Battery coating edge cutting and folding patch production line and coating edge cutting and folding patch process thereof

A technology for battery packs and production lines, which is applied in the direction of battery assembly machines, secondary battery manufacturing, battery pack components, etc., and can solve problems affecting bending flatness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

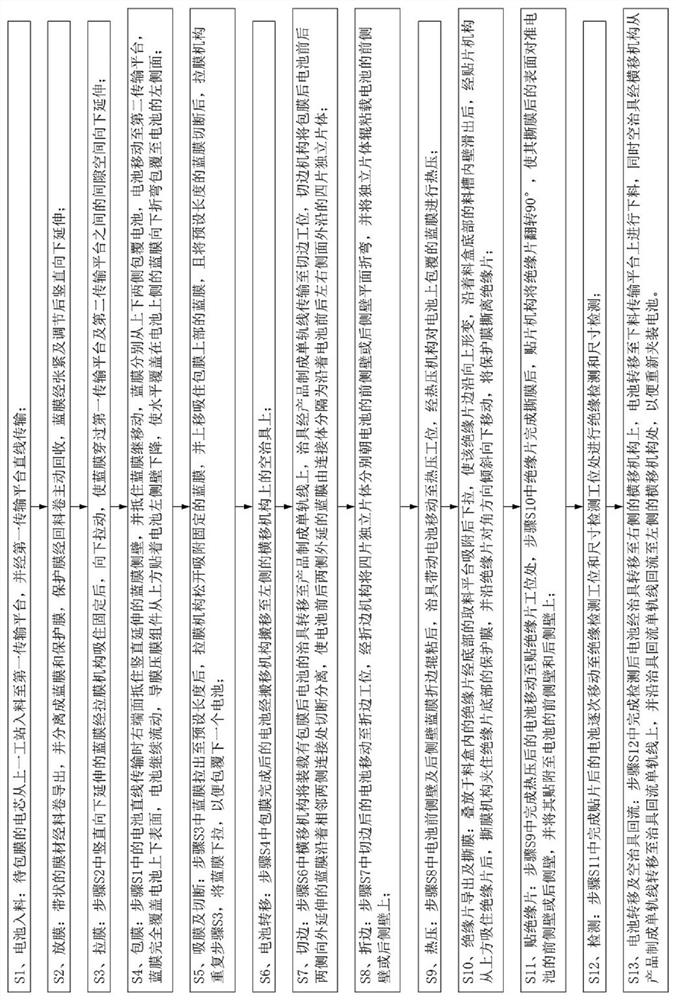

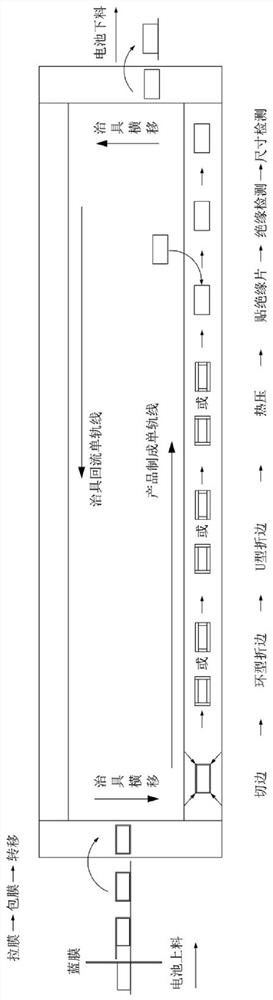

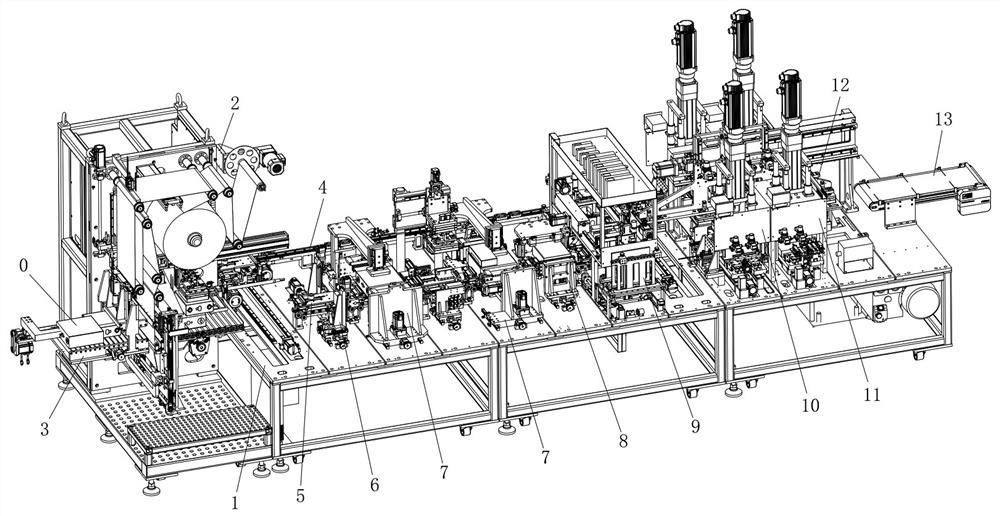

[0116] The present invention will be further described below in conjunction with accompanying drawing:

[0117] Such as Figure 1 to Figure 60As shown, the technical solution adopted by the present invention is as follows: a production line for battery film cutting and folding, including a film coating part, a cyclic transmission part, a film processing part and a detection and blanking part, wherein the above-mentioned cyclic transmission part includes parallel intervals The two single-track lines and the jig traverse mechanism arranged at both ends of the two single-track lines 4 form a rectangular path with the two single-track lines 4 and the jig traverse mechanism. One of the single-track lines 4 is a product manufacturing line, and the other The single track line is the return line of the jig, and the battery jig is slidably embedded on the single track line, and drives the battery jig to circulate along the rectangular path;

[0118] The above-mentioned coating part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com