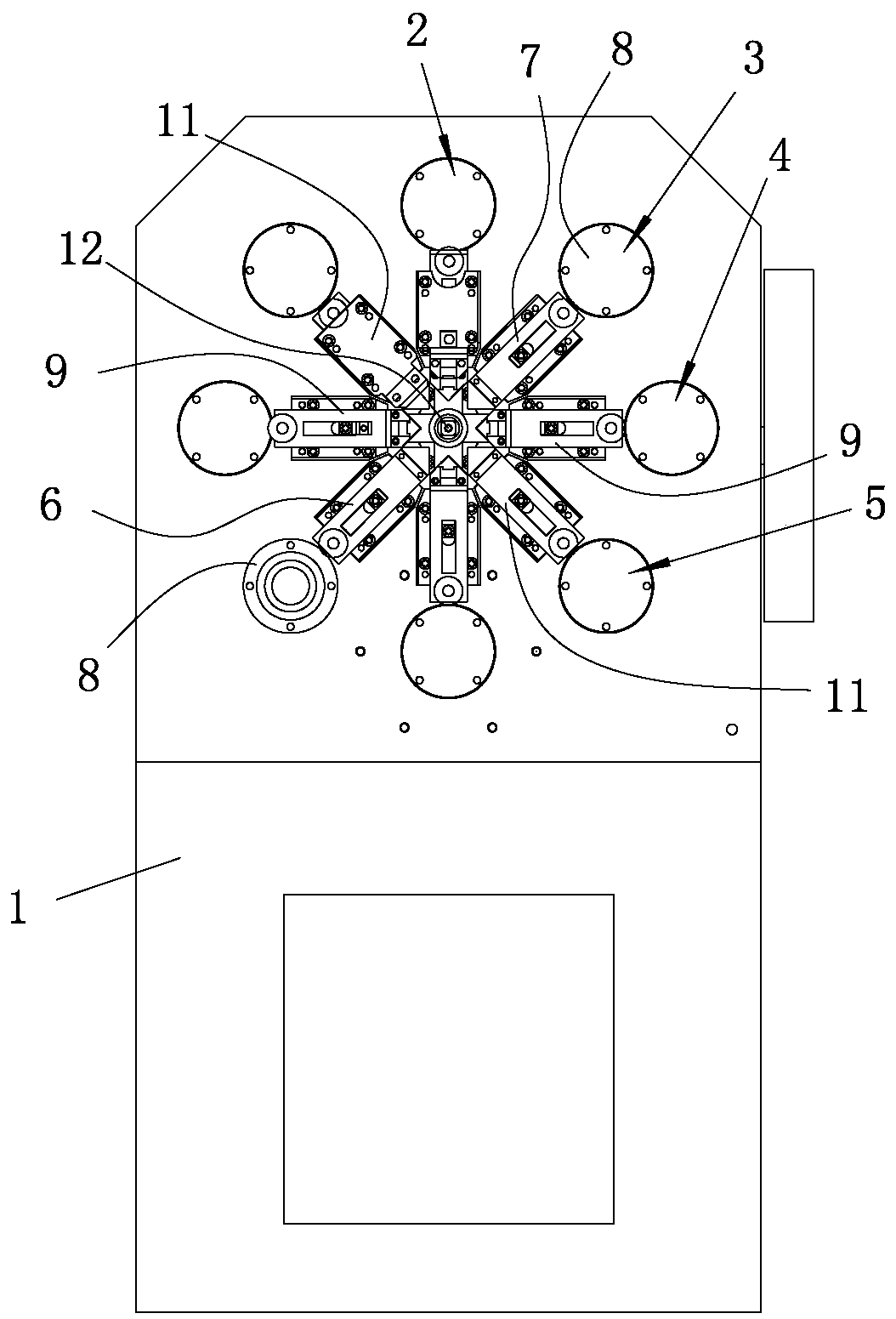

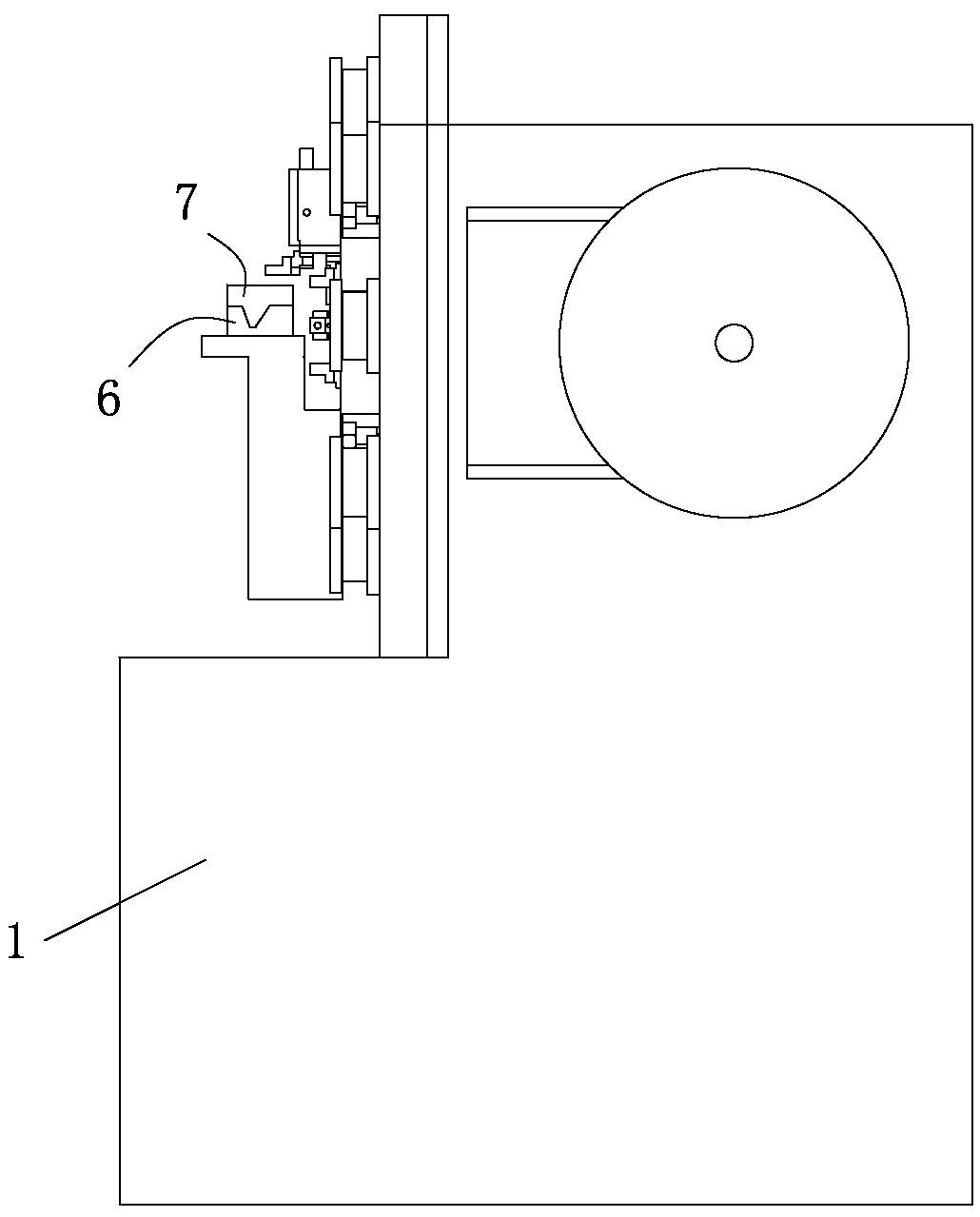

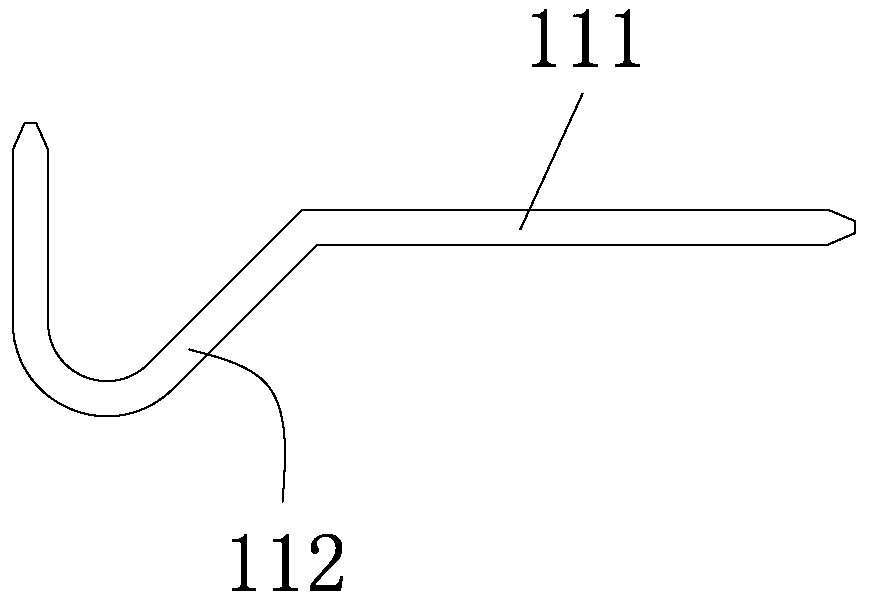

[0032] refer to Figure 1-Figure 3 , A production equipment with chamfered pins of the present invention includes a machine 1, a conveying mechanism 2, a forming mechanism 3, a chamfering mechanism 4 and a cutting mechanism 5 installed and arranged on the machine 1. The conveying mechanism 2 is used for Drive the external bar material to move, the bar material is straight, and the conveying mechanism 2 drives the bar material to move automatically; the forming mechanism 3 includes a relatively close or far away die 6 and a punch 7. The punch 6 and the punch 7 cooperate with each other so as to A bending part 112 is formed on the bar conveyed by the conveying mechanism 2, and the bending part 112 is roughly V-shaped. Of course, the bending part 112 can also be C-shaped, U-shaped or W-shaped; the chamfering mechanism 4 is forming Chamfering is performe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com