Multi-wire tin dipping crimping machine

It is a technology of end-typing machine and tin dipping, which is applied in the direction of line/collector parts, electrical components, circuits, etc. It can solve the problems of bloated structure, poor continuity, and low efficiency, and achieve high degree of automation, simple and ingenious structure, and easy work. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

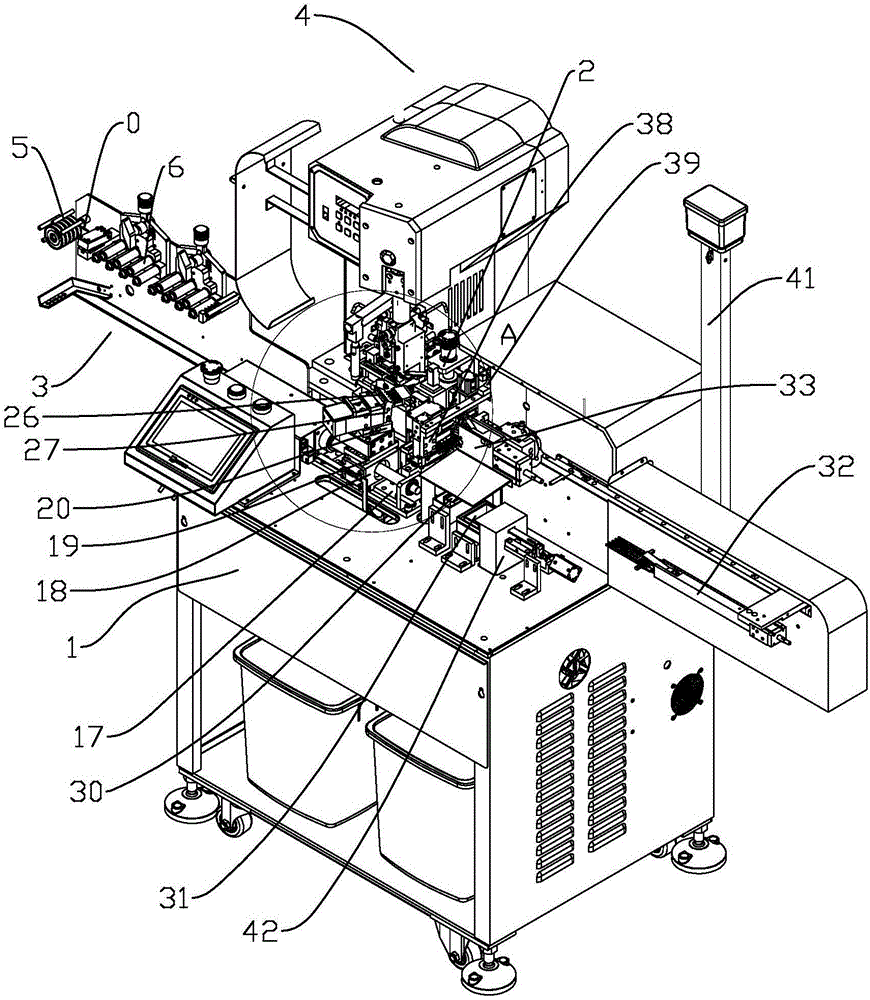

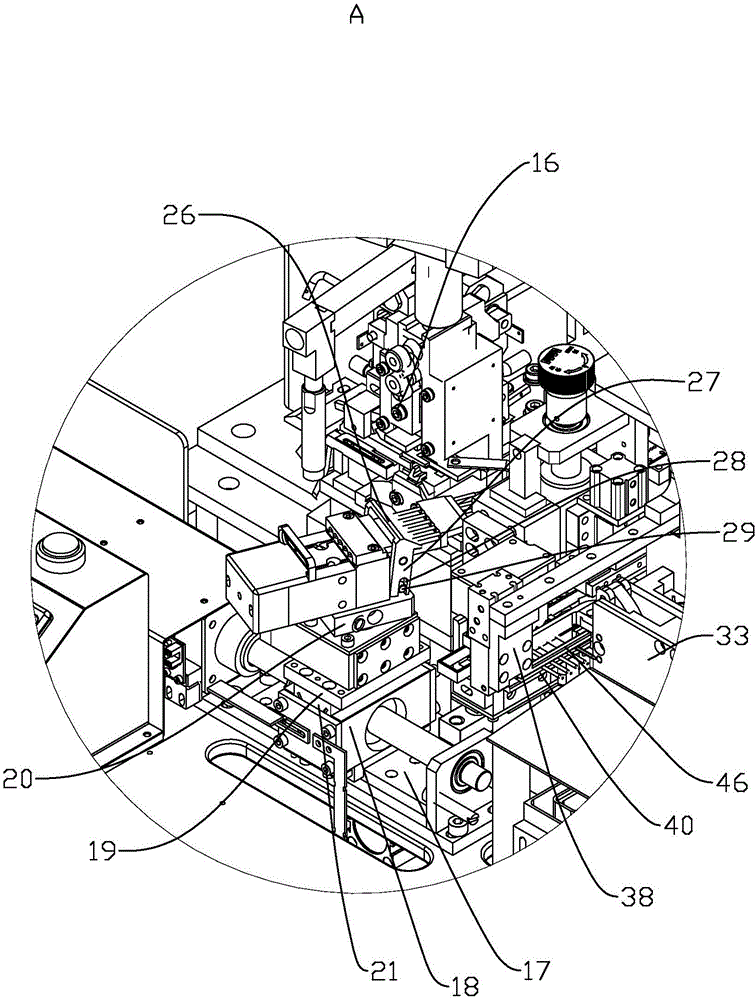

[0046] refer to Figure 1 to Figure 8 , the present invention is a multi-line dipping and tinning machine, which includes a frame 1 and is arranged on the frame 1:

[0047] The wire feeding device is used to feed the wire 0 to the subsequent device;

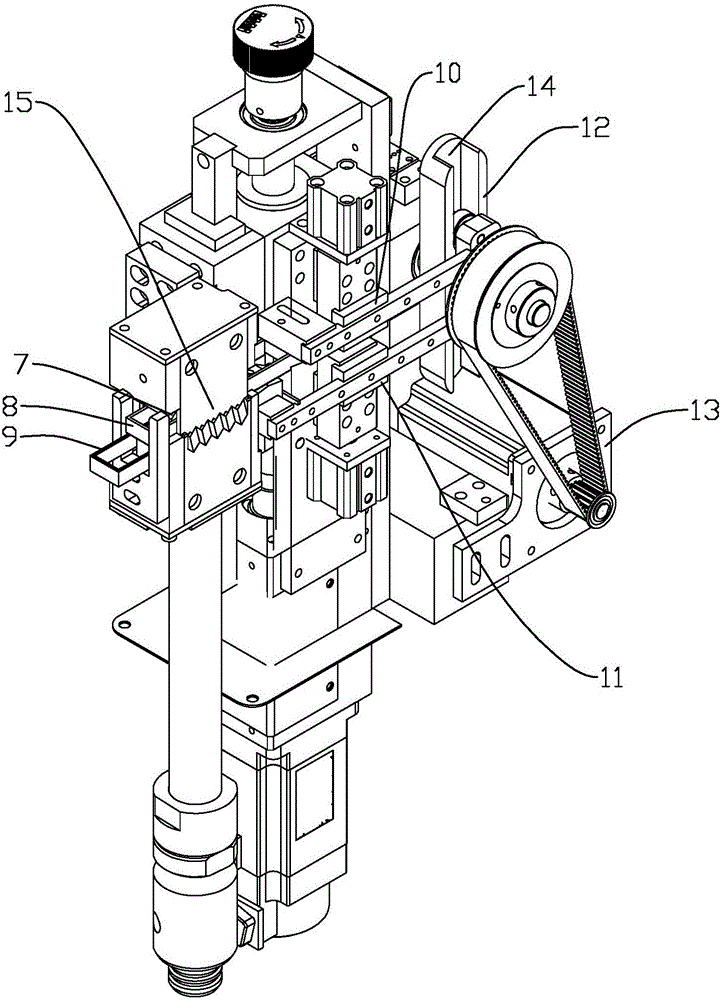

[0048] The knife holder device 2 is used for cutting, peeling, twisting and rubbing the wire 0;

[0049] The end-typing device 4 is located between the tool rest device and the wire feeding device 3, and is used for performing terminal processing on the end of the wire 0 between the knife rest device 2 and the wire feeding device 3;

[0050] The tin dipping device is located on the other side of the knife rest device 2 relative to the end device 4, and is used for dipping the end of the cut wire 0 close to the knife rest device 2.

[0051] The wire feeding device 3 includes a discharge reel 5 and a stress relief device. The discharge reel 5 is rotatably installed on the frame 1, and the discharge reel 5 is wound with a wire 0. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com