Automatic cold noodle cutting-off and gathering device

A technology of automatic cutting and cold skin, applied in metal processing and other directions, can solve problems such as low efficiency, different lengths of cold skin, difficult to arrange neatly, and achieve the effect of reducing workload, improving work efficiency and consistent length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A kind of Liangpi automatic cutting and gathering device, such as figure 1 and figure 2 As shown, it includes a base plate 1, a first support frame 2, a motor 3 and a cutting mechanism 4. The right side of the base plate 1 is provided with a first support frame 2, and a motor 3 is installed on the top of the first support frame 2. On the base plate 1 and the second A cutting mechanism 4 is provided at the lower part of the supporting frame 2, and the cutting mechanism 4 is connected with the motor 3.

[0062] When in use, first place the prepared Liangpi, start the motor 3, the output shaft of the motor 3 rotates to make the cutting mechanism 4 work, the cutting mechanism 4 moves up and down to cut the Liangpi, turn off the motor 3, so that the cutting mechanism 4 stops cutting the Liangpi, and again When in use, repeat the above operations.

Embodiment 2

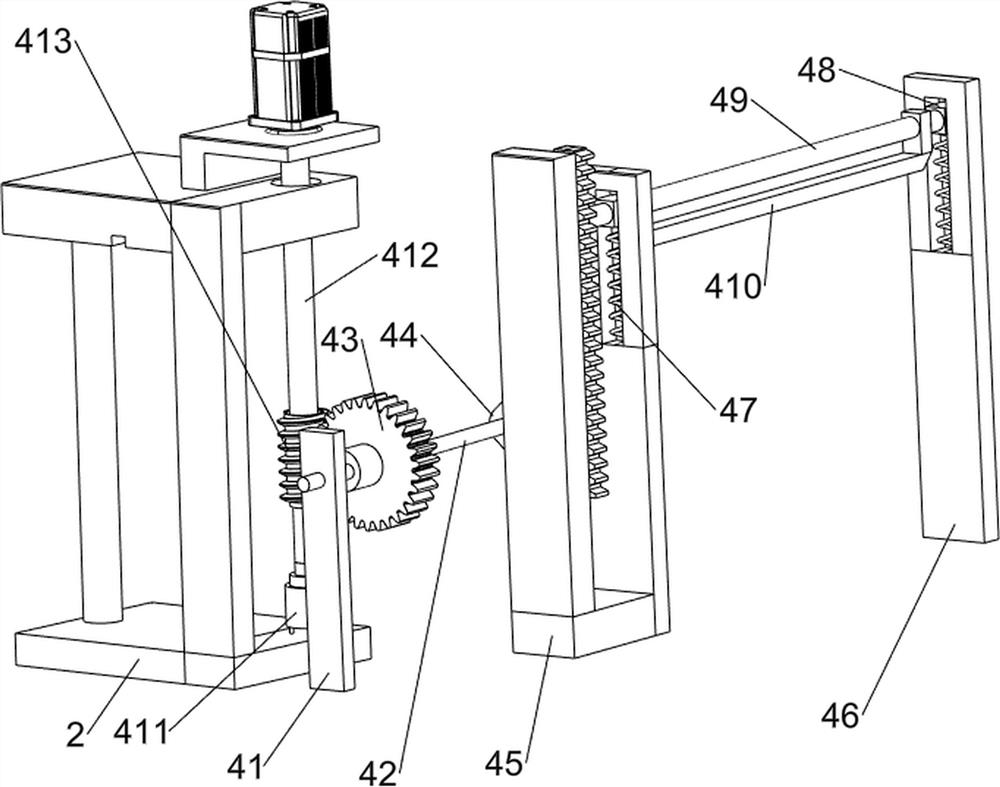

[0064] On the basis of Example 1, such as figure 2 and image 3As shown, the cutting mechanism 4 includes a first support rod 41, a first main shaft 42, a worm wheel 43, a first half gear 44, a slideway 45, a second support frame 46, a first spring 47, a slider 48, a second main shaft 49. Cutting knife 410, support 411, third main shaft 412, worm 413 and first rack 414, first support rods 41 are provided on the left and right sides of the bottom plate 1, and the first support rod 41 on the right is located on the first At the rear of the support frame 2, a first main shaft 42 is provided in rotation between the top of the first support bar 41, the right part of the first main shaft 42 is provided with a worm wheel 43, the left part of the first main shaft 42 is provided with a first half gear 44, and on the bottom plate 1 The rear side of the right part is provided with a slideway 45, the slideway 45 is positioned at the rear of the first support bar 41 on the left side, the...

Embodiment 3

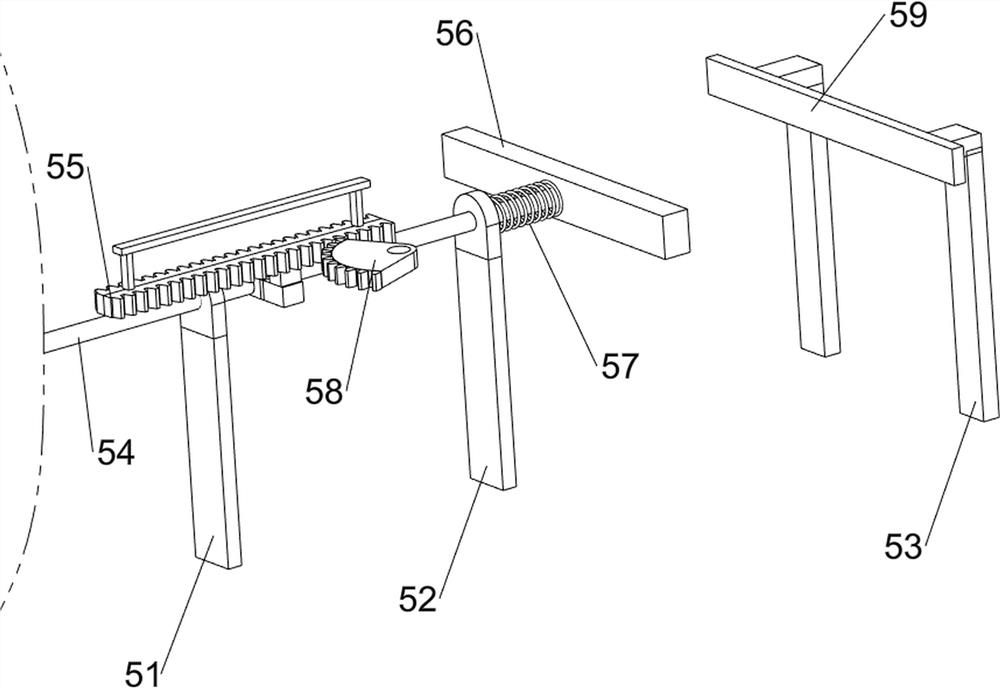

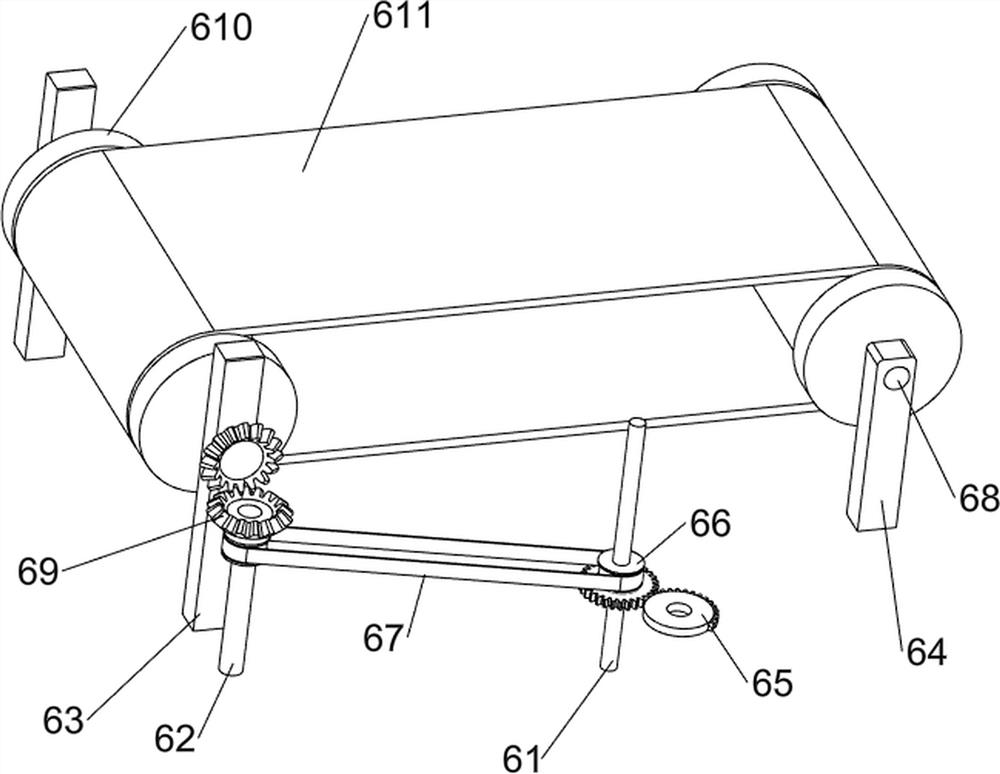

[0067] On the basis of Example 2, such as figure 1 , Figure 4 and Figure 5 As shown, it also includes a retracting mechanism 5 and an intermittent motion mechanism 6, the base plate 1 is provided with a retracting mechanism 5, and the upper left part of the base plate 1 is provided with an intermittent motion mechanism 6, and the retracting mechanism 5 and the intermittent motion mechanism 6 are all connected to the third main shaft 412 connect.

[0068] When in use, the Liangpi is first placed on the intermittent motion mechanism 6, and after the motor 3 is started, the output shaft of the motor 3 rotates to drive the intermittent motion mechanism 6 to intermittently transmit the Liangpi to the cutting knife 410 for cutting, and at the same time drives the retracting mechanism 5 to intermittently cut the cut The cold skin is collected in time, and then the cold skin is removed, so that the cold skin can be automatically cut off without interruption, and the above operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com