Patents

Literature

52results about How to "Convenient chamfering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saw blade type numerical control cutting and chamfering machine

The invention relates to a cutting and chamfering machine, in particular to a saw blade type numerical control cutting and chamfering machine for performing chopping cutting or chamfering on a hollow pipe fitting. The adopted technical scheme is that the saw blade type numerical control cutting and chamfering machine is characterized in that a clamping disc and a rack are in running fit, wherein a rotary disc is hinged with a cutting and chamfering device mounting rack; one side of the mounting rack is hinged with the rotary disc, and the other side of the mounting rack is provided with a long through hole; the rotary disc is provided with a mounting rack locking mechanism at a position of a limiting pin; the cutting and chamfering machine comprises a motor, a transmission component and a cutting or chamfering blade mounting rack; the motor is fixedly arranged on the mounting rack; the transmission component is fixedly arranged on the mounting rack through a bearing; and a motor output shaft is in linked and matched with the transmission component. By using the technical scheme, cutting or chamfering treatment can be performed on the pipe fitting; and in addition, the mechanism can realize one-time cutting or chamfering of the pipe fitting, and the cutting and chamfering machine automatically withdraws to the original position with great convenience.

Owner:ZHEJIANG AOTAI MACHINE MFG

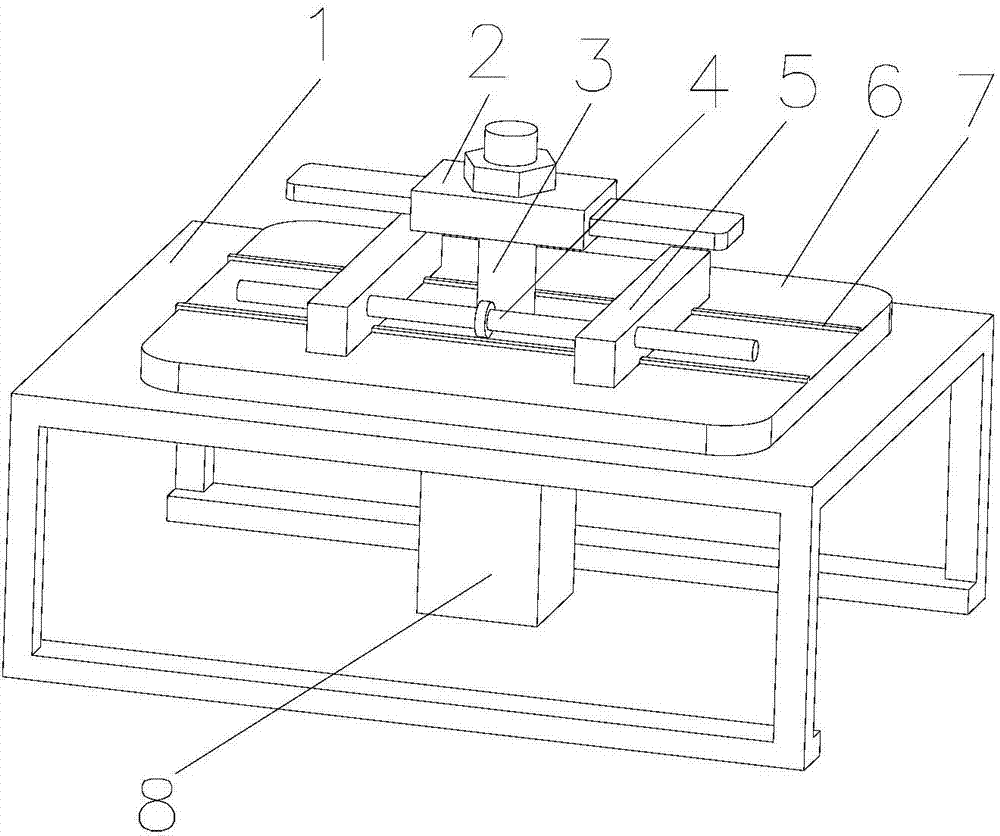

Universal gear ring chamfering tool

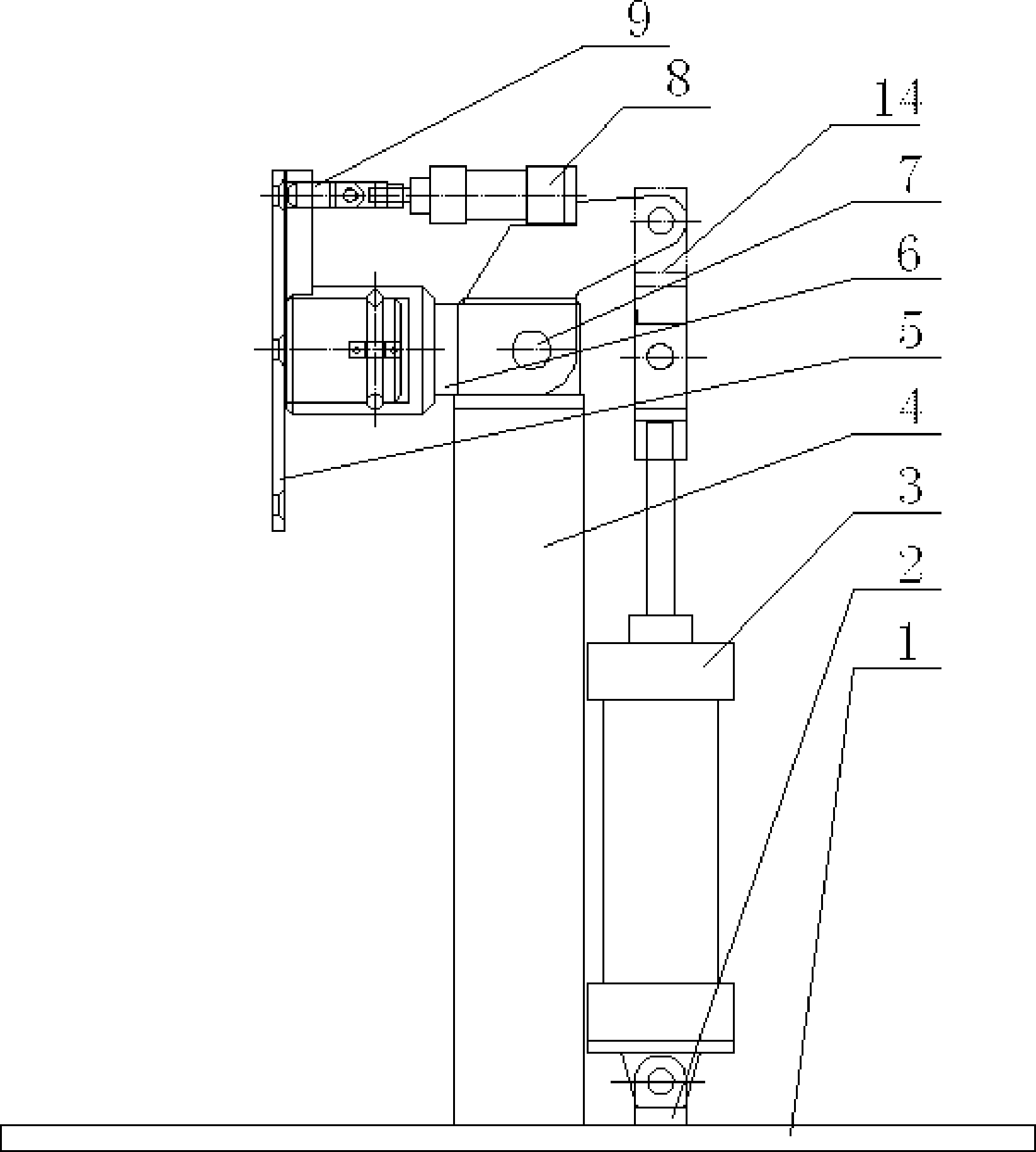

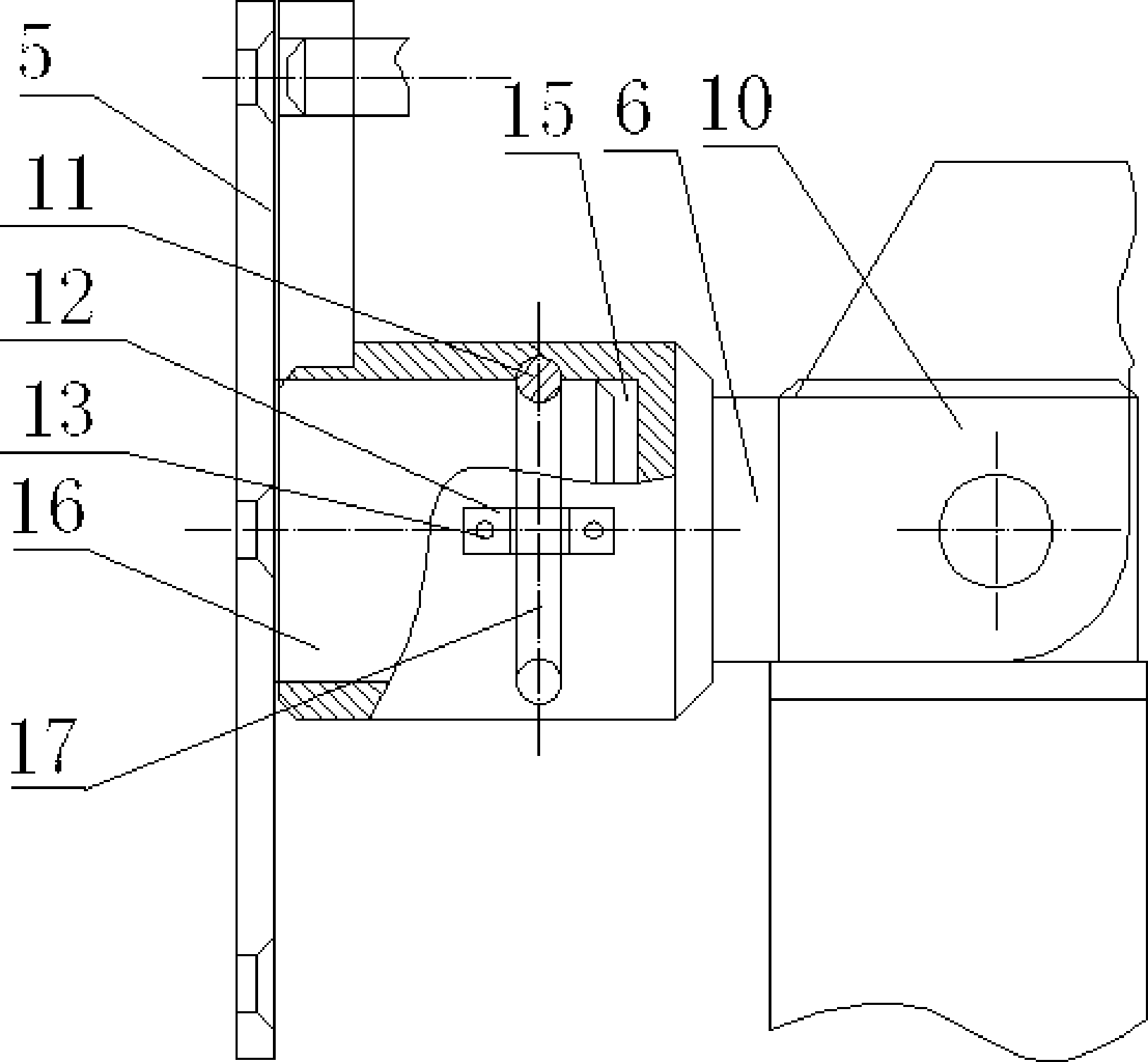

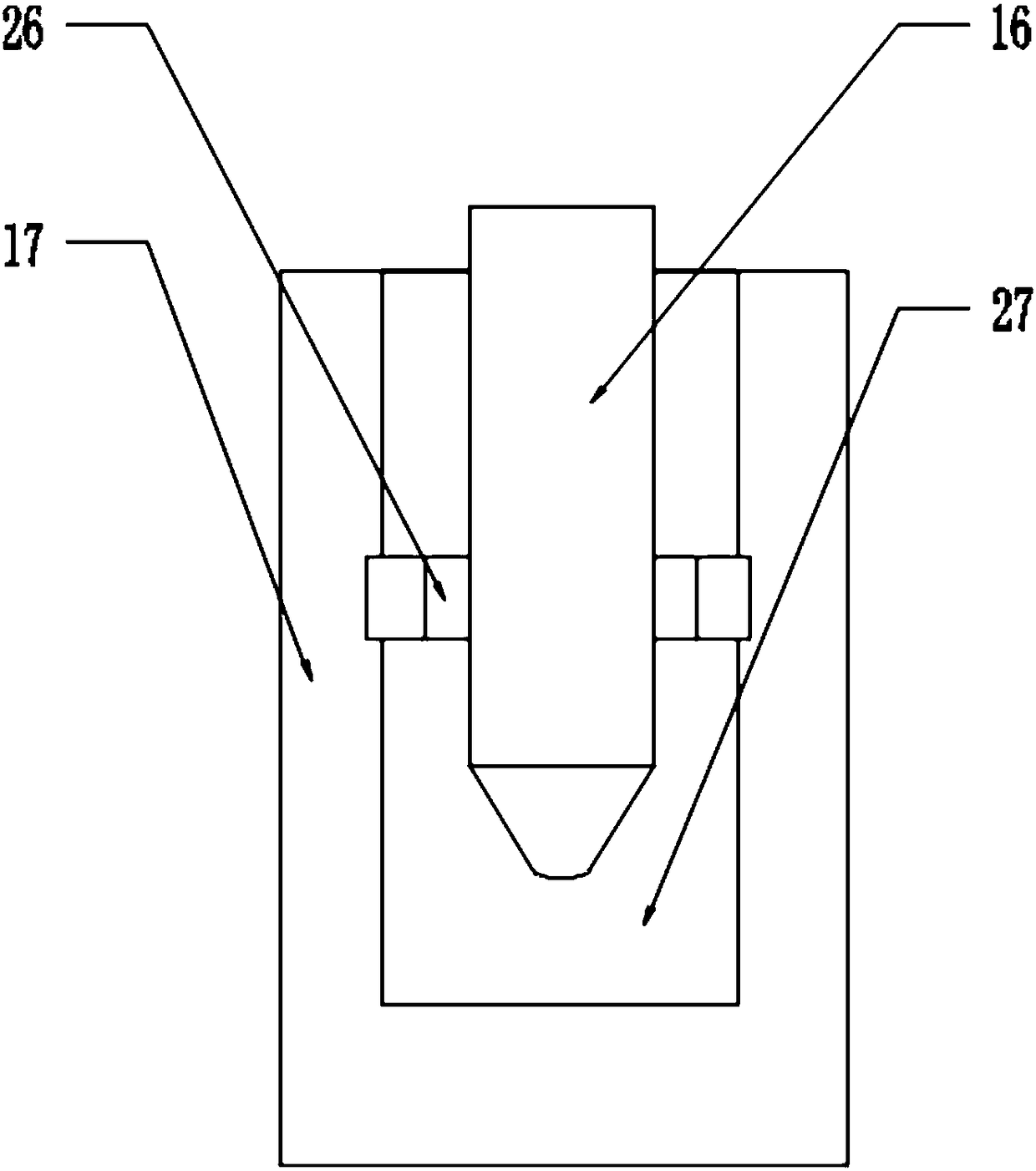

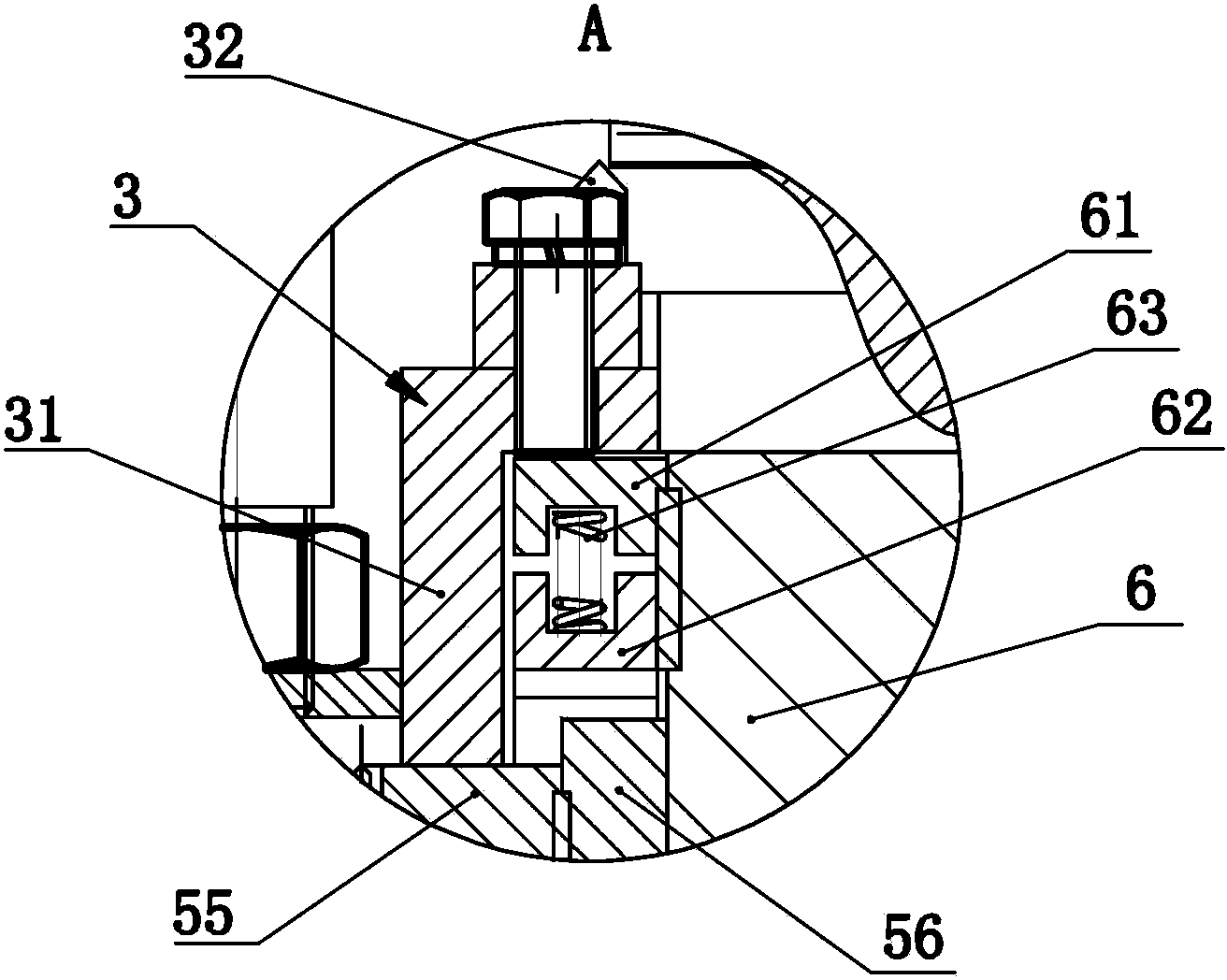

InactiveCN104772638AConvenient chamferingAdjustable lengthPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention relates to the technical field of gear ring chamfering tools, in particular to a universal gear ring chamfering tool. A gear ring positioning mechanism comprises a fixed seat, a pair of positioning blocks are slidably connected to the fixed seat, and a lead screw with reverse threads at the two ends is arranged between the positioning blocks; a gear ring pressing device comprises a base and a pressing plate with two telescopic ends, a hydraulic cylinder is fixed on the lower surface of the base, the fixed seat is fixed on the upper surface of the base, and the extension end of the hydraulic cylinder sequentially penetrates through the base and the fixed seat to be fixedly connected with the pressing plate; a gear ring is arranged between the fixed seat and the pressing plate, and the positioning blocks make contact with the inner wall of a gear ring through hole of the gear ring. According to the universal gear ring chamfering tool, the lead screw can be regulated according to the diameter size of the gear ring through hole until the positioning blocks tightly extrude on the inner wall of the gear ring through hole, meanwhile, the length of the pressing plate can be regulated, the pressing plate is pulled to fix the gear ring on the fixed seat through the hydraulic cylinder, and therefore a machine tool can perform gear ring chamfering conveniently.

Owner:JIANGSU YAMEITE GEAR

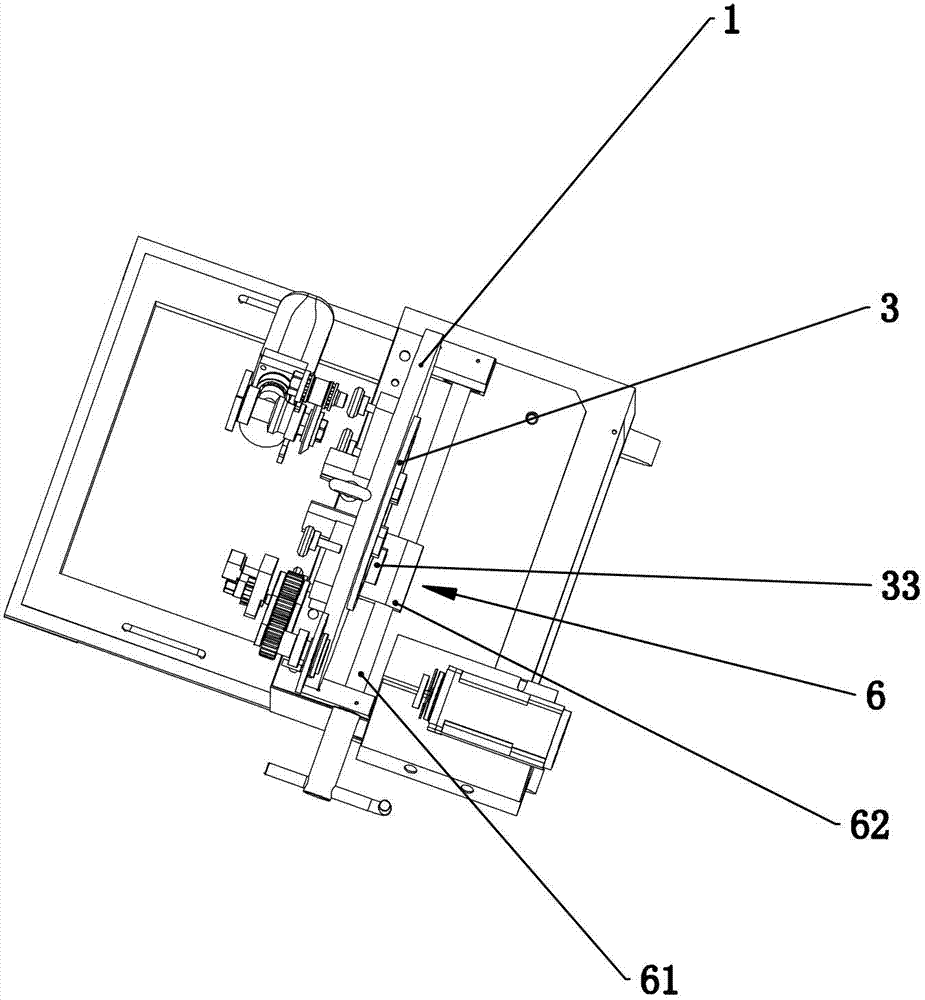

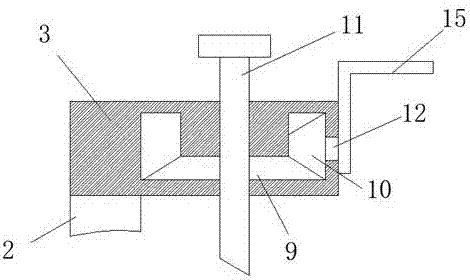

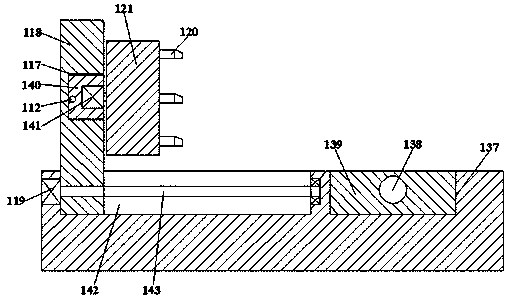

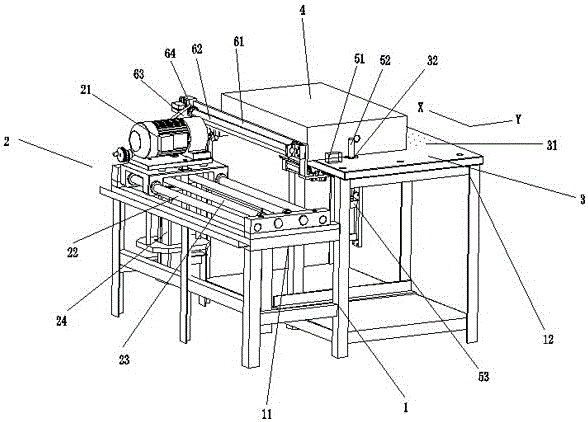

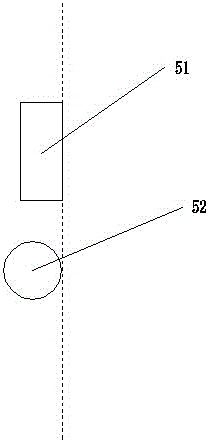

Variable-frequency edge grinding machine and grinding method thereof

InactiveCN104942674ACompact structureThe grinding method is simple and fastEdge grinding machinesEngineeringMechanical engineering

The invention relates to a variable-frequency edge grinding machine and a grinding method thereof. The variable-frequency edge grinding machine comprises a rack, wherein a lathe head with an operation opening formed in the middle is arranged at the upper part of the rack and can reciprocate transversely; a horizontal rotating shaft driven by a variable-speed driving mechanism to rotate is arranged on one side of the lathe head; one end of the horizontal rotating shaft transversely penetrates the operation opening; a horizontal clamping shaft which is driven by the variable-speed driving mechanism to rotate and can move transversely is arranged on the other side of the lathe head; two clamps which work together to clamp a lens are respectively arranged at the end part, transversely penetrating the operation opening, of the horizontal clamping shaft and at the end part, transversely penetrating the operation opening, of the horizontal rotating shaft; a grinding head support capable of moving forwards and backwards is arranged on the rear side of the lathe head; a grinding wheel located on the rear side of the operation opening and used for grinding the lens is arranged on the grinding head support. The variable-frequency edge grinding machine not only is compact in structure but also can be conveniently used for edge grinding of the lens, and the grinding method is simple and quick.

Owner:福州恒光光电有限公司

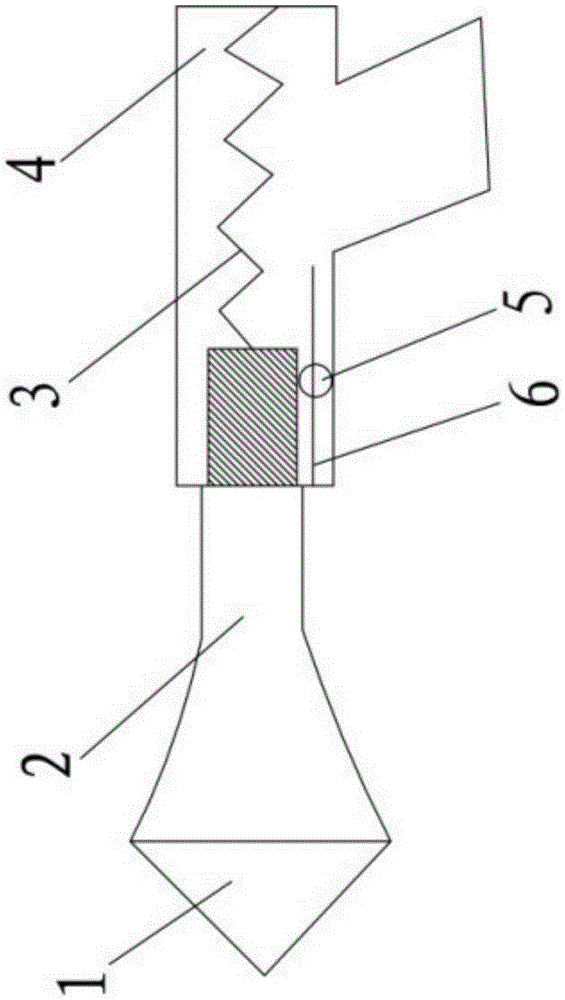

Double-blade chamfer cutter

InactiveCN104190969AExtended service lifeReduce wearCutting insertsTurning toolsEngineeringMechanical engineering

The invention relates to the field of tool equipment, in particular to a double-blade chamber cutter. The double-blade chamber cutter comprises a cutter head and a cutter handle. The cutter head is arranged on the front section of the cutter handle. The cutter head and the cutter handle are integrally formed. The double-blade chamber cutter is characterized in that the cutter head comprises two cutting edge mounting parts arranged on the cutter head; cutting edges are arranged on the outer sides of the cutting edge mounting parts; the cutter head is conical; a chip groove is formed between the mounting parts; the upper side face of the cutter head is provided with vent holes communicated with the upper surface of the cutter handle; the side surface of the cutter handle is provided with a plurality of round holes communicated with the vent holes; the middle portion of the cutter handle is provided with a cavity; one side of the cavity is provided with an opening, a circular-arc-shaped protrusion is arranged at the opening, and the inner side of the circular-arc-shaped protrusion is arranged in the cutter handle; the inner side edge of the circular-arc-shaped protrusion is connected with the inner surface of an inner cavity of the cutter handle through a spring; the circular-arc-shaped protrusion is provided with a cutting edge. The double-blade chamber cutter is good in heat dissipation effect and capable of removing burrs.

Owner:CHANGZHOU XILI ALLOY TOOLS

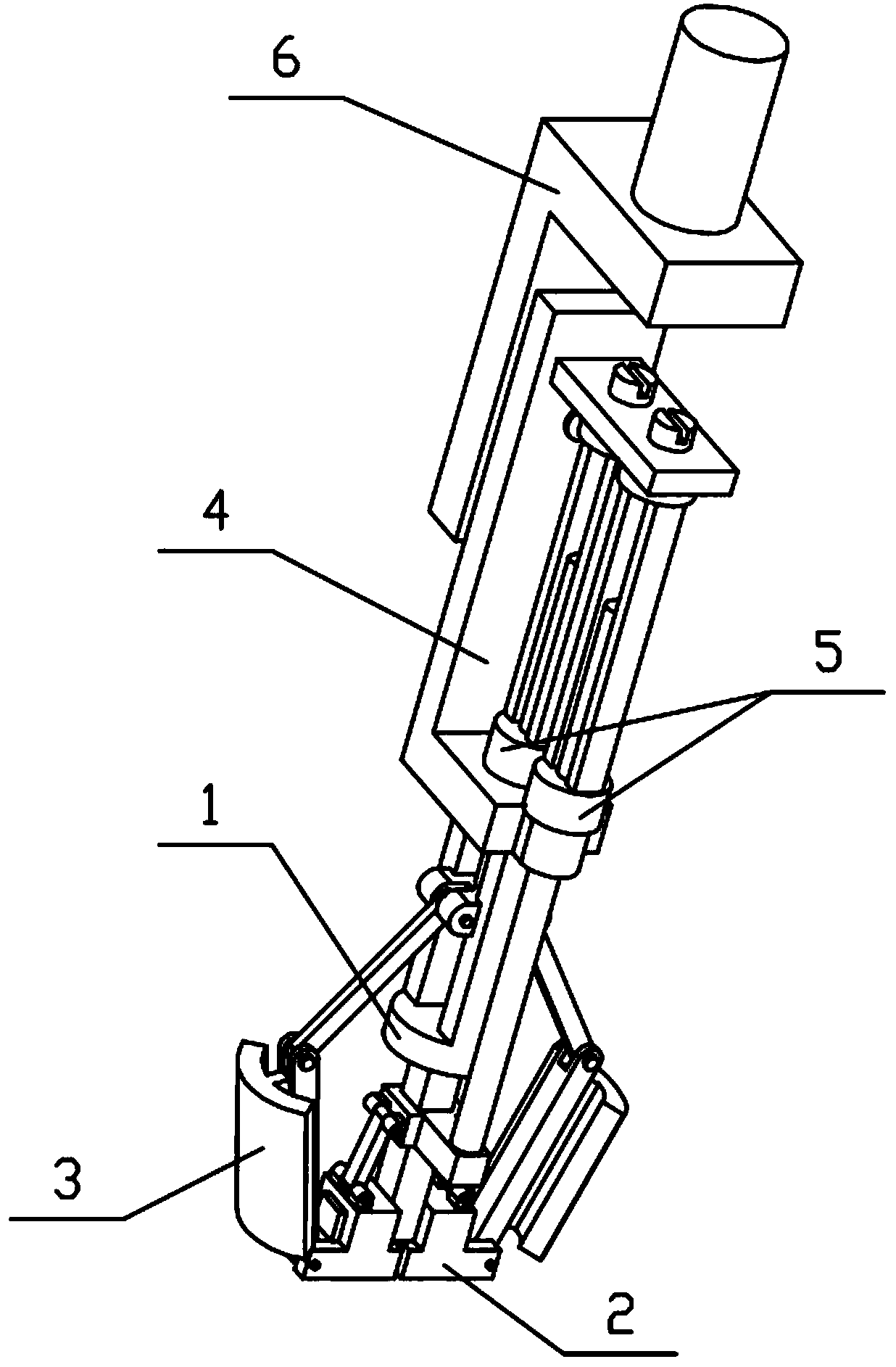

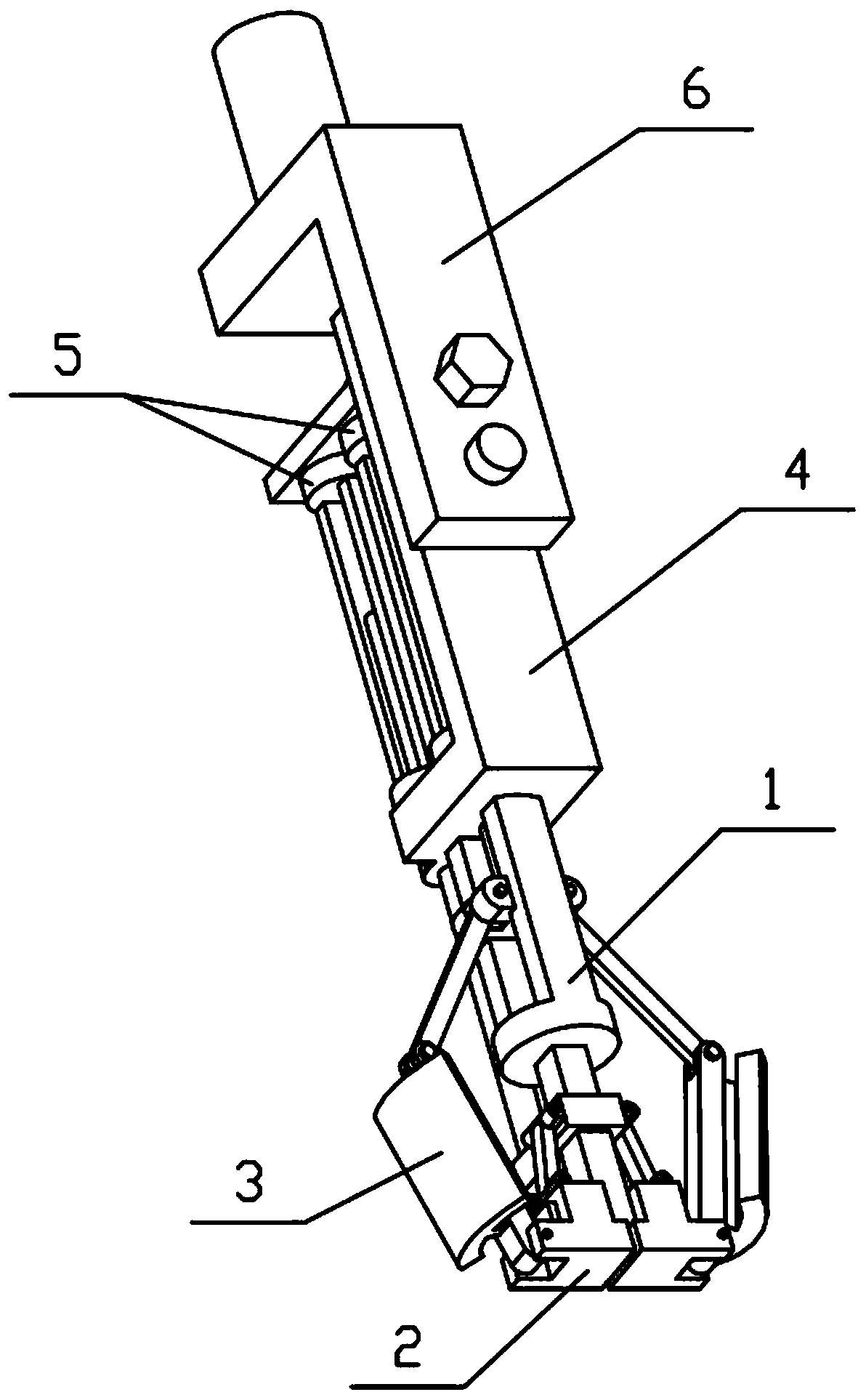

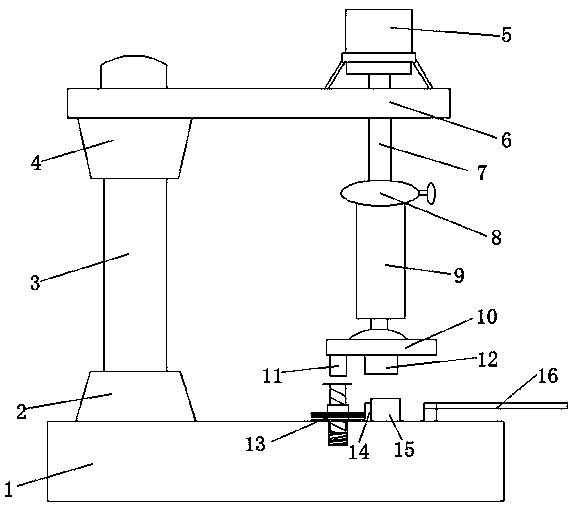

Rotary grinding operating platform

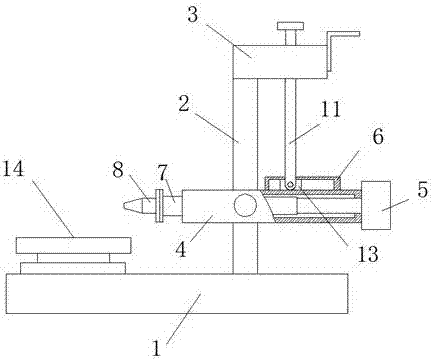

ActiveCN102935612AEasy to deburrConvenient chamferingGrinding machinesRotary stagePulp and paper industry

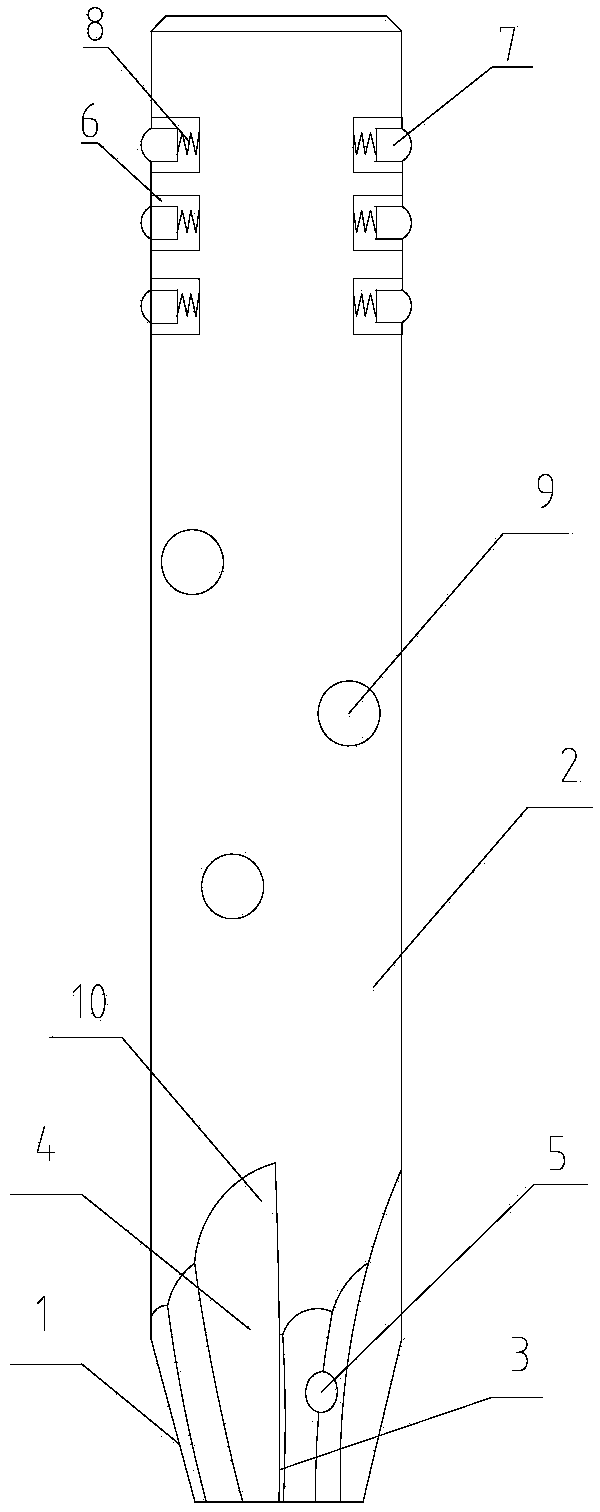

The invention discloses a rotary grinding operating platform which is provided with a base (1), an upright (4), a rotary support (6), a rotating platform (5), a first hydraulic oil cylinder or air cylinder (3) and a second hydraulic oil cylinder or air cylinder (8), wherein the bottom end of the upright (4) is fixedly connected with the base (1); the rotary support (6) is hinged at the top end of the upright (4); the rotating platform (5) is rotatably connected to the first end of the rotary support (6); a cylinder base of the first hydraulic oil cylinder or air cylinder (3) is hinged with the base (1), and a piston rod of the first hydraulic oil cylinder or air cylinder (3) is hinged with the second end of the rotary support (6); a cylinder base of the second hydraulic oil cylinder or air cylinder (8) is fixed on the rotary support (6); the surface of the rotating platform (5), close to the second hydraulic oil cylinder or air cylinder (8), is provided with at least one locating hole or groove for inserting a piston rod of the second hydraulic oil cylinder or air cylinder (8); and when the piston rod of the second hydraulic oil cylinder or air cylinder (8) is inserted into the locating hole or groove, the rotating platform (5) can not rotate because of being located, and the piston rod of the first hydraulic oil cylinder or air cylinder (3) stretches, so that the position of the rotating platform (5) can be adjusted between a vertical direction and a horizontal direction.

Owner:HUNAN TONGDA AUTOMOTIVE INTERIOR PARTS

Chamfering machine for valve corners

PendingCN107160255AAdjustable distanceFlexible useEdge grinding machinesGrinding drivesHydraulic cylinderClassical mechanics

The invention discloses a chamfering machine for valve corners. The chamfering machine for the valve corners comprises a base, a supporting rod is perpendicularly fixed on the top of the base, and an installing shell is fixed on one side of the supporting rod. A hollow guiding shell is arranged between the installing shell and the base, and the hollow guiding shell is rotatably connected with the supporting rod. A hydraulic cylinder is fixed on one side of the hollow guiding shell, and a rectangular connecting rod is fixed at the end, located in the hollow guiding shell, of a piston rod of the hydraulic cylinder. A chamfering grinding wheel is fixed at the end, away from the hydraulic cylinder, of the rectangular connecting rod. The chamfering grinding wheel is located on the side, away from the hydraulic cylinder, of the hollow guiding shell. A hollow limited block is fixed on the side, close to the installing shell, of the hollow guiding shell. According to the chamfering machine for the valve corners, the structures such as a clamp base, a hand rocking rod, a rotating shaft, a bevel gear, a bevel gear ring and an adjusting screw rod are matched to used so that the hollow guiding shell can be bodily rotated, and then the angle of the chamfering grinding wheel can be adjusted, the chamfered corners with different angles can be made, and usage is flexible.

Owner:JIANGSU SUGAO FLUID MACHINERY

Four-edge chamfering cutter

The invention relates to the field of cutter machining, in particular to a four-edge chamfering cutter. The four-edge chamfering cutter comprises a cutter bit and a cutter handle. The cutter bit is arranged at the front end of the cutter handle, and the cutter bit and the cutter handle are integrally formed. The four-edge chamfering cutter is characterized in that the cutter bit comprises four cutting edge installation parts arranged on the cutter bit, cutting edges are arranged on the outer sides of the installation parts, the cutter bit is in a taper shape, chip removal grooves are formed between the installation parts, the taper of the cutter bit is 28 degrees, the upper side face of the cutter bit is provided with vent holes communicated with the upper surface of the cutter handle, circular holes communicated with the vent holes are formed in the side surface of the cutter handle, a plurality of grooves are formed in the upper end of the cutter handle, circular-arc-shaped protrusions are arranged in the grooves, and the bottom ends of the protrusions are connected with the bottoms of the grooves through springs. The four-edge chamfering cutter is good in heat dissipating effect and clamping effect and capable of reducing resonance produced when the cutter works.

Owner:CHANGZHOU XILI ALLOY TOOLS

Cable tunnel construction method

PendingCN110607805AReduce constructionReliable constructionCable installations on groundArtificial islandsControl lineEngineering

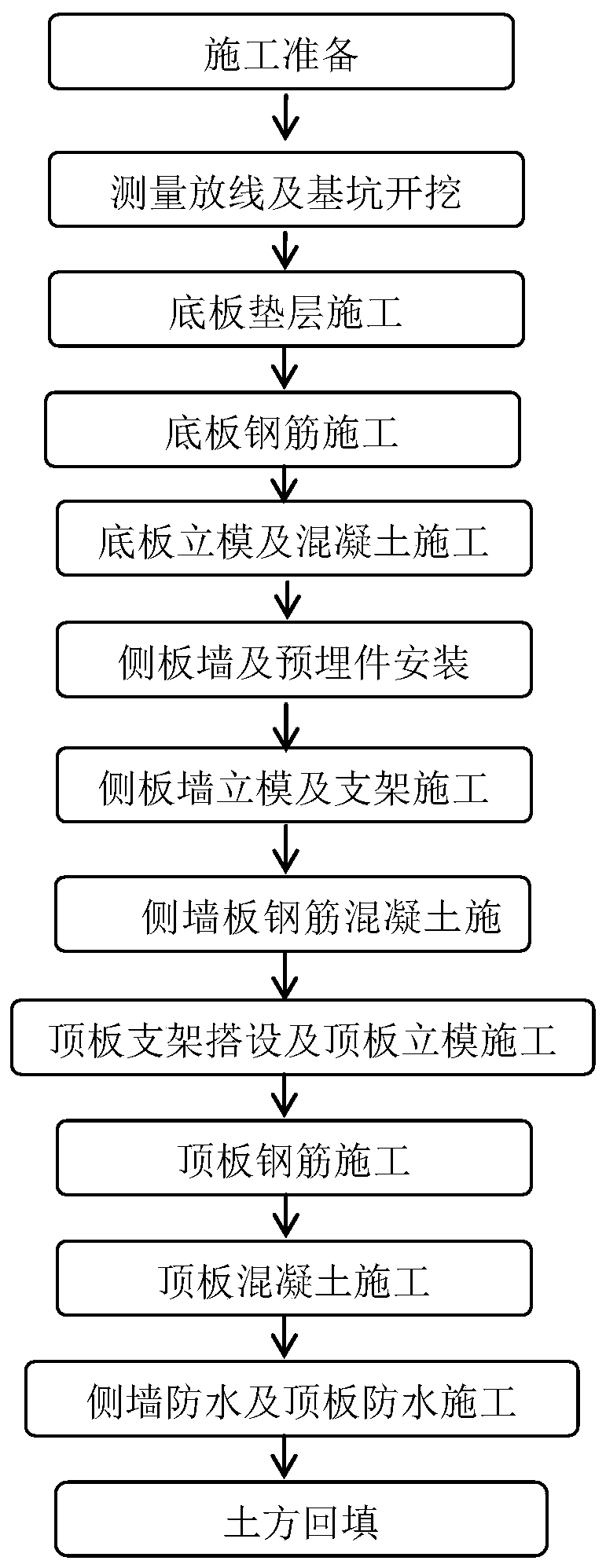

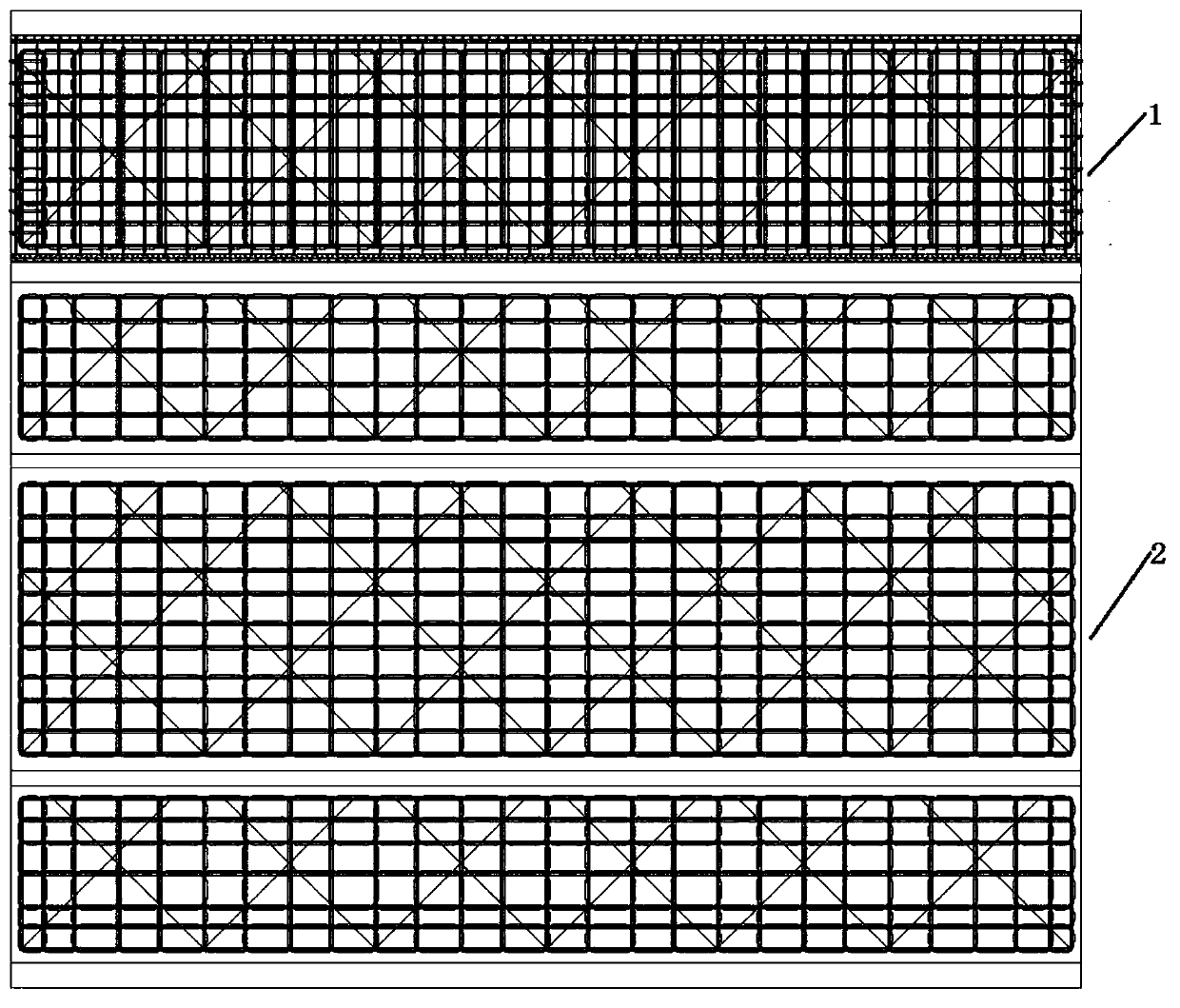

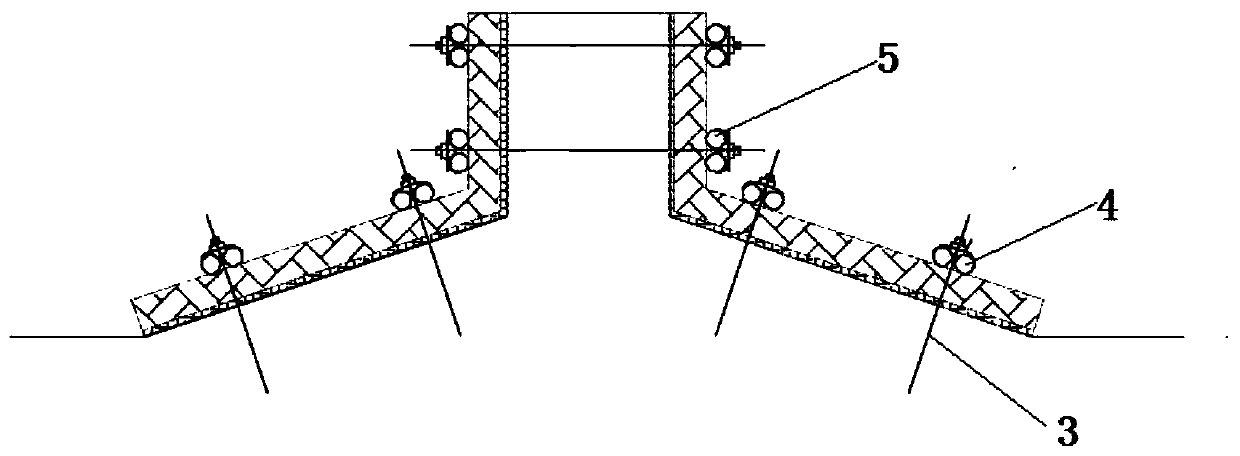

The invention discloses a cable tunnel construction method, and relates to the field of urban tunnel construction. The construction method comprises the construction steps of bottom plate construction, side wall plate construction, roof construction and waterproofing construction of side walls and a roof. Before bottom plate construction, a plurality of steel bars are uniformly distributed and embedded in an excavated cushion foundation pit in the transverse direction and the longitudinal direction, and after concrete pouring of the cushion layer is finished, the axis line, the sideline line and the control line are laid off on the cushion layer; side wall plate construction needs to be started after the bottom plate concrete has certain strength, a formwork support is erected, then binding construction of rear side wall plate steel bars is conducted, and casings and embedded parts are installed in time; the roof structure needs to be supported by a spigot-and-socket plate buckle fullsupport frame before roof construction; waterproofing construction of the side walls and the roof comprises laying an upper waterproofing coiled material and a lower waterproofing coiled material, andthen laying a layer of grid cloth on the upper waterproofing coiled material. The construction method is relatively low in cost and reliable and safe in construction, and can ensure quality of a mainbody structure.

Owner:STATE GRID JIANGSU ELECTRIC POWER ENG CONSULTING CO LTD +1

Portable metal pipeline opening chamfering device

InactiveCN112621506AConvenient chamferingAffect normal useEdge grinding machinesGrinding drivesEngineeringMetal

The invention discloses a portable metal pipeline opening chamfering device. The portable metal pipeline opening chamfering device comprises a base, storage cavities with outward openings are formed in the left side and the right side in the base correspondingly, a lifting plate is arranged in the base and located between the storage cavities in the left side and the right side, and a lifting plate is arranged in the lifting plate in an up-down sliding mode. A fixing rod cavity is formed between the storage cavities in the left side and the right side of the lifting plate in a communicating mode, a fixing rod is arranged in the fixing rod cavity in a left-right sliding mode, and a rotating main shaft is arranged in the upper end face of the base in a rotating mode. The portable metal pipeline opening chamfering device can first support and fix the inner wall of a metal pipe, then adjust the position of a grinding plate according to the thickness of the metal pipe wall, chamfering accuracy is guaranteed, meanwhile, in the chamfering process, metal chips on the inner side of the pipe wall can be removed in time, the metal chips are prevented from falling into a pipeline and affecting normal use of the pipeline, and the portable metal pipeline opening chamfering device is good in portability and facilitates chamfering of the metal pipeline on site.

Owner:上海霞爱金属材料有限公司

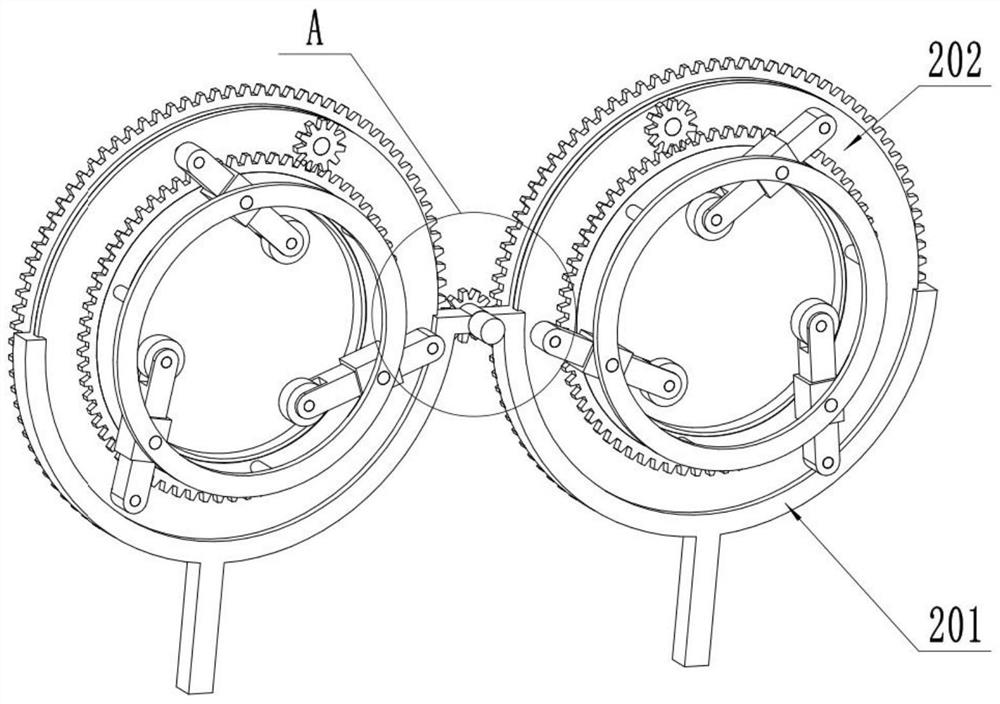

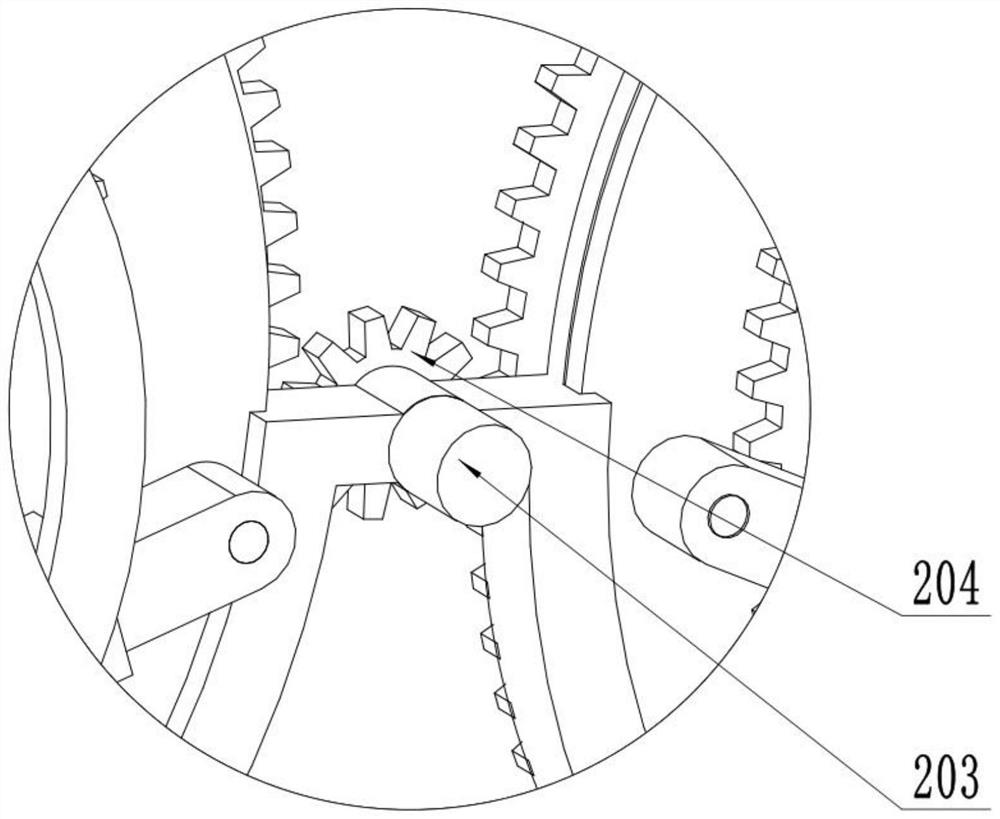

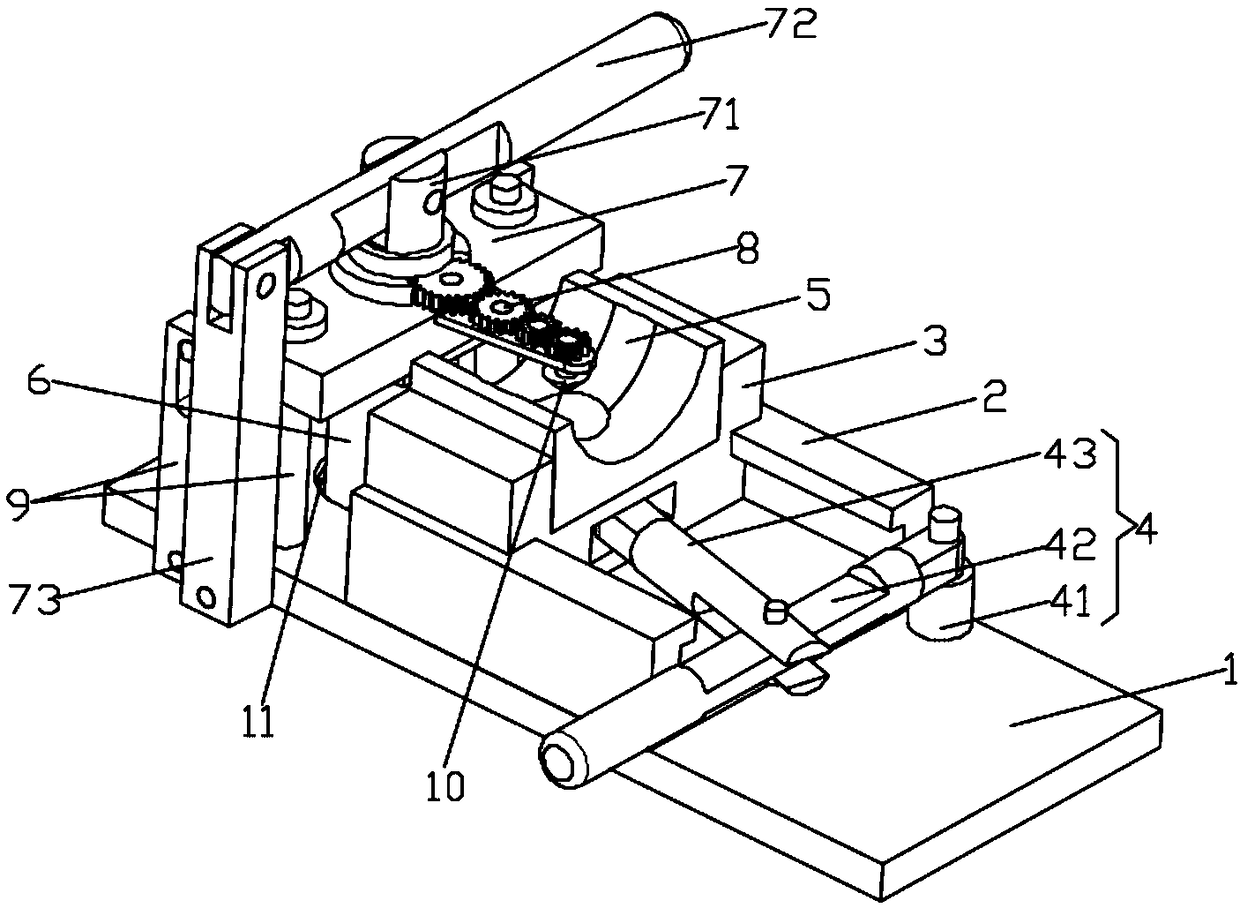

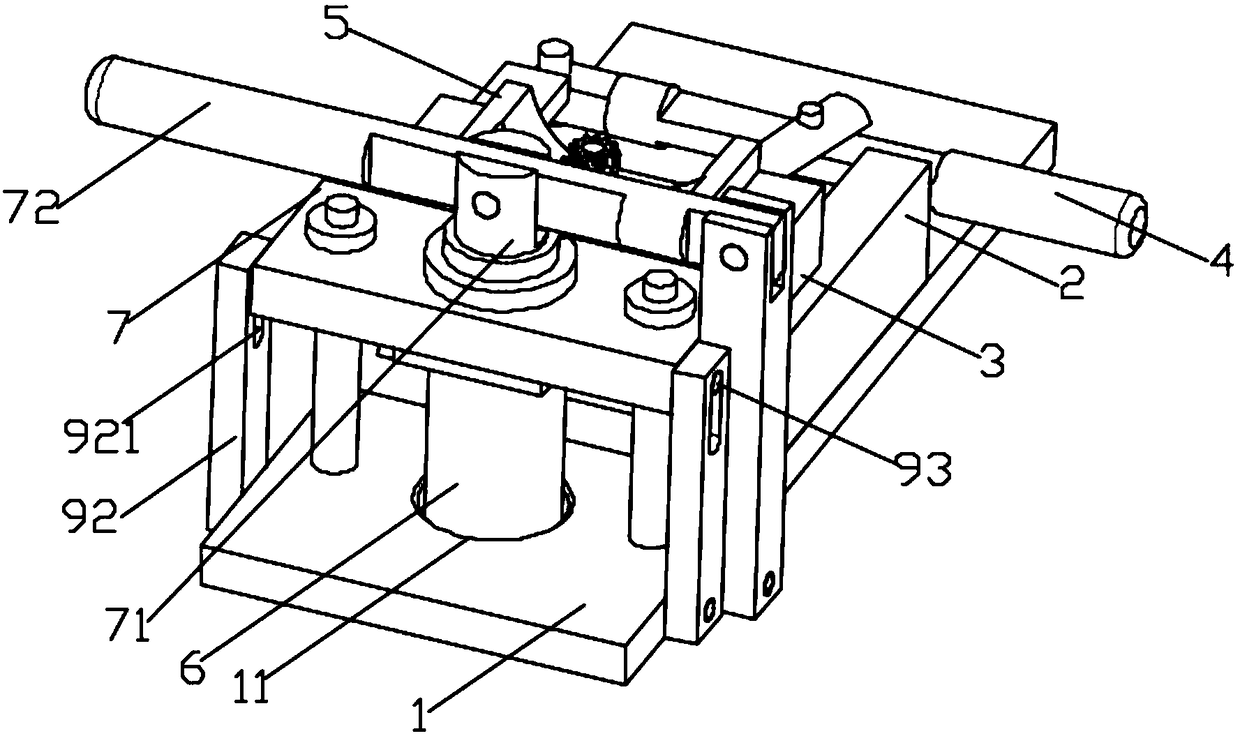

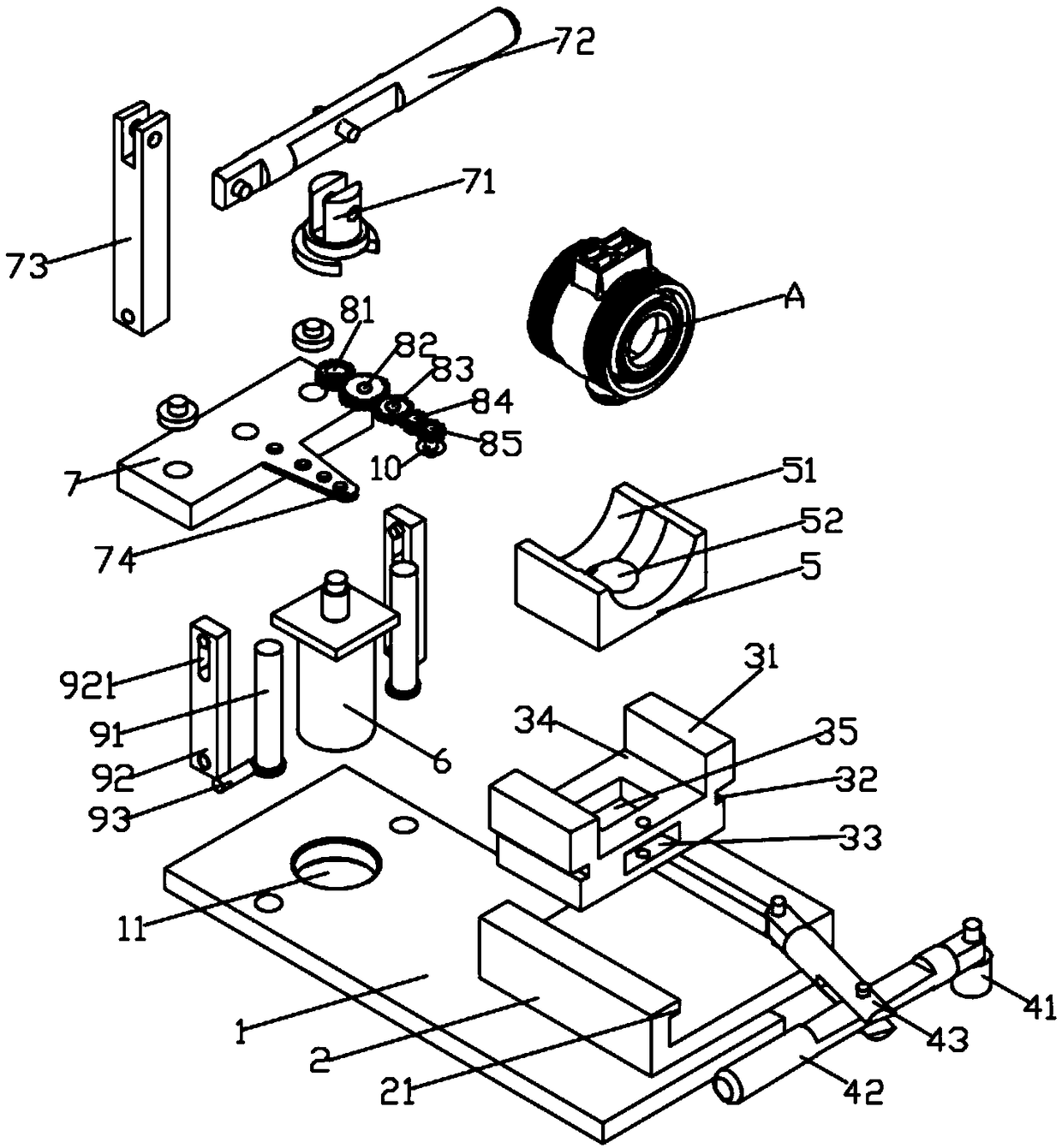

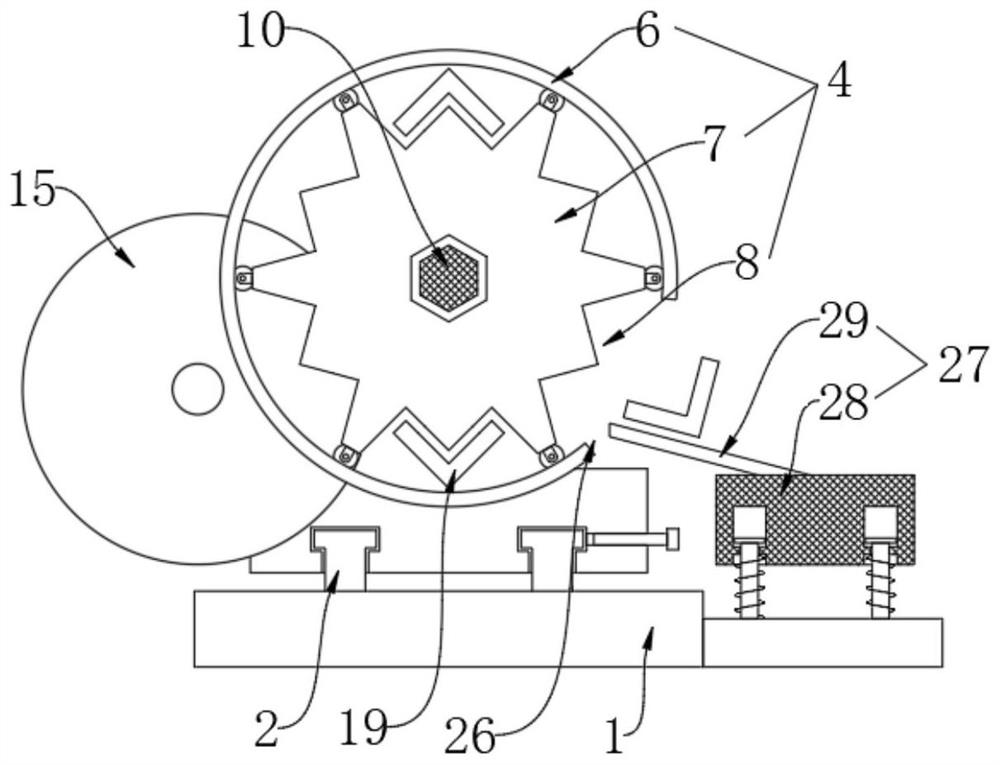

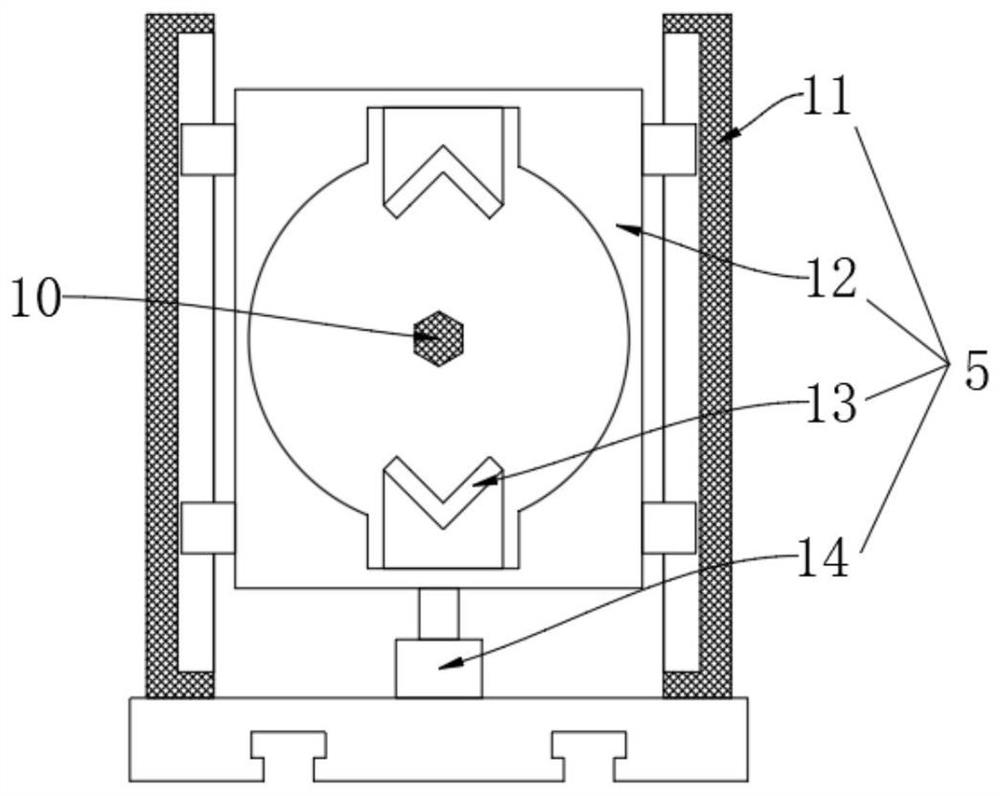

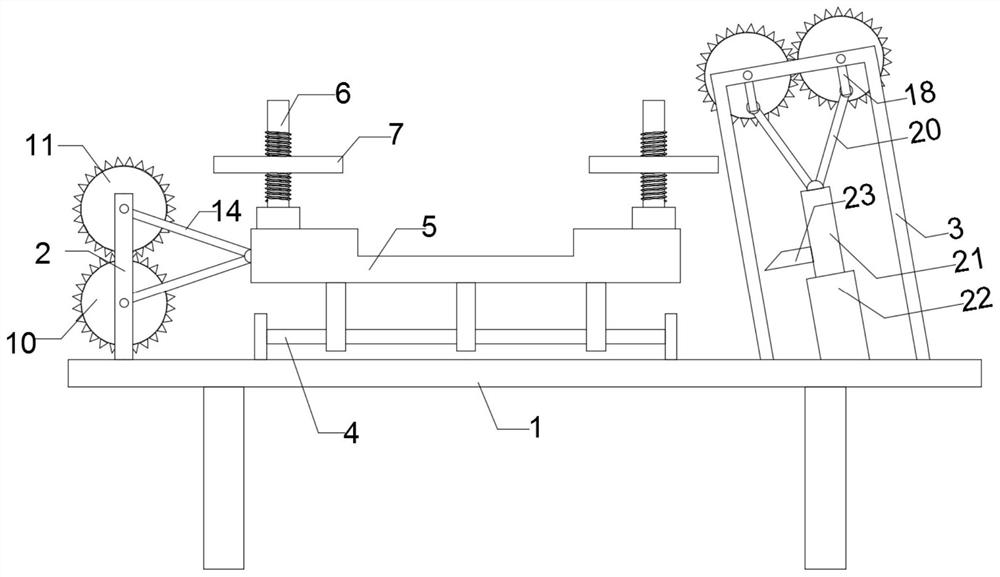

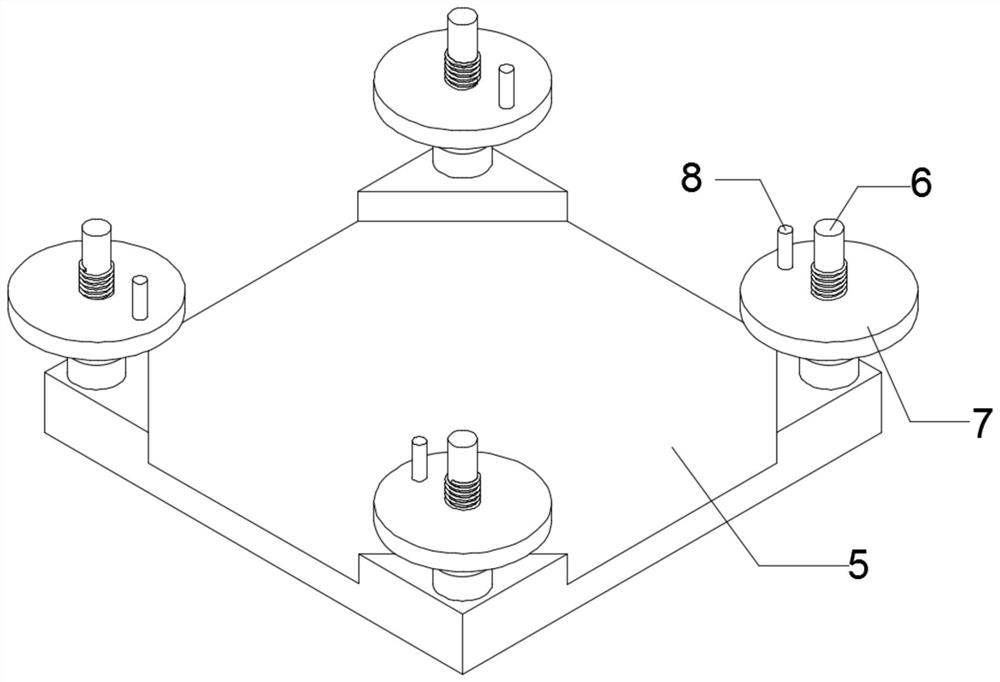

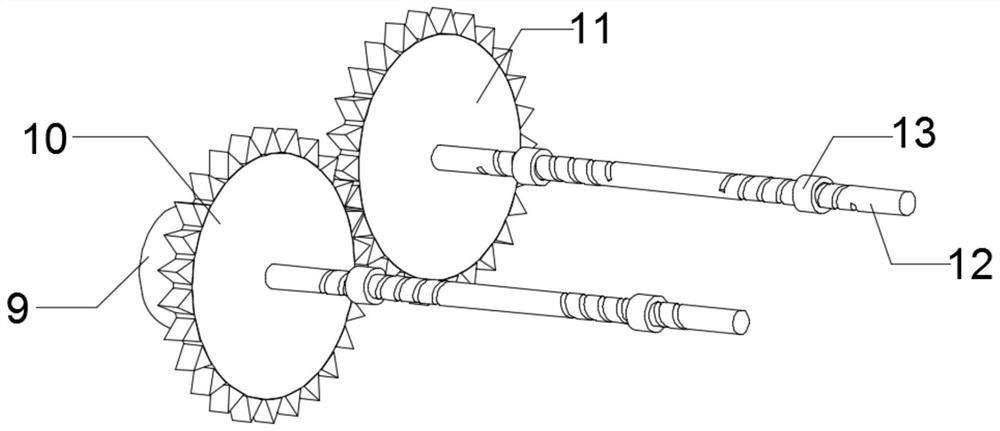

Chamfering device for stainless steel bolt machining

PendingCN114799234AConvenient chamferingAutomatically adjust the positionTurning machinesPositioning apparatusStructural engineeringMachining

The invention discloses a chamfering device for stainless steel bolt machining, and relates to the technical field of bolt machining, the chamfering device comprises a bottom plate, a centering mechanism, a conveying mechanism and a chamfering mechanism, the centering mechanism and the chamfering mechanism are both arranged on the bottom plate, and the conveying mechanism is arranged on the centering mechanism; the conveying mechanism is used for conveying bolts; by arranging the centering mechanism, a bolt can be automatically positioned, and the conveying mechanism can be rotated, so that the bolt can be chamfered conveniently; by arranging the conveying mechanism, outer hexagon bolts can be supported, and the outer hexagon bolts can also be conveyed; by arranging the chamfering device, the position of a cutter and the size of a chamfer can be automatically adjusted according to different diameters of bolts.

Owner:江苏森吉米尔金属制品有限公司

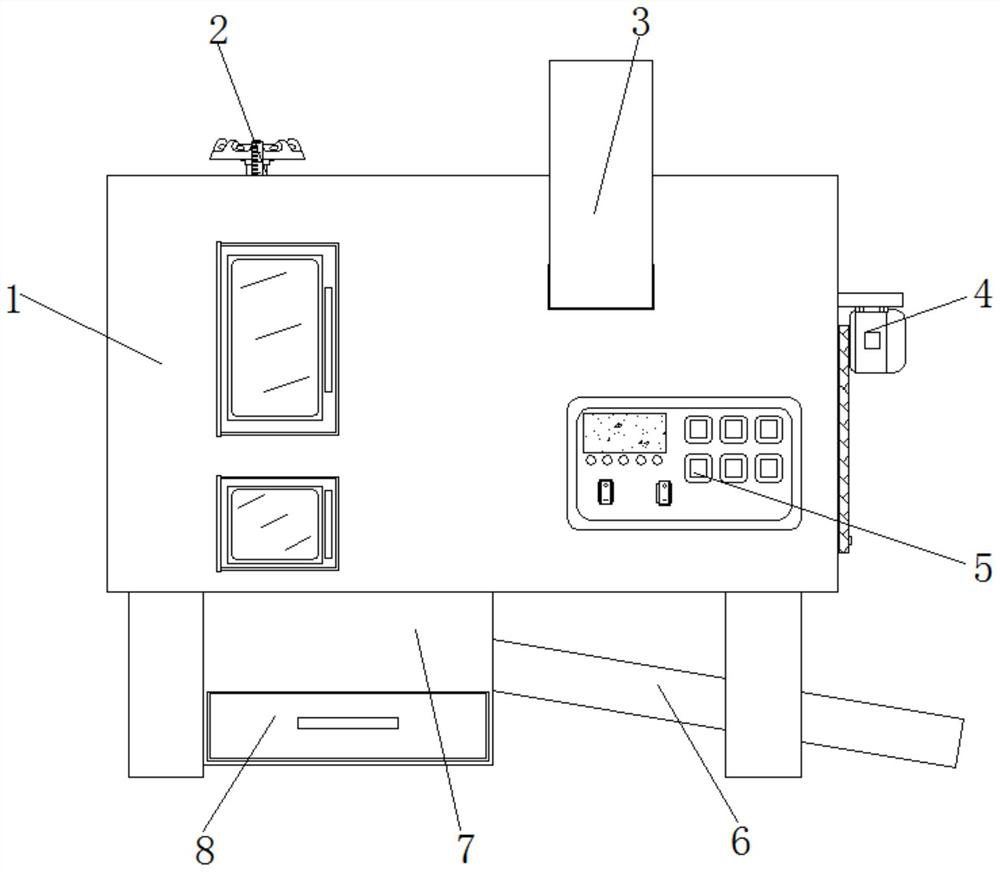

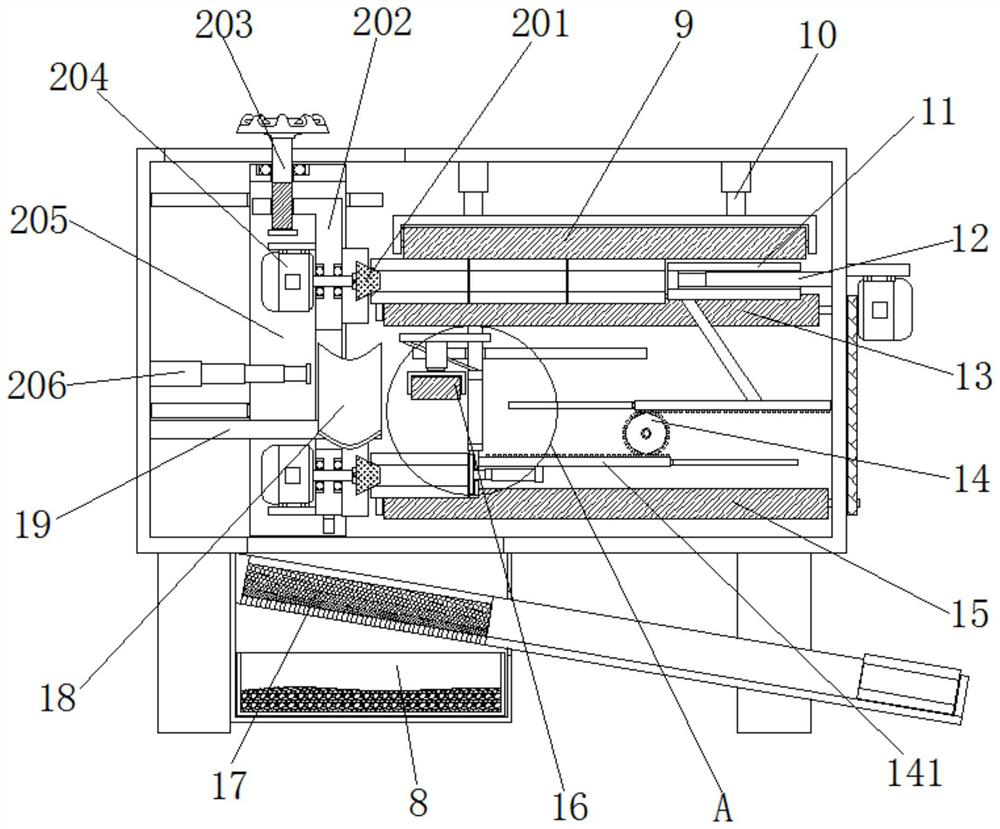

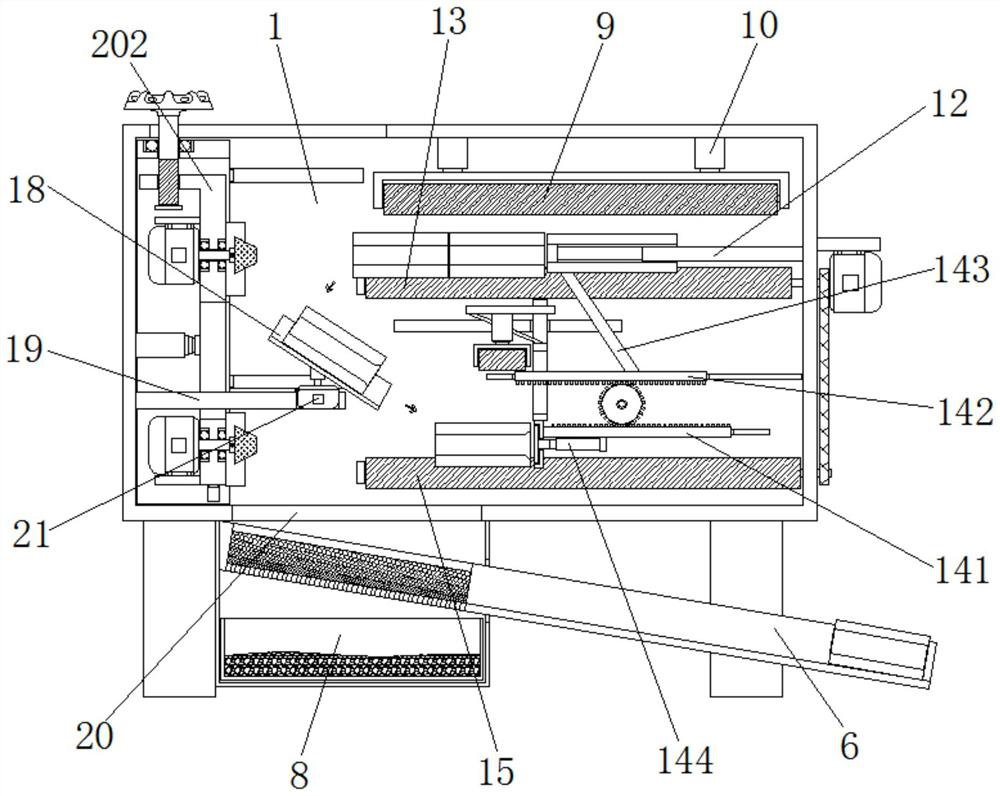

Precise chamfering device for flat plate processing

InactiveCN108068217AConvenient chamferingWorking accessoriesMetal working apparatusWater sprayFlat panel

The invention discloses a precise chamfering device for flat plate processing. The precise chamfering device comprises a device body, wherein the device body consists of a box body arranged at one side of the device body, a drawer arranged at one side of the box body and a pull ring arranged at one side of the drawer, wherein the drawer and the box body move through the pull ring. According to theprecise chamfering device for flat plate processing disclosed by the invention, parameters can be set and regulated through a display screen according to a to-be-chamfered size; a gear and a fixed rack drive a movable processing shaft to move; an up-down shifter arranged at one side of the processing shaft can move up and down; a rotary disc can rotate to replace a chamfering knife arranged inside a knife placing box; a water spray tube fixed through a fixing plate can spray out certain water in use to cool a processed flat plate part; and a Y2-90L-4 electric motor can conveniently rotate tocut and chamfer at certain angle.

Owner:安徽携行信息科技有限公司

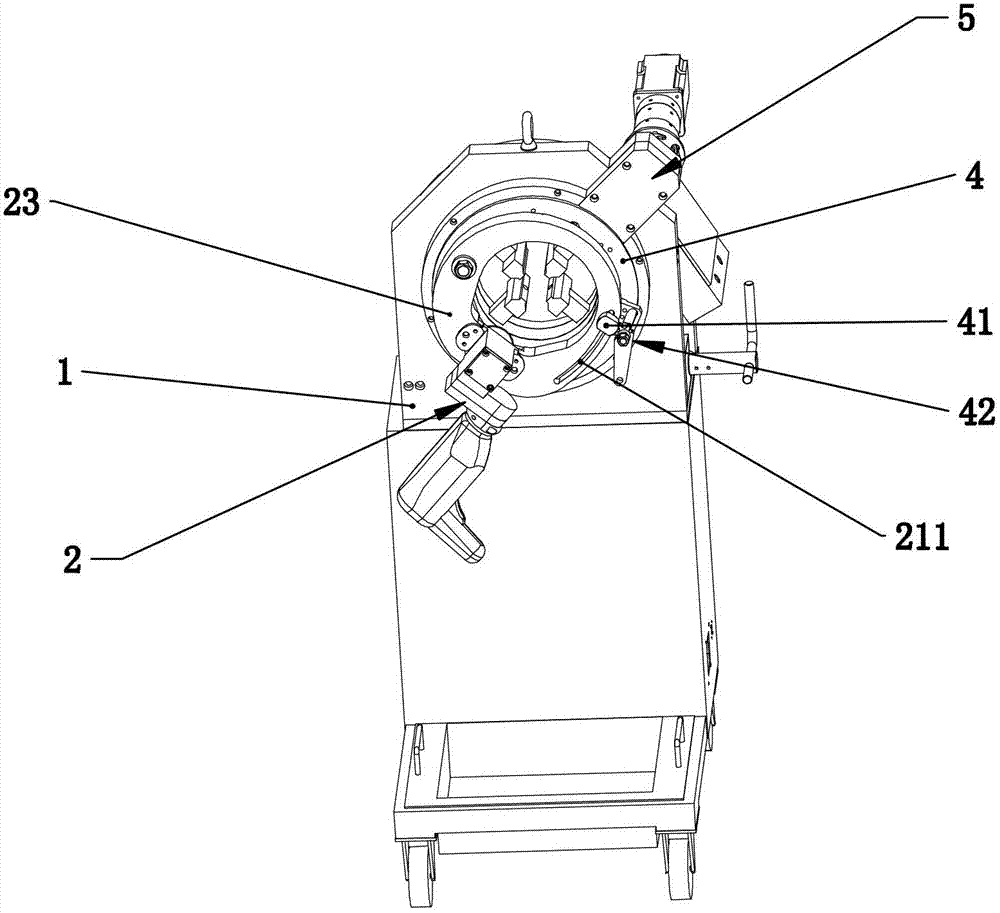

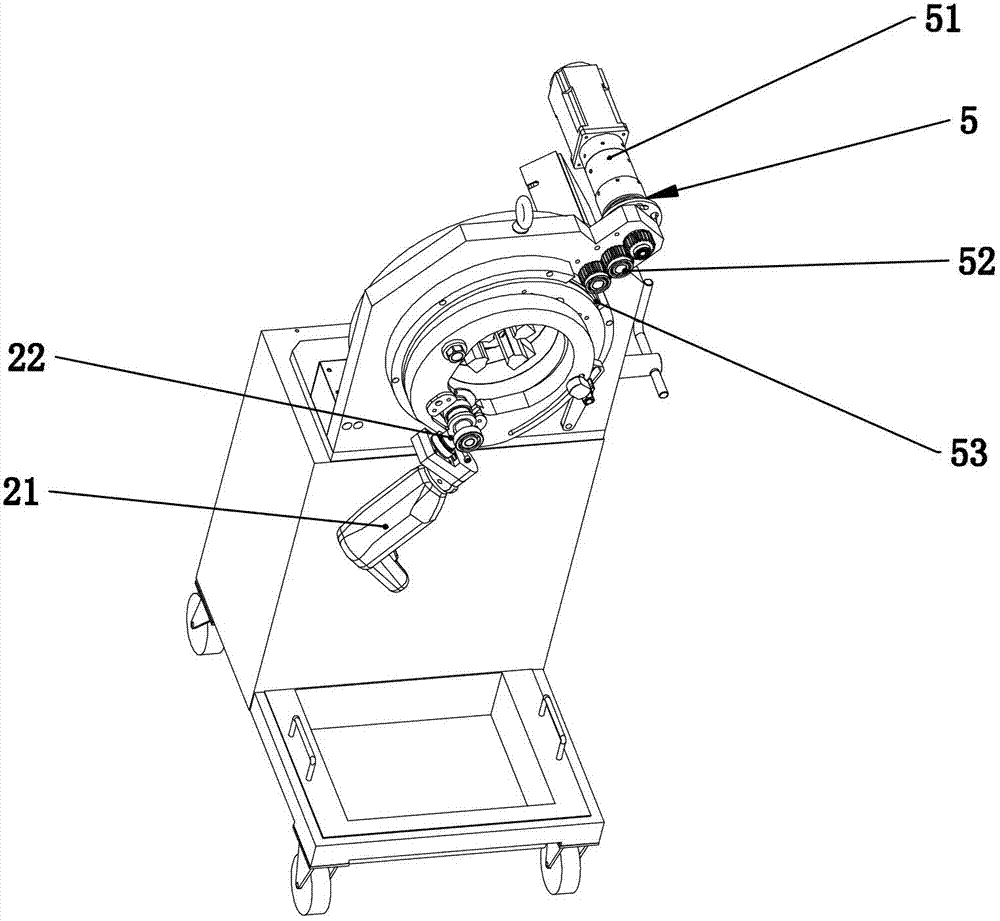

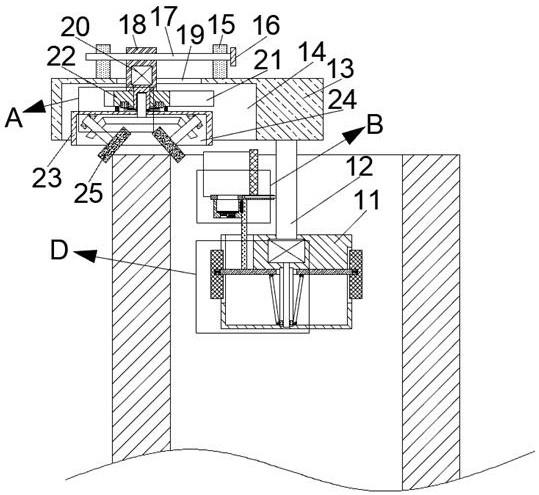

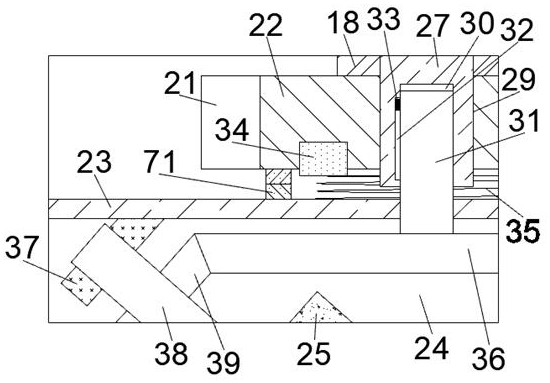

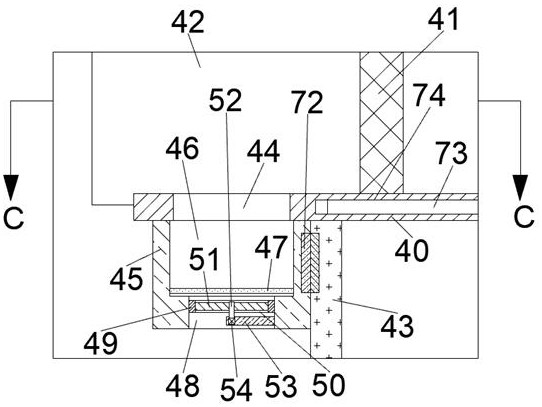

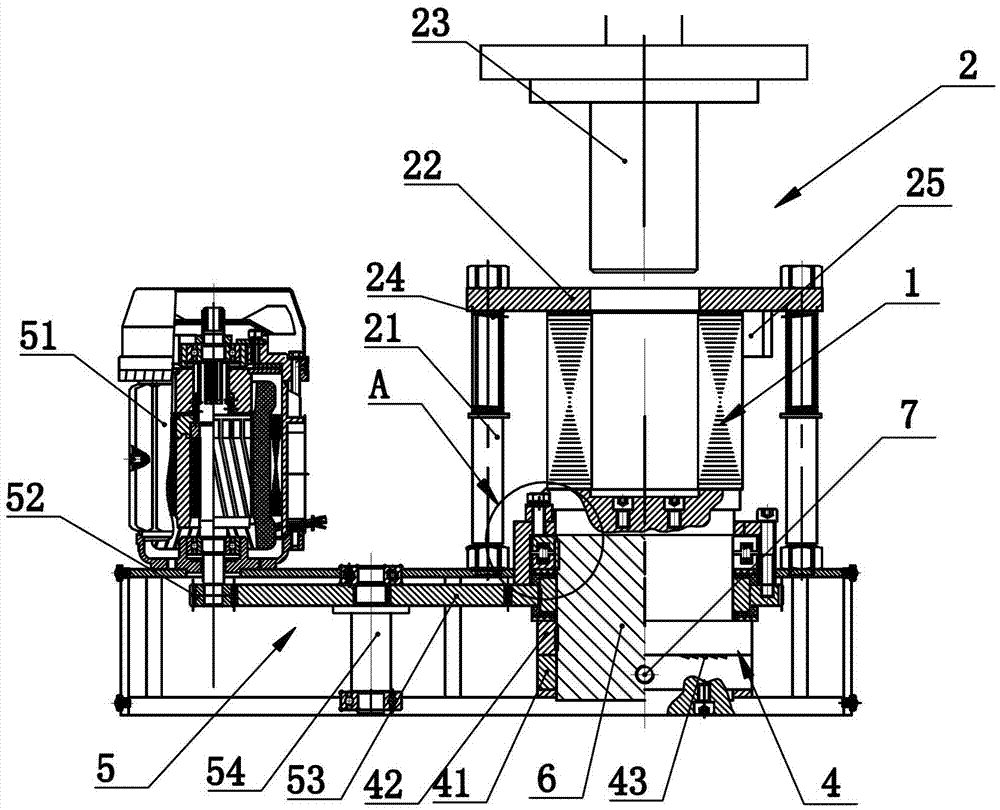

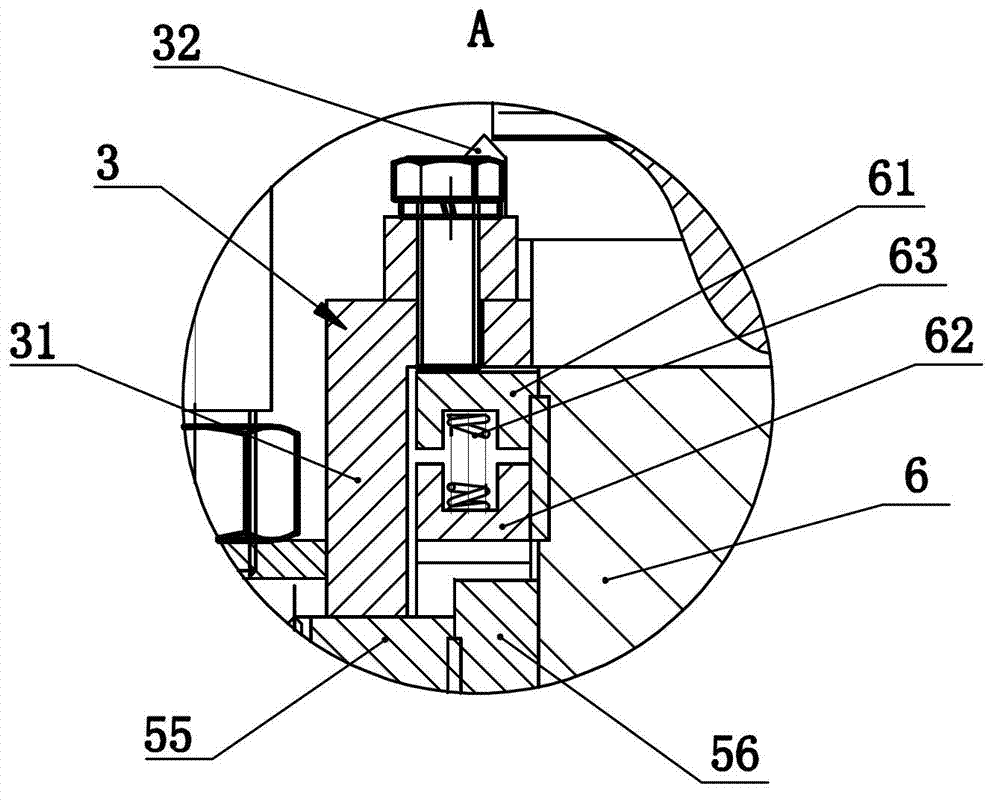

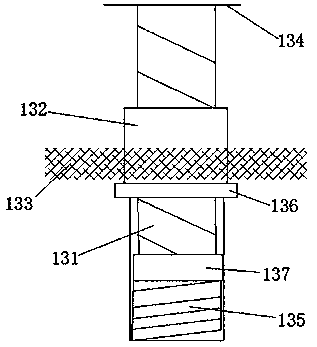

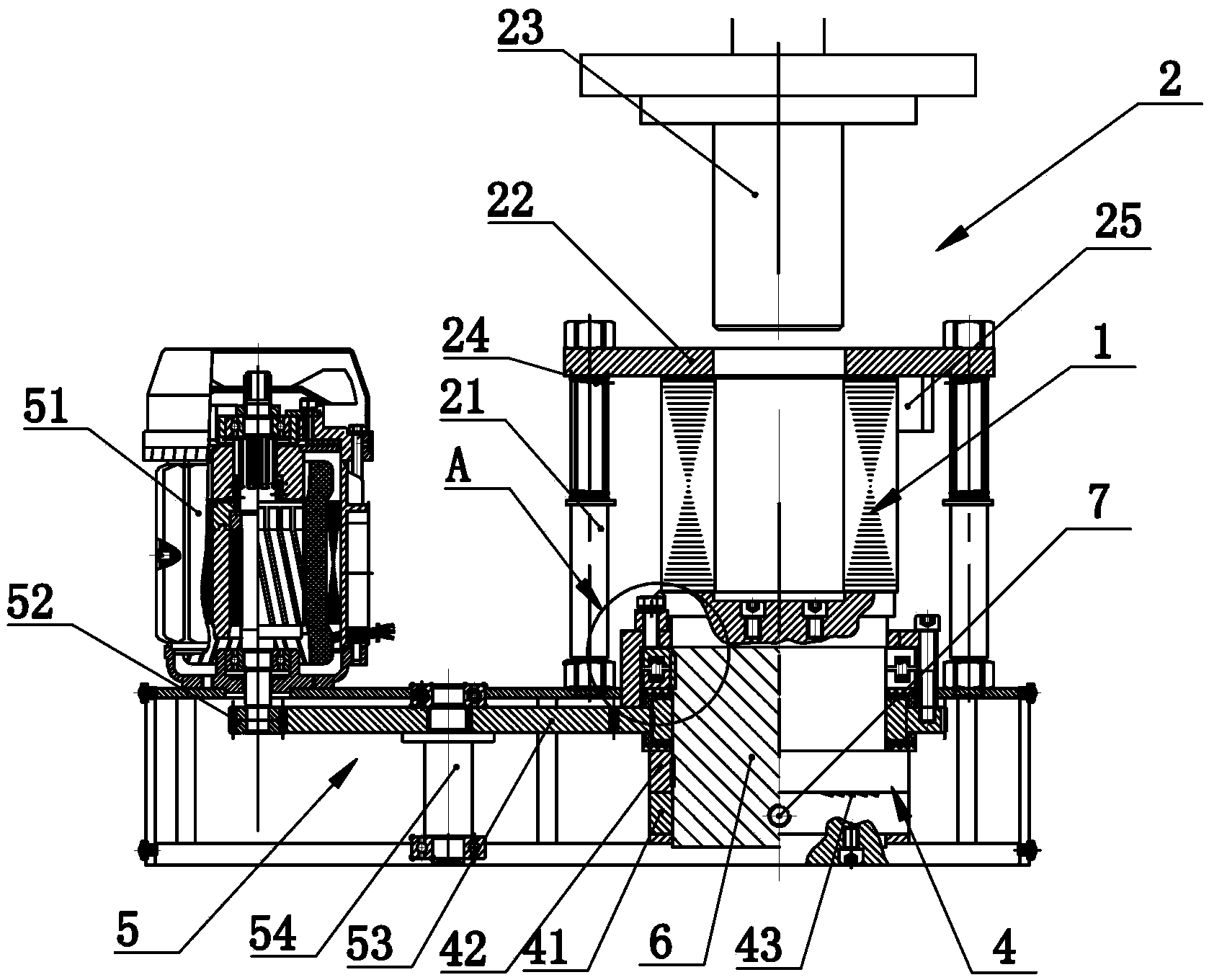

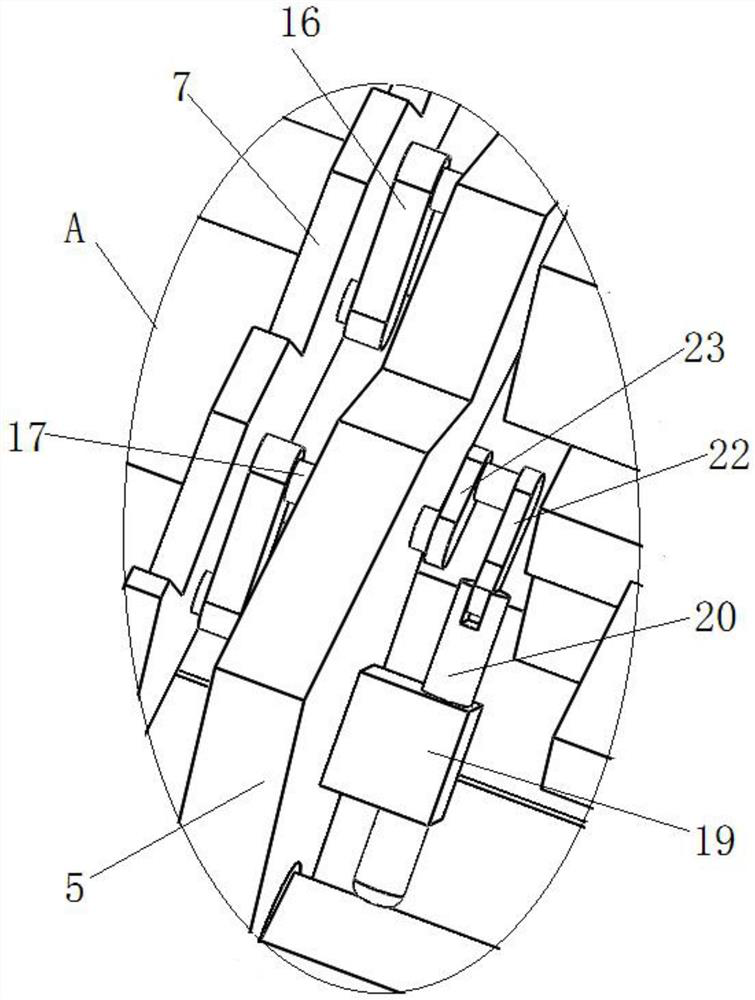

Self-buckled special chamfering device for stator core

ActiveCN102868260AImprove processing efficiencyReduce manufacturing costManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to a self-buckled special chamfering device for a stator core, which comprises a pressing mechanism for pressing both ends of the stator core, a chamfering cutter component, a displacement driving mechanism for driving the chamfering cutter component to move close to or away from the excircle position at one end of the stator core, and a rotary driving mechanism for driving the chamfering cutter component to rotate around the excircle at one end of the stator core to chamfer the excircle at the end of the stator core. The technical scheme of the invention has the effects of improving the machining efficiency and lowering the production cost.

Owner:ZHEJIANG KAIXUN MECHANICAL & ELECTRICAL

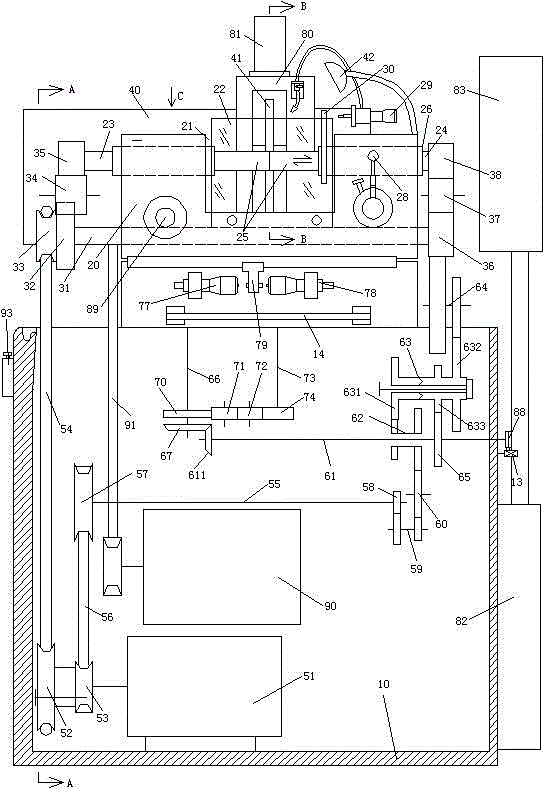

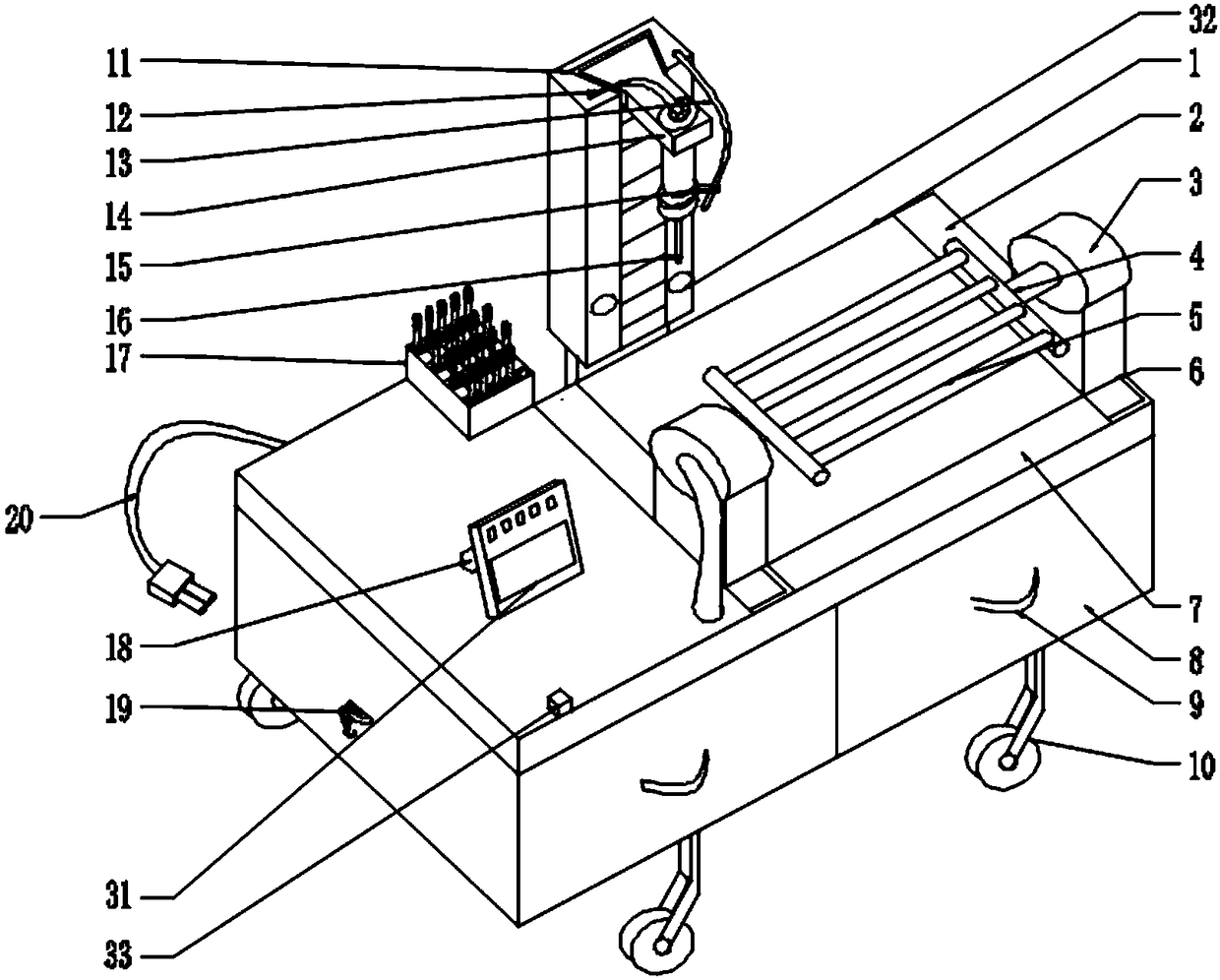

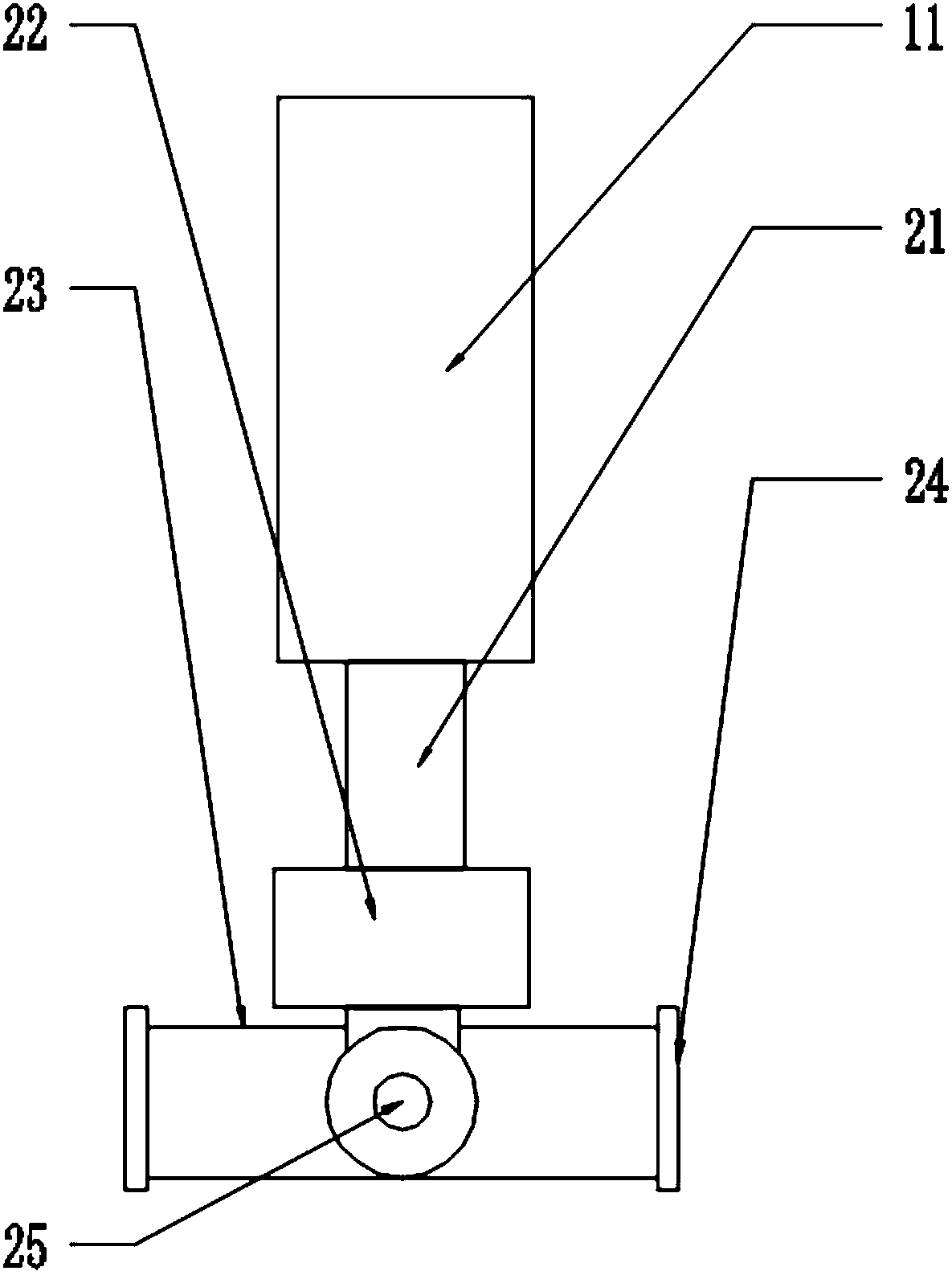

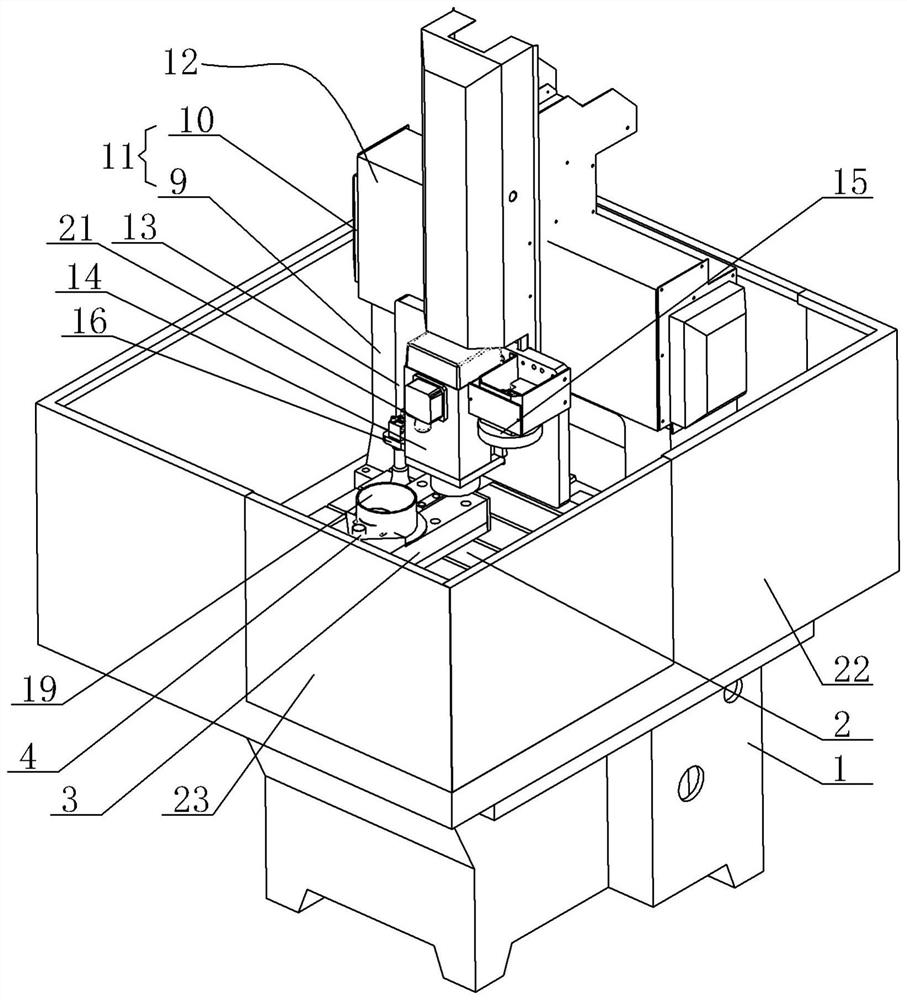

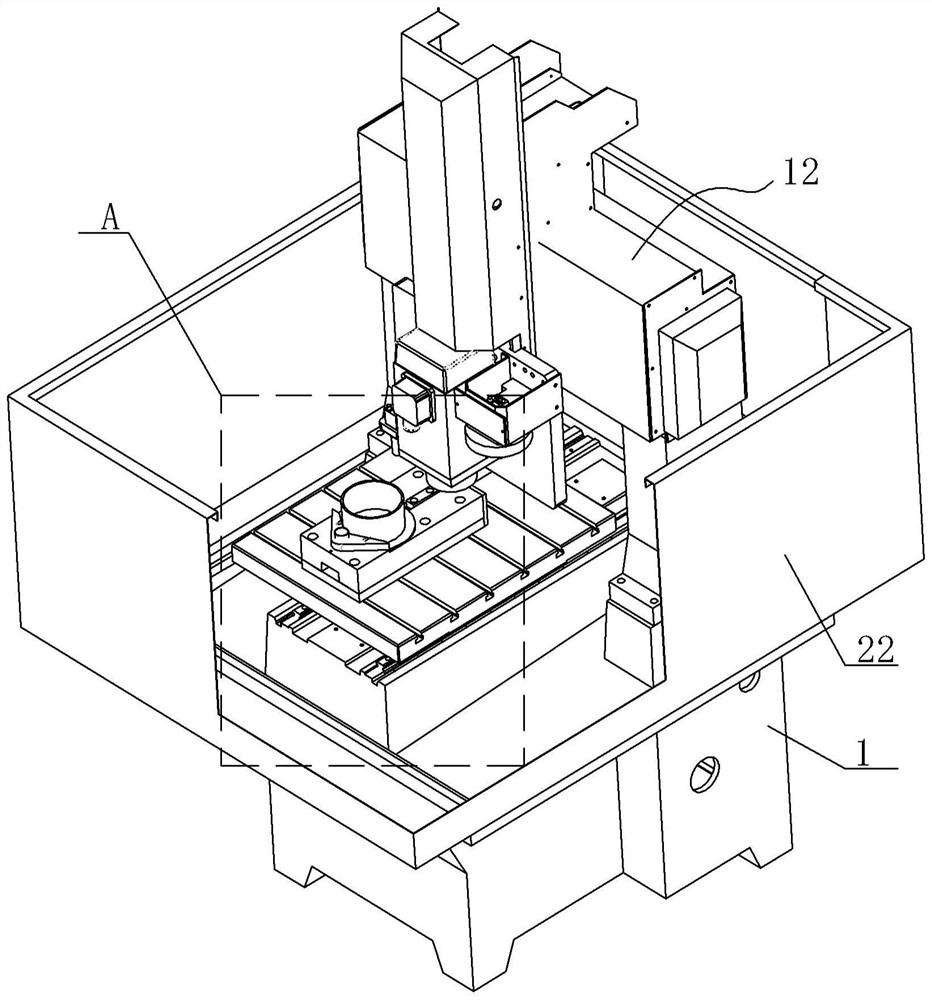

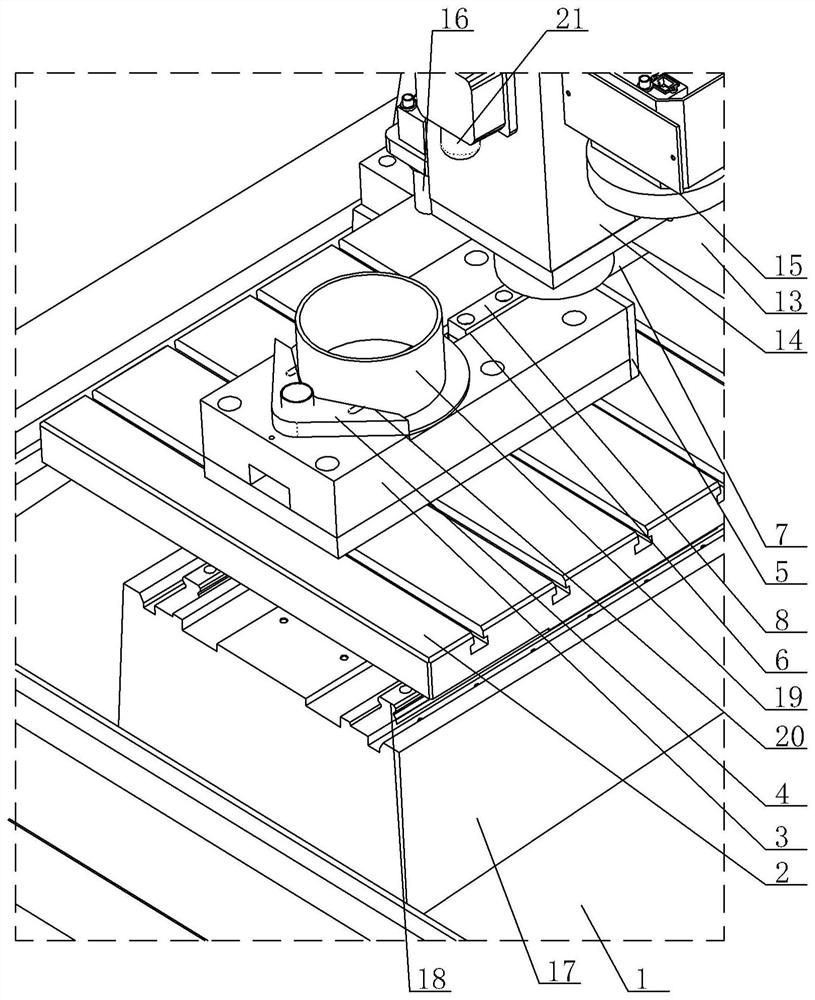

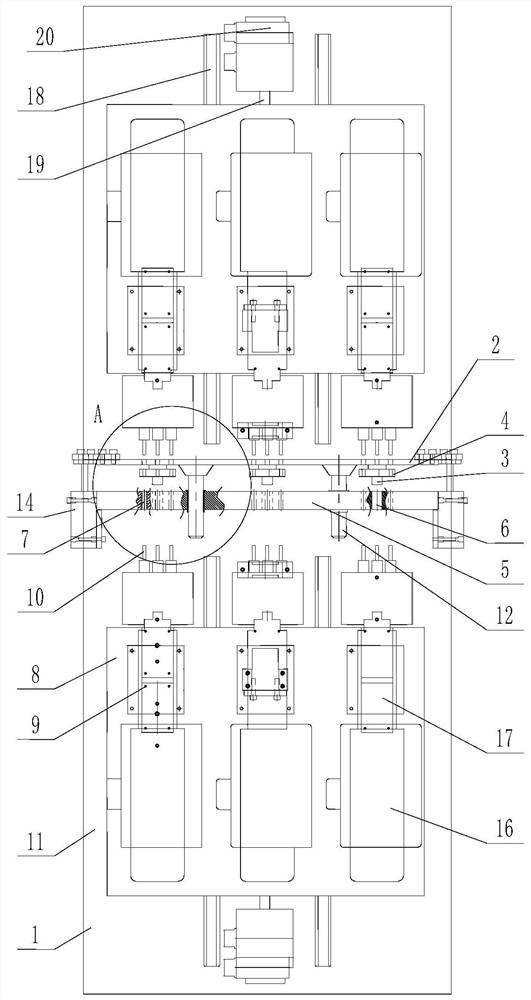

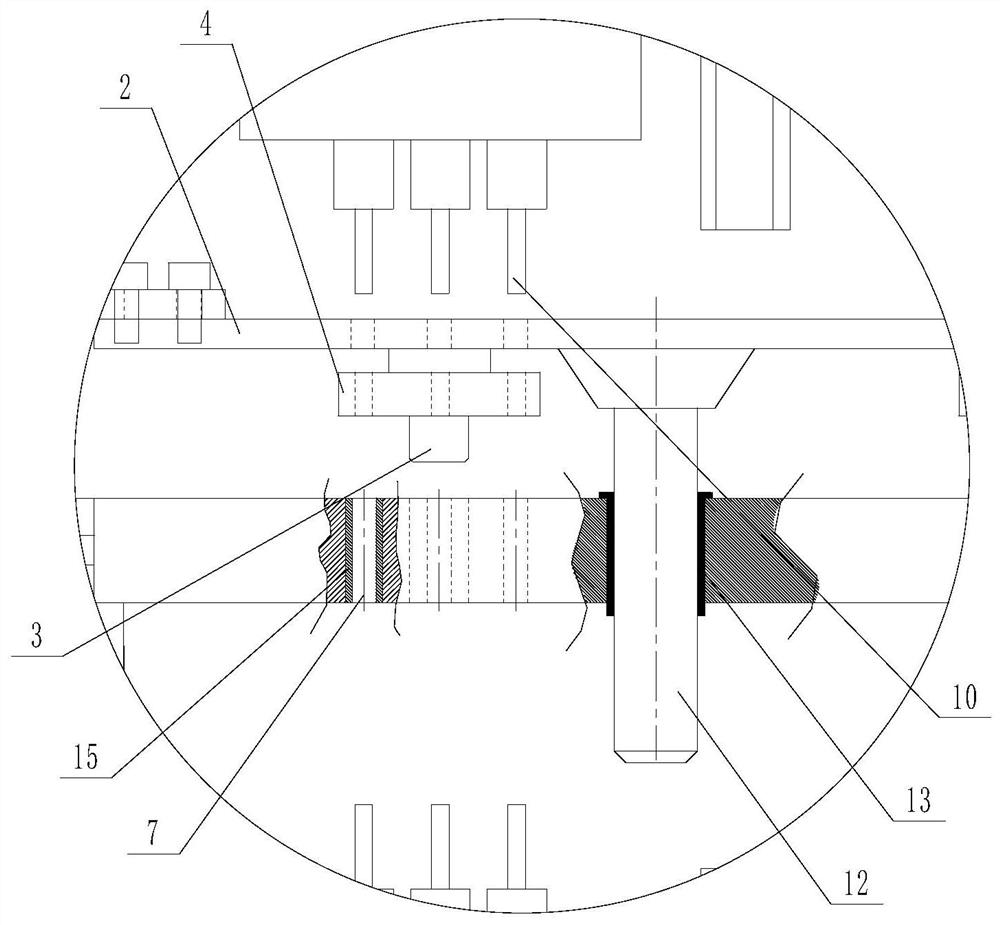

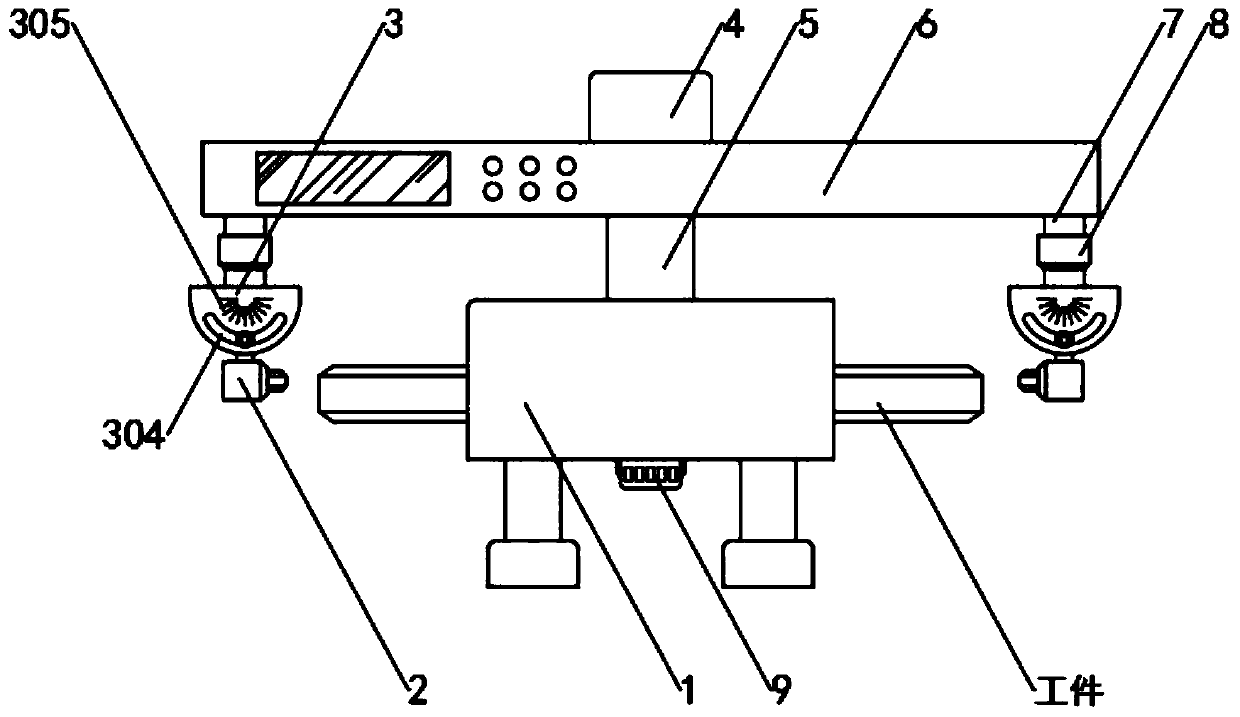

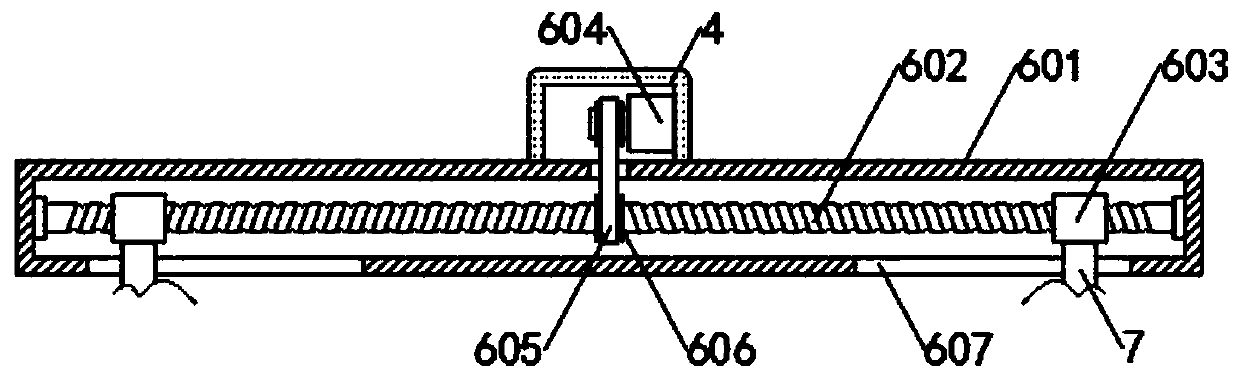

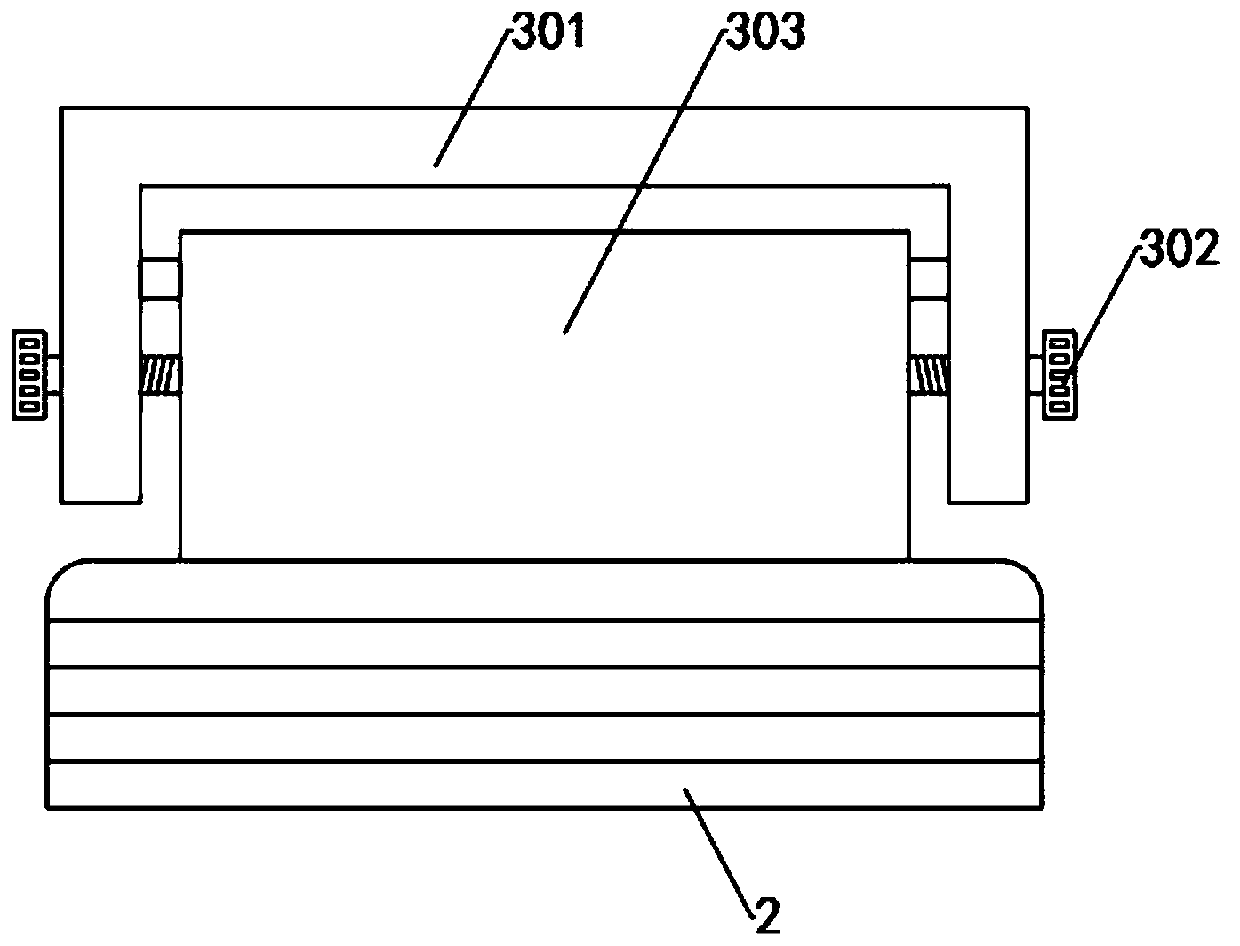

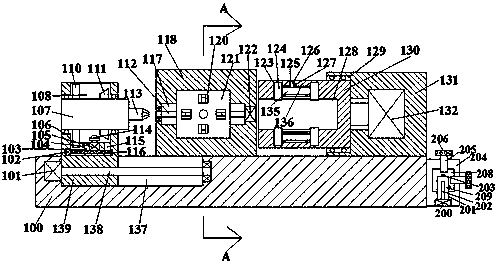

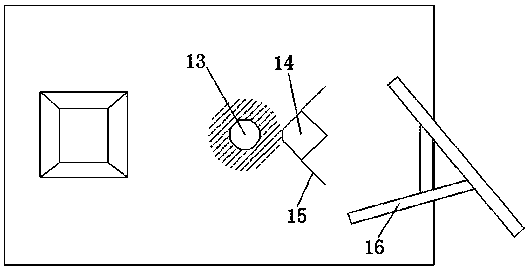

Disc part flexible chamfering machine based on machine vision

PendingCN111843570AReduce labor costsPrecise positioningAutomatic control devicesMeasurement/indication equipmentsMachine visionMachine

The invention provides a disc part flexible chamfering machine based on machine vision. According to the disc part flexible chamfering machine based on machine vision, after a workpiece is placed in acorresponding area of a workbench, the whole equipment automatically finishes recognition and positioning of an end surface hole of the workpiece, and then finishes chamfering of the hole; and the chamfering is fast and convenient, the labor cost is saved for enterprises, and the product quality is improved. The disc part flexible chamfering machine based on machine vision comprises a base; a machining platform is arranged in a central area, in the width direction, of the upper surface of the base; a backlight source module is fixedly mounted at the front part of the upper surface of the machining platform; a tooling locating plate is fixedly arranged at the front end of the upper surface of the backlight source module; a cylinder mounting plate is fixedly arranged on the rear end surfaceof the backlight source module; a concave guide groove is formed in the central position, in the width direction, of a rear section area of the backlight source module; a pressing cylinder is fixedlymounted on the cylinder mounting plate; a piston pressing head of the pressing cylinder is placed in the concave guide groove; and one part of the piston pressing head is convex upwards on the uppersurface of the backlight source module.

Owner:苏州麻雀智能科技有限公司

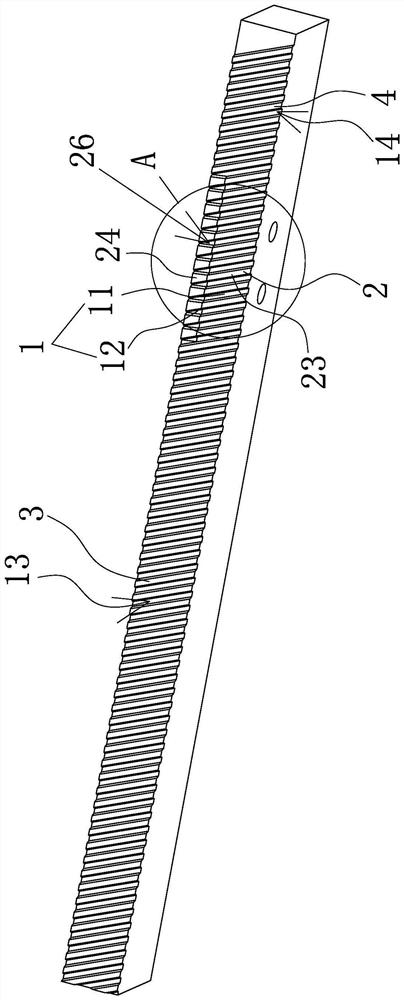

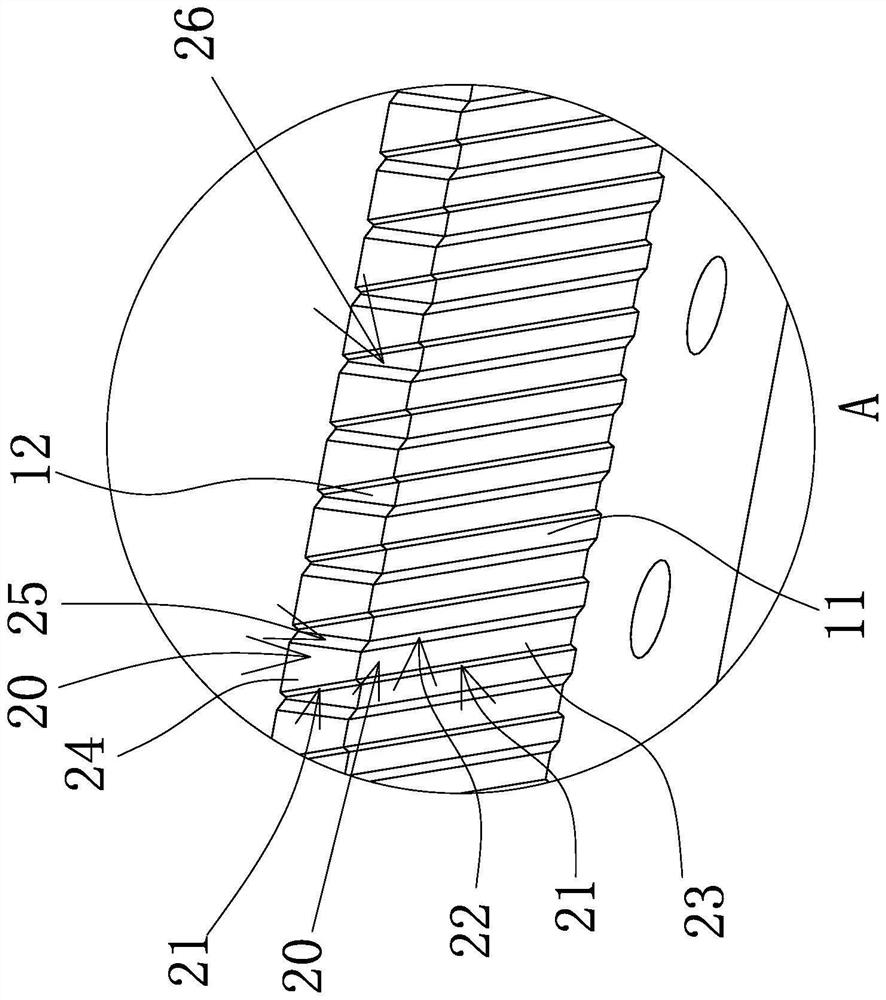

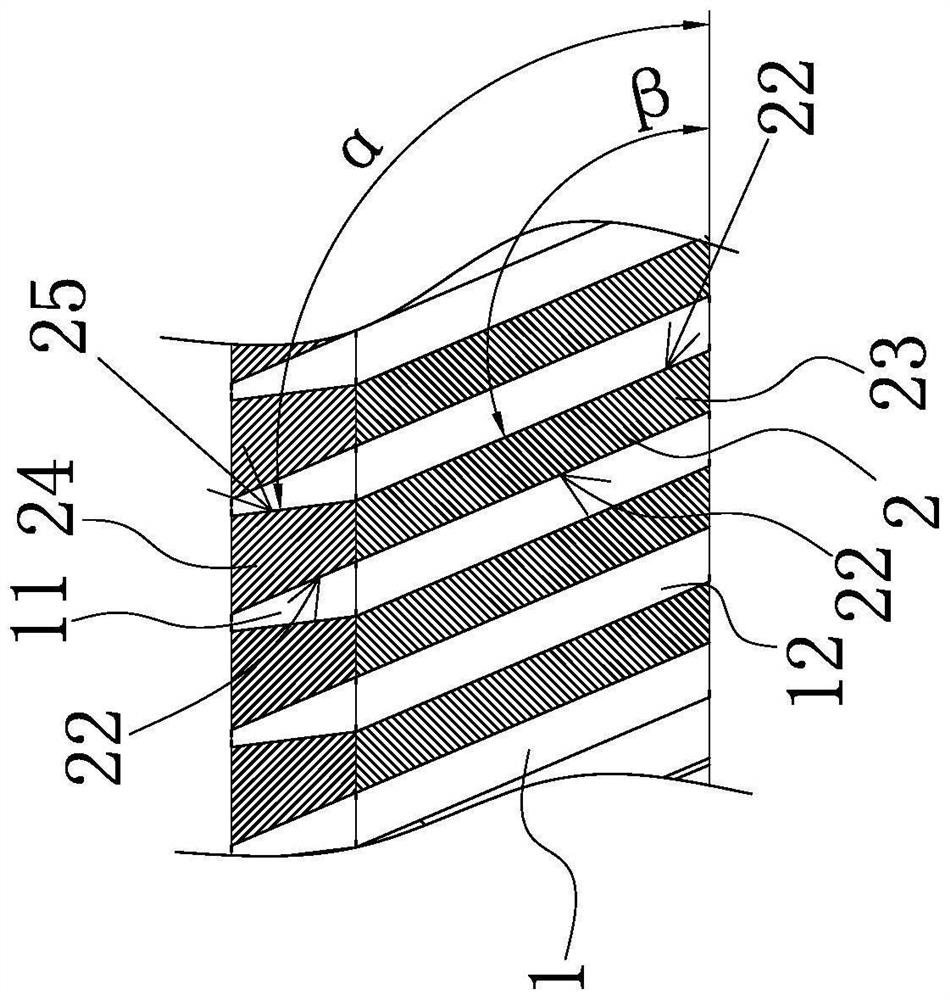

Planet wheel thread rolling plate and thread rolling process thereof

The invention provides a planet wheel thread rolling plate and a thread rolling process thereof, and belongs to the technical field of cold stamping machining. The problem that chamfering is very difficult to machine on a rack on an existing planet wheel is solved. The thread rolling plate comprises a body, a plurality of thread rolling racks which are obliquely arranged at uniform intervals are arranged on the body, each thread rolling rack is provided with a top face, a forward rack face and a reverse rack face, an inclined face intersecting with the reverse rack face is arranged on the side, located on the reverse rack face, of each thread rolling rack, the inclined direction of the inclined faces is the same as that of the reverse rack faces, and the included angles alpha between the inclined faces and the side surfaces where the long edges of the body are located are less than the included angles beta between the reverse rack faces and the side surfaces where the long edges of the body is located, after thread rolling, uniform rack grooves are formed in the periphery of a blank planet wheel of the thread rolling racks, and the inclined surface forms an arc-shaped chamfer surface on the groove wall on one side of each rack groove. By means of the design, chamfering machining on the planet gear rack is very convenient.

Owner:YUHUAN PUTIAN UNIDIRECTIONAL DEVICE CO LTD

Gear drilling and chamfering integrated device

PendingCN111702495AGuaranteed uptimeHigh precisionOther manufacturing equipments/toolsMovement controlDrill hole

The invention discloses a gear drilling and chamfering integrated device. The gear drilling and chamfering integrated device comprises a frame body, wherein a positioning plate which is arranged in the transverse direction is fixedly arranged in the longitudinal middle of the upper end of the frame body; a mandrel which is arranged outwards is fixedly connected to the surface of one side of the positioning plate; a gear to be machined can be arranged on the mandrel in a sleeving mode and can be matched with the mandrel; the end face of the gear is attached to and supported on the side face ofthe positioning plate; a clamping plate is arranged on the outer end face of the mandrel in a spaced mode; the clamping plate and the positioning plate are arranged in parallel; an inserting hole allowing the mandrel to be inserted therein is formed in the position, corresponding to the mandrel, of the clamping plate; a clamping plate longitudinal movement control mechanism is arranged between theclamping plate and the positioning plate and is used for driving the clamping plate to move longitudinally, so that the outer end of the mandrel is inserted into the inserting hole, and the clampingplate abuts against and is supported on the outer end face of the gear so as to clamp the gear; and a plurality of pairs of guide holes which are formed at intervals in the circumferential direction of the gear are formed in the positioning plate and the clamping plate in pairs in the left-right direction. The gear drilling and chamfering integrated device has the advantages that drilling and chamfering of the gear can be completed more conveniently, the machining efficiency can be improved, and the working intensity can be reduced.

Owner:重庆赛之源齿轮制造有限公司

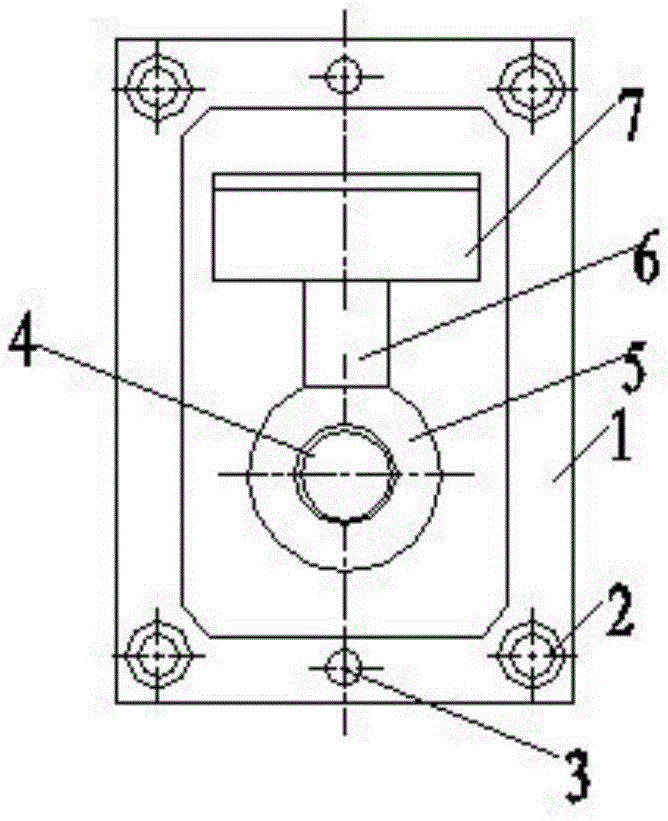

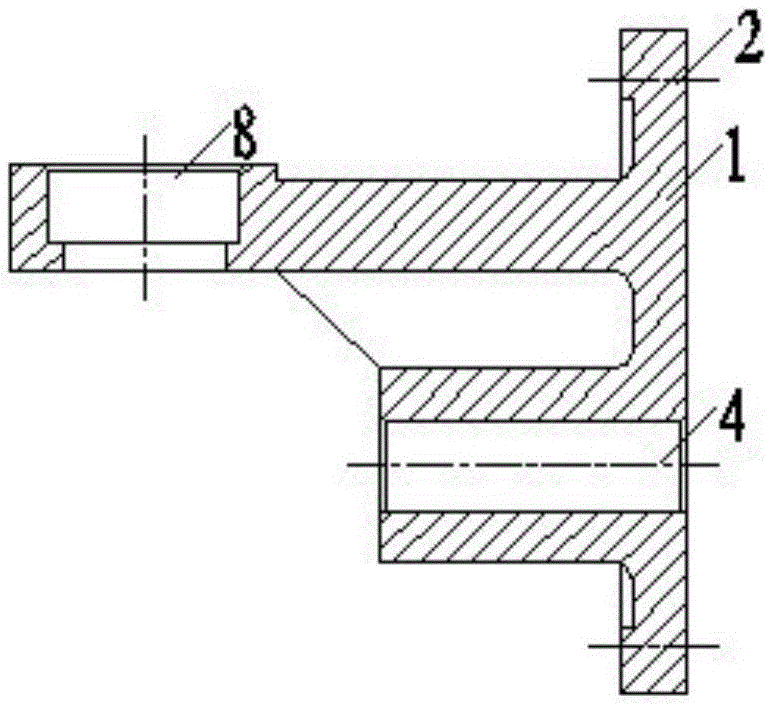

Milling and drilling machine fixing seat

InactiveCN106808217ANot easy to damageHigh strengthLarge fixed membersAgricultural engineeringMachine tool

The invention discloses a milling and drilling machine fixing seat, which belongs to the technical field of mechanical device design, and comprises a fixing plate, cylindrical holes, a locating hole, a horizontal axle hole, a horizontal axle seat, a rib plate, a vertical axle seat and a vertical axle hole. The fixing plate is a rectangular solid thin plate; the cylindrical holes are processed on four corners of the fixing plate; the fixing plate is fixedly connected with a mechanical tool column by adopting inner hexagon screws; the horizontal axle seat and the vertical axle seat are vertically arranged on the front side face of the fixing plate; the horizontal axle seat is a cylinder; the horizontal axle hole is drilled in the horizontal axle seat; an axle line of the horizontal axle hole is located in a horizontal direction; the vertical axle seat is formed by combining a rectangular solid thin plate and a semi-cylindrical thin plate; the vertical axle hole is drilled at the combination part of the rectangular solid thin plate and the semi-cylindrical thin plate; an axial line of the vertical axle hole is vertical. The milling and drilling machine fixing seat disclosed by the invention has high support strength and good safety, the parts is not easy to damage and accurate to locate, the fixing plate is fixed reliably, and the strength of the horizontal axle seat and the vertical axle seat is high.

Owner:安徽鸿远机电科技有限公司

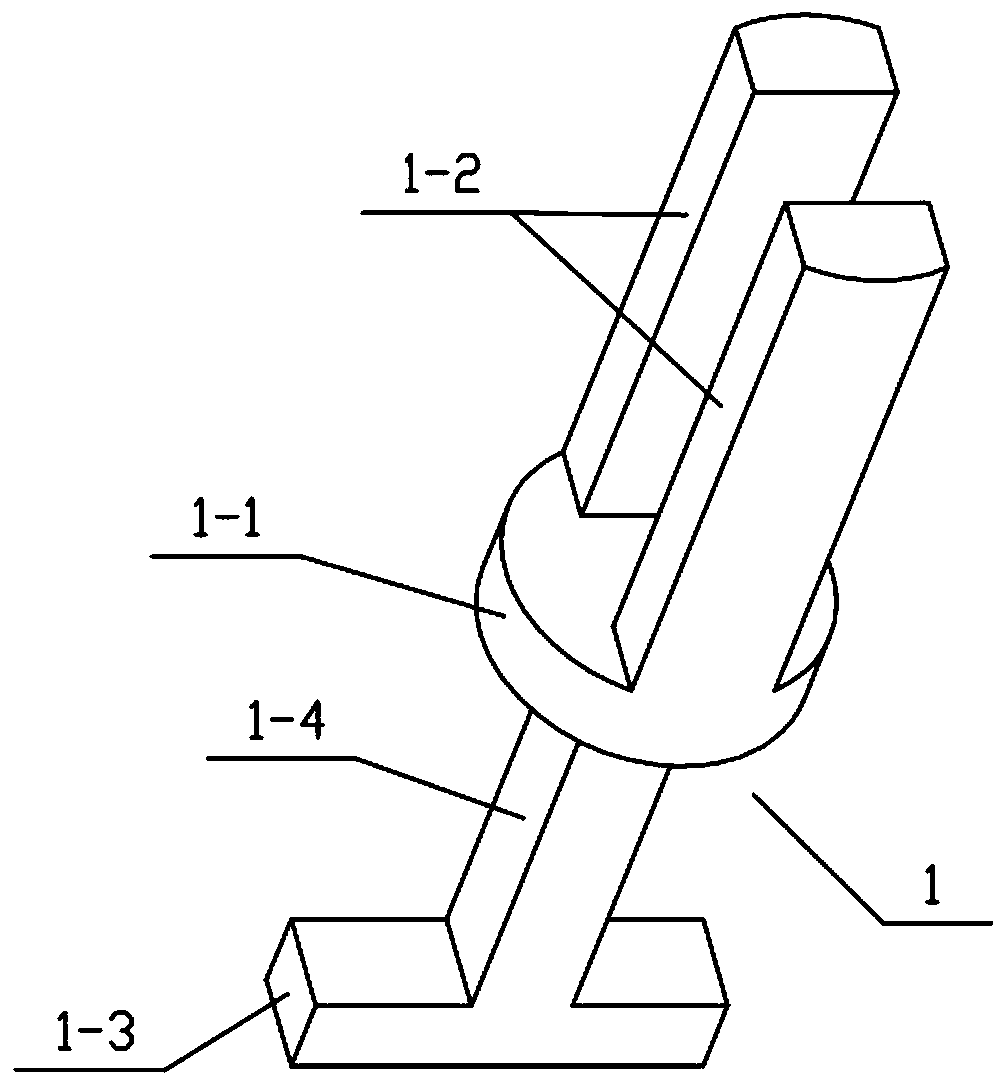

A ceramic inner hole grinding device

ActiveCN109366271BConvenient chamferingAchieve grindingGrinding machine componentsRevolution surface grinding machinesMachiningMaterials science

The invention relates to ceramic machining tools, in particular to a ceramic inner hole grinding and polishing device. Inclinations of two arc grinding pieces can be adjusted, and therefore a ceramicinner hole can be conveniently chamfered; when a hole needs to be ground, only the two arc grinding pieces can be adjusted to be horizontal, the interval between the upper ends and the interval between the lower ends of the two arc grinding pieces can be adjusted, and ceramic inner holes of different diameters can be ground and chamfered. The middle end and the left and right ends of a bottom telescopic frame are in sliding connection with a frame body, the middle of a grinding mechanism is in sliding connection to the frame body, the left end and the right end of the grinding mechanism are inhinged connection with the left end and the right end of the bottom telescopic frame, an upper frame is fixedly connected to the upper end of the frame body, two rotary adjusting parts are arranged,and the two rotary adjusting parts are rotatably connected to the upper frame.

Owner:陶伟珍

Chamfering device for disc-shaped workpiece

PendingCN110666612ARealize chamferEasy to useEdge grinding machinesGrinding carriagesCircular discElectric machinery

The invention discloses a chamfering device for a disc-shaped workpiece. The chamfering device comprises an operation table and a grinding mechanism. The operation table is arranged in a square shape.The inner cavity of the operation table is provided with a rotary table which is in transmission connection with an output shaft of a first motor fixed on the lower surface wall of the operation table. According to the invention, through the arrangement of a second motor, a belt pulley, and a belt, a second threaded rod can rotate. During the rotation of the second threaded rod, a second threadedsleeve can enable an adjusting mechanism and the grinding mechanism to move horizontally through a first connecting rod, so that workpieces of different diameters are chamfered. The arrangement of ahydraulic rod allows the adjusting mechanism and the grinding mechanism to move vertically, so that workpieces of different thicknesses are ground. The device has a higher degree of automation, and isconvenient for operators to use.

Owner:湖南恒裕汽车零部件有限公司

Milling tool with multifunctional blade compensation

InactiveCN108747481AEasy maintenanceConvenient positioning and processingFeeding apparatusOther manufacturing equipments/toolsEngineeringMachine tool

The invention discloses a milling tool with multifunctional blade compensation. The milling tool comprises a machine tool, and a power machine body arranged on the top end face of the machine tool; the left end face of the power machine body is internally provided with a circular groove with an opening leftward; the interior of the circular groove is connected to a firmware sleeve in a running fitmanner, and the firmware sleeve extends right and left; the left end of the firmware sleeve extends out of the circular groove; the firmware sleeve is internally provided with a firmware hole with anopening leftward, and the right end face of the firmware sleeve is in power connection with a first motor of which the outside surface is embedded in and fixedly connected to the inner wall of the right end of the circular groove; the circumferential inner wall of the firmware hole is provided with bilaterally symmetrical grooves in a communicating manner, and a ring groove is arranged between the two grooves in the communicating manner; and the top of the ring groove is provided with a first cavity in the communicating manner. The milling tool has the advantages of the simple structure, easyoperation, convenient fixation and chambering, and stable machining.

Owner:邓聪迪

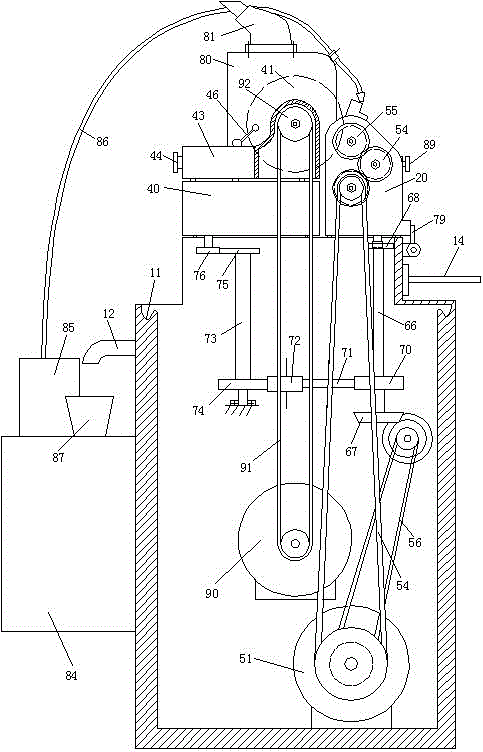

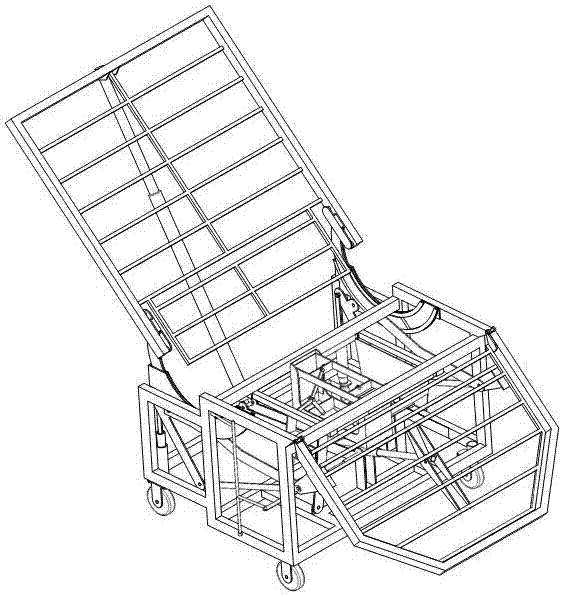

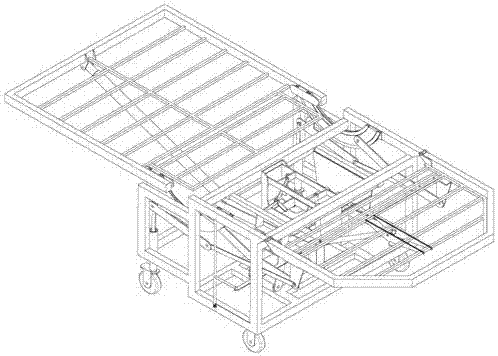

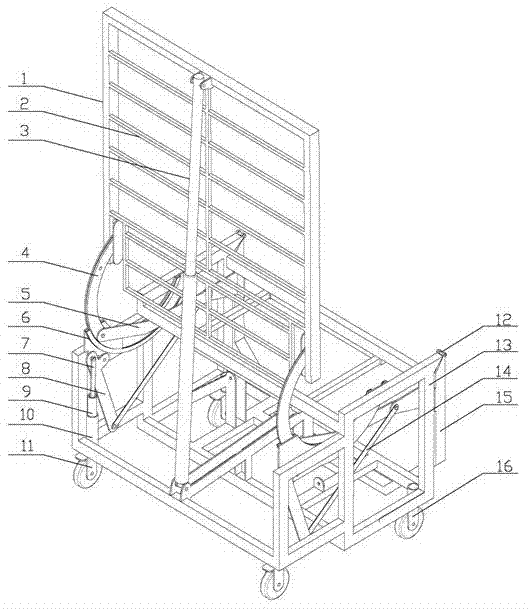

Multifunctional Electric Nursing Bed

ActiveCN105250096BIn line with engineering principlesEliminate oppressionNursing bedsAmbulance serviceEngineeringGravity center

The invention relates to a nursing bed, particularly to a multifunctional electric nursing bed. The multifunctional electric nursing bed comprises a bed frame, a bed board, a bed body pull-up moving mechanism, a vertical lifting convenient mechanism and a lower bed board positioning mechanism, wherein the bed board comprises a seat board, a lower bed board and a back board, the back board moves upwards and backwards during the sitting process and consistent with the movement principle of ergonomics, the pressure of the back board on the back of the human body when people sit up can be completely eliminated, the seat board is inclined downwards towards rear wheels, and the slippage of the human body is effectively prevented; the bed frame comprises an upper bed frame, a main sit frame and a lower bed frame, the upper bed frame drives the back board to sit up by virtue of the bed body pull-up moving mechanism, the lower bed frame is linked to be laid down, the movement amplitude of the gravity center of the bed body is reduced, the distance between the front wheel and the rear wheel is smaller, the lateral width of the bed body at a sit-up state is less than 0.7m, so that the multifunctional electric nursing bed is convenient for entering / exiting from an ordinary room door. The multifunctional electric nursing bed has characteristics of economical performance, practicability, stability and durability, and is not only applicable to large-sized institutions and fields such as hospitals, nursing home and the like, but also suitable for ordinary families to use.

Owner:范天浩

Inner hole automatic chamfering device

Owner:ZHONGSHAN UNIVERSAL ENTERPRISE LTD

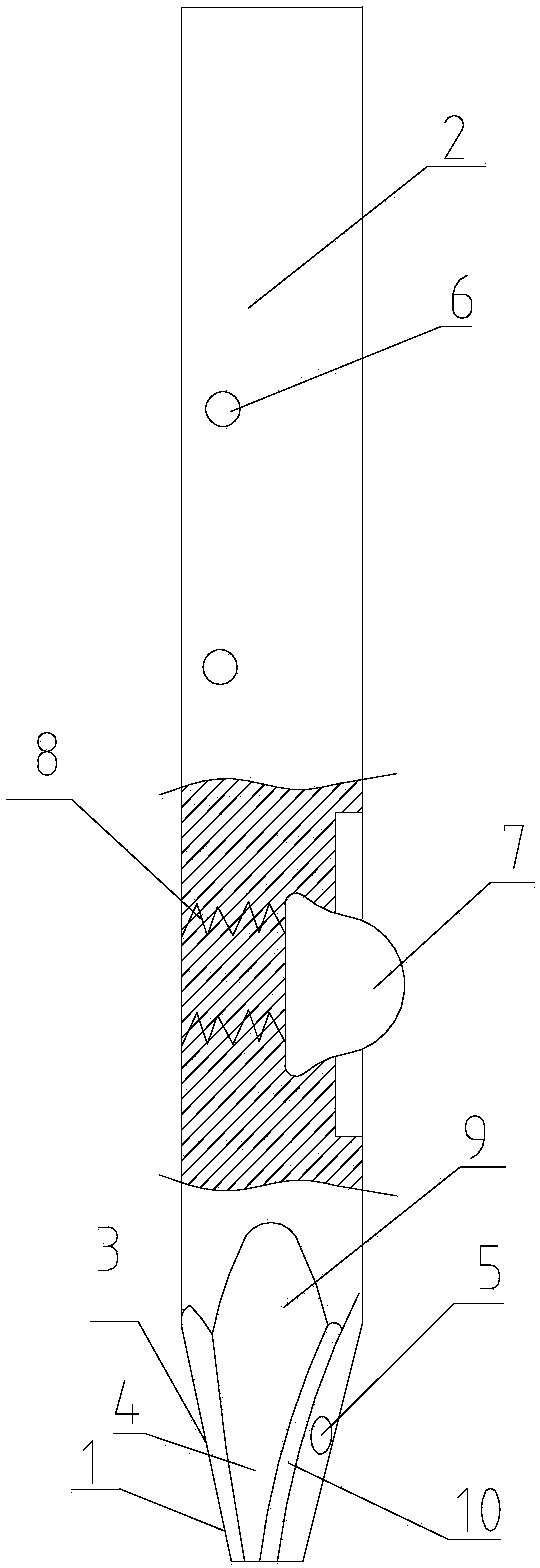

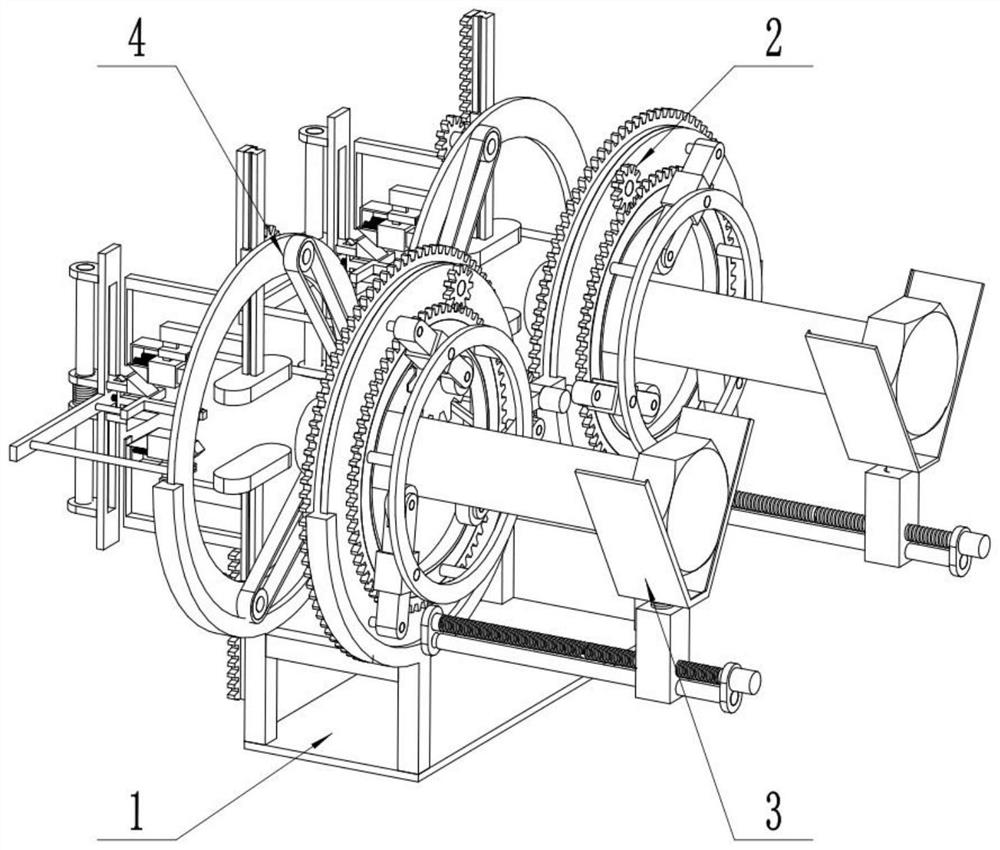

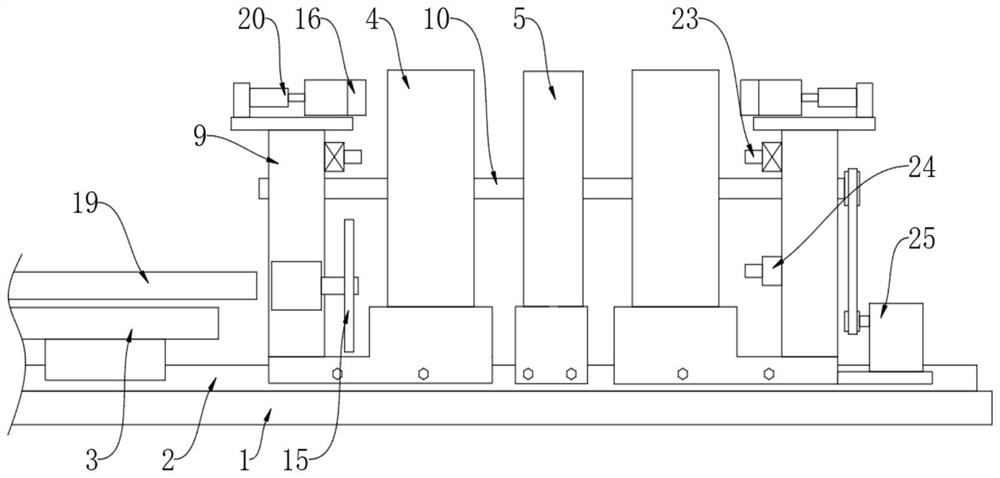

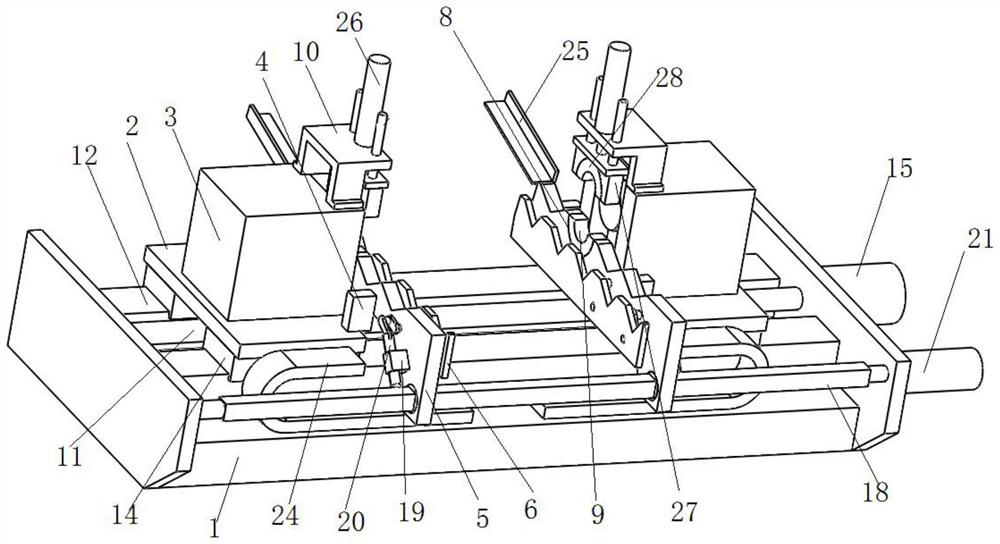

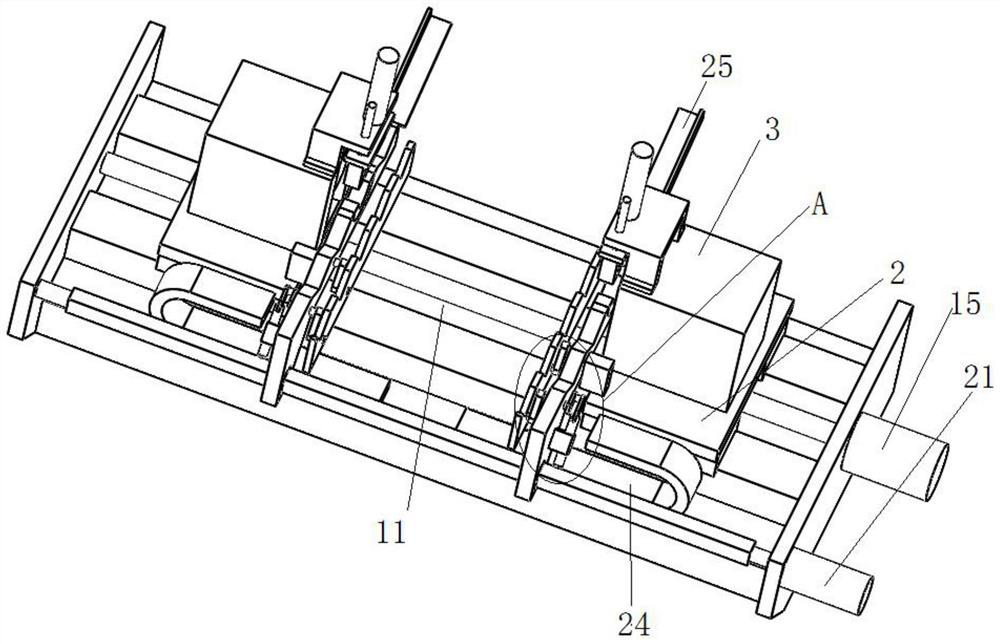

A cutting system for transmission tower production

ActiveCN113997085BImprove work efficiencyEasy to useOther manufacturing equipments/toolsMetal working apparatusTransmission towerTurning frames

The invention discloses a cutting system for power transmission tower production, comprising a base plate, the upper surface of the base plate is provided with a sliding rail, and the surface of the sliding rail is respectively slidably installed with a feeding table, a material turning frame and a material limiting frame. There are two turning frames, which are symmetrically arranged on the left and right sides of the material limiting frame. The material turning frame includes a sliding seat, the upper surface of the sliding seat is fixedly connected with a limiting ring, and a rotating disk is rotatably connected in the limiting ring. The surface of the disc is provided with a V-shaped groove. In this cutting system, by setting the material limit frame and the material turning frame, the angle steel is inserted into the two material turning frames, and the material limit frame can be used to implement the pressing and fixing of the angle steel, and the saw disc cutting machine cuts the angle steel, along with the material. The rotation of the flip frame, the cut angle steel rises, the chamferer chamfers both ends, removes burrs, cuts the angle steel, and then performs chamfering and shaping, which is completed at one time, thereby achieving the effect of improving work efficiency and making it more convenient to use. .

Owner:QINGDAO WUXIAO GRP

High-precision adjustable auxiliary machining equipment for neodymium-iron-boron magnet

ActiveCN114211344ARealize automatic steeringConvenient chamferingEdge grinding machinesGrinding work supportsEngineeringMachining

The high-precision adjustable auxiliary machining equipment comprises a main body bin, first lower mounting rollers are symmetrically arranged in the middle positions of the two sides in the main body bin, and second lower mounting rollers are symmetrically arranged at the bottoms of the ends, close to the first lower mounting rollers, of the two sides in the main body bin; and two groups of second electric lifting rods are mounted at one end, close to the first lower mounting roller, of the top in the main body bin. A servo motor is controlled to drive an arc-shaped material guide plate to rotate by 90 degrees anticlockwise, then a first electric push rod can be controlled to extend, and a material pushing pipe is used for pushing a circular ring neodymium-iron-boron magnet between two groups of first lower mounting rollers to move towards one end close to a fixed plate until the first group of circular ring neodymium-iron-boron magnets are overturned and fall into the arc-shaped material guide plate; and at the moment, the unchamfered ends of the first group of circular neodymium-iron-boron magnets face the second group of polishing heads, so that the automatic direction adjustment of the circular neodymium-iron-boron magnets by the equipment is realized.

Owner:深圳市东方熊磁电制品有限公司

Round hole chamfering device for automobile die

InactiveCN106807978AConvenient chamferingImprove chamfering efficiencyPortable power-driven toolsPortable drilling machinesEngineeringDrill bit

The car mold round hole chamfering device includes a drill bit, a drill handle and a casing. The two ends of the drill handle are respectively connected to the drill bit and the casing. A spiral groove body, the spiral groove body is matched with the sliding sleeve, and a spring is connected to the end of the spiral groove body. The present invention does not require too much cutting force, so it does not need more pneumatic tools for preparation, and can conveniently chamfer the round hole of the automobile mold anytime and anywhere, so that the chamfering efficiency is greatly improved and the cost is also greatly reduced.

Owner:王彩云

Chamfering machine

ActiveCN108422048AEasy to set upConvenient chamferingMaintainance and safety accessoriesMechanical engineering

The invention relates to a chamfering machine. A support base is arranged at one end above a chamfering machine base; a support rack is arranged at the upper end of the support base; a lifting base isarranged at the upper end of the support rack; a balance beam is arranged on the lifting base; a driving device is arranged on the balance beam; a lifting track is arranged on the driving device; anadjusting component is arranged at the lower end of the lifting track; a lifting rod is arranged at the lower end of the adjusting component; a fixing base is arranged at the lower end of the liftingrod; a pressing block and a cutter are arranged on the lower end surface of the fixing base; the other end above the base is an operation platform; a cleaning device and a square spacer are arranged on the operation platform; the cleaning device is positioned right below the pressing block; burr is arranged on the edge below the cleaning device; when being extruded by the pressing block downwards,the cleaning device can rotate to clean chamfering sweeps; limiting plates matched with a chamfered plate are respectively arranged on two sides of chamfering sides of the spacer; the heights of thelimiting plates are greater than that of the spacer. By adopting the chamfering machine, sweeps can be conveniently cleaned, and particularly plate-shaped articles can be conveniently chamfered.

Owner:庐山市环绿时代农业科技开发有限公司

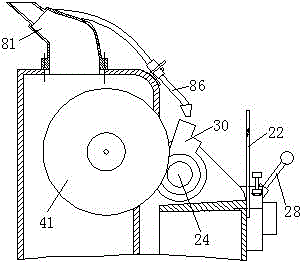

Air floatation circumferential chamfering machine

InactiveCN105834525AConvenient chamferingReduce frictionLarge fixed membersMechanical engineeringBreathing

The invention discloses an air floatation circumferential chamfering machine. The air floatation circumferential chamfering machine comprises a rack, a feed gear and a discharging device, wherein the feed gear and the discharging device are arranged on the rack, the feed gear comprises a cutter bit, a motor, a motor guide plate, a lifting cylinder, a cylinder guide sleeve, a rodless cylinder rod and a guide shaft, a horizontal workpiece placing table is arranged at the upper part of the discharging device, a plurality of ventilation holes are evenly formed in the horizontal workpiece placing table, the discharging device is further provided with an air supply mechanism, and the air supply mechanism supplies air from bottom to top through the ventilation holes. When the chamfering machine chamfers the circumference of a workpiece, the workpiece can be more easily rotated.

Owner:CHUNG CHUN STEEL MOLD MACHINERY IND SUZHOU

Special chamfering device for self-fastening stator core

ActiveCN102868260BImprove processing efficiencyReduce manufacturing costManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to a self-buckled special chamfering device for a stator core, which comprises a pressing mechanism for pressing both ends of the stator core, a chamfering cutter component, a displacement driving mechanism for driving the chamfering cutter component to move close to or away from the excircle position at one end of the stator core, and a rotary driving mechanism for driving the chamfering cutter component to rotate around the excircle at one end of the stator core to chamfer the excircle at the end of the stator core. The technical scheme of the invention has the effects of improving the machining efficiency and lowering the production cost.

Owner:ZHEJIANG KAIXUN MECHANICAL & ELECTRICAL

Plastic pipe chamfering device

The invention discloses a plastic pipe chamfering device which comprises a workbench, sliding tables are symmetrically arranged on the workbench in a sliding mode, a chamfering machine body used for chamfering the two ends of a plastic pipe is fixedly installed on the sliding tables, and a fixing plate used for containing the plastic pipe is fixedly installed on one side of a tool bit of the chamfering machine body through an installation block. The chamfering machine comprises a chamfering machine body, a fixing plate is arranged on the chamfering machine body, a transferring plate used for moving a plastic pipe is rotationally arranged on the fixing plate through a linear reciprocating mechanism, placing grooves are formed in the fixing plate and the transferring plate, a clamping groove is formed in the position, corresponding to a tool bit of the chamfering machine body, of the fixing plate, and a clamping block is detachably installed in the clamping groove through a bolt. A support is fixedly installed at the upper end of the chamfering machine body, and a clamping mechanism corresponding to the clamping block is arranged on the support. The two ends of the plastic pipe can be better chamfered, clamping is stable, the chamfering efficiency is high, and feeding and discharging are convenient and fast.

Owner:重庆益弘防务科技有限公司

Automatic chamfering equipment for building aluminum template sealing plate

InactiveCN113510314APromote sportsEasy clampingWork clamping meansFeeding apparatusStructural engineeringIndustrial engineering

The invention discloses automatic chamfering equipment for a building aluminum template sealing plate. The automatic chamfering equipment comprises a base, a left support, a right support and a clamping mechanism, a plurality of positioning rods are symmetrically fixed on the base, and the clamping mechanism is arranged on the plurality of positioning rods in a sliding manner; a pushing mechanism for pushing the clamping mechanism to move left and right is arranged on the left support, and the left support is arranged on the left side of the upper end of the base; the right support is arranged on the right side of the upper end of the base, and a chamfering mechanism used for chamfering a sealing plate is arranged on the right support; and the clamping mechanism comprises a placing plate, a screw rod and a rotating disc. According to the automatic chamfering equipment for the building aluminum template sealing plate, by arranging the clamping mechanism, the sealing plate can be clamped conveniently, and therefore the sealing plate is prevented from deviating in the chamfering process; by arranging the pushing mechanism, the clamping mechanism can be conveniently driven to move towards the direction of the chamfering mechanism, so that the chamfering degree is conveniently controlled; and by arranging the chamfering mechanism, the sealing plate can be conveniently chamfered.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

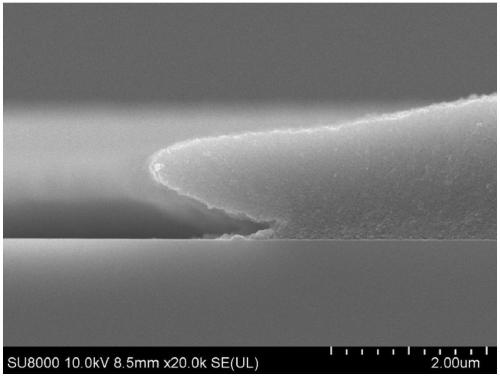

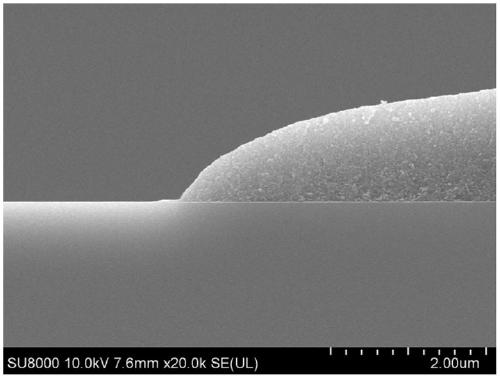

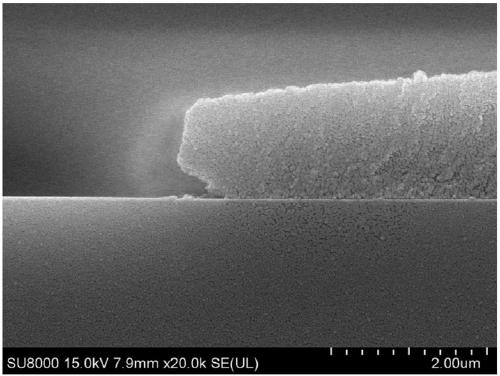

Photosensitive resin composition, application thereof and color filter

PendingCN111324010AIncrease surface enrichment concentrationConvenient angleOptical filtersPhotosensitive materials for photomechanical apparatusPolymer scienceColor gel

The invention provides a photosensitive resin composition, application thereof and a color filter. The photosensitive resin composition comprises a modified photoinitiator, alkali-soluble resin and amonomer, wherein the modified photoinitiator is formed by connecting a benzophenone main group and a hydrogen-containing silicone oil substituent group. The photosensitive resin composition is appliedto the color filter. The color filter comprises the photosensitive resin composition which is subjected to photocuring. According to the photosensitive resin composition provided by the invention, the curing degree of a chamfer formed in an exposure process is relatively high, the chamfer is not easy to be broken by a developing solution, and a slope angle with a proper angle and a smooth surfacecan be obtained.

Owner:GUAN ETERNAL MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com