Plastic injection molding machining mold facilitating heat dissipation and workpiece arrangement

A technology of injection molding processing and mould, which is applied in the field of molds for plastic injection molding processing, and can solve problems such as waste of time, semi-solid residue, and waste of injection molding raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

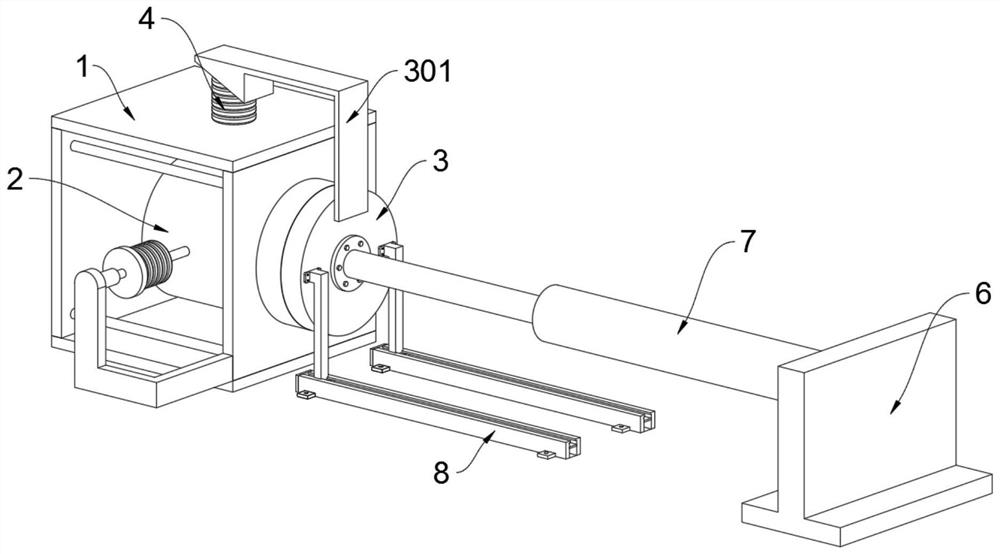

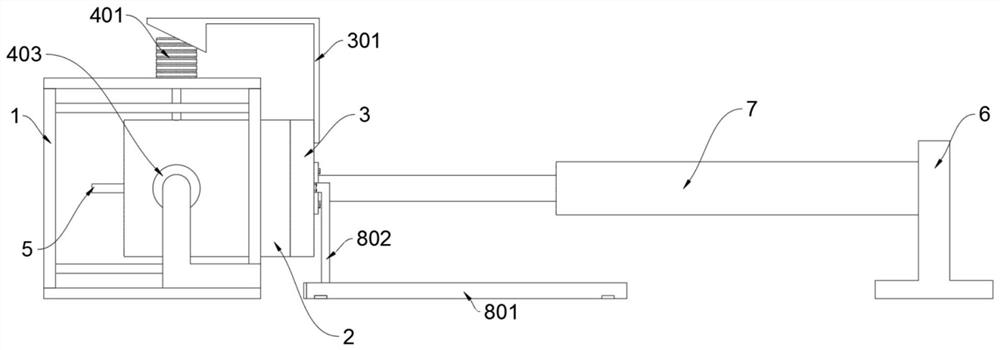

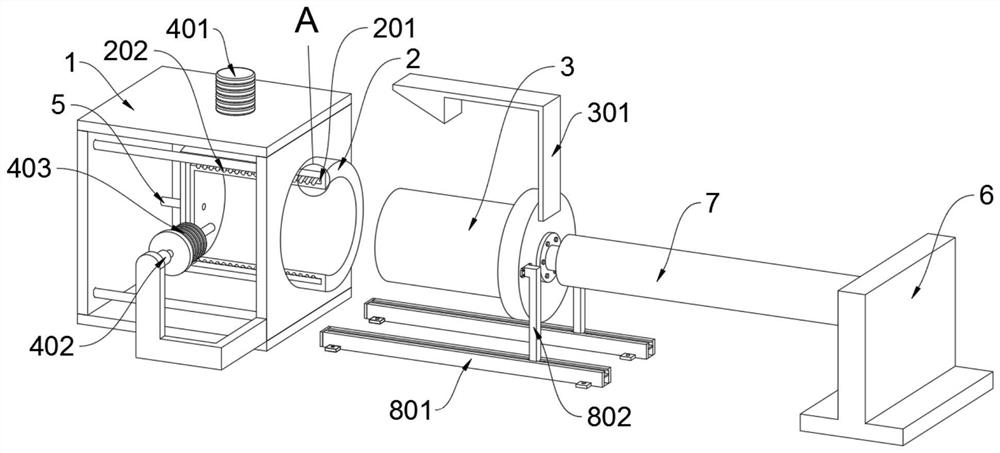

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides a mold for plastic injection molding which is convenient for heat dissipation and workpiece arrangement, which comprises a frame body 1; Also be provided with feed pipe 5; Refer to as Figure 7 and Figure 8 , the feed tank 503 has an L-shaped structure, and a number of circulation holes 50401 are opened in a circular array on the retaining ring 504; when the liquid is injected, the locking rod 505 moves forward under the thrust of the liquid to contact the head end of the pipe body 501, At this time, the elastic member 506 is in a compressed state, and at this time, the feeding groove 503 is in a communication state with the pipe body 501, thereby maintaining the normal circulation of the plastic liquid; refer to as Figure 7 and Figure 8 , when the liquid injection is finished, the locking lever 505 is pushed back to the original position by the elastic force of the elastic member 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com