Patents

Literature

47results about How to "High chamfering precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

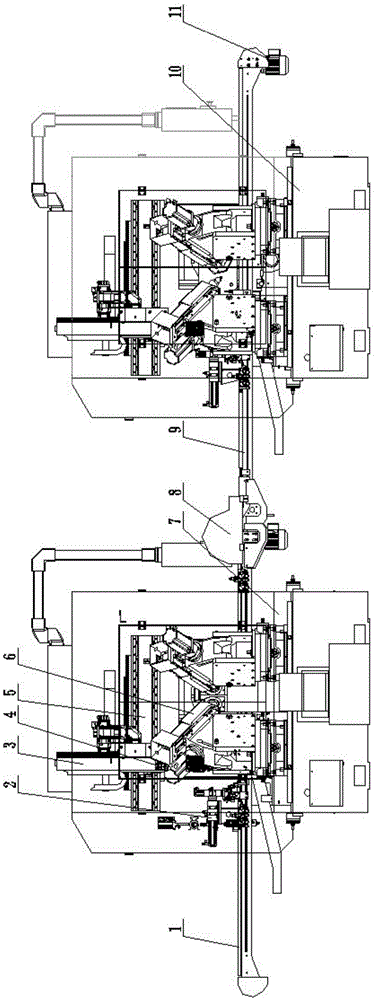

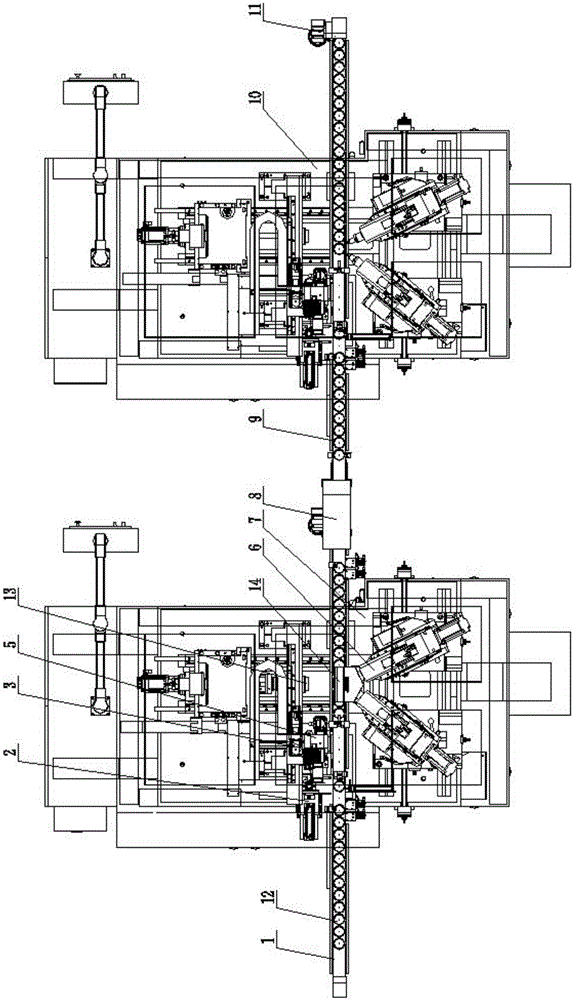

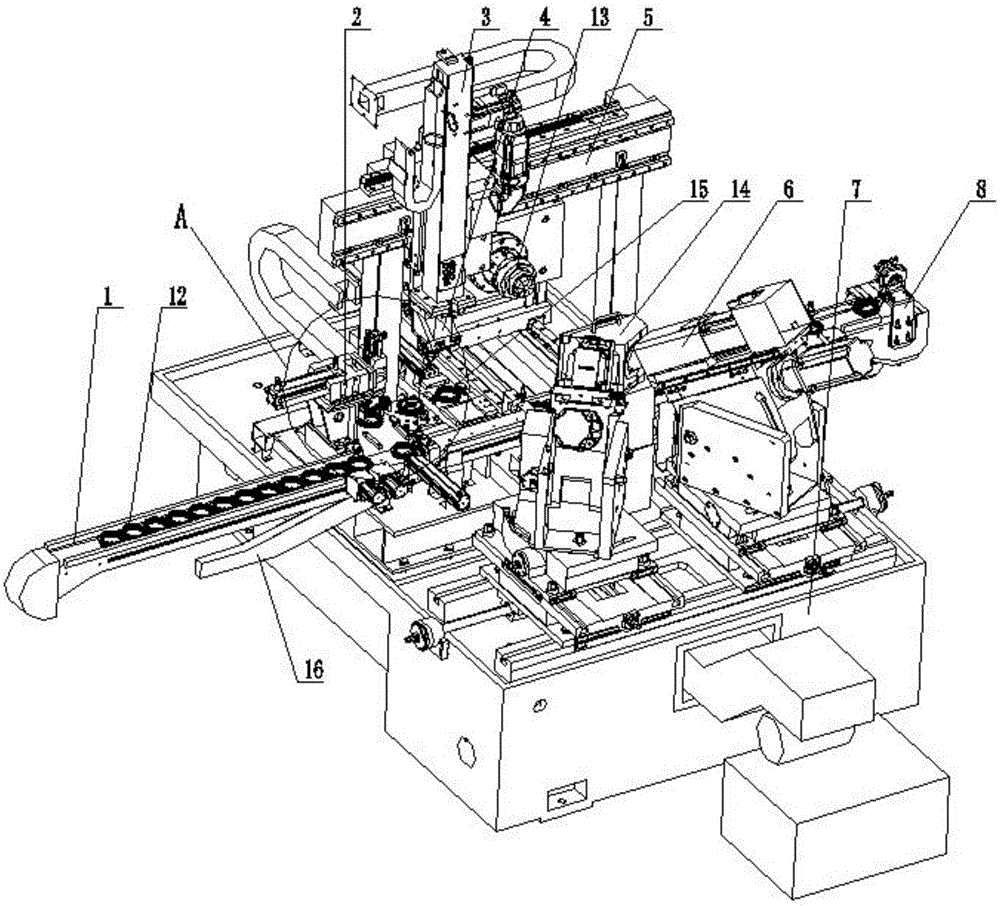

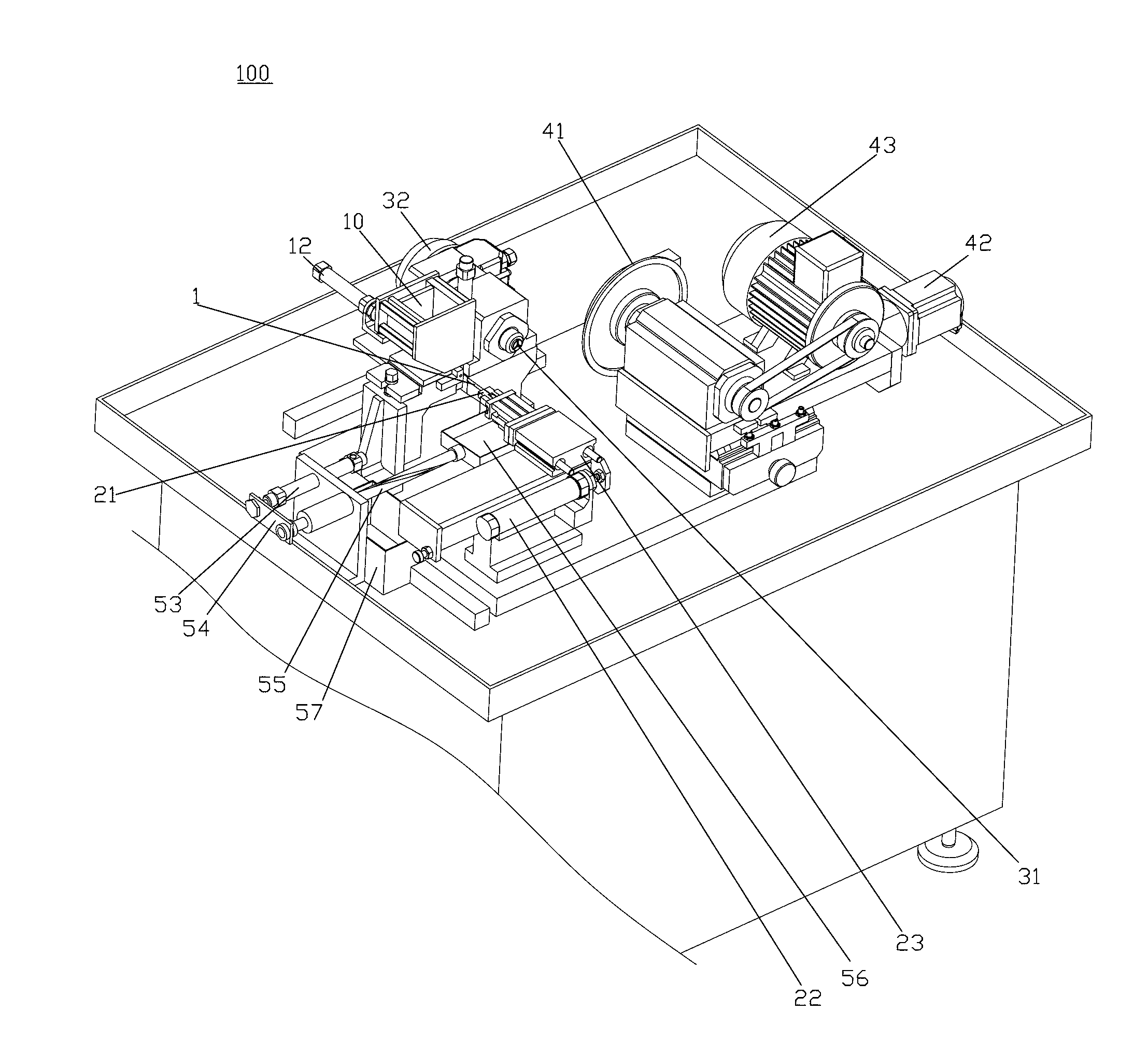

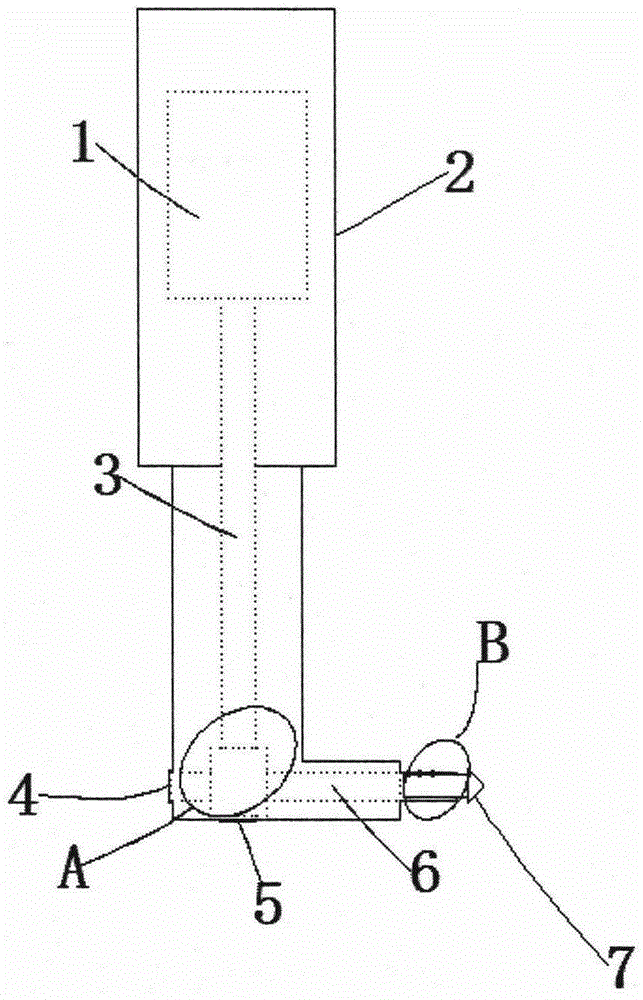

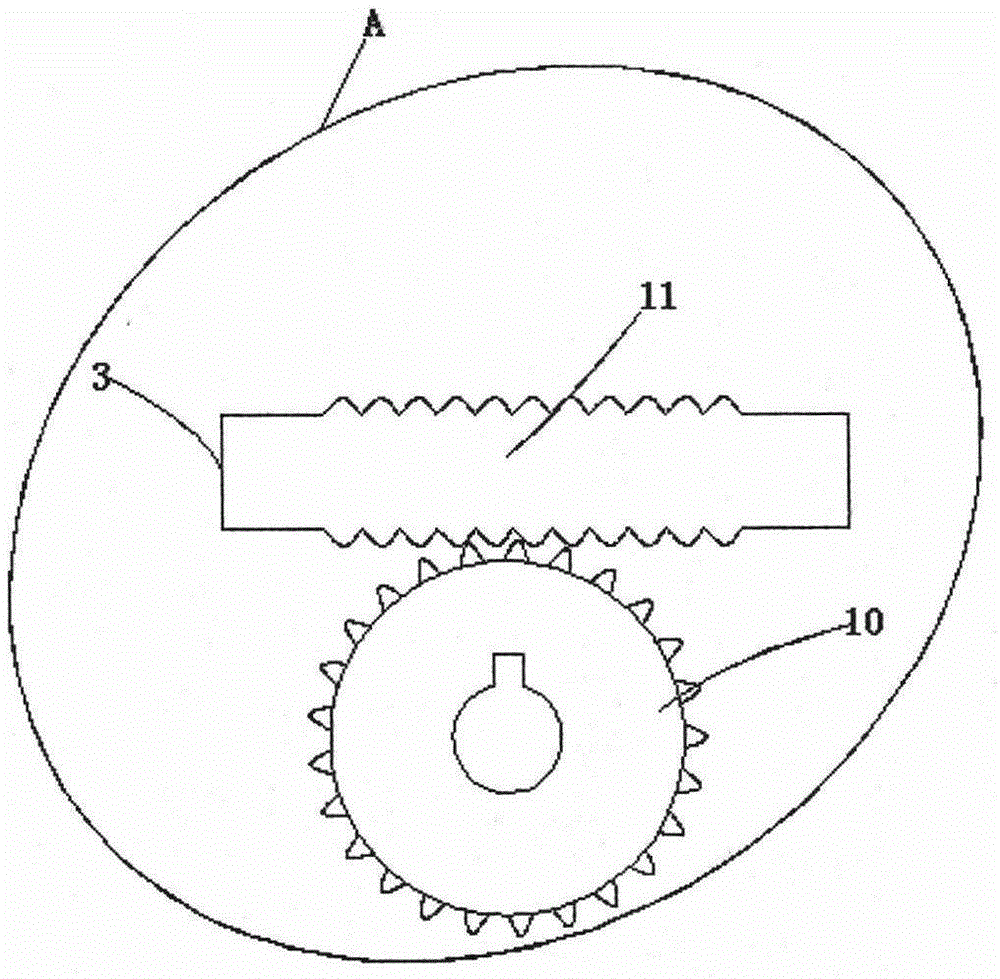

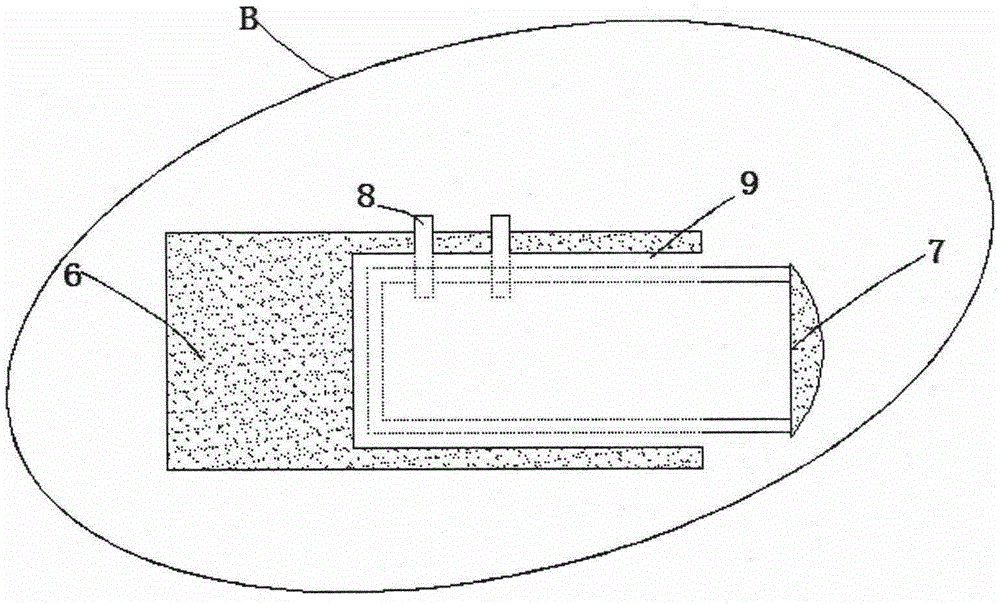

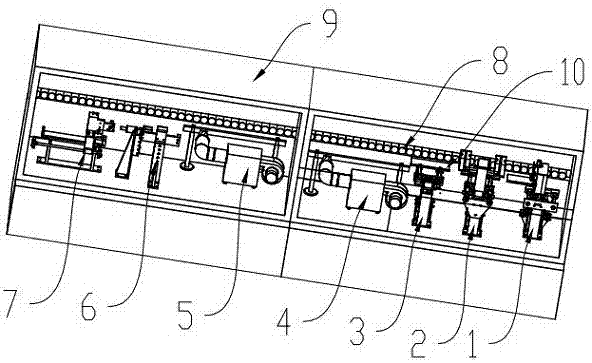

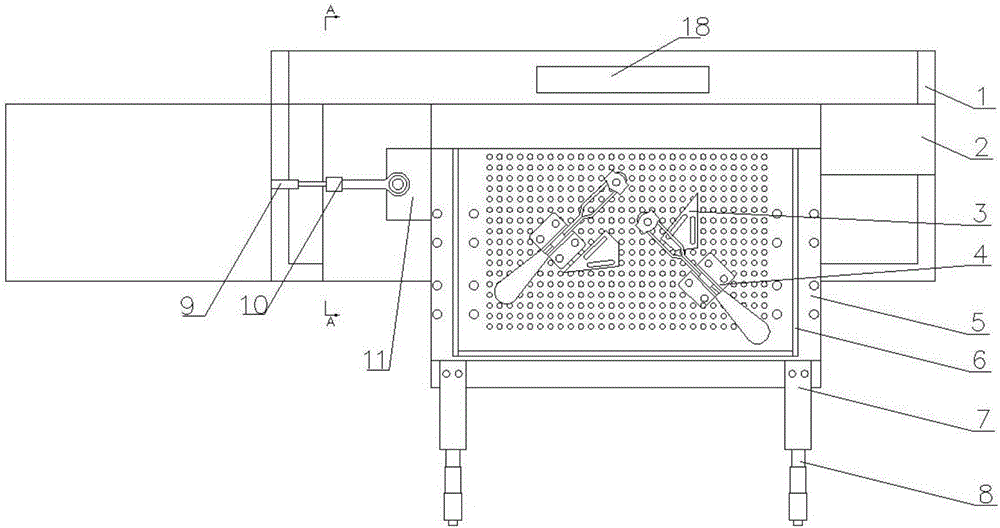

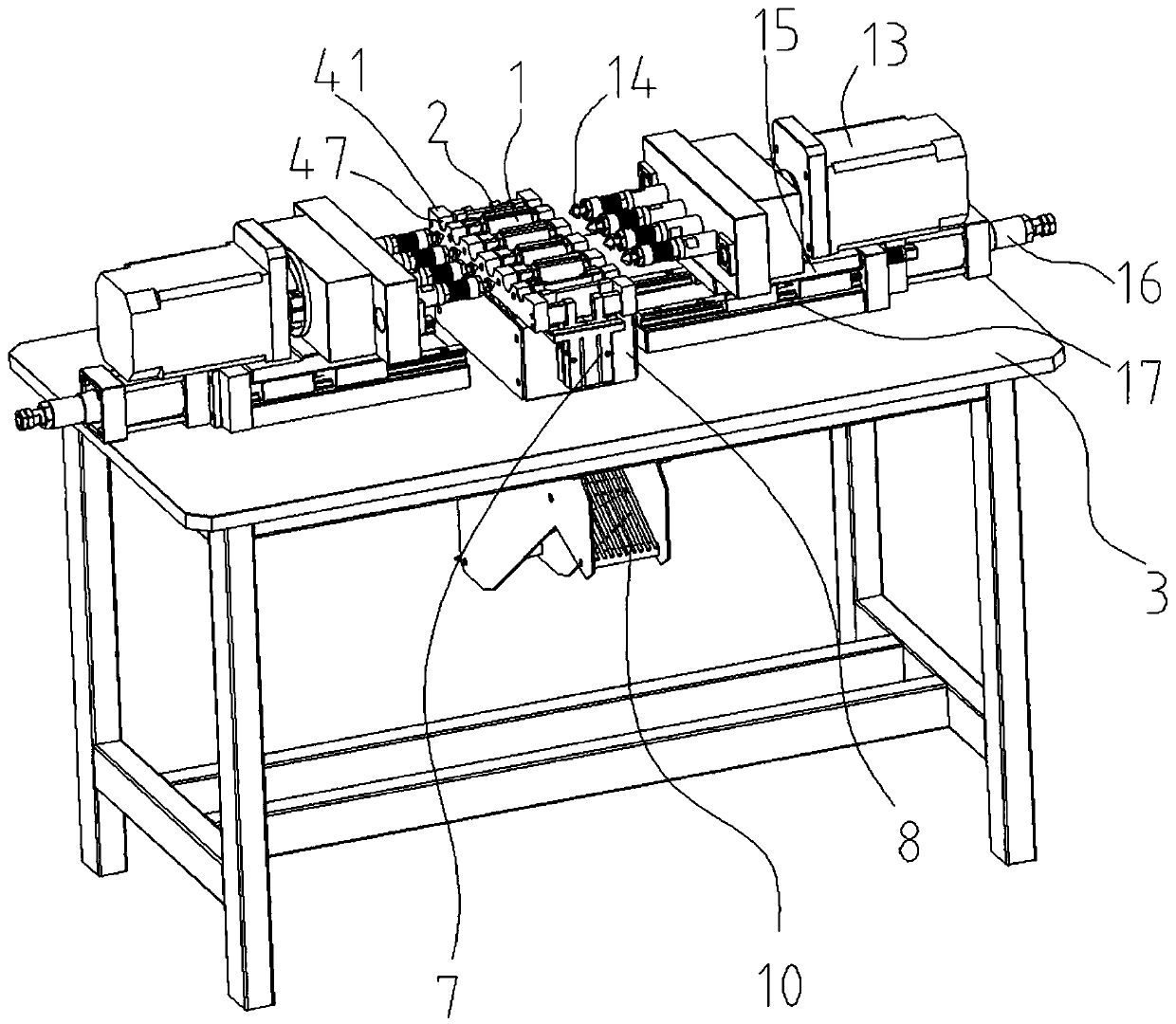

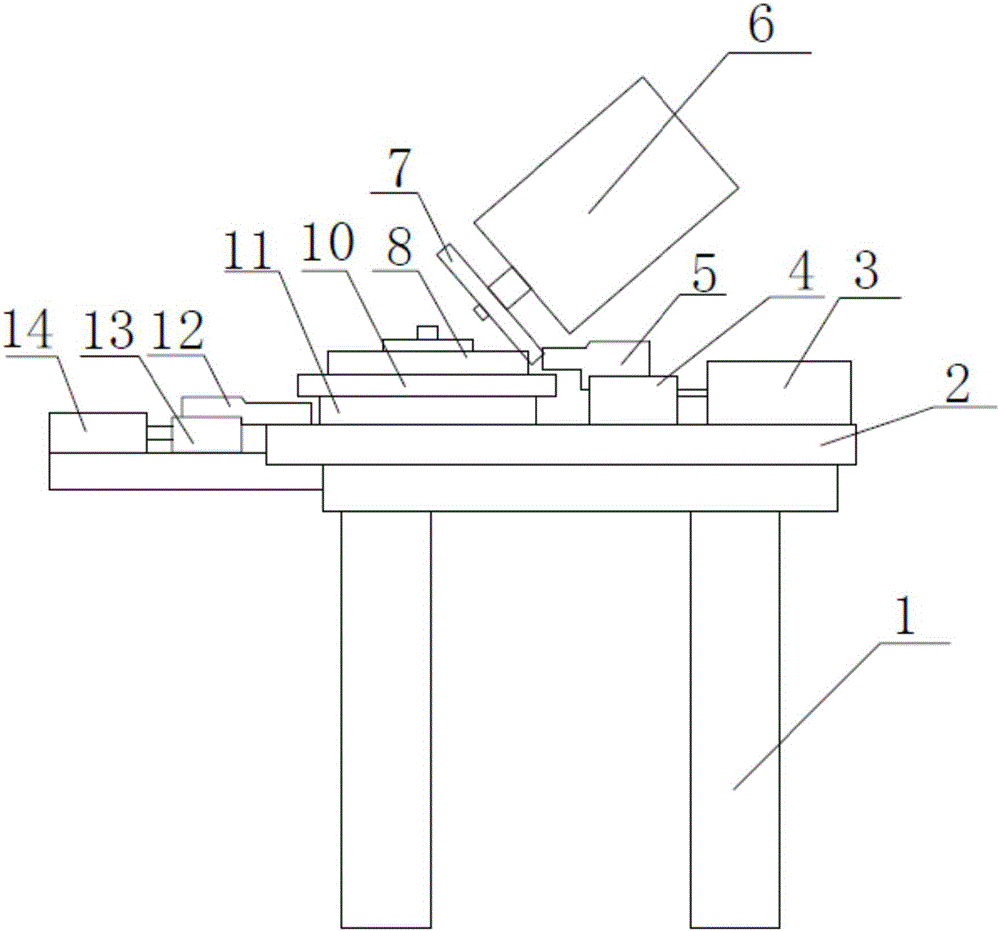

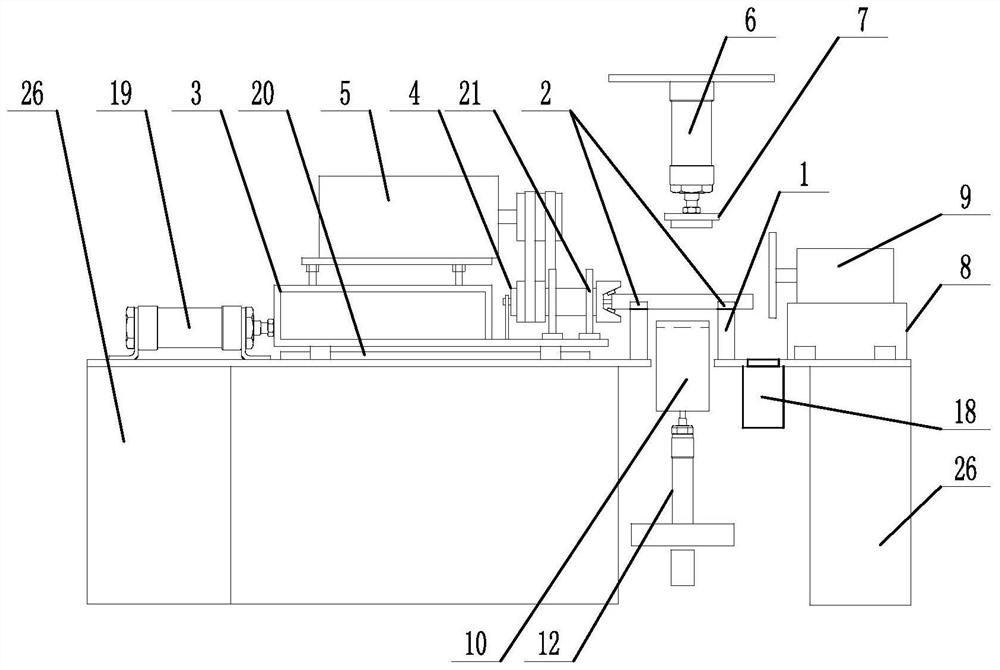

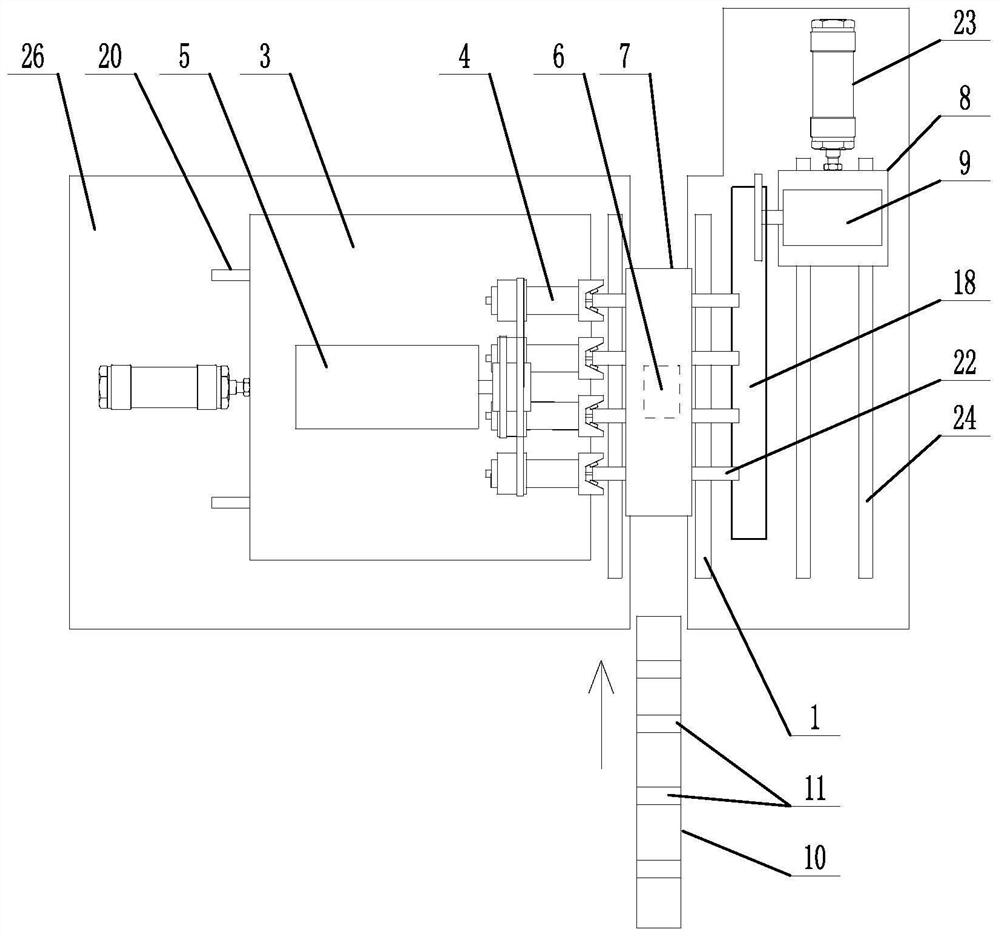

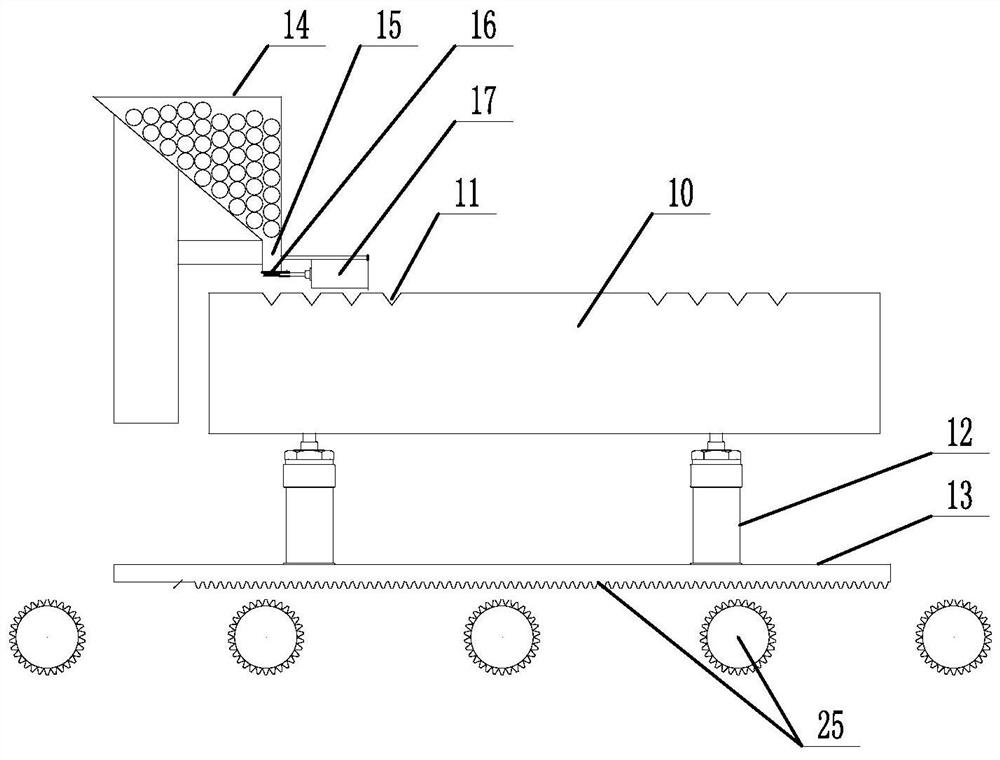

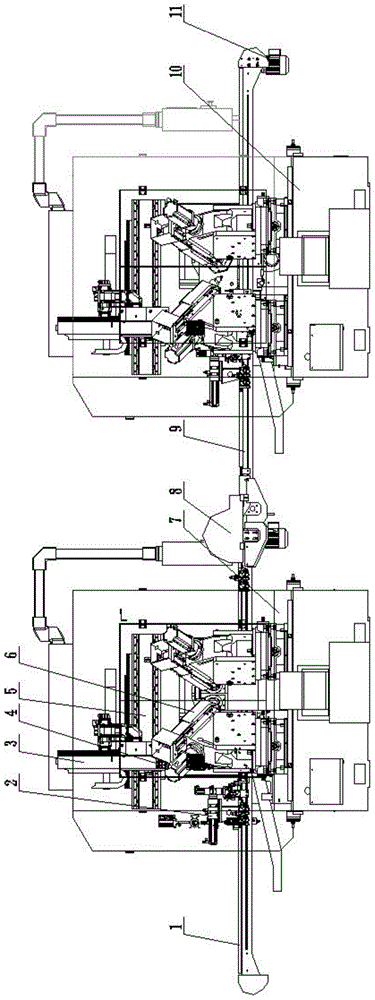

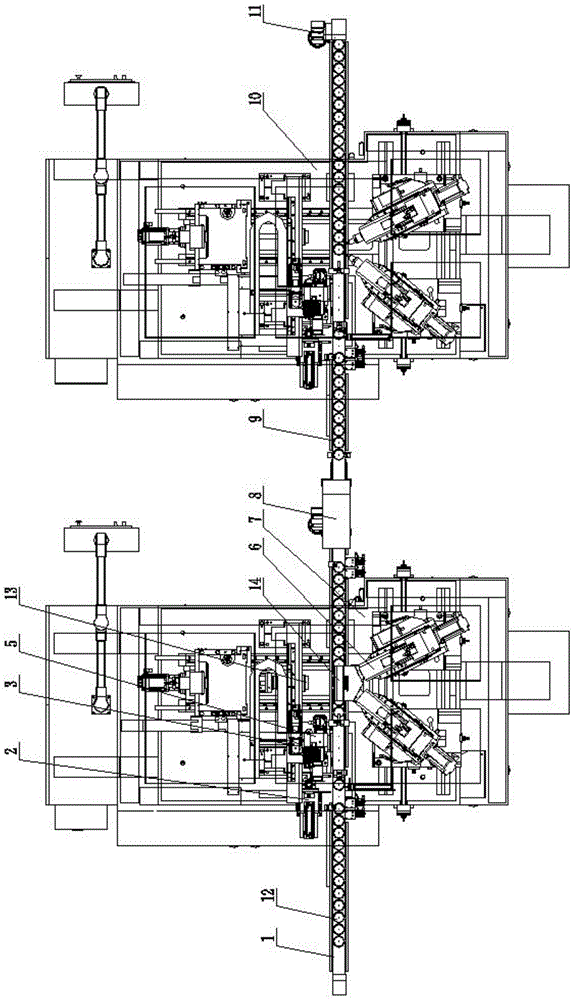

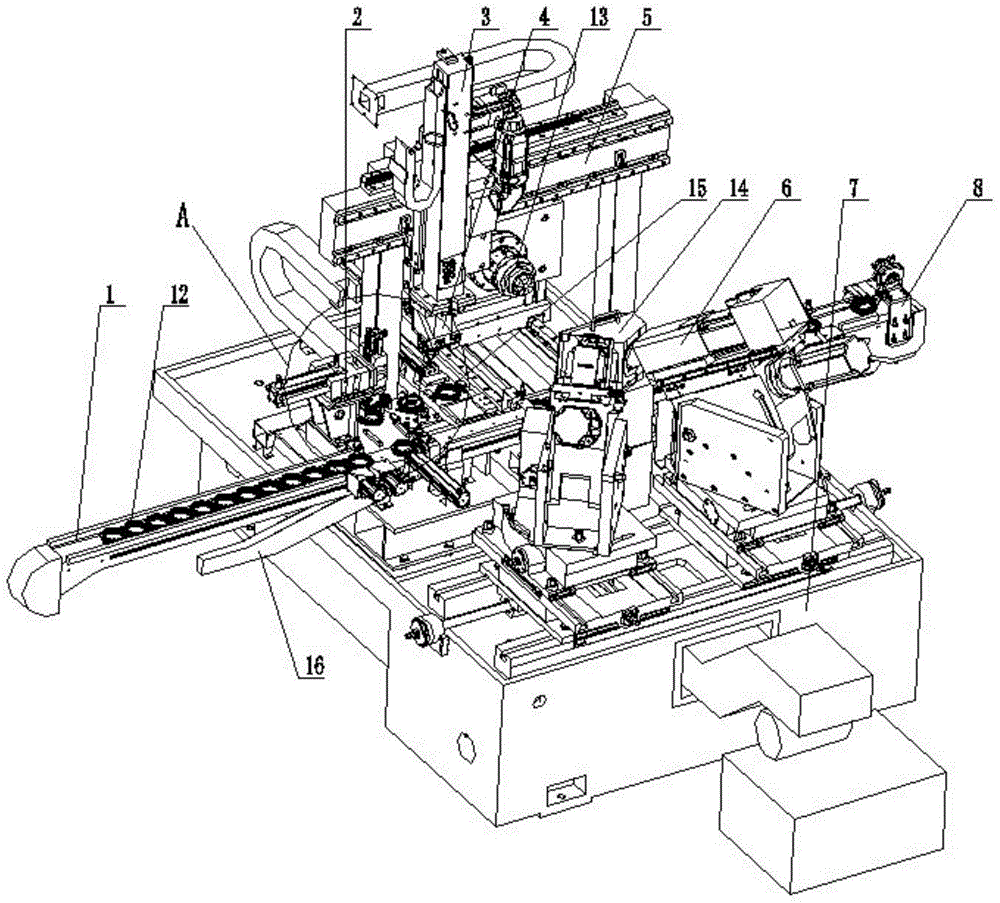

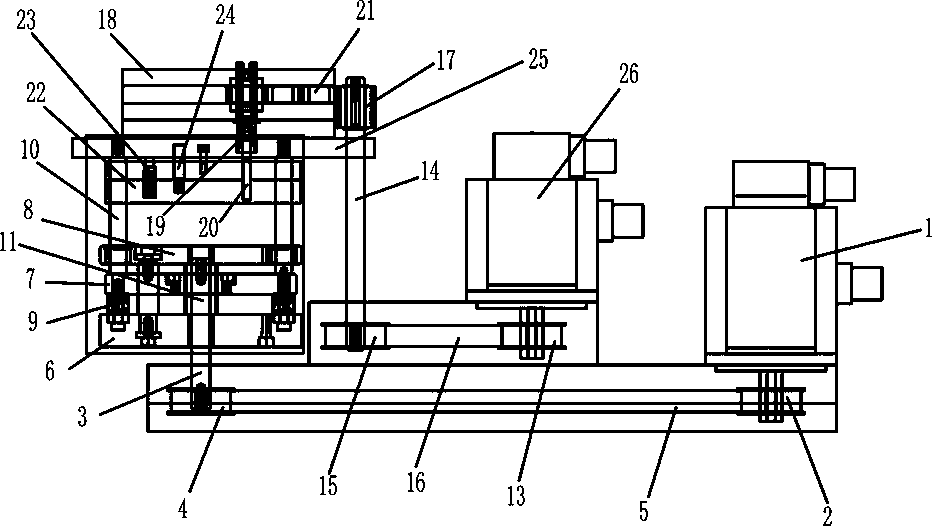

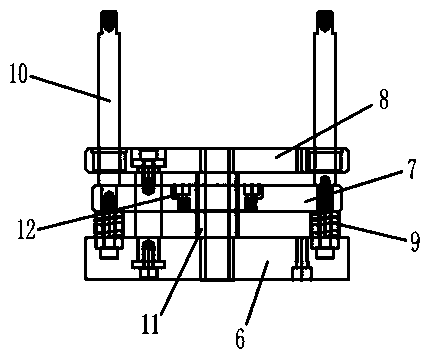

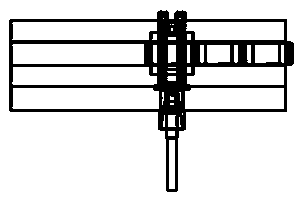

Double-face chamfering continuous machining system for gear sleeve of vehicle synchronizer

ActiveCN105149698AReduce configurationGuaranteed accuracyMetal working apparatusMaintainance and safety accessoriesDrive motorMachining system

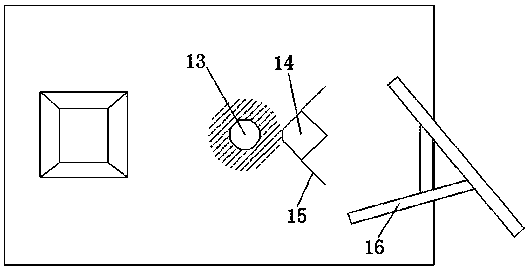

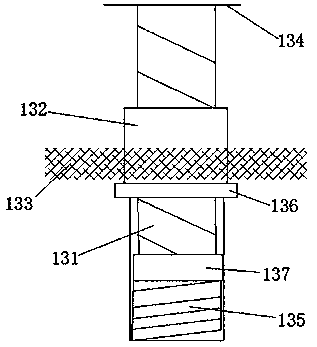

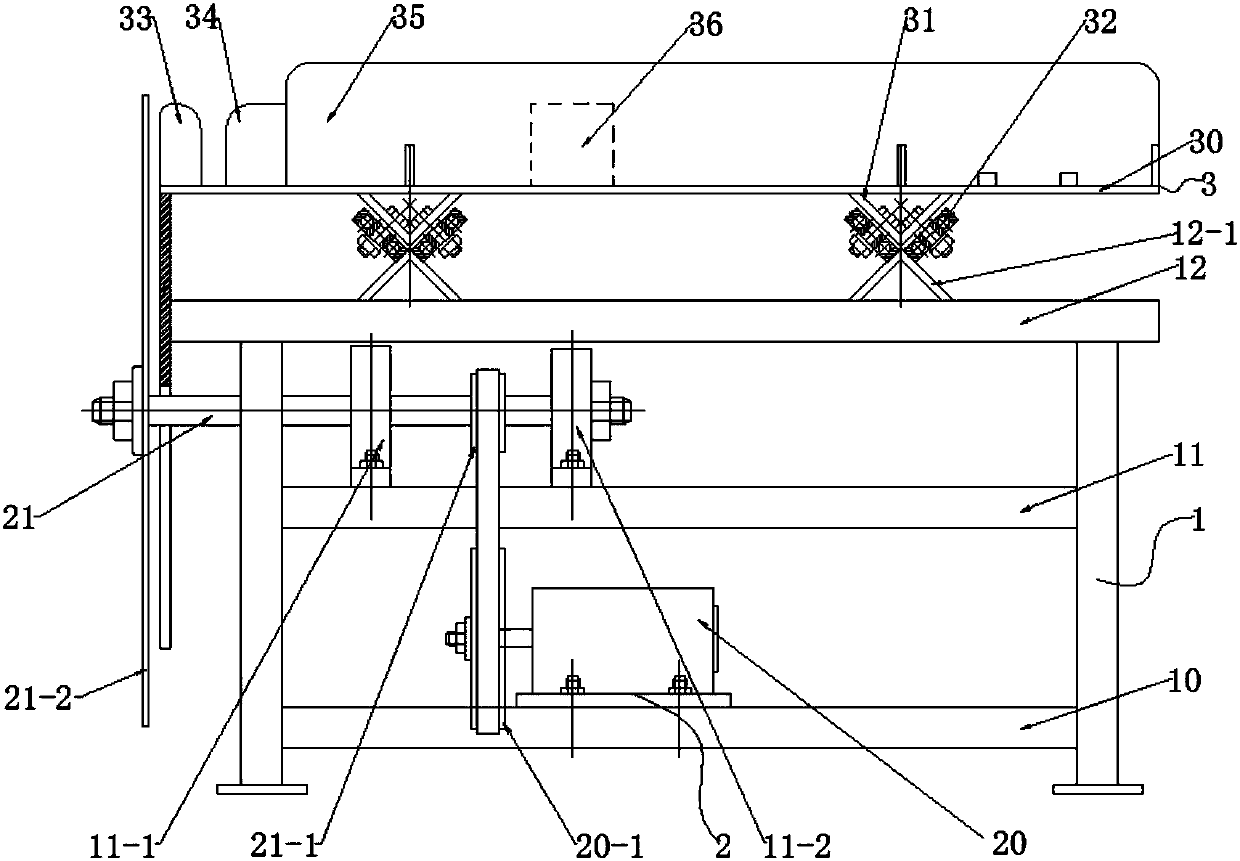

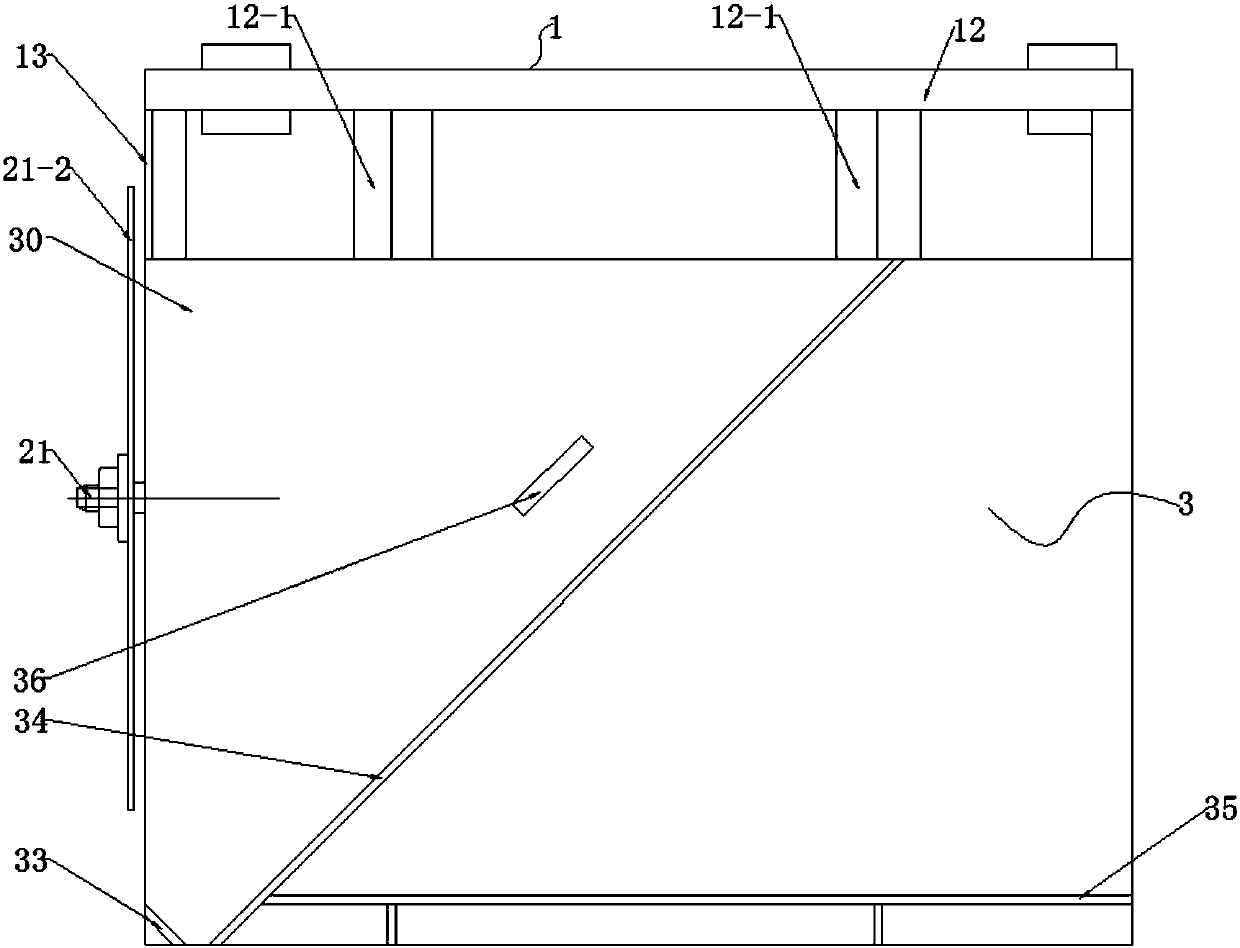

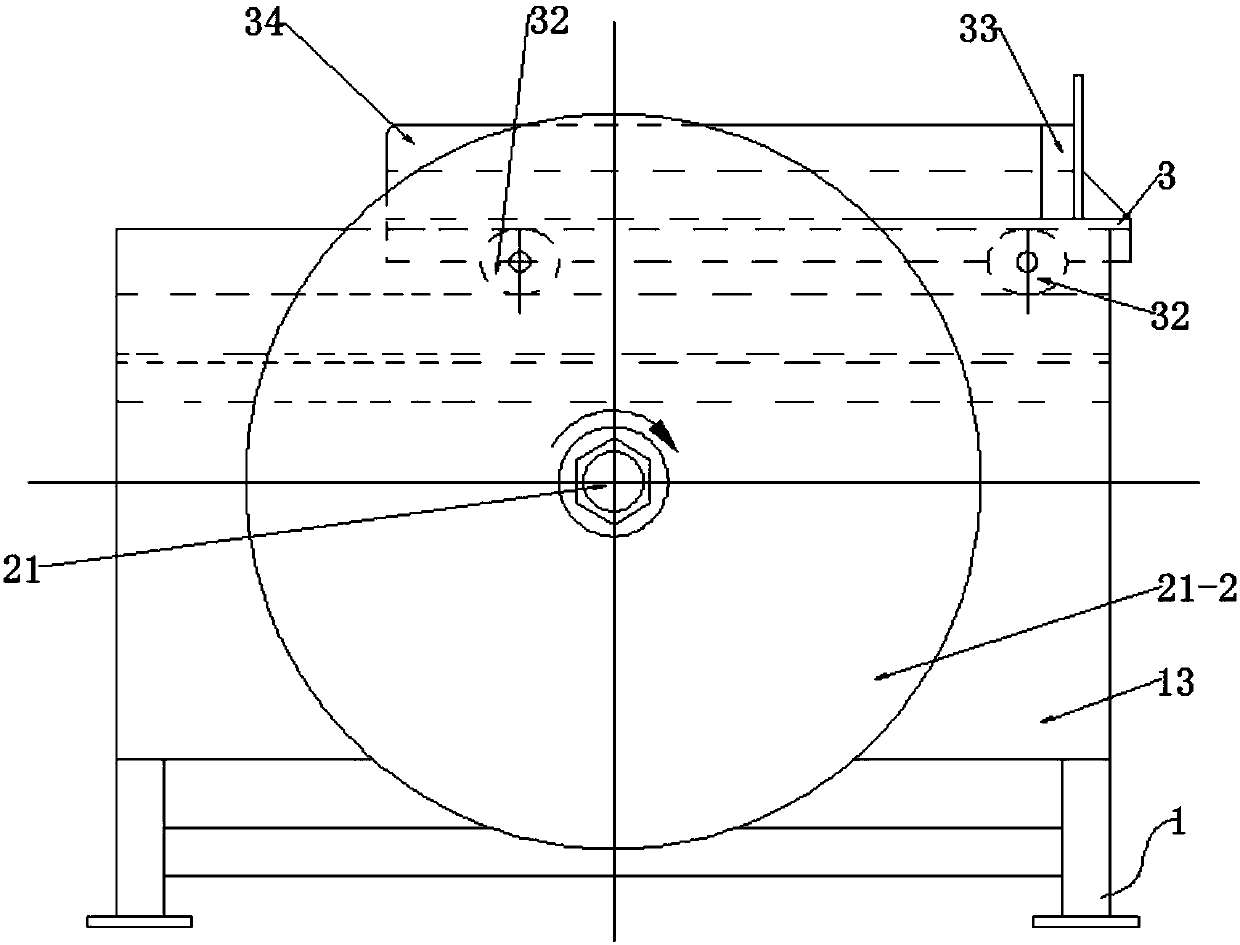

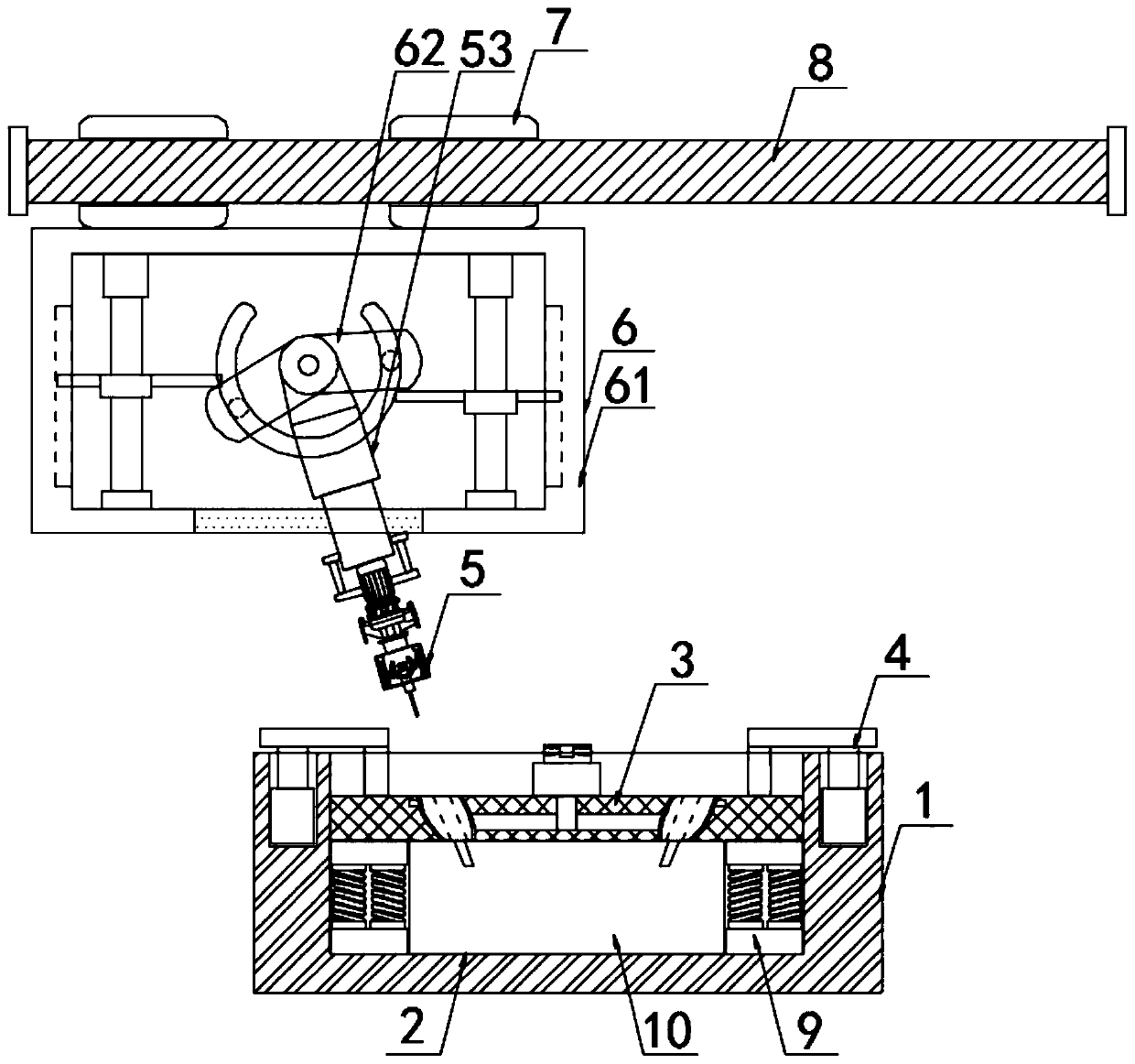

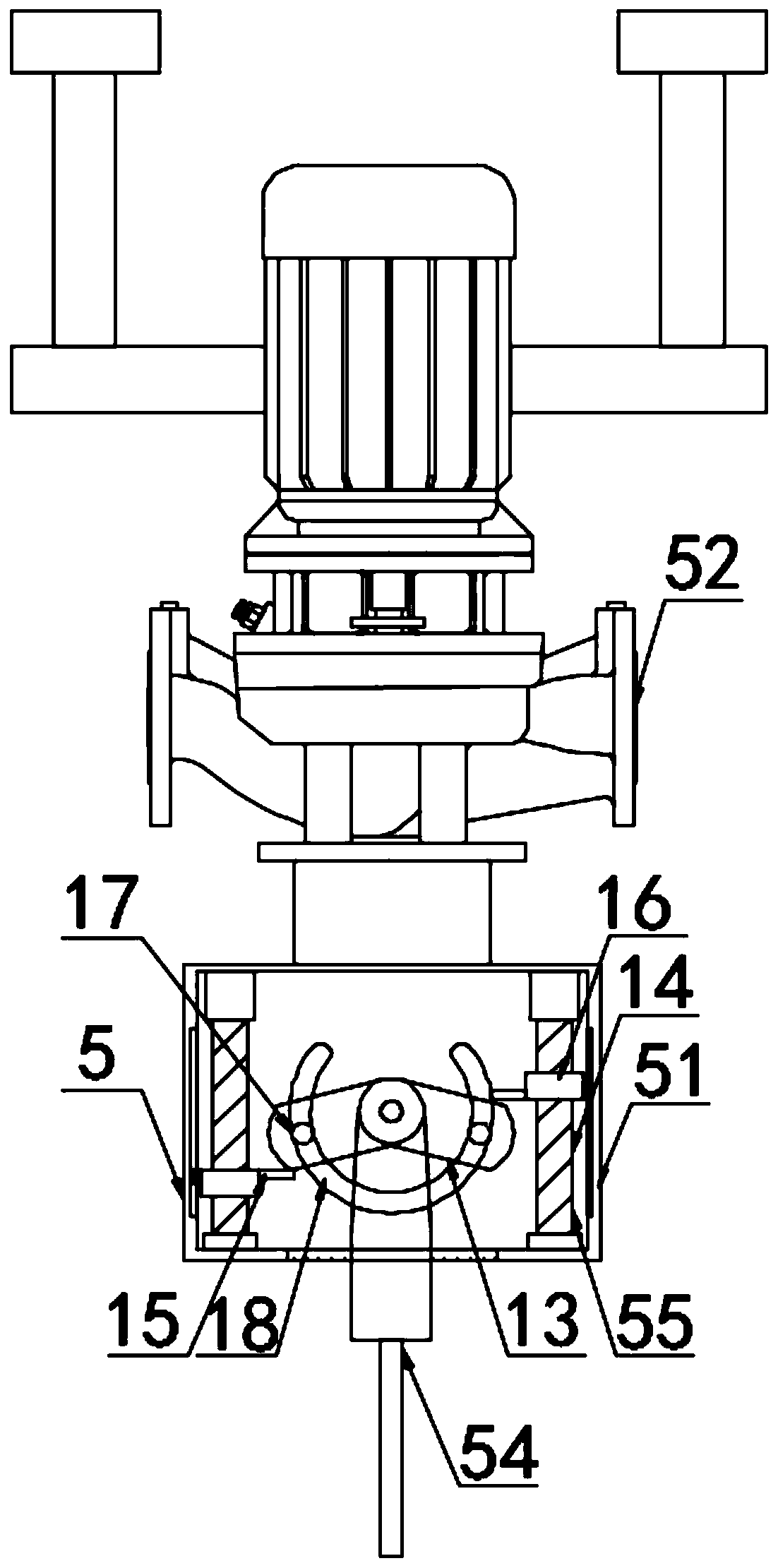

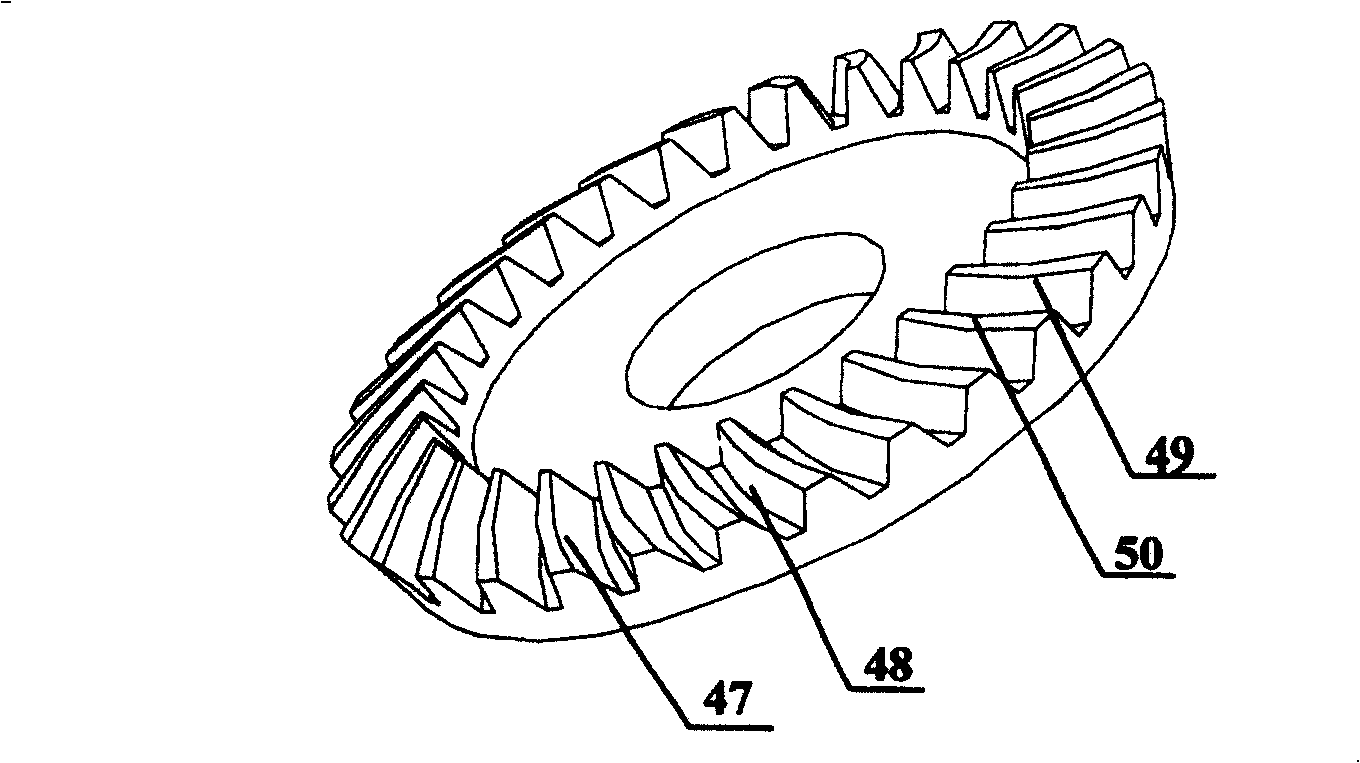

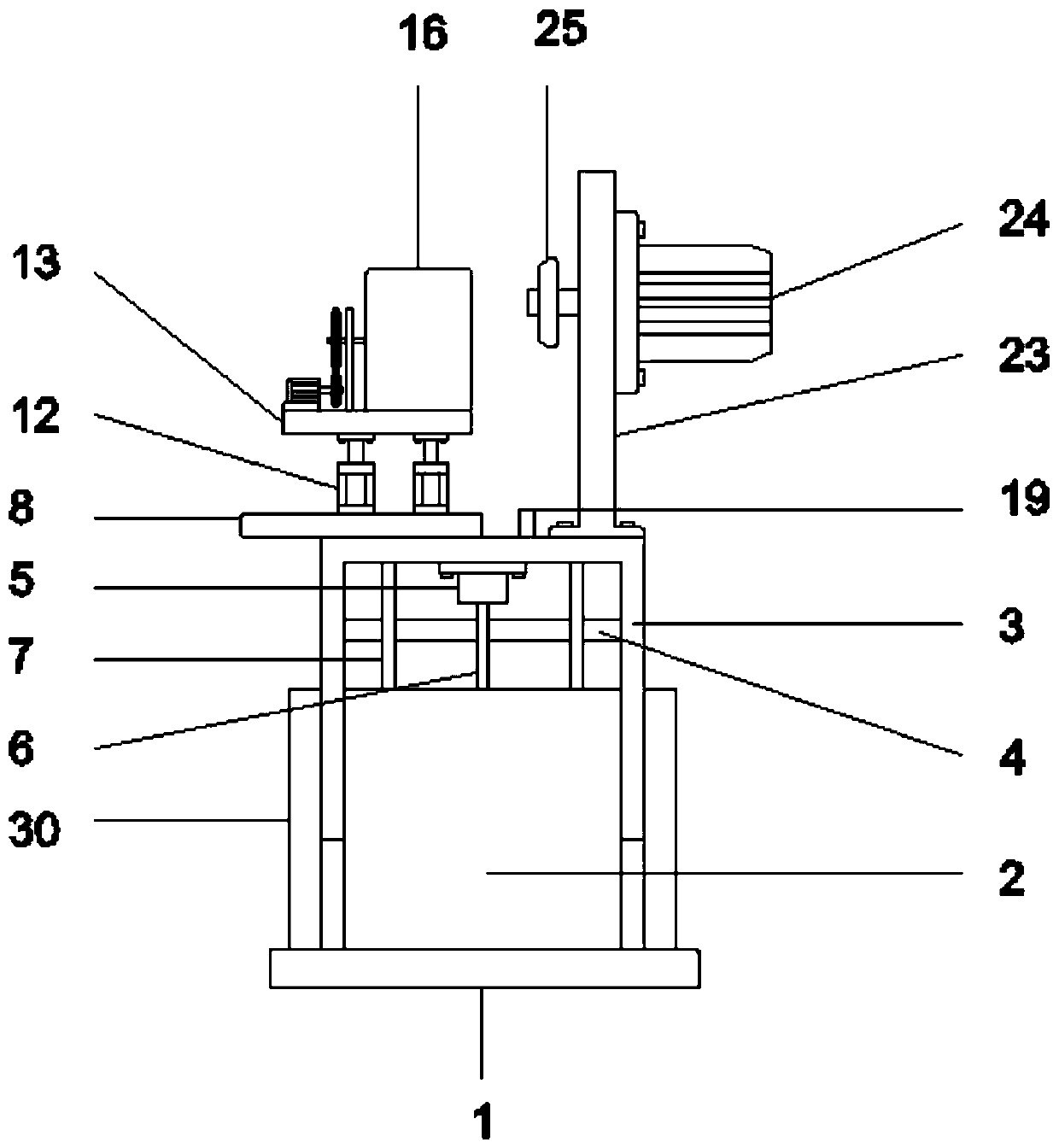

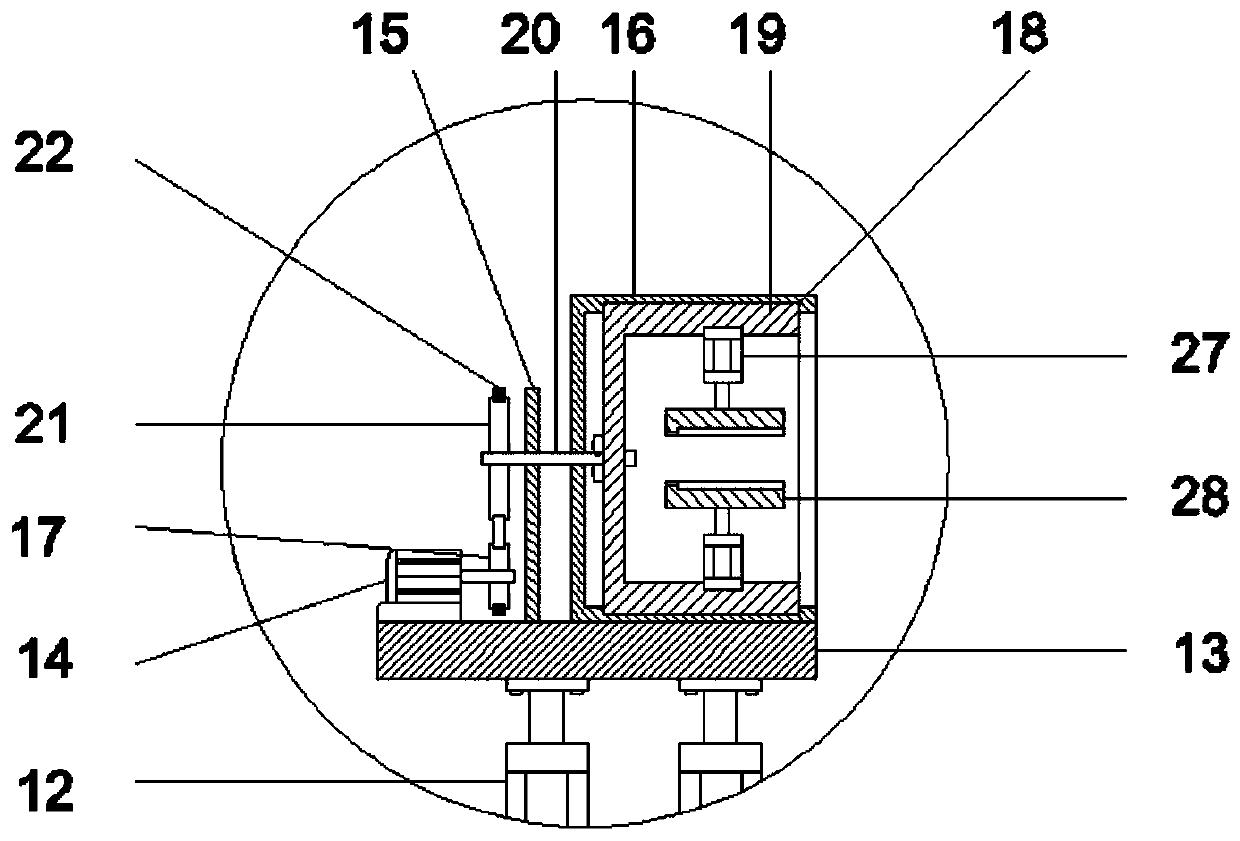

The invention relates to a double-face chamfering continuous machining system for a gear sleeve of a vehicle synchronizer. The double-face chamfering continuous machining system is formed by two same double-cutter machining chamfering machines and a linear feeding mechanism penetrating two chamfering machine machining stations transversely; the two same double-cutter machining chamfering machines are arranged into a row in parallel, each chamfering machine comprises a cutter for conducting chamfering machining, a workpiece driving machine head and a tooth alignment mechanism, a center line where the two cutters are located is arranged to right face the workpiece driving machine heads, tooth alignment mechanisms are arranged at front end working procedure components of the workpiece driving machine heads, and the workpiece driving machine heads are installed on a machine head base; each chamfering machine is horizontally and fixedly provided with a linear type feeding mechanism at the position, in front of the workpiece driving machine heads and behind the two cutters, of the corresponding machine body, and each linear type feeding mechanism is driven by a driving motor to drive a transmission belt in a material way to rotate; and a tooth sleeve turnover mechanism is installed between the two linear type feeding mechanisms, and pushing air cylinders are fixedly installed on the outer sides, corresponding to the tooth alignment mechanisms, of the material way. By means of the machining system, double-face chamfering machining of an overall tooth sleeve can be completed at a time, the production efficiency is greatly improved, meanwhile, allocation of a feeding mechanical arm and a feeding mechanism is omitted, and the overall machining area is decreased.

Owner:TIANJIN DAXIN PRECISION MECHANICAL EQUIP

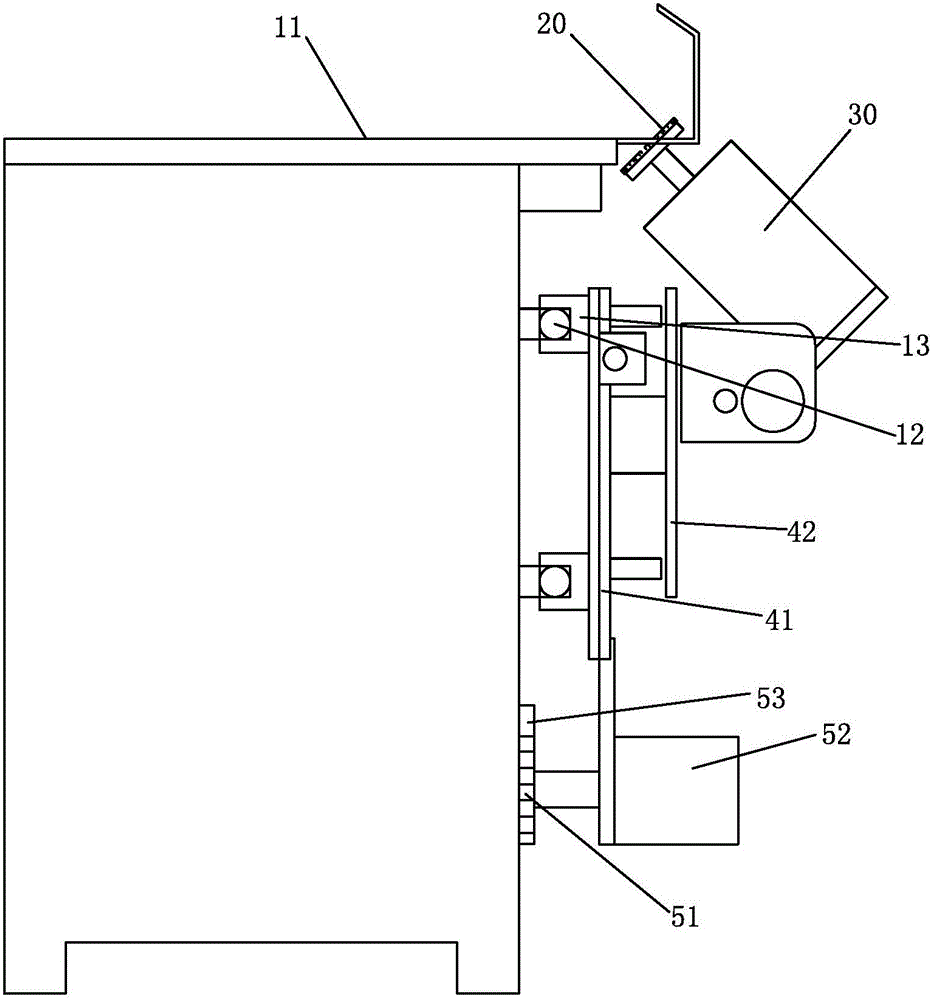

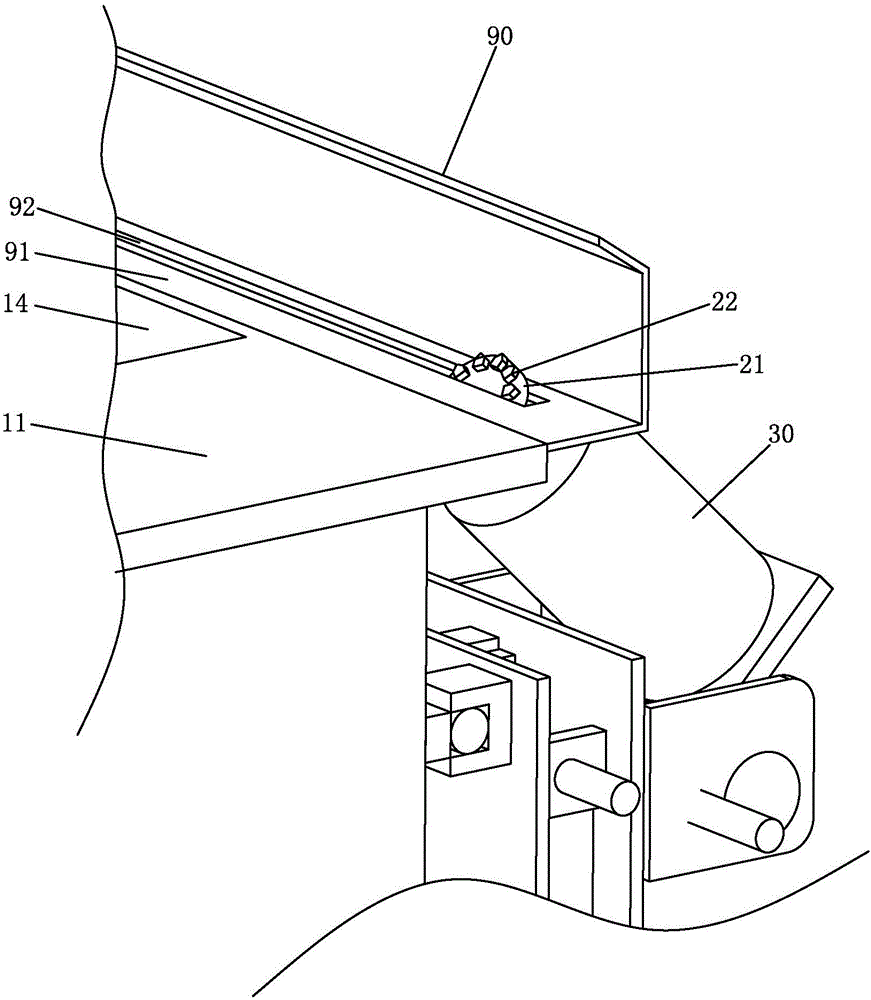

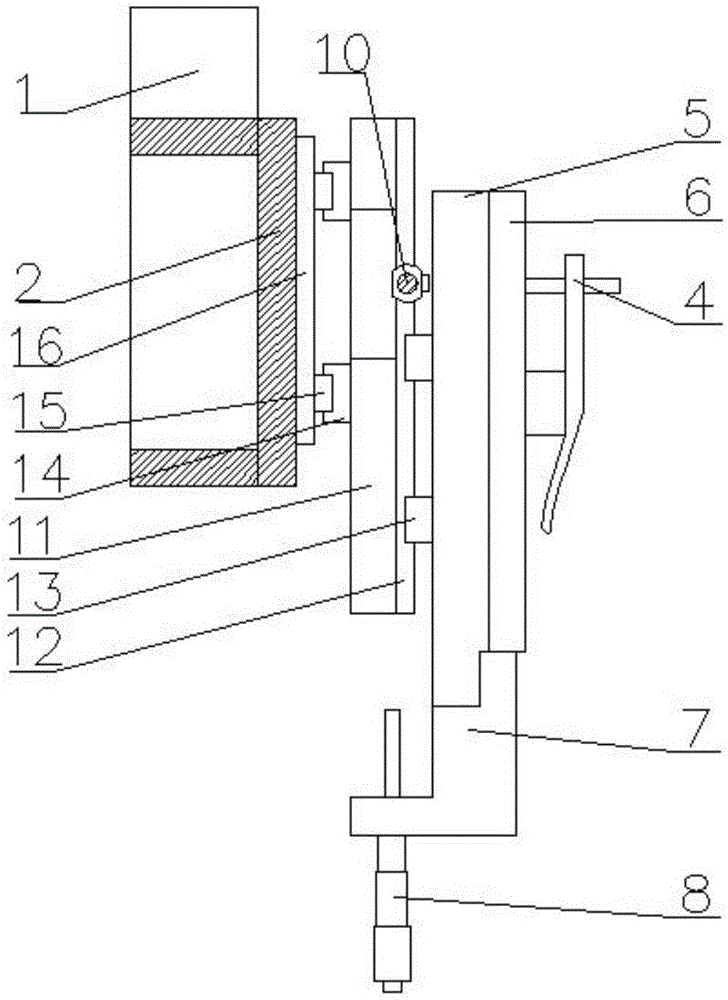

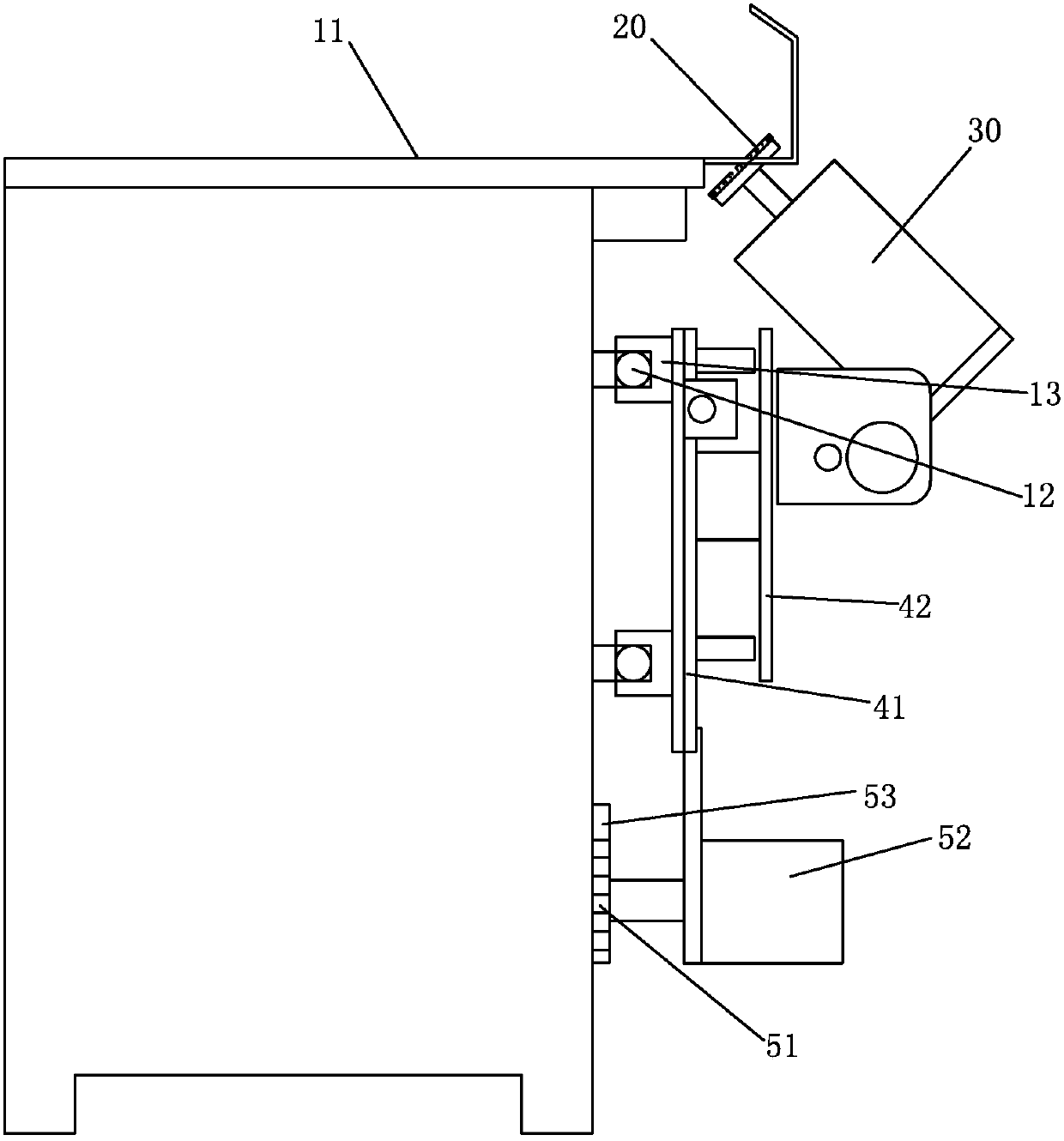

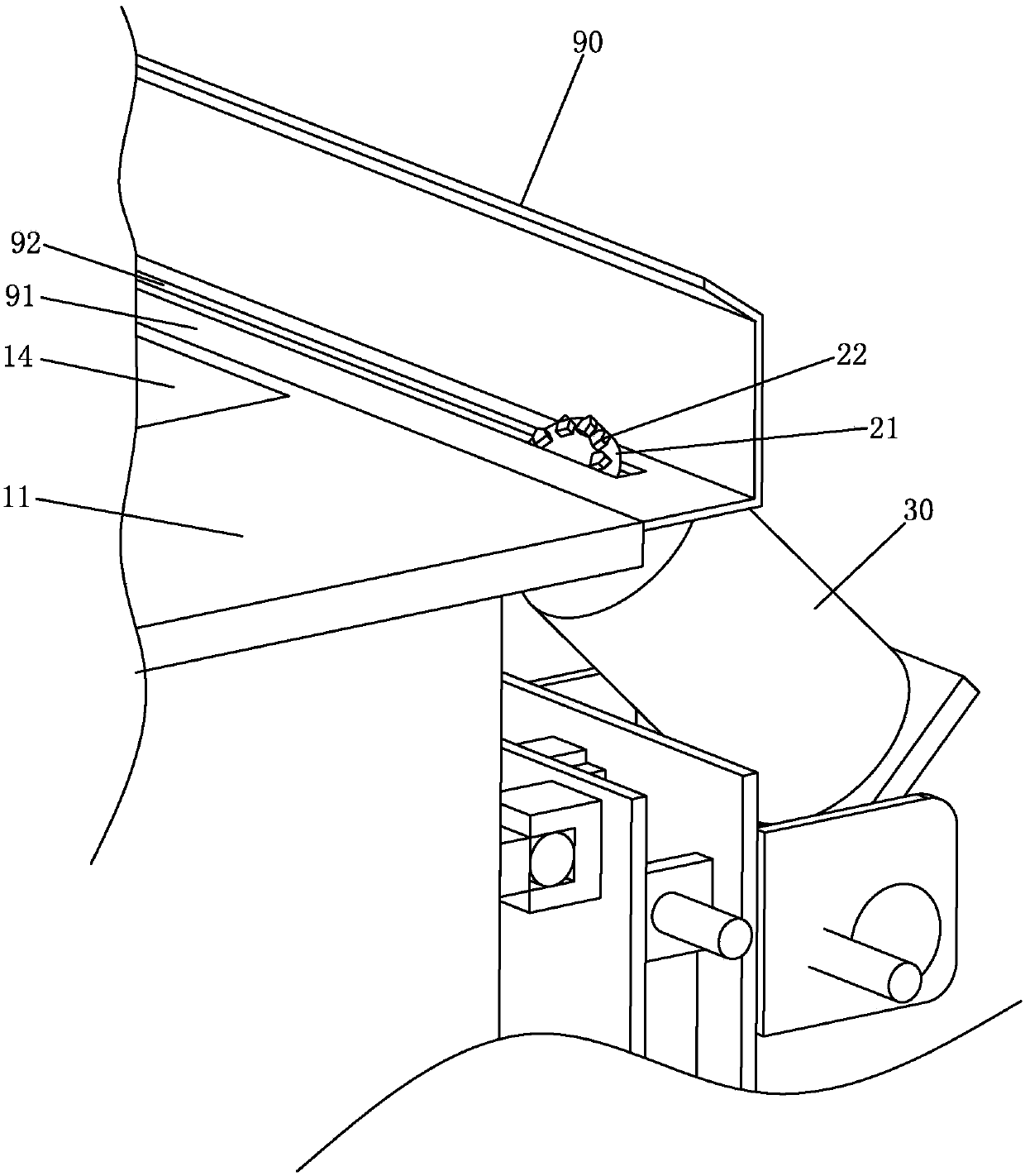

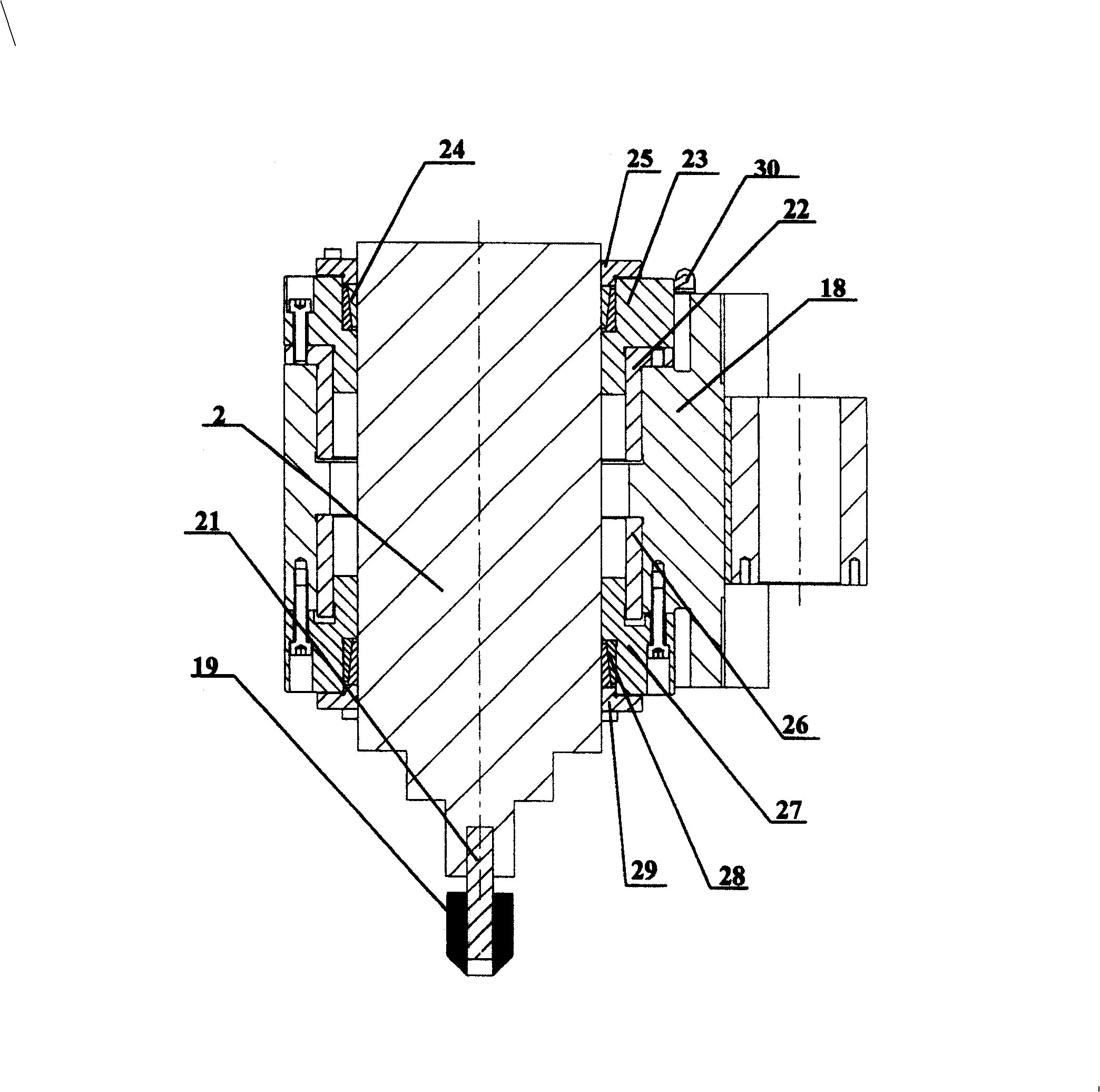

Chamfering machine

ActiveCN105904030AReduce labor costsImprove securityEdge grinding machinesPositioning apparatusMotor driveEngineering

The invention discloses a chamfering machine which comprises a rack provided with a working table, a chamfering tool, a first chamfering motor, a movable body and a walking driving device, wherein the chamfering tool is arranged on the side of the working table in an oblique manner; the first chamfering motor drives the chamfering tool to rotate; a positioning structure for positioning a workpiece is arranged on the working table; the first chamfering motor is mounted on the movable body; the movable body is connected onto the rack through a sliding guide mechanism in a sliding manner and is connected with the walking driving device; the walking driving device is used for driving the movable body and the first chamfering motor to walk so as to chamfer the workpiece positioned on the working table. According to the invention, on one hand, the human cost is saved and the security coefficient is high; on the other hand, the walking driving device drives the first chamfering motor to walk so as to enable the chamfering speed to always stay the same, the chamfering precision is high, the chamfering effect is excellent, and the stability and standard during chamfering are improved.

Owner:JOMOO KITCHEN & BATHROOM

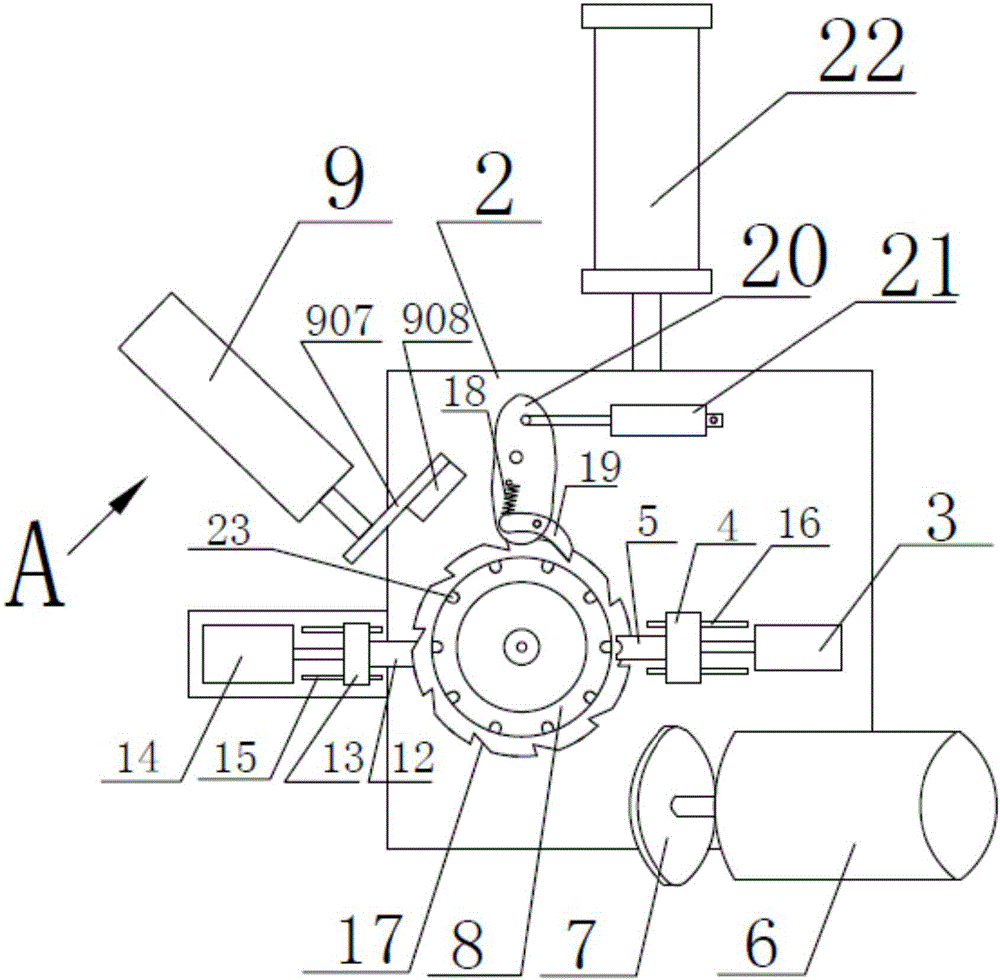

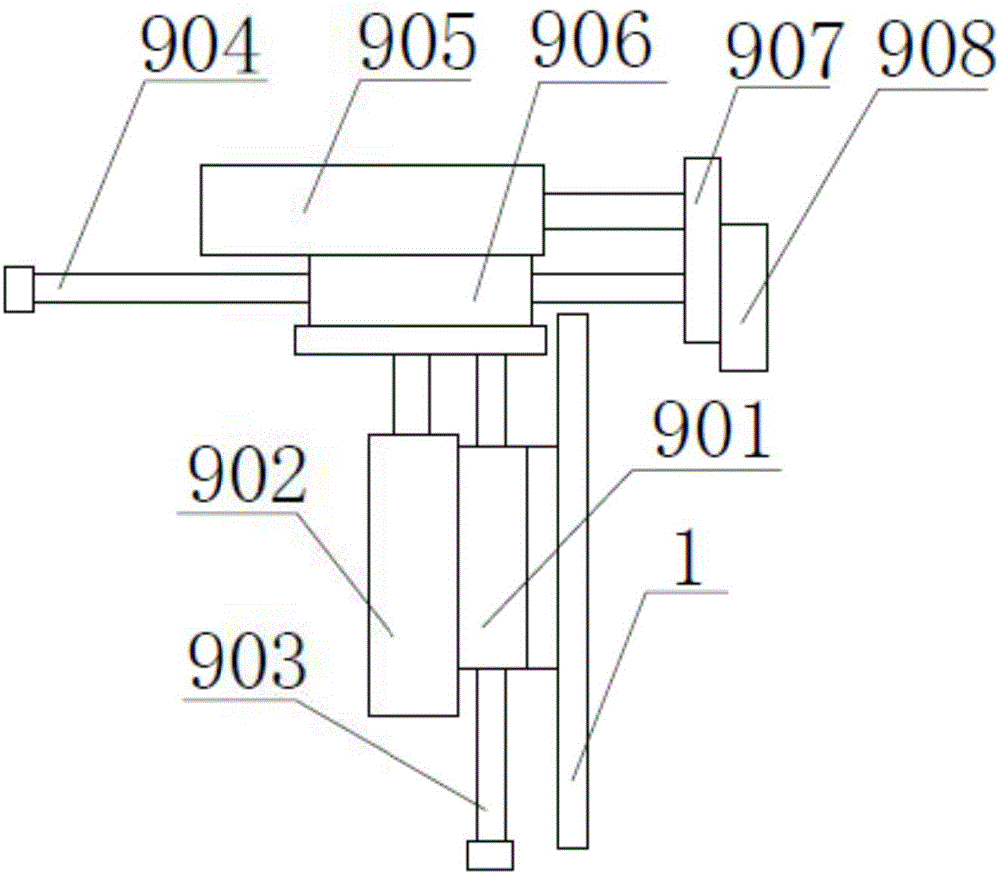

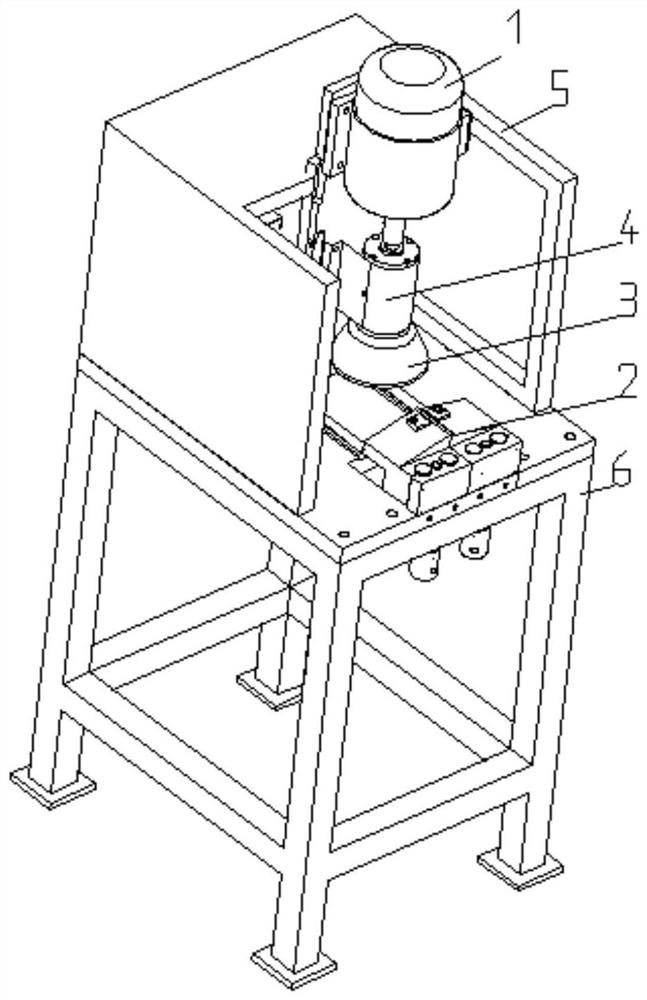

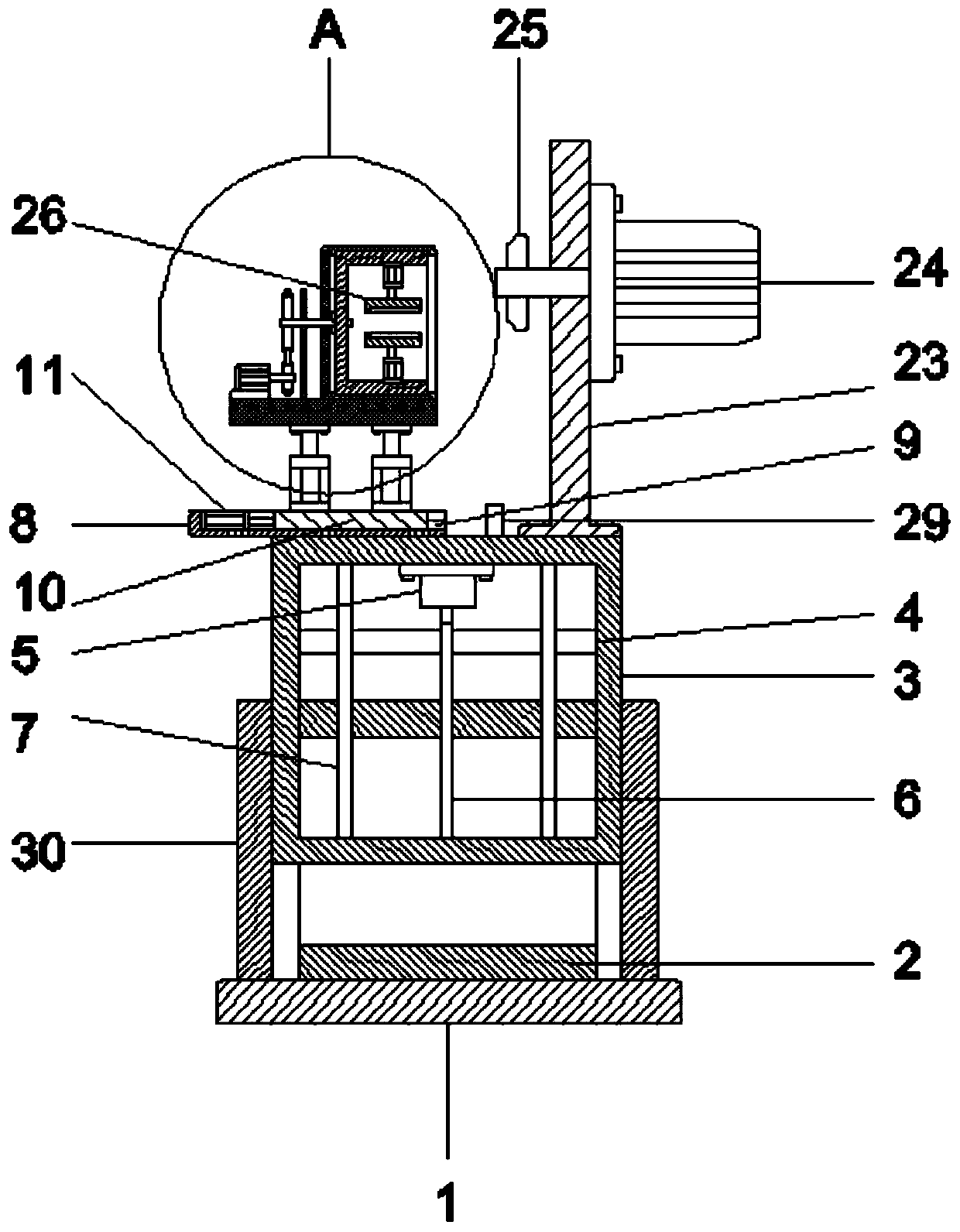

Automatic chamfering machine

InactiveCN103009202AHigh degree of automationHigh chamfering precisionEdge grinding machinesEngineeringMechanical engineering

The invention discloses an automatic chamfering machine. A discharging port for drawing out a workpiece is formed at the bottom of a feeding groove. A handover mechanism comprises clamp jaws, a first lateral sliding mechanism and a first longitudinal sliding mechanism, wherein the clamp jaws can be driven to align at the workpiece through the fit sliding of the first lateral sliding mechanism and the first longitudinal sliding mechanism, draw the workpiece out of the feeding groove and convey the workpiece to a clamp device. The clamp device comprises telescopic fastening heads and a rotating mechanism. When the workpiece is conveyed to the clamp device by the clamp jaws, the telescopic fastening heads retract after holding the workpiece and then fasten and fix the workpiece. The workpiece is driven by the rotating mechanism to rotate through the telescopic fastening heads. An abrasive disc device comprises an abrasive disc, a second lateral sliding mechanism and a driving device arranged on the second lateral sliding mechanism, wherein the abrasive disc is arranged on the driving device, pushed by the second lateral sliding mechanism to approach and / or depart from the workpiece, and driven by the driving device to rotate and carry out chamfering processing on the workpiece. The automatic chamfering machine disclosed by the invention can realize automatic feeding, clamping, fixing and chamfering.

Owner:上海华测先越材料技术有限公司

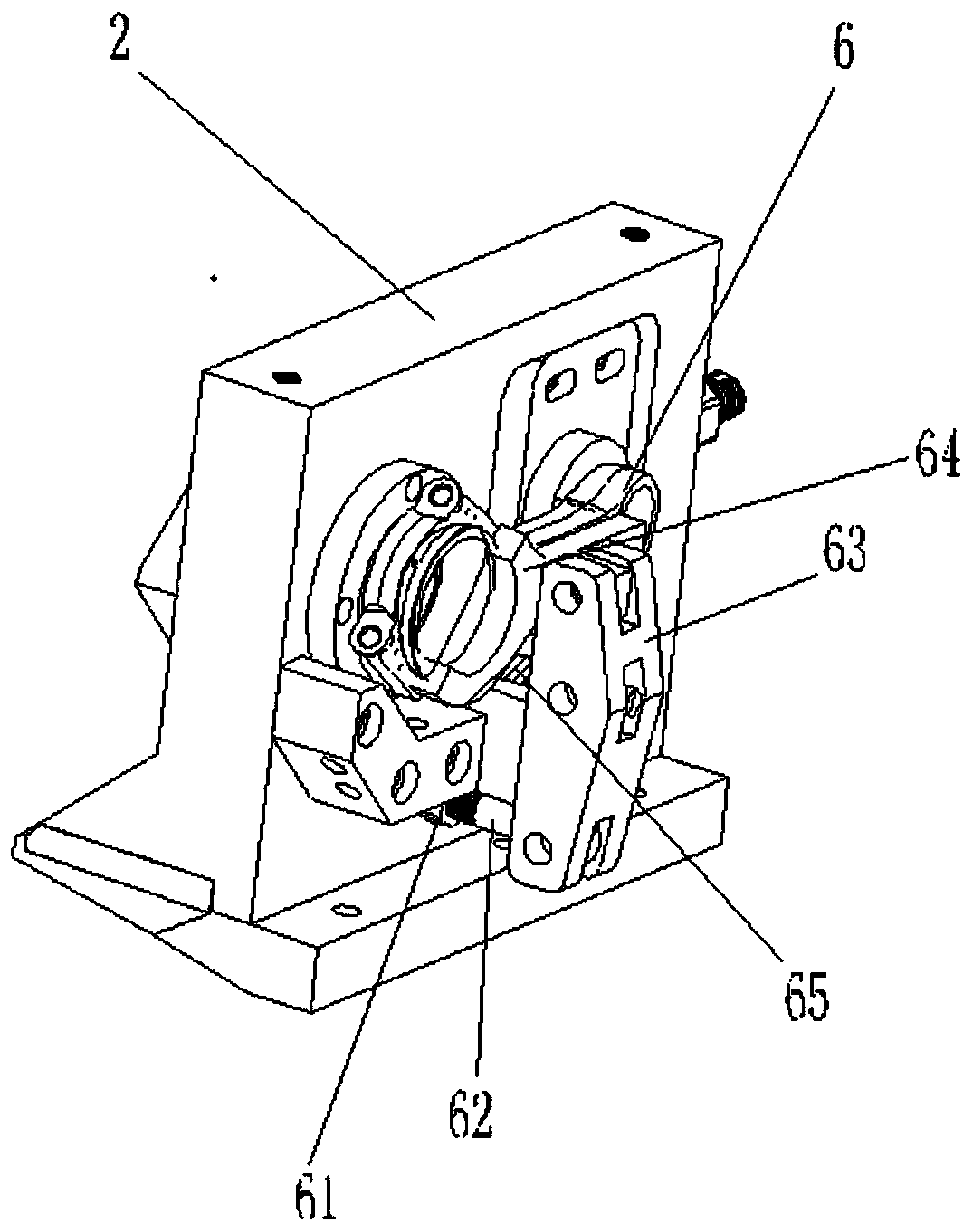

Chamfer device for annular fastening member

InactiveCN108890350AReduce labor costsHigh chamfering precisionPositioning apparatusMetal-working holdersSlide plateEngineering

Owner:嘉善信道五金塑料模具厂

In-pipe circular hole chamfering machine

The invention discloses an in-pipe circular hole chamfering machine which comprises a housing and a chamfering cutter head, wherein a driving motor is arranged at the upper part of an inner cavity of the housing; a rotating shaft of the driving motor is fixedly connected with one end of a first driving shaft; a worm molded integrally is arranged at the other end of the first driving shaft; a first rolling bearing is arranged at the side wall of the inner cavity of the housing; a second rolling bearing is arranged at the bottom of the inner cavity of the housing; the bottom of the worm is connected with the inner cavity of the second rolling bearing in an inserting manner; the inner cavity of the first rolling bearing is connected with a second driving shaft in an inserting manner; a turbine matched with the worm is mounted on the left side of the second driving shaft; a groove is formed in the right side of the second rolling bearing; the left side of the chamfering cutter head is connected with an inner cavity of the groove in an inserting manner; and the chamfering cutter head is in bolted connection with the groove through bolts. Compared with the conventional chamfering machine, the in-pipe circular hole chamfering machine allows a worker to carry out in-pipe circular hole chamfering operation more conveniently, the labor intensity is low, and the chamfering accuracy is high.

Owner:XINCHANG COUNTY YULIN STREET QUANSHUN MACHINERY PLANT

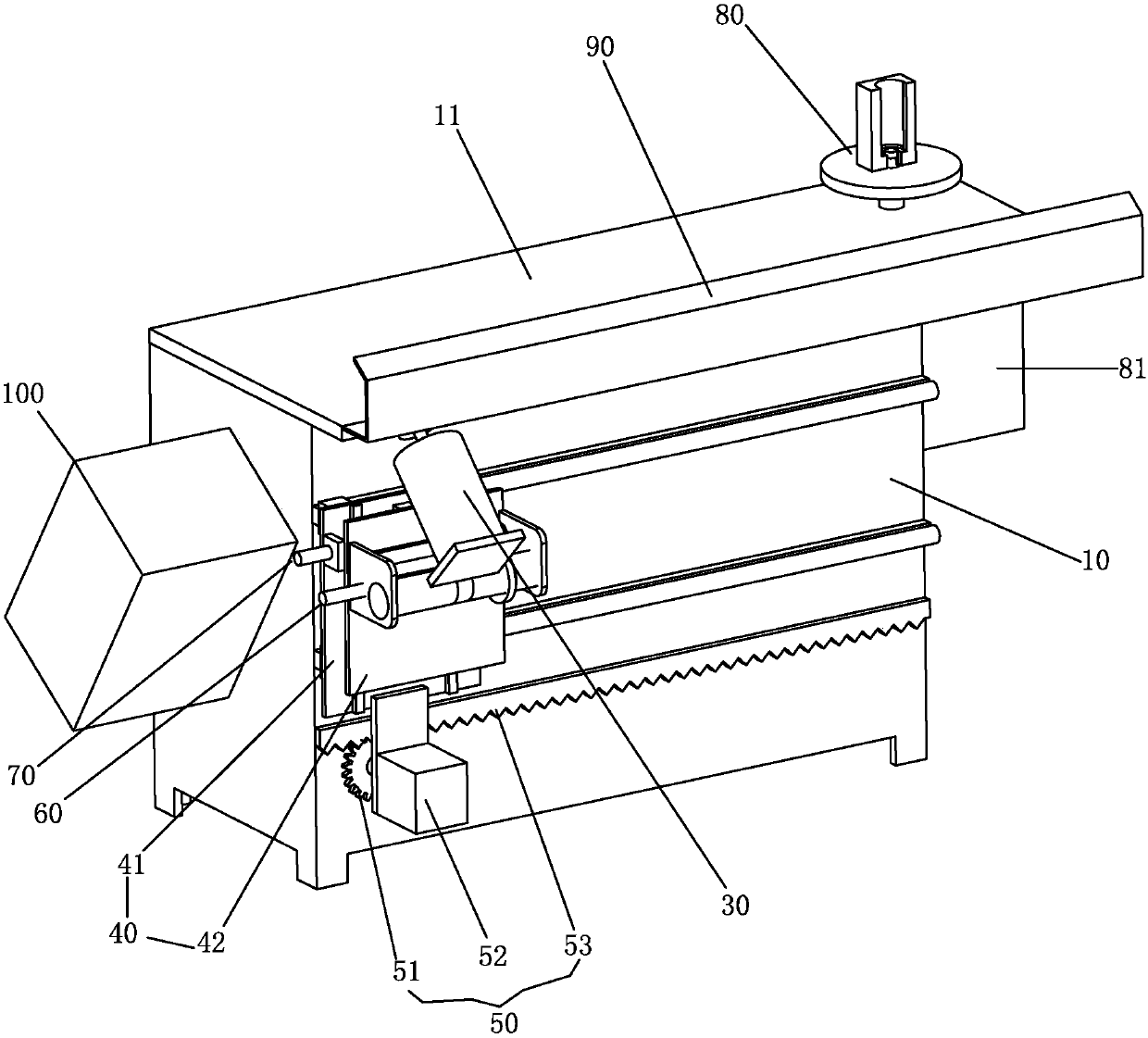

Automatic plate trimming machine

InactiveCN107009480ARealize follow-up trimmingGuaranteed accuracyLiquid surface applicatorsProfiling/shaping machinesVertical edgeEngineering

The invention discloses an automatic plate trimming machine. The automatic plate trimming machine comprises a frame; the frame is provided with a pressing wheel set for providing the feeding power to plates; the pressing wheel set clamps the plates; and in a plate feeding direction, the frame is provided with upper and lower edge chamfering modules, an upper angle painting module, a lower angle painting module, an upper drying module, a lower drying module, a front vertical edge chamfering module and a back vertical edge chamfering module in sequence. The automatic plate trimming machine can realize machining of transverse and vertical edges of the plates, meanwhile, is provided with automatic painting and drying machining modules to form trimming equipment with higher automation degree, and has such characteristics as high machining precision and simple operation.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

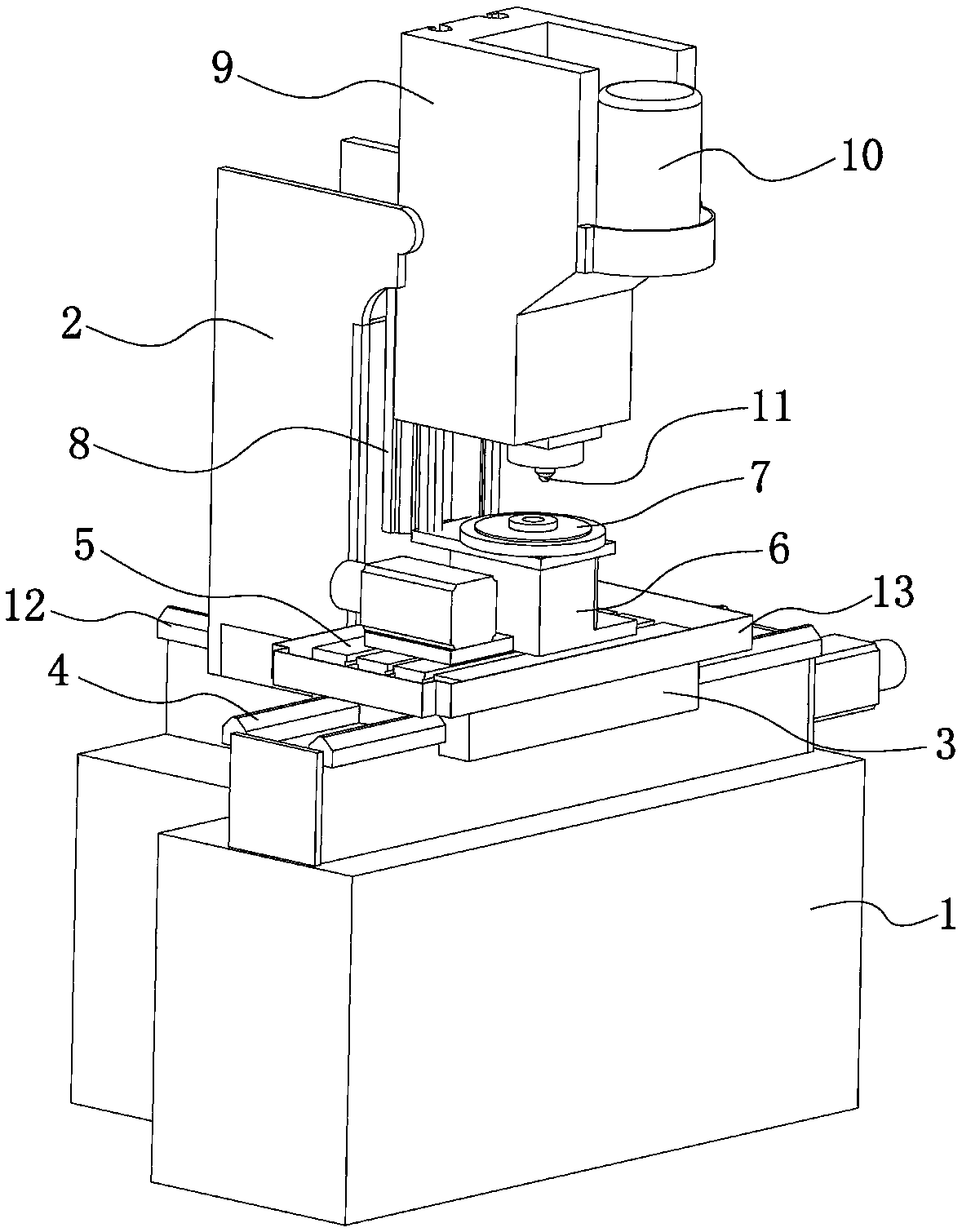

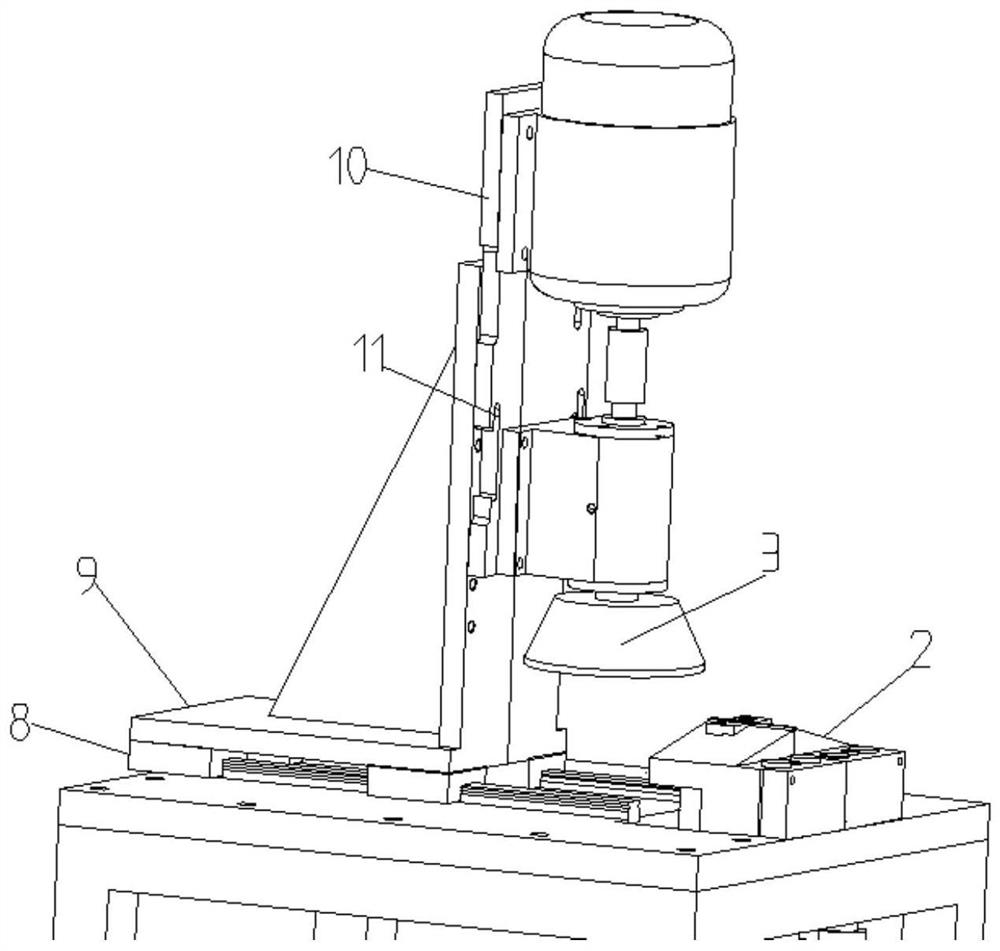

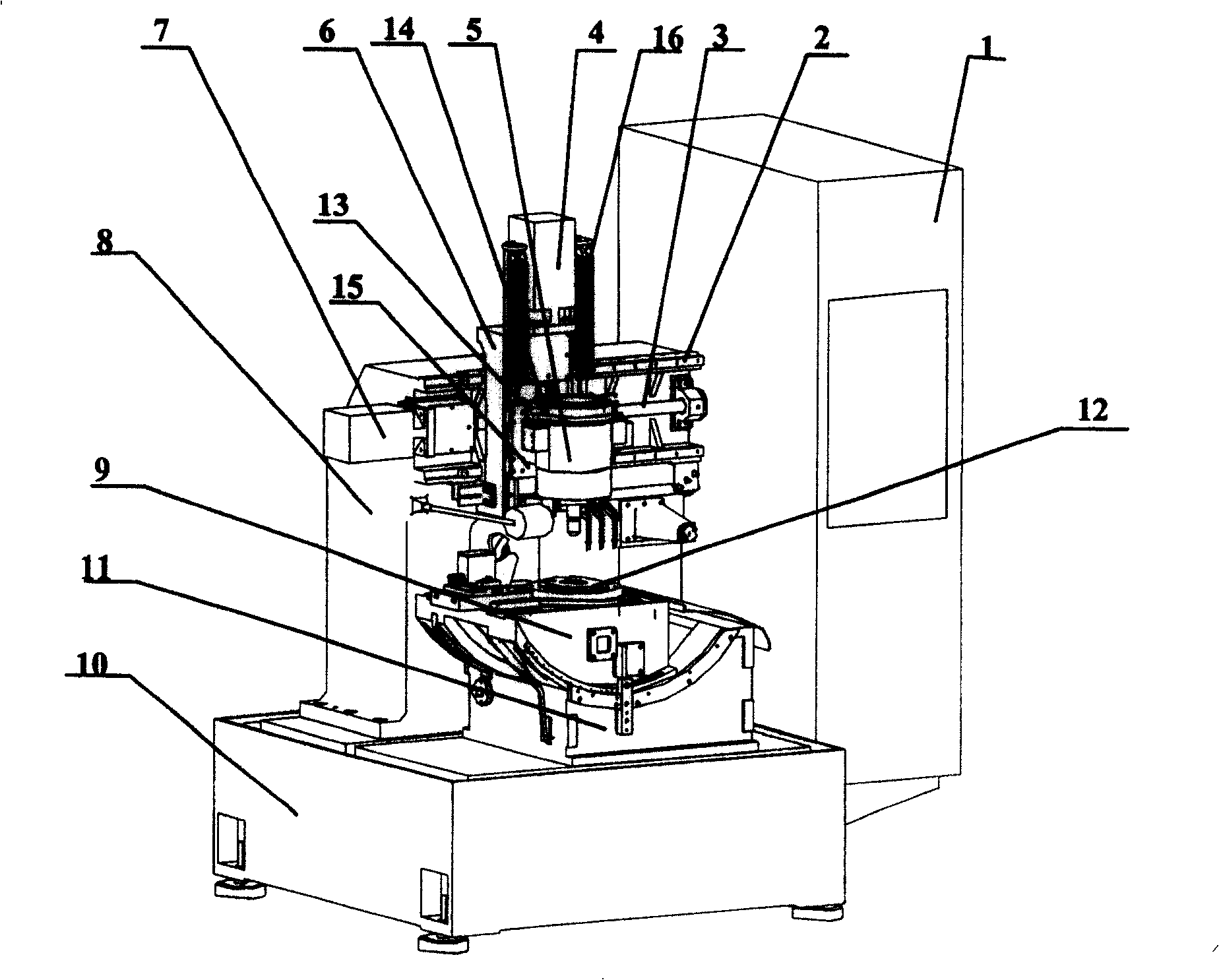

Numerical control bevel gear tooth top chamfering machine

PendingCN110270720AFast chamferingEasy to installGear-cutting machinesMaintainance and safety accessoriesNumerical controlMilling cutter

The invention provides a numerical control bevel gear tooth top chamfering machine, and belongs to the technical field of machining equipment. According to the machine, the problems that an existing chamfering machine is low in precision, complex in structure, high in manufacturing cost and not easy to popularize are solved. The numerical control bevel gear tooth top chamfering machine comprises a base, a box body and a worktable, wherein the box body and the worktable are arranged on the base, a transverse guide rail is fixedly connected to the base, the worktable is slidably connected to the transverse guide rail, the worktable moves in the X-axis direction, a supporting plate is fixedly connected to the worktable, a gearbox is arranged on the supporting plate, a rotary table is arranged above the gearbox, a vertical guide rail is fixedly connected to the box body, a machine head is slidably connected to the vertical guide rail, the machine head moves vertically in the Z-axis direction, a transmission motor is arranged at the top of the machine head, a ball head milling cutter is arranged on the bottom surface of the machine head, and the ball head milling cutter is driven to operate through the transmission motor. Through the improvement of the structure and the linkage track of a traditional chamfering machine, the machine has the advantages of being higher in chamfering precision, simple in structure and low in manufacturing cost.

Owner:ZHEJIANG DAPENG MACHINERY

Semi-automatic chamfering machine

InactiveCN106217169AReduce work intensityRealize semi-automationEdge grinding machinesGrinding carriagesFixed frameMicrometer

The invention provides a semi-automatic chamfering machine. The semi-automatic chamfering machine comprises a base frame, a bottom plate, locating plates, locking pliers, a work table, micrometers, a motor, a movable sliding plate and an air cylinder, wherein the bottom plate is arranged on the base frame; a sliding rail fixing plate is installed on the bottom plate, a second sliding rail is arranged on the sliding rail fixing plate, a plurality of second sliding blocks are arranged on the second sliding rail, the movable sliding plate is connected to the second sliding rail through the second sliding blocks, a first sliding rail is arranged on the movable sliding plate, a plurality of first sliding blocks are arranged on the first sliding rail, and the air cylinder is arranged on one side of the first sliding rail; the motor is arranged on the left side of the base frame and is connected to the movable sliding plate through a pull rod; the work table is arranged on the first sliding blocks, the front side of the work table is connected to a micrometer fixing frame, and the micrometer fixing frame is provided with the micrometers; and a PLC is arranged inside the base frame. Compared with the prior art, the semi-automatic chamfering machine has the beneficial effects that propulsive assistance of the air cylinder replaces manual thrust, and the micrometers limit a jig so that accuracy control can be realized.

Owner:湖南晶讯光电股份有限公司

Double-end chamfering device

PendingCN109530814AImprove securityImprove processing efficiencyWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention discloses a double-end chamfering device which comprises a rack, wherein a clamping mechanism is arranged on the rack and comprises a pair of sliding seats which can be close to or awayfrom each other, a clamping space is formed after the pair of sliding seats are close to each other and is communicated with a discharging mechanism, the discharging mechanism is located below the clamping space, and chamfering mechanisms are arranged on the two outsides of the pair of sliding seats and can be close to or away from the clamping mechanism. When the pair of sliding seats are close to each other, an operator can place a to-be-processed product into the clamping space, the pair of chamfering mechanisms are close to the clamping mechanism simultaneously to chamfer the product, after chamfering, the pair of sliding seats are away from each other, the processed product falls onto the discharging mechanism to be discharged, the operator doesn't need to fix the product, the safetyof the operation is improved, the processing efficiency is improved, at the same time, the clamping mechanism is used for clamping, the fixing effect is good, and the chamfering accuracy is high.

Owner:宁波宏科汽车部件有限公司

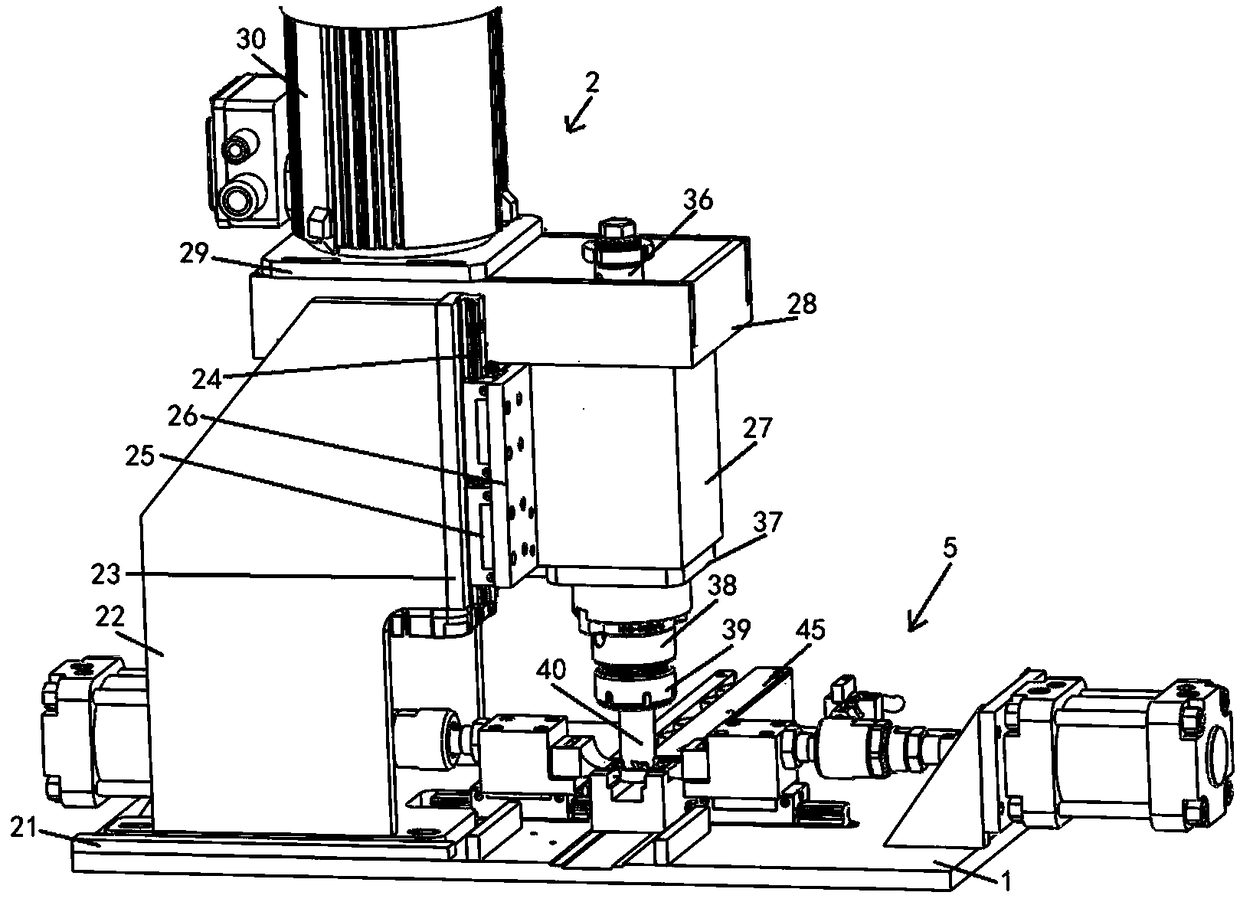

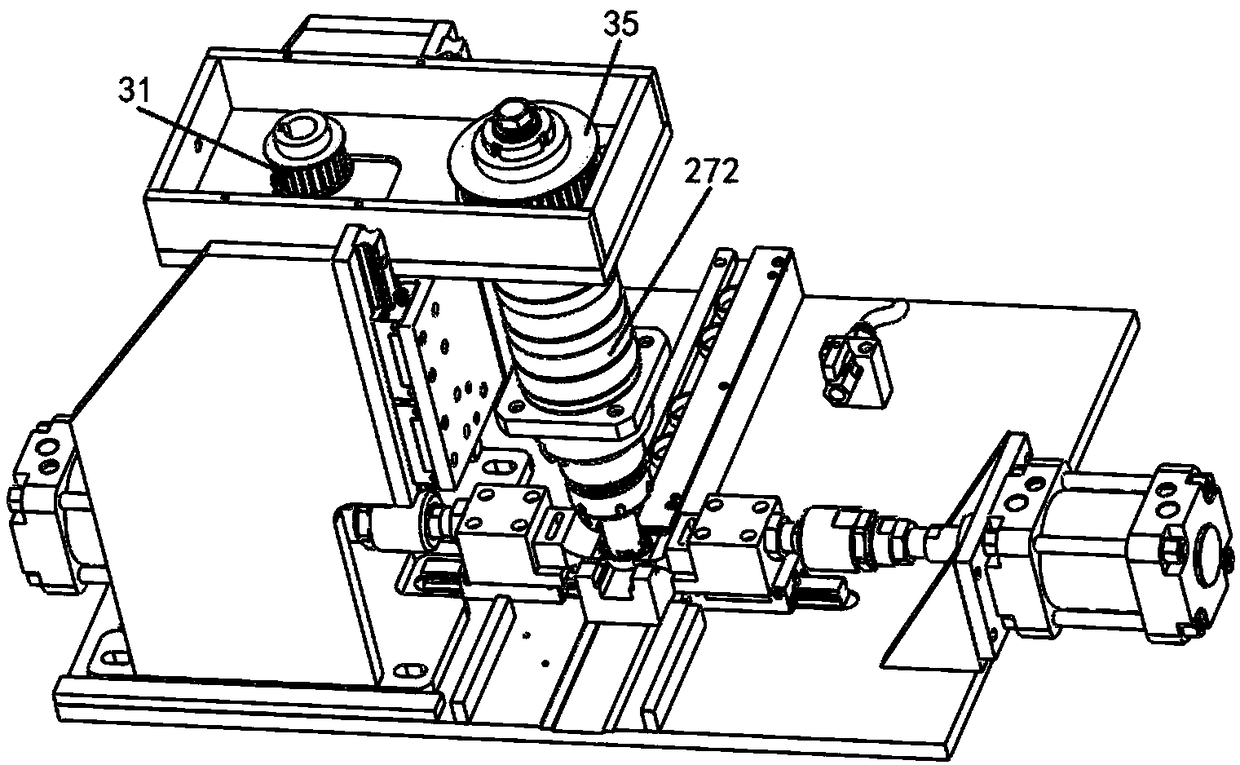

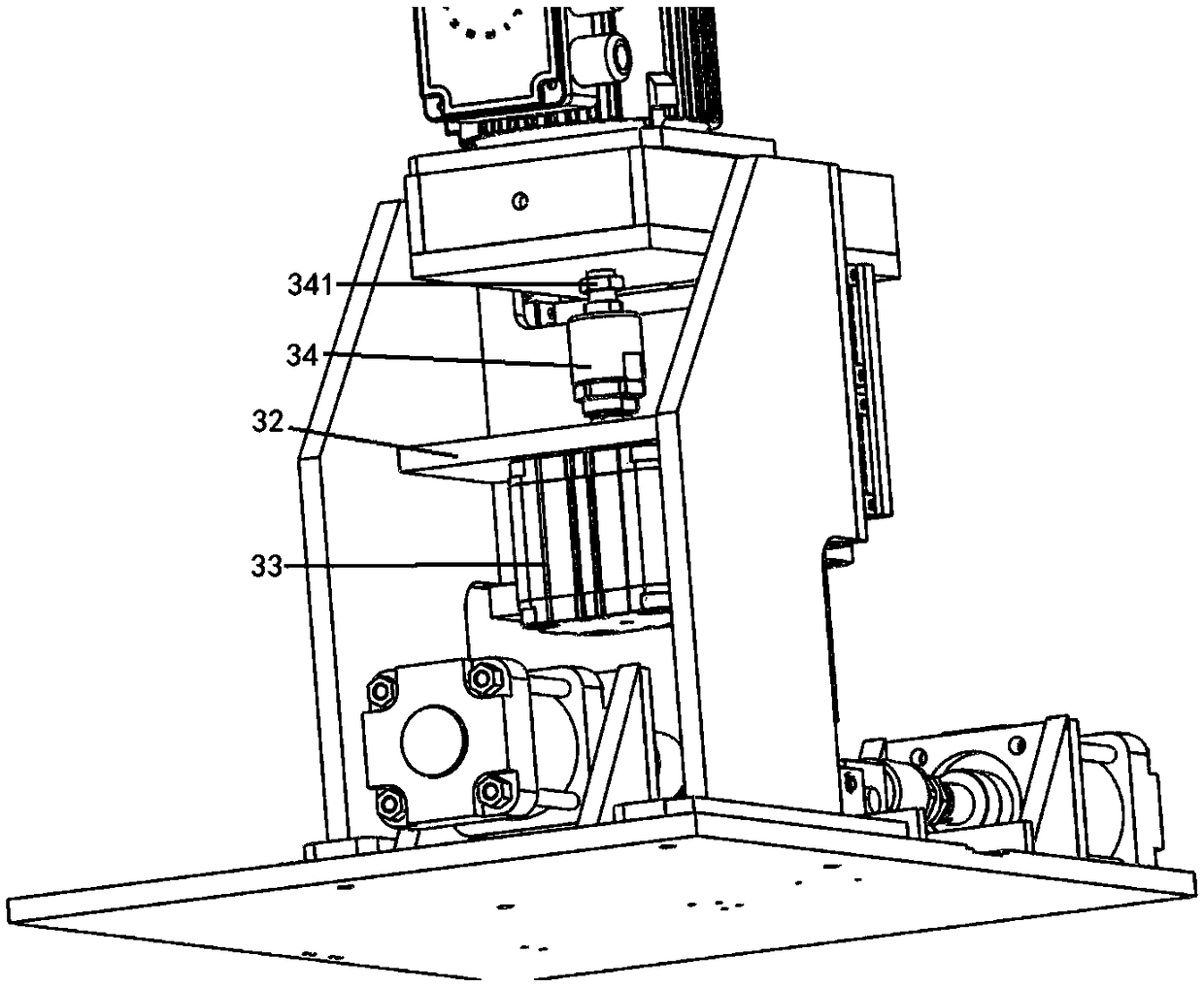

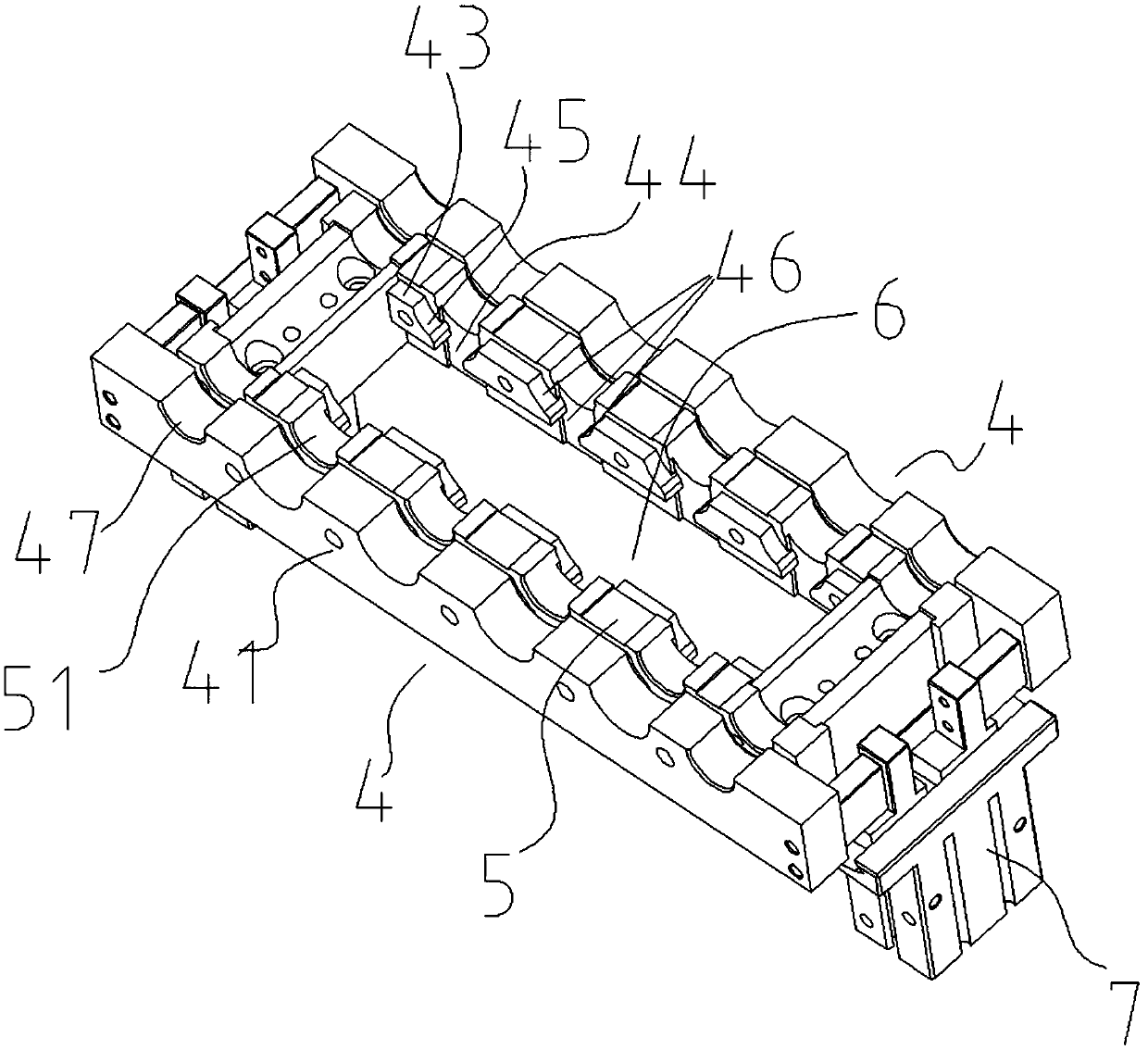

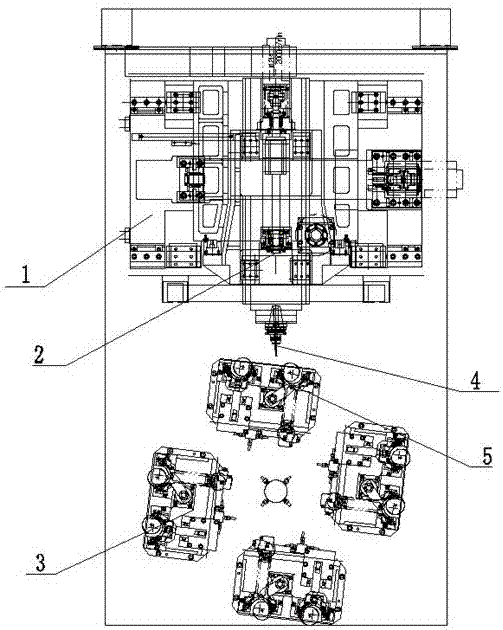

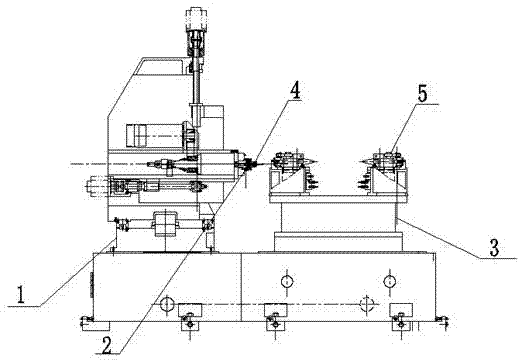

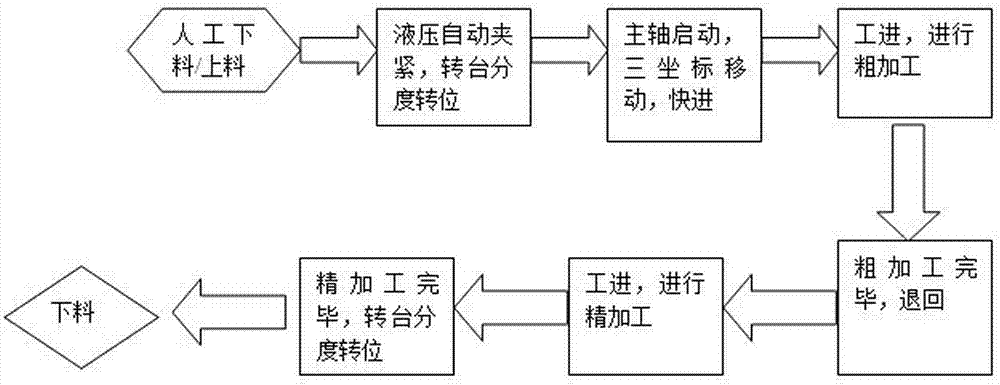

Chamfering machining equipment and chamfering machining method for curved surfaces of orifices of oil holes of connecting rods

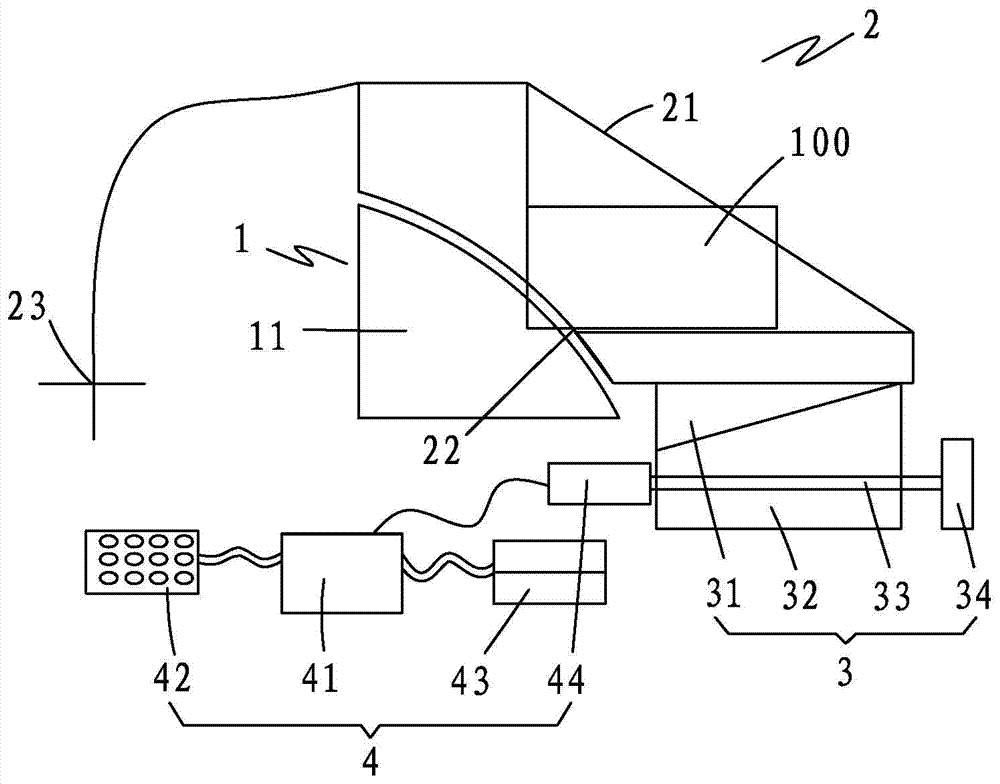

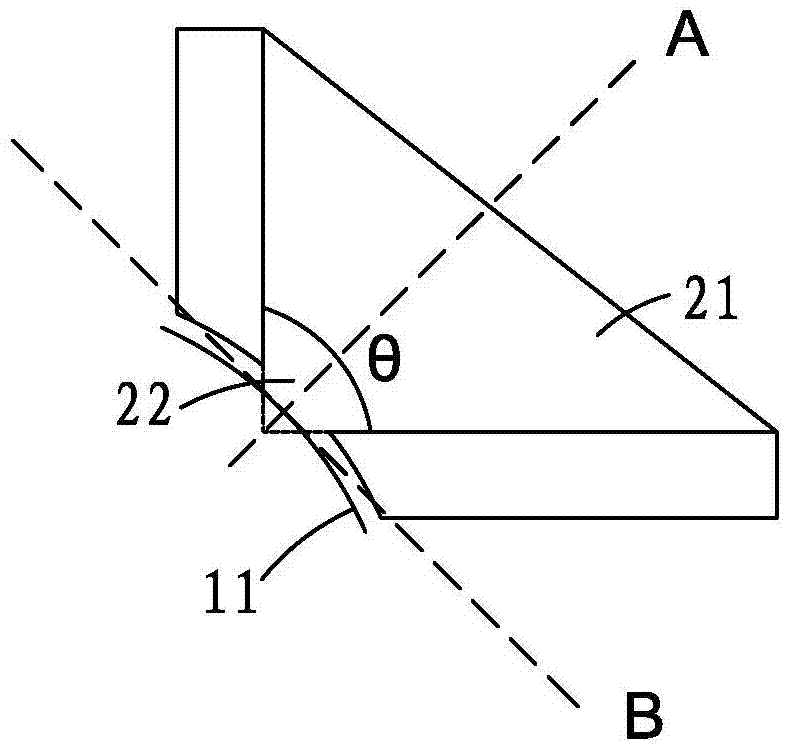

PendingCN107127381AImprove chamfering efficiencyHigh chamfering precisionMilling equipment detailsMilling cutterSurface roughness

The invention discloses chamfering machining equipment and a chamfering machining method for curved surfaces of orifices of oil holes of connecting rods, and relates to the field of machining technologies for connecting rods of engines. The chamfering machining equipment comprises a horizontal three-coordinate driving mechanism, a servo spindle driving mechanism and an indexing worktable. The servo spindle driving mechanism is arranged on the horizontal three-coordinate driving mechanism and can be driven by the horizontal three-coordinate driving mechanism to move, a milling cutter shank is arranged at an end of the servo spindle driving mechanism, and a milling cutter is fixed onto the milling cutter shank. The chamfering machining equipment and the chamfering machining method for the curved surfaces of the orifices of the oil holes of the connecting rods have the advantages that the chamfering efficiency and the precision of the profile tolerance of the machined curved surfaces can be improved, and the chamfering consistency and the surface roughness can be enhanced.

Owner:四川普什宁江机床有限公司

Automatic chamfering machine

InactiveCN106736943ARealize automatic loading and processingImprove work efficiencyEdge grinding machinesGrinding carriagesMachine partsMachining

The invention provides an automatic chamfering machine. The automatic chamfering machine comprises a rack, a machining platform, a feeding rotating disc, a feeding mechanism and a chamfering mechanism. The machining platform is slidably connected to the rack, the feeding rotating disc is rotatably connected to the machining platform, and the feeding mechanism is connected to the rack. The chamfering mechanism is connected to the rack. According to the automatic chamfering machine, through the feeding mechanism, to-be-machined parts can be stacked in a workpiece machining groove of a feeding disc; and along with rotation of the feeding disc, the parts in the workpiece machining groove are sequentially machined, so that automatic-feeding machining is achieved, and work efficiency is improved. During chamfering, the feeding disc and the parts on the feeding disc are fixed, shaking of the feeding disc is prevented, and thus chamfering accuracy is improved.

Owner:天津兴起工贸有限公司

a chamfering machine

ActiveCN105904030BReduce labor costsImprove securityEdge grinding machinesPositioning apparatusMotor driveEngineering

Owner:JOMOO KITCHEN & BATHROOM

Clamping ring chamfering equipment

PendingCN113134760AReduce adjustmentImprove convenienceEdge grinding machinesGrinding carriagesElectric machineEngineering

The invention discloses clamping ring chamfering equipment. The clamping ring chamfering equipment comprises a driving motor, a grinding wheel, two tools and a workbench, wherein the heights of the two tools can be independently adjusted, the driving motor is fixedly arranged on a motor support, the motor support is slidably connected with the workbench, the output end of the driving motor is connected with a rotating shaft, the grinding wheel is fixedly connected with the rotating shaft, the tools are fixedly arranged on the workbench, the heights of the two tools are adjusted according to chamfering parameters of the two ends of a clamping ring, and the motor support slides to drive the grinding wheel to slide to chamfer the clamping ring. According to the clamping ring chamfering equipment, the tools can be independently adjusted, the chamfering operation of a single part can be completed at a time, the transfer procedure and the additional tool adjusting procedure are reduced, and the production efficiency is improved; and the chamfering mode that parts are fixed and the grinding wheel moves is adopted to solve the problem that the chamfering size is not stable due to movement of the parts, and meanwhile operation convenience of workers is improved.

Owner:ZHEJIANG MEILI HIGH TECH

Chamfering processing technology for stones

InactiveCN108188859AControl precisionEasy to grind limitEdge grinding machinesGrinding carriagesEngineering

The invention relates to the field of stone processing technology, and particularly discloses a chamfering processing technology for stones. According to the chamfering processing technology for the stones, a chamfering device is used, so that a marble in the process of chamfering can be fixed, the relative distance between the polishing ball and the marble to be polished is kept, the chamfering process of the marble can be stably carried out; and in the process of processing, a power mechanism can drive the polishing ball to polish the marble stably; and at the same time, an arc-shaped bar can detect the unqualified marble, so that the chamfer can be polished again and the chamfer accuracy of the marble can be improved.

Owner:重庆丰胜天家具有限公司

Precise chamfering device for optical component

InactiveCN103878661AImprove yieldLow technical requirementsEdge grinding machinesAutomatic grinding controlDisplay deviceEngineering

The invention provides a precise chamfering device for an optical component. The precise chamfering device comprises a grinding device, a chamfering clamping device, a chamfering amount adjusting device and a control displaying device. The grinding device comprises a grinding shaft. The chamfering clamping device is provided with an angular clamping groove, a chamfering station opening and a rotating center deviating from the axis of the grinding shaft, and the chamfering station opening is located in the corner position of the inner end of the angular clamping groove. The grinding shaft is adjacent to the chamfering station opening and is located between the angular clamping groove and the rotating center. The angular bisector of the corner position of the inner end of the angular clamping groove is perpendicular to the tangent, passing through the angular bisector, of an outer circle of the grinding shaft. The chamfering amount adjusting device is connected with the chamfering clamping device and adjusts the angular clamping groove to rotate around the rotating center. The control displaying device is respectively connected with the chamfering amount adjusting device and the grinding device. The precise chamfering device can visually measure the chamfering amount in real time, the chamfering precision and consistency can be improved, and the operating requirement can be lowered.

Owner:郑凤金

Triple-head chamfering machine and control program thereof

ActiveCN103302357AGuaranteed stabilityGuaranteed chamfering effectProgrammable logic controllerVertical edge

The invention discloses a triple-head chamfering machine and a control program thereof. The triple-head chamfering machine includes a bed body, wherein a transverse cutting device is arranged at the back of the bed body; a vertical cutting device is arranged on the right side of the bed body; a workbench is arranged in front of the bed body; an electric control device is arranged below the workbench; and the transverse cutting device, the vertical cutting device and the workbench are all controlled by the electric control device. According to the invention, both a transverse cutting upper handpiece and a transverse cutting lower handpiece are adopted to chamfer the transverse upper and lower edges of a workpiece, a vertical cutting handpiece is adopted to chamfer the vertical edge of the workpiece, all edges of the workpiece can be chamfered without turning over the workpiece, and the chamfering efficiency is improved; a stepping motor is controlled by a programmable logic controller (PLC) of an electric controlling box, the transverse cutting upper handpiece is locked and the height of the workpiece is accurately sensed through the information fed back by a displacement sensor, so that the chamfering of the transverse upper and lower edges of the workpiece is consistent; the chamfering of the transverse edges is followed by that of the vertical edge, and size of the chamfering is adjusted through a transverse cutting pile and a vertical cutting pile; and the labor intensity is reduced through the application of an electromagnetic device and the gas floating function.

Owner:安徽新冀精密机械有限公司

Chamfering machine

ActiveCN108422048AEasy to set upConvenient chamferingMaintainance and safety accessoriesMechanical engineering

The invention relates to a chamfering machine. A support base is arranged at one end above a chamfering machine base; a support rack is arranged at the upper end of the support base; a lifting base isarranged at the upper end of the support rack; a balance beam is arranged on the lifting base; a driving device is arranged on the balance beam; a lifting track is arranged on the driving device; anadjusting component is arranged at the lower end of the lifting track; a lifting rod is arranged at the lower end of the adjusting component; a fixing base is arranged at the lower end of the liftingrod; a pressing block and a cutter are arranged on the lower end surface of the fixing base; the other end above the base is an operation platform; a cleaning device and a square spacer are arranged on the operation platform; the cleaning device is positioned right below the pressing block; burr is arranged on the edge below the cleaning device; when being extruded by the pressing block downwards,the cleaning device can rotate to clean chamfering sweeps; limiting plates matched with a chamfered plate are respectively arranged on two sides of chamfering sides of the spacer; the heights of thelimiting plates are greater than that of the spacer. By adopting the chamfering machine, sweeps can be conveniently cleaned, and particularly plate-shaped articles can be conveniently chamfered.

Owner:庐山市环绿时代农业科技开发有限公司

Chamfering machine for face plates

InactiveCN107685362APrecise positioningImprove processing efficiencyGuide fencesCircular sawsElectric machineryEngineering

The invention discloses a panel chamfering machine, which comprises a frame, a driving mechanism and a sliding positioning device. A beam 1 is arranged at the lower end of the frame, and a beam 2 is arranged in the middle. Bearings are respectively arranged on the beam 2 at a certain distance. Seat assembly 1 and bearing seat assembly 2, the upper end of the frame is provided with an upper frame, and the upper frame is provided with two parallel "V"-shaped guide rails, the driving mechanism is connected with the beam one on the one hand, and It is connected with the bearing seat assembly 1 and the bearing seat assembly 2, the sliding positioning device is connected with the "V" guide rail, the driving mechanism is composed of a motor and a pulley shaft, and the output shaft of the motor is provided with a large pulley. The pulley shaft is provided with a small pulley, and the end of the pulley shaft is provided with a thread, and a disc saw is set on the pulley shaft, and a sawdust baffle is provided on the side of the upper frame, so that multiple wooden panels can be reversed at one time. Corner operation improves the processing efficiency of wooden panels with accurate positioning and high chamfering precision.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Chamfering machine

ActiveCN108422048BEasy to set upConvenient chamferingMaintainance and safety accessoriesEngineeringMechanical engineering

The invention relates to a chamfering machine. A support base is arranged at one end above a chamfering machine base; a support rack is arranged at the upper end of the support base; a lifting base isarranged at the upper end of the support rack; a balance beam is arranged on the lifting base; a driving device is arranged on the balance beam; a lifting track is arranged on the driving device; anadjusting component is arranged at the lower end of the lifting track; a lifting rod is arranged at the lower end of the adjusting component; a fixing base is arranged at the lower end of the liftingrod; a pressing block and a cutter are arranged on the lower end surface of the fixing base; the other end above the base is an operation platform; a cleaning device and a square spacer are arranged on the operation platform; the cleaning device is positioned right below the pressing block; burr is arranged on the edge below the cleaning device; when being extruded by the pressing block downwards,the cleaning device can rotate to clean chamfering sweeps; limiting plates matched with a chamfered plate are respectively arranged on two sides of chamfering sides of the spacer; the heights of thelimiting plates are greater than that of the spacer. By adopting the chamfering machine, sweeps can be conveniently cleaned, and particularly plate-shaped articles can be conveniently chamfered.

Owner:庐山市环绿时代农业科技开发有限公司

Magnesium rod cutting and chamfering all-in-one machine

PendingCN112222843AEasy to fixConvenient chamferingWork clamping meansFeeding apparatusClassical mechanicsElectric machinery

The invention relates to a magnesium rod machining device, in particular to a magnesium rod cutting and chamfering all-in-one machine. The technical problem to be solved by the invention is to providethe magnesium rod cutting and chamfering all-in-one machine which can adapt to cutting and chamfering machining of magnesium rods with various models. The magnesium rod cutting and chamfering all-in-one machine comprises a magnesium rod supporting plate, a magnesium rod fixing mechanism, a chamfering mechanism and a cutting mechanism, wherein a first positioning groove is formed in the magnesiumrod supporting plate; the magnesium rod fixing mechanism is arranged above the magnesium rod supporting plate; the chamfering mechanism is arranged on one side of the magnesium rod supporting plate; the cutting mechanism is arranged on the other side of the magnesium rod supporting plate; the chamfering mechanism comprises a first moving seat, a chamfering device and a driving motor; the moving direction of the first moving seat is parallel to the axial direction of a magnesium rod; the chamfering device is fixedly connected with the first moving seat; and the driving motor is used for drivingthe chamfering device to rotate.

Owner:淄博德源金属材料有限公司

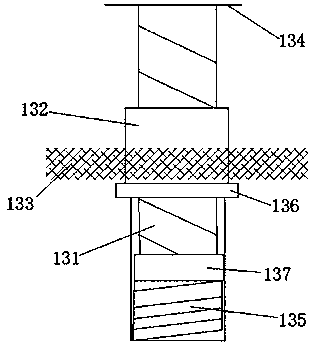

A Cylinder Head Camshaft Oil Hole Chamfering Device

ActiveCN109746527BHigh chamfering precisionAvoid scrappingFeeding apparatusLarge fixed membersCylinder headEngineering

The invention discloses an oil hole chamfering device of a cylinder head camshaft, and specifically relates to the field of automotive engine cylinder head manufacturing. The oil hole chamfering device comprises a feeding platform, the feeding platform is provided with a feeding slide groove, a calibration template is arranged at the top of the feeding slide groove, telescopic platen assemblies are arranged on both sides of the top of the calibration template, a chamfering mechanism is arranged above the calibration template, and an angle adjusting mechanism is arranged at the top of the chamfering mechanism. According to the oil hole chamfering device of the cylinder head camshaft, the calibration template is arranged, before air drill bit chamfering working, an air drill bit firstly penetrates through a reserved calibration groove in the calibration template, the air drill bit collides with the reserved groove in the process of penetrating through the reserved groove, a chamfering failure is avoided, cylinder head damaging and scrapping are avoided, an infrared ranging sensor is matched to be used, whether the air drill bit angle offsets or not can be detected, a first screw, a second screw and an electric cylinder are intelligently controlled by a PLC to work to control the air drill bit angle, and thus air drill bit chamfering precision is high.

Owner:安徽瑞林精科股份有限公司

Digital control tooth crest chamfering machine for curved tooth and angle gear

InactiveCN100443229CWork reliablyReasonable design structureEdge grinding machinesLarge fixed membersGear wheelInsertion stent

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

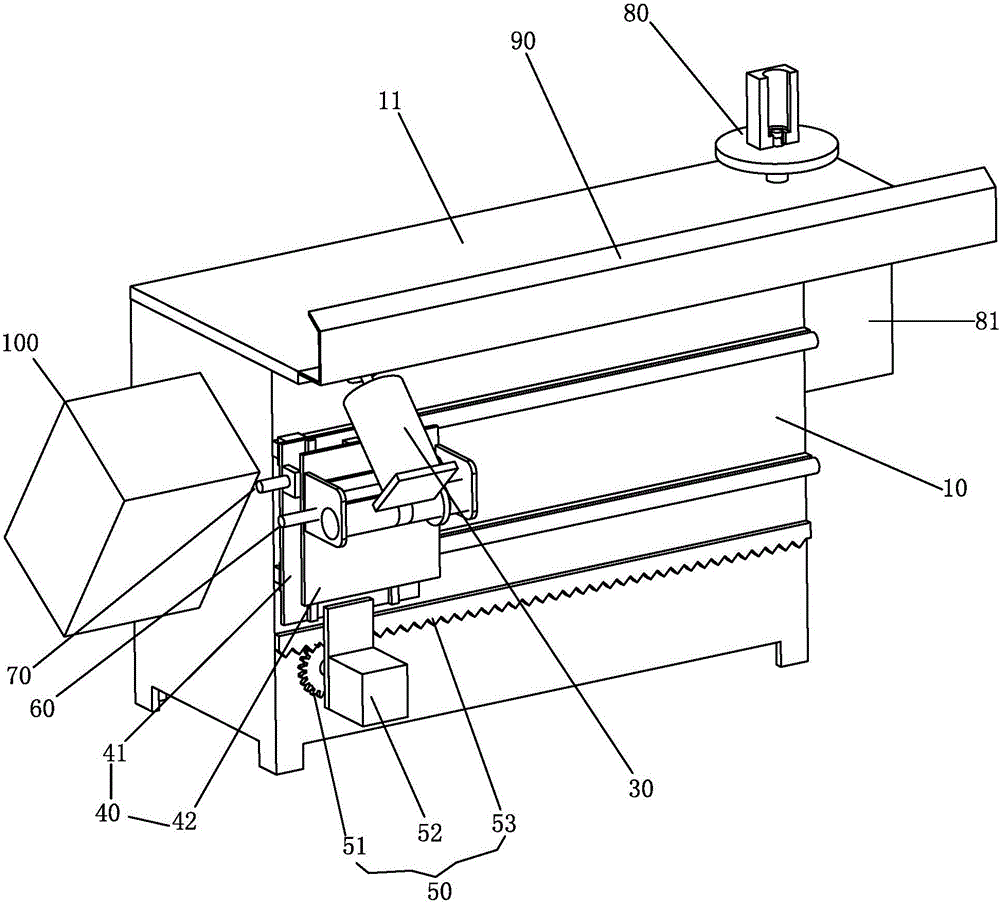

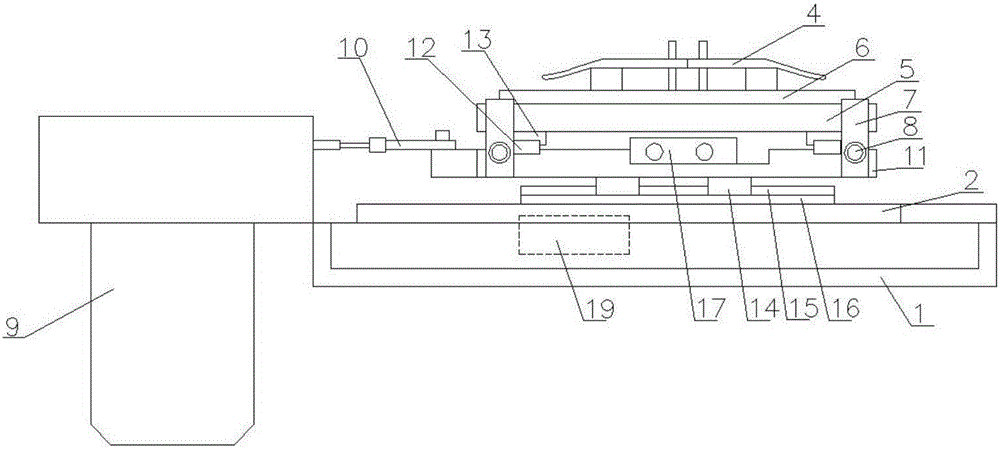

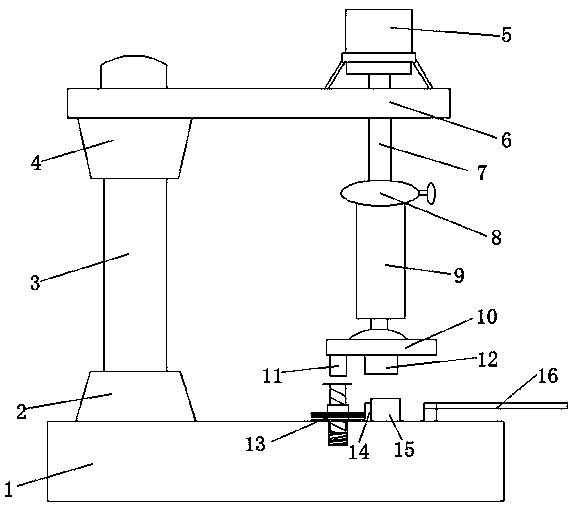

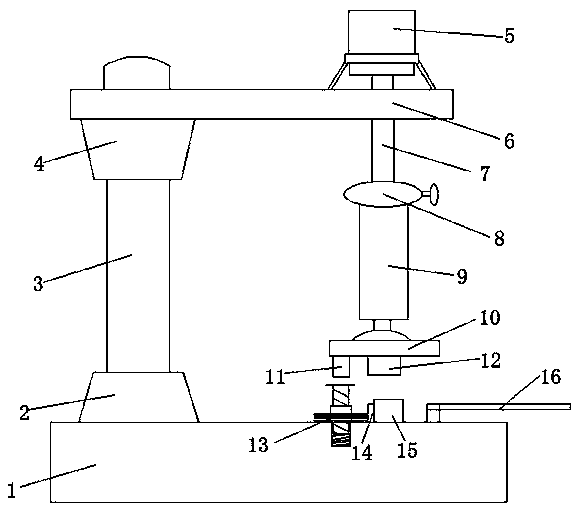

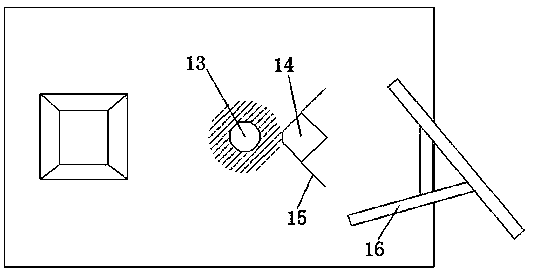

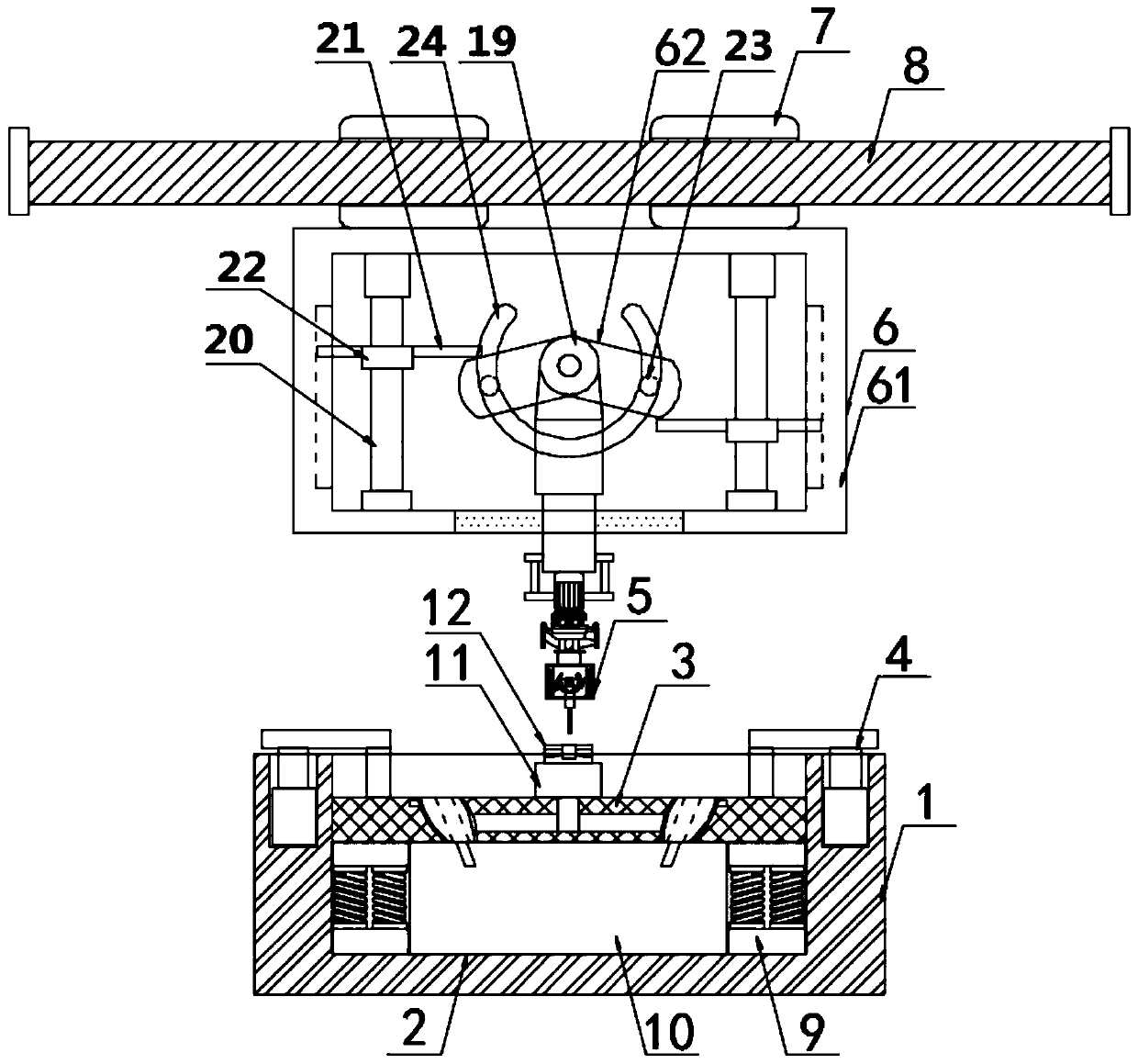

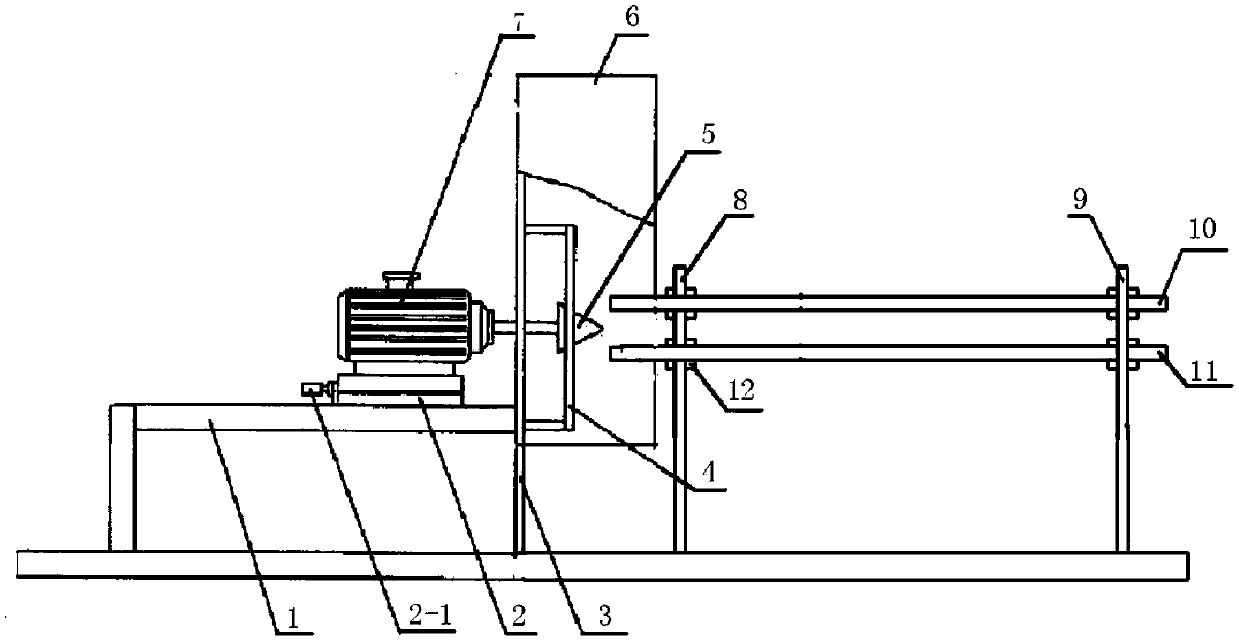

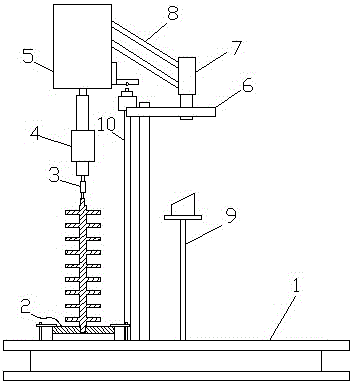

A glass round hole chamfering machine

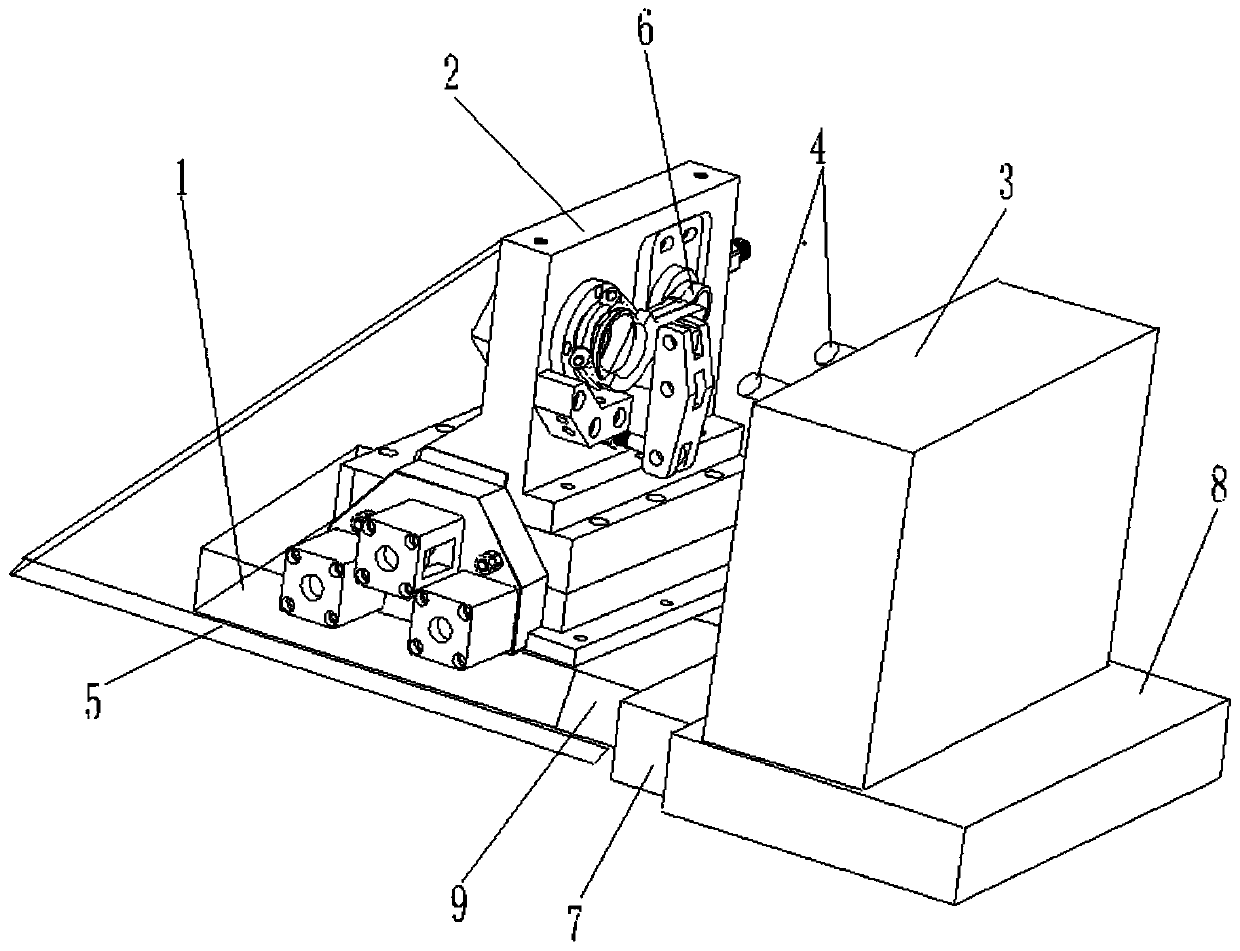

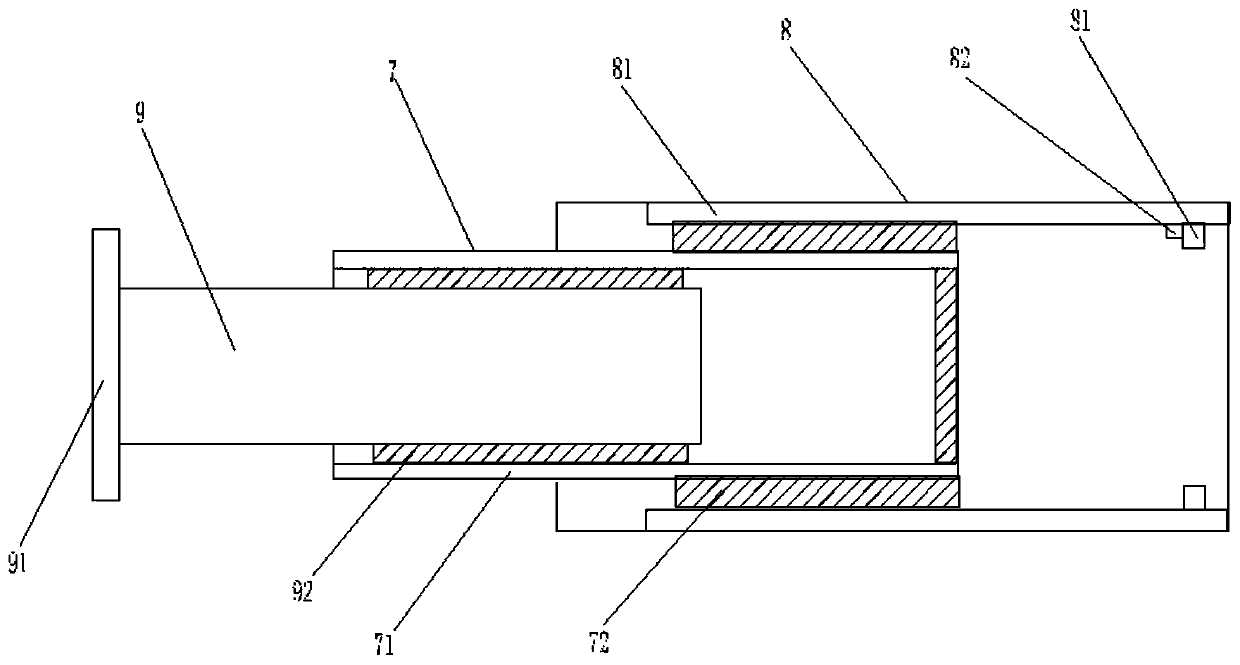

ActiveCN103551946BOvercoming unreliable flawsImprove the finishEdge grinding machinesSlide plateEngineering

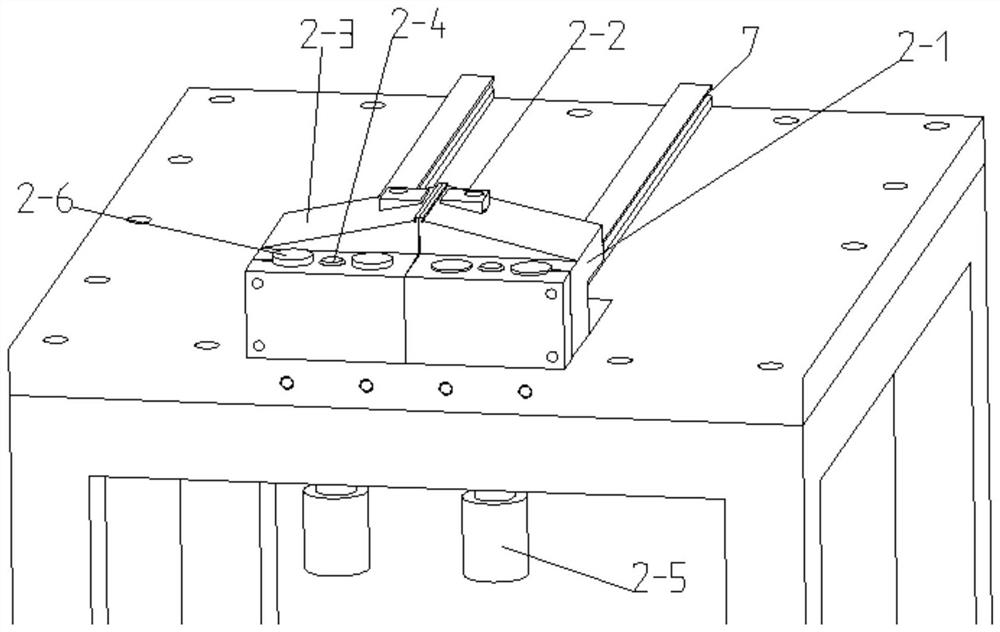

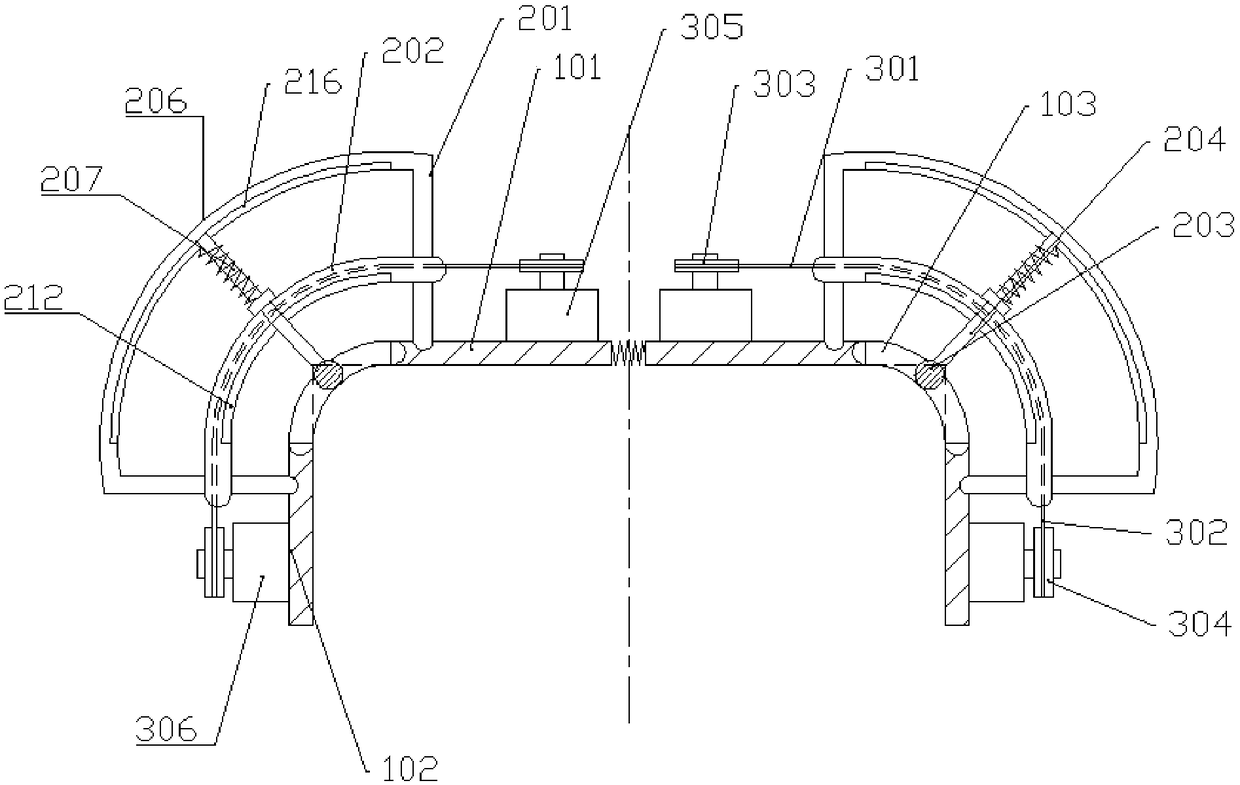

The invention provides a glass circular hole chamfering machine, comprising a machine frame (1), a positioning ball screw pair (2), a conical grinding head (5), a motor (7) and a positioning device. The glass circular hole chamfering machine is characterized in that the positioning device is located right ahead of the conical grinding head (5); the positioning ball screw pair (2) is horizontally and fixedly arranged on the machine frame (1); a feed adjustment handle (2-1) for adjusting the position of the motor (7) is arranged on the positioning ball screw pair (2); a sliding plate linearly moving left and right, of the positioning ball screw pair (2), fixes the motor (7); the conical grinding head (5) is fixedly installed on the output shaft of the motor (7); the machine frame (1) is provided with a vertical table board (3); the vertical table board (3) is provided with a hole for the passing of the output shaft of the motor (7); additionally, a workpiece supporting frame (4) taking the output shaft of the motor as the center is fixedly installed on the vertical table board (3). The glass circular hole chamfering machine has the outstanding advantages of simplicity in operation and low manufacture cost.

Owner:清远瑞达光学有限公司

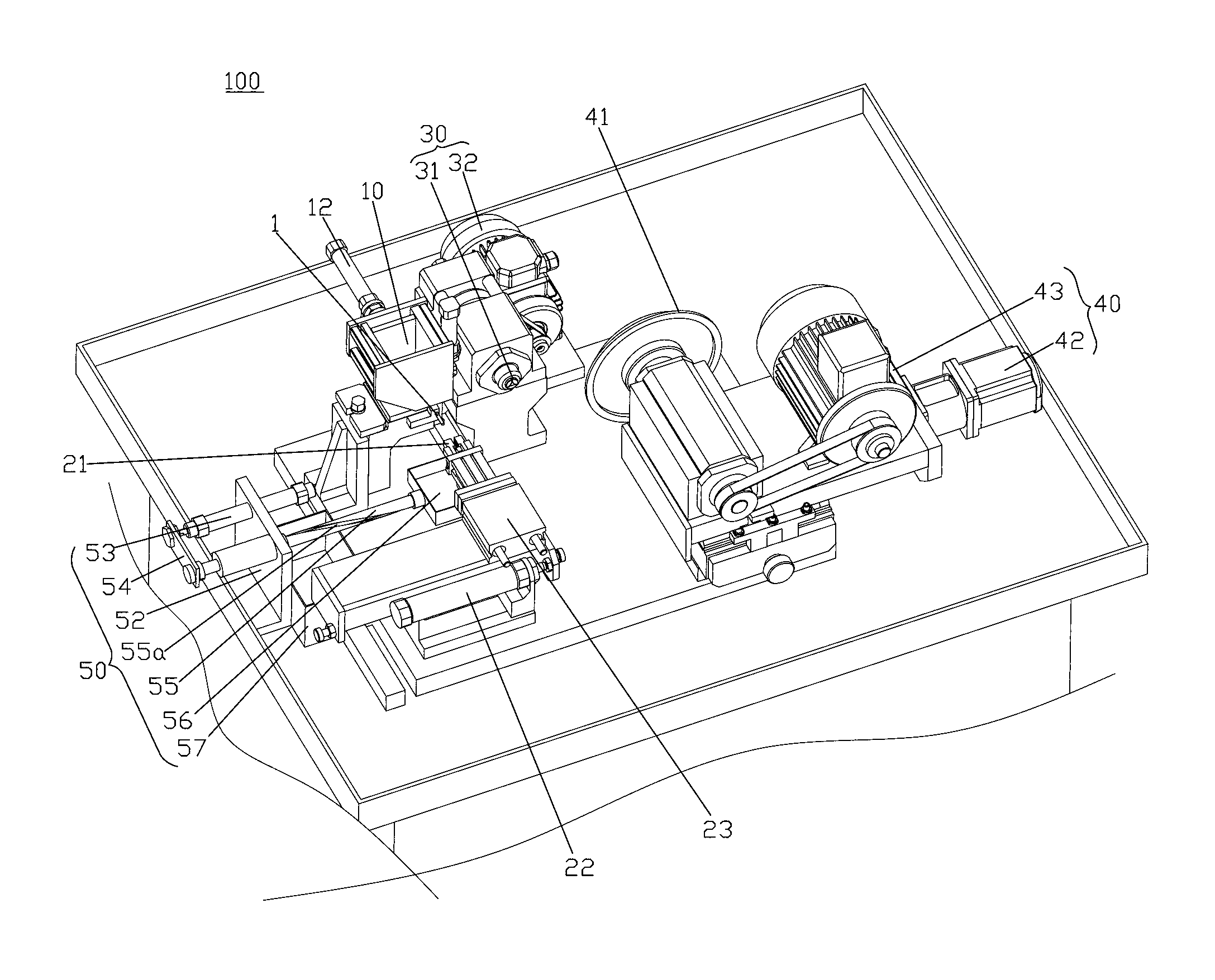

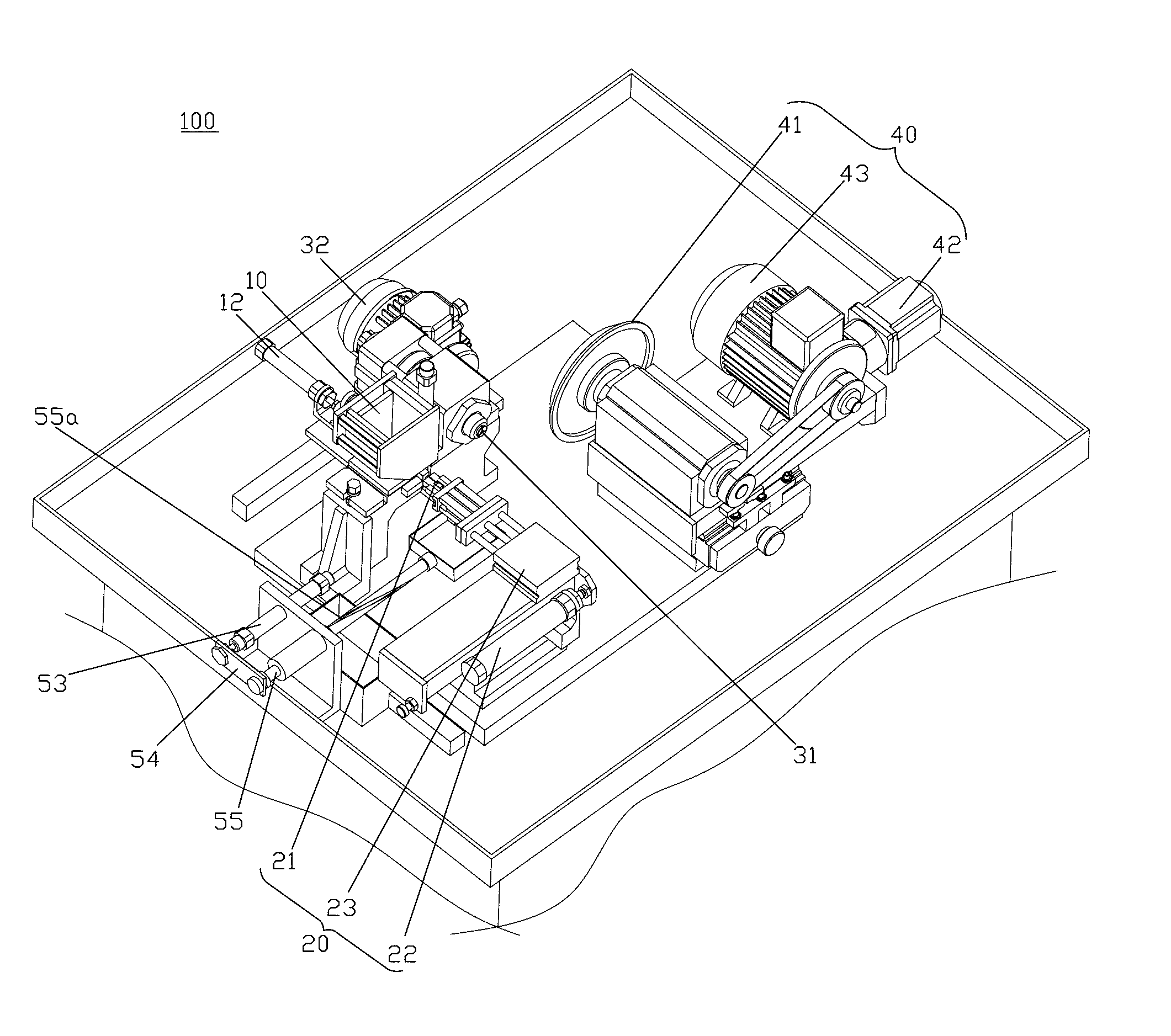

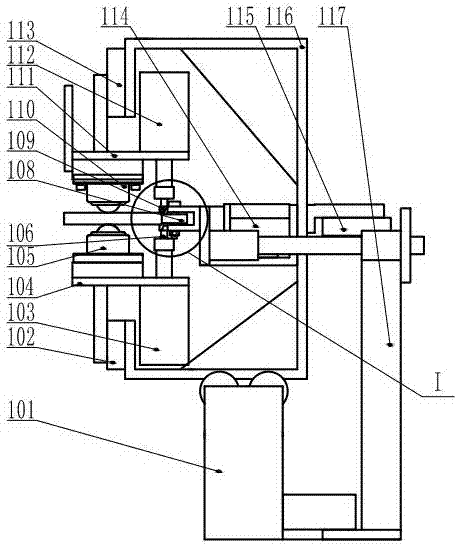

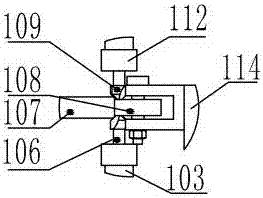

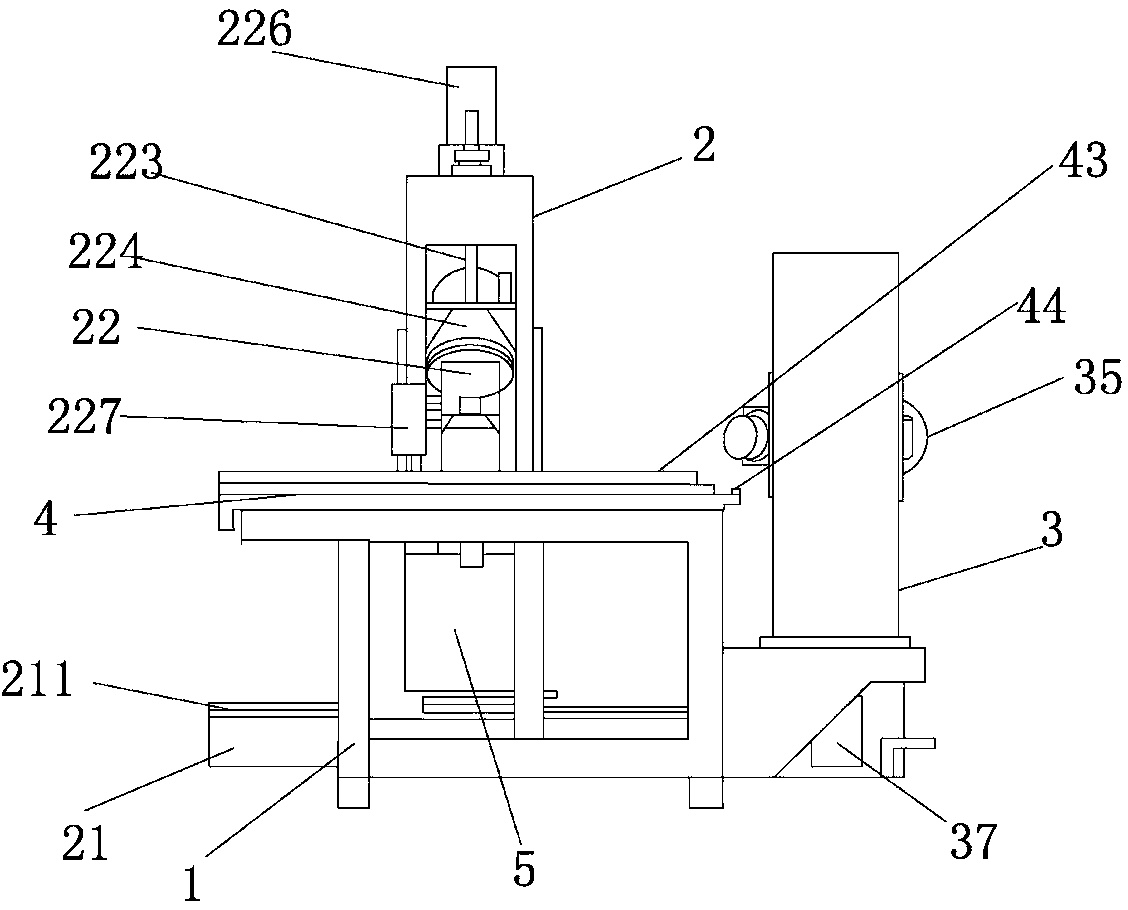

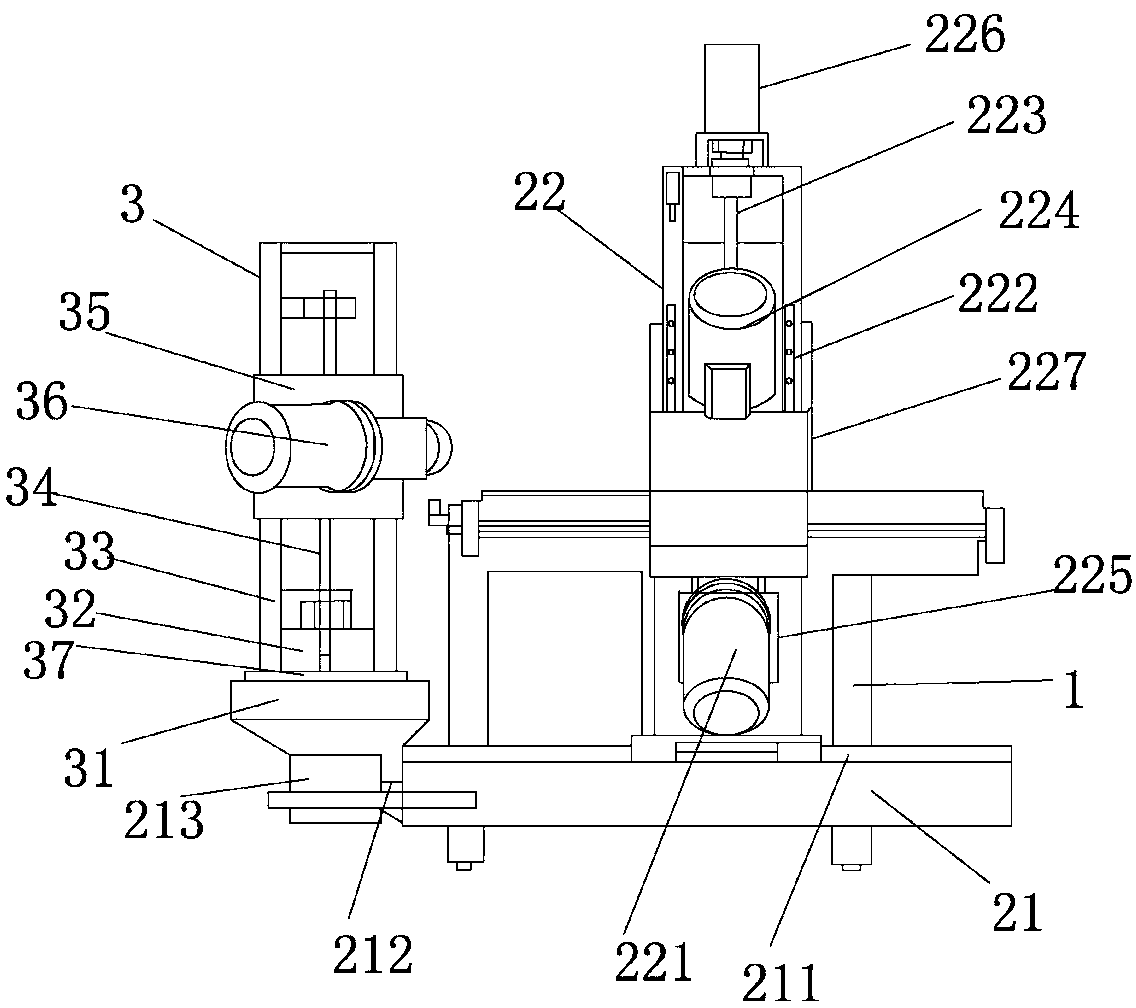

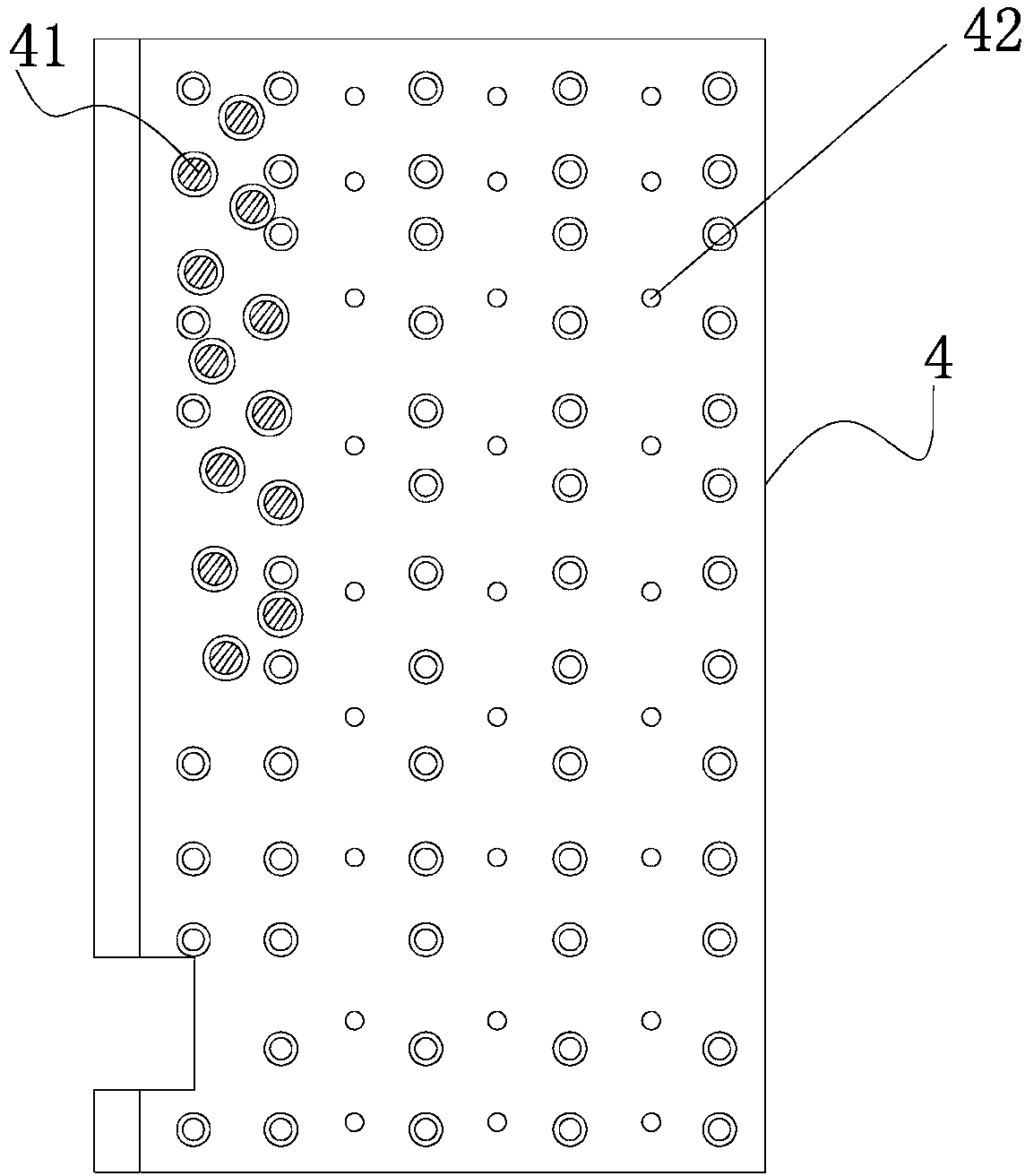

A continuous processing system for double-sided chamfering of automobile synchronizer gear sleeves

ActiveCN105149698BReduce configurationGuaranteed accuracyMetal working apparatusMaintainance and safety accessoriesTransmission beltEngineering

The invention relates to a double-face chamfering continuous machining system for a gear sleeve of a vehicle synchronizer. The double-face chamfering continuous machining system is formed by two same double-cutter machining chamfering machines and a linear feeding mechanism penetrating two chamfering machine machining stations transversely; the two same double-cutter machining chamfering machines are arranged into a row in parallel, each chamfering machine comprises a cutter for conducting chamfering machining, a workpiece driving machine head and a tooth alignment mechanism, a center line where the two cutters are located is arranged to right face the workpiece driving machine heads, tooth alignment mechanisms are arranged at front end working procedure components of the workpiece driving machine heads, and the workpiece driving machine heads are installed on a machine head base; each chamfering machine is horizontally and fixedly provided with a linear type feeding mechanism at the position, in front of the workpiece driving machine heads and behind the two cutters, of the corresponding machine body, and each linear type feeding mechanism is driven by a driving motor to drive a transmission belt in a material way to rotate; and a tooth sleeve turnover mechanism is installed between the two linear type feeding mechanisms, and pushing air cylinders are fixedly installed on the outer sides, corresponding to the tooth alignment mechanisms, of the material way. By means of the machining system, double-face chamfering machining of an overall tooth sleeve can be completed at a time, the production efficiency is greatly improved, meanwhile, allocation of a feeding mechanical arm and a feeding mechanism is omitted, and the overall machining area is decreased.

Owner:TIANJIN DAXIN PRECISION MECHANICAL EQUIP

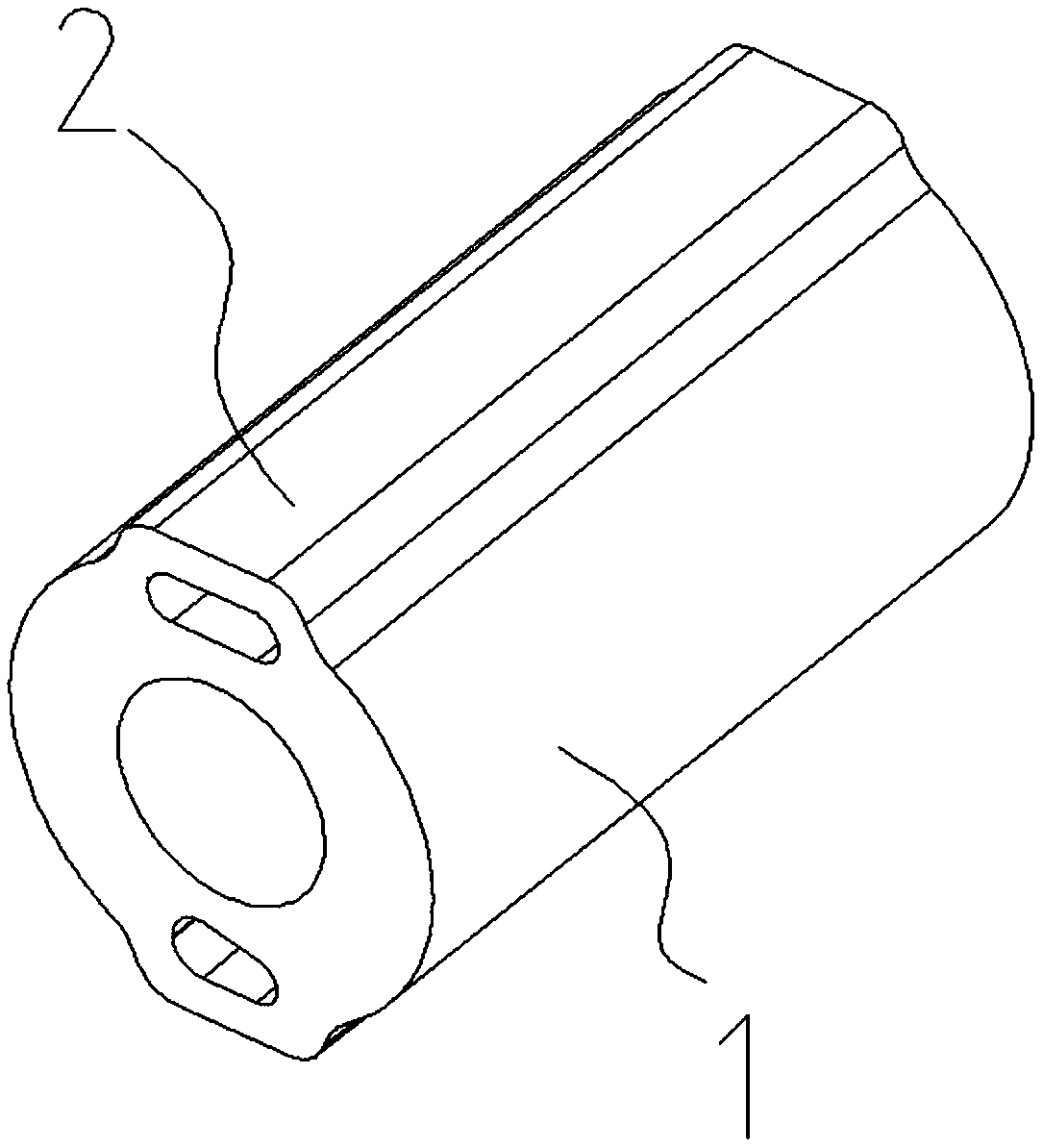

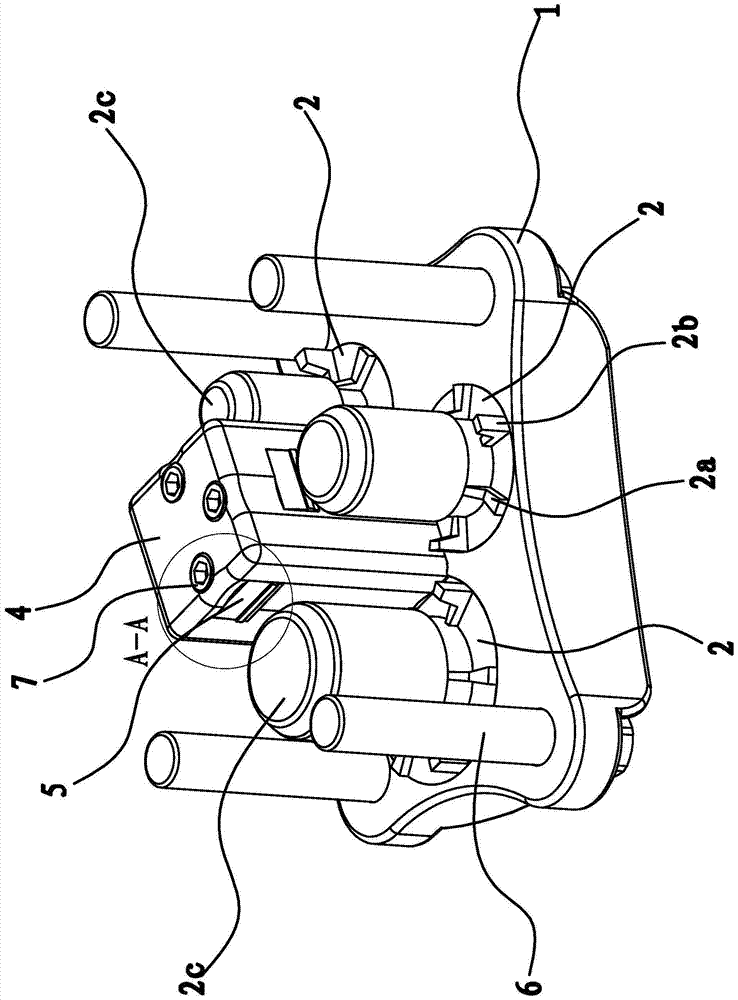

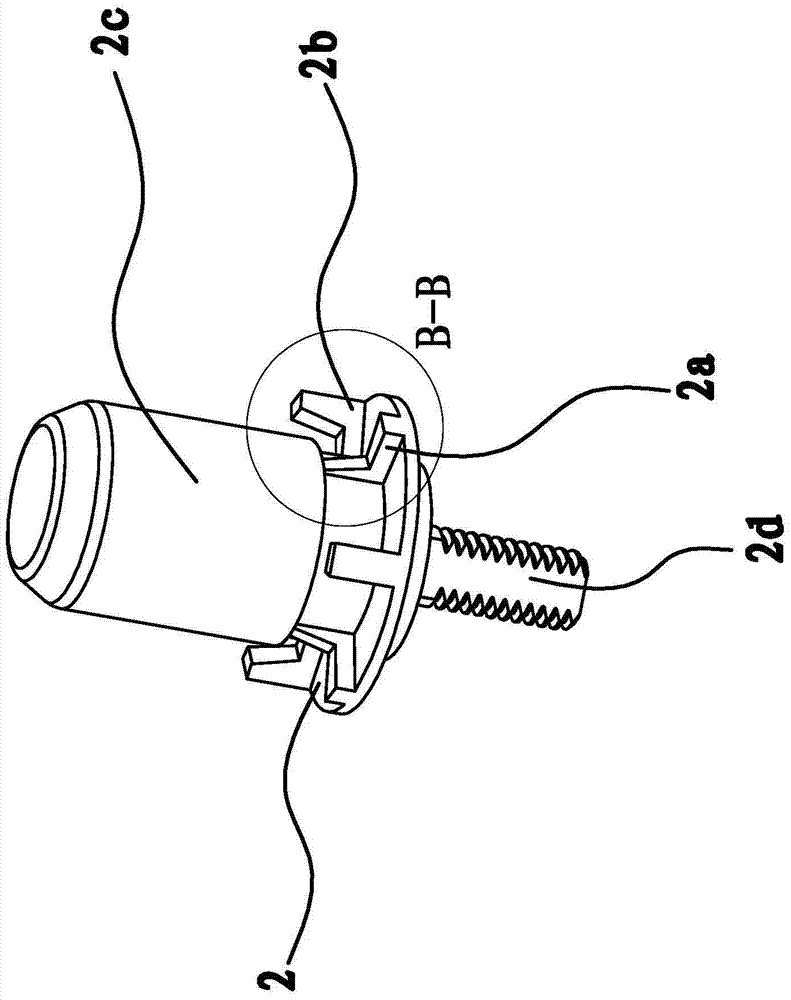

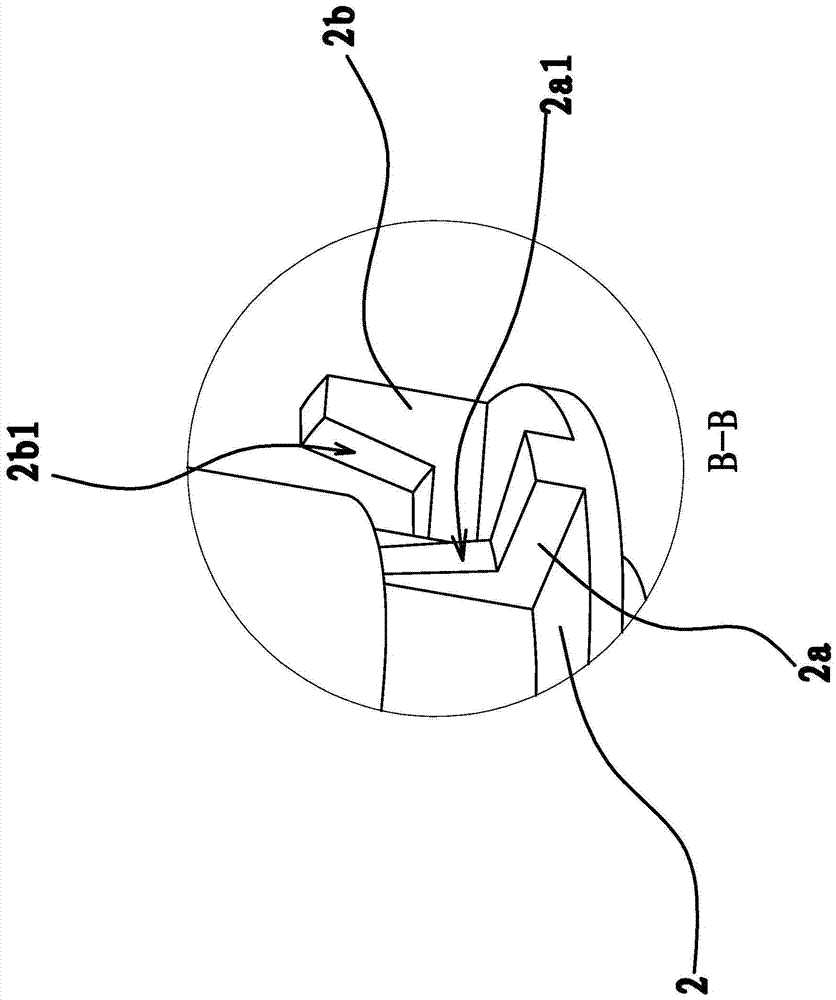

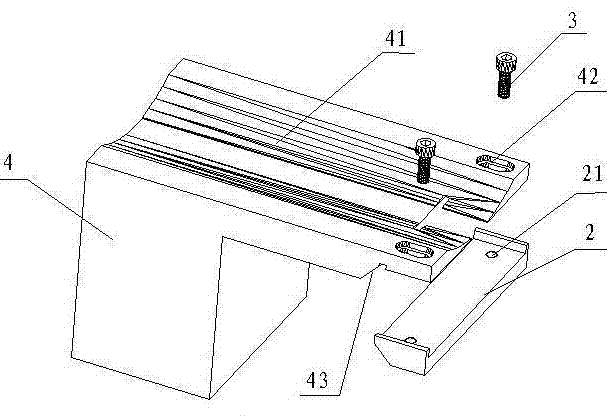

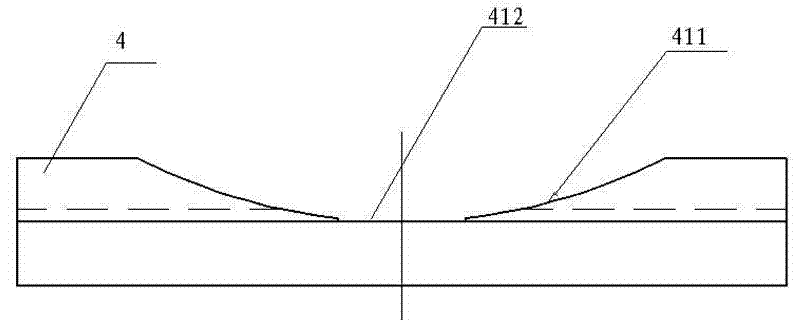

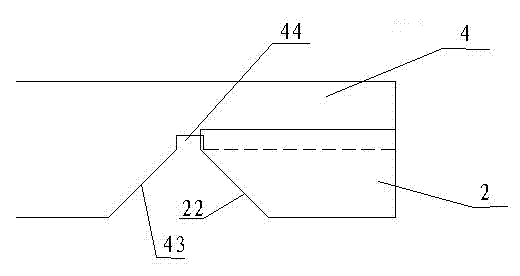

A processing tool for pipe fittings

The invention provides a machining tool of pipe fittings and belongs to the technical field of machinery, aiming at solving the problems of an existing inner and outer circle chamfering device for machining the pipe fittings that the machining precision is not high, the assembling is not convenient and the like. The machining tool of the pipe fittings comprises a base and a machining disc mounted on the base, wherein a plurality of convex inner chamfering blocks and outer chamfering blocks are integrally formed on the machining disc; an inner chamfering cutting surface is arranged on the outer side of each inner chamfering block, and an outer chamfering cutting surface is arranged on the outer side of each outer chamfering block; the inner chamfering blocks and the outer chamfering blocks are uniformly distributed in the peripheral direction by taking the center of the machining disc as the circle center; and the inner chamfering blocks and the outer chamfering blocks are arranged at intervals. The machining tool has the advantages that the chamfering angle of the pipe fittings is improved, the assembling is convenient and the like.

Owner:浙江金源铜业制造有限公司

Chamfer jig for adjustable type surface grinder

ActiveCN102189451BIncrease profitRealize chamferEdge grinding machinesPlane surface grinding machinesStructural engineeringGrinding wheel

The invention discloses a chamfer jig for an adjustable type surface grinder. The jig is used in coordination with the surface grinder and is characterized by comprising a jig seat, an adjustable sliding block and a locking screw which is used for adjusting the position of the adjustable sliding block on the jig seat, wherein the upper surface of the jig seat is provided with a forming groove which is used for accommodating the lower bottom surface of a grinding wheel of the surface grinder; and a V-shaped groove of which the included angle is 90 DEG is formed between the jig seat and the adjustable sliding block, is vertical to the forming groove and is intersected with the forming groove in a communicated way. In the chamfer jig, a workpiece to be machined is put into the V-shaped groove, the right-angle edge of the workpiece is exposed out from the communicated position to the forming groove on the upper surface of the jig seat, and the exposed part is ground off by the grinding wheel, so that a chamfer is realized. The invention has the advantages that: only the bottom surface of the grinding wheel is required to be used, the grinding wheel for grinding an angle is not needed,and the chamfer jig can be used for machining the chamfer in a handheld way, and has high chamfer accuracy and high speed.

Owner:JOUDER PRECISION INDAL KUSN

Chamfering device for central hole of crankshaft

InactiveCN106424859AHigh chamfering precisionImprove cooling effectTransportation and packagingCenter drillsCooling effectEngineering

The invention discloses a chamfering device for a central hole of a crankshaft. The chamfering device comprises a chamfering workbench, wherein a crankshaft clamping plate and a chamfering instrument are arranged on the chamfering workbench; the chamfering instrument comprises a chamfering drill bit, a drill chuck and a driver; a driver bracket is arranged on the chamfering workbench; the driver bracket comprises a support frame and a rotating shaft arranged on the support frame; a connecting rod is arranged between the rotating shaft and the driver; a cooling oil supply column is arranged on the chamfering workbench; the height of the cooling oil supply column is as same as that of the crankshaft. The chamfering device provided by the invention can quickly and effectively complete the chamfering tasks for the central holes in the two ends of the crankshaft. The chamfering device is higher in chamfering precision and excellent in cooling effect.

Owner:重庆都成荣锋机械制造有限公司

Improved type in-mold chamfering machine

PendingCN107695449ASolve the problem of control accuracySolve the strength problemGear wheelMotor shaft

The invention discloses an improved type in-mold chamfering machine comprising a rotary driving assembly, a feed driving assembly, a moving block feed device and a cutter fixing assembly. The rotary driving assembly is connected and matched with the cutter fixing assembly. The cutter fixing assembly is connected and matched with the moving block feed device. The moving block feed device is connected and matched with the feed driving assembly. The feed driving assembly comprises a feed driving motor with a braking function, a first synchronizing wheel installed on a feed driving motor spindle,a feed connecting shaft inserted into the moving block feed device, a second synchronizing wheel arranged on the feed connecting shaft in a sleeving mode, and a first synchronizing belt arranged between the first synchronizing wheel and the second synchronizing wheel in a sleeving mode and used for transmission. The improved type in-mold chamfering machine is simple in structure and reasonable indesign, the defects in precision control of feed quantity and rigidity strength of a traditional in-mold chamfering machine can be overcome, and due to the fact that two independent servo driving mechanisms are used and a conveying belt is used for replacing most gear assemblies, the chamfering precision is improved effectively.

Owner:DONGGUAN FOUROCEAN MACHINERY TOOLS

A carbon rod end chamfering device

ActiveCN109483361BAchieve clampingRealize chamferEdge grinding machinesGrinding drivesGraphite carbonHydraulic cylinder

The invention discloses a carbon rod end part chamfering device, and relates to the technical field of graphite carbon rod machining equipment. The carbon rod end part chamfering device comprises a base, the base is provided with a lower frame body, the lower frame body is slidably connected with an upper frame body, and a first motor, fixing rods and a lead screw are fixed to the inner side of the upper frame body; a first supporting plate is fixed to the top of the upper frame body, the first supporting plate is provided with a cylinder and a sliding block, and a first hydraulic cylinder isfixed to the top of the sliding block; a second supporting plate is connected to a telescopic rod of the first hydraulic cylinder, and a second motor, a support plate and a cylinder frame are sequentially arranged on the top of the second supporting plate; and a cylinder is slidably connected in the cylinder frame, a rotating shaft is fixed to the left side of the cylinder, a supporting base is arranged on the right side of the first supporting plate, the supporting base is fixed to the top of the upper frame body, a sand mill is installed on the supporting base, and clamping devices are symmetrically arranged on the inner side of the cylinder along the axis. The carbon rod end part chamfering device has a high carbon rod chamfering precision and is suitable for chamfering of carbon rods with different specifications.

Owner:亳州市亚珠新材料有限公司

Big and small head boring integrated machining equipment for engine connecting rod

PendingCN111250757AIncrease productivityImprove processing efficiencyLarge fixed membersPositioning apparatusEngineeringMachine tool

The invention relates to the technical field of engine parts, in particular to big and small head boring integrated machining equipment for an engine connecting rod. The big and small head boring integrated machining equipment for the engine connecting rod comprises a machine tool base and a fixing plate arranged on the machine tool base, wherein a connecting rod clamp is arranged on the fixing plate; the equipment further comprises a boring cutter device arranged corresponding to the connecting rod clamp; the machine tool base is connected with the boring cutter device through a telescopic device; the boring cutter device comprises a boring cutter disc and two boring cutter bodies arranged on the boring cutter disc; and the machine tool base is arranged on a sliding table. The big and small head boring integrated machining equipment for the engine connecting rod has the advantages of high working efficiency, higher machining precision and lower rejection rate.

Owner:YULIN CHENGXIN MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com