Self-adaptive automatic shearing system for steel bar and steel belt welding line

A technology of reinforced steel and welding line, applied in the field of adaptive automatic shearing PLC control system of steel strip shearing line, which can solve the problems of automatic production line of unreinforced steel strip products and achieve the effect of ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

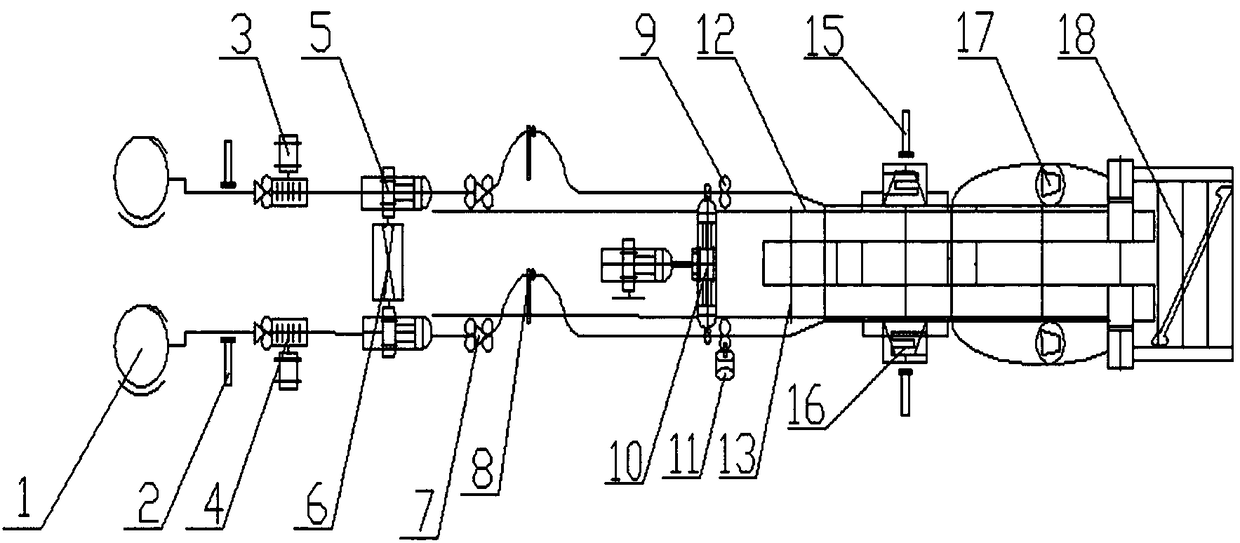

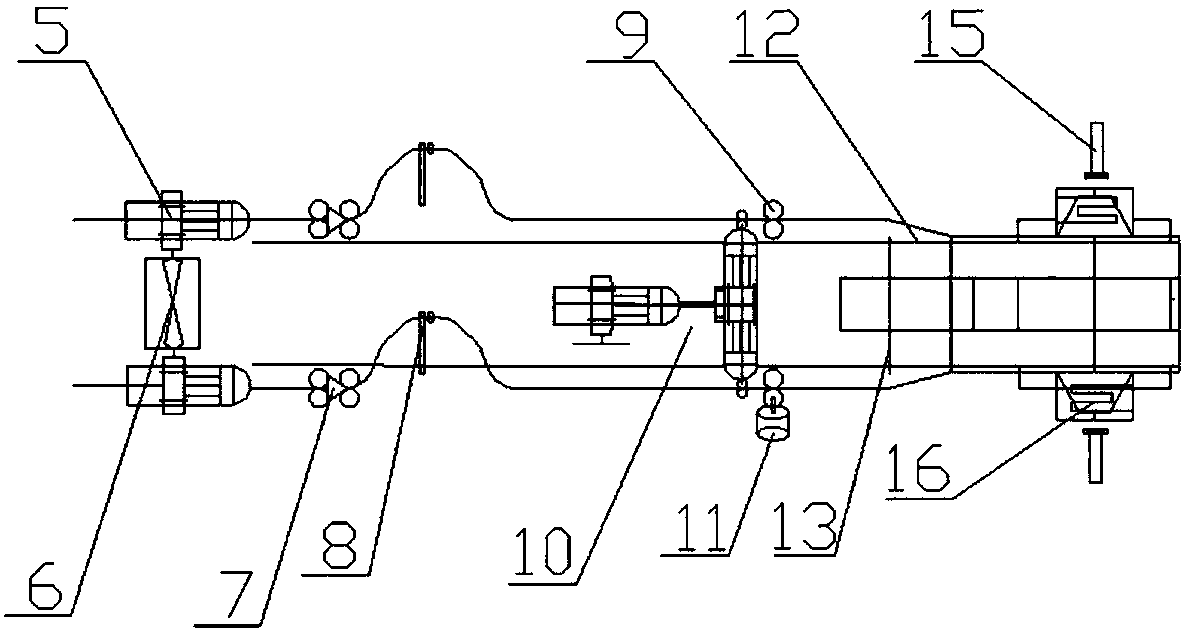

[0021] The technical solutions in the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work belong to this application The scope of the new type of protection.

[0022] In the embodiment of the present invention, the control system adopts a PLC controller, and the PLC controller is a Siemens S7-200smart controller. The steel bar 12 mentioned in the embodiment of the present invention and the short material 13 are formed, and its appearance is like a ladder. The short sections make up the parry in the middle.

[0023] Such as figure 1 and figure 2 As shown, the present invention includes a coil straightening system 4 driven by an asynchronous motor 3. After the steel bar wound on the steel bar coil 1 is straightened by the coil straightening system 4, the long mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com