Chamfering device for disc-shaped workpiece

A chamfering device, disk-shaped technology, applied in the direction of machine tools, grinding workpiece supports, grinding drive devices, etc. suitable for grinding the edge of workpieces, can solve the problems of limited use and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

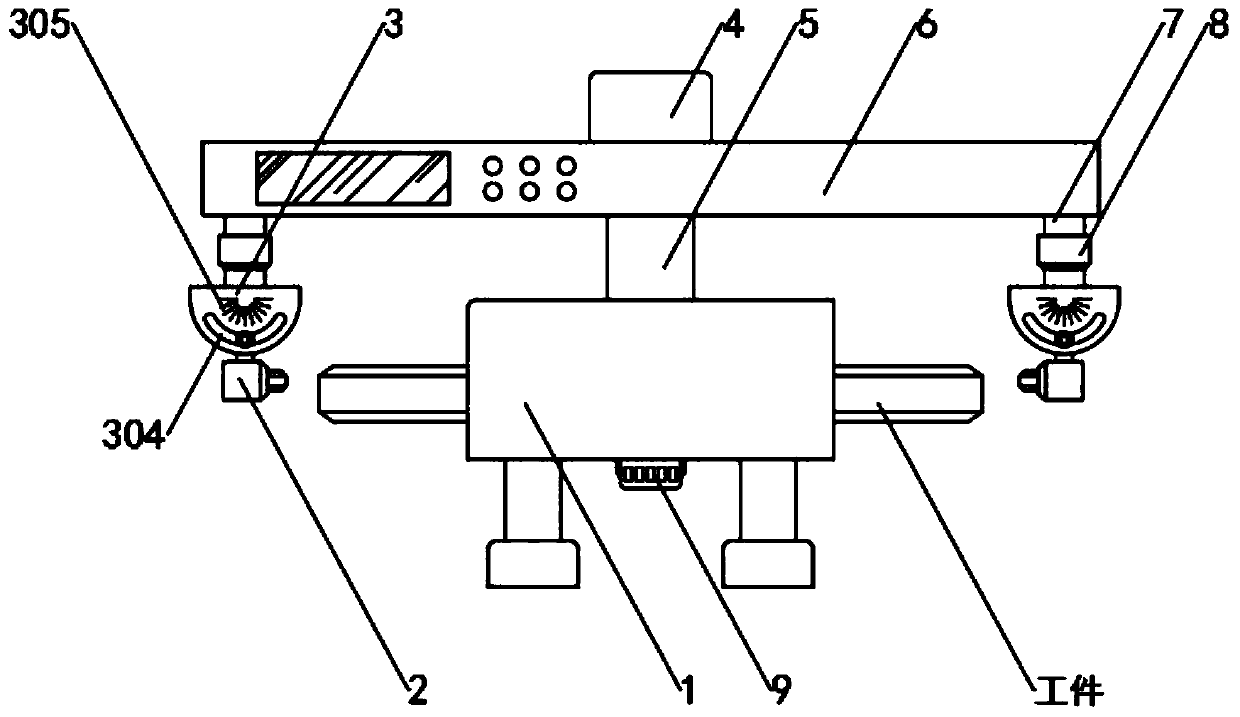

[0035] see Figure 1-5 , a chamfering device for a disc-shaped workpiece, comprising an operating table 1 and a grinding mechanism 2, the operating table 1 is arranged in the shape of a "mouth", the inner cavity of the operating table 1 is provided with a turntable 11, and the rotating table 11 is fixed on the operating table 1 The output shaft of the first motor 9 on the lower table wall is connected by transmission. The output shaft of the first motor 9 can drive the turntable 11 to rotate. The upper position is adjusted. A limit mechanism 5 is provided between the moving mechanism 6 and the console 1. The limit mechanism 5 is used to clamp and fix the workpiece. Both sides of the bottom of the moving mechanism 6 are equipped with a hydraulic rod 8 and an adjusting mechanism. 3 and the grinding mechanism 2, the adjusting mechanism 3 is used to adjust the grinding angle of the grinding mechanism 2 to meet different usage requirements.

Embodiment 2

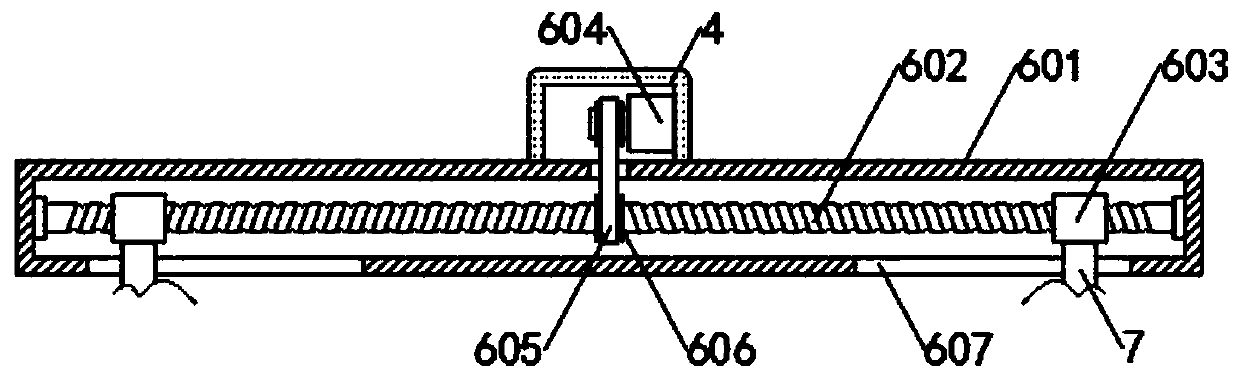

[0037] see figure 1 and Figure 5 , the moving mechanism 6 includes a fixed housing 601, the inner cavity of the fixed housing 601 is provided with a second threaded rod 602 in the horizontal direction, and the second threaded rod 602 is connected to the inner surface walls on both sides of the fixed housing 601 through bearings. , the outside of the second threaded rod 602 is screwed with two second threaded sleeves 603, the second threaded rod 602 is a two-way thread, the two second threaded sleeves 603 are arranged symmetrically about the center of the second threaded rod 602, the second threaded During the rotation of the rod 602, the two second threaded sleeves 603 approach or move away from the center of the second threaded rod 602 at the same time. The lower surface wall of the second threaded sleeve 603 is fixed with the first connecting rod 7, and the first connecting rod 7 The through groove 607 opened through the lower surface wall of the fixed housing 601 extends ...

Embodiment 3

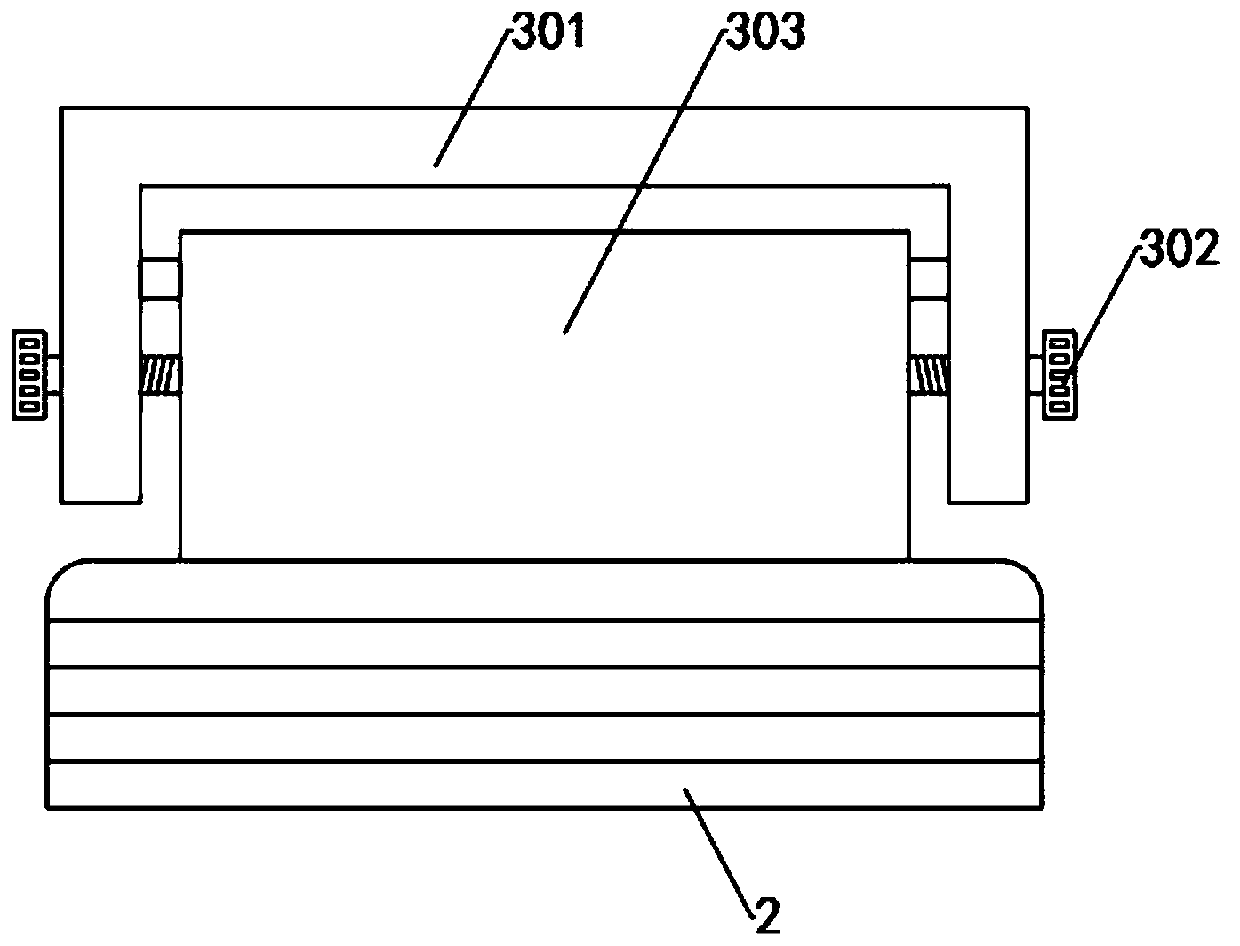

[0039] see figure 1 and image 3 , the adjustment mechanism 3 is arranged between the hydraulic rod 8 and the grinding mechanism 2, the adjustment mechanism 3 includes an inverted U-shaped connecting frame 301, the connecting frame 301 is fixed on the telescopic end of the hydraulic rod 8, and the inner wall of the connecting frame 301 rotates through a rotating shaft. plate 303, the grinding mechanism 2 is fixed on the lower surface wall of the rotating plate 303, the hydraulic rod 8 can drive the connecting frame 301 and the grinding mechanism 2 to move in the vertical direction, and the front and rear end inner walls of the connecting frame 301 are all provided with arc-shaped slides. Groove 304, two chute 304 are all provided with locking bolt 302 and locking bolt 302 and the front and rear surface wall of rotating plate 303 are screwed connection, and locking bolt 302 can slide in the inside of chute 304, and locking bolt The diameter of the end portion of 302 is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com