Disc part flexible chamfering machine based on machine vision

A disk-type parts, machine vision technology, applied in the field of disk-type parts flexible chamfering machine, can solve problems such as danger, lack of flexibility, and different sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

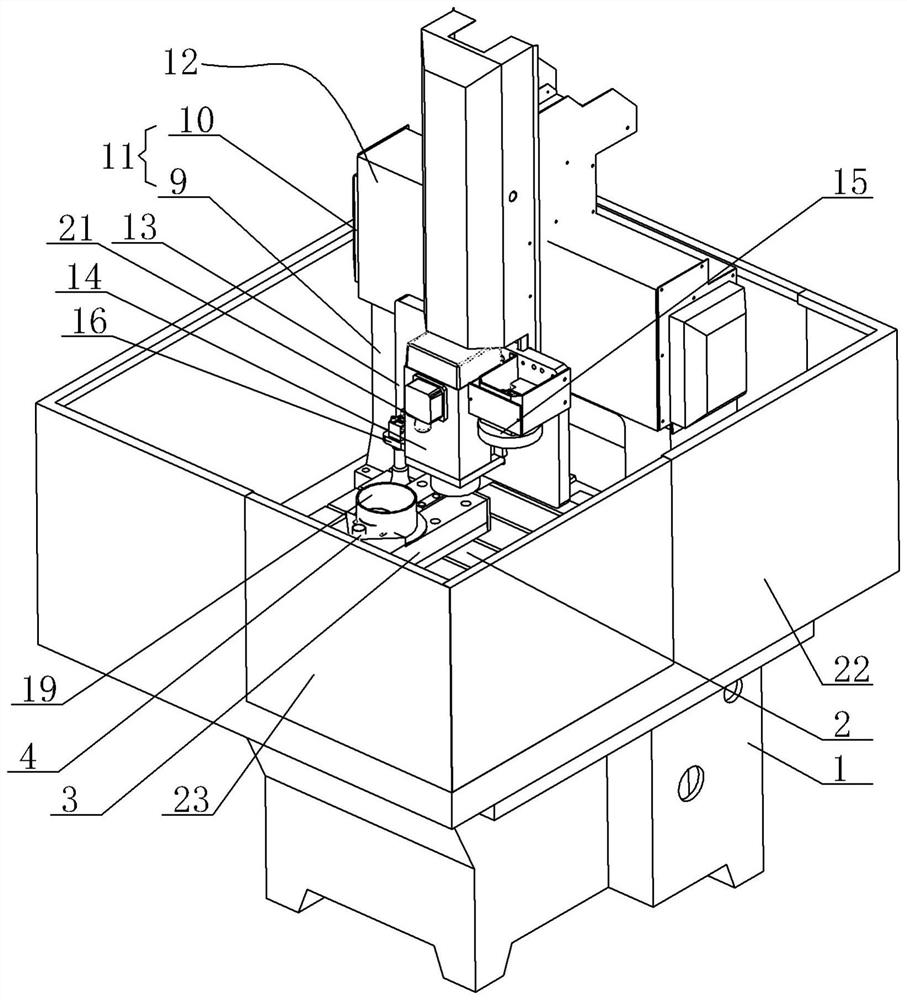

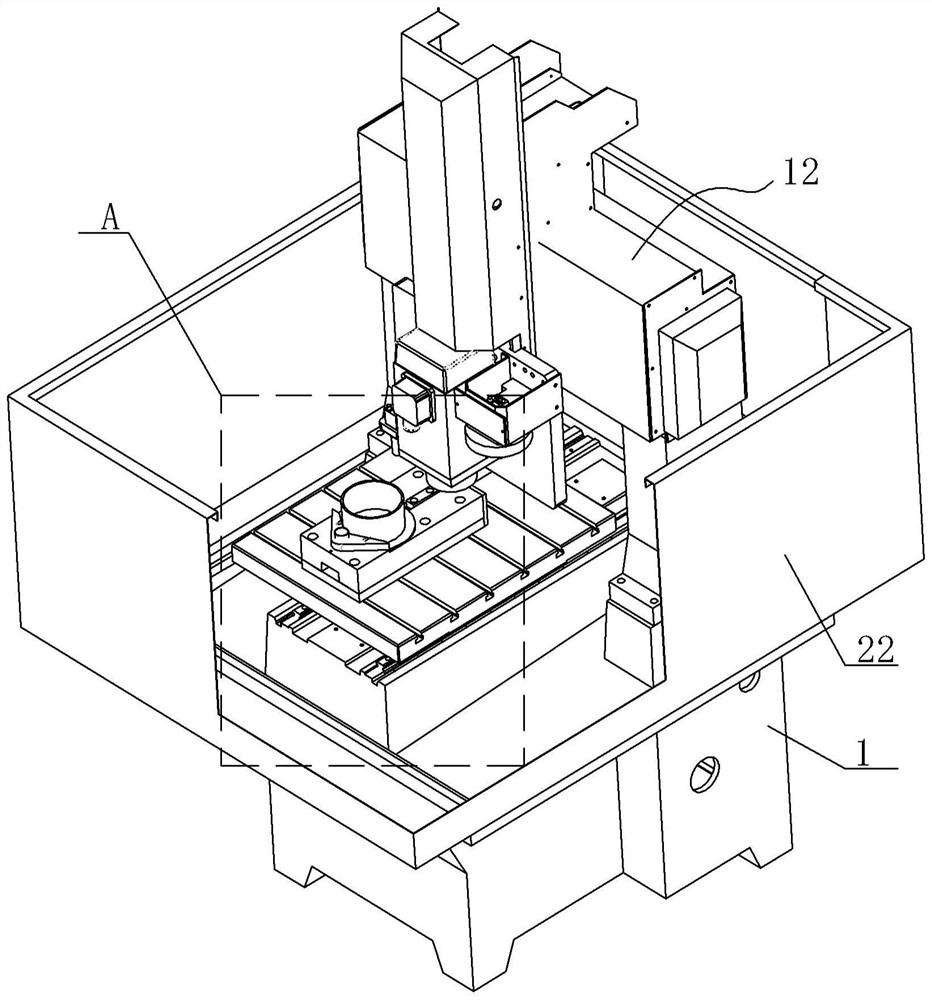

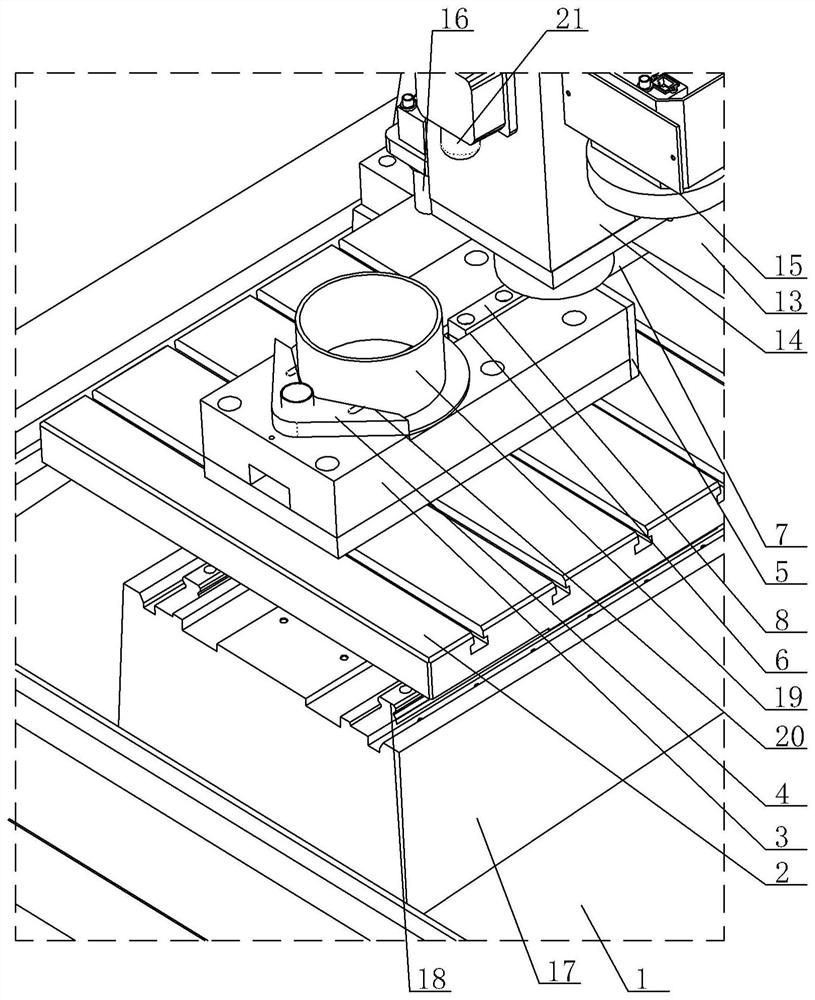

[0021] Flexible chamfering machine for disc parts based on machine vision, see Figure 1-Figure 3 : It includes a base 1, a processing platform 2 is provided in the central area of the upper surface of the base 1 in the width direction, a backlight light source module 3 is fixedly mounted on the front of the upper surface of the processing platform 2, and a front end of the upper surface of the backlight light source module 3 is fixed There is a tool positioning plate 4, a cylinder mounting plate 5 is fixed on the rear surface of the backlight light source module 3, a concave guide groove 6 is provided at the center of the width direction of the rear section of the backlight light source module 3, and the compression cylinder 7 is fixed on The cylinder mounting plate 5, the piston pressing head 8 of the pressing cylinder 7 is placed in the recessed guide groove 6. The piston pressing head 8 protrudes on the upper surface of the backlight light source module 3, and the width di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com