Breaker closing resistor tripping mechanism and breaker using same

A technology of closing resistor and tripping mechanism, which is applied to high-voltage air circuit breakers, circuits, electric switches, etc., and can solve problems such as large operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

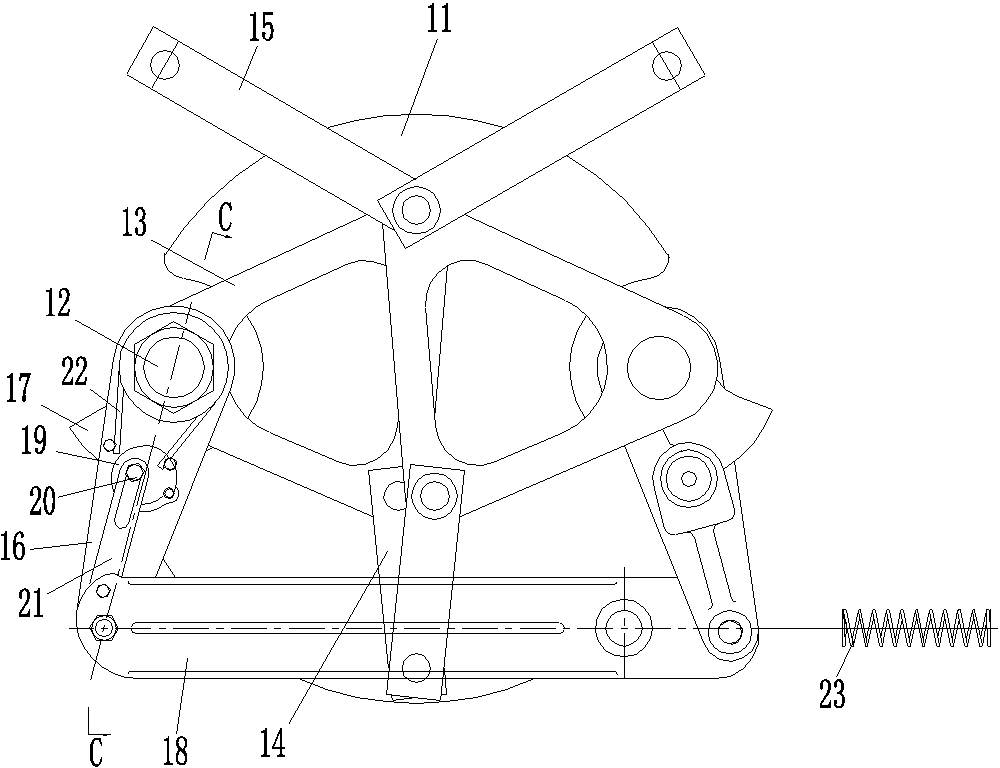

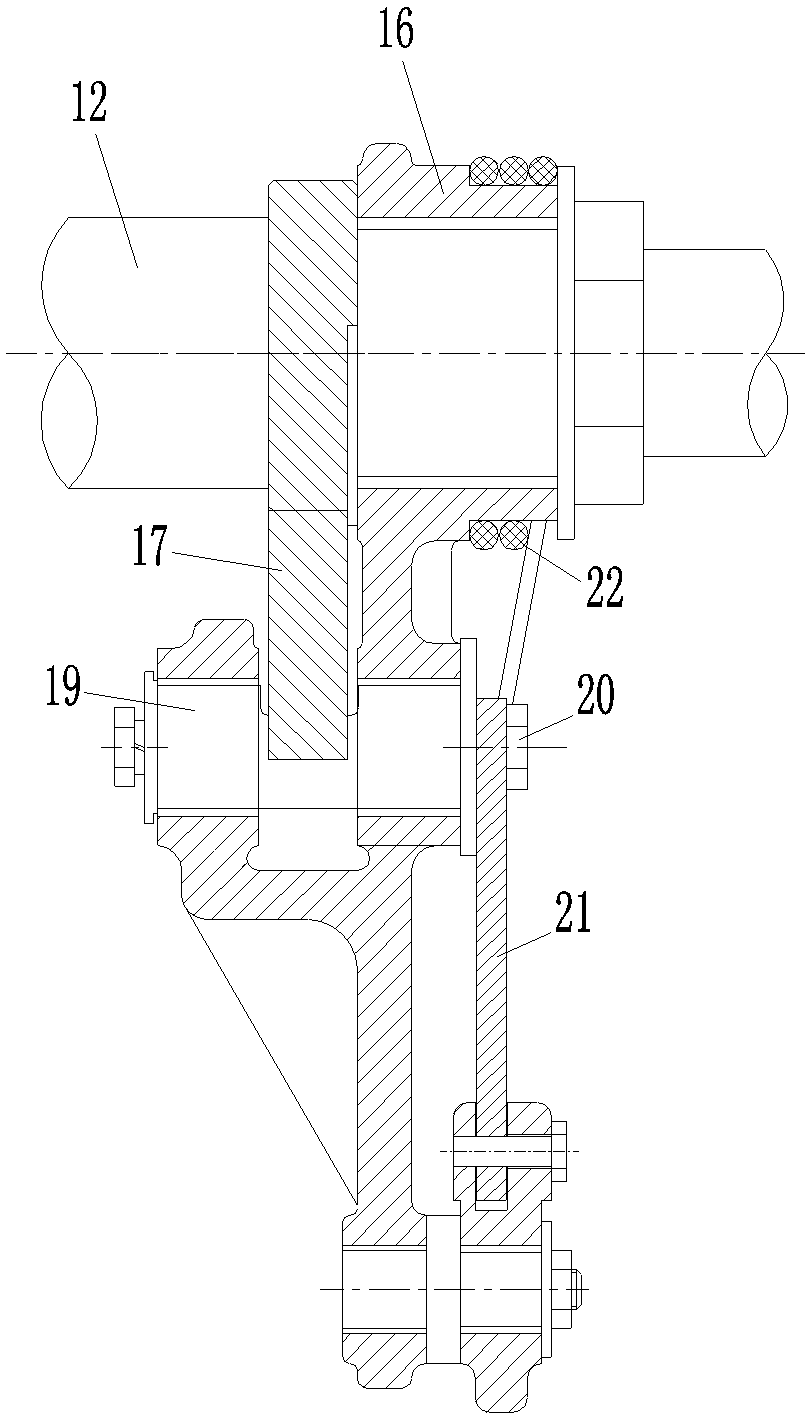

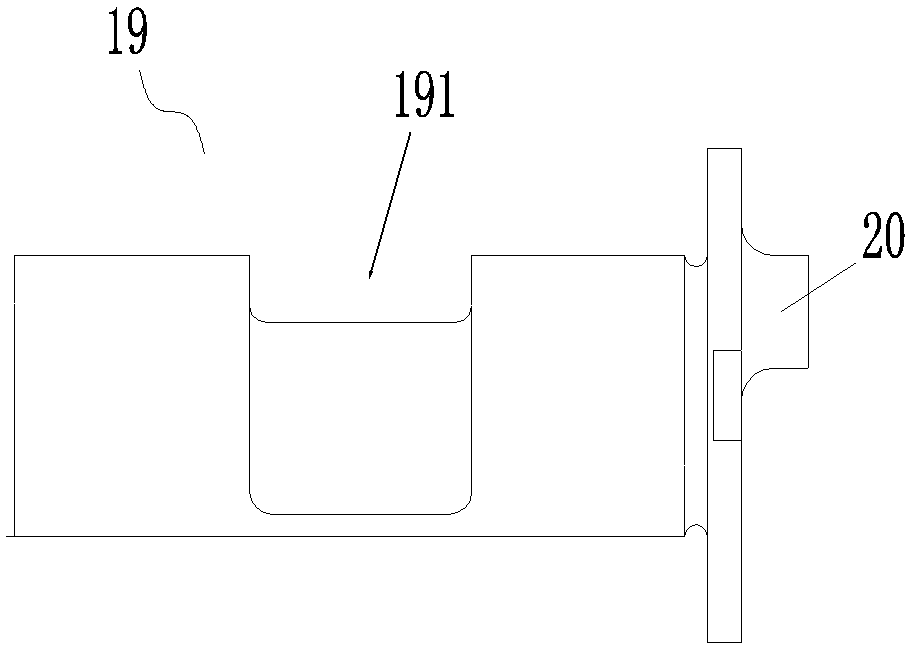

[0025] Examples of circuit breaker closing resistor tripping mechanisms, such as Figure 1-6 As shown, the circuit breaker closing resistance tripping mechanism includes a mechanism box 11, and a transmission part 13 is installed in the mechanism box 11 through a rotating shaft 12. In this embodiment, the transmission part 13 is specifically a triangular frame structure. One of the apexes of the formed triangle is in anti-rotation fit with the rotating shaft 12, and hinge points are respectively formed at the other two apexes of the triangle. The hinge axes of the two hinge points are parallel to the rotating shaft 12, and one of the hinge points The connecting lever 14 of the operating mechanism is hinged, and the connecting lever 15 of the arc extinguishing chamber is hinged at another hinge point. The connecting lever 14 of the operating mechanism is used for transmission connection with the operating mechanism of the circuit breaker, and the connecting lever 15 of the arc e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com