Automatic sealing system for IC product packaging

A technology of automatic sealing and product packaging, applied in the direction of automatic packaging control, packaging, packaging machines, etc., can solve the problems of decreased operation efficiency, injury to the operator's hand, hand fatigue, etc., to save equipment costs, improve propulsion efficiency, Good effect of limit coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

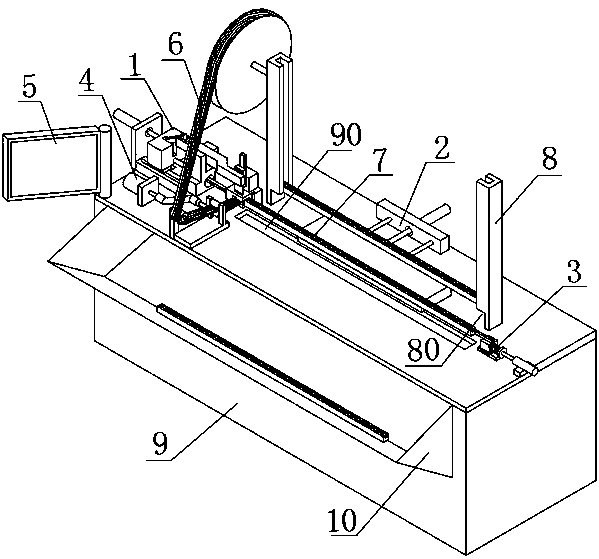

[0038] Such as figure 1 As shown, this embodiment provides an automatic sealing system for IC product packaging, including a workbench 9, and a rubber plug plugging assembly 1, a pushing assembly 2, a pushing assembly 3, and a rubber stopper guide assembly provided on the workbench 9. 4. The storage component 8, the workbench 9 is provided with a collection hole 90, the rubber plug plugging component 1 and the pushing component 3 are arranged at both ends of the collection hole 90, and the collection hole 90 and the pushing component 2 are located on both sides of the storage component 8;

[0039] The storage assembly 8 is used for stacking and storage of the packaging tube 7 parallel to the collection hole 90, and the bottom end of the storage assembly 8 is provided with a discharge port 80 adapted to the single packaging tube 7;

[0040] The rubber plug plugging assembly 1 includes a plugging cavity 1011, a cutter 111, and a plug rod 108. The plugging cavity 1011 and the collecti...

Embodiment 2

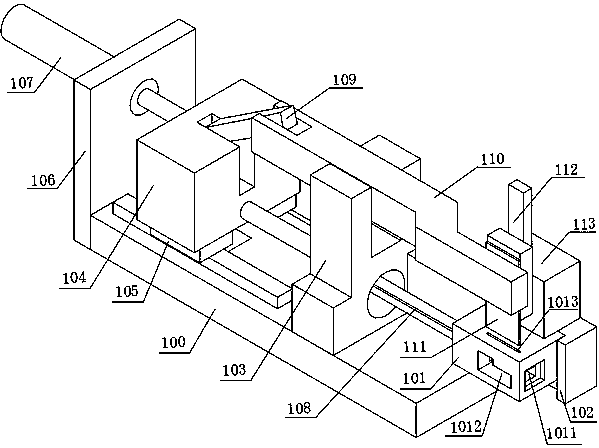

[0046] Such as figure 2 As shown, on the basis of Embodiment 1, this embodiment provides a specific structure of a rubber plug plugging assembly 1. The rubber plug plugging assembly 1 further includes a plugging head 101. One side of the plugging head 101 is fixed to the plugging head base 102, and the opposite side is provided with a rubber plug strip insertion hole 1012. The plugging cavity 1011 is penetrated and opened in the plugging head 101. On the end surface, the top surface of the plugging head 101 is provided with a cutting hole 1013, and the plugging cavity 1011, the rubber plug insertion hole 1012, and the cutting hole 1013 are connected;

[0047] The cutter 111 is installed above the plugging head 101, and the cutter 111 can be vertically inserted into the plugging cavity 1011 through the cutting hole 1013, and punching the rubber stopper 6;

[0048] The plug rod 108 is horizontally spaced and arranged on the side of the plug driving head 101 away from the collection ...

Embodiment 3

[0059] Further, on the basis of the above embodiment 2, such as figure 2 As shown, in this embodiment, the cutter 111 and the push rod 108 share a driving mechanism, which facilitates continuous control of the two actions of cutting and plugging, and can save equipment cost and energy consumption. The cutter 111 is vertically installed at the front end of a second rotating arm 110, the end of the second rotating arm 110 is hingedly connected to the front end of a first rotating arm 109, and the end of the first rotating arm 109 is connected with a plugging cylinder 107; The tail end of the rod 108 is horizontally connected to the plugging cylinder 107. When working, first, the plugging cylinder 107 drives the cutter 111 downwards and vertically into the plugging cavity 1011 through the hinged first rotating arm 109 and the second rotating arm 110, and punching and cutting off the rubber stopper strip 6. The plugging cylinder 107 will also push the plug rod 108 to move a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com