Double-end-face numerical control chamfering machine tool and method for ultra-large internal tooth gear

A processing machine tool and super-large technology, which is applied in the field of high-efficiency chamfering processing machine tools for the upper and lower end faces of super-large internal gears and gear chamfering processing machine tools, and can solve problems such as uneven chamfering, poor chamfering quality, and low chamfering efficiency , to achieve the effect of adjustable chamfer size and shape, low manufacturing cost, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

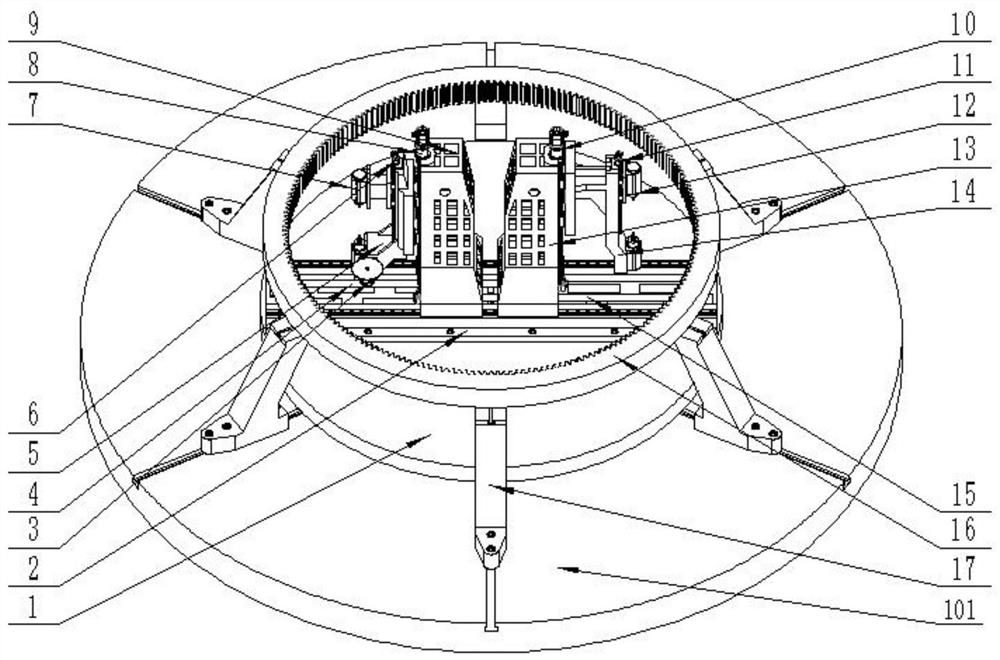

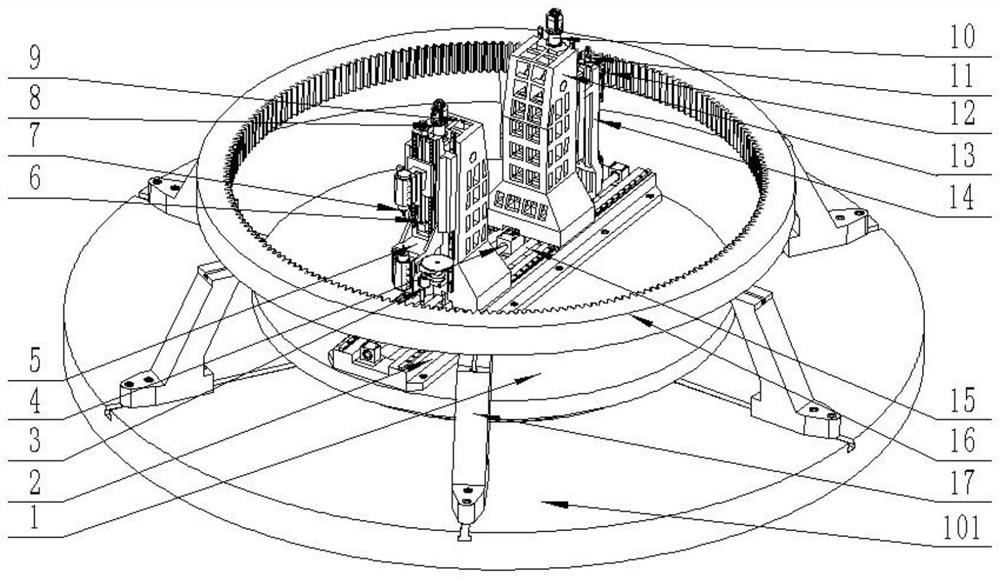

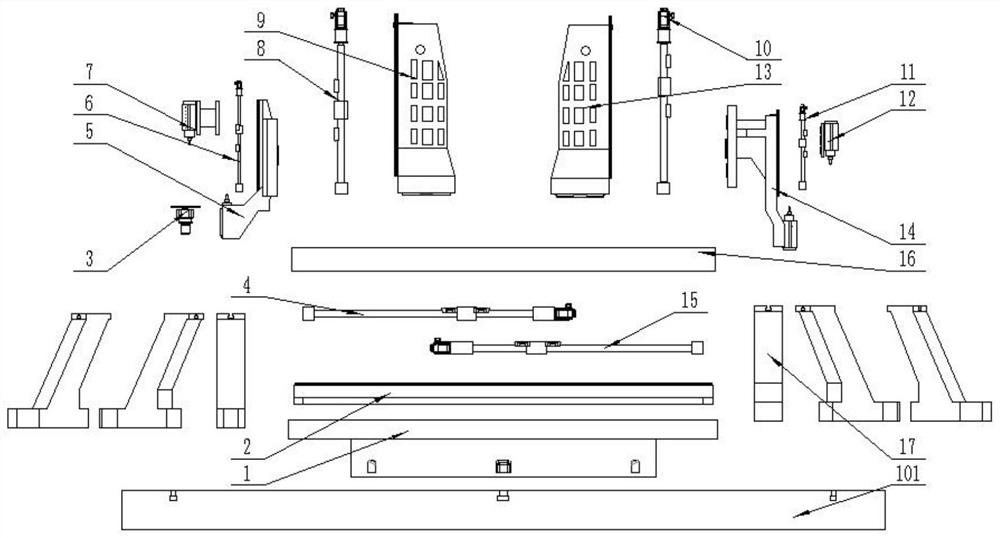

[0053] The present invention is described below in conjunction with accompanying drawing:

[0054] The invention relates to a CNC chamfering machine tool for double-end faces of super-large internal teeth gears, which adopts a processing form in which the workpiece is fixed and the machine tool rotates. The high-speed rotating special carbide milling cutter is used to realize simultaneous chamfering of the upper and lower end faces of super-large internal gears, and the machine tool can be used to deburr and polish the tooth roots and tops of the gears.

[0055] This machine tool includes CNC turntable 1, horizontal radial slide table 2, column one 9, column two 13, Y1 tool rest assembly 5, Y2 tool rest assembly 14, Y3 tool assembly 7, Y4 tool assembly 12, X1 axis radial feed System 4, X2 axis radial feed system 15, Y1 axis vertical feed system 8, Y2 axis vertical feed system 10, Y3 axis vertical feed system 6, Y4 axis vertical feed system 11, wire brush deburring system 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com