Full-automatic bidirectional chamfering system for end part of steel bar, and working method thereof

A fully automatic, steel bar technology, applied in the field of machinery, can solve the problems of unachieved unilateral leveling, difficult processing, easy jamming of steel bars, etc., to maintain the consistency of chamfering quality, compact device structure connection, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

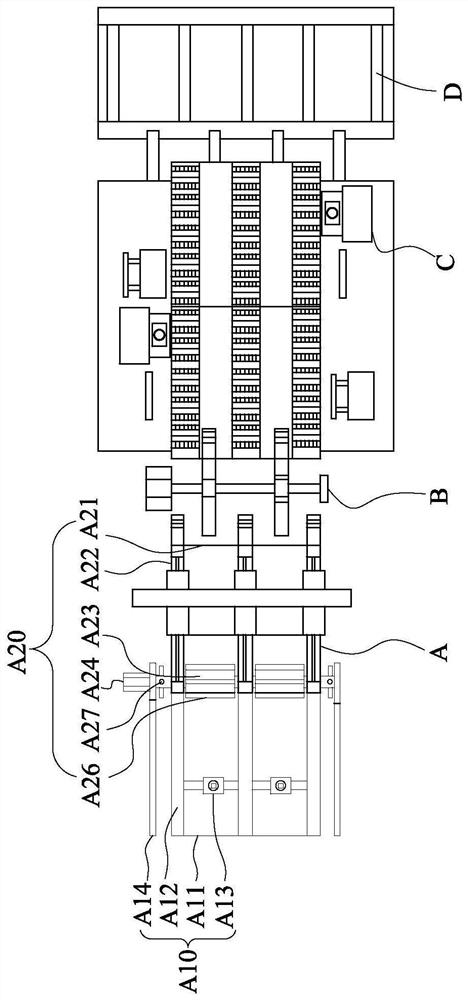

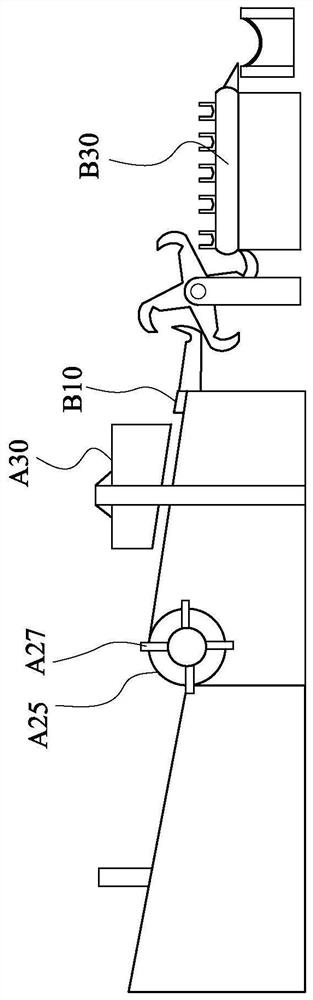

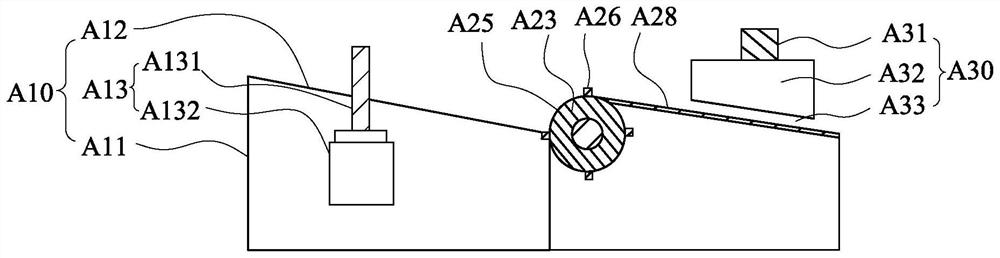

[0040] see Figure 1 to Figure 7, which is a structural schematic diagram of a fully automatic two-way chamfering system for steel bar ends provided by the present invention. A fully automatic two-way chamfering system for steel rod ends, which includes a steel rod feeding mechanism A, a steel rod turning and transferring mechanism B arranged on one side of the steel rod feeding mechanism A, and a steel rod turning and transferring mechanism B arranged on the side of the steel rod feeding mechanism A The steel bar turning and transferring mechanism B is away from the steel bar bidirectional chamfering mechanism C on the side of the steel bar feeding mechanism A, and a steel bar bidirectional chamfering mechanism C is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com