Wiper motor cover plate assembly multi-position assembly machine

A technology of motor cover and plate assembly, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., and can solve the problems of automatic multi-station work assembly, high labor cost, fixing pads and shock-absorbing pads installed on the box cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

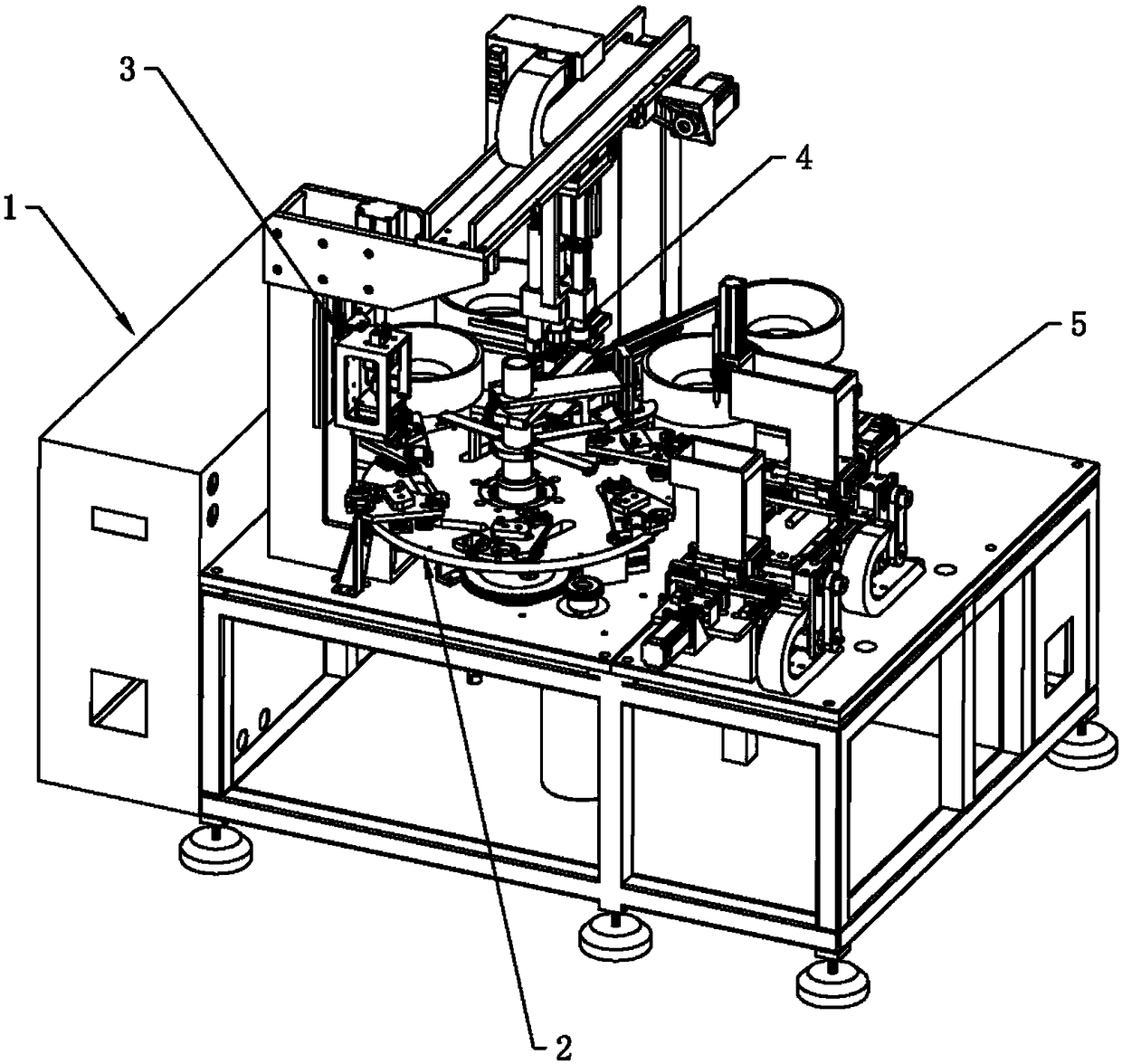

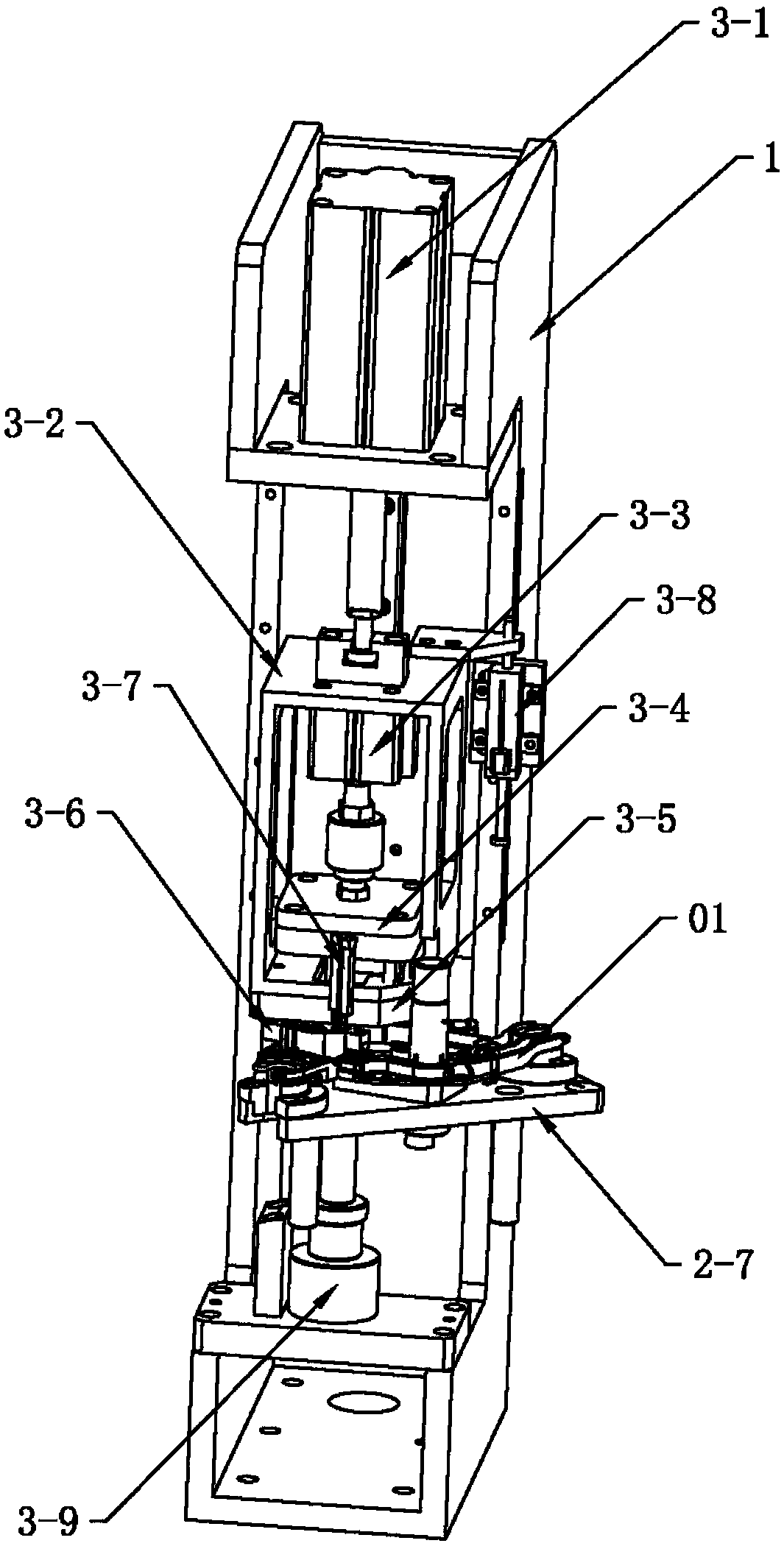

[0043] see figure 1 , the multi-station assembly machine of the wiper motor cover assembly of the present embodiment includes a frame assembly 1, a turntable mechanism 2, a press-cut conductive strip mechanism 3, a rubber pad installation mechanism 4, a soldering and dispensing mechanism 5, and a rubber pad installation The mechanism 4 and the solder and glue dispensing mechanism 5 are arranged outside the turntable 2-1.

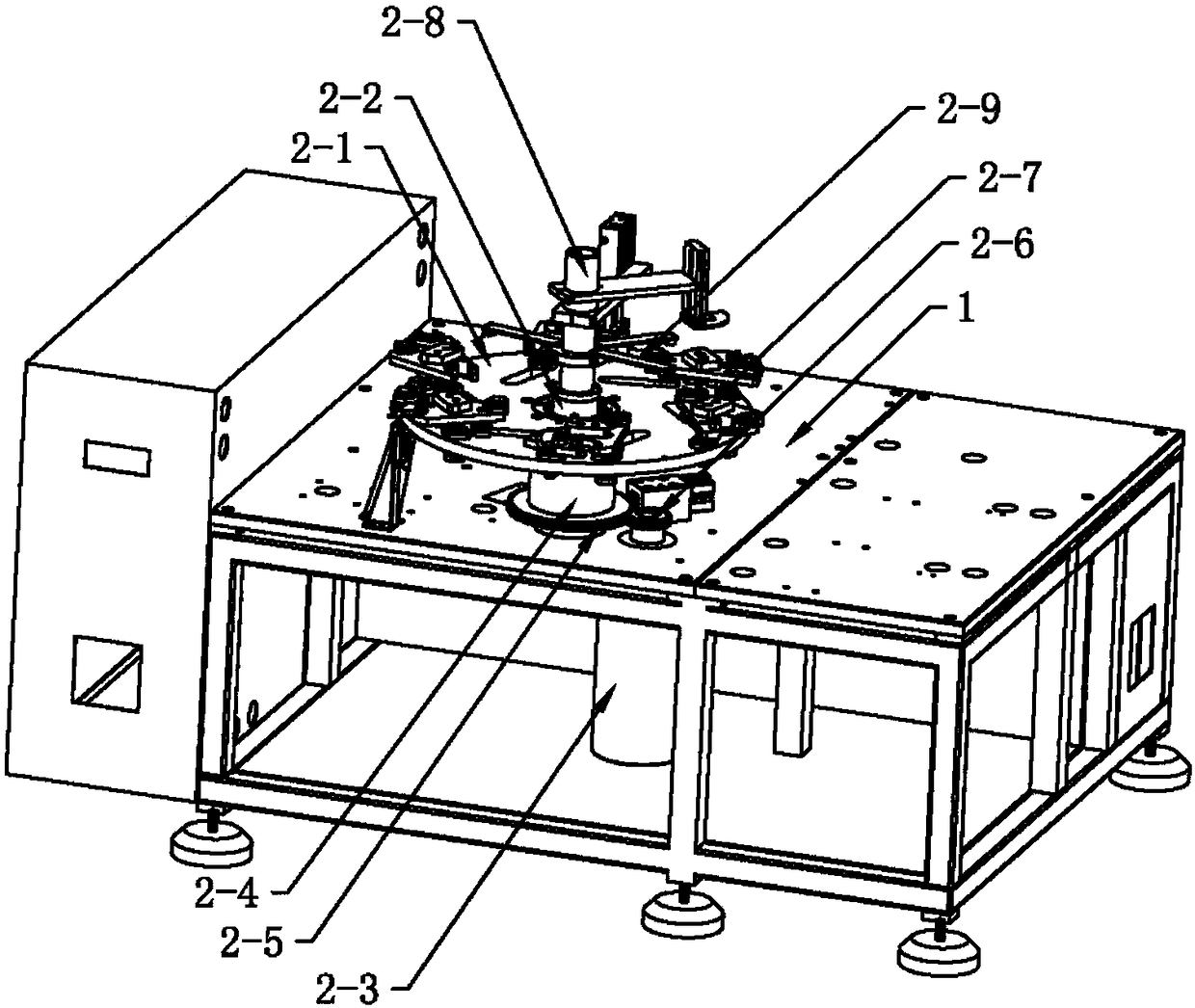

[0044] see figure 1 and figure 2, the turntable mechanism 2 is provided with a turntable 2-1, a central shaft 2-2 and a motor 2-3, the central shaft 2-2 is fixed on the frame assembly 1, the central shaft 2-2 is equipped with a bearing 2-4, and the bearing 2-4 The outer ring of the bearing 2-4 is fixedly connected with the rotating disk 2-1, and the outer ring of the bearing 2-4 is also fixedly connected with a gear plate 2-5, and the gear plate 2-5 meshes with the driving gear 2-6 on the output shaft of the motor 2-3, The turntable 2-1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com