Patents

Literature

87results about How to "Realize automatic cut off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Video stream transmission method and device

ActiveCN103731758AAvoid video streamingAchieve stabilityTransmissionSelective content distributionIp addressTransmission performance

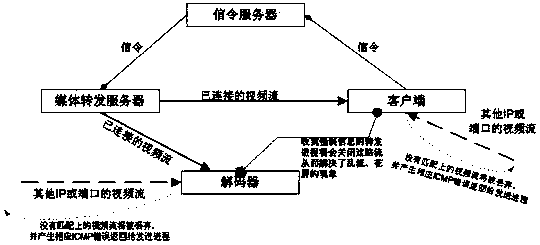

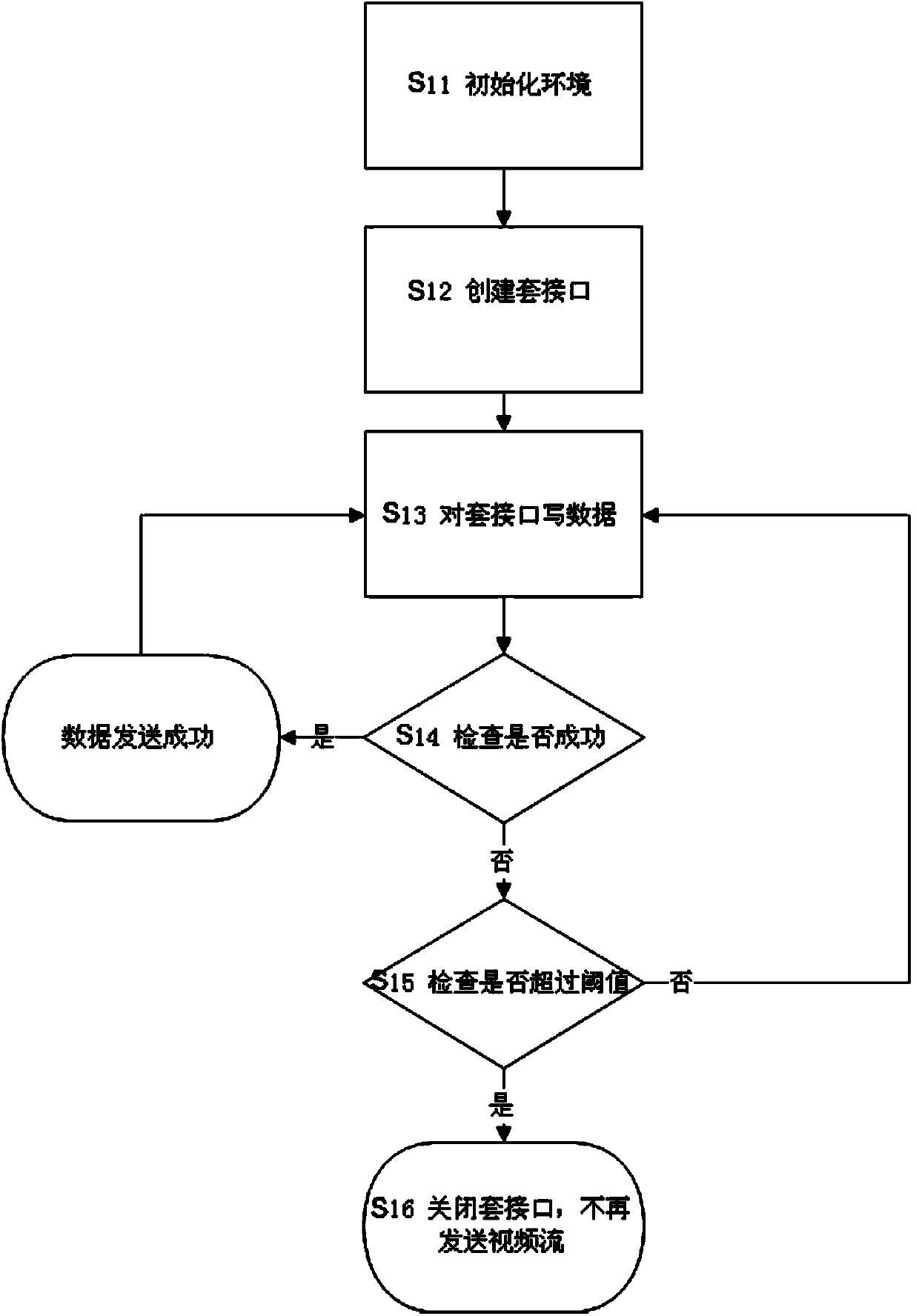

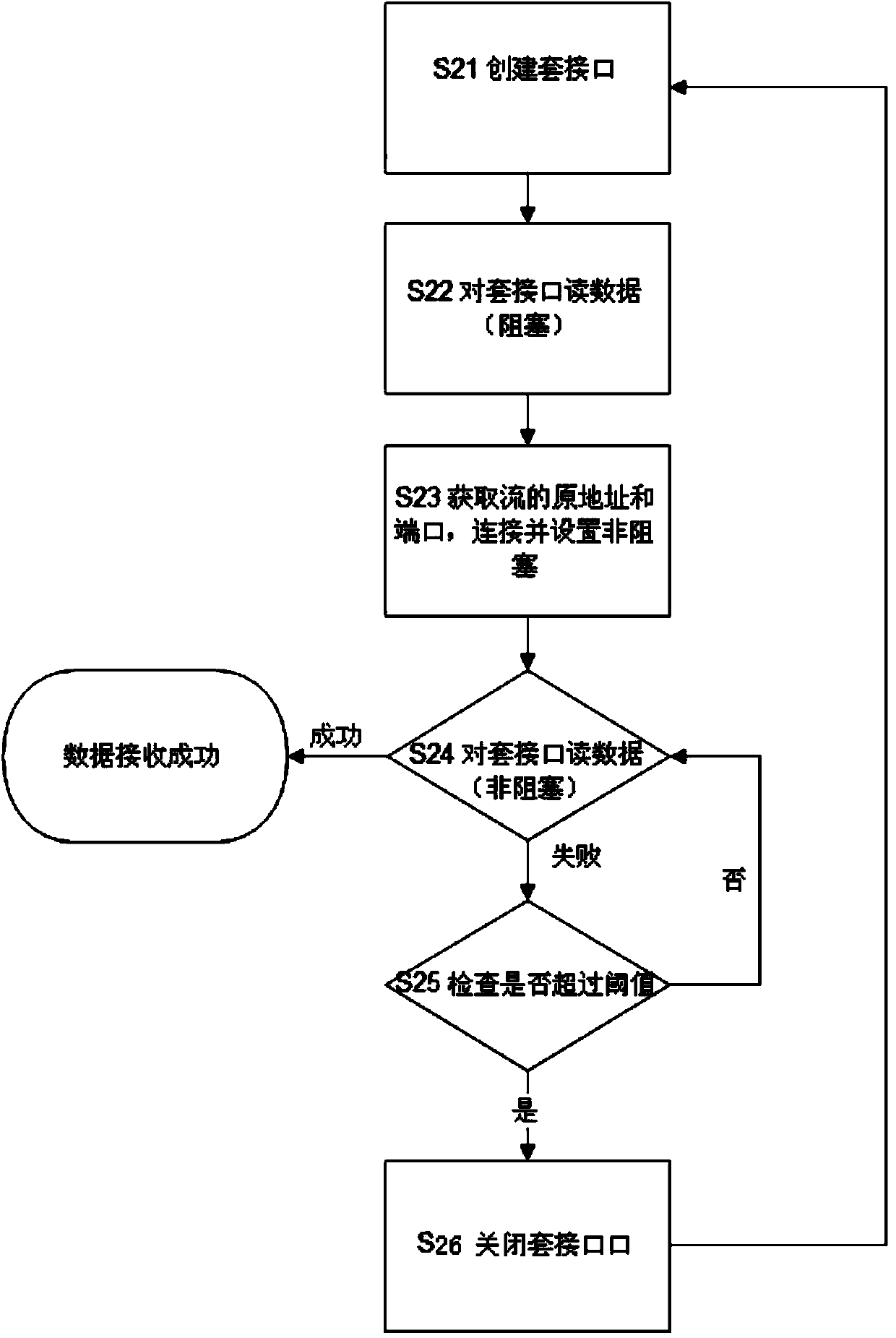

The invention relates to a video stream transmission method and device. The video stream transmission method includes the steps of building a UDP socket, setting whether inner core detection has a mistake which can be immediately known or not, recording the IP address and the port number of an opposite end, then immediately executing the calling procedure, detecting the mistake in the calling procedure, setting a threshold value according to the field network condition to remove the possibility of erroneous judgment on video stream interruption caused by the network environment, and when a value is larger than the preset threshold value, closing the socket of a video stream, enabling the video stream to be not sent or received. According to the video stream transmission method and device, phenomena such as video series flow and video density current can be effectively avoided, the video stream transmission performance is improved, and the network transmission pressure is reduced.

Owner:湖南欧迈特网络科技有限公司

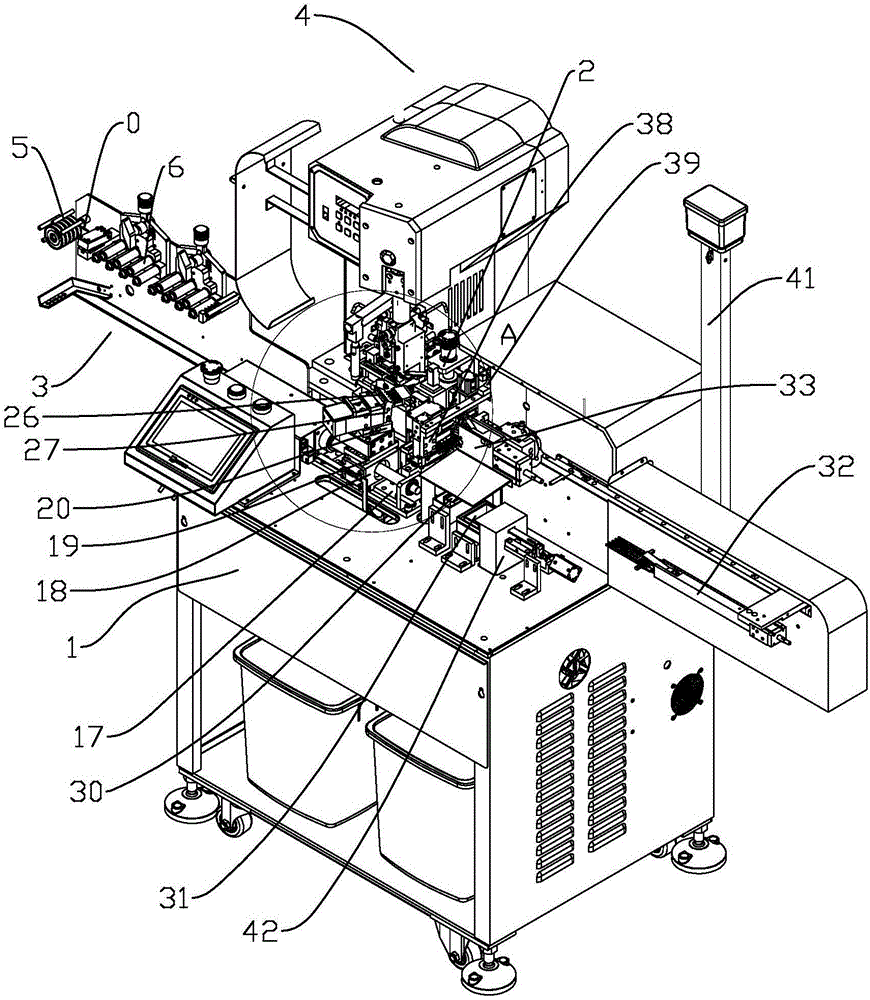

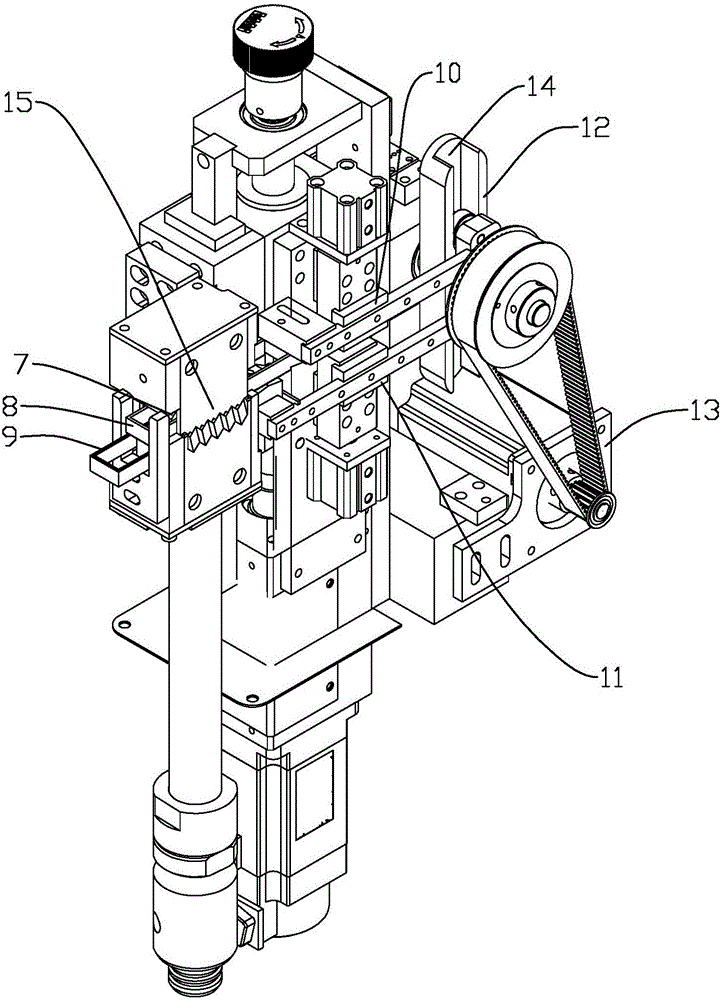

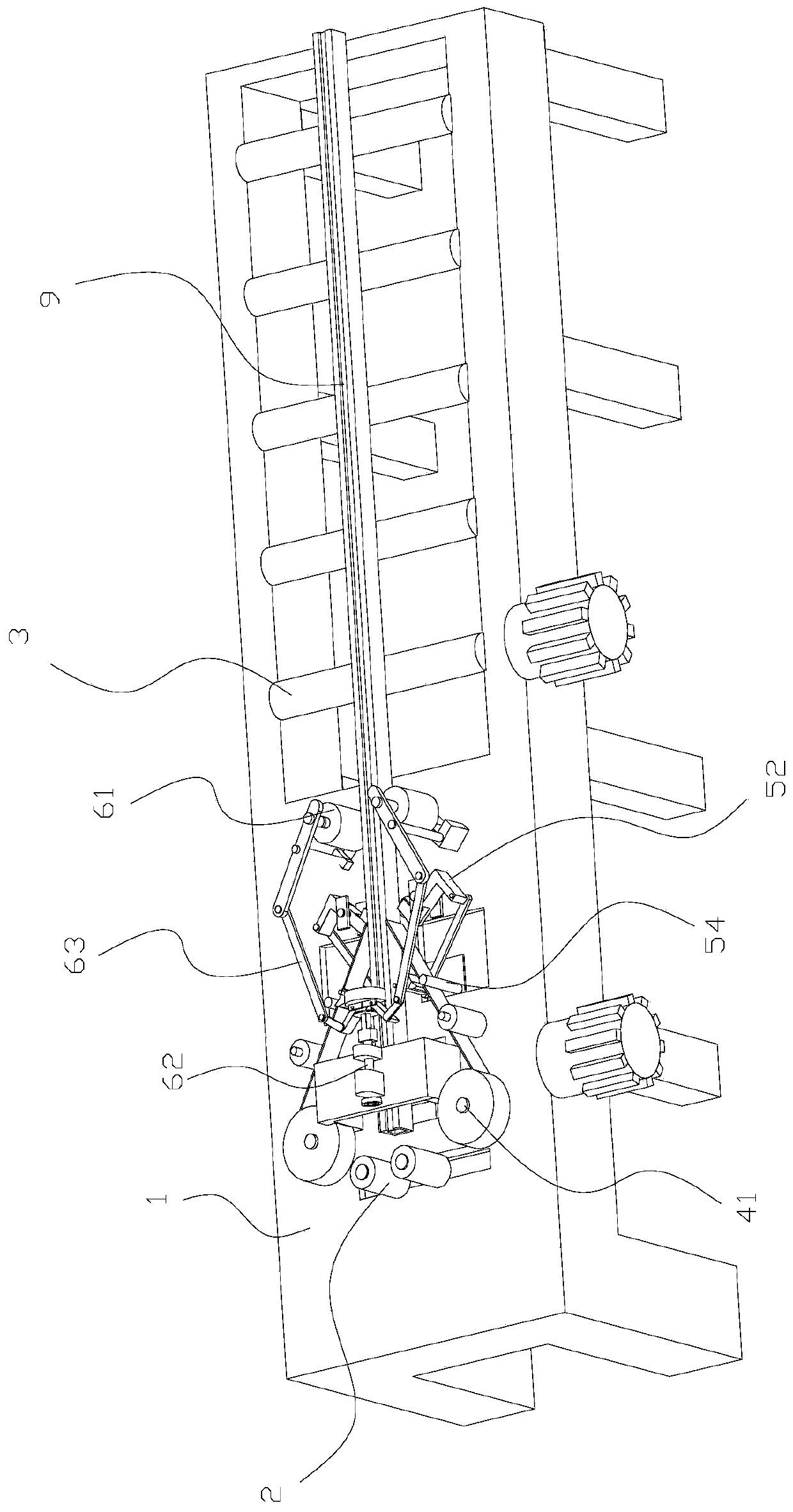

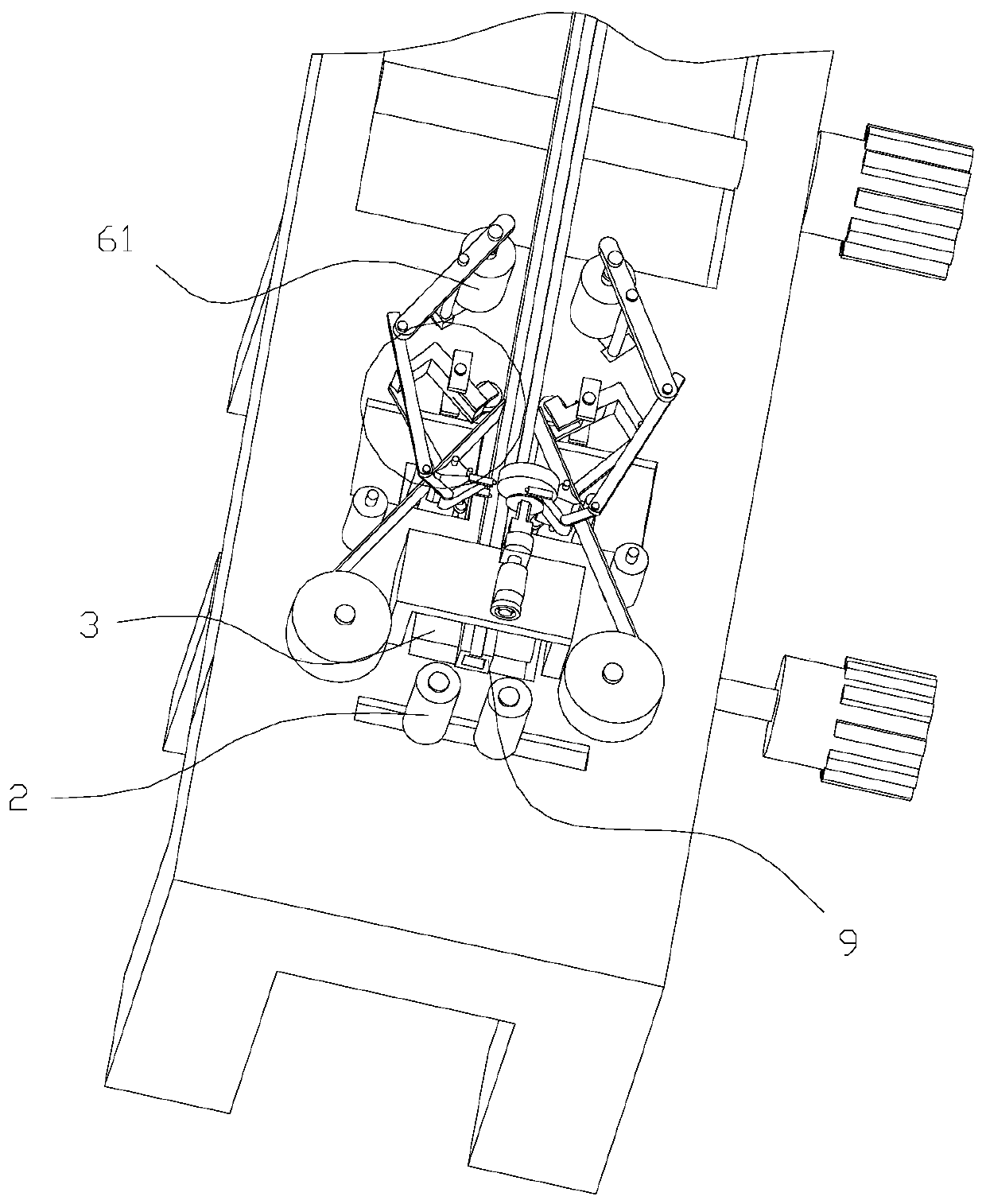

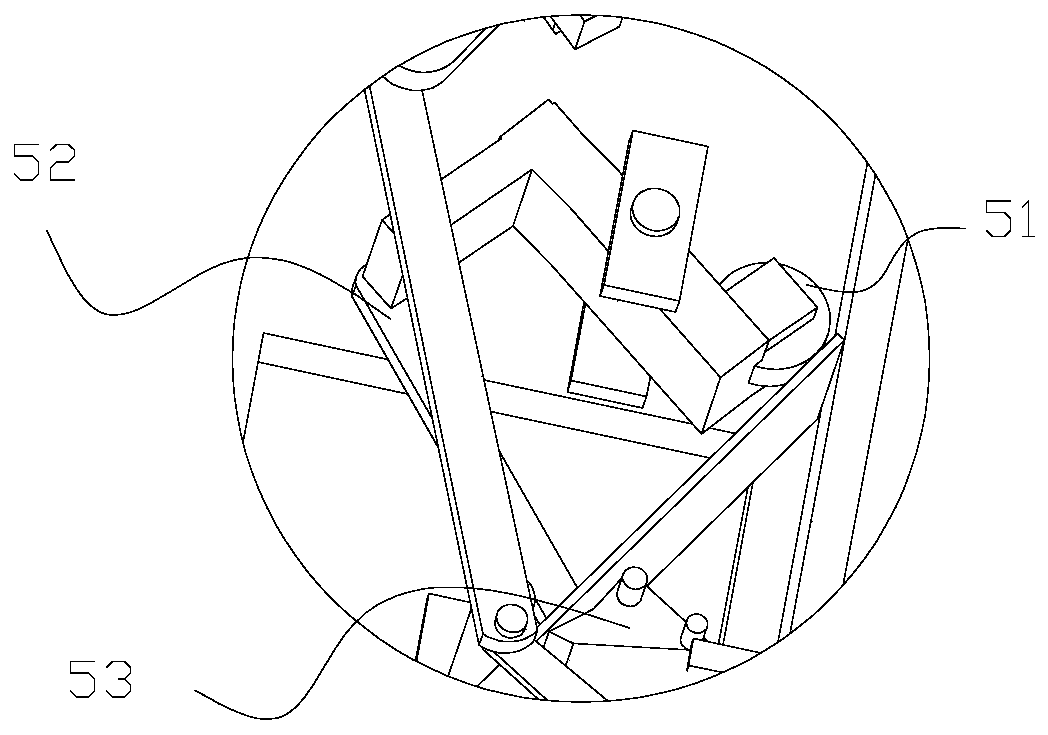

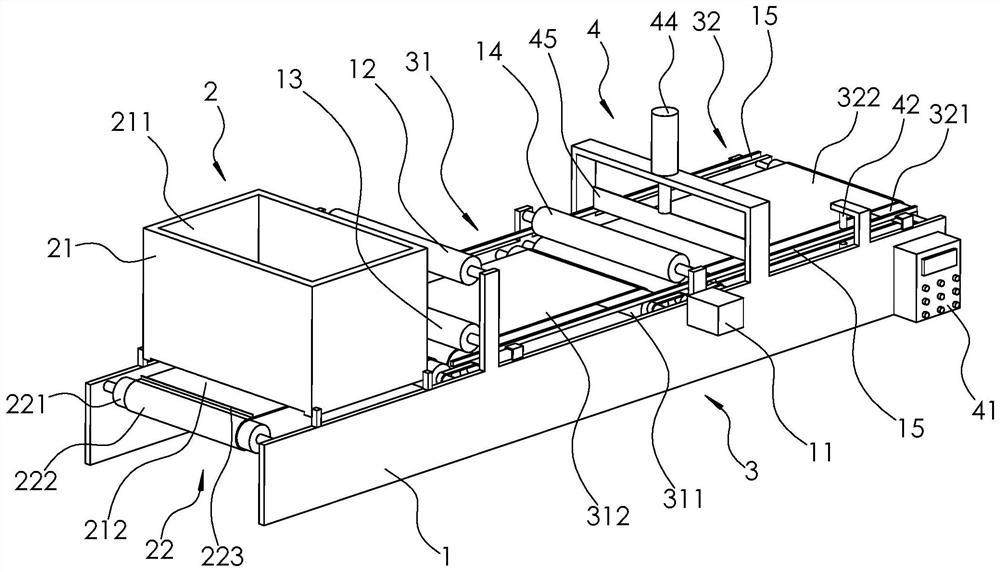

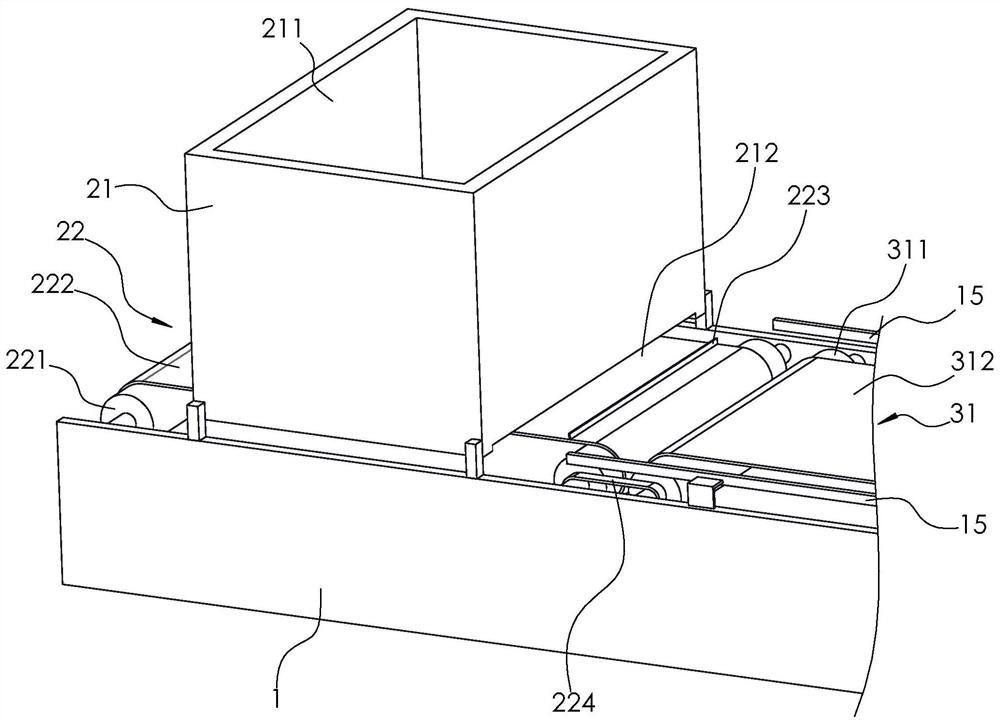

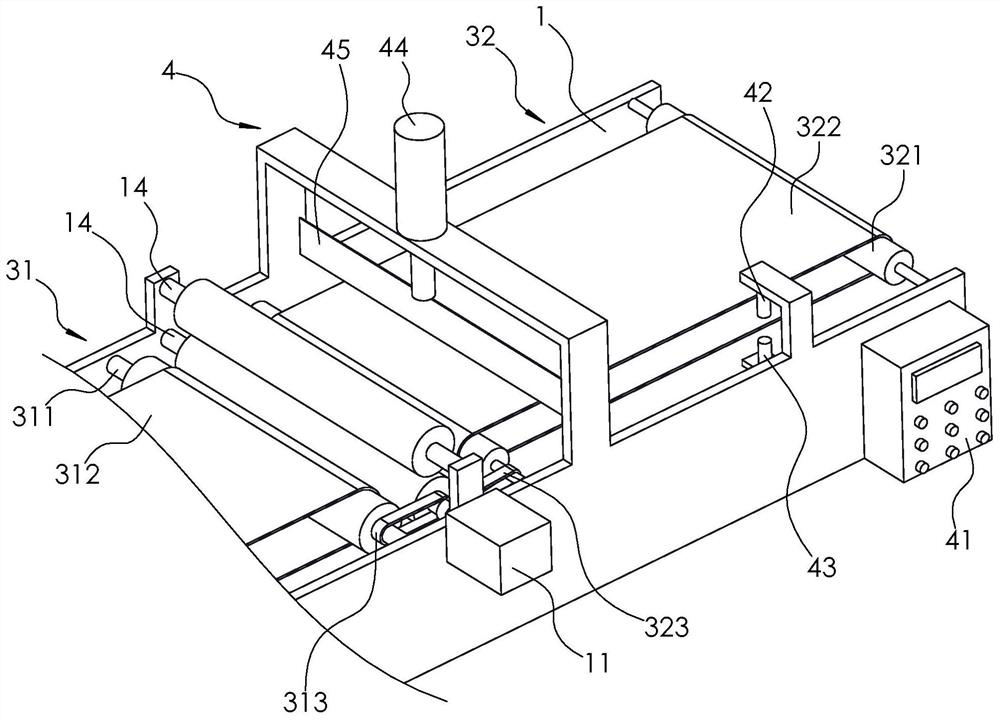

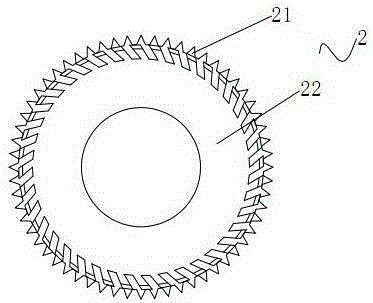

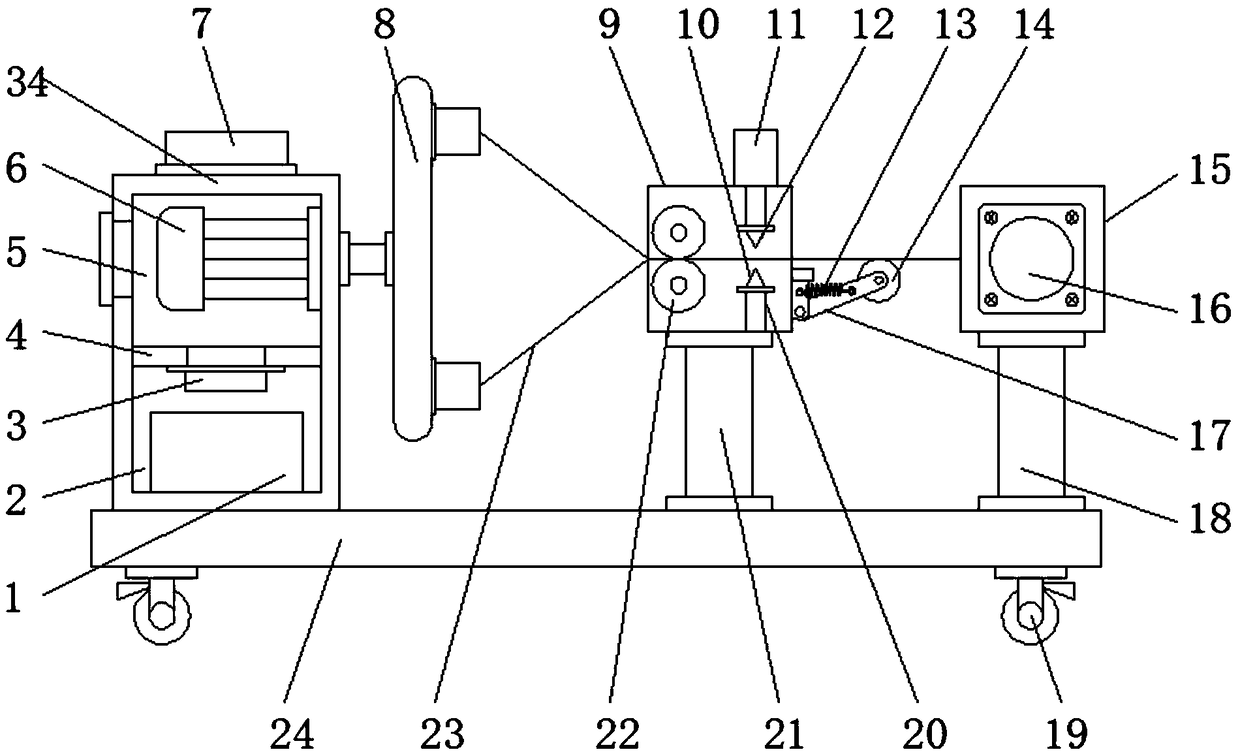

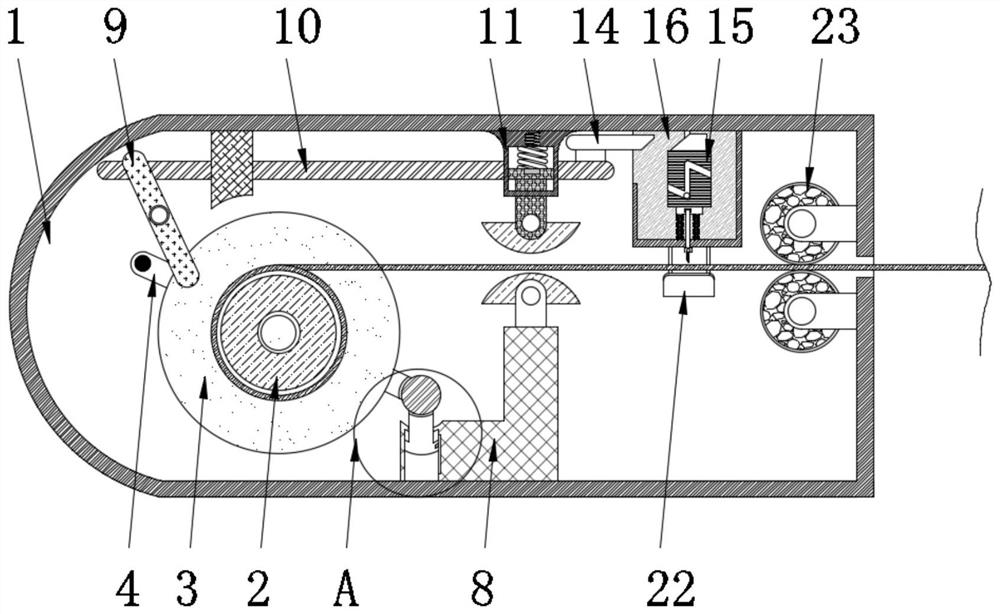

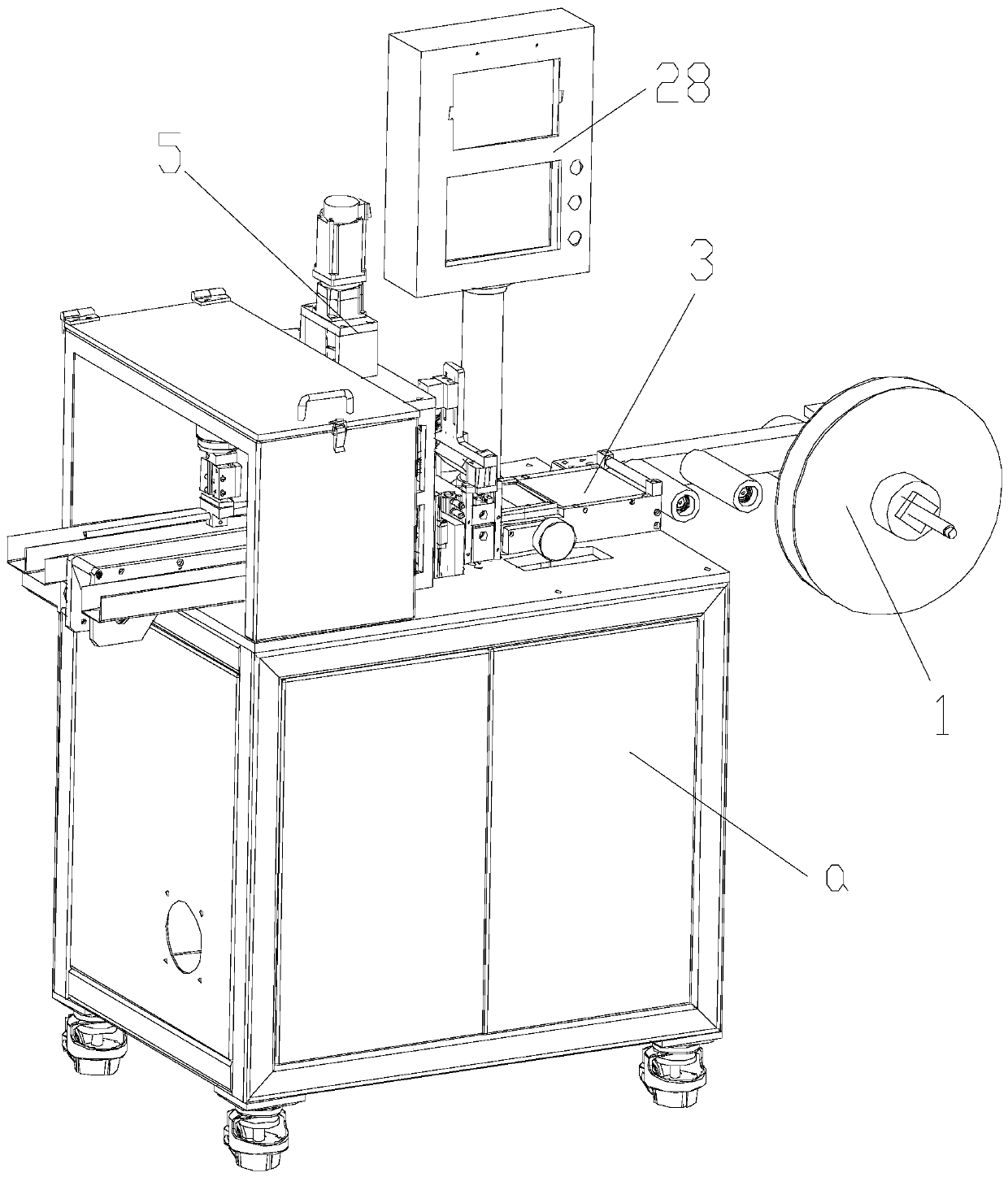

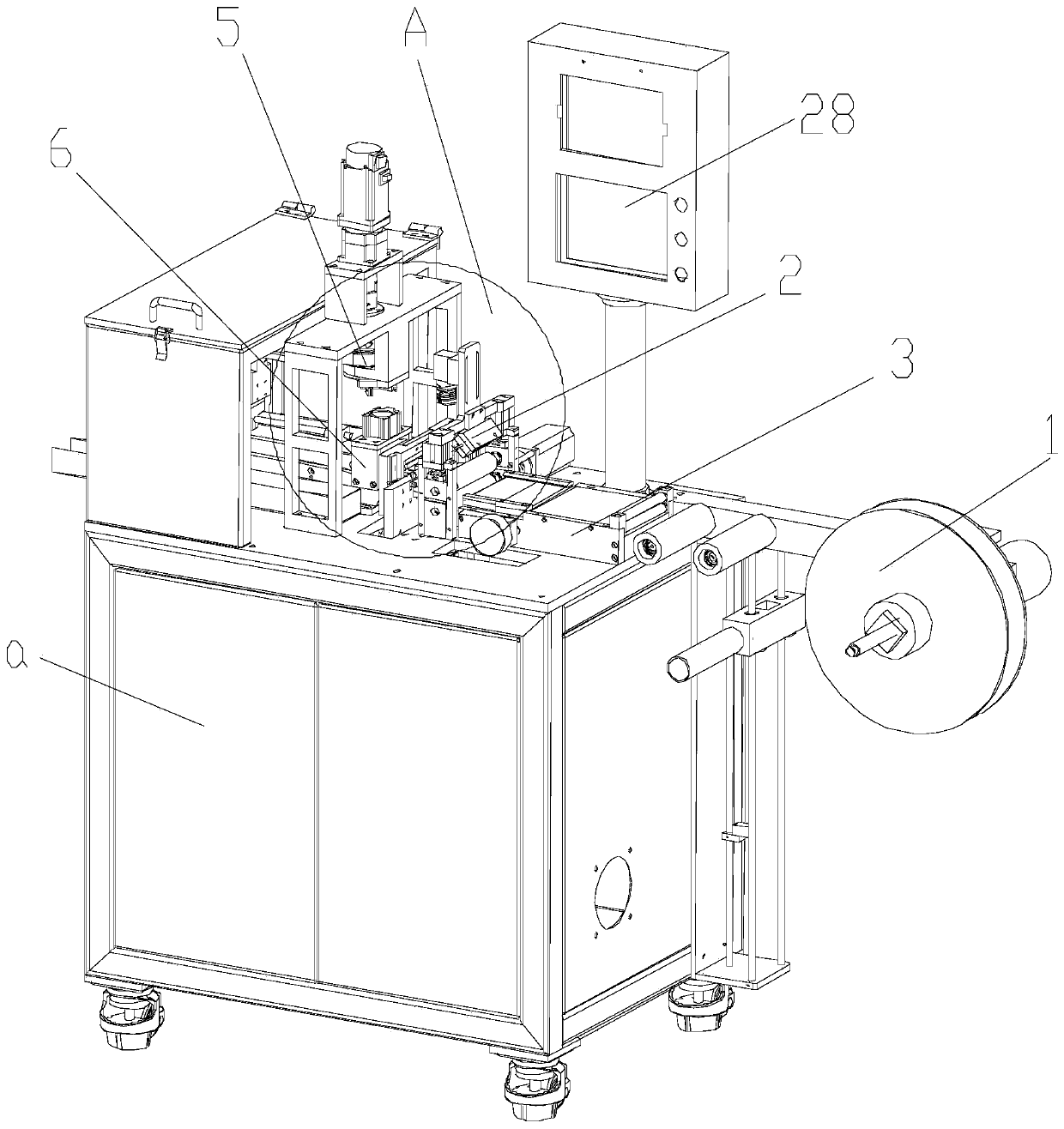

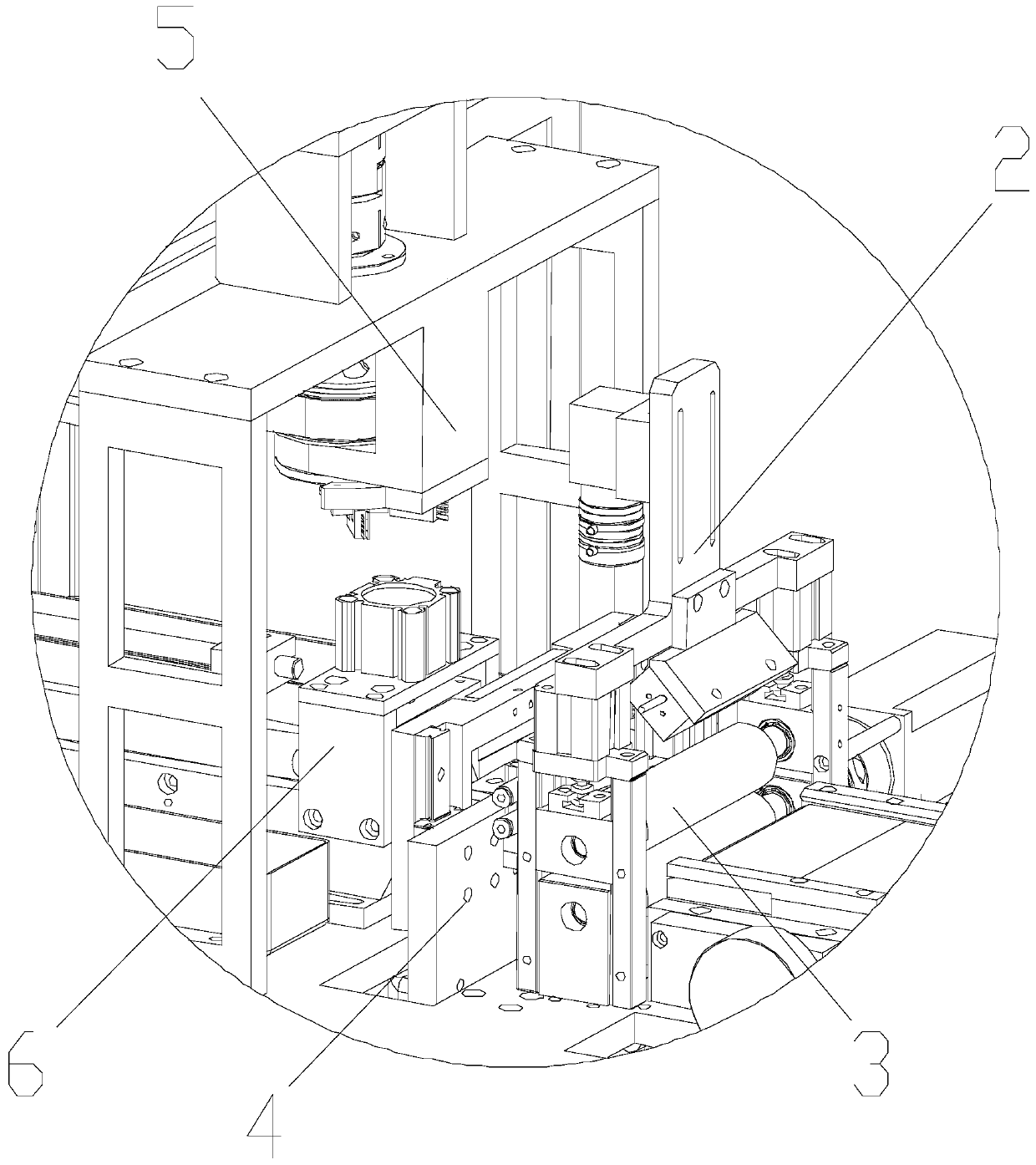

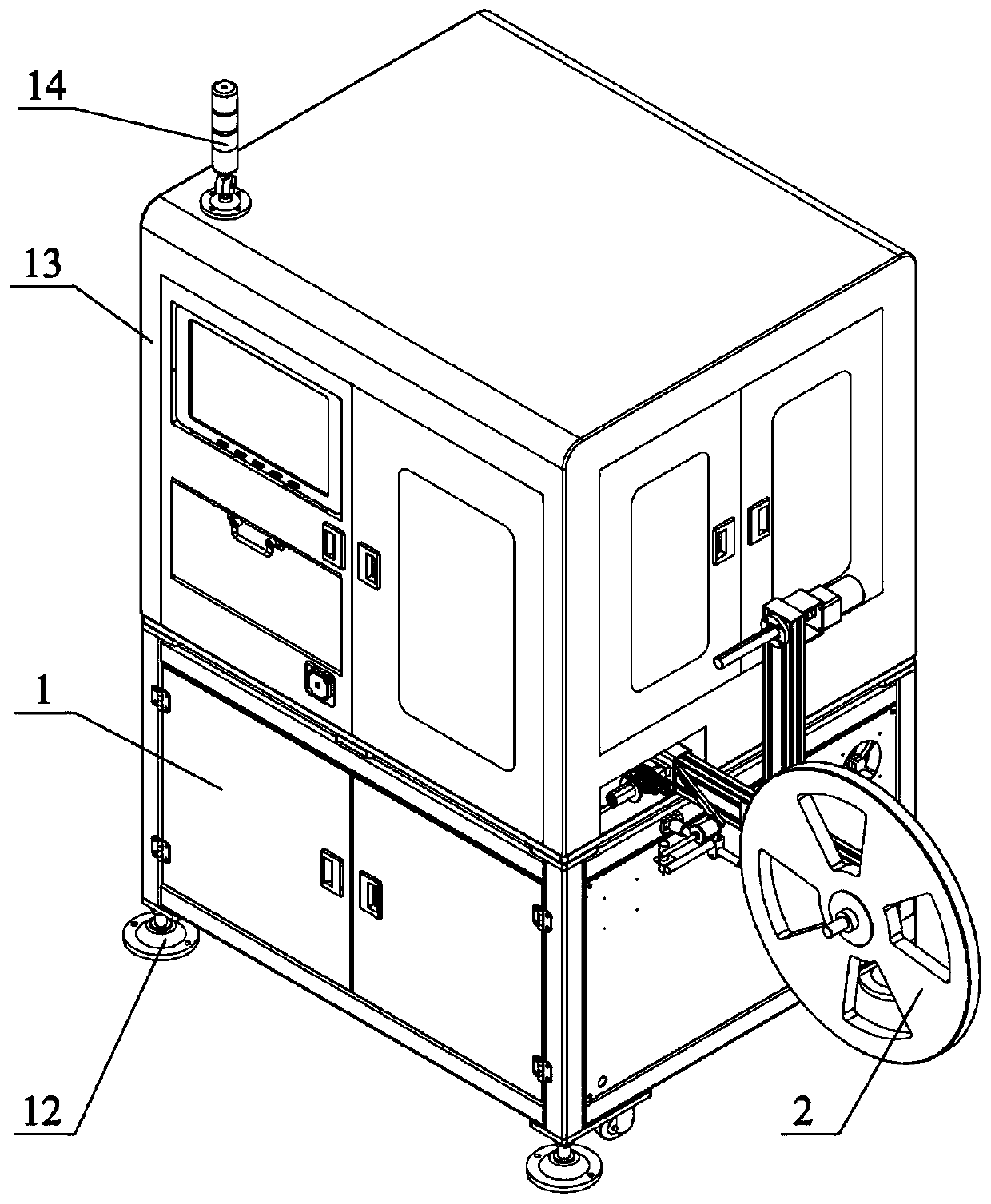

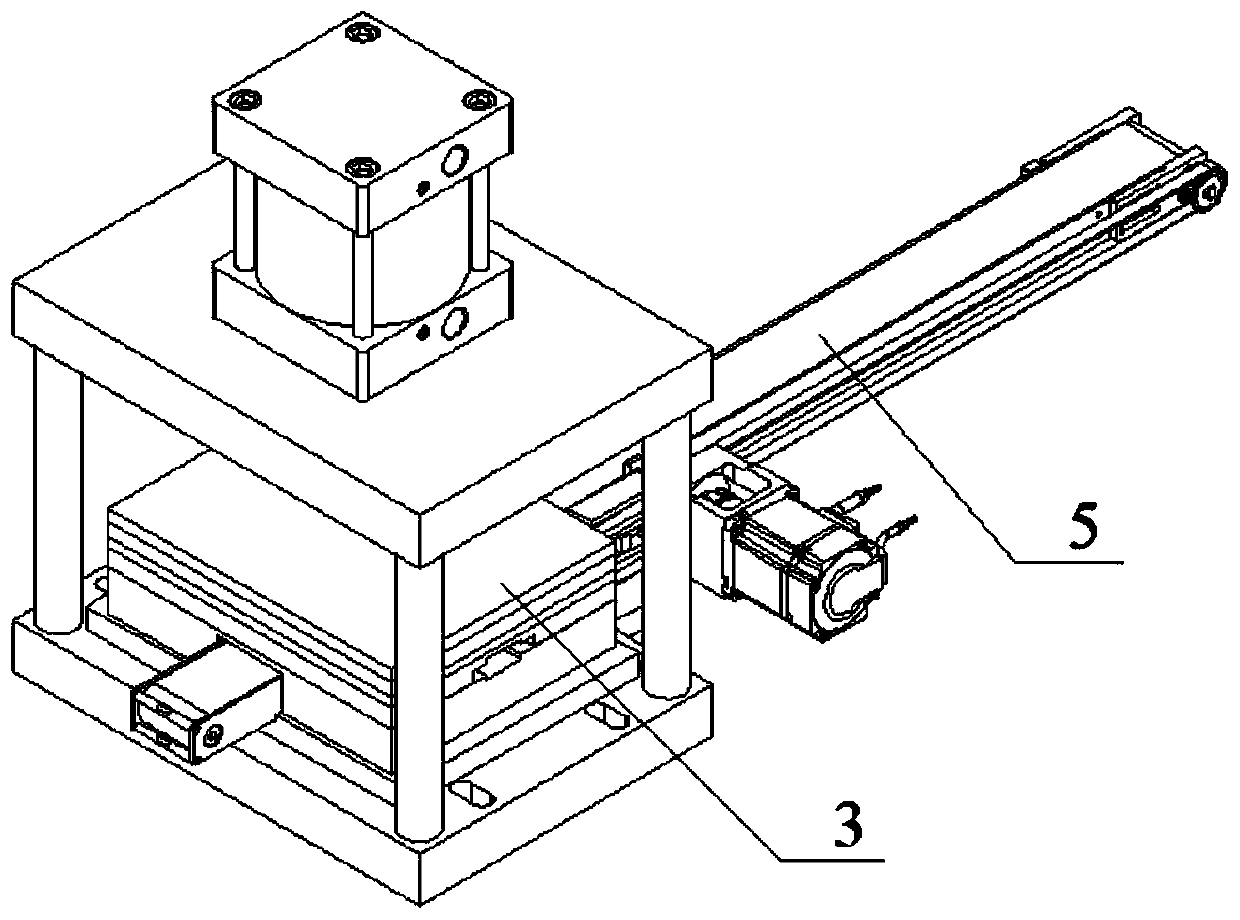

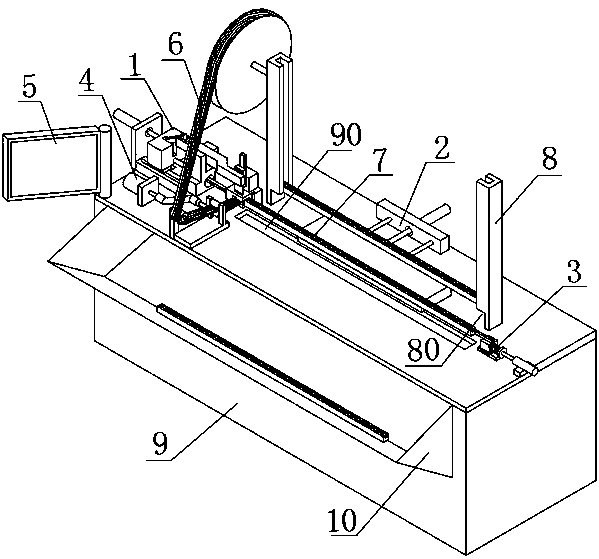

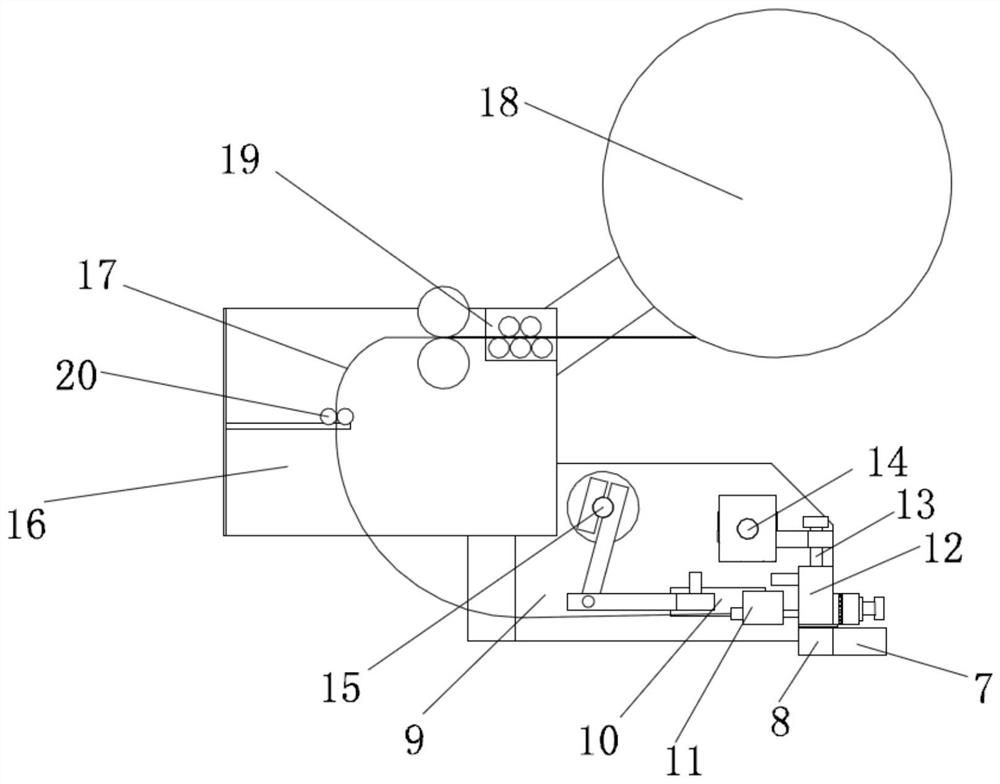

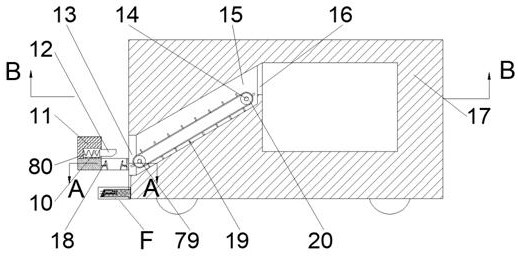

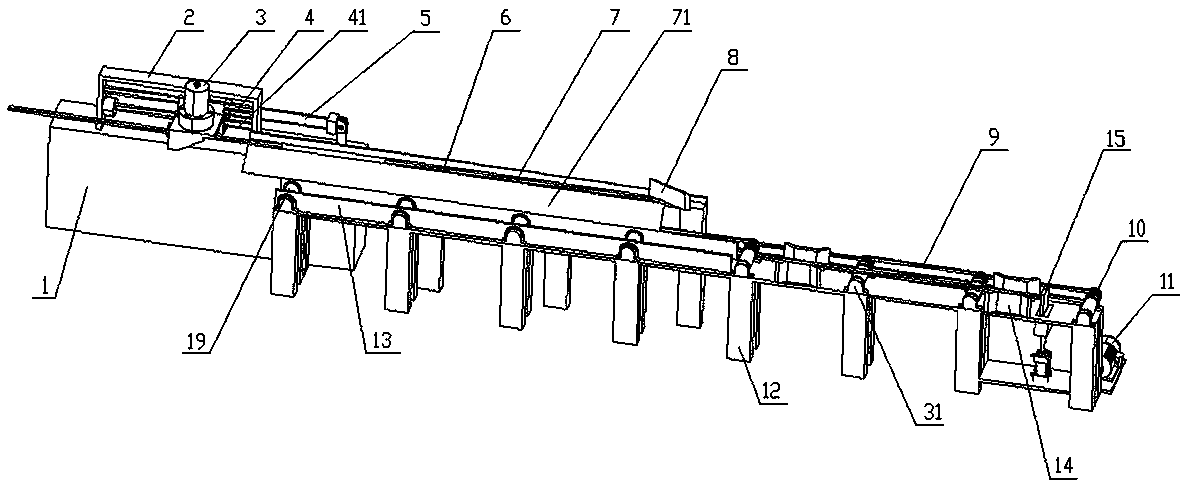

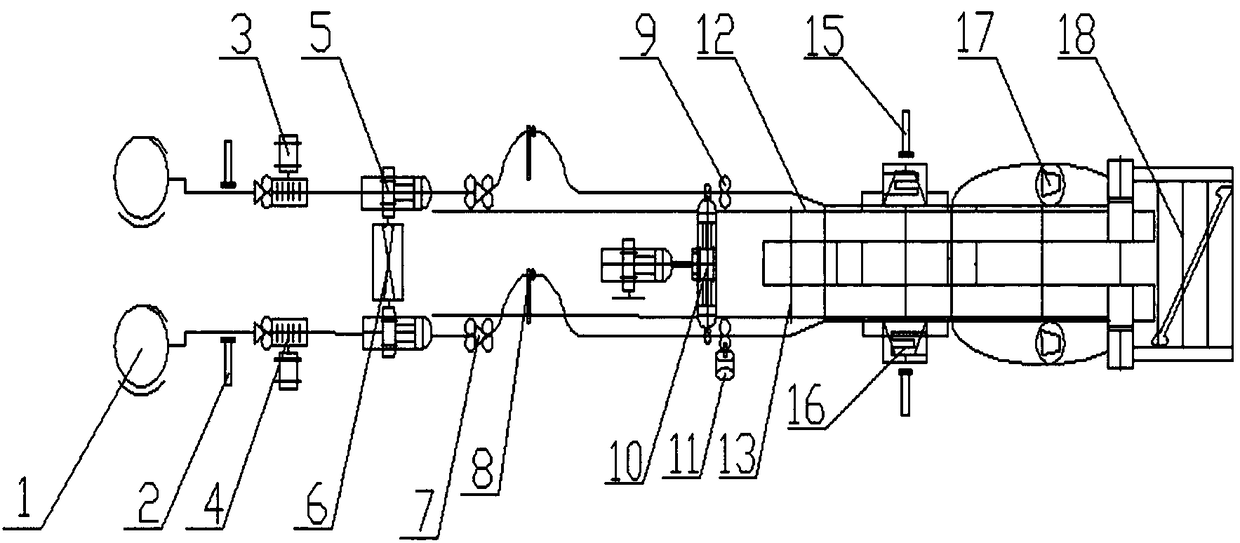

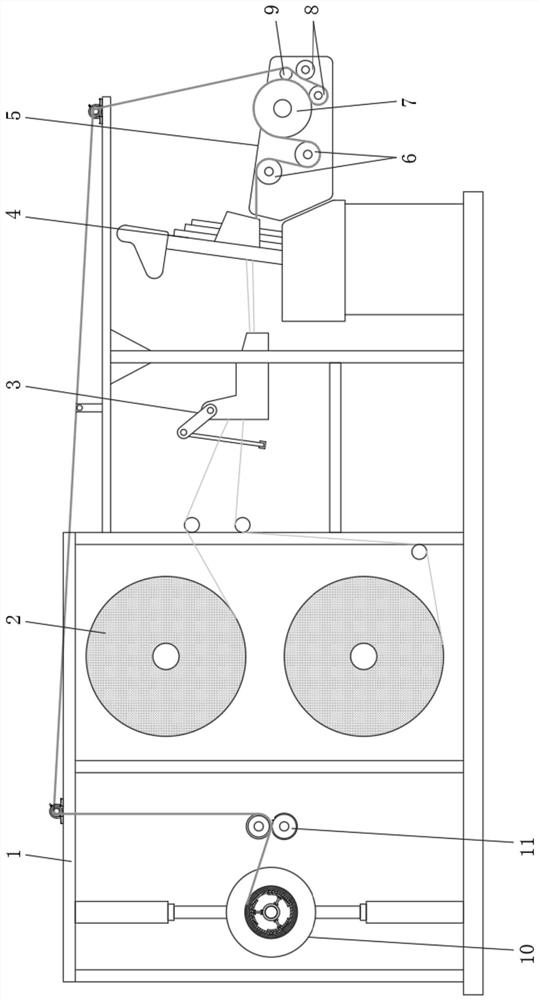

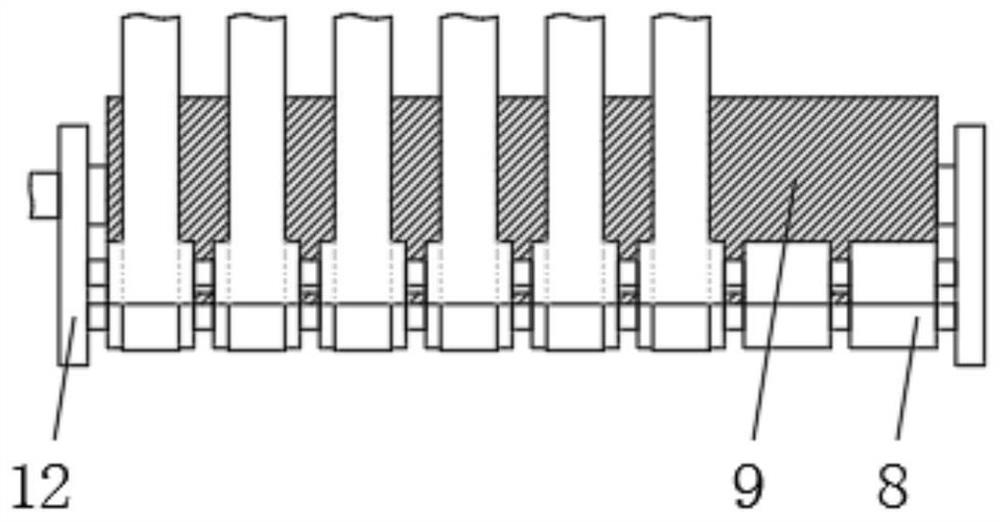

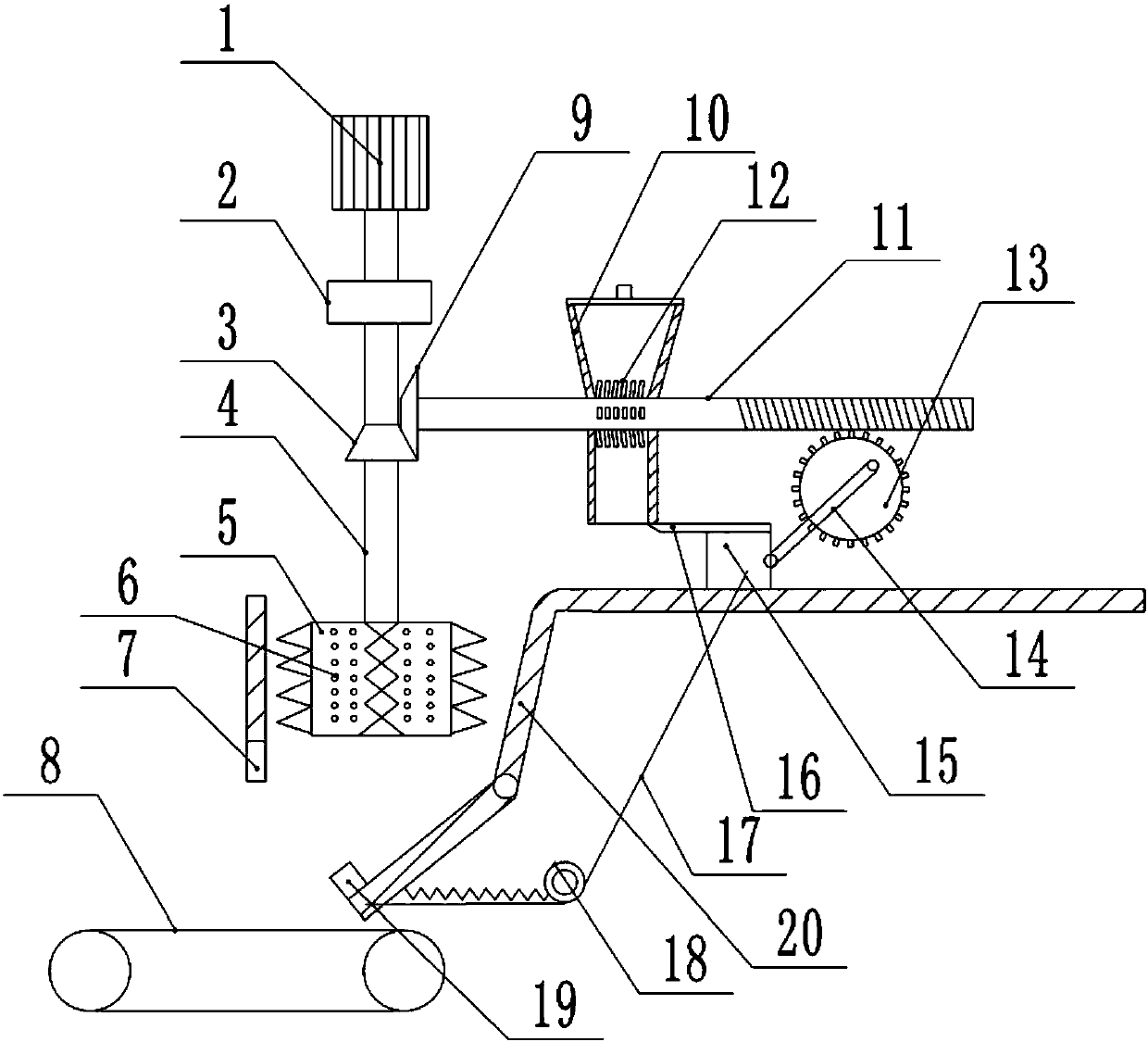

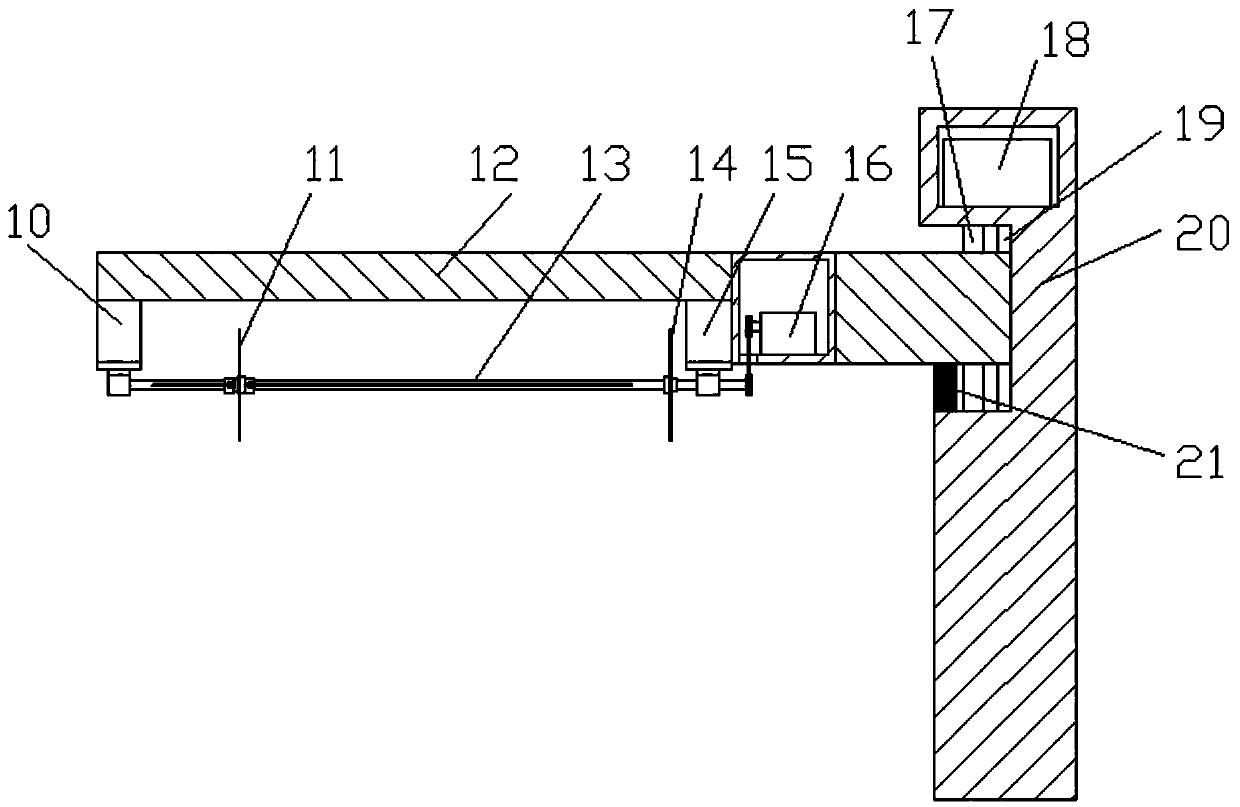

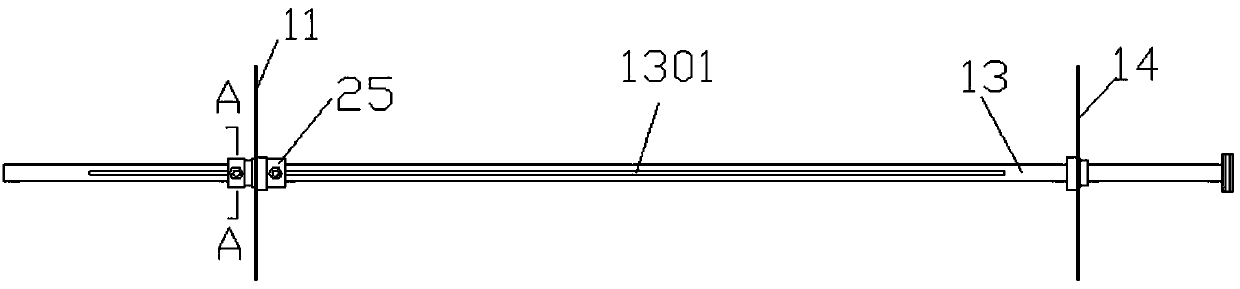

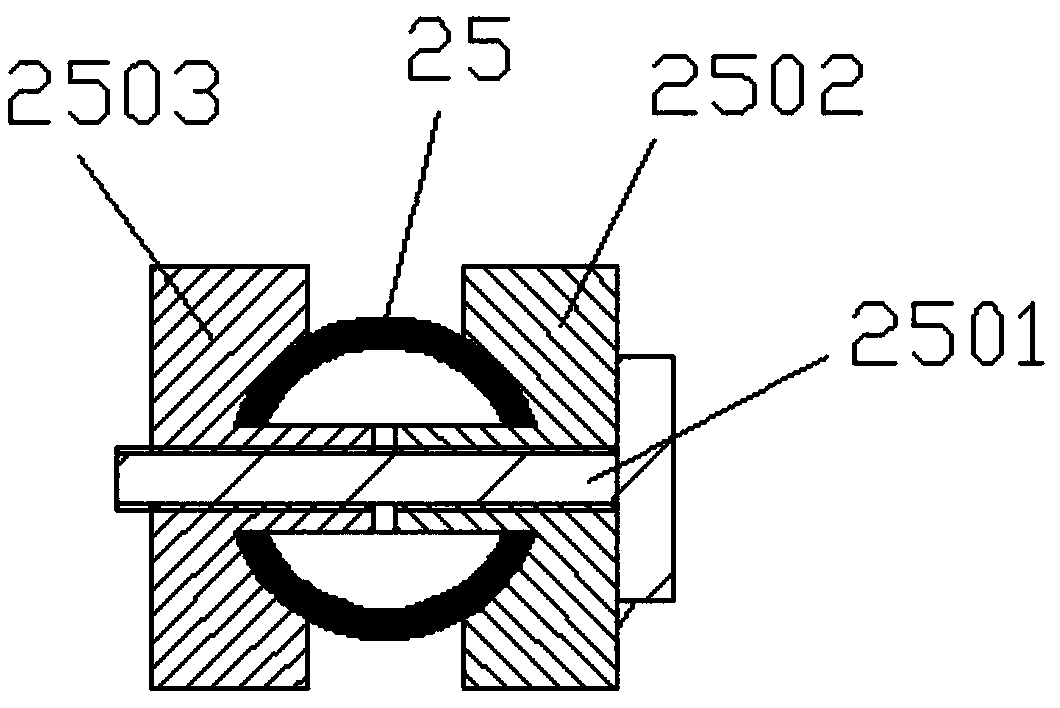

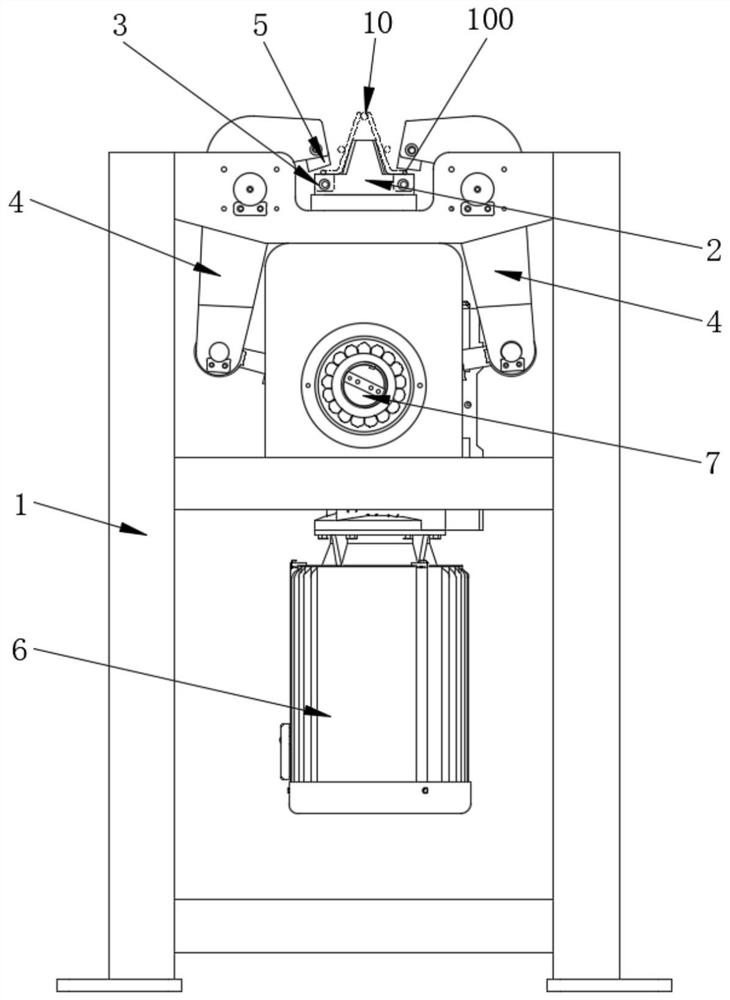

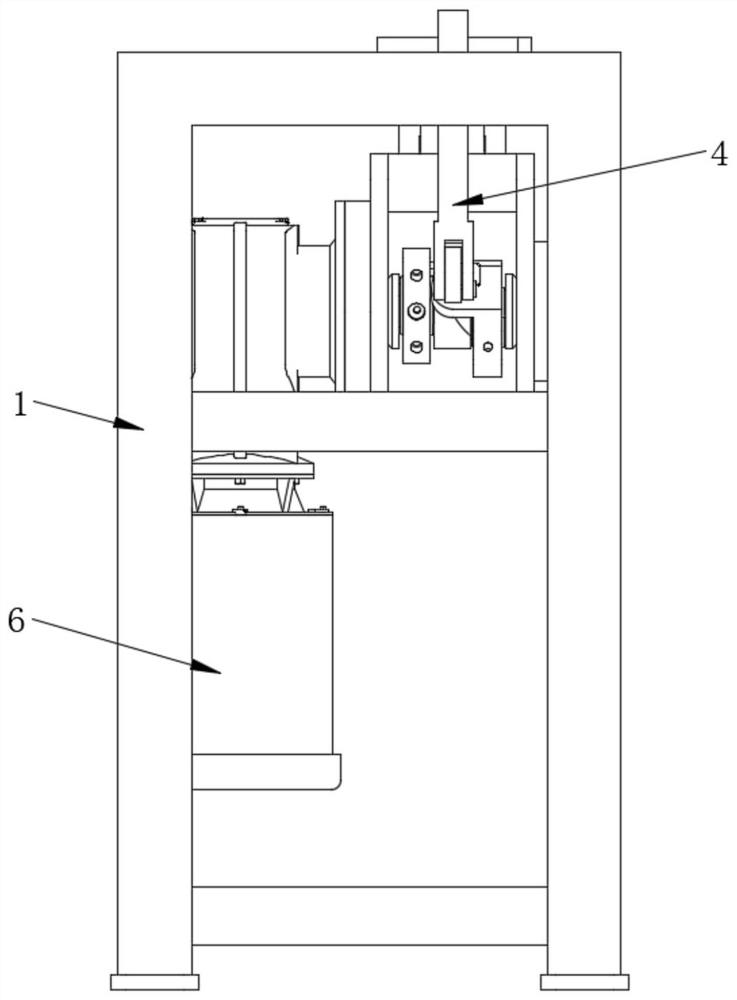

Multi-wire tin dipping crimping machine

ActiveCN106099609ARealize automatic cut offHigh degree of automationConnection formation by deformationEngineeringTin

The invention discloses a multi-wire tin dipping crimping machine which comprises a frame, a wire feeding device, a knife rest device, a crimping device, and a tin dipping device, wherein the wire feeding device, the knife rest device, the crimping device, and the tin dipping device are arranged on the frame. The wire feeding device is used for conveying a conductive wire to subsequent devices. The knife rest device performs cutting-off, stripping, and twisting treatments on the conductive wire. The crimping device is arranged between the knife rest device and the wire feeding device and used for performing the crimping treatment on an end part of the conductive wire between the knife rest device and the wire feeding device. The tin dipping device is arranged at the other side of the knife rest device relative to the crimping device and used for performing the tin dipping treatment on the end part of the cut-off conductive wire close to the knife rest device. The multi-wire tin dipping crimping machine realizes automatic cutting off, crimping, tin dipping and finished product collection of the conductive wire through the above structure. The automation degree is high, and the structure is simple and ingenious. The work is stable, and the work efficiency is high.

Owner:邓州市亚泰机械有限公司

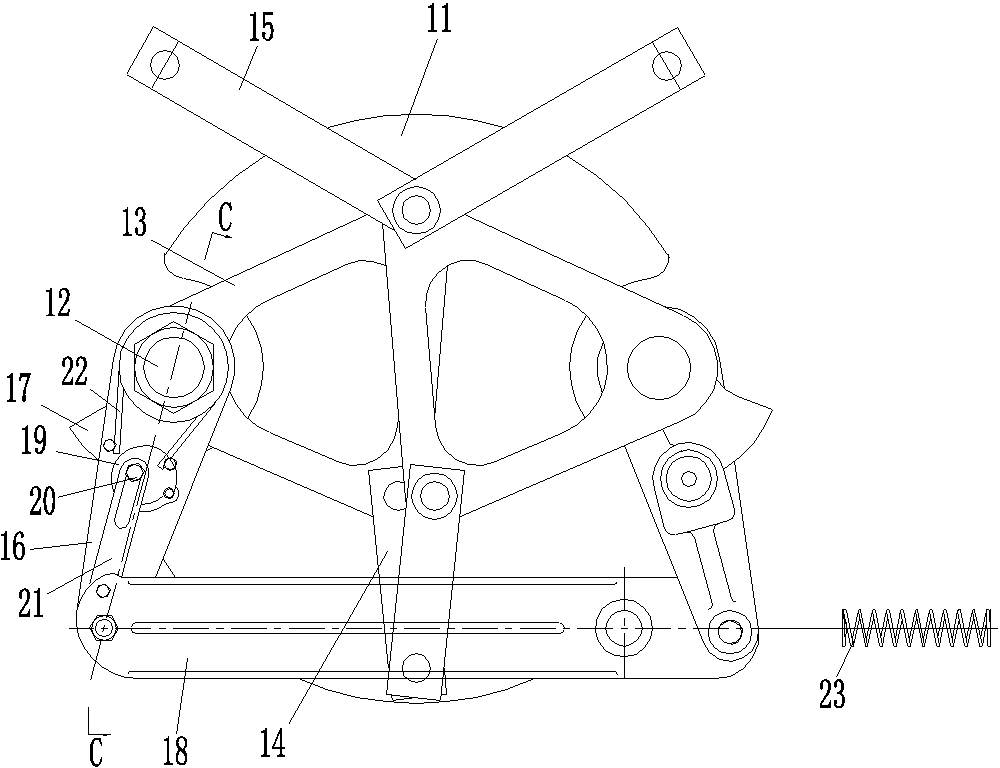

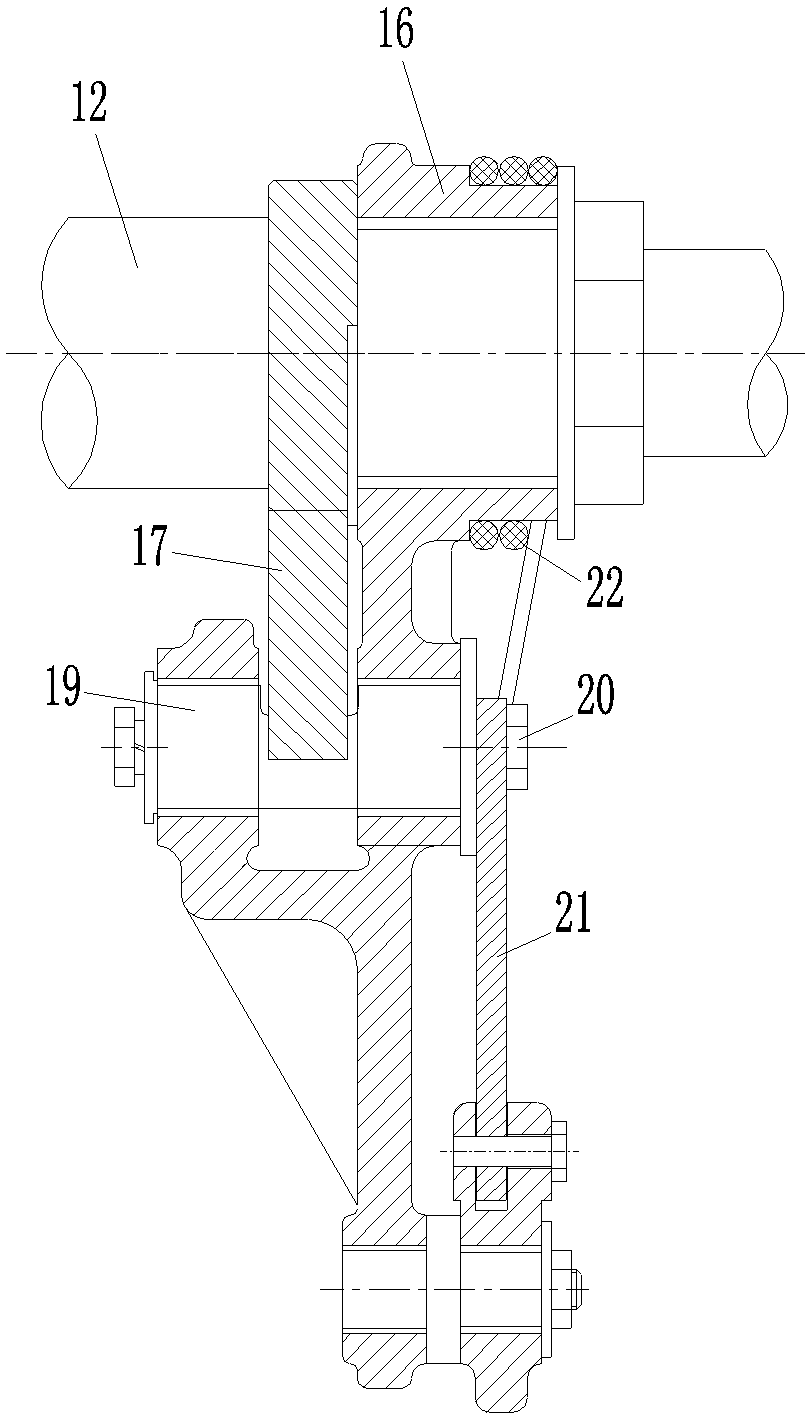

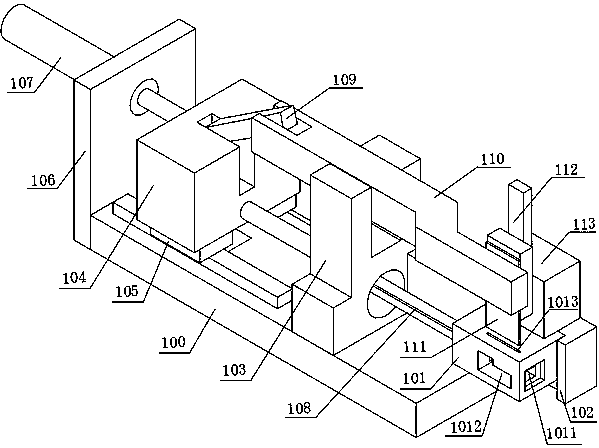

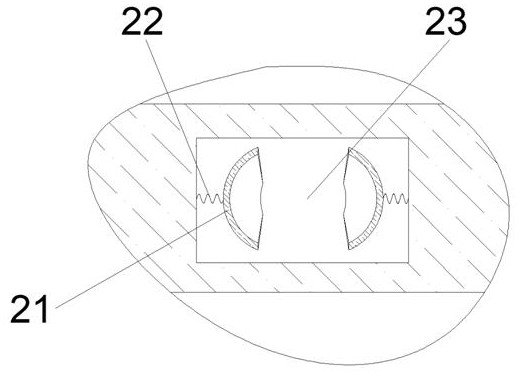

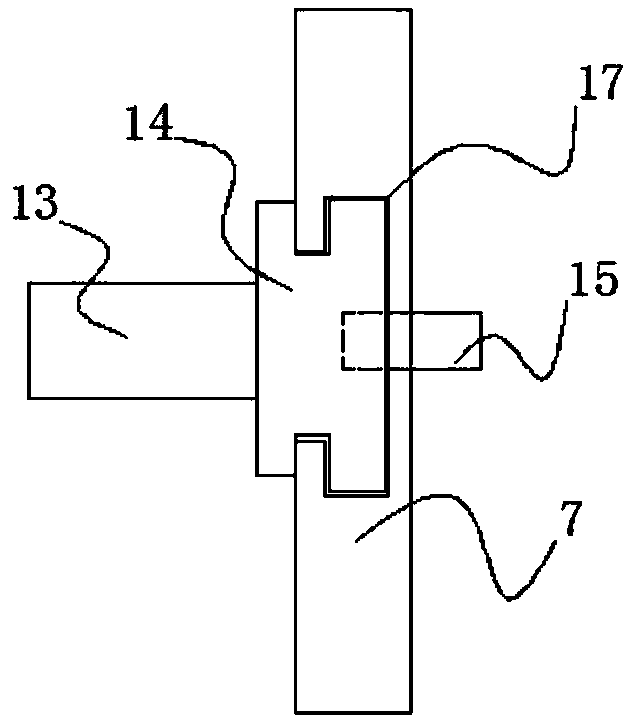

Breaker closing resistor tripping mechanism and breaker using same

InactiveCN104143469ARealize automatic cut offHigh-tension/heavy-dress switchesAir-break switchesEngineeringCircuit breaker

The invention relates to the field of breakers, in particular to a breaker closing resistor tripping mechanism and a breaker using the same. The breaker closing resistor tripping mechanism comprises a mechanism box, a transmission component is rotationally assembled in the mechanism box through a rotating shaft, two hinge points are arranged on the transmission component, and the hinge axes of the two hinge points are both parallel to the rotating shaft. The rotating shaft is further provided with a crank arm and a plate stirring switch, the crank arm is in rotating fit with the rotating shaft, a switch shaft is rotationally assembled between the two ends of the crank arm, the switch shaft is parallel to the rotating shaft, a radial notch used for avoiding the plate stirring switch is arranged on the outer circumferential face of the switch shaft, the end, away from the rotating shaft, of the crank arm is further connected with a resistor connecting rod in a hinged mode, the resistor connecting rod is used for driving a closing resistor to be connected and disconnected, and a linkage connecting piece is arranged between the resistor connecting rod and the switch shaft. When the breaker is closed in place, the notch in the switch shaft exactly faces the plate stirring switch, thus, it can be ensued that the crank arm drives the closing resistor to be reset when the breaker is closed in place, and the closing resistor is automatically cut off after the closing of contacts of an arc extinguish chamber of the breaker.

Owner:STATE GRID CORP OF CHINA +2

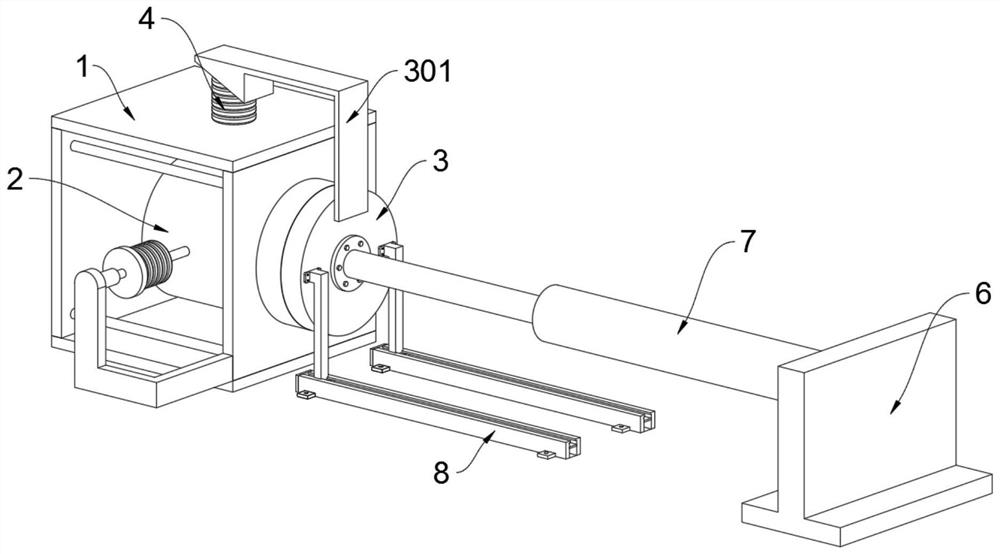

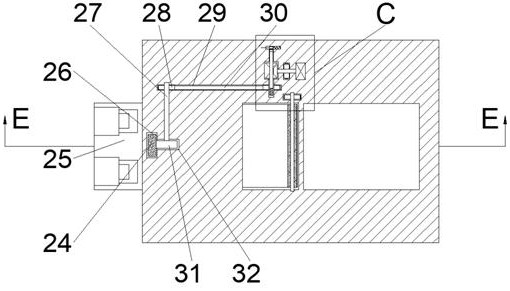

Self-film-cutting type aluminum profile double-side-face synchronous film pasting machine

InactiveCN110697122AImprove film application efficiencyEasy to installPackagingWebs handlingThin membraneEngineering

The invention discloses a self-film-cutting type aluminum profile double-side-face synchronous film pasting machine. A contact roller and a cutting knife are in linkage through a transmission mechanism, wherein the contact roller is located behind a film rolling roller, and a part of the contact roller coincides with the conveying track of an aluminum profile; a knife edge of the cutting knife makes contact with a film guiding roller; when the contact roller rotates to the outer surface of the contact roller through the transmission mechanism to make rolling contact with the outer surface of the area, subjected to film pasting, in the aluminum profile, the cutting knife can rotate, a gap exists between the knife edge of the cutting knife and the film guiding roller, and an elastic device deforms; a film unwound from the film rolling roller can pass through the gap; and two sets of film pressing rollers are symmetrically arranged at the two ends of a clamping mechanism, telescopic rodsdo telescopic motion to be used for adjusting the distance between the two ends of the clamping mechanism, and the two sets of film pressing rollers make rolling contact with the corresponding side faces of the area, subjected to film pasting, in the aluminum profile correspondingly. The self-film-cutting type aluminum profile double-side-face synchronous film pasting machine has the advantages that synchronous film pasting of the two opposite side faces of the aluminum profile is achieved, the mechanical structure for automatically cutting off the film is optimized, and operation convenienceis improved.

Owner:奋安铝业股份有限公司

Printed matter surface film laminating equipment

ActiveCN113147171AImprove lamination efficiencyReduce wasteLamination ancillary operationsLaminationHydraulic cylinderPaperboard

The invention relates to the technical field of film laminating , in particular to printed matter surface film laminating equipment which comprises a support and a motor arranged on the support. An unwinding roller and two hot-pressing rollers are rotationally connected onto the support; the two hot-pressing rollers are arranged up and down in a spaced mode; an output shaft of the motor is connected to one of the hot-pressing rollers; the support is further provided with a conveying mechanism and a cutting mechanism located between the hot-pressing rollers and the output end of the conveying mechanism; the cutting mechanism comprises a control panel, an infrared transmitter, an infrared receiver and a hydraulic cylinder; the infrared transmitter, the infrared receiver and the hydraulic cylinder are arranged on the support and coupled to the control panel; the infrared transmitter and the infrared receiver are arranged up and down in a spaced mode; a paperboard on the conveying mechanism penetrates through the position between the infrared transmitter and the infrared receiver in a sliding mode; a piston rod of the hydraulic cylinder extends in the vertical direction and is connected with a cutter; the cutter and the infrared transmitter are sequentially arranged in the moving direction of the paperboard; and the horizontal distance between the cutter and the infrared transmitter is equal to the length or the width of the paperboard. According to the printed matter surface film laminating equipment provided by the invention, the film laminating efficiency of the paperboard can be improved.

Owner:杭州美利建印刷有限公司

Cutting machine

InactiveCN106737945AReasonable structural designBeautiful chamfer qualityMulti-purpose machinesRotary cutting toolsBar productEngineering

The invention relates to a cutting machine comprising a rack, cutters and a feeding mechanism arranged on the rack and used for conveying a product to be cut. A rotating main shaft is further arranged on the rack. The cutters are mounted on the rotating main shaft which is connected with motors. Each cutter comprises a saw blade in the middle and chamfering blades located on the two sides of the saw blade, and the outer diameter of each chamfering blade is less than the outer diameter of each saw blade. The cutting machine is reasonable in structure design. After the saw blades cut the product to be cut with a certain depth, the chamfering blades conduct chamfering on the two ends of the cut product to be cut separately, and after chamfering is finished, the saw blades cut off the product to be cut to form a plurality of circular wood strips or circular plastic bars with chamfers. Automatic cut-off and chamfering of wooden plug bar products or plastic bar products are achieved. The cutting and chamfering are high in speed, good in quality and high in good product rate. The production cost is saved greatly, the labor intensity is reduced, and the production efficiency is improved. The circular wood strip products or the circular plastic bar products have the attractive chamfering quality.

Owner:曾胜发

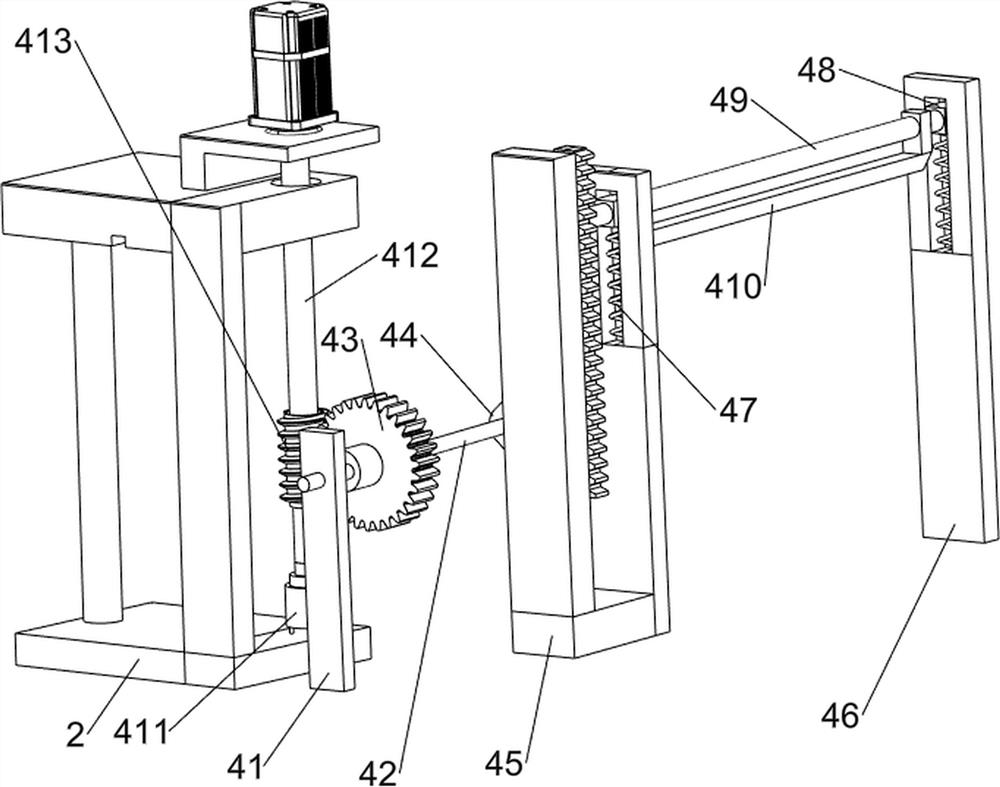

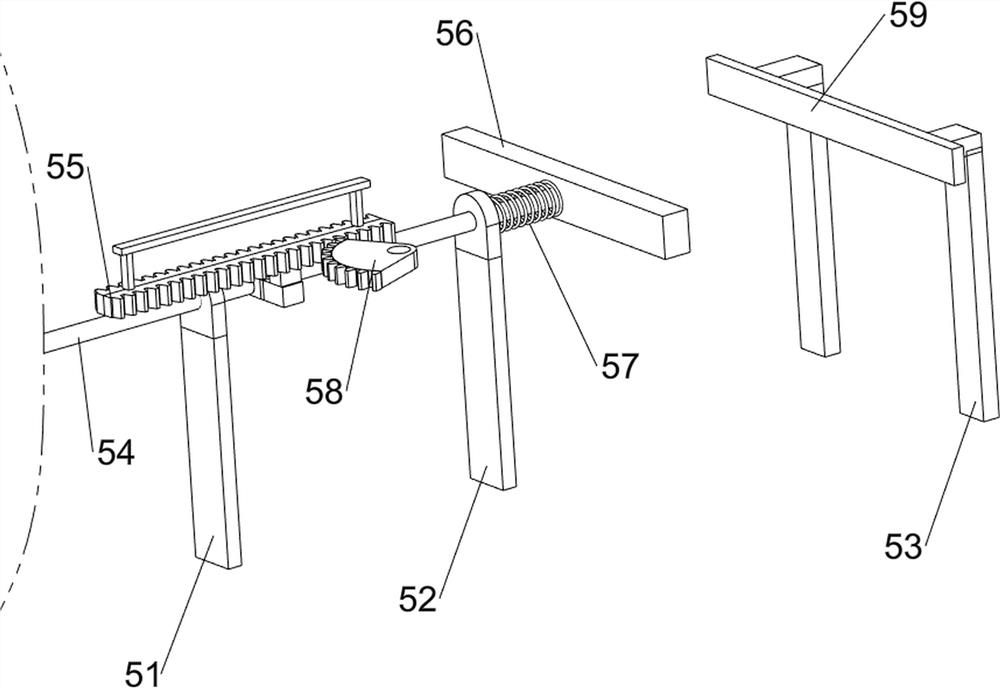

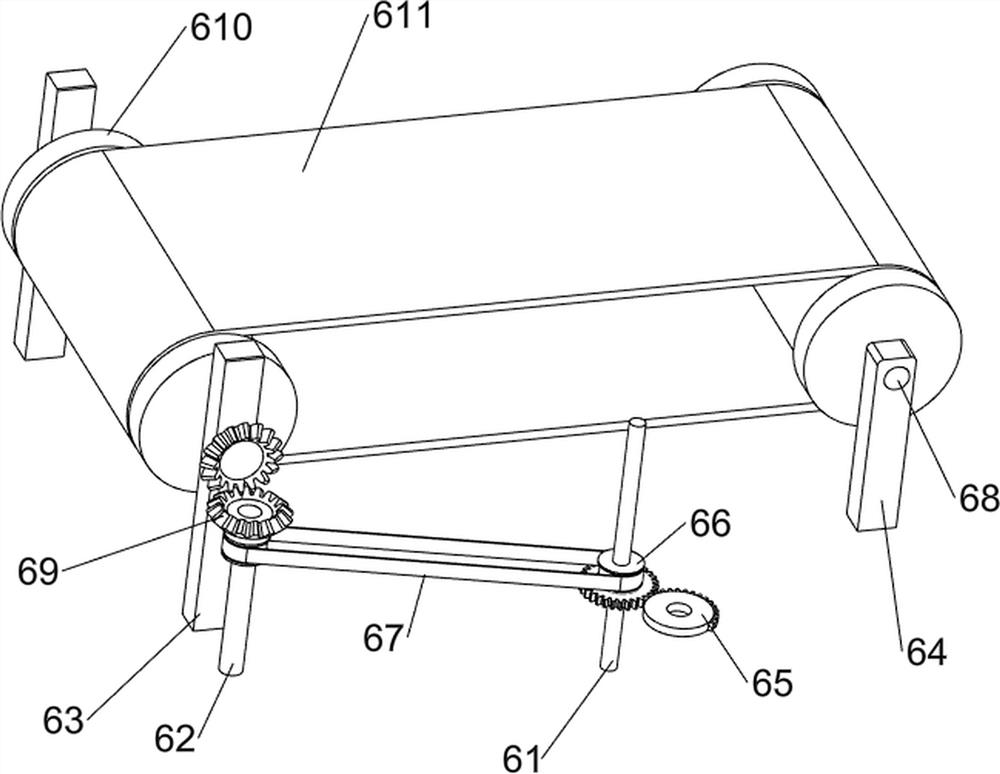

Automatic cold noodle cutting-off and gathering device

PendingCN112476520AReduce workloadImprove work efficiencyMetal working apparatusElectric machineryEngineering

The invention relates to a cutting-off and gathering device, in particular to an automatic cold noodle cutting-off and gathering device. The invention provides the automatic cold noodle cutting-off and gathering device which can efficiently realize automatic cutting and automatic gathering. The automatic cold noodle cutting-off and gathering device comprises a bottom plate, a first supporting frame, a motor and cutting-off mechanisms, wherein the first supporting frame is arranged on the right side of the bottom plate, the motor is installed at the top of the first supporting frame, and the cutting-off mechanisms are arranged on the bottom plate and the lower portion of the first supporting frame, and the cutting-off mechanisms are connected to the motor. According to the automatic cold noodle cutting-off and gathering device, through efficient cooperation of the cutting-off mechanisms, a gathering mechanism and an intermittent motion mechanism, the purpose of automatically cutting offand gathering cold noodles is achieved, the working efficiency is improved, the workload of workers is reduced, through intermittent meshing of a first half gear and a first rack, a cut-off tool is controlled to move up and down, automatic cut-off of the cold noodles is achieved, and the lengths of the cut-off cold noodles are consistent.

Owner:罗群燕

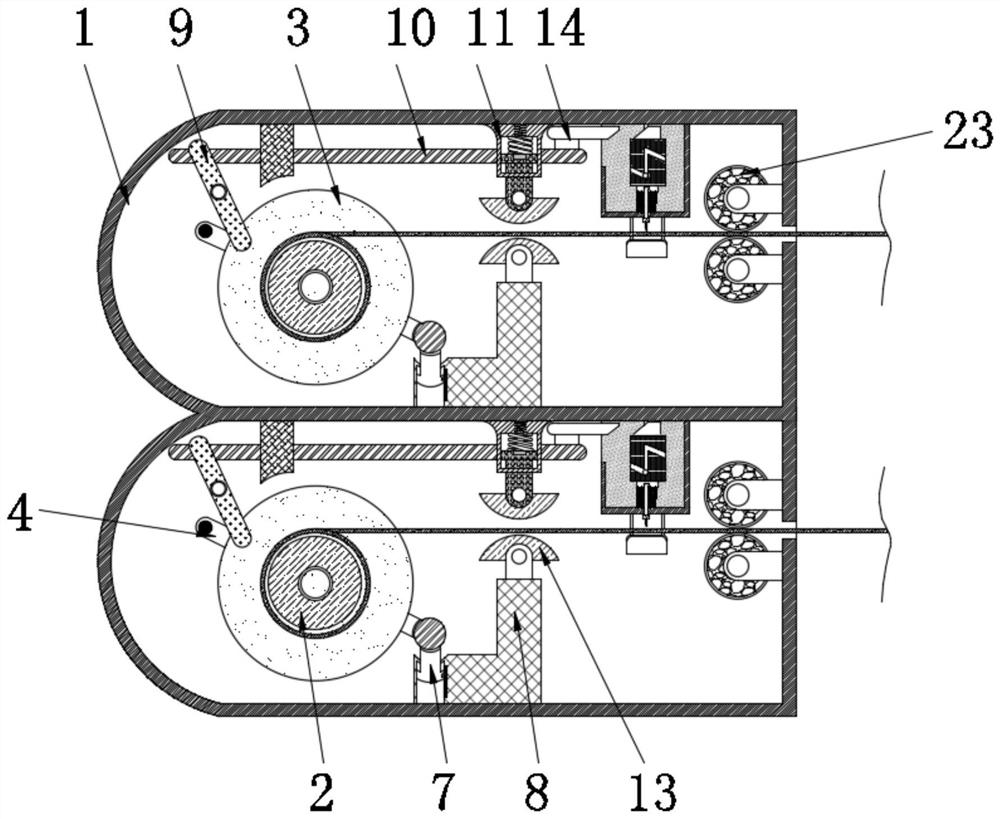

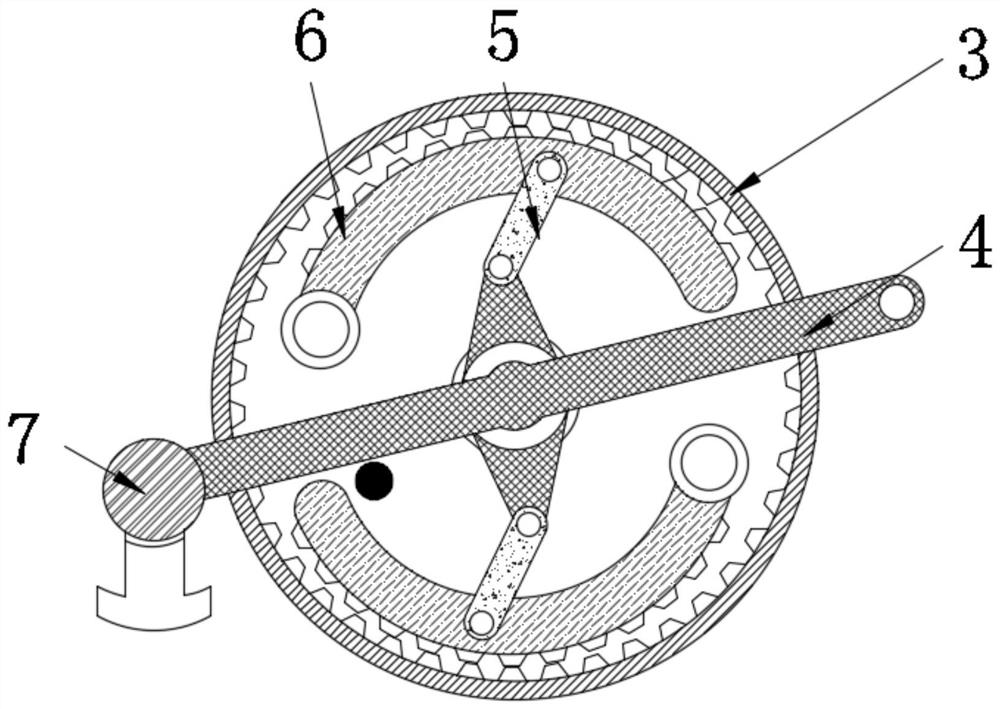

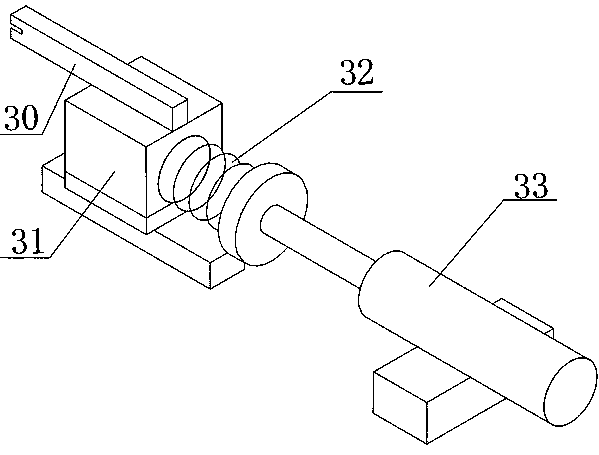

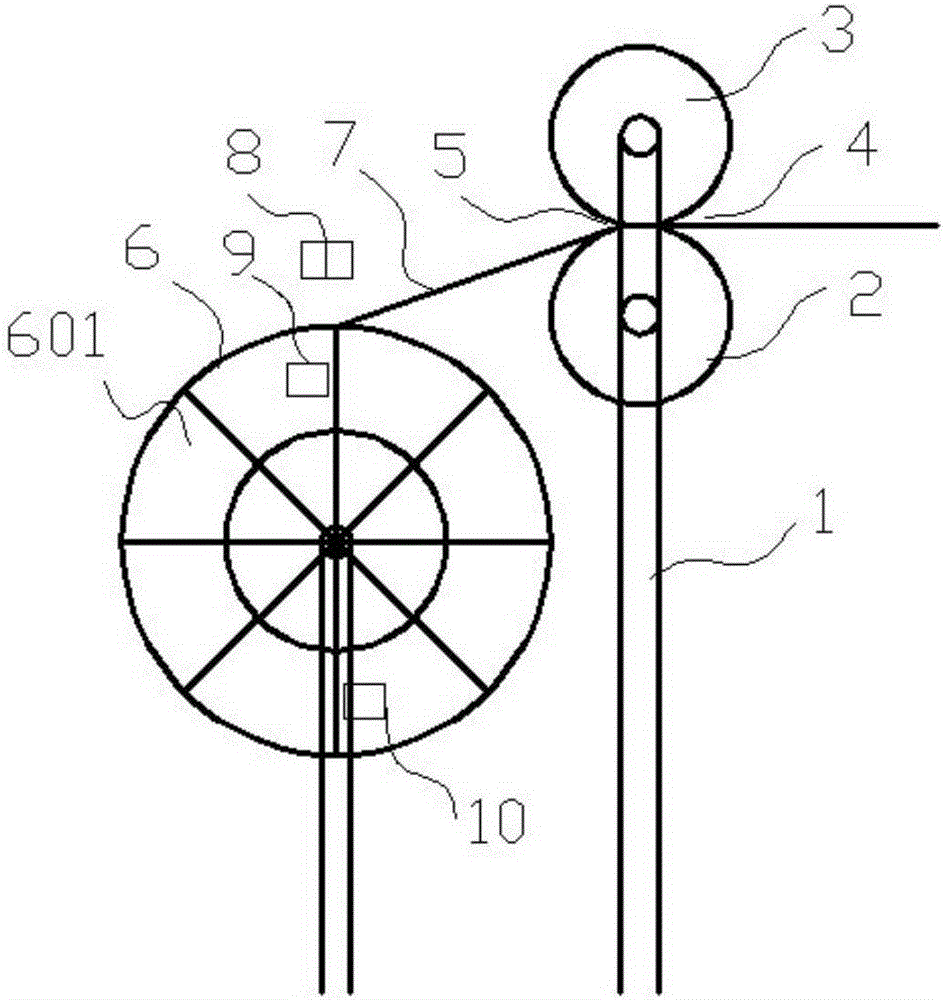

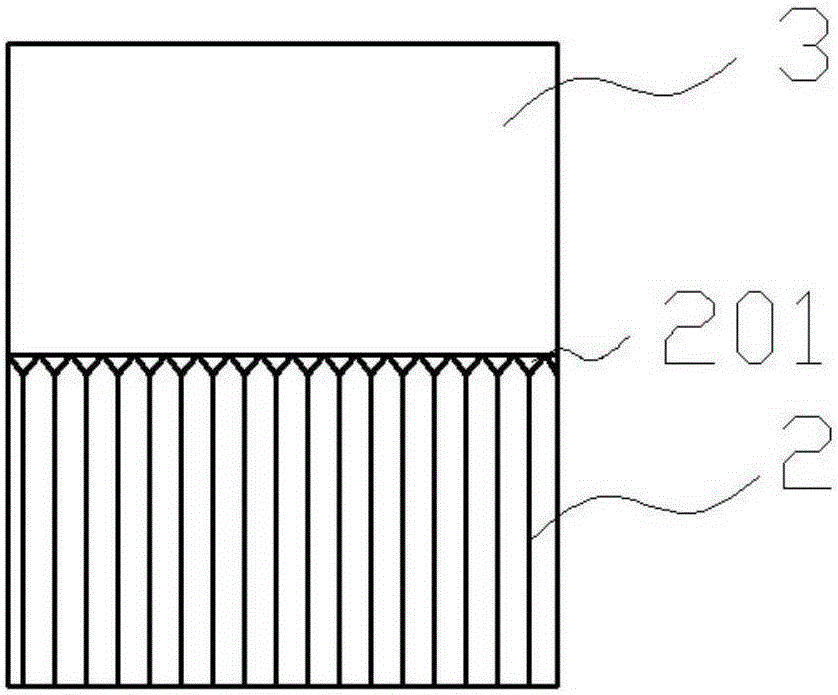

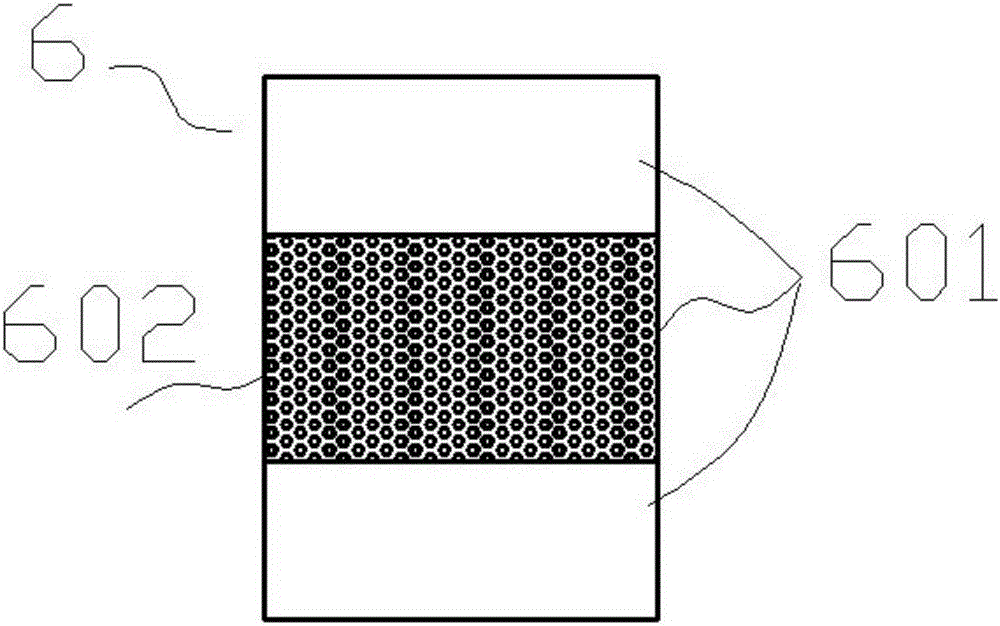

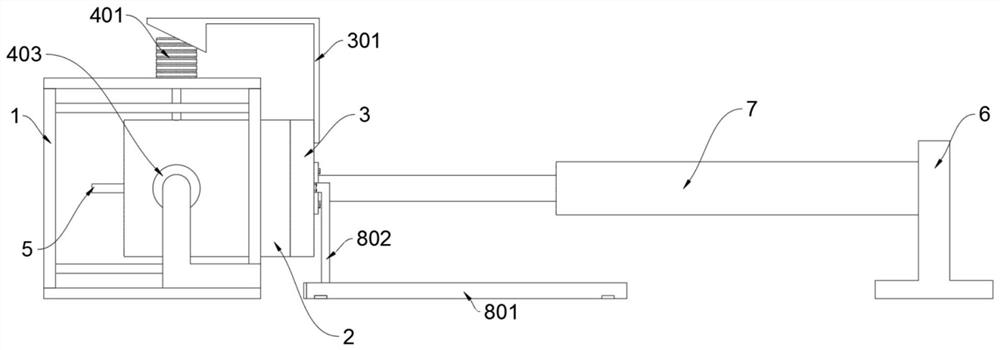

Textile twisting device

InactiveCN108468112ARealize winding tensionRealize automatic cut offContinuous wound-up machinesEngineeringMechanical engineering

The invention discloses a textile twisting device. The device comprises a bottom plate, a casing and a turntable, a wire twisting seat is fixedly supported on the middle position of the top of the bottom plate through a second column, the top of the bottom plate on one side of the wire twisting seat is fixedly connected with a U-shaped support frame through a first column, both ends of the U-shaped support frame are detachably provided with winding rollers through a first mounting seat and a second mounting seat, the top of the bottom plate on other side of the wire twisting seat is provided with the casing, a rotating motor is installed inside an internal drive compartment of the casing, an output shaft of the rotating motor penetrates through the casing and is fixedly connected with theturntable, the winding roller is mounted on the turntable, the winding roller is evenly wound with a wire, and one side, away from the winding roller, of the wire penetrates through the wire twistingseat and is fixedly connected to the winding roller. The outer sides of grooves on both sides of a mounting block are fixedly connected with mounting seats through springs, clamping slots matched withthe winding roller are formed in the middles of the outer sides of the mounting seats, convenience is provided for installation and disassembling of the winding roller, and the device is convenient to use.

Owner:YANCHENG JUNLONG YARN CO LTD

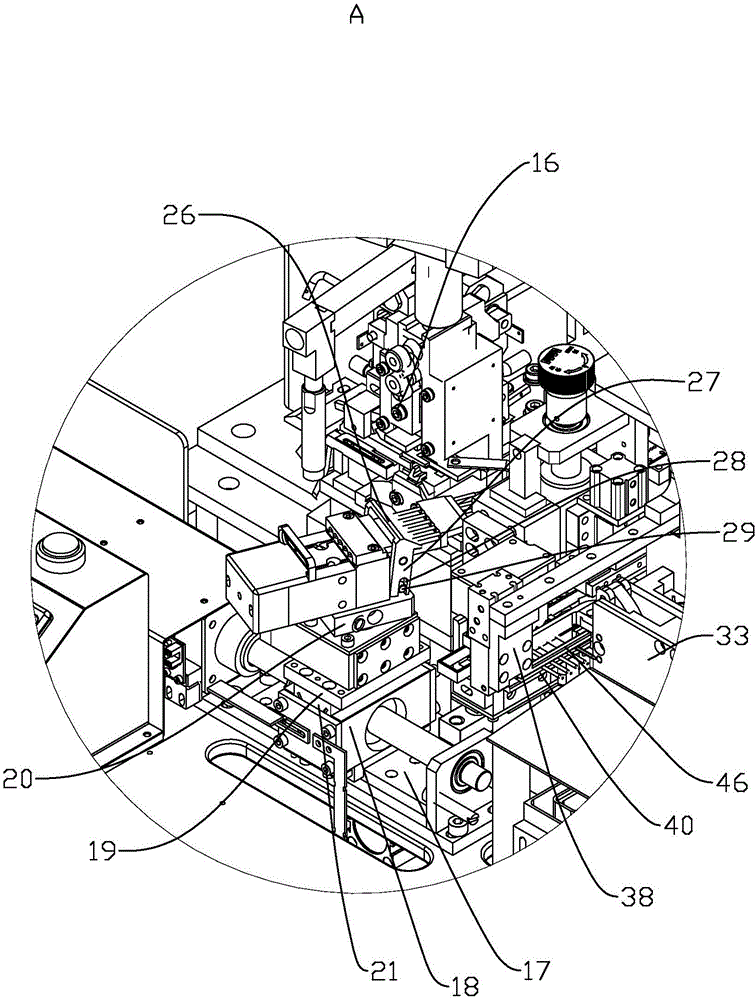

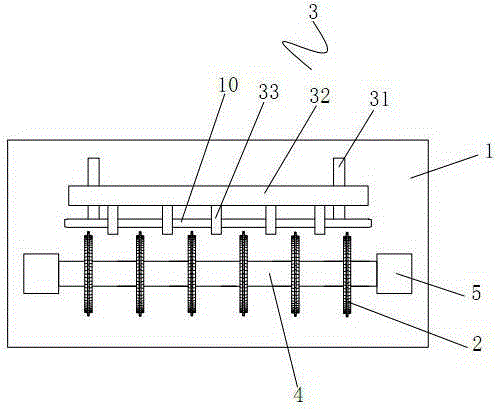

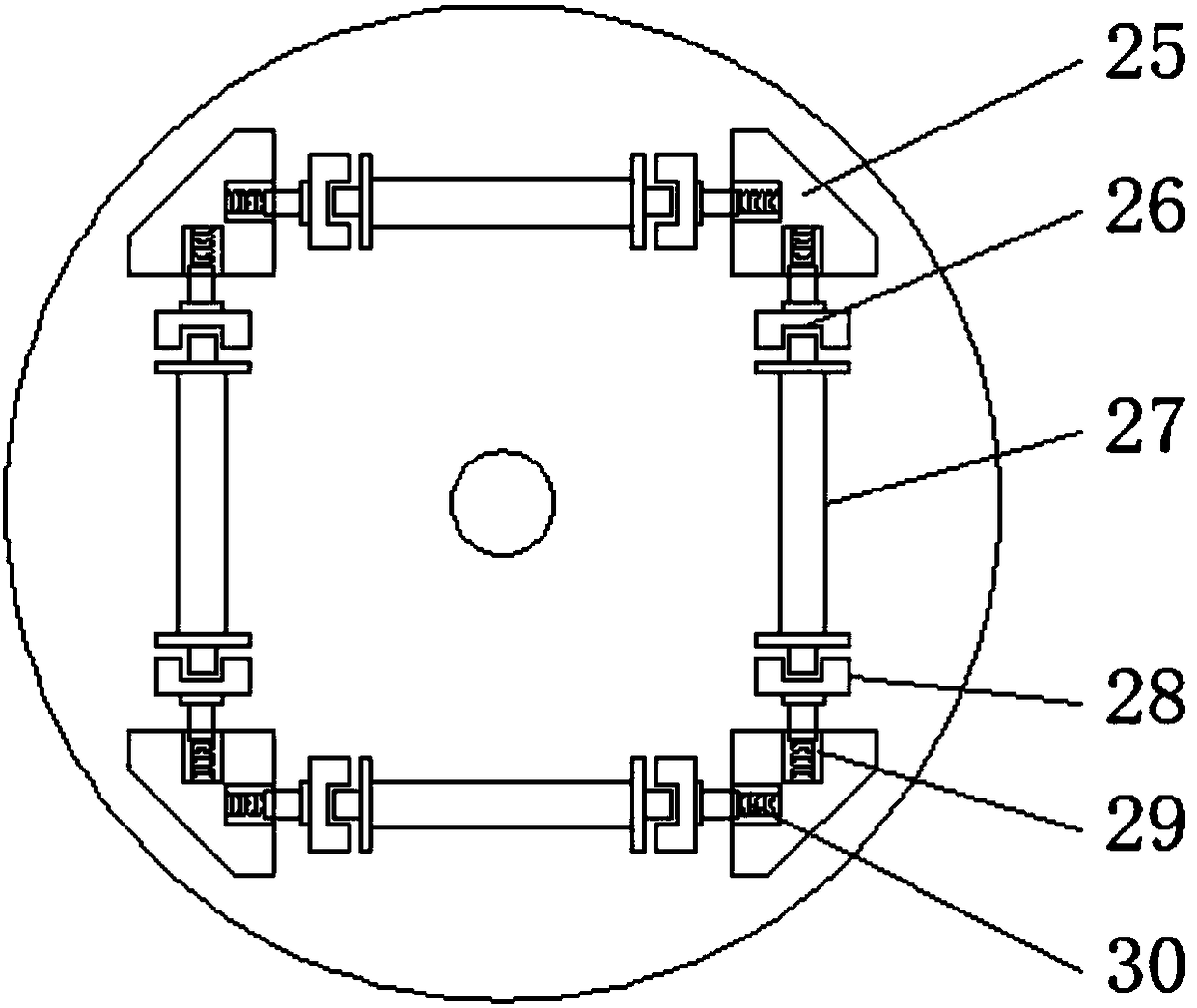

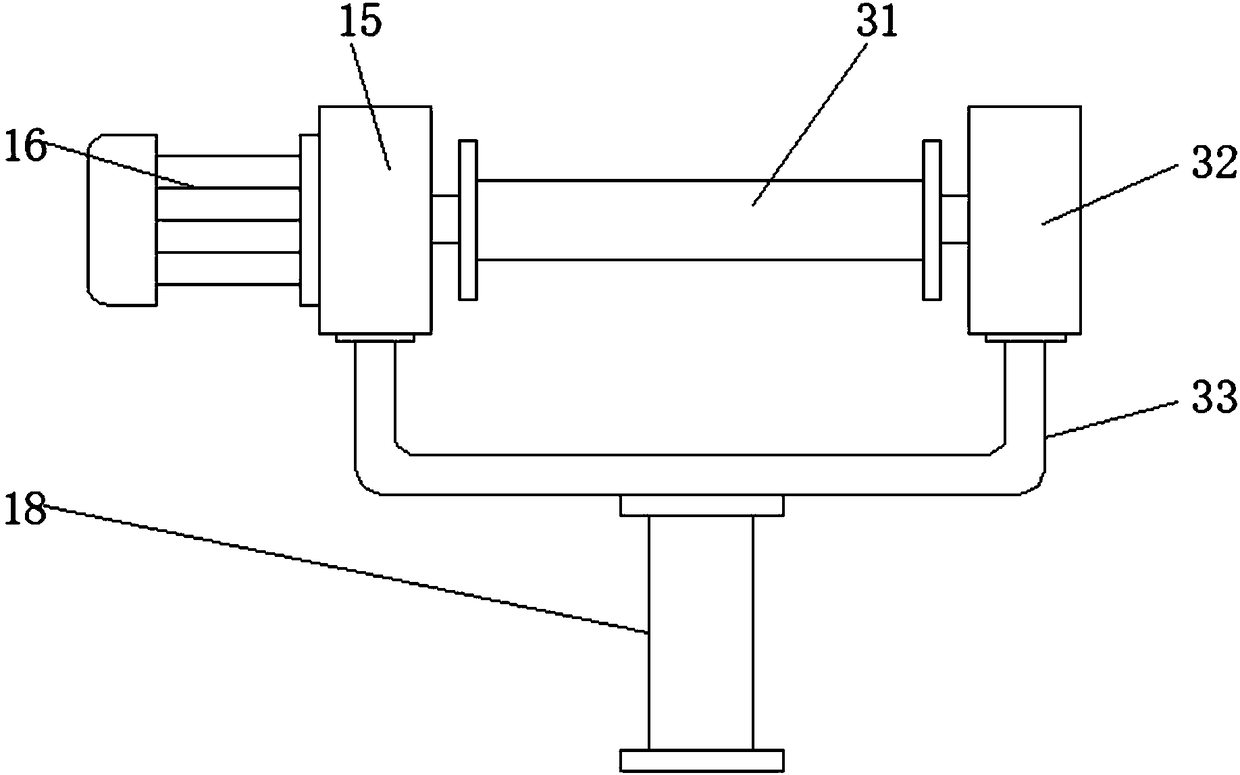

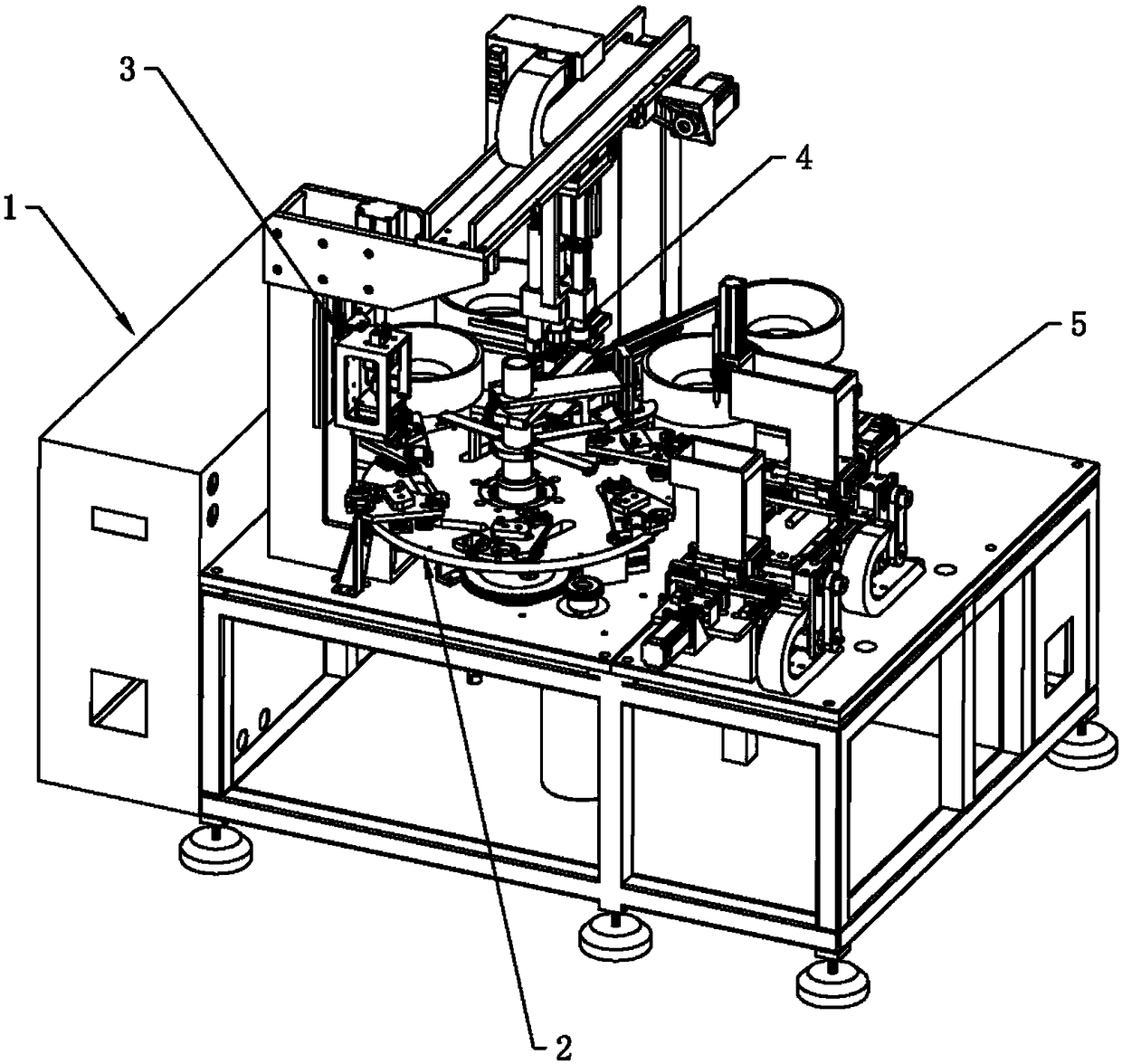

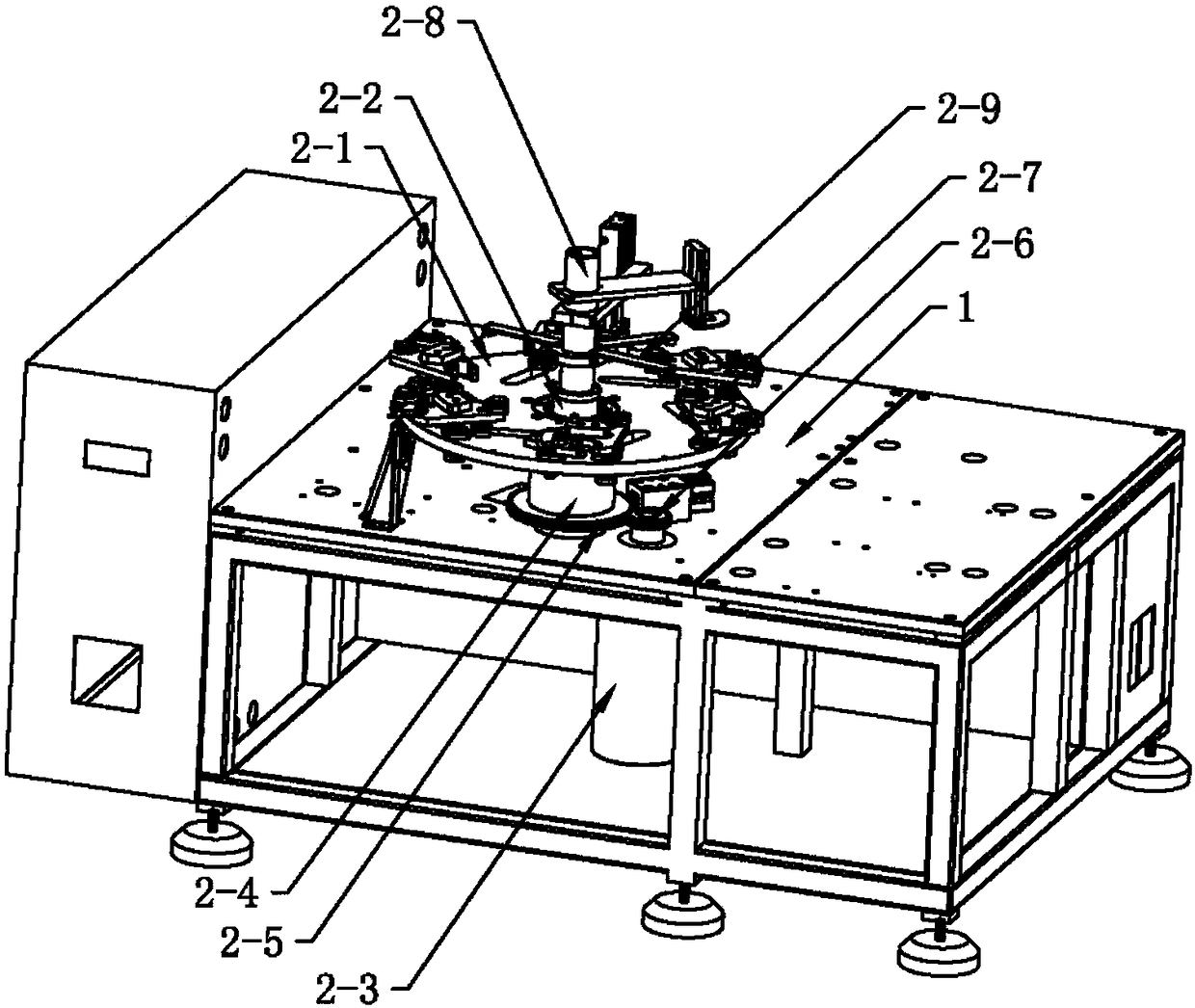

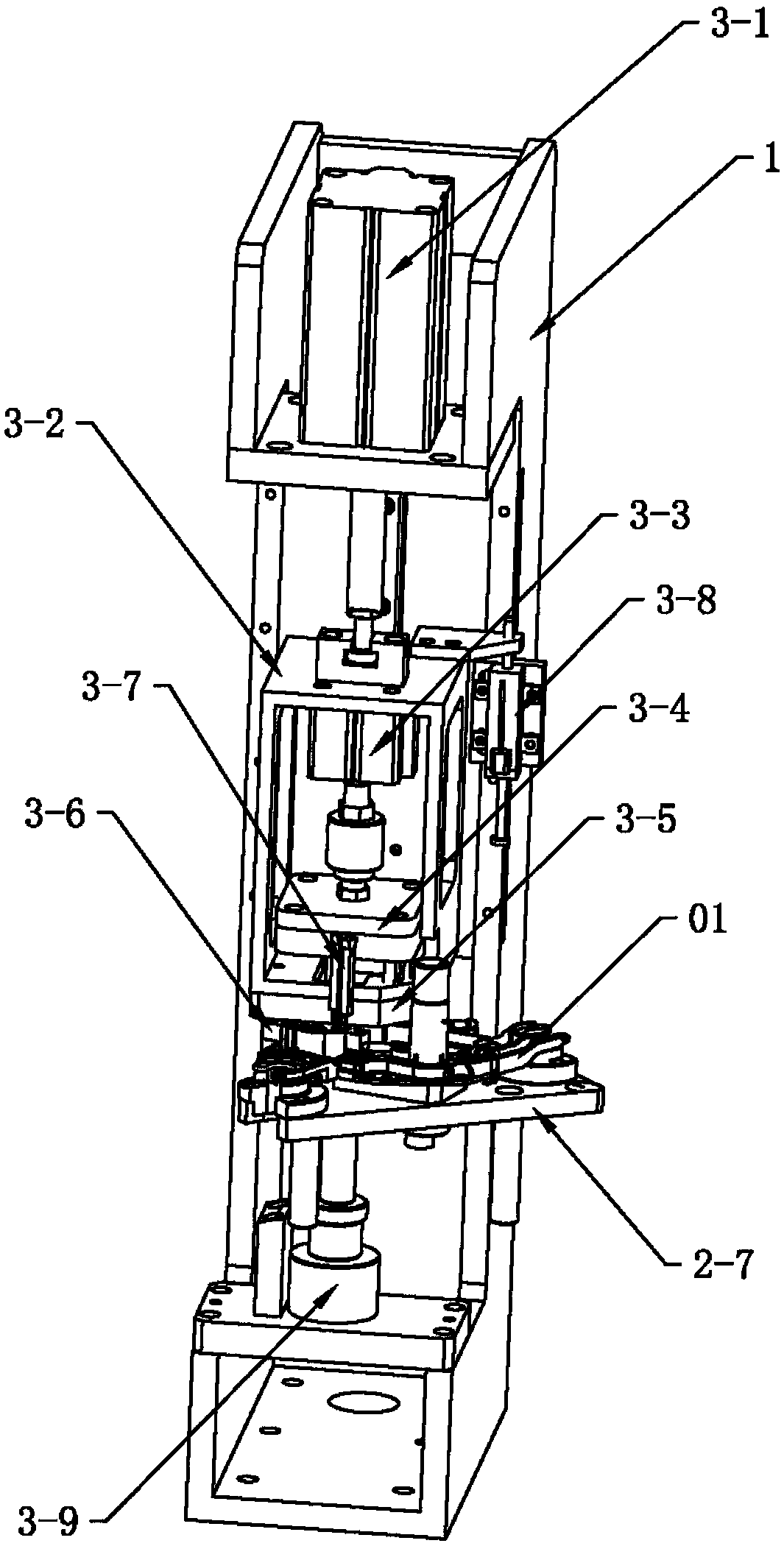

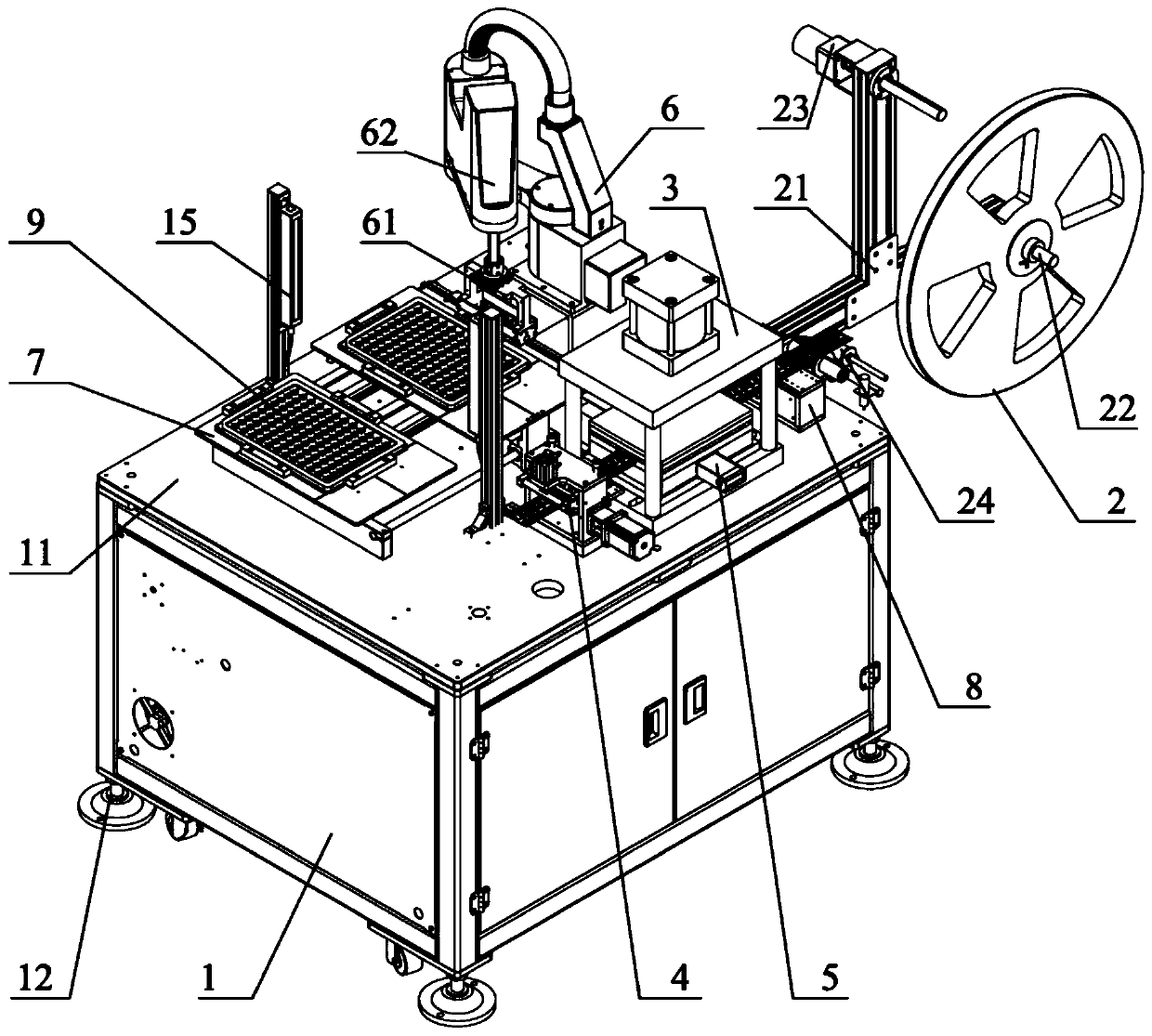

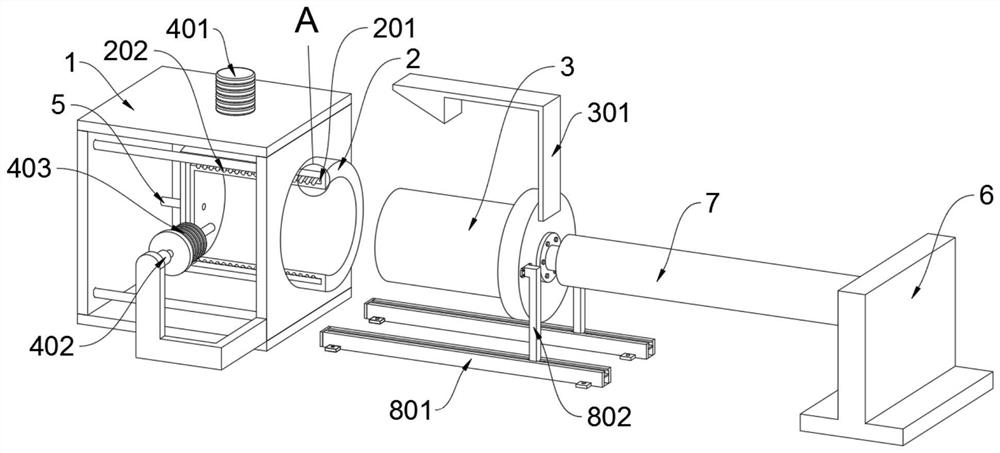

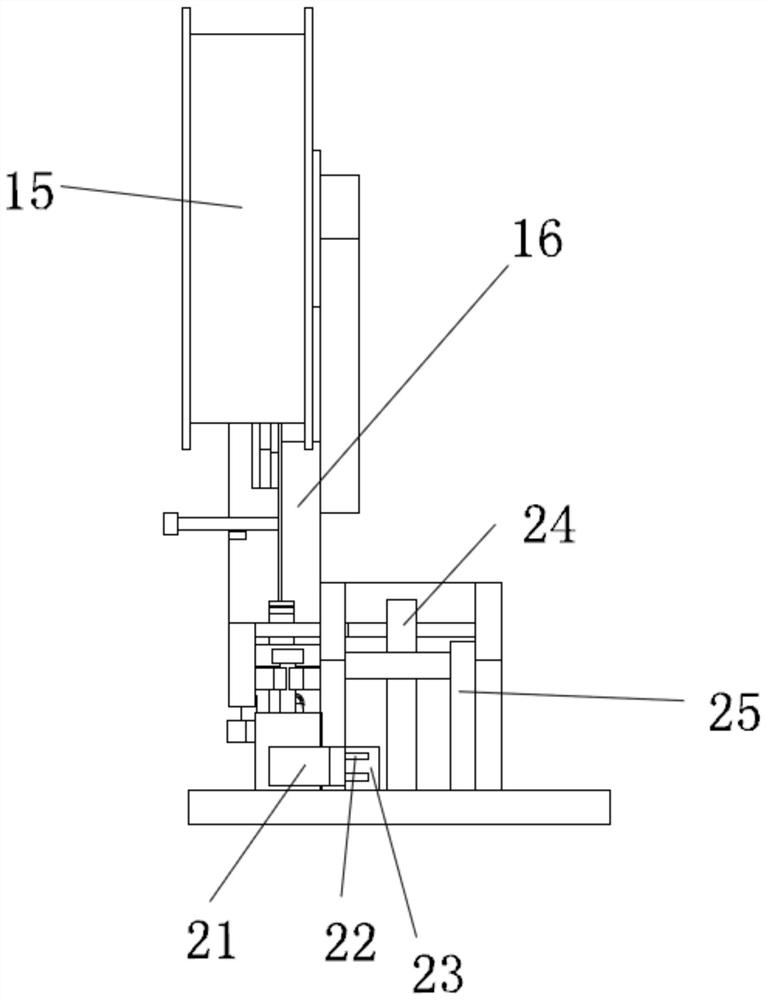

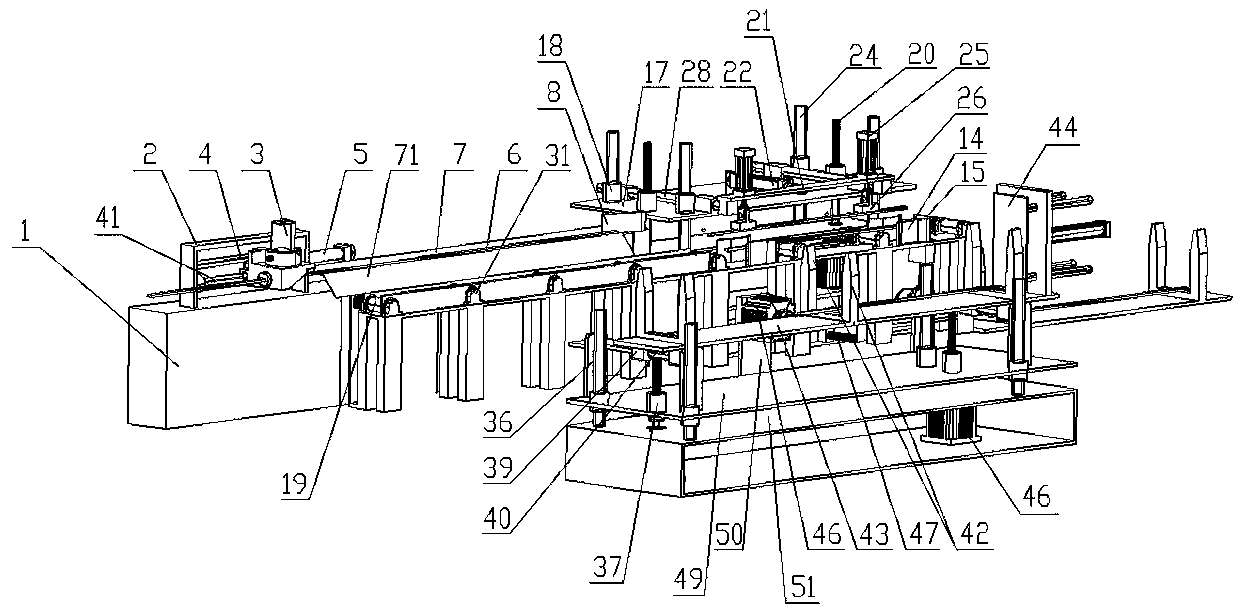

Wiper motor cover plate assembly multi-position assembly machine

PendingCN108788715ARealize automatic cut offNo manual cutting requiredAssembly machinesManufacturing dynamo-electric machinesAssembly machine

The invention provides a wiper motor cover plate assembly multi-position assembly machine. The wiper motor cover plate assembly multi-position assembly machine comprises a rack assembly, a rotary diskmechanism, a conductive bar press-cutting mechanism, a rubber pad mounting mechanism and a soldering tin and adhesive dispensing mechanism. The rubber pad mounting mechanism and the soldering tin andadhesive dispensing mechanism are arranged on the outer side of a rotary disk. The conductive bar press-cutting mechanism comprises a first cylinder, a sliding seat, a second cylinder, a clamping plate, a pressure head and a cutoff rod. The sliding seat is slidably arranged on the rack assembly through a sliding pair. The first cylinder is fixed to the rack assembly and drives the sliding seat torise and drop. The pressure head is mounted on the lower portion of the sliding seat. The second cylinder is fixed to the sliding seat. The clamping plate is fixed to a telescopic rod of the second cylinder. The cutoff rod is mounted on the clamping plate and penetrates through the pressure head. The first cylinder drives the pressure head to drop in place to press a conductive plate on a workpiece, the cutoff rod is aligned with a connecting section between two adjacent conductive bars, the second cylinder drives the cutoff rod to rush downwards to cut off the connecting section. In this way, the conductive plate on a wiper motor cover plate assembly is automatically cut off without manual cutoff, and the working efficiency is improved.

Owner:GUANGZHOU JIANENG AUTOMATION EQUIP CO LTD

Automatic cutting-off device in textile fabric winding process

InactiveCN112064188ANeat cutting effectRealize automatic cut offWeft knittingTextile selvedgesRolling-element bearingStructural engineering

The invention provides an automatic cutting-off device in a textile fabric winding process. A round wheel is slidably mounted in a mounting plate, an inclined groove is formed in the surface of the round wheel, a bottom block is mounted at the bottom of the round wheel through a rolling bearing, and a compression spring is fixedly connected between the lower surface of the bottom block and the lower wall of the interior of the mounting plate; and connecting rods are fixedly mounted on the front surface and the rear surface of the bottom block, and a cutter is fixedly mounted between every twoadjacent connecting rods. The diameter of a fabric on the outer surface of a winding roller is larger and larger, thus a movable rod is driven to move leftwards, based on a lever principle, the movable rod drives a transverse rod to slide rightwards in a top seat, when the push block moves rightwards, the round wheel is pressed by an inclined face to move downwards in the mounting plate, meanwhile, through design of the inclined groove and a protruding column, the round wheel is driven to rotate clockwise by a certain distance, the connecting rod on the lower surface of the bottom block and the cutters are driven to move downwards together, the textile fabric is cut off on the upper surface of a cutter holder, and therefore the purpose of automatic cutting in the winding process is achieved.

Owner:梁春惠

Detecting and cutting machine with automatic classification detection function

The invention relates to the field of flexible flat cable (FFC) manufacturing equipment, in particular to a detecting and cutting machine with an automatic classification detection function. The detecting and cutting machine comprises a machine frame, a feeding component, a detecting component, a first conveying component, a cutting component, a classification detection component and a second conveying component, wherein the feeding component, the detecting component, the first conveying component, the cutting component, the classification detection component and the second conveying componentare sequentially disposed on the machine frame. The classification detection component comprises a classification detection bracket fixed to the upper part of the second conveying component, a classification detection plate rotatably connected to the classification detection bracket about the axis in the horizontal direction, a classification detection cylinder fixed to the lower part of the classification detection plate, a vacuum chuck fixed to the lower part of the classification detection cylinder for adsorbing products on the second conveying component and a classification detection motor for driving the classification detection plate to rotate. Through the cooperation of the detecting component, the cutting component and the classification detection component, automatic cutting of the products and automatic classification of good products and defective products are achieved, a lot of manpower and time are saved, and production efficiency is improved.

Owner:深圳市今日之星电子科技有限公司

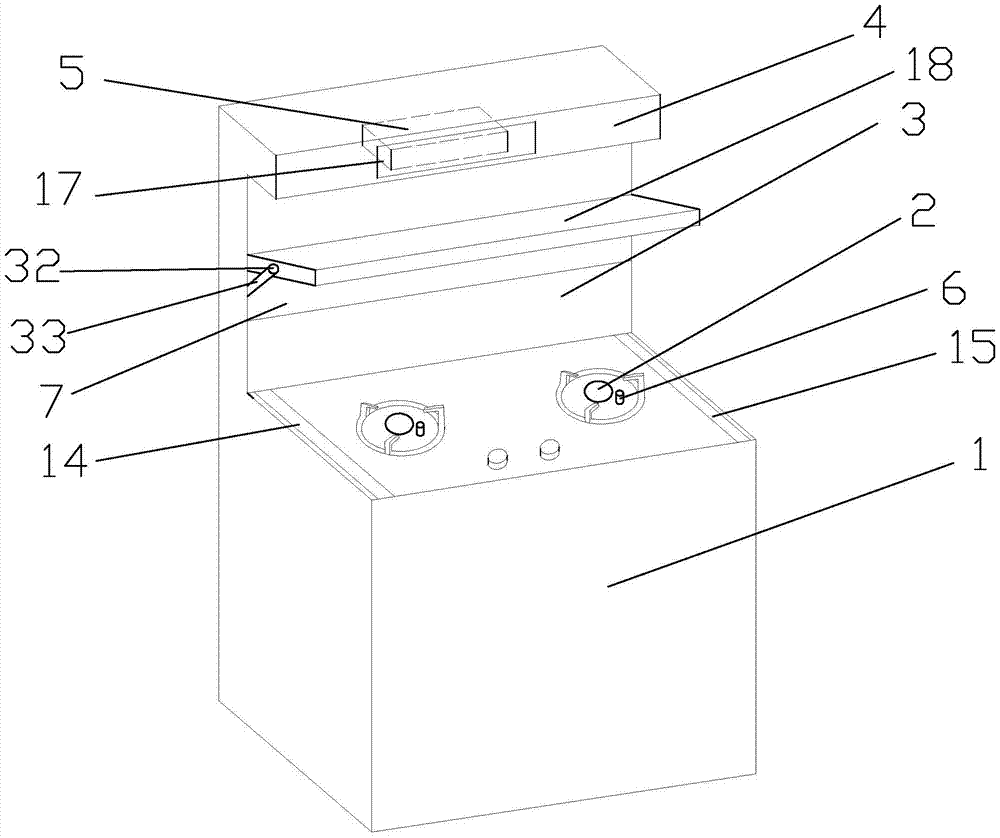

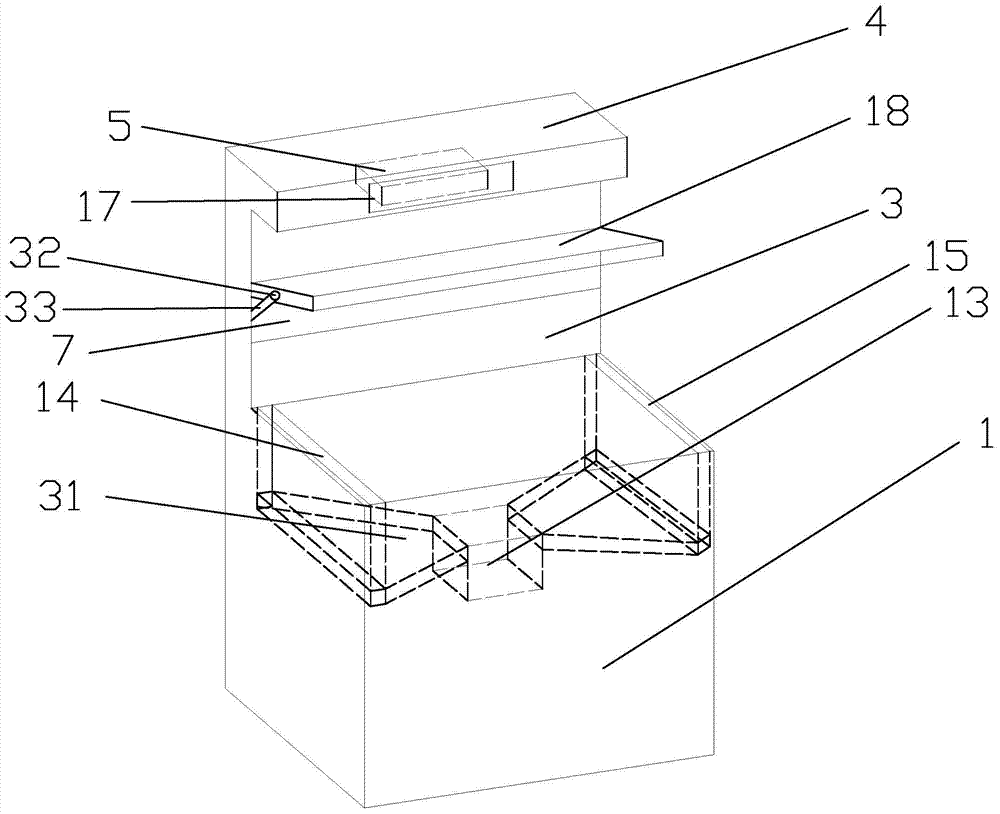

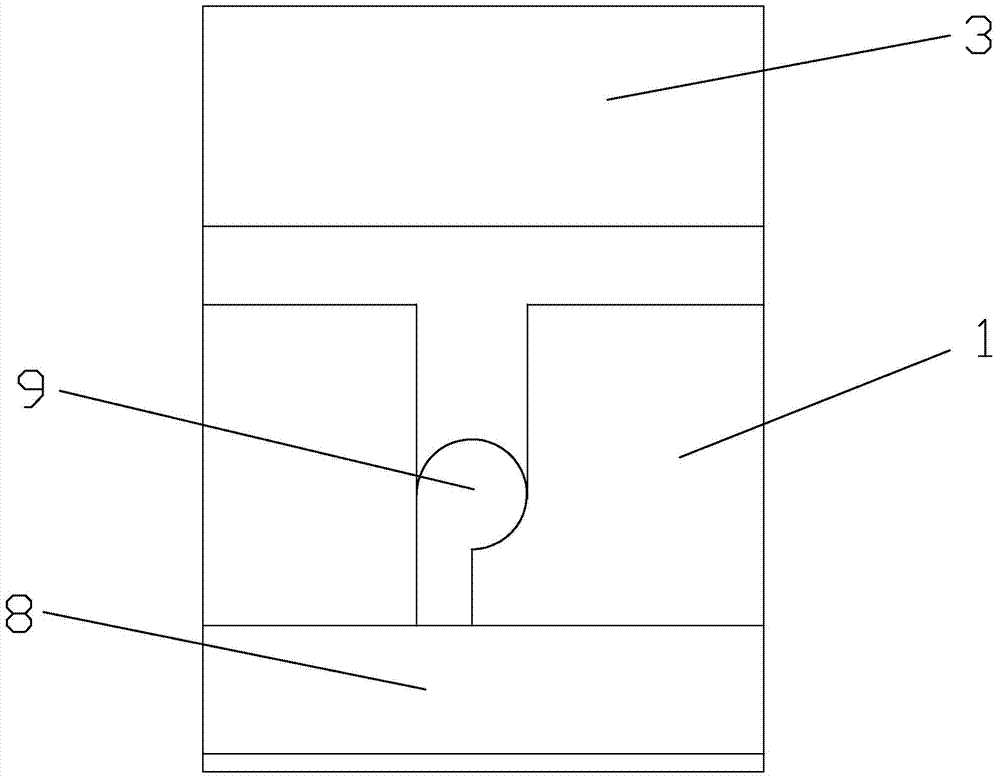

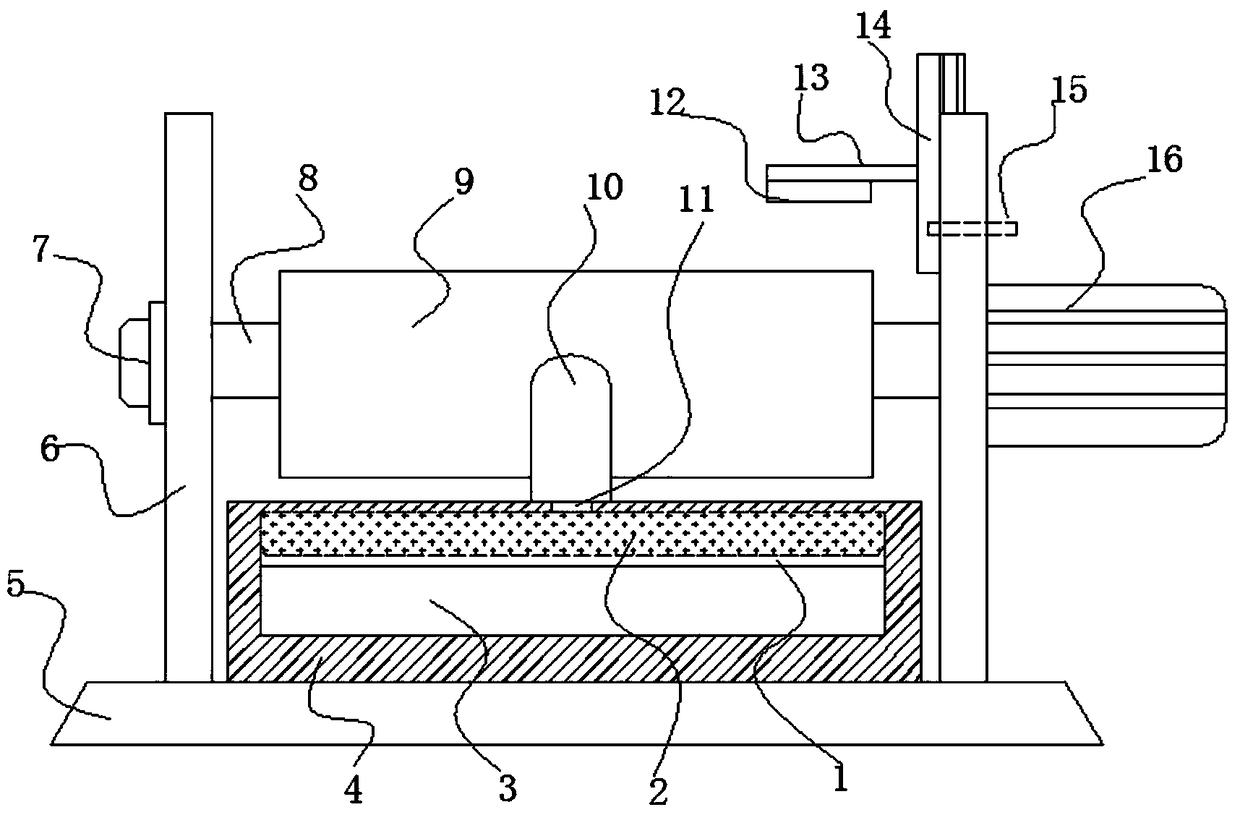

Intelligent temperature control ion induction super suction integrated stove

ActiveCN105371332BRealize automatic cut offRealize automatic controlDomestic stoves or rangesLighting and heating apparatusSolenoid valveEngineering

The present invention proposes an intelligent temperature-controlled ion induction super-absorption integrated cooker capable of improving the safety performance of the integrated cooker and the oil fume absorption effect. machine (3), the range hood (3) is connected with a top cover (4), the top cover (4) is provided with a controller (5), the cooker (2) is provided with a sensor needle (6), and the range hood (3) is provided with There are air suction port (7), exhaust pipe (8), fan (9), temperature sensor (10) is arranged at the air suction port (7), and the cooker (2) is connected with solenoid valve (11), solenoid valve (11) A gas pipeline (12) is connected, an air curtain generator (13) is arranged inside the box body (1), the air curtain generator (13) is connected with an air supply pipeline (31), and the left side of the cooker (2) is provided with Air outlet one (14) and the right side are provided with air outlet two (15), and air outlet one (14) and air outlet two (15) are all sealed and connected with the air supply pipeline (31).

Owner:ZHEJIANG KODEAR KITCHEN ELECTRICAL APPLIANCES

Automatic cut-off, blanking and packaging machine

PendingCN111017345ARealize automatic cut offEasy to operatePackagingIndustrial engineeringBelt conveyor

The invention provides an automatic cut-off, blanking and packaging machine. The machine comprises a rack, wherein the rack is provided with a material discharging device, a stamping blanking device and a material pulling device in sequence, a belt conveyor is arranged below a blanking port of the stamping blanking device, an automatic material taking device for grabbing products and a placing device for placing the grabbed products are arranged at the discharging end of the belt conveyor, the stamping blanking device can punch the products from a material belt, the punched products automatically falls onto the belt conveyor to be conveyed, and the automatic material taking device can automatically grab the products conveyed on the belt conveyor, and automatically place the grabbed products on the placing device. According to the machine, automatic cut-off, blanking and packaging of the products are achieved, manpower and time are effectively saved, the situations that the products areprone to being missed, and the products are polluted are avoided, the application range is wide, and stability and reliability are high, so that the production efficiency and the overall quality of the products are improved, the production cost is reduced, and production management and control are facilitated.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

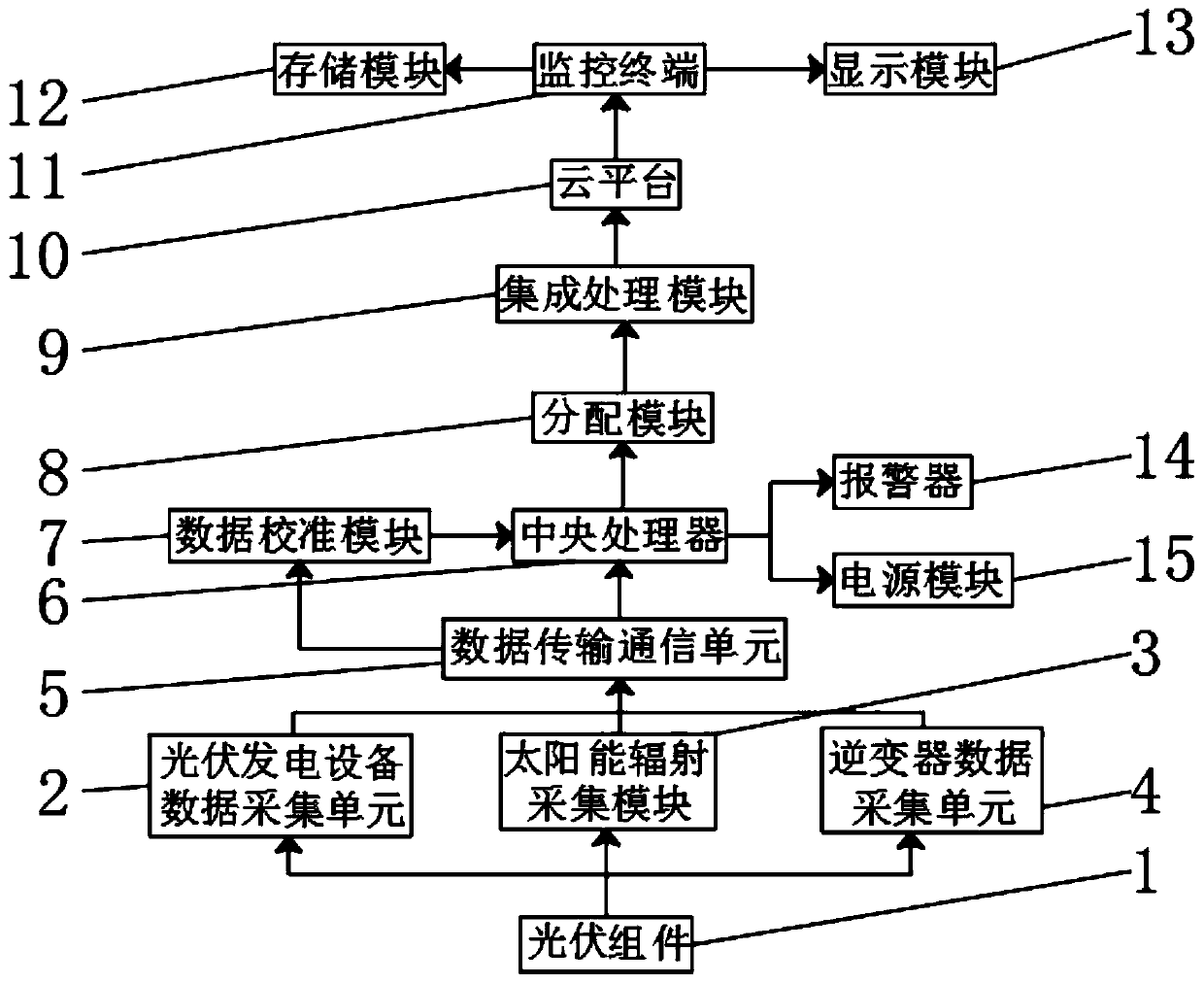

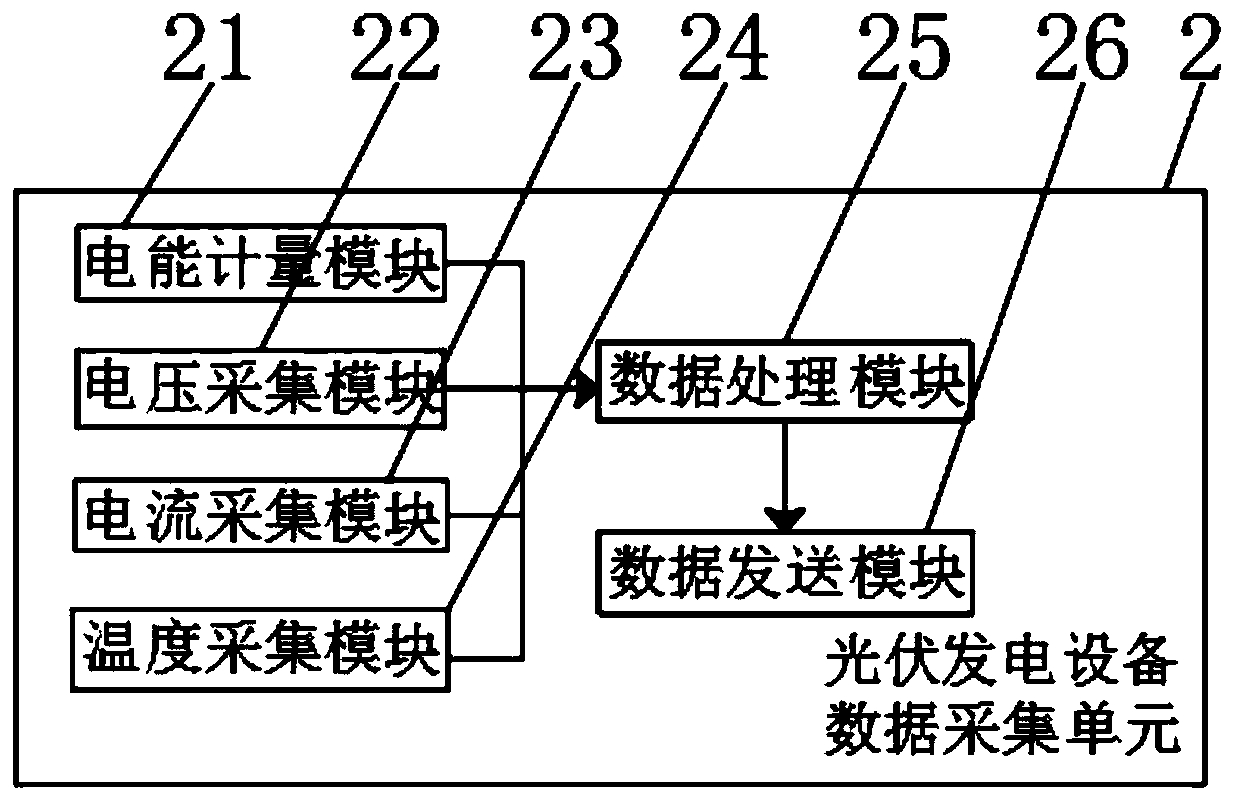

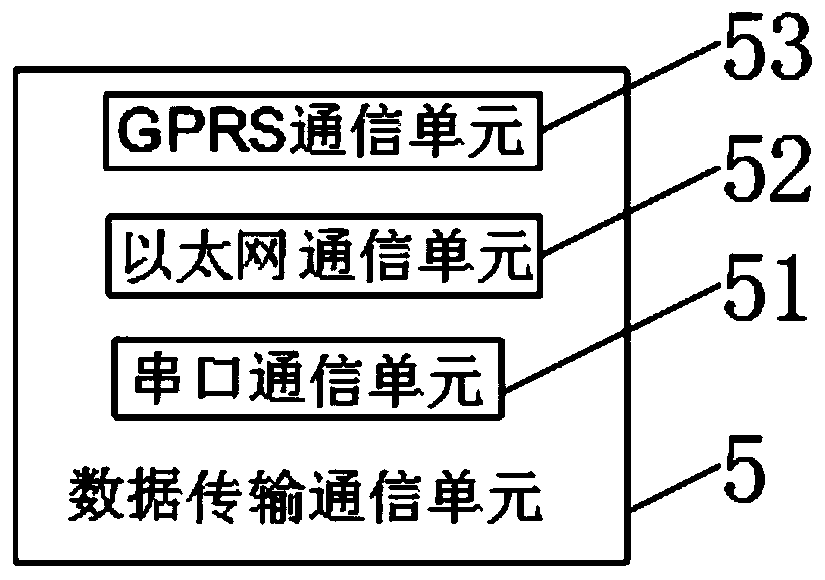

Outdoor photovoltaic data acquisition device

InactiveCN110048673AIncrease varietyEnsure comprehensivenessPhotovoltaic monitoringCircuit arrangementsCommunication unitPower switching

The invention discloses an outdoor photovoltaic data acquisition device, and belongs to the technical field of photovoltaic data acquisition. A photovoltaic assembly is in electrical output connectionwith a photovoltaic power generation equipment data acquisition unit for performing data acquisition on photovoltaic power generation equipment, a solar radiation acquisition module for performing data acquisition on solar radiation intensity, and an inverter data acquisition unit for performing data acquisition on an inverter. A data transmission communication unit is in electrical output connection with a central processing unit for processing acquired data and a data calibration module for calibrating the acquired data; the central processing unit is in electrical output connection with analarm, a power module and a distribution module for performing category distribution on the acquired data. The number of data acquisition ways is large, parameter data acquisition is comprehensive, automatic classified induction and arrangement can be achieved, and when parameter data acquisition is abnormal, an alarm can be automatically given out, and a power switch can be automatically cut off.

Owner:JIAXING UNIV

Automatic sealing system for IC product packaging

PendingCN111196387ARealize automatic cut offRealize continuous operationPackaging automatic controlPackaging machinesEngineeringElectrical and Electronics engineering

The invention provides an automatic sealing system for IC product packaging. The automatic sealing system comprises a worktable with a collection hole; a rubber plug inserting and plugging assembly and an ejecting and pushing assembly are arranged on two ends of the collection hole; the collection hole and a propulsion assembly are located on both sides of a storage assembly; the storage assemblyis used for storing packaging tubes parallel to the collection hole in a stacked manner; a discharge opening adaptive to the single packaging tubes is formed in the bottom end of the storage assembly;the rubber plug inserting and plugging assembly comprises an inserting and plugging cavity, a cutter and a pushing and plugging rod; the inserting and plugging cavity and the collection hole are collinear; after the propulsion assembly pushes the packaging tubes on the lowest layer to a part above the collecting hole through the discharge opening, the ejecting and pushing assembly acts on the rear ends of the packaging tubes, so that opening ends of the packaging tubes are inserted into the inserting and plugging cavity; and after a rubber plug strip guiding assembly transfers a rubber plug strip to the inserting and plugging cavity, the cutter can cut off the rubber plug strip into single rubber plugs, and the pushing and plugging rod can drive the rubber plugs to be inserted into the opening ends of the packaging tubes. Through the cooperation of the cutter and the pushing and plugging rod in the inserting and plugging cavity, the rubber plug strip is automatically cut off and the packaging tubes are blocked at the same time, and the packaging tubes are automatically sealed and collected efficiently and quickly.

Owner:四川明泰微电子科技股份有限公司

Bean starch sheet cutting device with automatic cut-off function

InactiveCN105216037AQuality improvementGreat tasteMetal working apparatusFood preparationProduction rateMechanical engineering

The invention discloses a bean starch sheet cutting device with an automatic cut-off function. The bean starch sheet cutting device comprises a bracket, a cutting part for cutting a bean starch sheet into bean vermicelli, a third cylinder fixing the bean vermicelli, an automatic cutter and a power mechanism. According to a bean starch sheet steaming device provided by the invention, the cutting part is set to be two cylinders, and grooves are formed in the cylinders at an equal distance for extruding and cutting the bean starch sheet into vermicelli, so that the uniformity of the vermicelli is improved, and quality and mouthfeel of the vermicelli are improved. A third cylinder is arranged behind the cutting part for absorbing and fixing the vermicelli, so that the vermicelli is prevented from swinging, and the vermicelli is kept in order. Perimeters of the cylinders are adopted for measurement, and a water-jet cutting machine is utilized to automatically cut off the vermicelli to obtain the vermicelli with a uniform length, so that the production rate is increased.

Owner:广西壮香缘食品有限公司

Plastic injection molding machining mold facilitating heat dissipation and workpiece arrangement

InactiveCN111844662AImprove cooling effectRealize automatic cut offPlastic injection moldingCooling effect

The invention provides a plastic injection molding machining mold facilitating heat dissipation and workpiece arrangement, relates to the field of injection molding machining, and solves the problem that an existing device cannot achieve mixing of cooling gas in a mold female base through a mechanical linkage means to improve the cooling effect, the existing device cannot achieve automatic close-range cutting after injection molding is completed, on the one hand, manual cutting wastes time, and injection molding raw material is wasted. The plastic injection molding machining mold facilitatingheat dissipation and workpiece arrangement comprises a frame body, and the mold female base is welded on the frame body; plastic liquid is jetted into the mold female base through a feeding pipe, at the moment, a locking rod moves forwards to make contact with the head end of the pipe body under the thrust effect of the liquid, an elastic piece is in a compressed state at the moment, a feeding groove is in communication with the pipe body at the moment, and therefore the normal distribution of the plastic liquid is kept; after liquid injection is finished, the locking rod is pushed by the elastic force of the elastic piece to return to the initial position, and the pipe body returns to the initial sealing state.

Owner:潘武杰

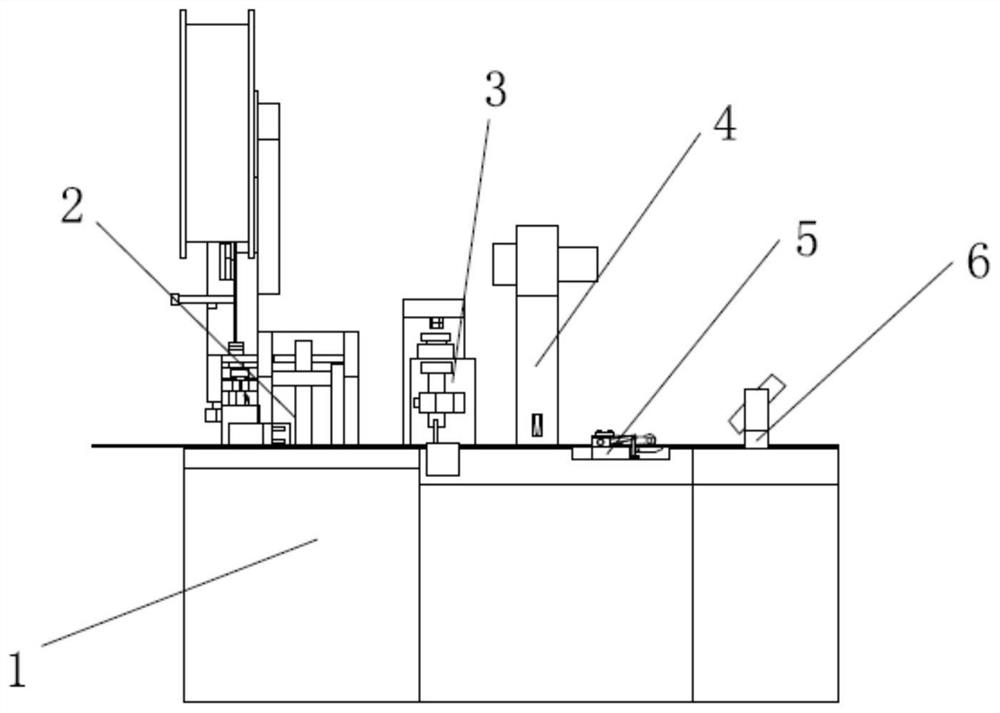

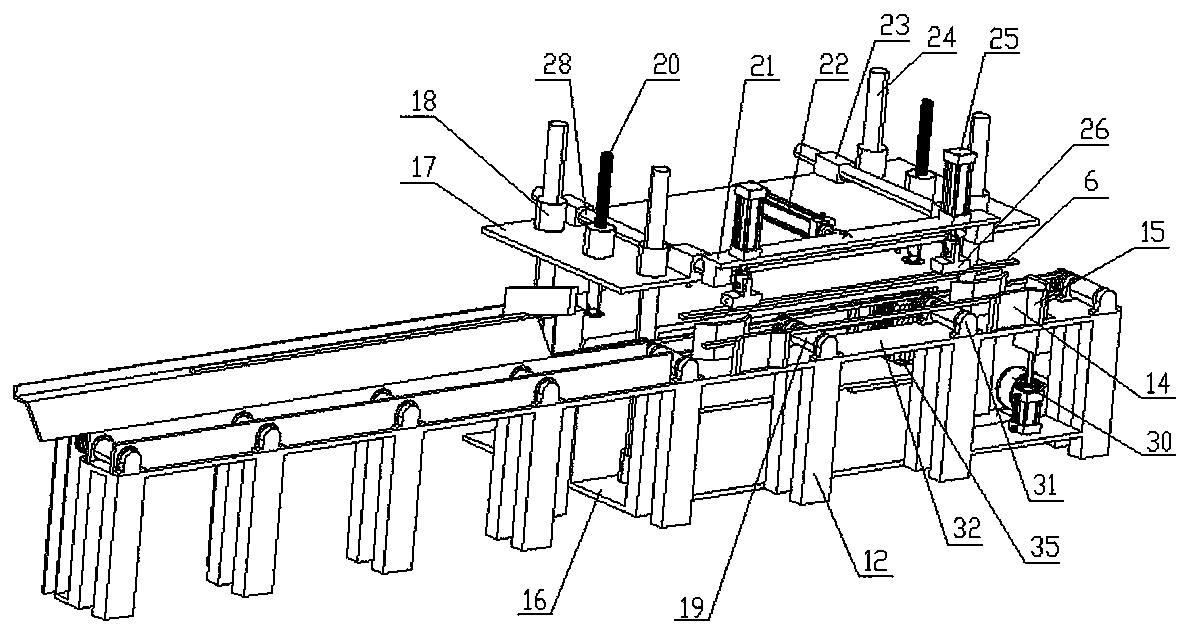

Full-automatic reed welding machine

ActiveCN113441808ARealize automatic cut offHigh degree of automationWelding/cutting auxillary devicesUsing mechanical meansWire cuttingEngineering

The invention relates to a full-automatic reed welding machine. The full-automatic reed welding machine comprises a machine table, a reed transmission platform and a contact welding machine, the reed transmission platform used for reed installation is installed on the upper end face of the machine table, the contact welding machine, a contact welding force detection machine, a contact trimming machine, a reed transmission machine and a detection structure are installed on the reed transmission platform from left to right, a silver wire transmission arm, a silver wire cutting-off base and a welding copper block are arranged in the contact welding machine, the silver wire transmission arm moves front and back, the front end of the silver wire transmission arm conveys a silver wire into the silver wire cutting-off base located on the reed transmission platform, the cut silver wire is welded into a reed structure in the reed transmission platform through the welding copper block with the rear portion moving downwards in an inclined mode, a shifting piece matched with a contact on the reed structure is arranged in the contact welding force detection machine, and a contact trimming rod capable of moving up and down is arranged on the contact trimming machine. The full-automatic reed welding machine has the characteristics of low energy consumption, stable reed transmission, high production efficiency, accurate positioning, improvement of product quality and the like.

Owner:BULL GRP CO LTD +1

Automatic cabbage harvester device

InactiveCN112166812ARealize automatic cut offReach harvestHarvestersAgricultural engineeringStructural engineering

The invention relates to the related field of harvesters, and discloses an automatic cabbage harvester device. The device comprises a harvester, wherein a processing body is fixedly connected to the left end face of the harvester, a storage cavity is formed in the harvester, a connecting cavity is formed in the left end wall of the storage cavity in a communicating mode, a conveying cavity extending towards the lower left portion is formed in the left end wall of the connecting cavity in a communicating mode, a lifting wheel cavity located on the left side of the conveying cavity is formed inthe harvester, a lifting cavity is formed in the left end wall of the lifting wheel cavity in a communicating mode, and a cutting body sliding cavity with a leftward opening is formed in the lower endwall of the lifting cavity in a communicating mode. A cutting knife is driven to rotate through friction between a friction block and a cutting wheel to automatically cut off cabbage rhizomes, meanwhile, through friction fit between a friction wheel and a lifting plate and power fit between a bevel gear and a shaft, operation of a conveying belt and lifting of a supporting plate are achieved, therefore harvesting and conveying of cabbages are achieved, the automation degree of cabbage collecting is greatly improved, efficiency is improved, and production quality is guaranteed.

Owner:杭州千川苗智能科技有限公司

Flat steel production device with cutting-off, blanking and discharging functions

PendingCN107755777ARealize automatic cut offRealize automatic nestingShearing machinesMetal working apparatusProduction lineEngineering

Owner:WUXI TIANCHI STEEL BAND CO LTD

Adhesive tape winding device for self-adhesive paper production

InactiveCN108750760AImprove applicabilityQuickly adjust the thicknessWebs handlingAdhesive beltDrive shaft

The invention discloses an adhesive tape winding device for self-adhesive paper production. The adhesive tape winding device for self-adhesive paper production comprises a base, supporting plates which are vertically arranged are welded to the two ends of the top of the base, a horizontal transmission shaft is rotatably connected between the two supporting plates, the outer wall of the transmission shaft is sleeved with a winding drum, a drive mechanism is arranged on the outer wall of one side of one supporting plate, a sliding groove is formed in the outer wall of the side, close to the other supporting plate, of one supporting plate, a controller is fixed to the outer wall of one side of the other supporting plate through a screw, a sliding plate is in sliding connection to the inner wall of the sliding groove, and a horizontal bottom plate is welded to the outer wall of one side of the sliding plate. When adhesive tape is wound to reach the set thickness, adhesive tape and a pressure sensor make contact, the pressure sensor transmits a signal to a controller, an air cylinder is controlled to be started through the controller, a cut-off knife is driven by a piston rod of the aircylinder to move downwards, the adhesive tape is cut off, the adhesive tape is automatically cut off, and adaptation is high.

Owner:浙江绿洲胶粘制品有限公司

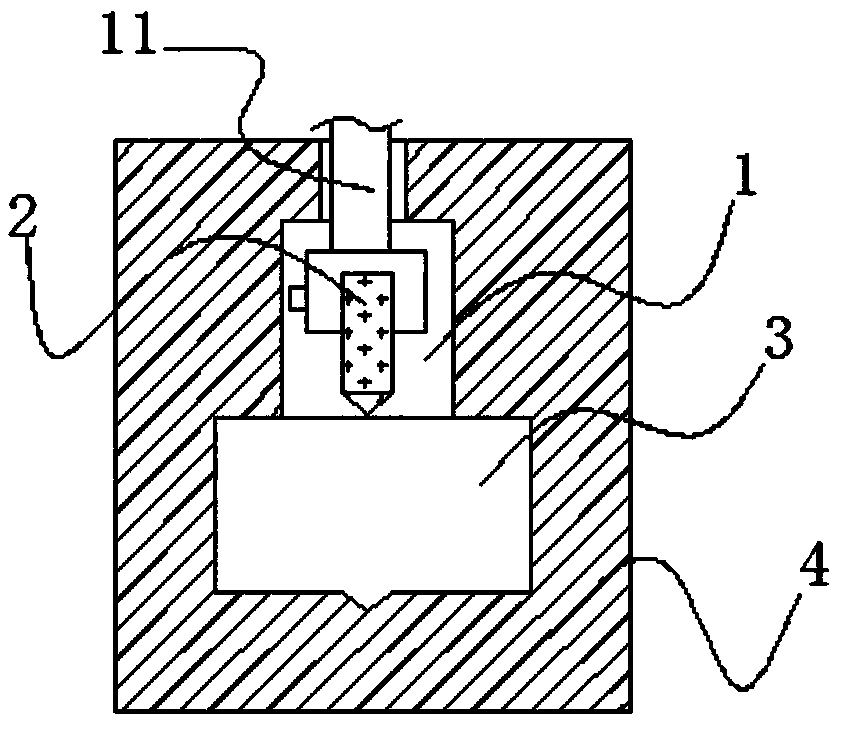

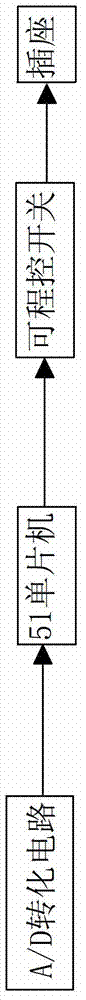

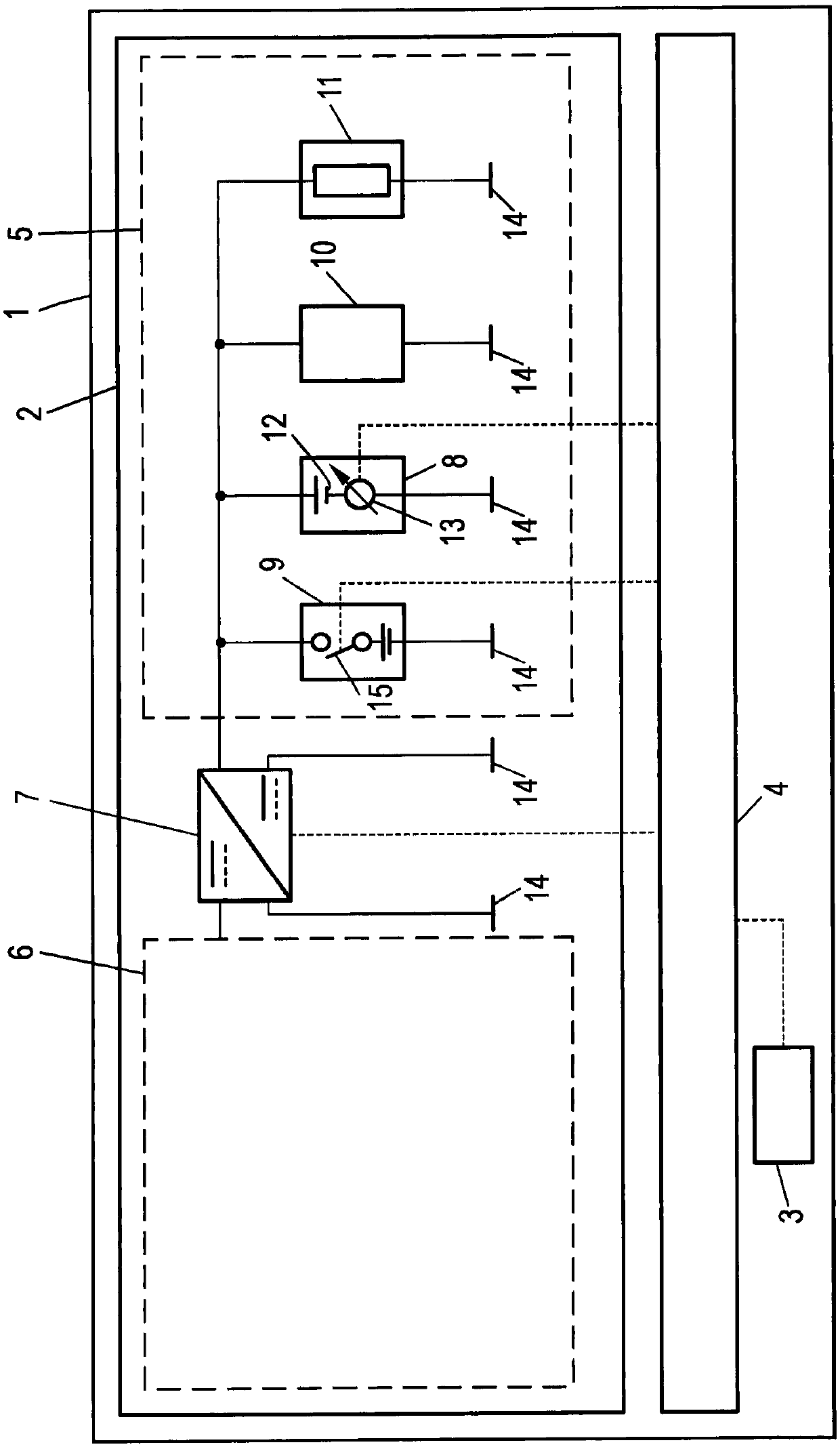

Safety socket

InactiveCN103715560AAvoid burningSimple structureCoupling device detailsIntelligent control systemEngineering

The invention discloses a safety socket which can automatically cut off the power supply according to the socket current. The safety socket includes a socket box. The socket box is provided with jacks. The inside of the socket box is provided with an intelligent control system. The safety socket can automatically cut off the power supply according to the socket current, so the burnout of an electrical appliance on the socket caused by the overcurrent is prevented, and the safety of the electrical appliance is guaranteed. The safety socket is simple in structure, strong in practicality, and low in cost.

Owner:李信

Self-adaptive automatic shearing system for steel bar and steel belt welding line

InactiveCN108544244AGuaranteed uptimeRealize automatic cut offOther manufacturing equipments/toolsMetal working apparatusSteel barEngineering

The invention discloses a self-adaptive automatic shearing system for a steel bar and steel belt welding line. The system comprises a coil stock straightening system driven by an asynchronous motor, asteel bar wound around a steel bar coil is straightened through the coil stock straightening system, long materials and short materials are welded into steel bars and steel belts through a welding system and then enter a shearing mechanism to be sheared, and a storage cache and feedback system is further arranged between the shearing mechanism and the coil stock straightening system. By means ofreasonable structural design, the coil stock straightening system and a synchronous feeding device are matched, meanwhile, the storage cache and feedback system is introduced on the movement trajectory of the long materials between the coil stock straightening system and the synchronous feeding device, certain discharge cache can be carried out on steel bars between the coil stock straightening system and the synchronous feeding device, and therefore when a shearing working procedure is carried out on the steel bars and the steel belts, the steel bars and the steel belts on the shearing working procedure section can be suspended to be sheared, the coil stock straightening system does not need to be stopped, and safe and reliable operation of the system is ensured.

Owner:XI'AN PETROLEUM UNIVERSITY

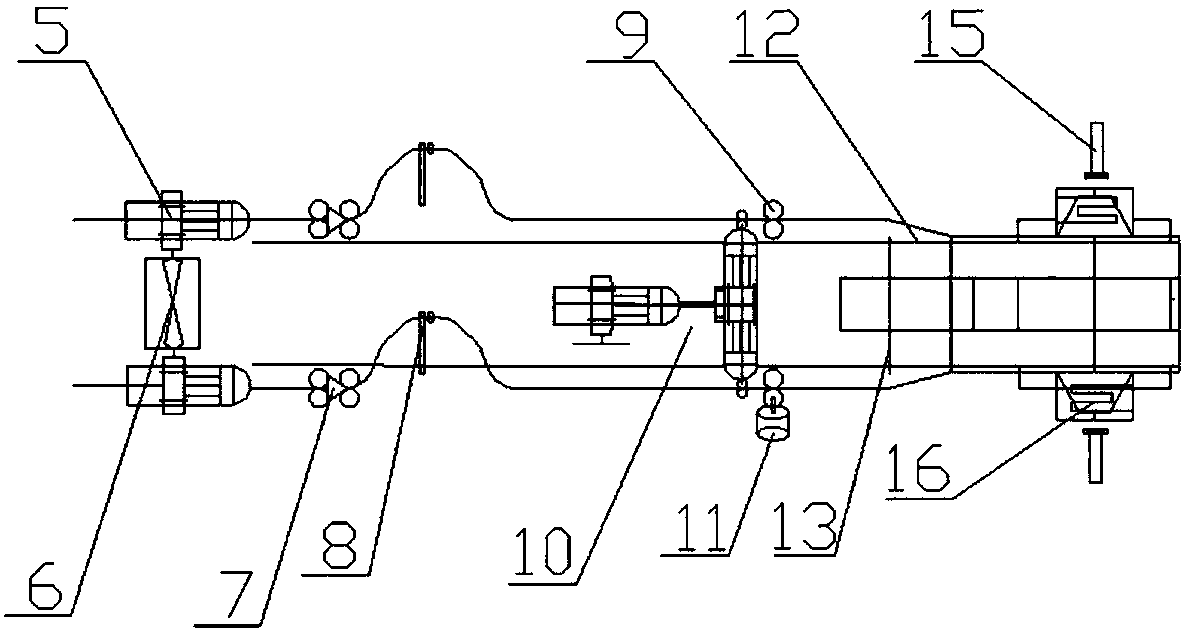

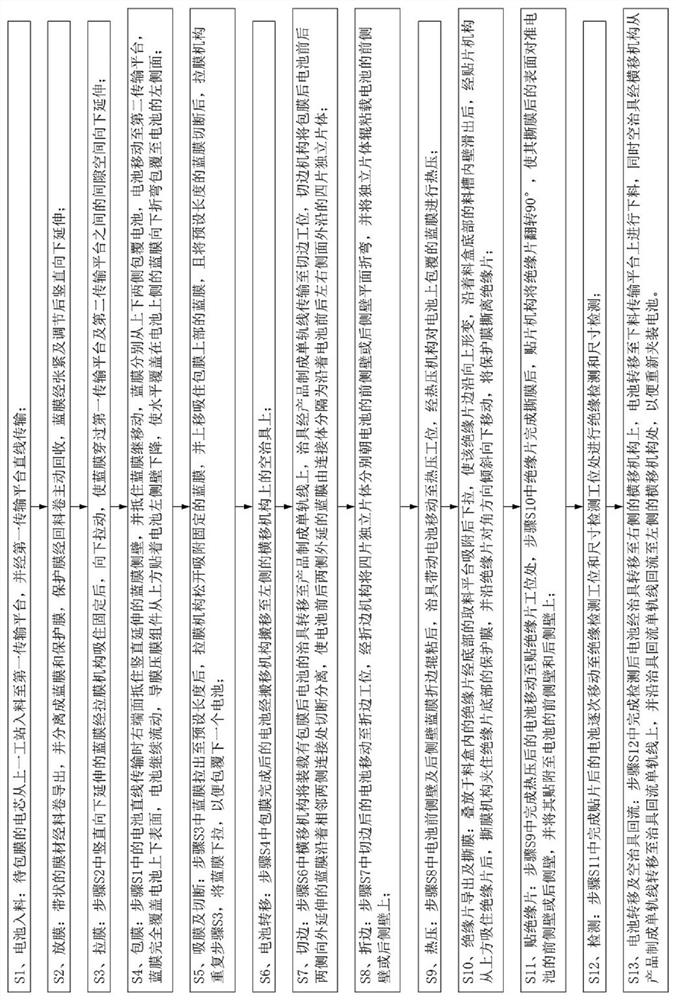

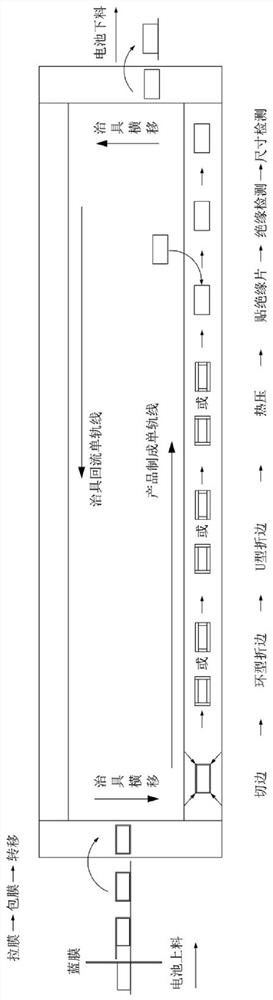

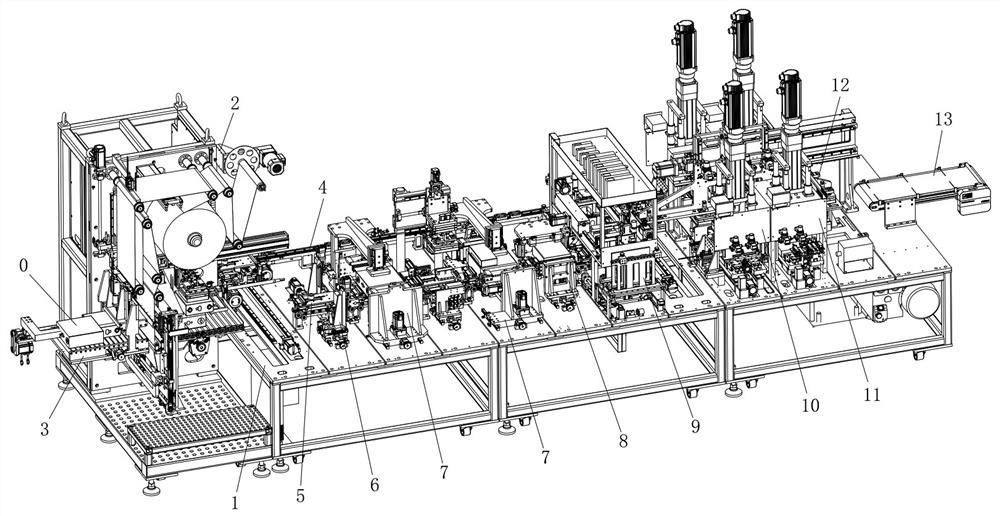

Battery coating edge cutting and folding patch production line and coating edge cutting and folding patch process thereof

ActiveCN114162657AAchieve recirculationIncrease production capacityAssembling battery machinesFinal product manufactureProduction lineElectrical battery

The battery coating edge cutting and folding patch production line comprises a coating part, a circulating transmission part, a film processing part and a detection discharging part, and the circulating transmission part comprises two single-rail lines arranged in parallel at an interval and jig transverse moving mechanisms arranged at the two ends of the two single-rail lines; the film coating part is arranged on one side of the monorail line and comprises a film releasing device and a film coating device which are arranged up and down; the film processing part is arranged on the monorail line and comprises an edge cutting mechanism, an edge folding mechanism, a hot pressing mechanism and a surface mounting mechanism which are sequentially arranged along the monorail line. According to the invention, the belt-shaped blue film can be automatically separated from the protective film and can be automatically cached and guided out, the belt-shaped blue film can finish automatic coating of the blue film in synchronous battery transmission, the jig carries the battery to finish automatic edge cutting, edge folding and insulation sheet pasting among the stations, the jig circulates and flows back, the capacity of the whole line is improved, and automatic full coating of the outer side of the battery is realized.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

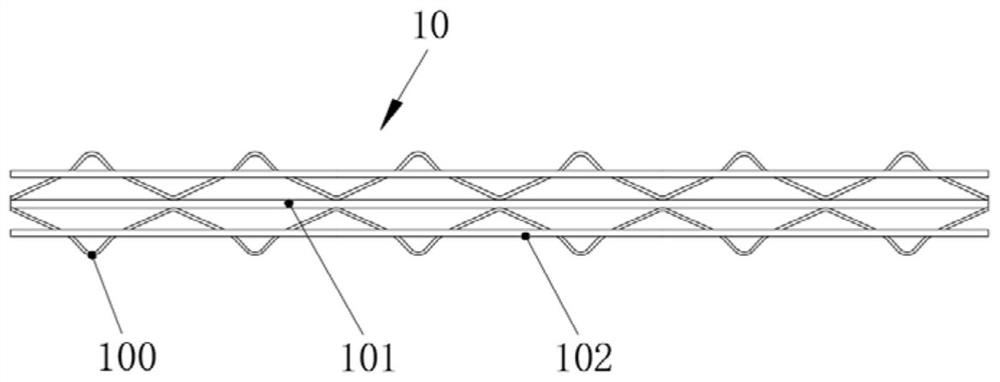

Anti-winding and rolling integrated ribbon loom

The invention discloses an anti-winding and rolling integrated ribbon loom which comprises a frame, a warping device, a spinning device, an anti-winding mechanism, a rolling mechanism and a cutting mechanism. The rolling mechanism, the cutting mechanism, a thread coil, the warping device, the spinning device and the anti-winding mechanism are sequentially arranged in the frame from right to left. According to the anti-winding and rolling integrated ribbon loom, a braid woven and formed through the spinning device enters the anti-winding mechanism and is sequentially wound around a first tiling roller, a driving roller, a second tiling roller and a third tiling roller, the surface of the driving roller is wrapped with roller leather, the friction force of the driving roller to the braid can be increased, and meanwhile under the action of the first tiling roller and the second tiling roller, the contact area between the braid and the surface of the driving roller is reasonably increased, the slipping phenomenon between the driving roller and the braid is avoided, under the action of the driving roller, the braid can be flattened and combed through the first tiling roller, and the braid is prevented from being folded and wound.

Owner:义乌亮彩织带有限公司

Method for operating an electrical system of a motor vehicle, and motor vehicle

ActiveCN107735276AMake sure there is no voltageGuaranteed uptimeElectric devicesElectric/fluid circuitMotor vehicle partOn board

The invention discloses a method for operating an electrical system of a motor vehicle, and a motor vehicle. The invention relates to a method for operating an electrical system (2) of a motor vehicle(1), said electrical system (2) comprising a first power source (8) for providing an operating voltage for at least one partial on-board network (5, 6) of the electrical system (2) and at least a second power source (7, 9), wherein an electrically conductive connection of the first power source (8) to the electrical system (2) is monitored for an intentional interruption and, in the event of a detected intentional interruption of the electrically conductive connection, the at least one second power source (7, 9) of the electrical system (2) is separated therefrom and / or deactivated.

Owner:AUDI AG

Processing device for fragrant pigs

The invention relates to a processing device for fragrant pigs. The processing device comprises a motor, a worktable, a first meat mincing bin and a second meat mincing bin. The second meat mincing bin is located below the worktable, and the top of the meat mincing bin is fixedly connected with the side of the worktable. A meat mincing piece is arranged in the second meat mincing bin, a second blade is arranged on the meat mincing piece, and a rotating shaft is connected to the meat mincing piece. The rotating shaft is connected with an output shaft of the motor, and a first bevel gear is connected to the rotating shaft. The outer side of the first bevel gear is engaged with a second bevel gear, and a lead screw is connected to the second bevel gear. The first meat mincing bin is located above the worktable, and the lead screw penetrates through the side of the first meat mincing bin. The portion, located in the first meat mincing bin, of the lead screw is connected with a first blade,and the end, away from the second bevel gear, of the lead screw is engaged with a worm gear. A sliding block is slidably connected to the worktable, a connecting rod is arranged between the sliding block and the end of the worm gear, and a third blade slidably connected with an outlet of the first meat mincing bin is arranged at the top of the sliding block. According to the processing device, fragrant pork is automatically minced, and the processing efficiency is improved.

Owner:周小龙

Cutting mechanism for cable wire processing

ActiveCN109604481ARealize automatic cut offAdjustable lengthCable/conductor manufactureElectronic waste recyclingDriving mode

The invention discloses a cutting mechanism for cable wire processing. The cutting mechanism includes a vertical column, a cable cutting assembly with the adjustable length is arranged at the upper end of the vertical column, and the cable cutting assembly includes a cross beam, a rotary shaft, a first cutting cutter, a second cutting cutter and a second motor; the left end of the cross beam is mounted on a straight line guiding way of the vertical column and connected with a lifting mechanism on the vertical column; and the two ends of the rotary shaft are mounted on a bearing seat at the lower ends of a first supporting seat and a second supporting seat, the rotary shaft is connected with the second motor in a driving mode, the first cutting cutter and the second cutting cutter are mounted on the rotary shaft, the second cutting cutter is fixed to the rotary shaft, the position of the second cutting cutter on the rotary shaft cannot be adjusted, the first cutting cutter is fixed to the rotary shaft, and the position of the first cutting cutter on the rotary shaft can be adjusted. According to the cutting mechanism for cable wire processing, automatic cable cutting can be achieved, meanwhile the cutting length of a cable wire can be adjusted, the production requirement is met, the production cost is lowered, and the production efficiency is improved.

Owner:天津六0九电缆有限公司

Truss footing cutting device

PendingCN112620539ARealize automatic cut offReduce labor intensityWire networkEngineeringStructural engineering

The invention belongs to the technical field of truss machining, and discloses a truss footing cutting device. The device comprises a rack, a fixed cutter holder, cutting arms and a driving piece, the fixed cutter holder is fixed to the rack, the fixed cutter holder is symmetrically provided with two fixed cutters, a truss can be arranged on the fixed cutter holder, and a truss footing of the truss is arranged on the fixed cutters. The two cutting arms are symmetrically installed on the rack, and movable cutters are arranged on the cutting arms; and the driving piece is mounted on the rack and used for driving the cutting arms to move, so that the cutting arms drive the movable cutters to get close to the fixed cutters and are matched with the fixed cutters to cut off the truss footing. According to the truss footing cutting device, automatic cutting of the truss footing of the truss can be achieved, manual cutting is not needed, the automation degree is higher, the production efficiency is improved, and the labor intensity and potential safety hazards of operators are reduced.

Owner:TJK MACHINERY TIANJIN

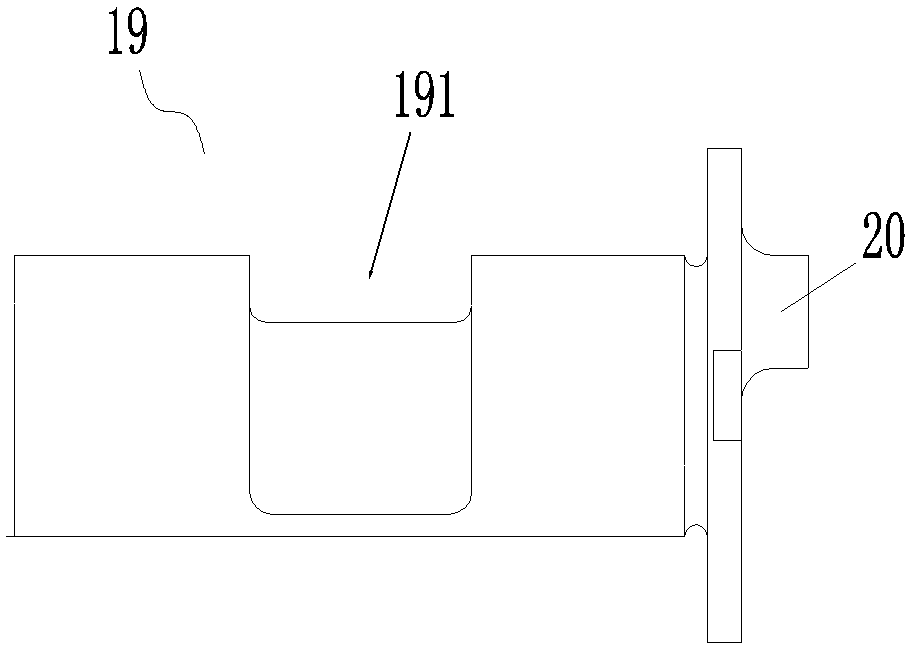

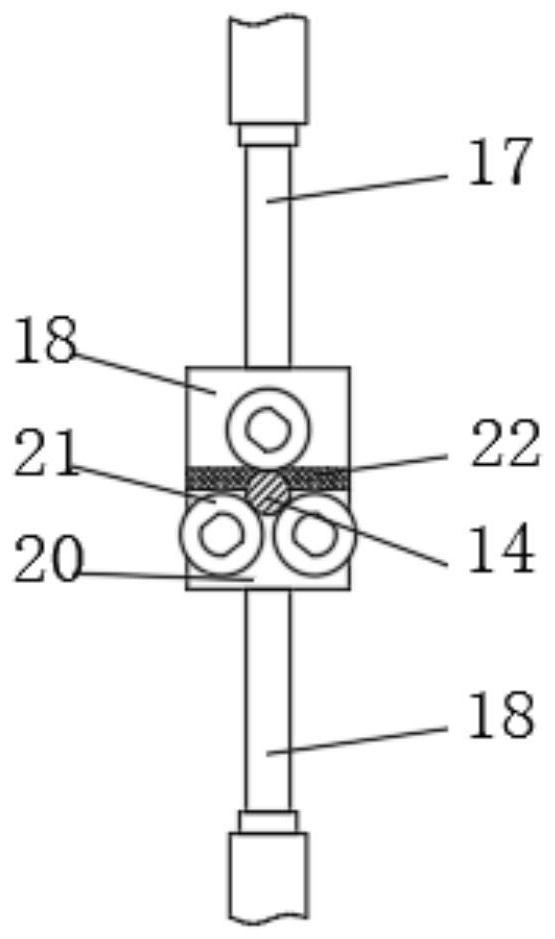

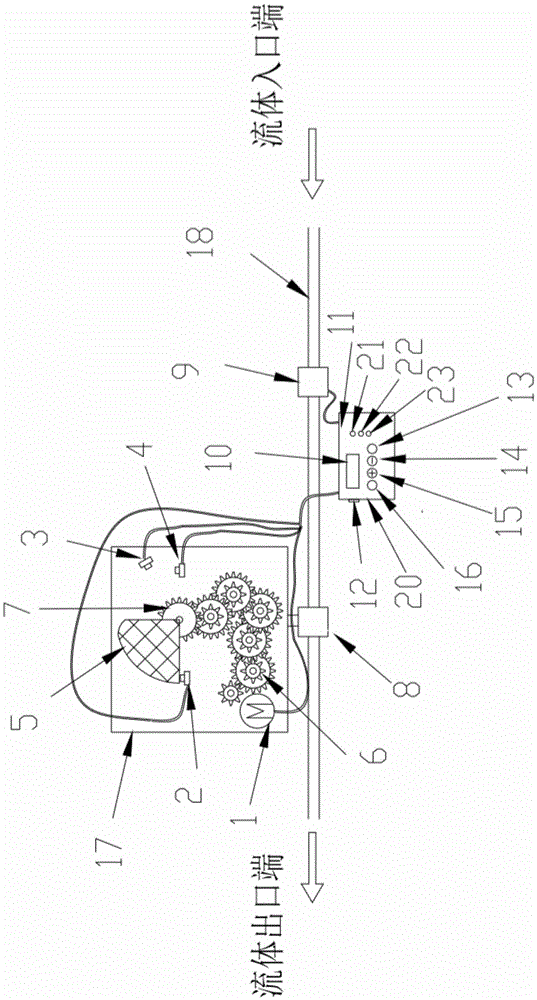

Fluid circuit breakage protector

ActiveCN105485392AEasy to controlRealize automatic cut offOperating means/releasing devices for valvesEqualizing valvesElectricityInductor

The invention discloses a fluid circuit breakage protector. The fluid circuit breakage protector is characterized by comprising a water inlet tube (18), a flow inductor (9), a valve (8), a valve electric actuator (17) and a control terminal (20), wherein the flow inductor (9) and the water inlet tube (18) are connected by threads; the flow inductor (9) is electrically connected to a control terminal (20) through a wire; the valve (8) and the water inlet tube (18) are in threaded connection; the water inlet tube (8) and the valve electric actuator (17) are in nested connection; and the valve electric actuator (17) is connected to a control terminal (20) through an electric wire. According to the fluid circuit breakage protector disclosed by the invention, the control panel and the control terminal can be in fixed power line connection, and can also be separately arranged but in wireless connection for fluid cut-off operation.

Owner:NANJING FANSKI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com