Carbon beam chamfering machine

A carbon beam chamfering machine and chamfering machine technology, which are applied in the directions of grinding machine parts, machine tools suitable for grinding workpiece edges, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

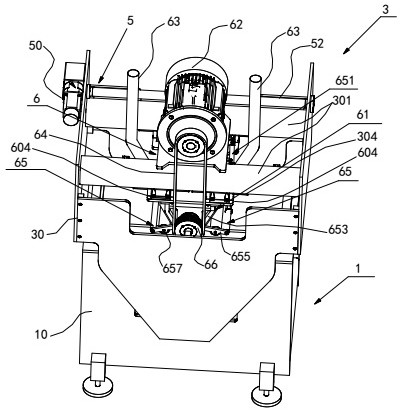

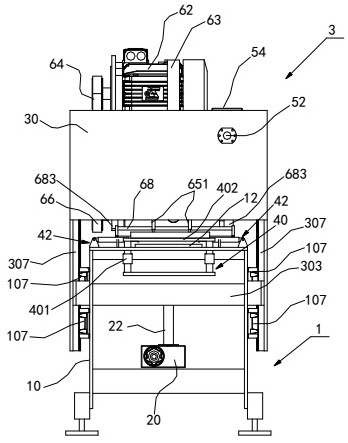

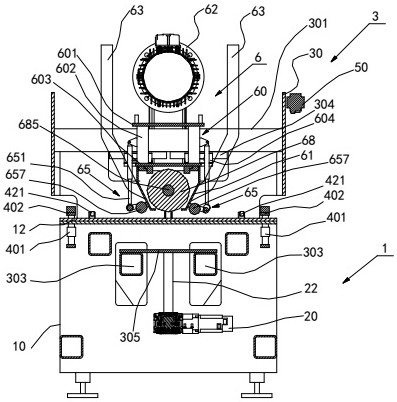

[0036] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0037] Herein, directional representations, such as "upper", "lower", "left", "right", "front", "rear", etc., are used to explain the structure and / or action of various parts of the disclosed embodiments, Not absolute, but relative. These representations are valid when the various parts of the disclosed embodiments are located in the positions shown in the figures, and if the position or frame of reference of the disclosed embodiments is changed, the representations are also changed according to the position or frame of reference of the disclosed embodiments. And change.

[0038] The "carbon beam" referred to in this article is the carbon fiber plate prepared to produce the predetermined length of the wind turbine blade girder. Of course, for different specifications of wind turbine blades, the predetermined length of the carbon fiber plate used to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com