Spherical milling cutter for machining stepped hole chamfer and machining method for machining stepped hole chamfer

The technology of a spherical milling cutter and a processing method, which is applied in the field of automobile parts processing, can solve the problems of high labor intensity, and achieve the effect of reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention provides a spherical milling cutter for processing stepped hole chamfering and a processing method for processing stepped hole chamfering. Detailed description. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

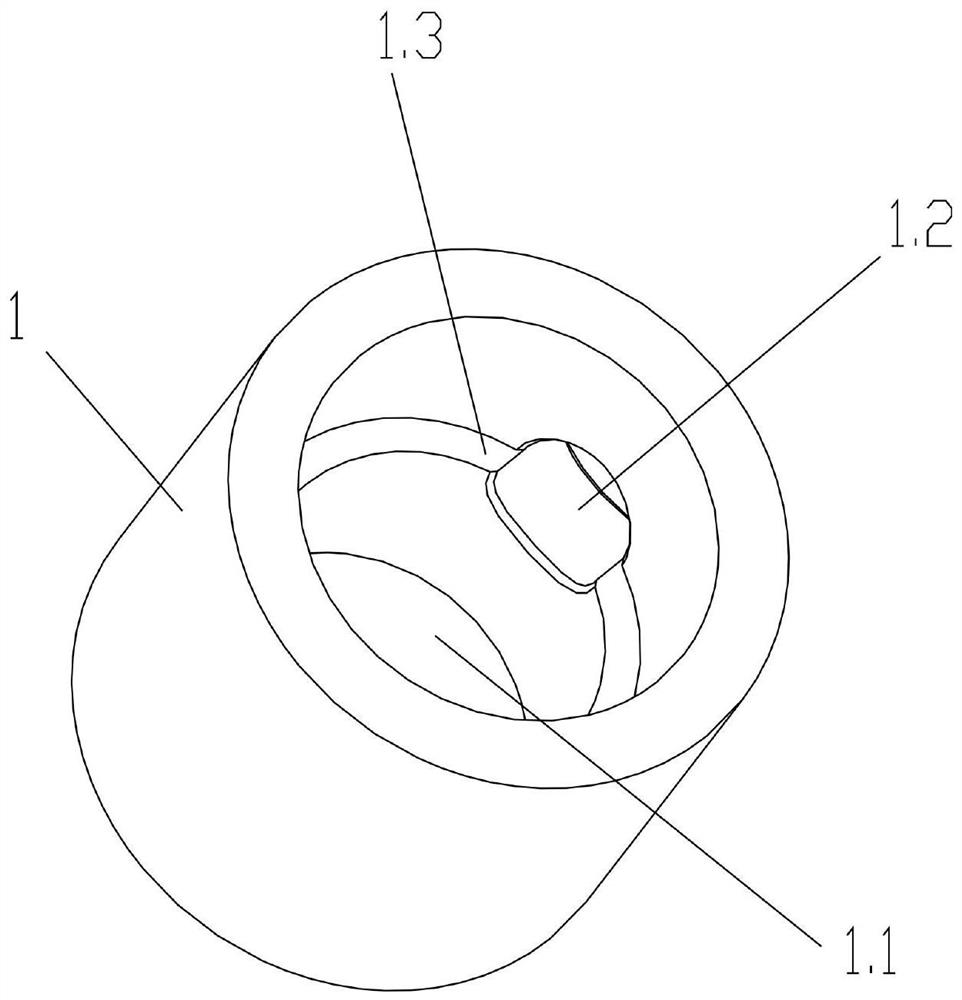

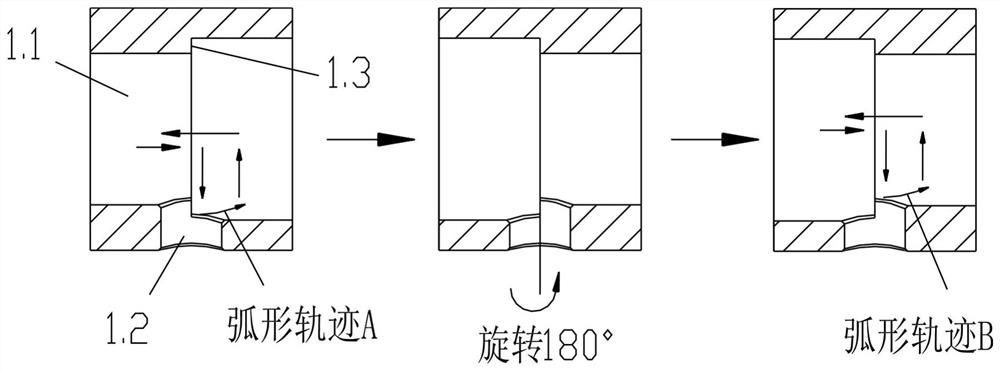

[0039] refer to Figure 1-4 , a processing method for processing step hole chamfering, comprising the following steps:

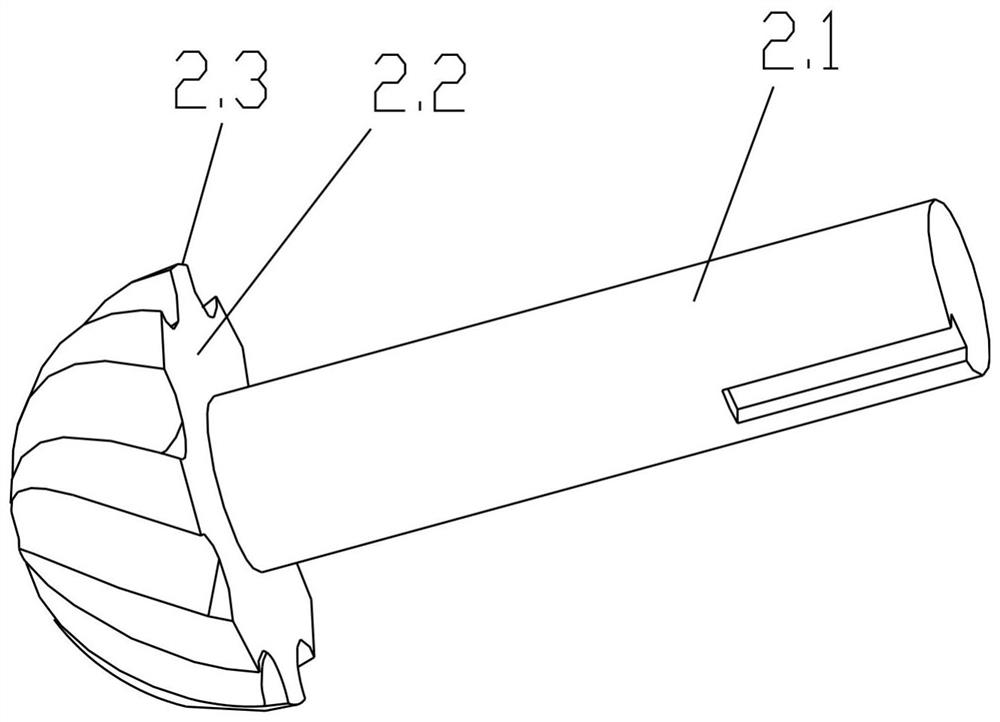

[0040] a. Select spherical milling cutter 2. Among them, the selected spherical milling cutter 2 includes a handle 2.1 and a spherical cutter head 2.2, the spherical cutter head 2.2 is less than or equal to half a sphere, and a blade 2.3 is provided on the outer surface of the spherical cutter head 2.2, and the diameter of the handle 2.1 is smaller than the largest The outer diameter of the widest part of the blade 2.3, and the axis of the handle 2.1 is perpendicular to the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com