Detecting and cutting machine with automatic classification detection function

A cutting machine and functional technology, applied in sorting, household appliances, other household appliances, etc., can solve the problem of consuming a lot of human resources and time costs, and achieve the effect of saving manpower and time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

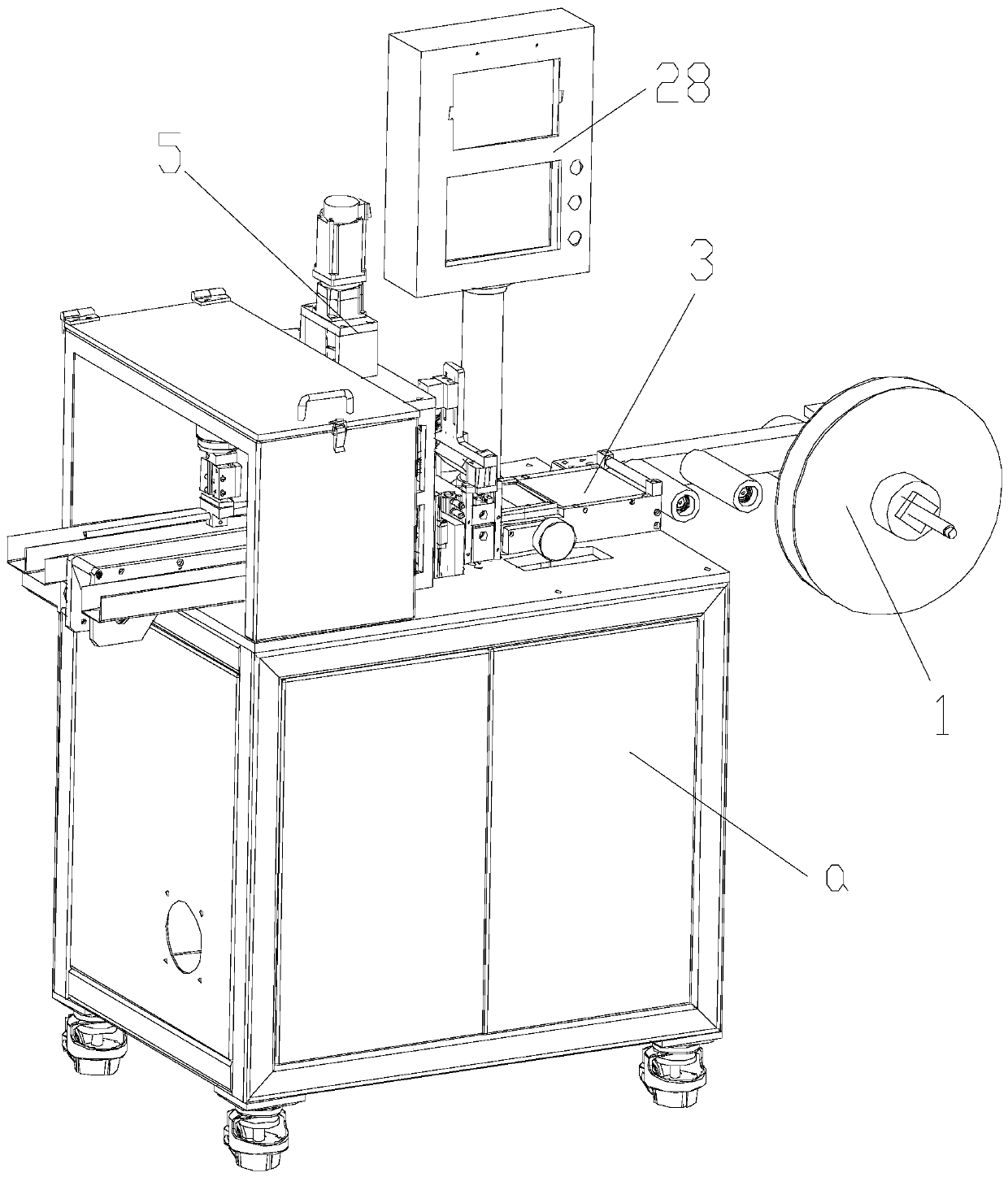

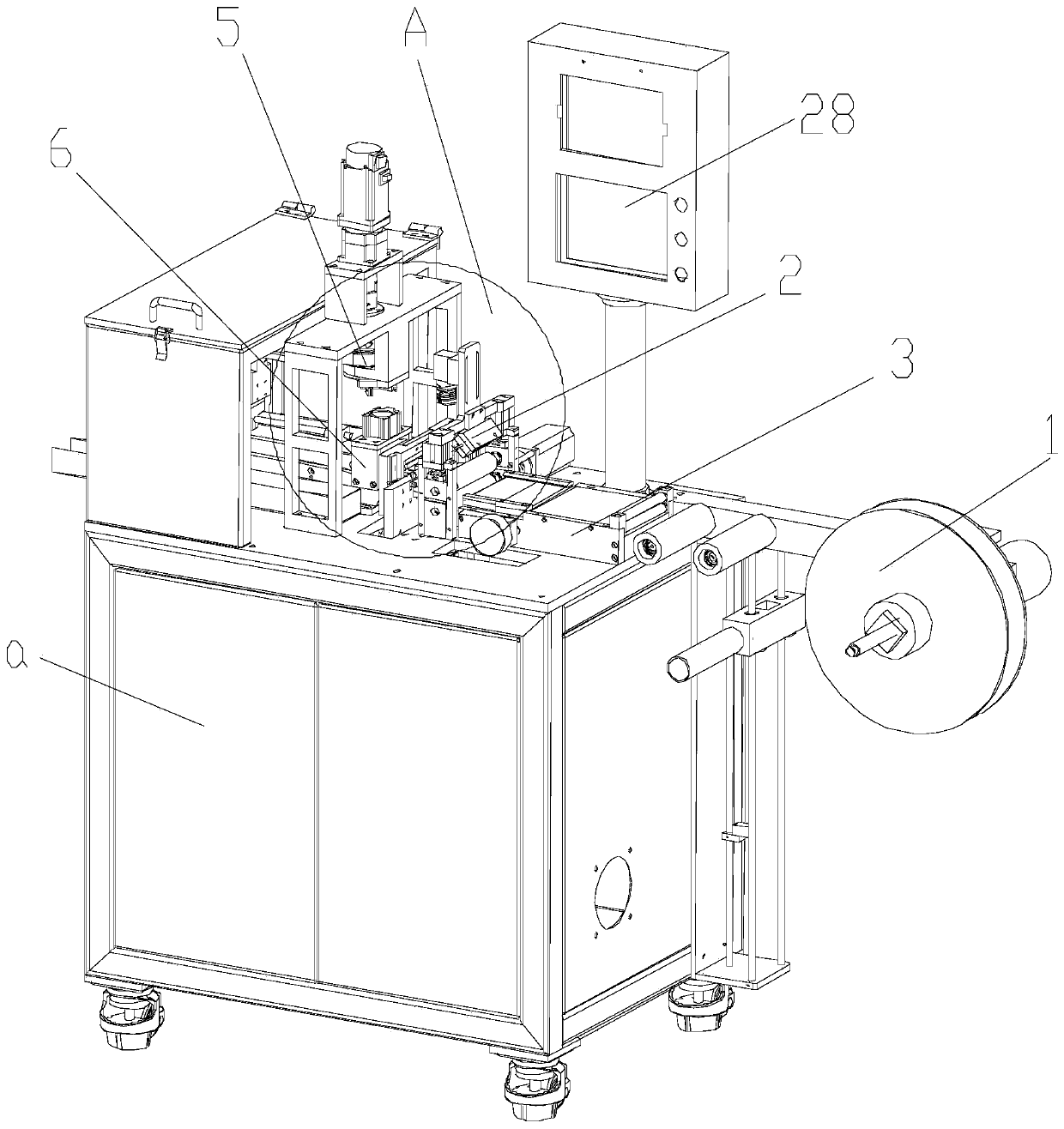

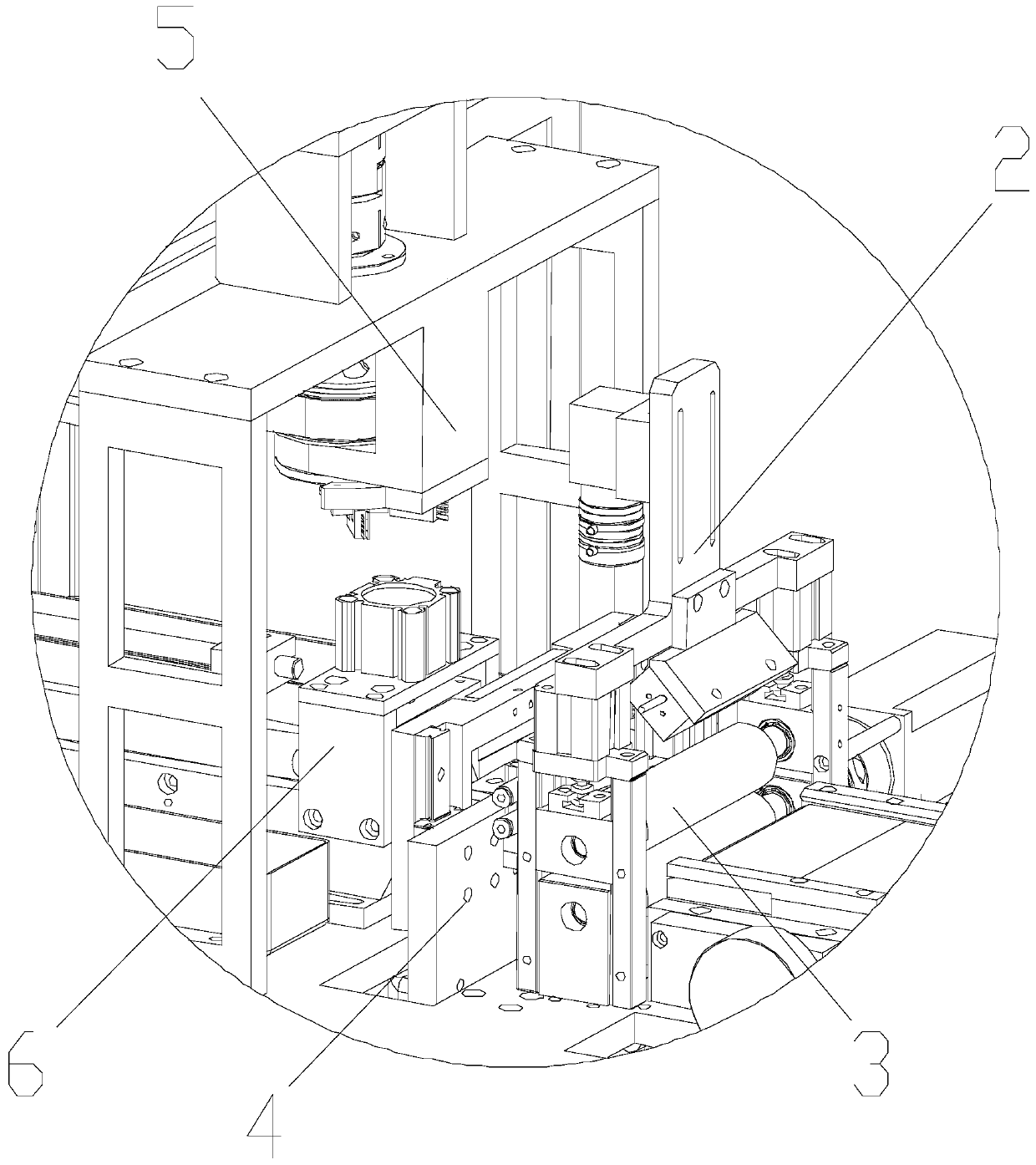

[0033] Such as Figure 1 to Figure 16 As shown, the present embodiment provides a detection and cutting machine with an automatic sorting function, which includes a frame a, and also includes a product (similar to FFC, a long strip) that is placed on the frame a in sequence product), a detection component 2 for detecting whether the product is qualified, a first conveying component 3 for transporting the product at the feeding component 1 to the detection component 2, and a shearing component for the detected product The cut-off assembly 4, the sorting assembly 5 for detecting the products after cutting and sorting, and the second conveying assembly 6 for delivering the products cut by the cutting assembly 4 to the sorting assembly 5, the sorting as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com