Adjustable double-sided chamfering tool for optical element

A technology of optical components and chamfering tools, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low processing efficiency, inability to guarantee processing accuracy, and poor chamfering consistency, so as to reduce labor costs , Guaranteed processing quality, good effect of chamfering consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment, but should not limit protection scope of the present invention with this.

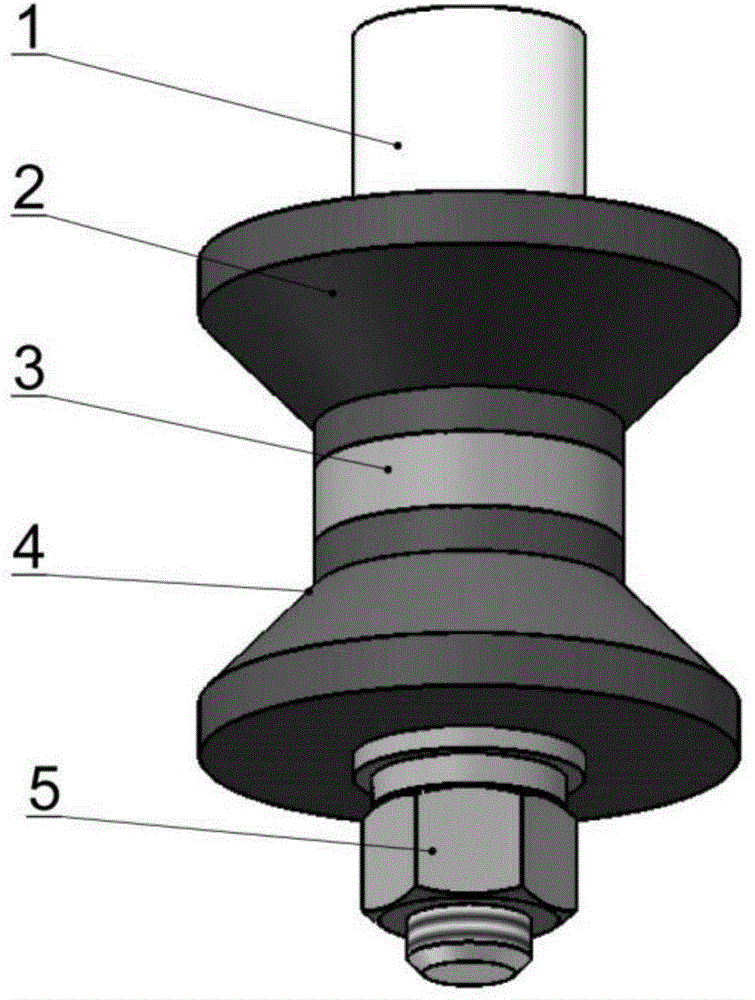

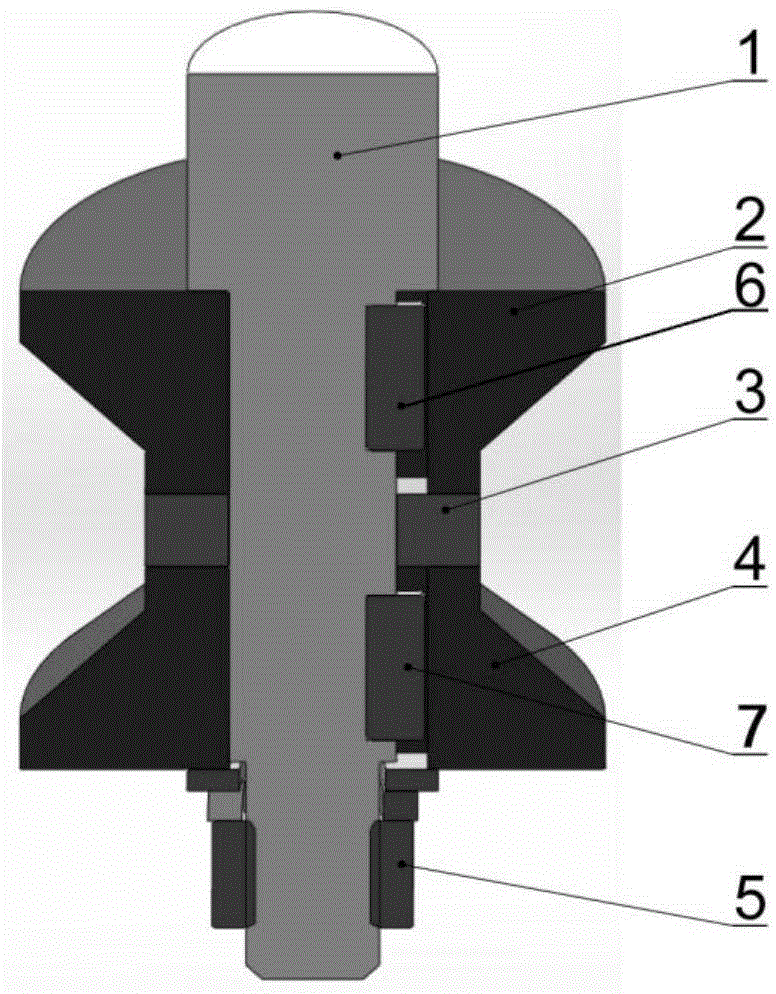

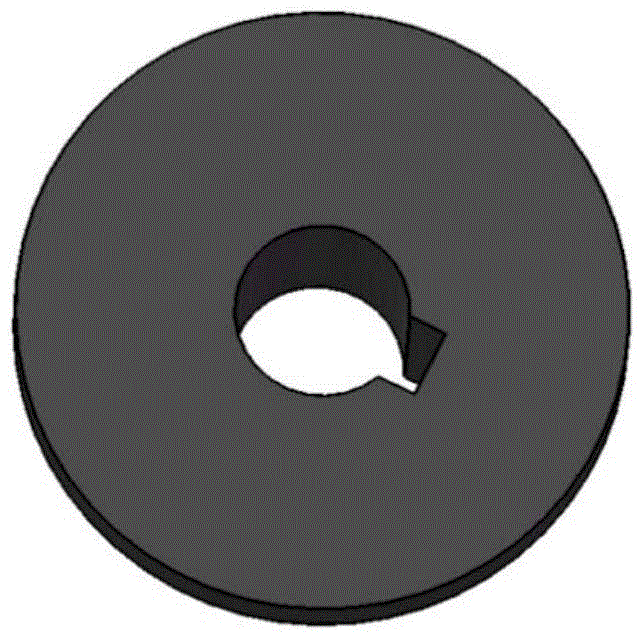

[0019] refer to figure 1 , figure 1 It is a three-dimensional structural schematic diagram of the best embodiment of an adjustable optical element double-sided chamfering tool of the present invention. It can be seen from the figure that the adjustable optical element double-sided chamfering tool of the present invention includes a fixed shaft 1, an upper forming grinding wheel 2, and a grinding wheel washer 3 , the lower forming grinding wheel 4, the fastening nut 5, the upper flat key 6 and the lower flat key 7, the fixed shaft 1 has an upper keyway, a lower keyway and an external thread, the upper forming grinding wheel 2 and the lower forming grinding wheel 4 The shaft holes are all provided with grooves for accommodating flat keys, and the upper flat keys 6 are placed in the upper key grooves of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com