Heat recycling system and method for VOCs

A heat recovery and heat exchanger technology, applied in the field of VOCs heat recovery and utilization system, can solve the problems of air pollution, heat, waste, etc., and achieve the effects of efficient collection, fast intake air preheating, and good redox ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

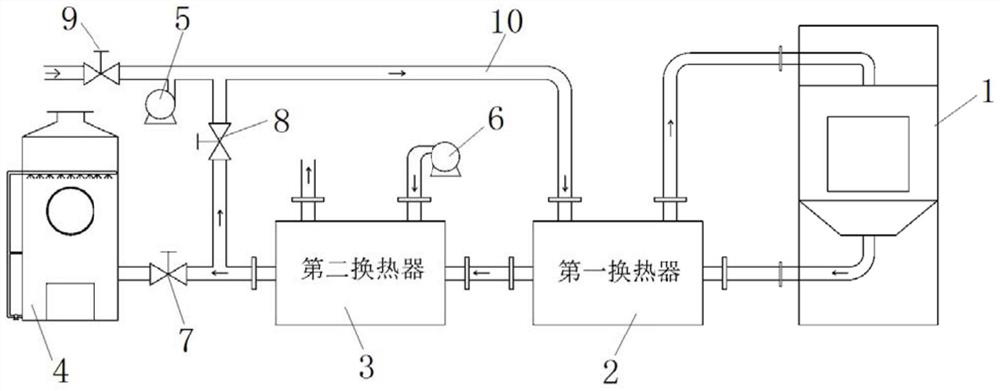

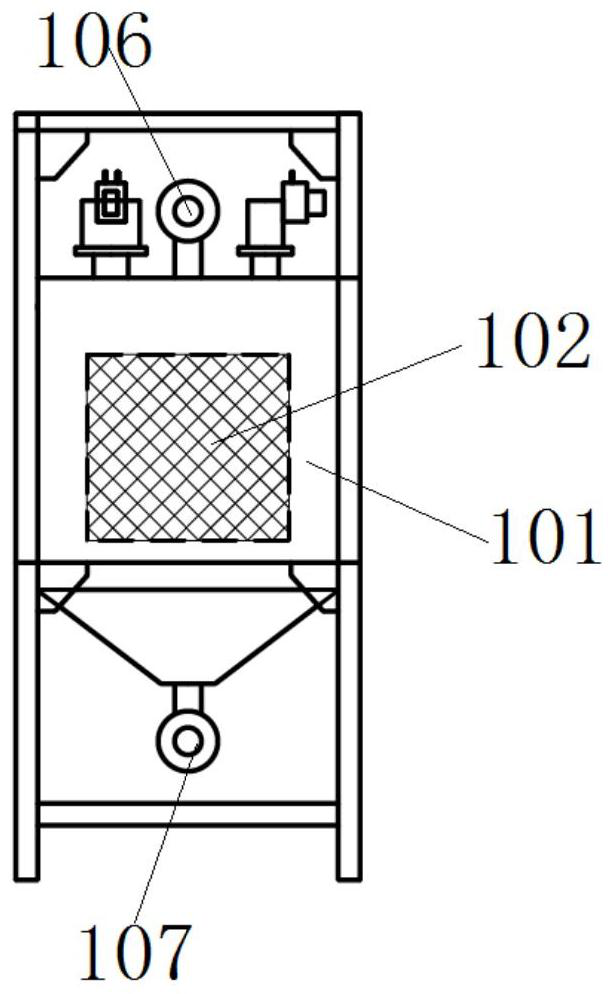

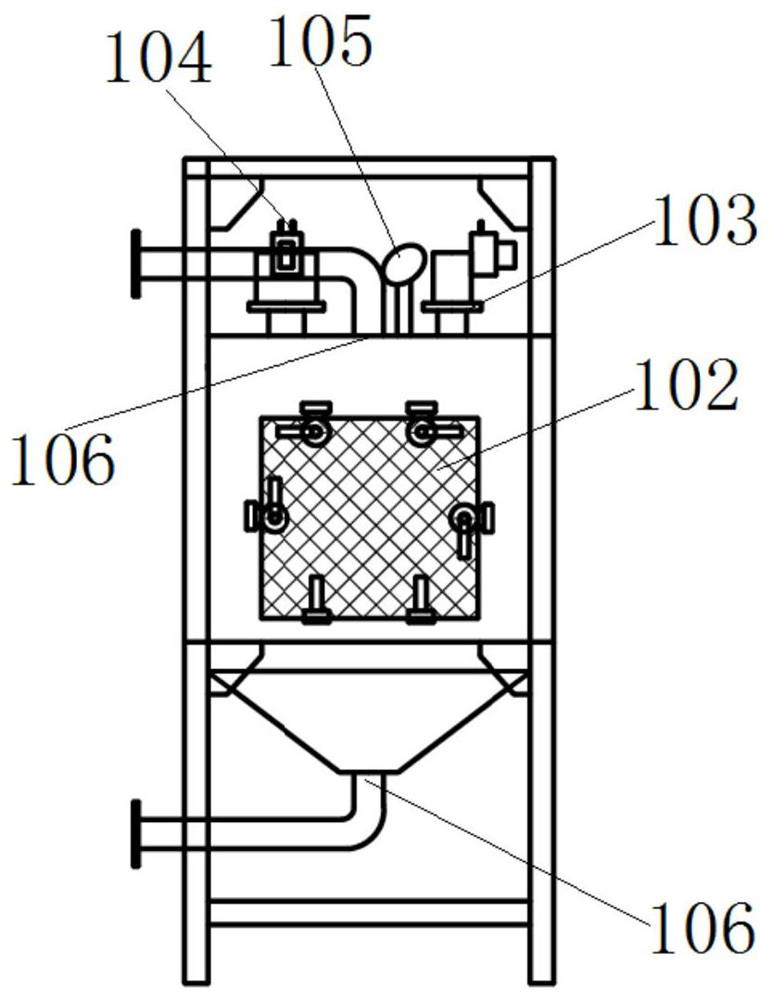

[0059] A VOCs heat recovery and utilization system described in this embodiment includes an air intake system, a processing system, a heat recovery system, a waste heat reuse system, an exhaust gas absorption detection system, a plurality of solenoid valves, and an automatic control cabinet; wherein, the air intake The system includes an air pump 5 and an air intake channel 10, the processing system includes a microwave catalytic combustion device 1, the heat recovery system includes a first heat exchanger and a second heat exchanger, and the waste heat reuse system includes a second heat exchanger 3 and a fresh air device 6 .

[0060] Specifically, the VOCs gas source is connected to the air inlet of the air pump 5, the air outlet of the air pump 5 is connected to one end of the air inlet passage 10, and the other end of the air inlet passage 10 is connected to the shell side inlet of the first heat exchanger 2, and the second The shell side inlet of a heat exchanger 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com