Patents

Literature

51results about How to "No need for manual grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

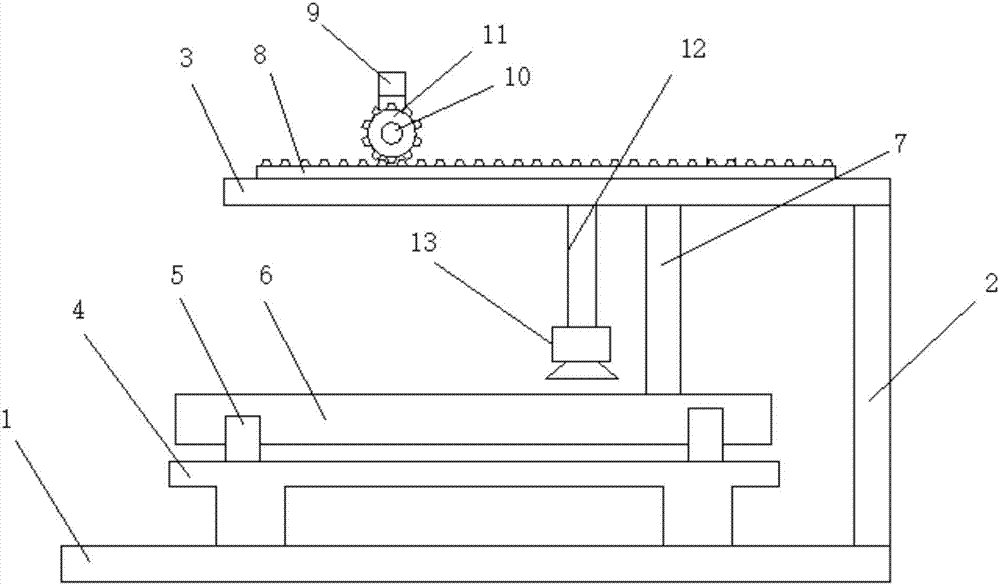

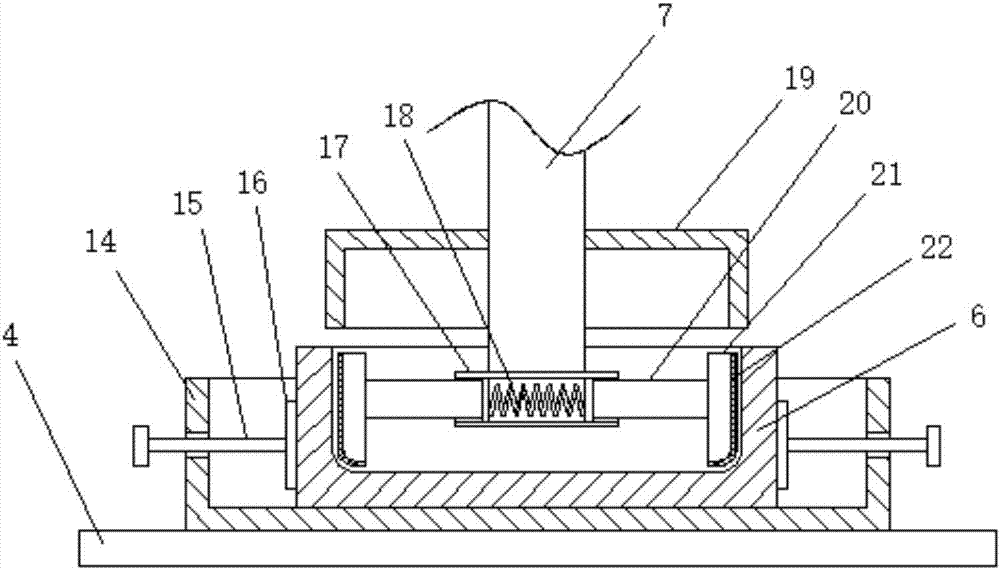

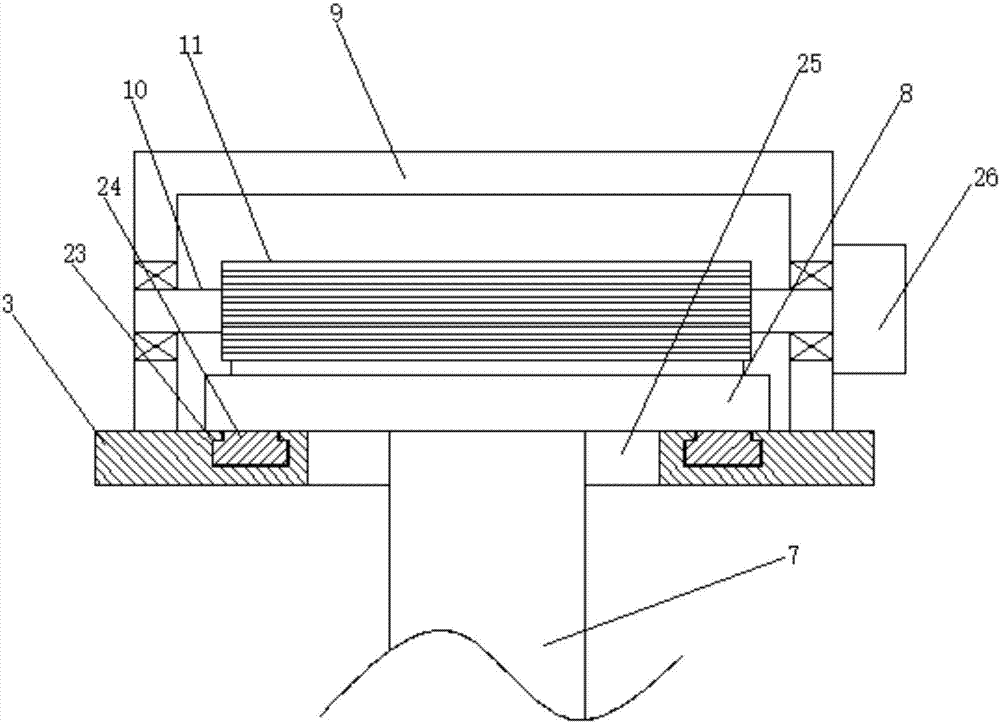

Numerical control cutting machine

InactiveCN102303175AFull range of mobilityQuality improvementGas flame welding apparatusControl systemEngineering

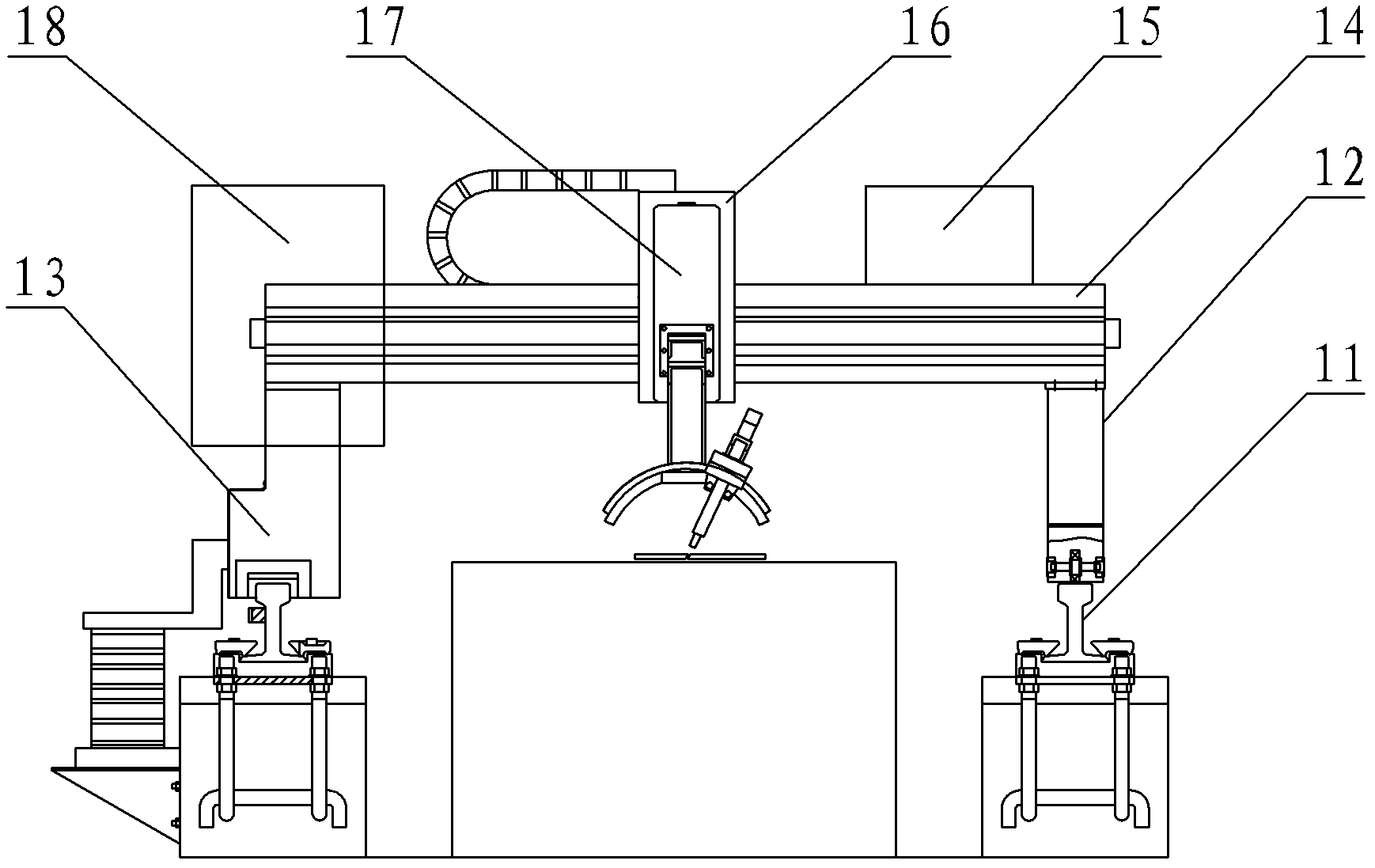

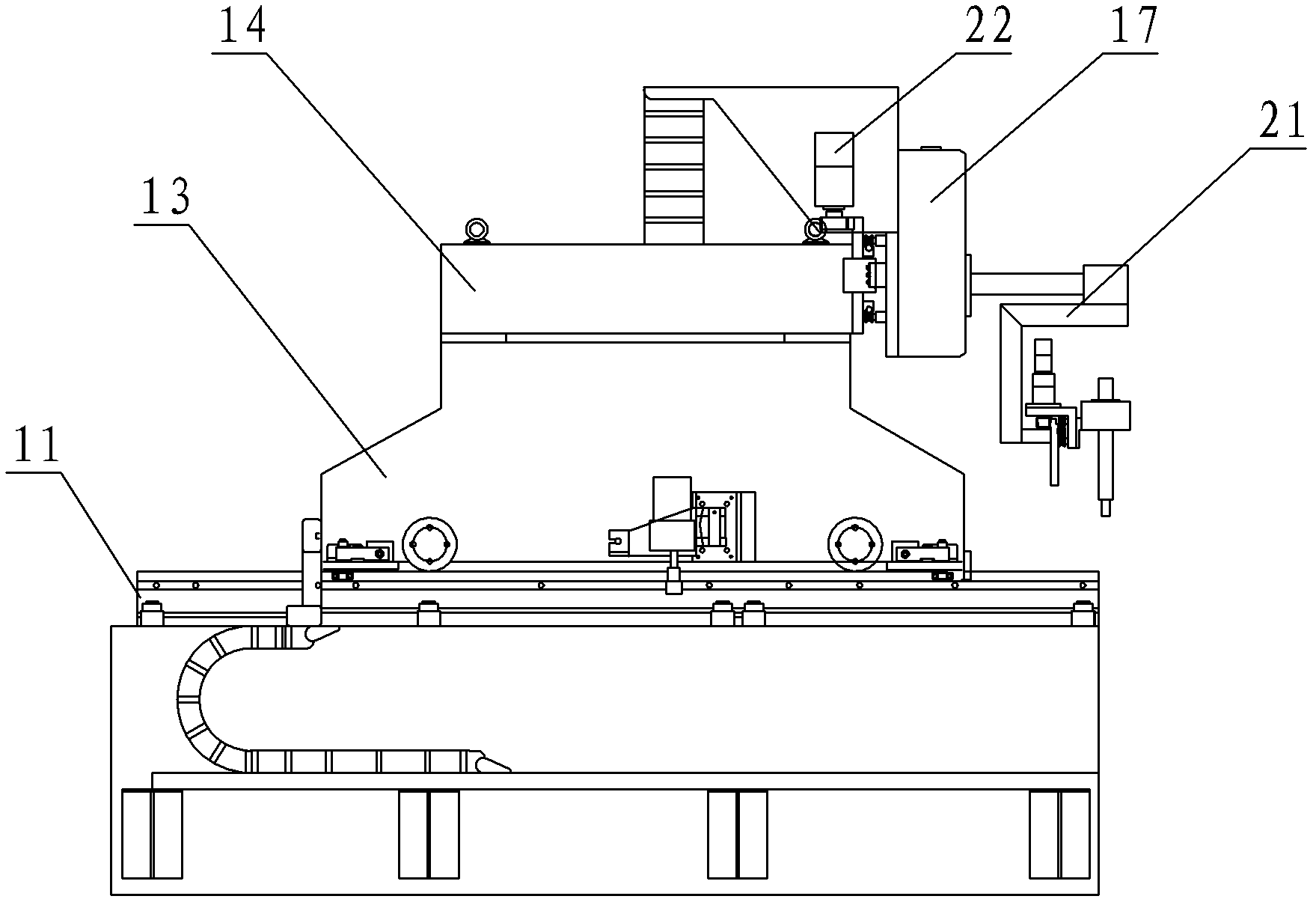

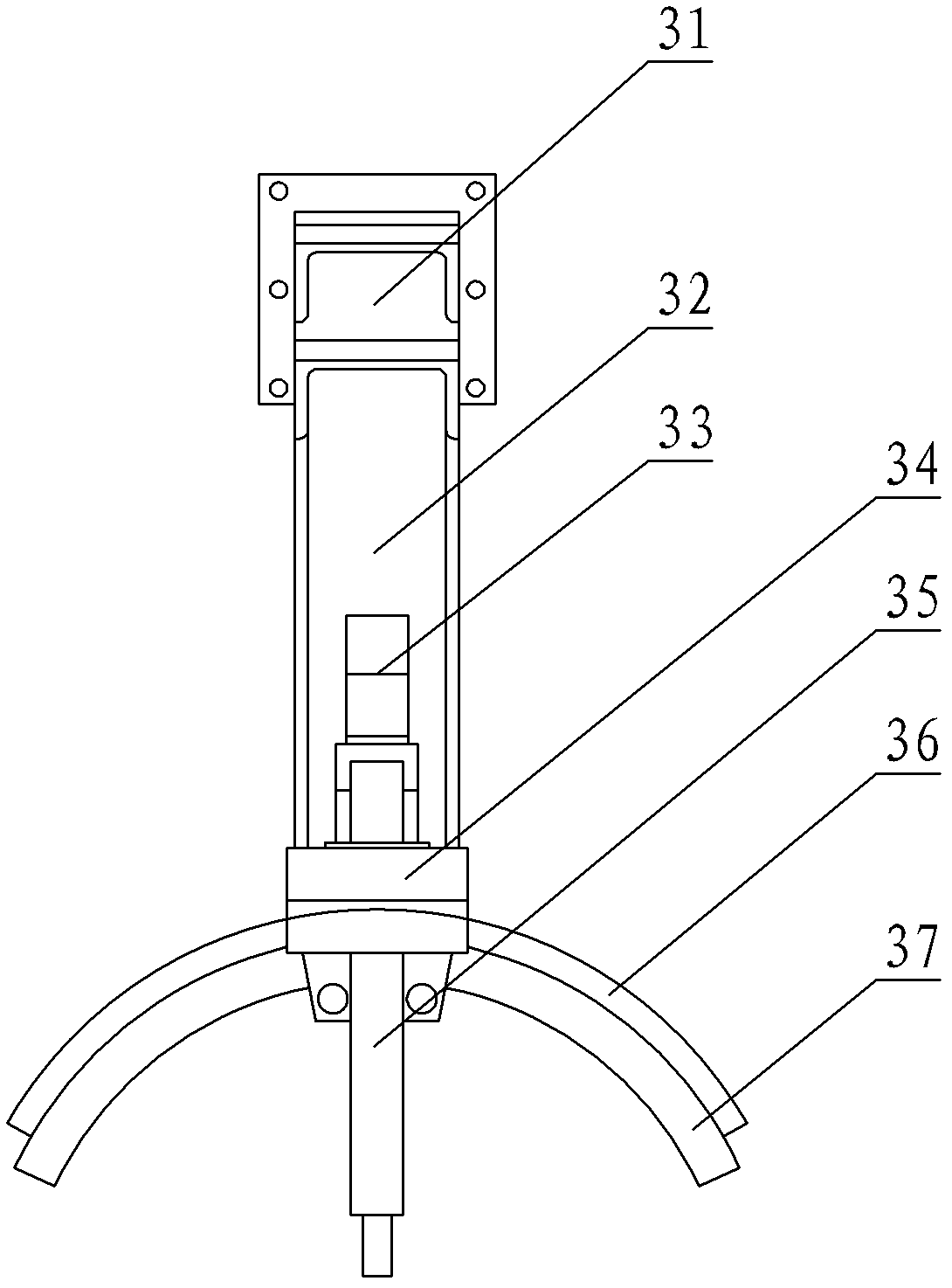

The invention discloses a numerical control cutting machine, which comprises a longitudinal guide rail, a machine frame arranged on the longitudinal guide rail, and a numerical control system, a cutting control system, a transverse movement system, a lifting mechanism and a deflection device which are arranged on the machine frame, wherein a longitudinal driving rack is arranged on the longitudinal guide rail and is matched with a longitudinal driving gear; the longitudinal driving gear is arranged on the machine frame; the lifting mechanism is arranged on the transverse movement system; and the deflection device is arranged on the lifting mechanism. The numerical control cutting machine has the advantages of high production efficiency, quality of beveled edges and accuracy, low labor intensity of workers and the like and is controlled automatically in the whole process, angles of the beveled edges are easy to ensure, and the generality of workpieces is high.

Owner:昆山芬特机器制造有限公司

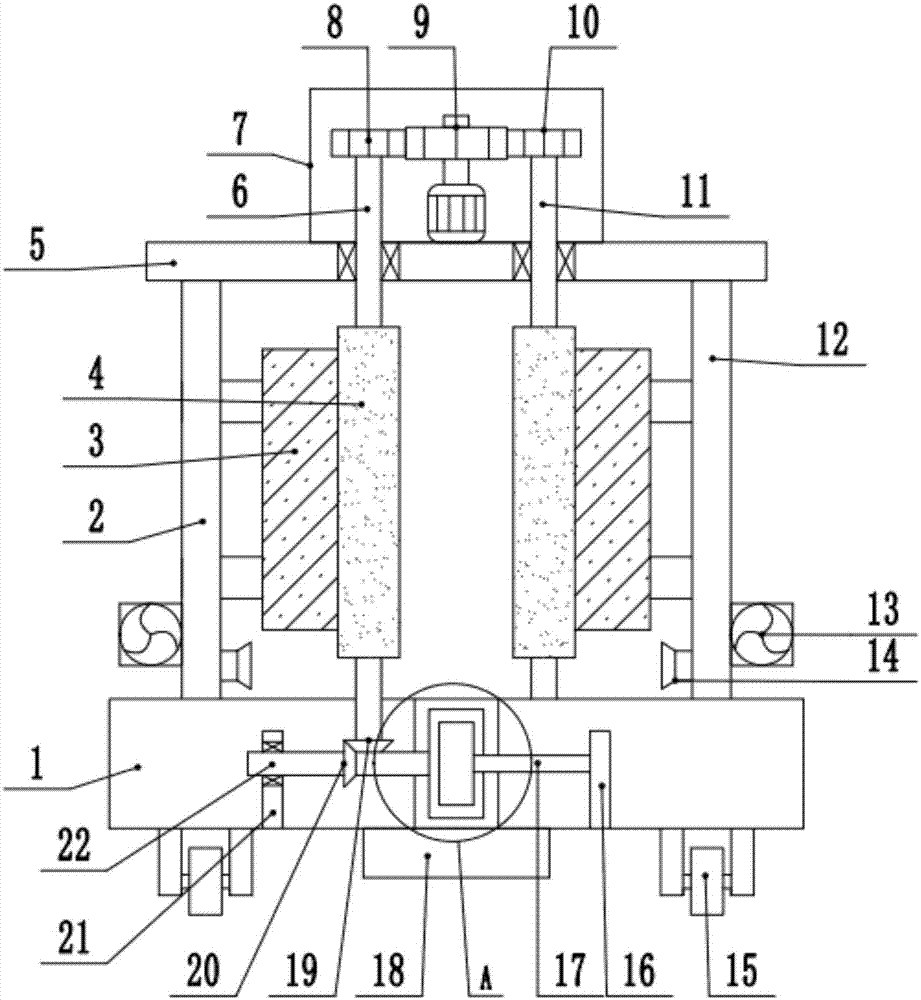

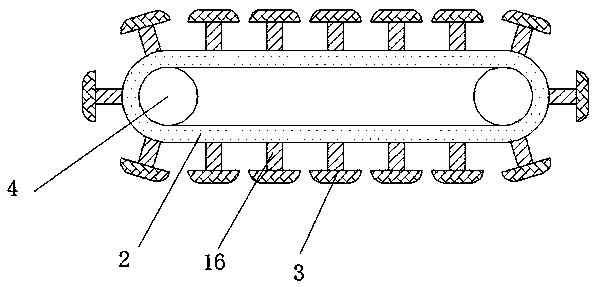

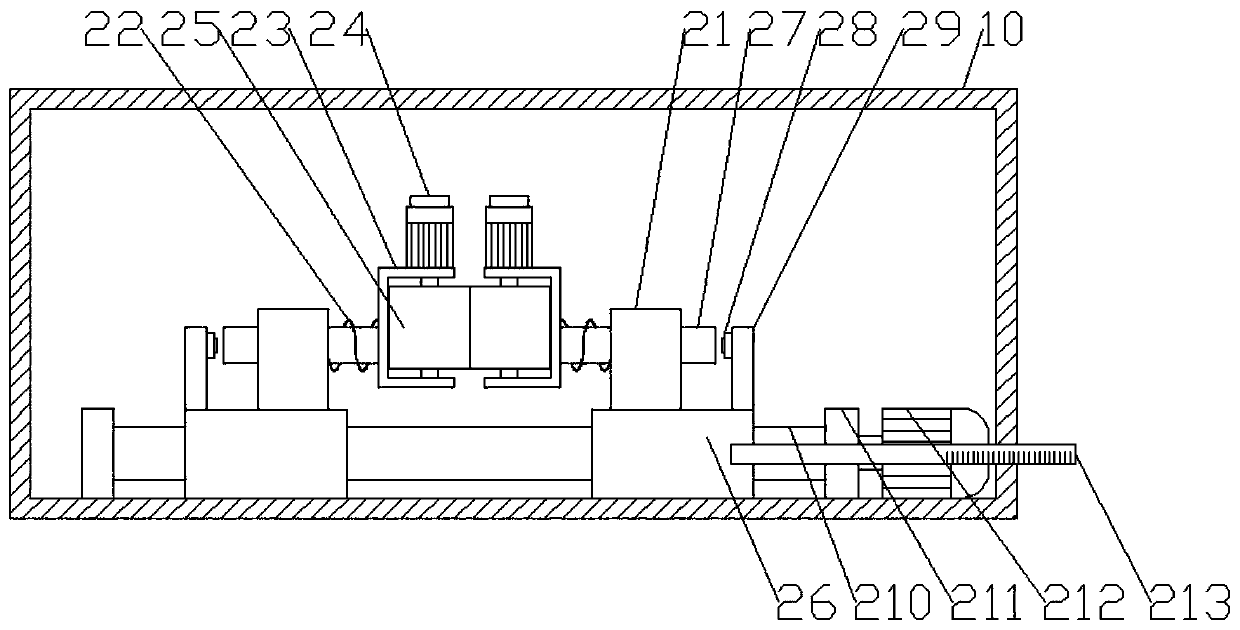

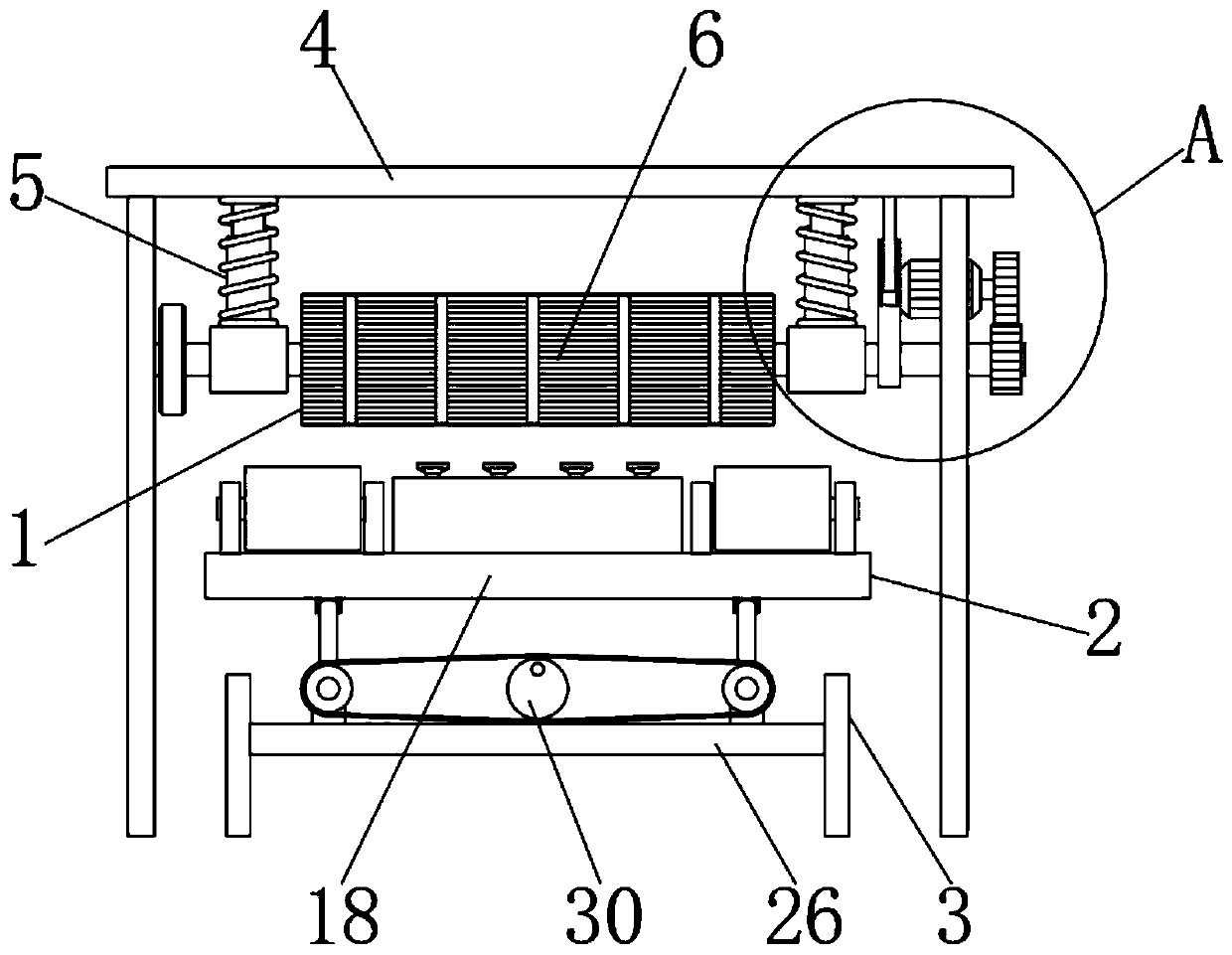

Steel plate double-sided rust removal device convenient for rust removal

InactiveCN107322444ANo need for manual grindingEasy to operateGrinding carriagesGrinding machinesSteel platesSheet steel

The invention discloses a double-sided derusting device for steel plates which is convenient for rust cleaning, which comprises a base, a first rotating shaft, a second rotating shaft, a plastic sleeve and a disc for removing iron; the middle positions of the first rotating shaft and the second rotating shaft are fixed Grinding rollers are installed; a second left bracket and a second right bracket are installed symmetrically inside the base, the plastic sleeve is installed on the second left bracket through the rotation of the third rotating shaft, and an iron removal disc is arranged inside the plastic sleeve , the right side of the iron removal disc is fixedly installed on the second right bracket through a fixed rod; a collection box is also fixedly installed at the middle position of the underside of the base. The invention drives the two grinding rollers to rotate by driving the motor to remove rust on both sides of the steel plate without manual grinding, saving time and effort; it is also equipped with a fan, a cleaning brush and an iron removal disc, which can collect the rust generated during grinding, so that Centralized processing, easy to operate and clean and tidy.

Owner:朱小龙

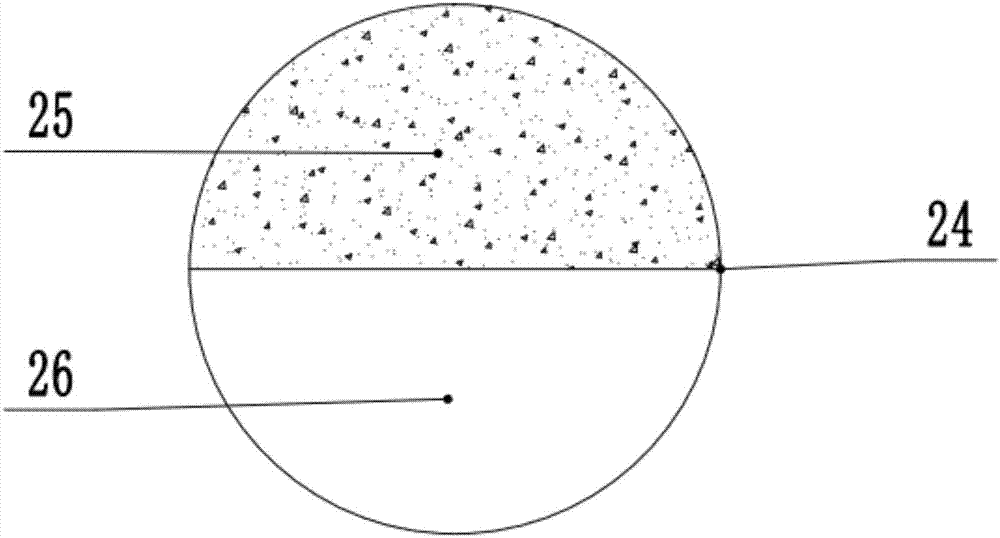

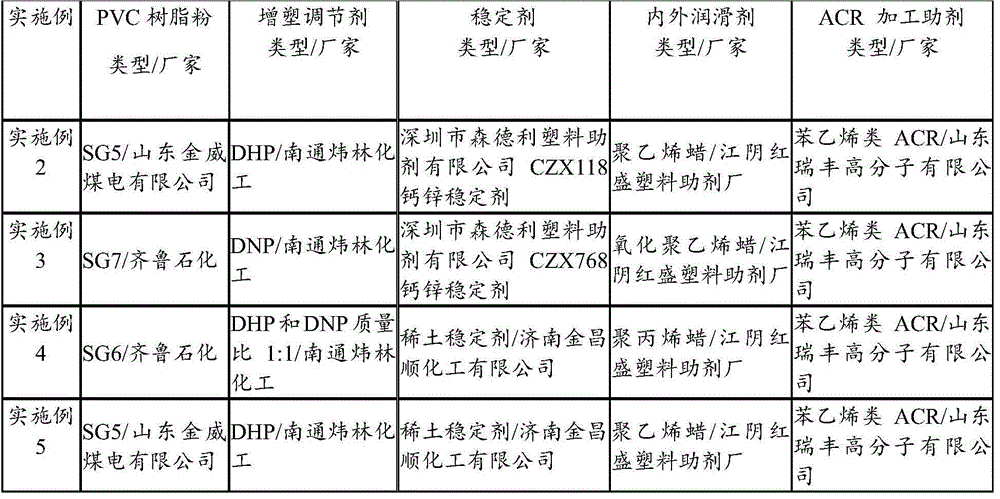

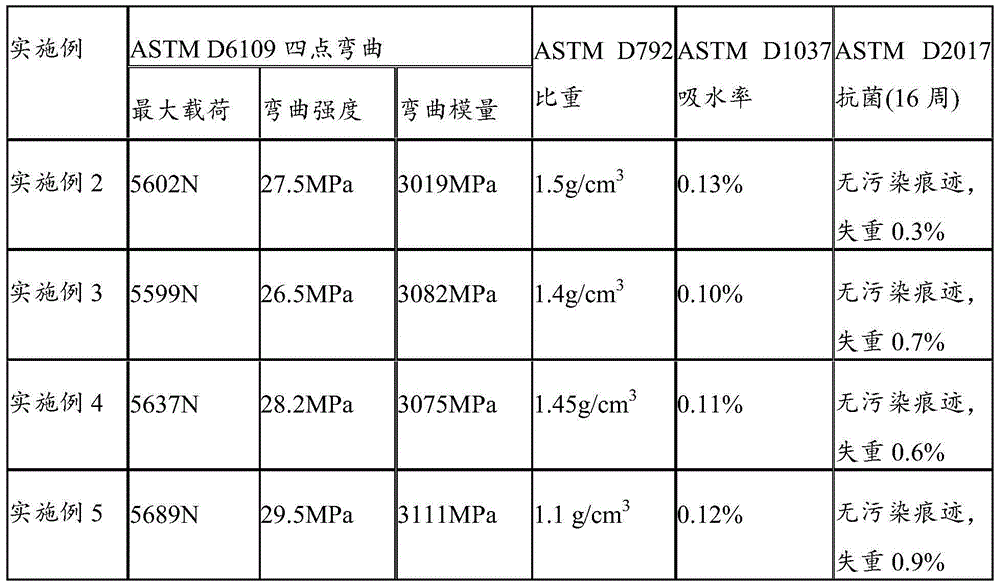

Formula of wood-plastic bathroom plate and production method

ActiveCN103993697AGood antibacterialImprove mildew resistanceConstruction materialPorositySurface layer

The invention relates to a wood-plastic bathroom plate. The wood-plastic bathroom plate comprises a surface layer and a bottom layer, and the surface layer comprises 1-2 parts by weight of a nanometer silver-ion modified carbon black antibacterial agent. Compared with conventional wood-plastic materials, the wood-plastic bathroom plate has the following advantages: 1) the wood-plastic bathroom plate is capable of well resisting bacteria and preventing mildew because the surface of the plate posses the antibacterial layer, and the wood-plastic bathroom plate has relatively good waterproofness because the antibacterial layer on the surface is relatively low in porosity; and the wood-plastic bathroom plat is wide in raw material resource, low in cost, energy-saving and environment-friendly, and is an ideal bathroom decoration plate replacing common density plates and multi-layer plates; 2) the wood-plastic bathroom plate is easy to process without being limited by processing length, has hard and flat surface crust which does not need manually polishing, helps to save labor resource, and is 100% recyclable after being used for years; and 3) the production technology is simple and easy to operate, and the wood-plastic bathroom plate is good in stability and easy to process.

Owner:山东宜居新材料科技有限公司

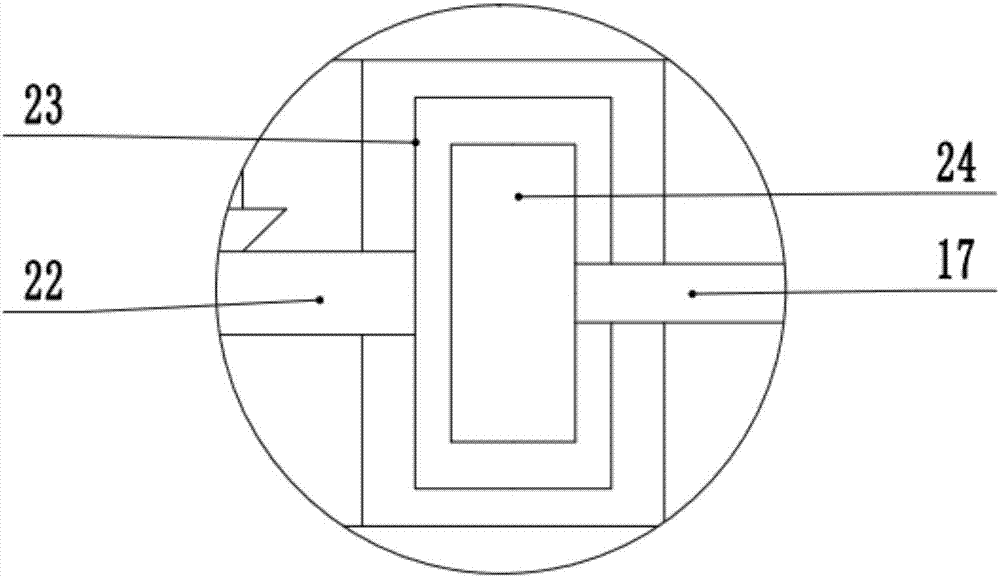

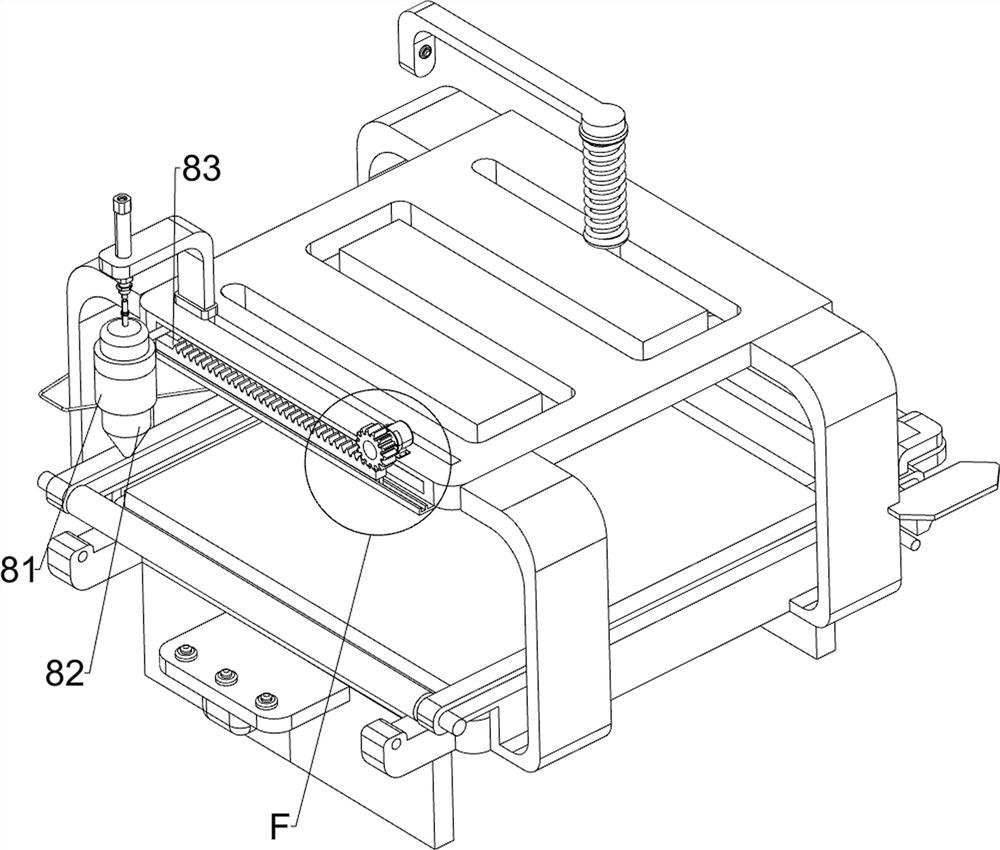

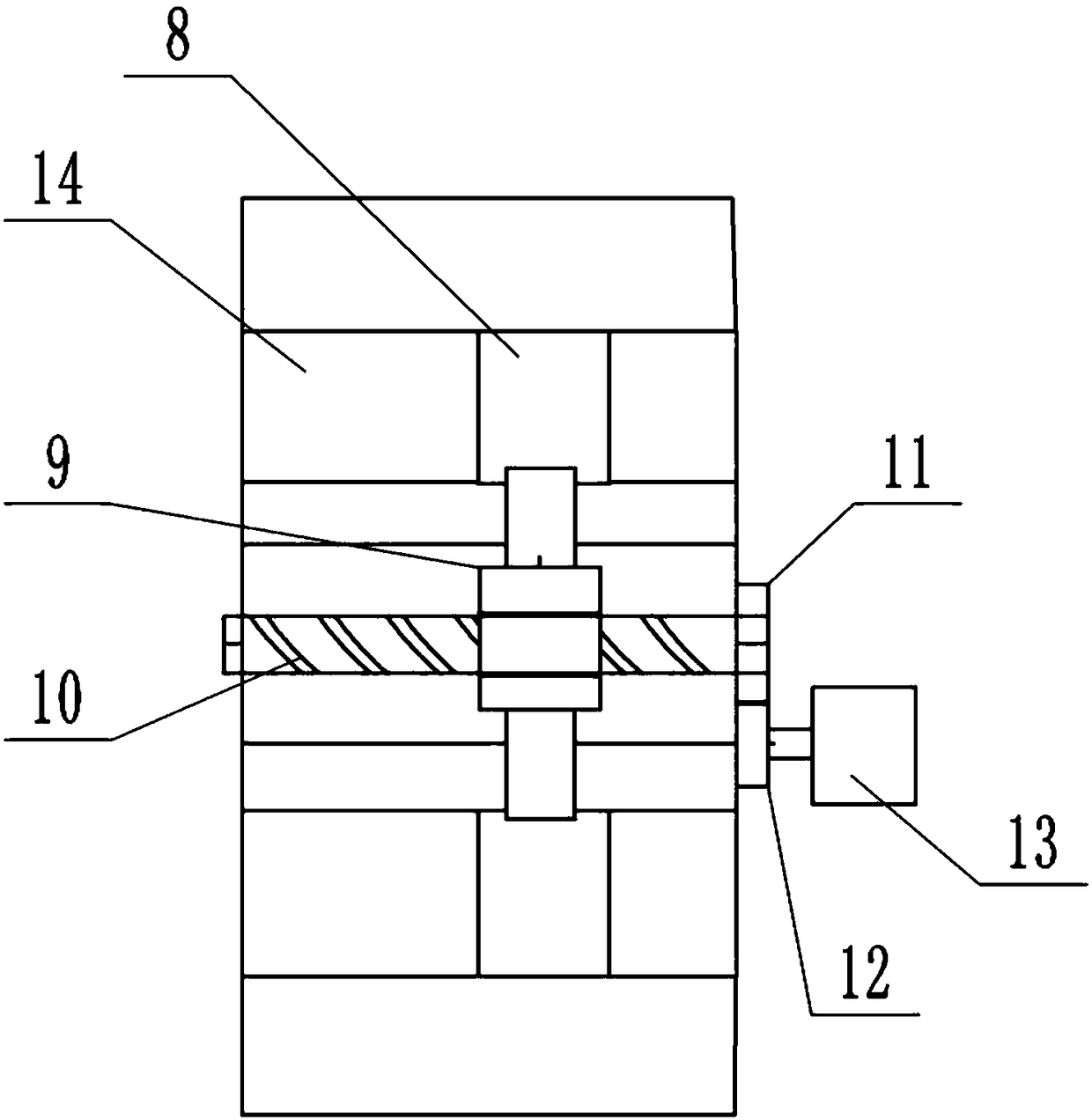

Deburring device for inner side wall of C-shaped guide rail

InactiveCN107150272ATimely processingImprove grinding effectEdge grinding machinesGrinding drivesFurringPulp and paper industry

The invention discloses a deburring device for the inner wall of a C-shaped guide rail, which comprises a bottom plate, a side plate, a top plate and an operation platform. Both ends of the upper end surface of the operation platform are provided with clamping devices for fixing the two ends of the guide rail. A rack and a mounting frame are arranged, and a horizontal shaft is installed on the mounting frame, and a driving gear is arranged on the horizontal shaft. And the driving gear is meshed with the rack, the lower end surface of the rack is connected with the upper surface of the top plate through a sliding mechanism, the bottom end of the rack is provided with a vertical bar, and the bottom end of the vertical bar is provided with a guide cylinder perpendicular to it, and the guide cylinder Both ends are provided with connecting rods, the opposite ends of the two connecting rods are provided with mounting plates, the mounting plates are provided with friction plates, the bottom end of the rack is also provided with a suspension rod, and the lower end of the suspension rod is provided with a vacuum cleaner. The invention has a simple structure, can be repeatedly deburred and polished, has a good grinding effect, does not need manual grinding, has high grinding efficiency, can process debris after grinding in time, is simple to operate, and has strong practicability.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

Automatic pipeline polishing device for ocean engineering

PendingCN113752107ANo need for manual grindingImprove grinding efficiencyGrinding carriagesRevolution surface grinding machinesGear wheelEngineering

The invention discloses an automatic pipeline polishing device for ocean engineering, and relates to the field of ocean engineering. The automatic pipeline polishing device comprises a main box body, wherein one side of the main box body is fixedly provided with a connecting cylinder, the connecting cylinder is movably sleeved with a polishing mechanism, one side of the connecting cylinder is fixedly provided with an axis cylinder, the axis cylinder is provided with expanding gears, an electric telescopic rod is fixedly mounted on the inner wall of one side of the axis cylinder, an expanding column is fixedly mounted at the output end of the electric telescopic rod, a plurality of expanding racks are fixedly mounted on the outer wall of the peripheral side of the expanding column, and the expanding gears are engaged with the expanding racks correspondingly; and a traveling mechanism is mounted on one side of each expanding gear. And under the action of the polishing mechanism, the inner wall of the peripheral side of the pipeline is ground according to the traveling route, automatic grinding can be conducted, manual grinding is not needed, the grinding efficiency is high, grinding is uniform, and the grinding effect is good.

Owner:刘欢

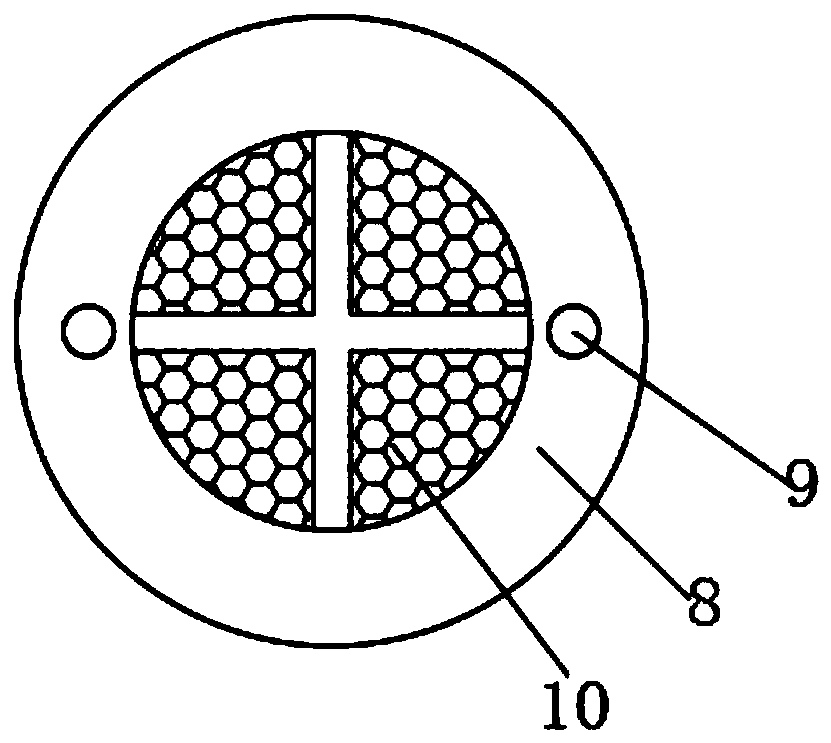

Deburring mechanism and filter screen assembly

InactiveCN110883632AAchieve rotationEasy clampingEdge grinding machinesGrinding machine componentsEngineeringScreen filter

The invention belongs to the field of filter screen processing, and particularly relates to a deburring mechanism and a filter screen assembly. The deburring mechanism comprises a supporting table, wherein an electric motor is fixedly installed at the upper end of the supporting table; a square rod is arranged at the upper end of a rotating shaft of the electric motor; the square rod and the rotating shaft are of an integrated structure; the outer side of the square rod is slidably sleeved with a square sleeve; the upper end of the square sleeve is welded with a supporting disc; and the upperend of the supporting disc is provided with a mounting ring. The electric motor is designed on the supporting table; the square rod is arranged at the upper end of the rotating shaft of the electric motor; the square sleeve is mounted on the square rod; the supporting disc is mounted on the square sleeve; the supporting disc is provided with the filter screen assembly composed of the mounting ring, a filter screen and a fastening ring, so that the clamping is convenient; and an air cylinder is adopted for driving a pressing disc to clamp the filter screen assembly, a bearing is mounted on thedriving disc, the bearing is arranged in a bearing housing, and the bearing housing is fastened and connected with a connecting plate at the lower end of an air cylinder rod, so that the pressing disccan rotate, and the filter screen assembly can be pressed and can rotate as well.

Owner:安徽省唯一纺织有限公司

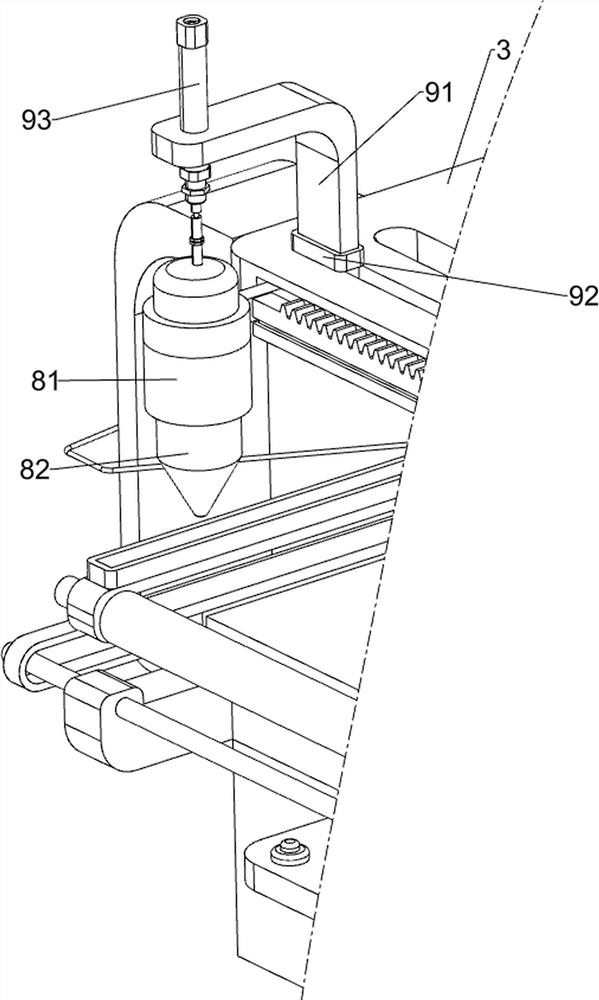

Automatic processing machine for manufacturing shaving board

ActiveCN110480463ANo need for manual grindingImprove slotting efficiencyGrinding drivesMulti-purpose machinesAutomatic processing

The invention relates to an automatic processing machine for manufacturing a shaving board. The automatic processing machine comprises a mounting table, a driving device, a cutting and polishing device and a limiting mechanism, wherein the driving device is arranged at the upper end of the mounting table, the cutting and polishing device is arranged at the lower end of the driving device, and thelimiting mechanism is arranged in the middle of the mounting table. The automatic processing machine for manufacturing the shaving board can solve the problems that when an existing shaving board machining device is used for machining the shaving board, the shape of grooves machined by a grooving cutter is mostly single, and one grooving cutter can only open one groove; when the grooves of different shapes need to be machined in the shaving board, various cutters need to be prepared, and the replacement process of the cutter is complex; the inner walls of the formed grooves are rough, and theinner walls of the grooves are usually required to be polished manually; and however, manual polishing is inconvenient due to the fact that the inner spaces of the formed groove are small, and the like.

Owner:江苏汇丰木业有限公司

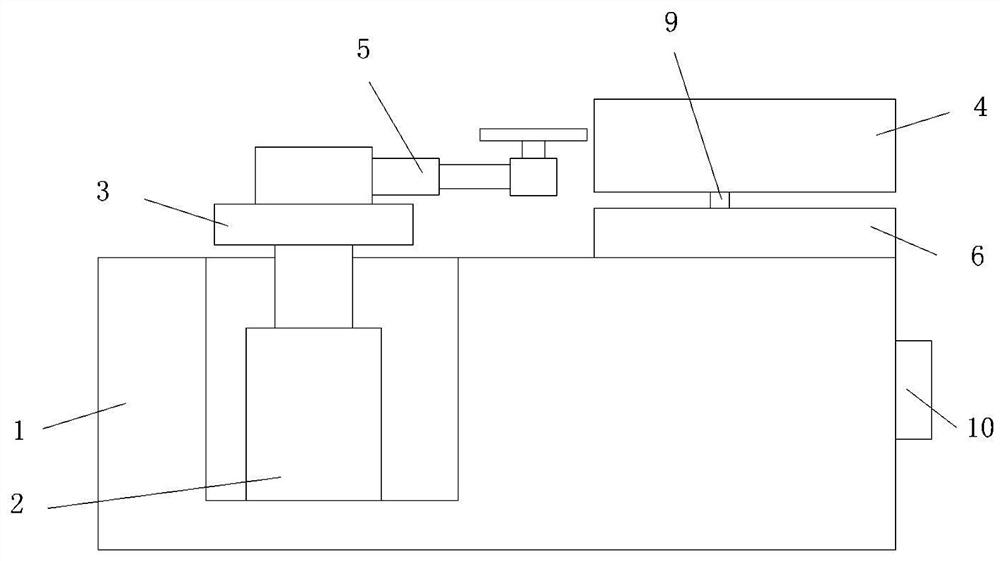

Circuit board welding device for intelligent manufacturing

InactiveCN113478043APrevent movementAutomatic grindingGrinding drivesWelding/soldering/cutting articlesPolishingAir pump

The invention relates to a welding device, in particular to a circuit board welding device for intelligent manufacturing. According to the circuit board welding device for intelligent manufacturing, alcohol can be automatically wiped, and accurate welding can be achieved. The circuit board welding device for intelligent manufacturing comprises a first supporting plate, first fixing frames, a fixing plate and a second supporting plate, the first fixing frames are symmetrically installed at the upper parts of the two sides of the first supporting plate, the fixing plate is mounted between the upper parts of the inner sides of the first fixing frames, and the second supporting plate is installed in the middle of the upper part of one side of the first supporting plate. According to the circuit board welding device, air in an ejecting block can be pumped away through an air pump, the ejecting block can suck a circuit board, the circuit board is prevented from moving, then a third motor and a second motor serve as driving force, a polishing plate can be driven to reciprocate leftwards and rightwards once, and therefore the circuit board is automatically polished, manual polishing is not needed, and time and labor are saved.

Owner:江西环境工程职业学院

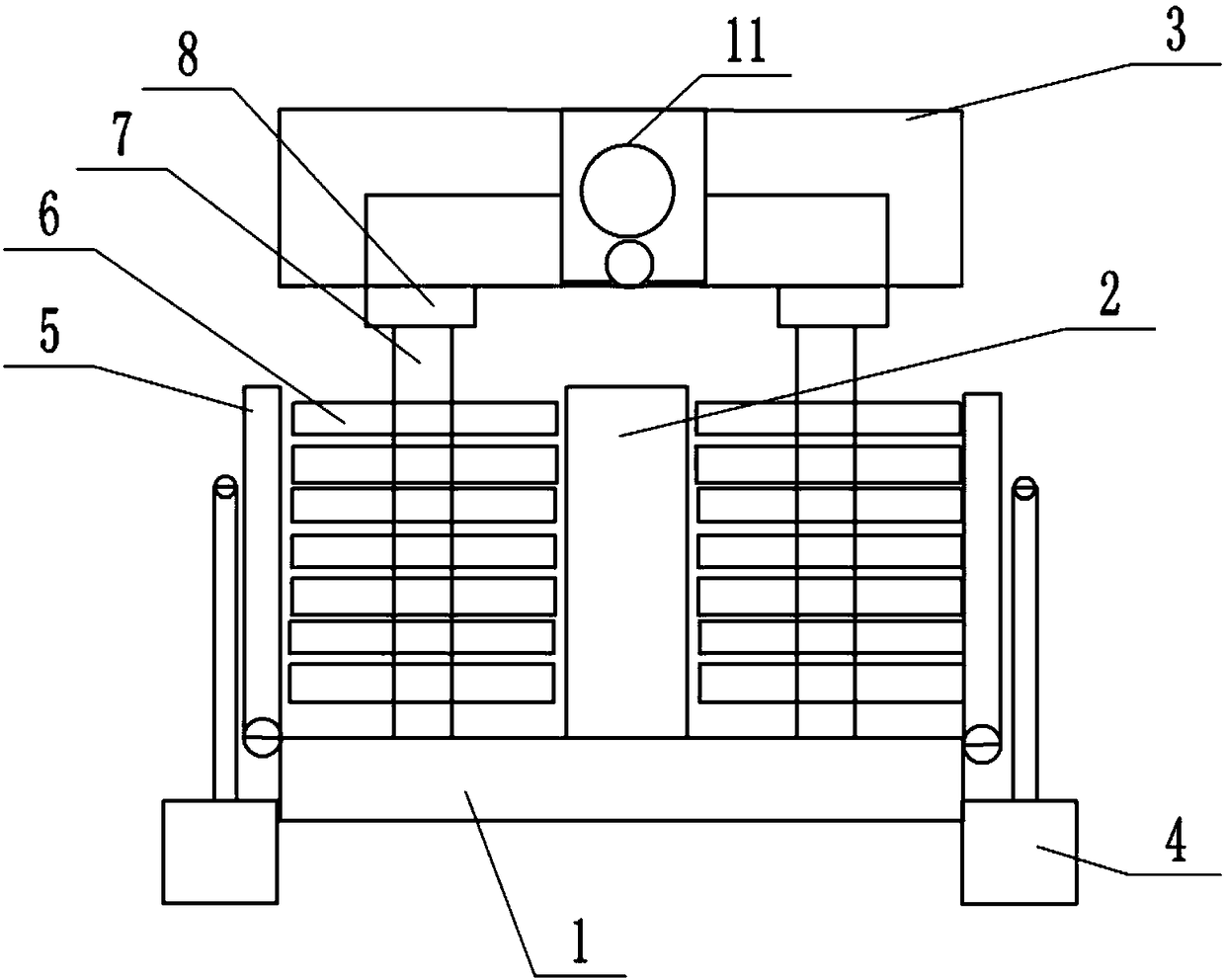

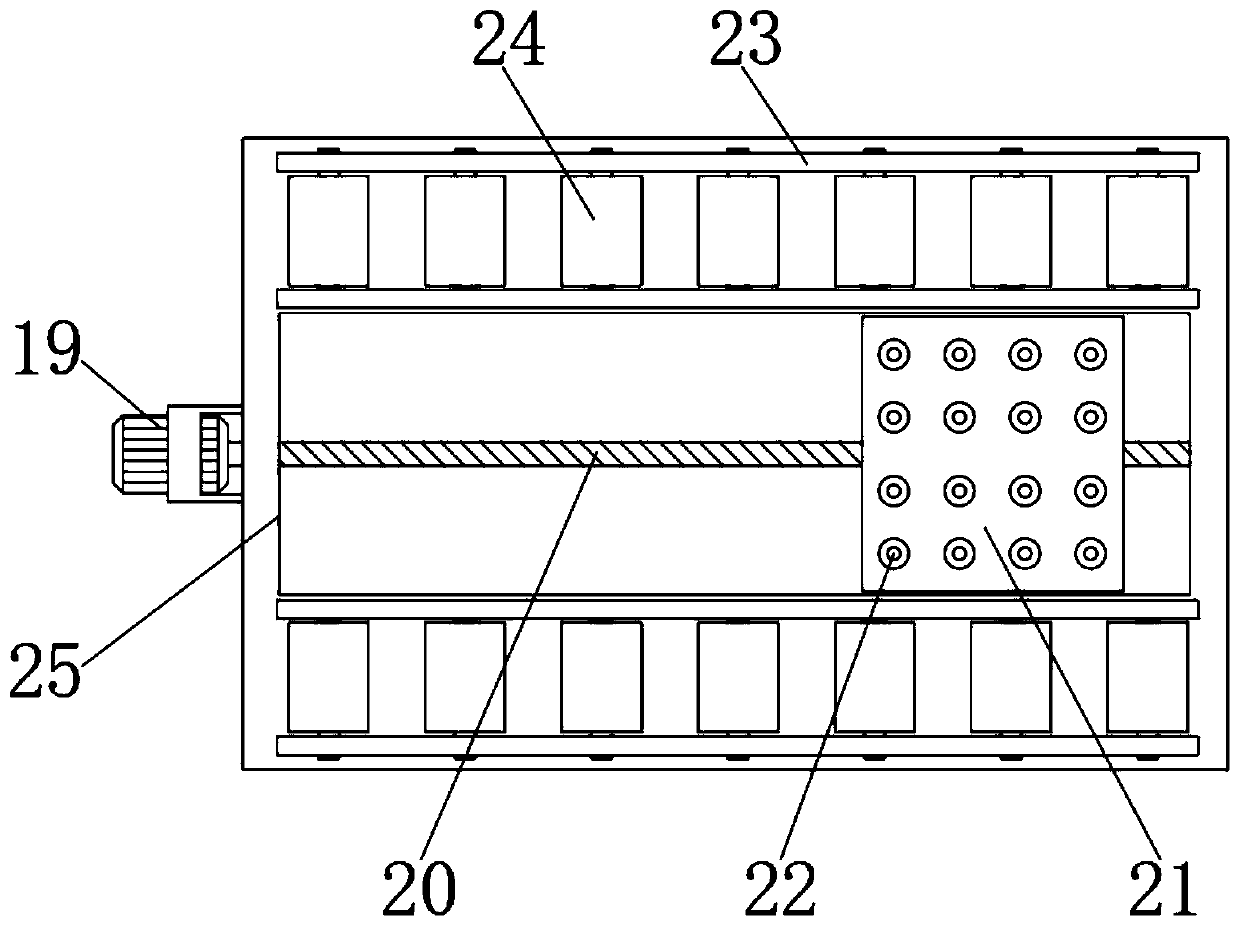

Solar photovoltaic panel grinding device

InactiveCN108326673AReduce labor intensityNo need for manual grindingSeat surface grinding machinesGrinding work supportsPhotovoltaic solar energyEngineering

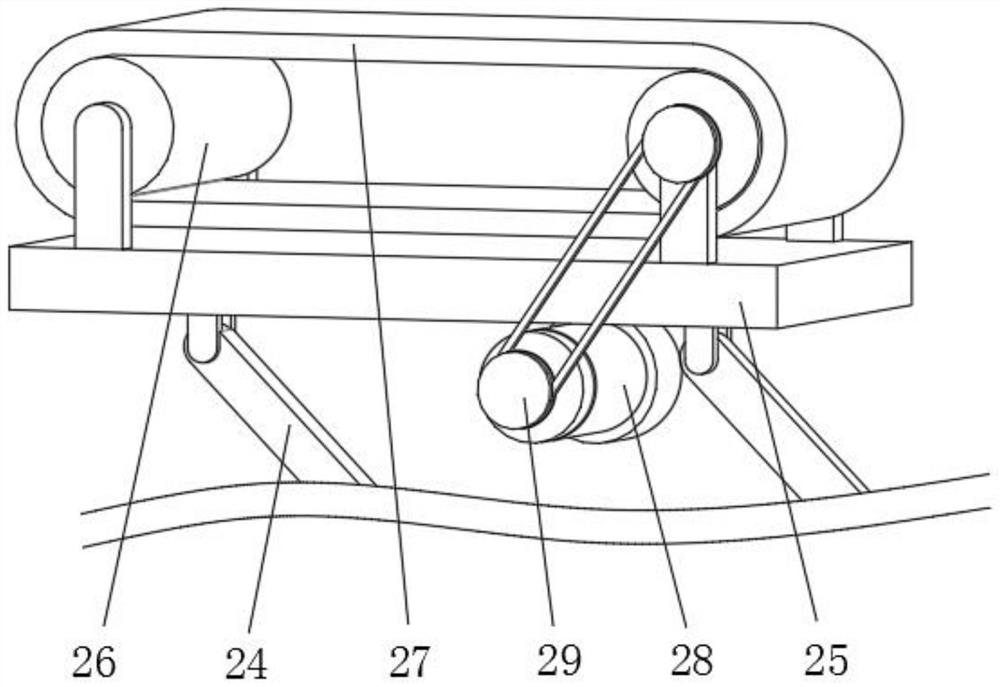

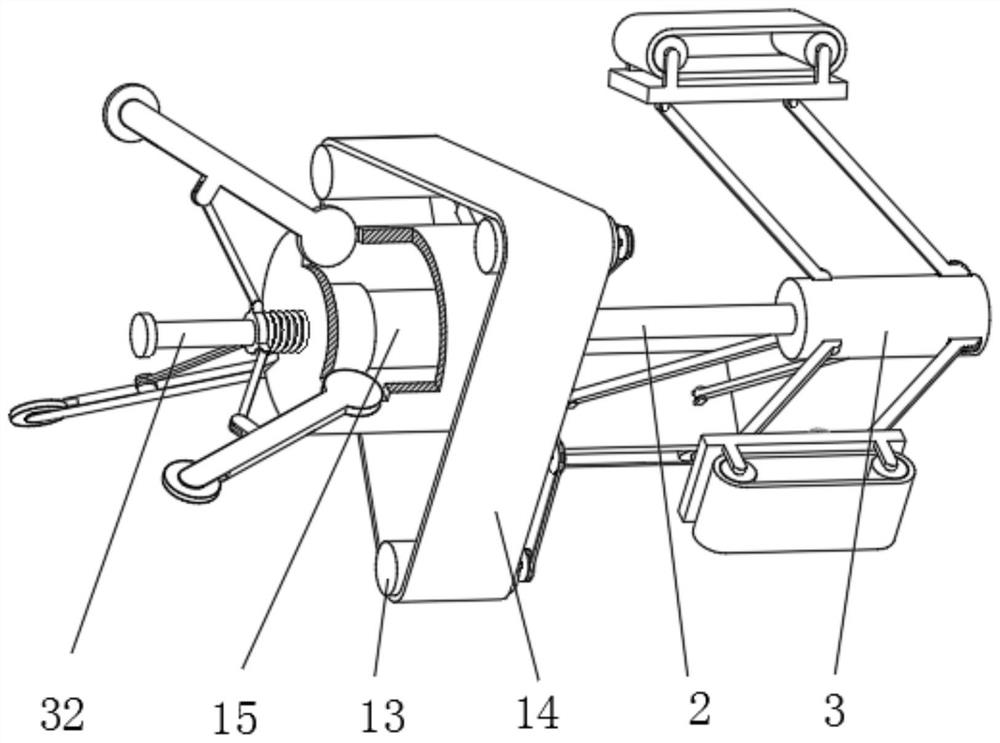

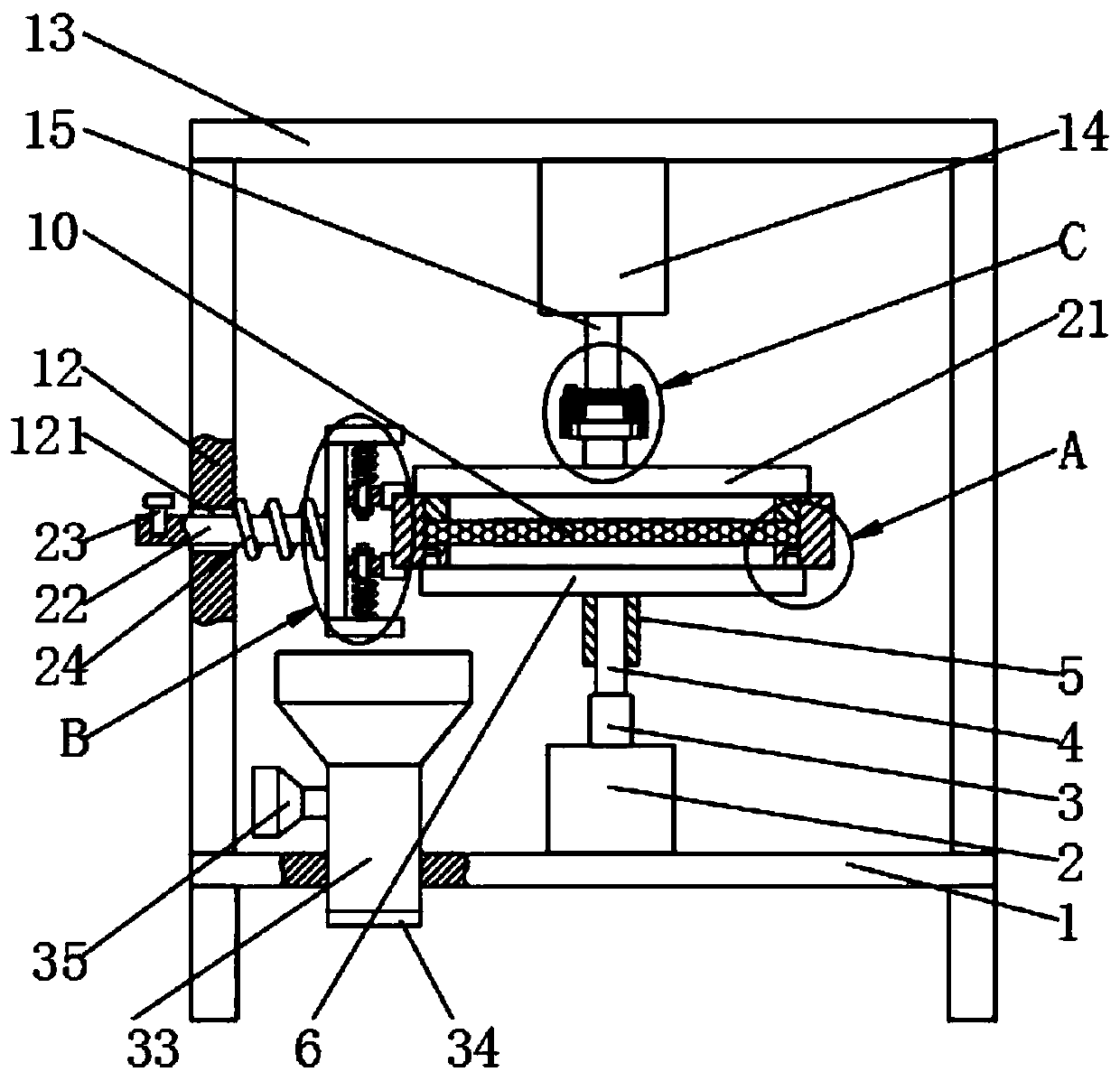

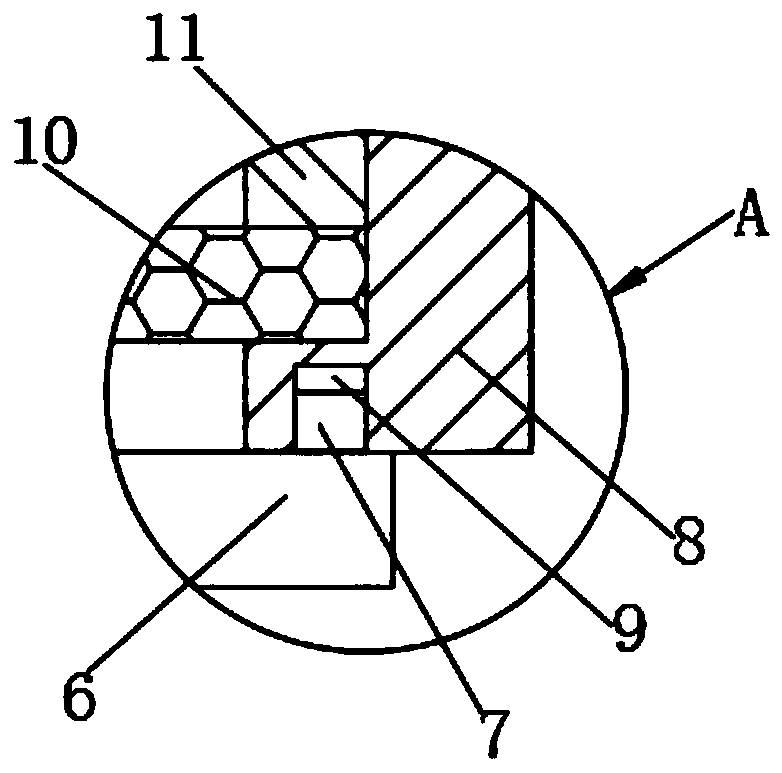

The invention specifically discloses a solar photovoltaic panel grinding device comprising a baseplate. A top plate is arranged above the baseplate, and the middle part of the baseplate is fixedly provided with a locating plate; cover plates are hinged to the both sides of the baseplate, and a plurality of overlapped solar photovoltaic panels to be ground are arranged between each cover plate andthe locating plate; a plurality of sand particles are spread between every two solar photovoltaic panels, and the parts, located at the central axis positions of the locating plate and the cover plates, of the baseplate are provided with driving belts; the driving belts are distributed at the front and rear ends of the solar photovoltaic panels in the moving direction, and combined at the upper part of the solar photovoltaic panel at the uppermost layer; the sides, facing the solar photovoltaic panels, of the cover plates and the locating plate are provided with sanding layers; and the top plate is internally provided with a driving mechanism. According to the scheme, manual grinding is not required, so that the labor intensity of workers is reduced, and meanwhile a plurality of solar photovoltaic panels are ground in one time; and the production and processing efficiency is improved.

Owner:宁波德深机械设备有限公司

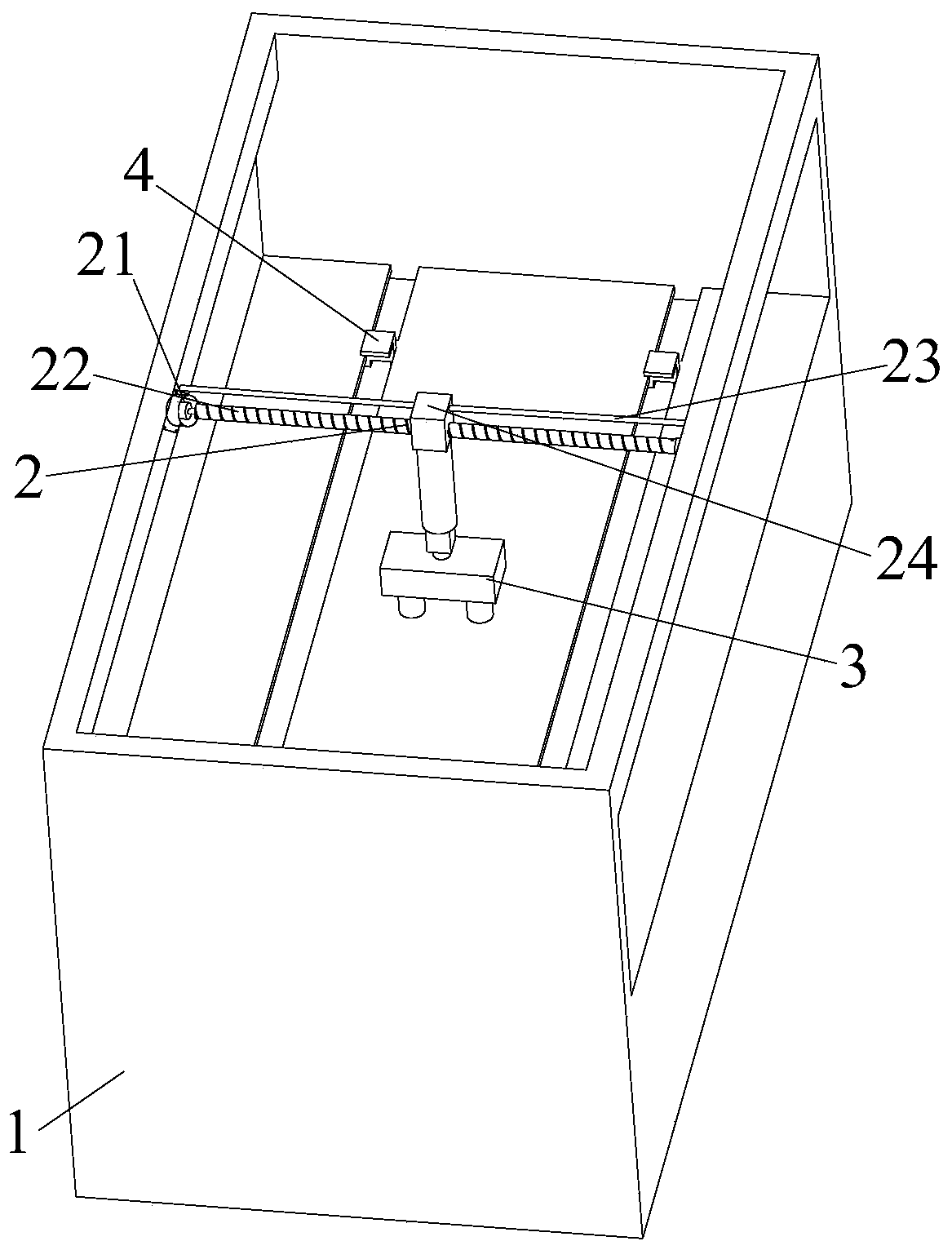

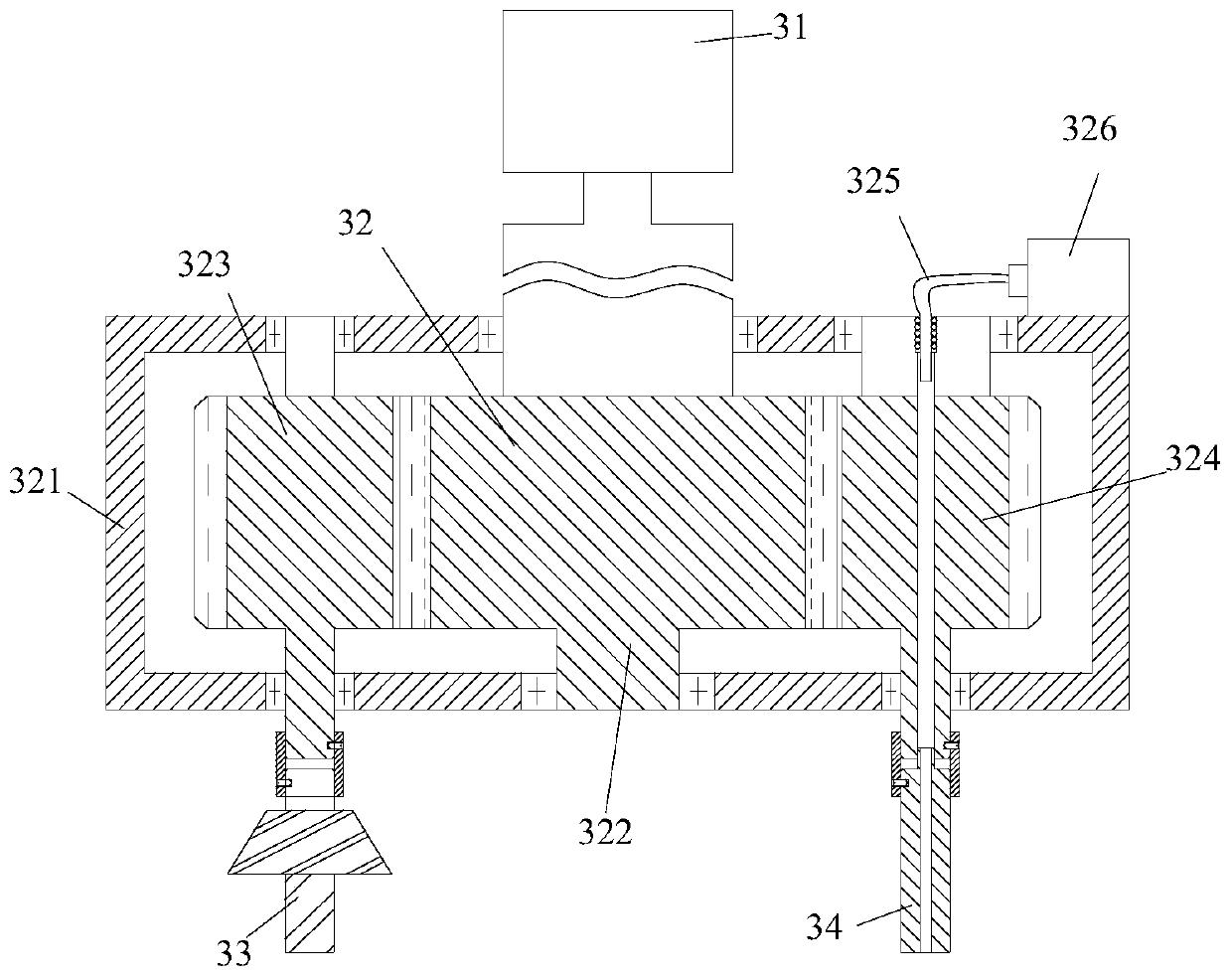

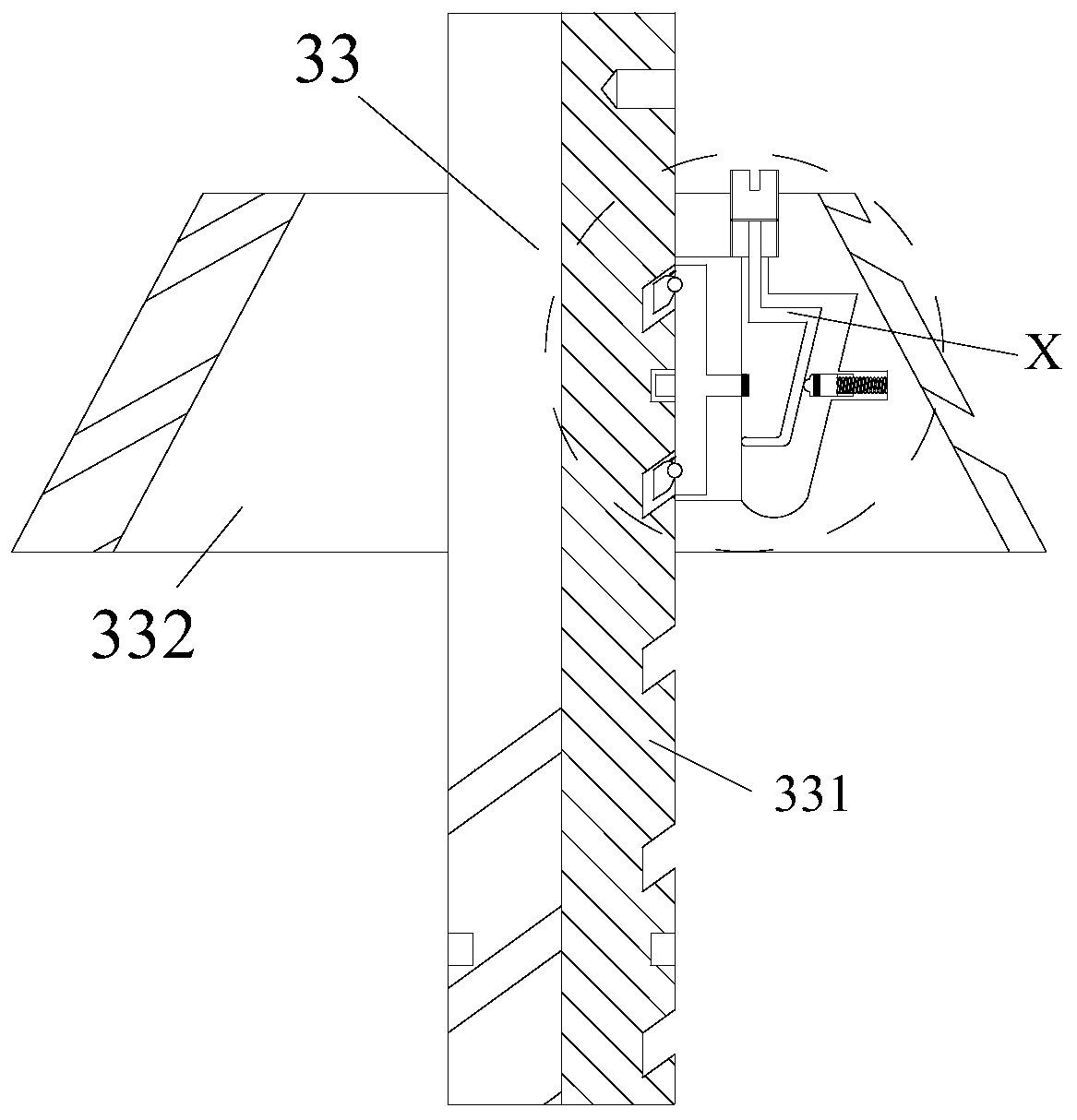

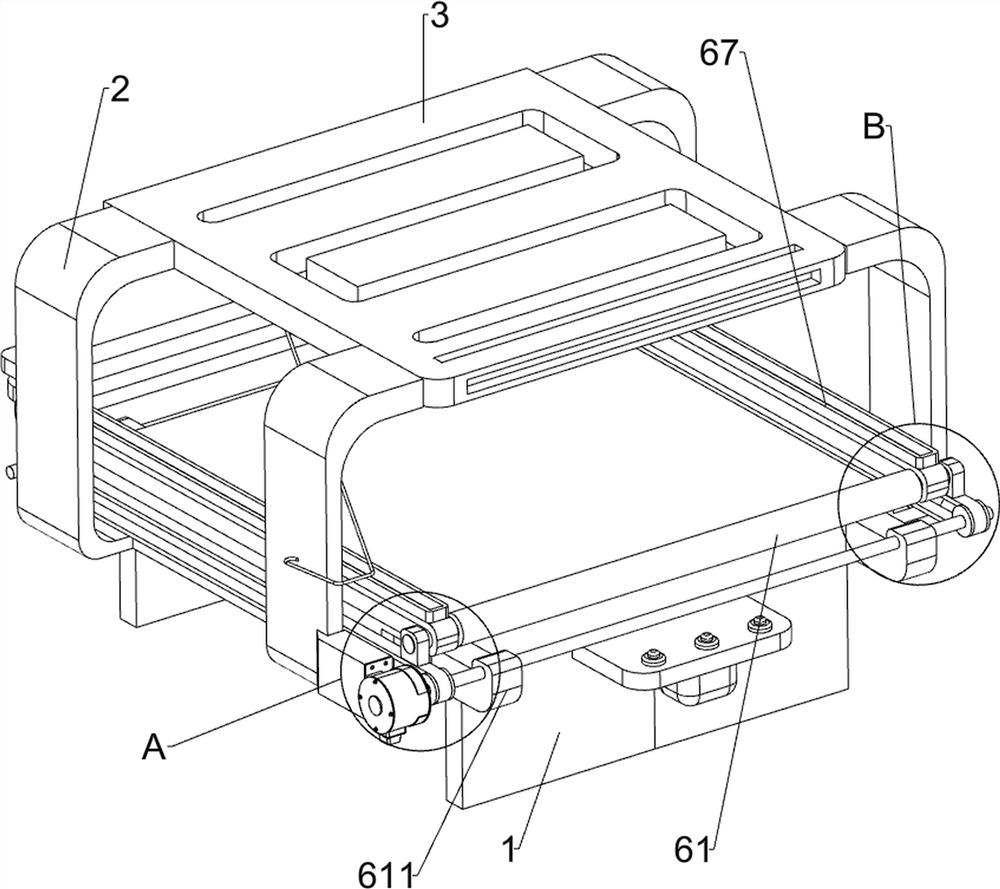

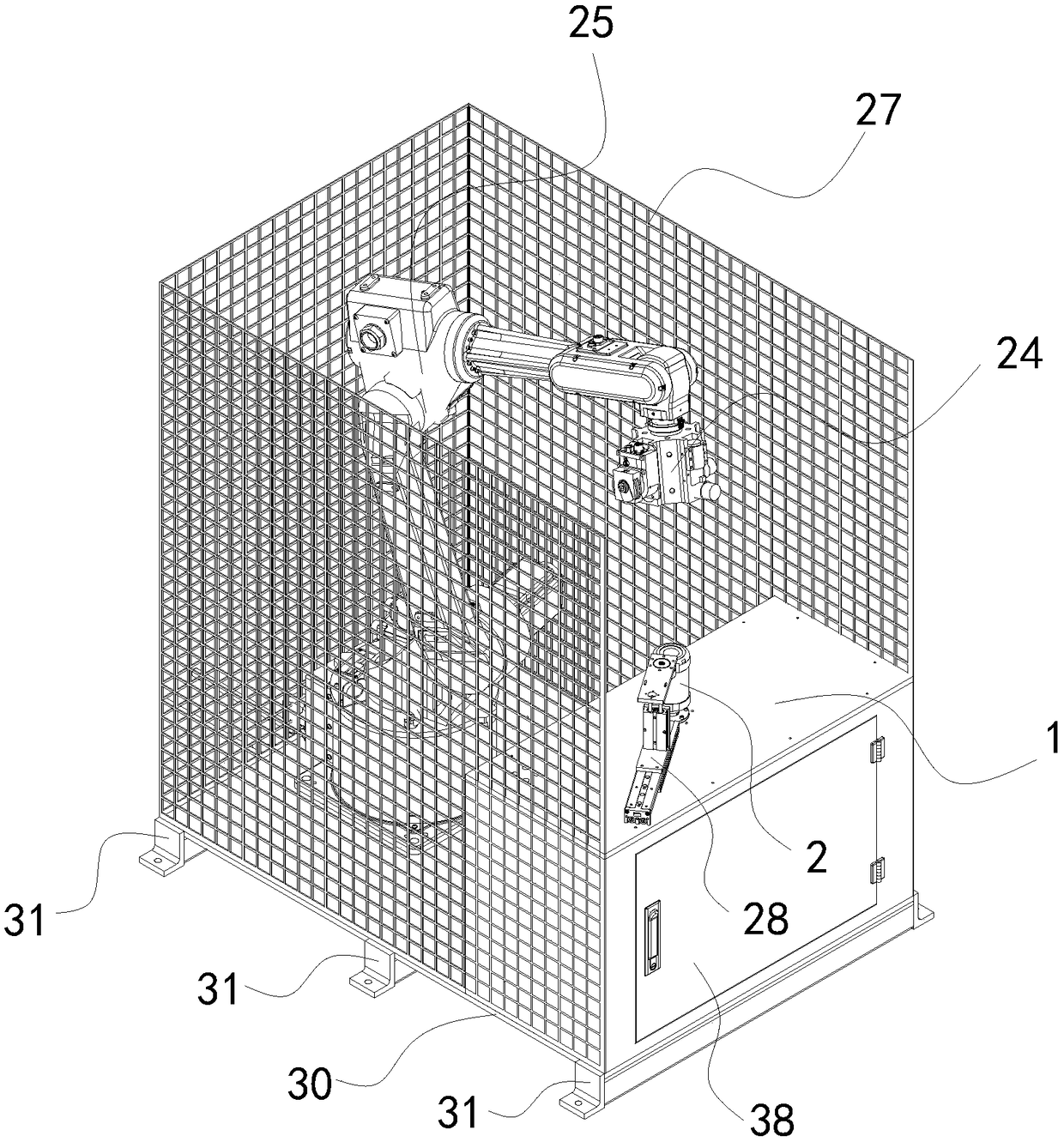

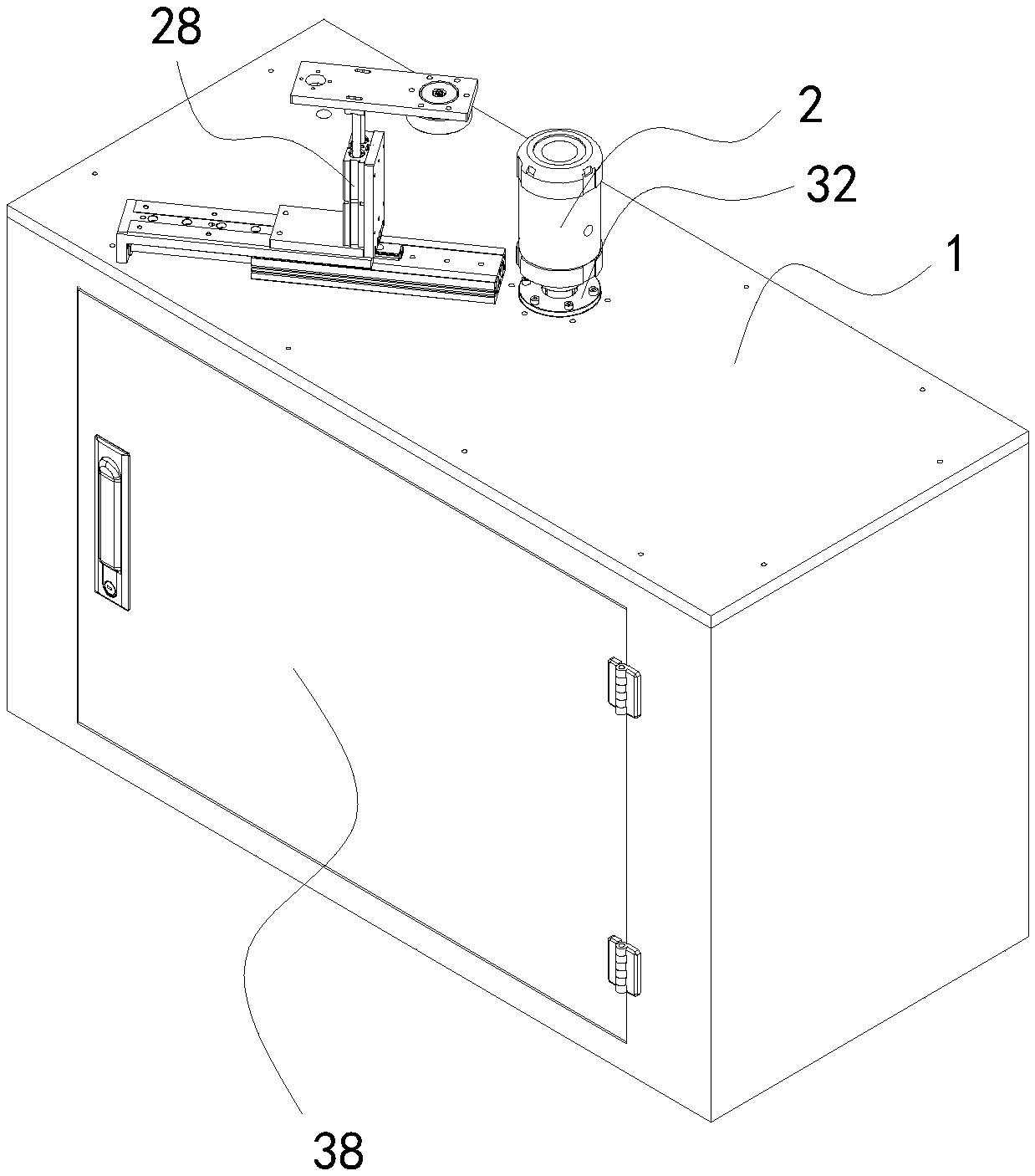

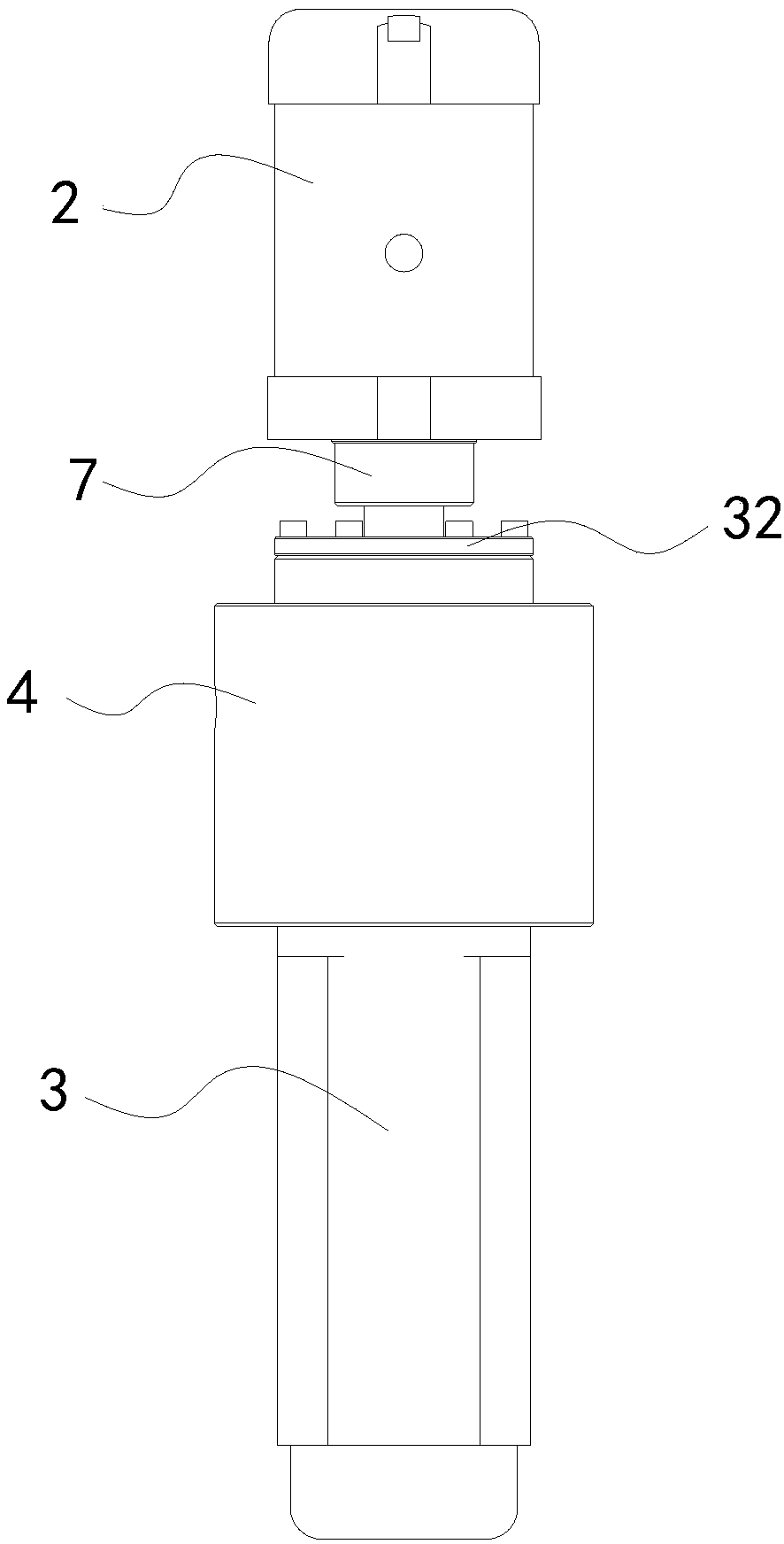

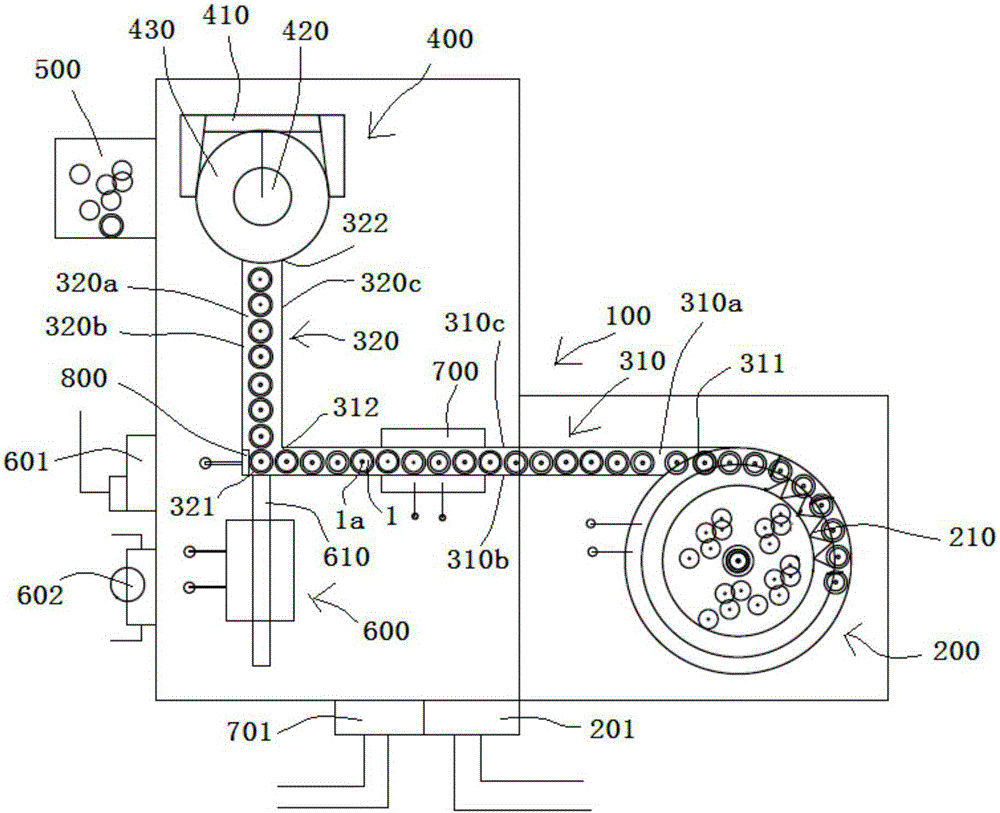

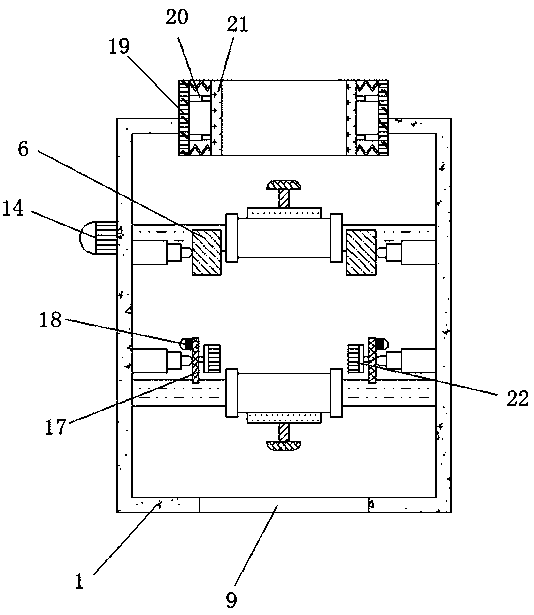

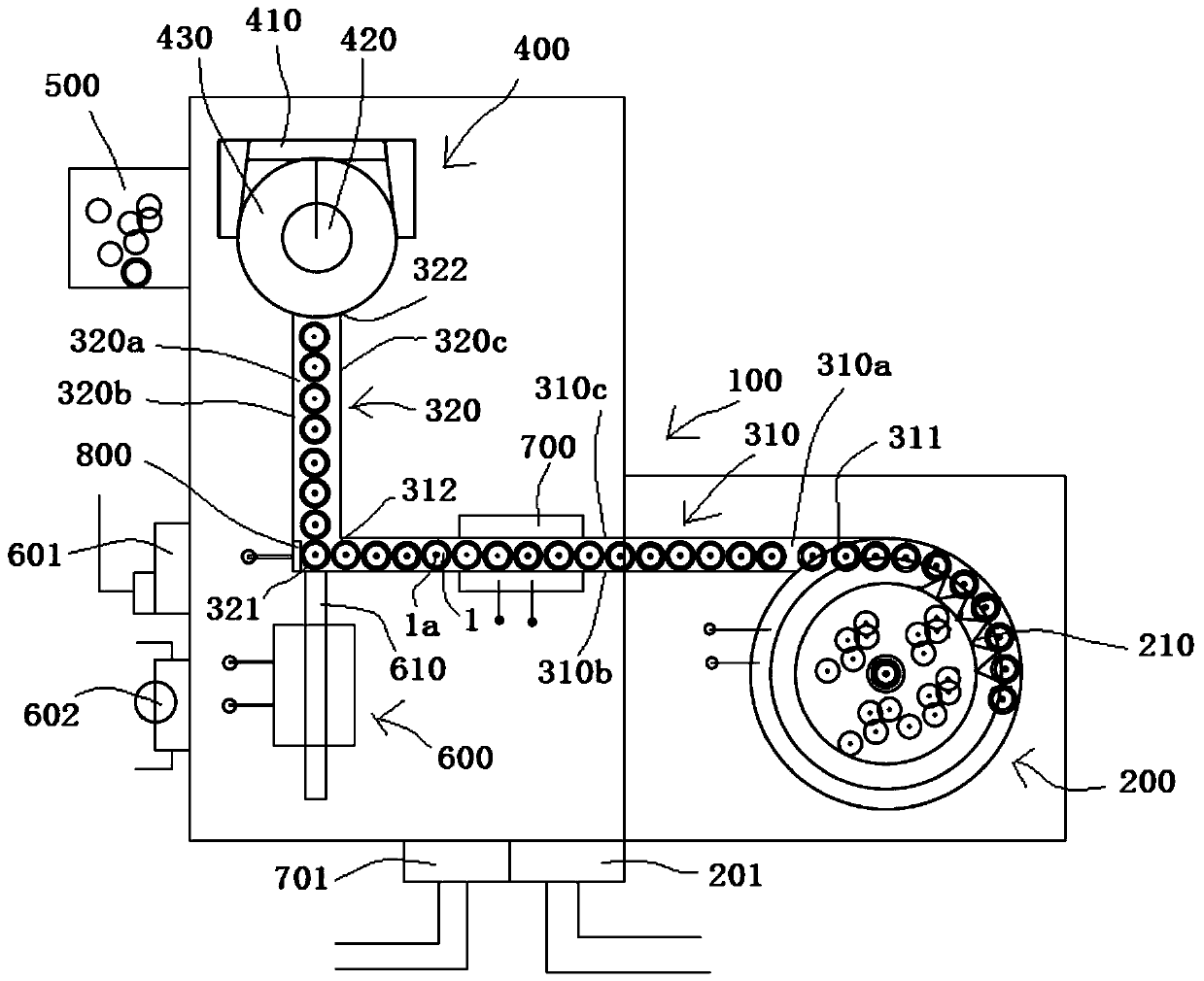

Workstation for polishing plastic cylindrical workpiece

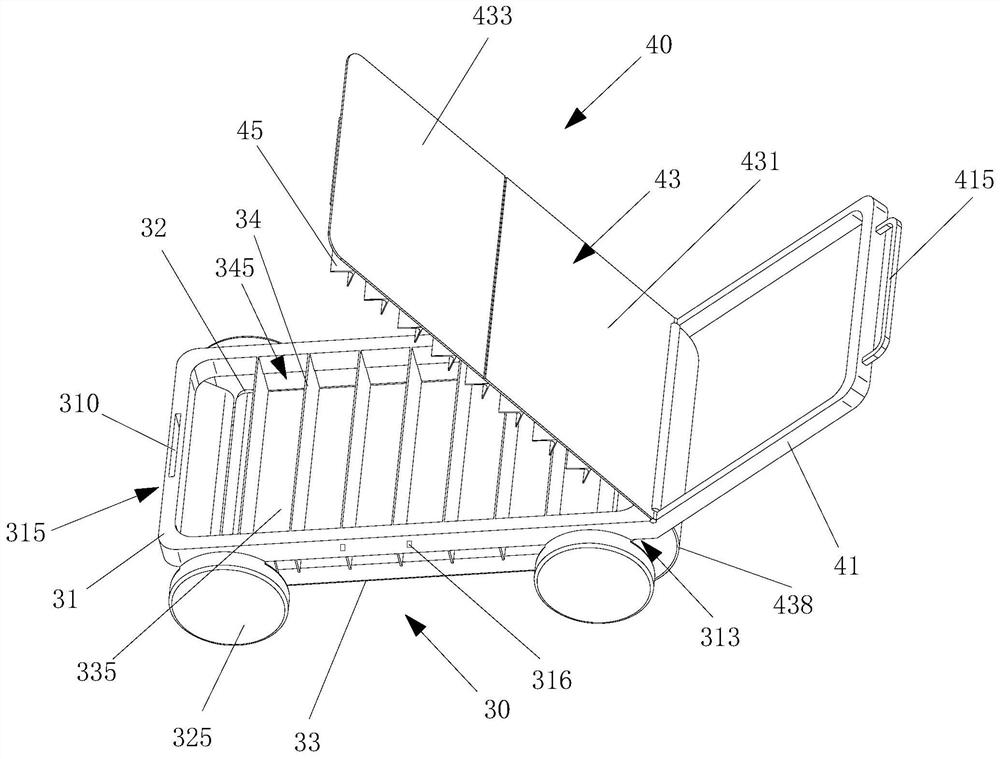

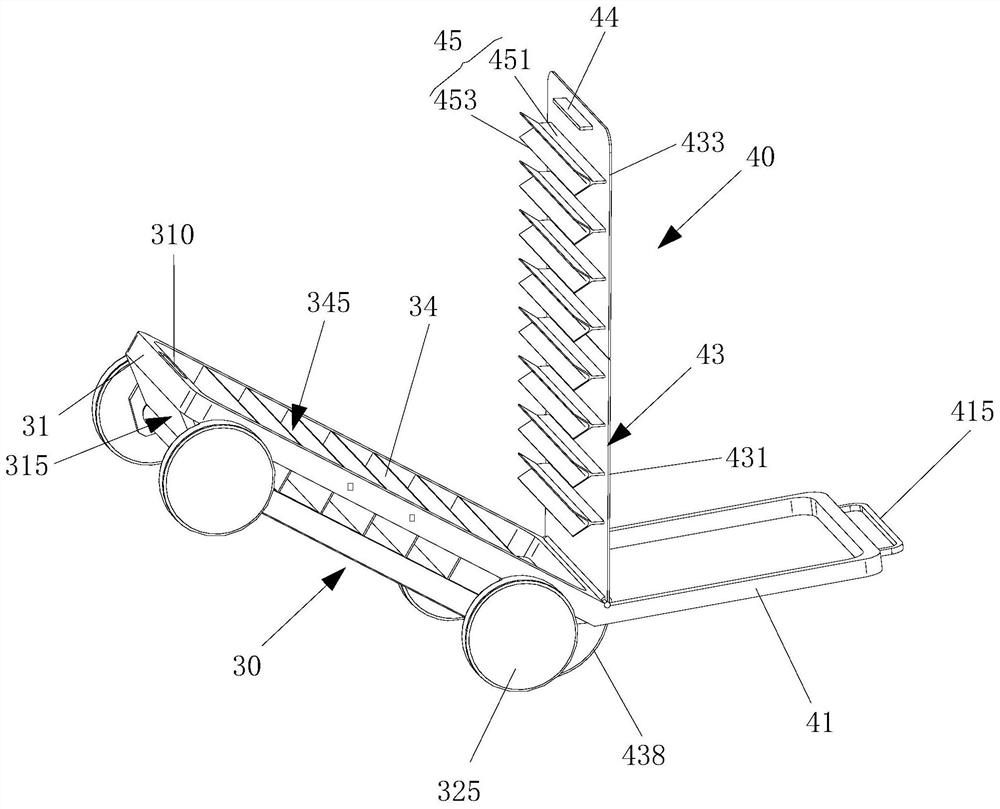

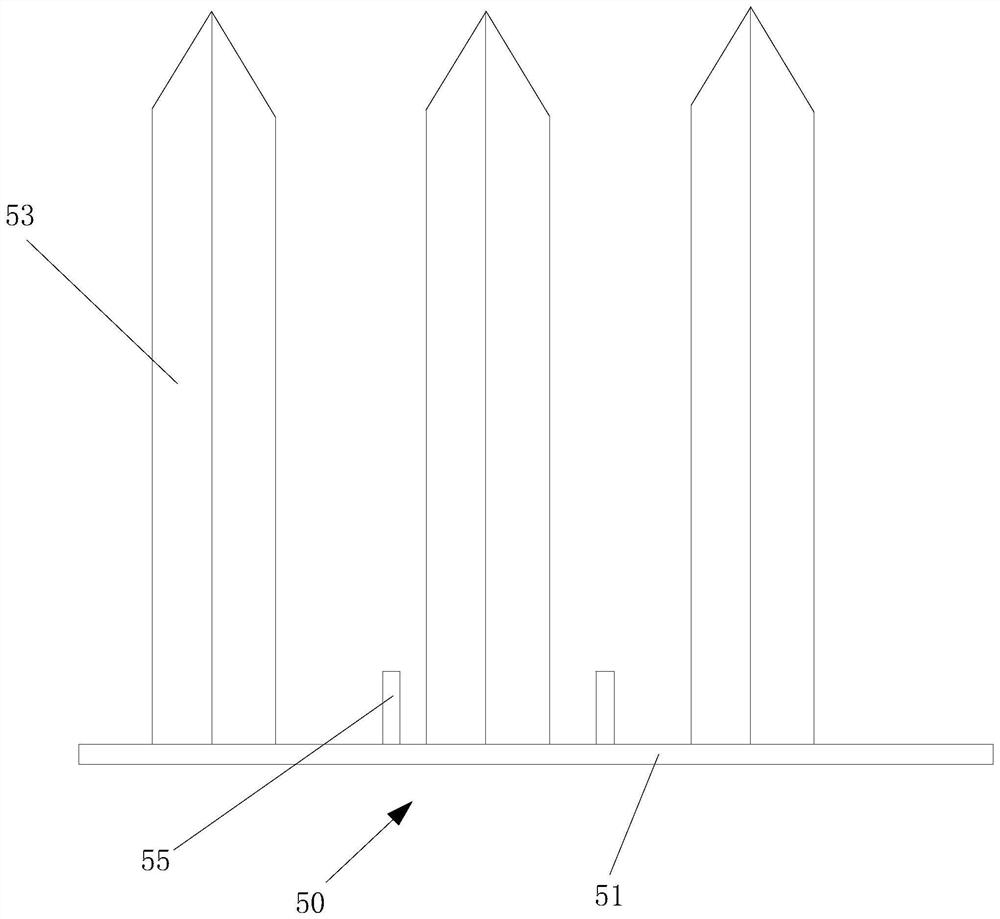

PendingCN108262654AAchieve grindingConsistentRevolution surface grinding machinesGrinding drivesEngineeringWorkstation

The invention relates to the field of polishing workstation, in particular to a workstation for polishing a plastic cylindrical workpiece. The workstation for polishing the plastic cylindrical workpiece comprises a base assembly, a polishing assembly and a workpiece jig platform assembly. The polishing assembly and the workpiece jig platform assembly are both fixed to the base assembly, and the polishing assembly is located on one side of the workpiece jig platform assembly. The workpiece jig platform assembly comprises a workbench, a pressing device and a fixing rotary device. The workbench is connected with the base assembly, and the pressing device and the fixing rotary device are fixed to the workbench. The fixing rotary device comprises a profile modeling jig and a drive device drivesthe profile modeling jig to rotate, and the drive device is fixed to the workbench. By means of the workstation for polishing the plastic cylindrical workpiece, the polishing of the plastic cylindrical workpiece is achieved, the labor is saved, the machining polishing efficiency is accelerated, and the cylindrical workpiece with consistence and high yield can be polished.

Owner:CHONQING HUASHU ROBOT CO LTD

Artificial tooth material and preparation method thereof

ActiveCN103284889BHigh strengthMeet needsImpression capsDentistry preparationsParaffin waxMicrocrystalline wax

Owner:珠海市红旌发展有限公司

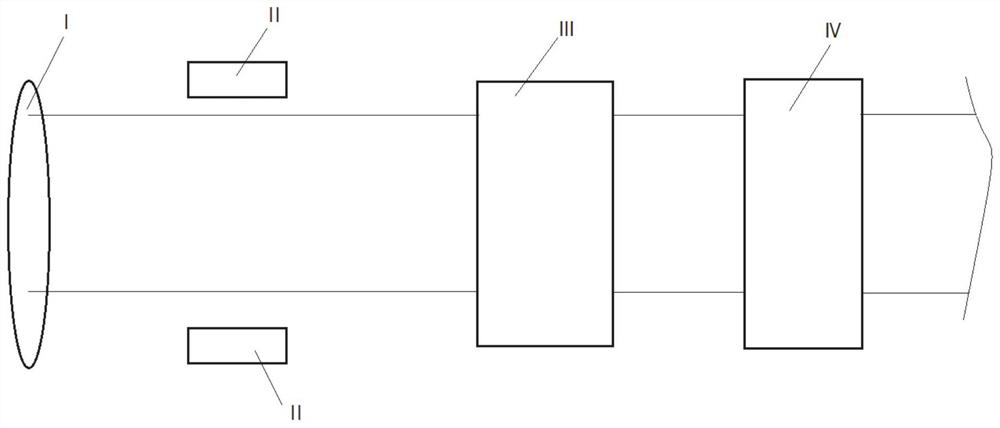

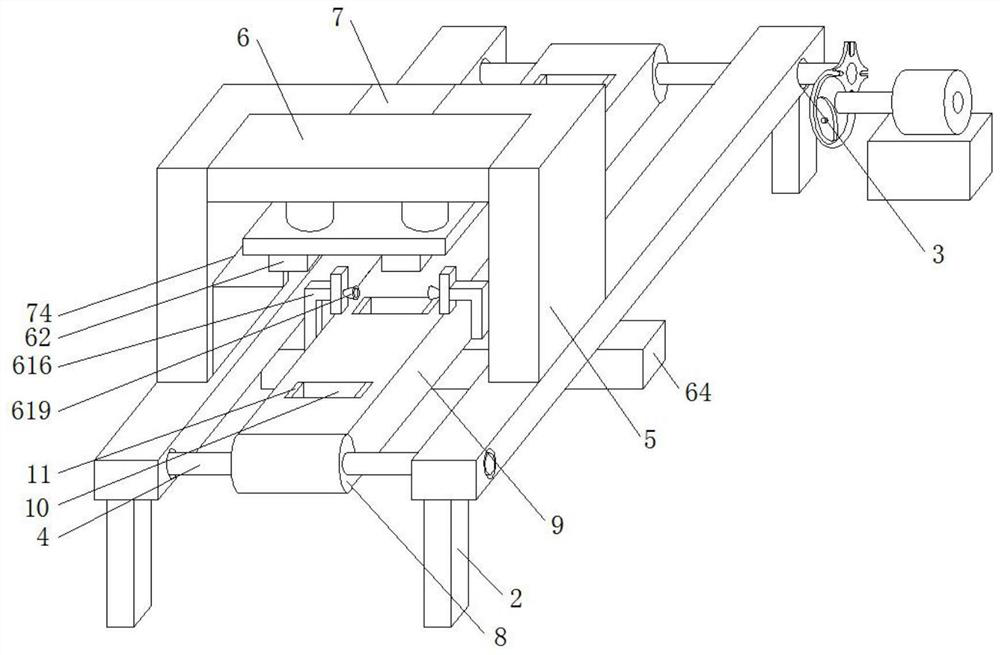

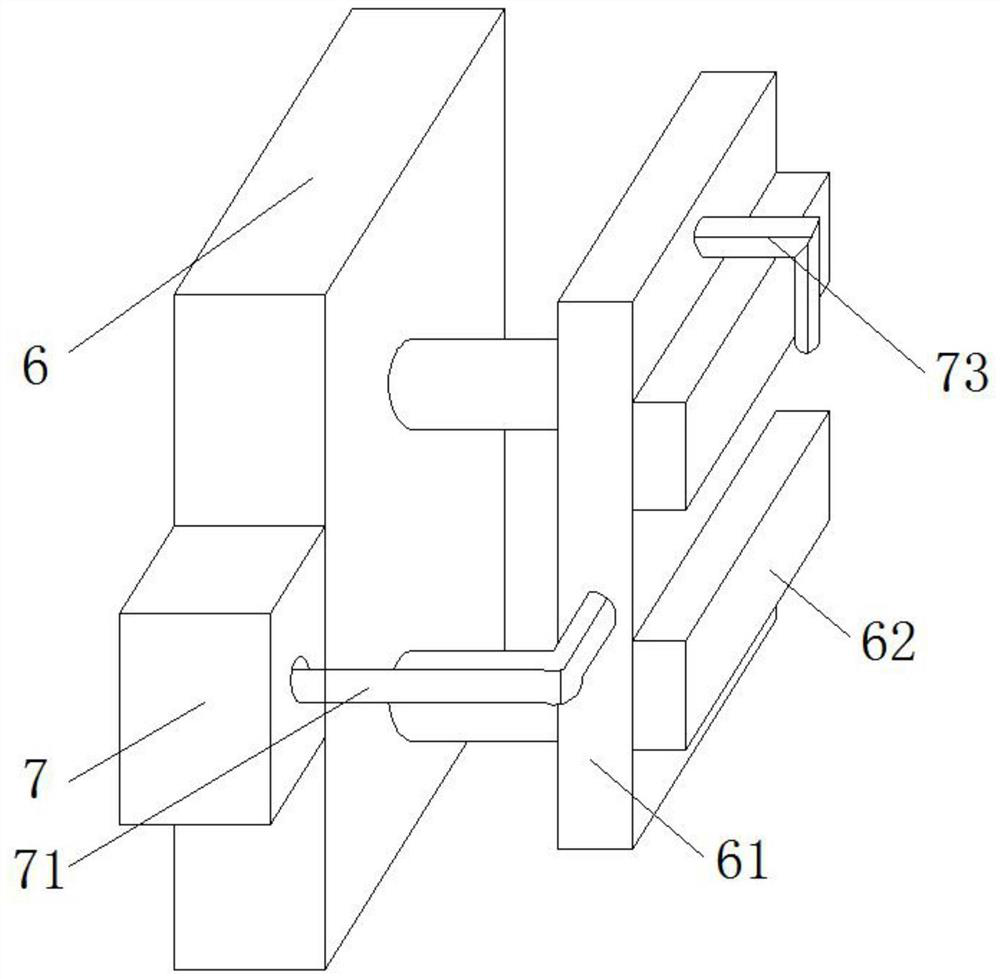

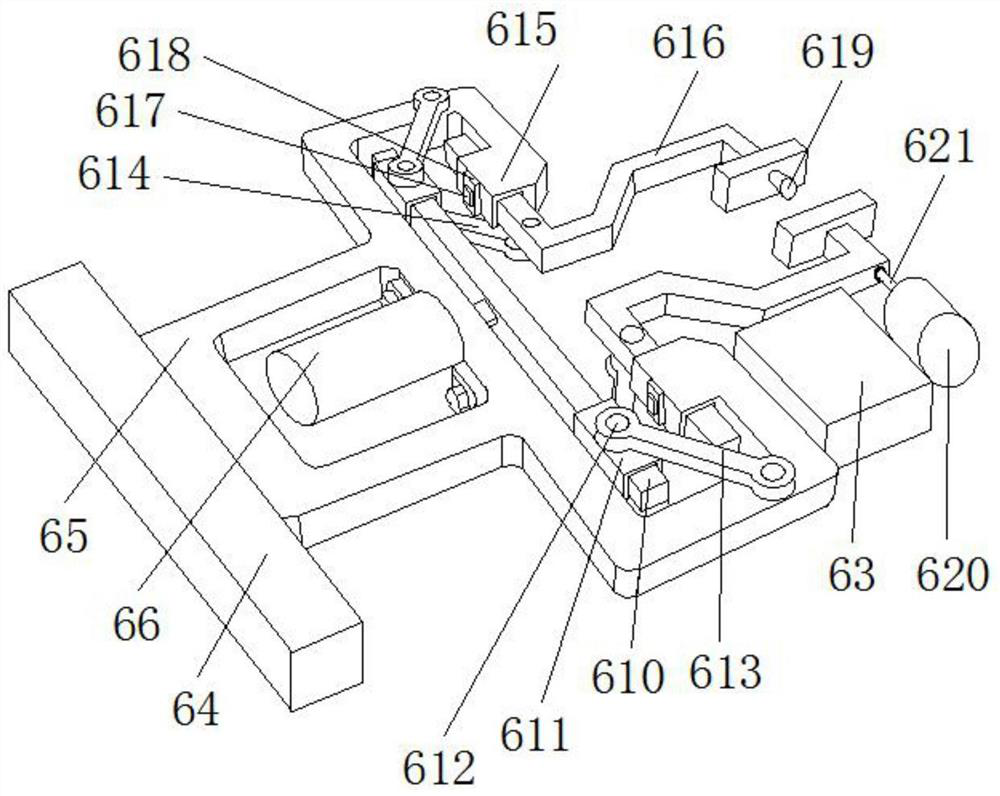

Trimming machine for end faces of pins

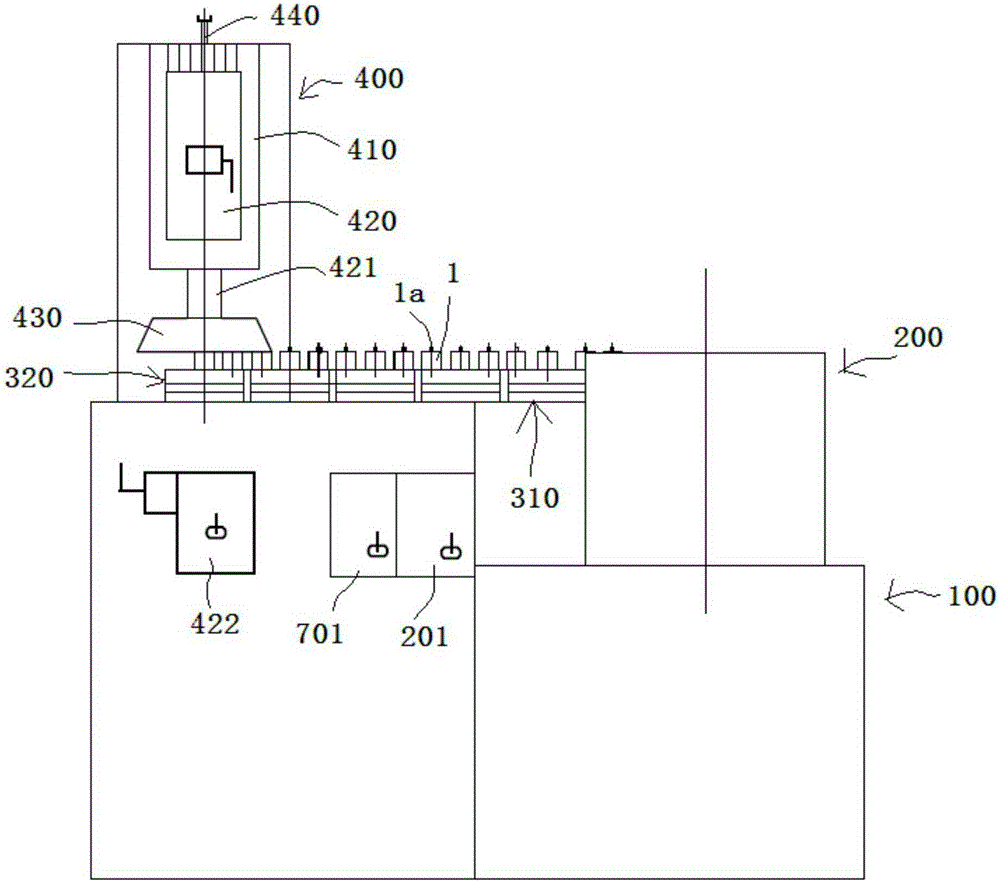

ActiveCN105252360AAchieve the purpose of polishingFully automated working processGrinding feedersPlane surface grinding machinesButt jointGraphite

The invention discloses a trimming machine for the end faces of pins. The trimming machine comprises a machine table, a graphite pin feeding device arranged on the machine table, a first feeding guide trough, a second feeding guide trough, a polishing device, a receiving disc and a linear pushing device. The first feeding guide trough and the second feeding guide trough are arranged on the machine table. The first end of the second feeding guide trough is in butt joint with the second end of the first feeding guide trough. The polishing device is arranged above the second end of the second feeding guide trough. The receiving disc is arranged on the machine table. The linear pushing device is arranged on the outer side of the first end of the second feeding guide trough. A conductive block electrically connected with a driving switch of the linear pushing device is arranged on the inner side wall and the inner bottom wall of the first end of the second feeding guide trough. According to the trimming machine, through connection achieved when the graphite pins are in contact with the conductive block and disconnection achieved when the graphite pins are not in contact with the conductive block, the pushing end of the linear pushing device is driven to push the graphite pins on the second feeding guide trough to forwards move, and then the aim of polishing the graphite pins is achieved. The whole working process is full automatic, manual polishing is avoided, and working efficiency is greatly improved.

Owner:SHANGHAI HONGFENG IND

Edge grinding device for display screen glass processing

PendingCN114505752ANo need for manual grindingWaste of manpower and material resourcesEdge grinding machinesGrinding drivesElectric machineryEngineering

The edge grinding device for display screen glass machining comprises a workbench, a telescopic piece is fixedly connected to the bottom side of the interior of the workbench, a moving mechanism is fixedly connected to the top of the telescopic piece, and a grinding mechanism is fixedly connected to the moving mechanism; a first sensor and a second sensor are arranged at the front end and the rear end of the interior of the moving mechanism correspondingly, the right side of the workbench is fixedly connected with a supporting mechanism used for containing glass, a first motor is arranged on the supporting mechanism, and the output end of the first motor is fixedly connected with a fixing assembly. The glass grinding device has the advantages that the moving mechanism drives the grinding mechanism to grind glass, when the grinding wheel assembly grinds irregular glass in the moving and grinding process, certain force is given to the grinding wheel assembly, then a first spring drives a connecting column to retract or stretch, and the grinding wheel assembly can grind the irregular glass; irregular glass can be ground, and manual grinding is not needed.

Owner:安徽尼睿光电科技有限公司

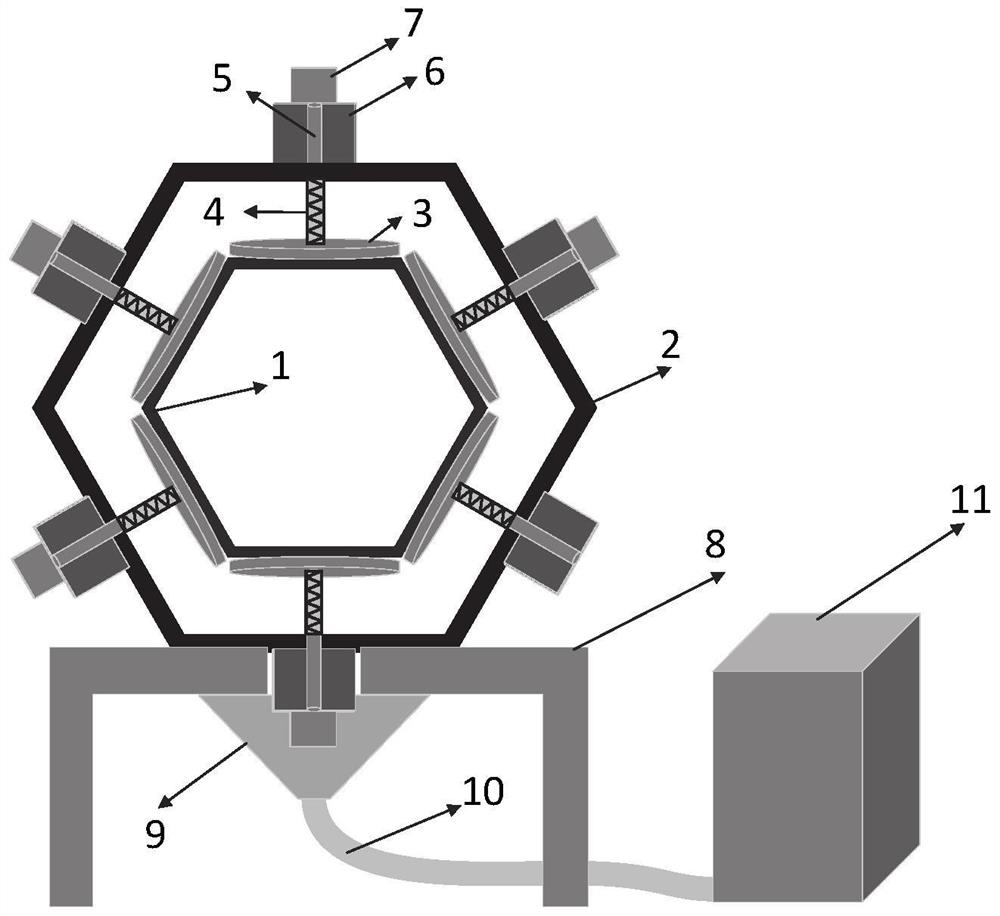

Anode tube roughness grinding system and method

PendingCN113084624ANo need to carryNo need for manual grindingGrinding drivesGrinding feed controlProduction lineEngineering

The invention discloses an anode tube roughness grinding system and method. The anode tube roughness grinding system comprises a supporting frame matched with an anode tube in shape, and the supporting frame is connected with a fixed base; a grinding device is arranged on the supporting frame and corresponds to each surface of a regular hexagonal anode tube, and the grinding devices can be in contact with the outer surface of the anode tube; and an opening is formed in the bottom end of the supporting frame, and a dust collecting device is arranged at the position of the opening. By designing the automatic grinding system, roughness grinding is directly conducted on the surface of the anode tube at the tail end of an anode tube production line, the anode tube does not need to be carried, manual grinding is not needed, the automation degree is high, manpower and material resources are saved, and the production efficiency is greatly improved.

Owner:QILU UNIV OF TECH

Formula of wood-plastic bathroom plate and production method

ActiveCN103993697BGood antibacterialImprove mildew resistanceConstruction materialPorositySurface layer

Owner:山东宜居新材料科技有限公司

Scrap removal device for bamboo floor processing and good in dust removal effect

InactiveCN108942468AGood dust removal effectIncrease air circulationGrinding carriagesGrinding feed controlScrapEngineering

The invention discloses a scrap removal device for bamboo floor processing and good in dust removal effect. The scrap removal device comprises a shell. Mounting columns are arranged at the two ends ofthe inner walls of the two sides of the shell. The opposite ends of every two opposite mounting columns are connected with the same roller through bearings. The outer walls of the circumferences of the two rollers are connected with the same conveying belt in a sleeved manner, and extending rods distributed at equal distance are arranged at the position of the middle of the side, away from the rollers, of the conveying belt. Containing pieces are arranged at the ends, away from the conveying belt, of the extending rods, and a bamboo floor is placed at the tops of the containing pieces locatedat the top of the conveying belt. Penetrating holes are formed at the bottoms of the outer walls of the two sides of the shell. The scrap removal device is good in dust removal effect, circulation ofair in the shell is improved, the cooling effect is achieved, and the temperature is effectively prevented from being too high; scrap removal and grinding of the two sides of the bamboo floor are achieved, manual grinding is not needed later, and time and labor are saved; and the scrap removal device is suitable for scrap removal and grinding of bamboo floors of different width sizes, and adjustment is convenient.

Owner:ANJI CHENFENG MACHINERY

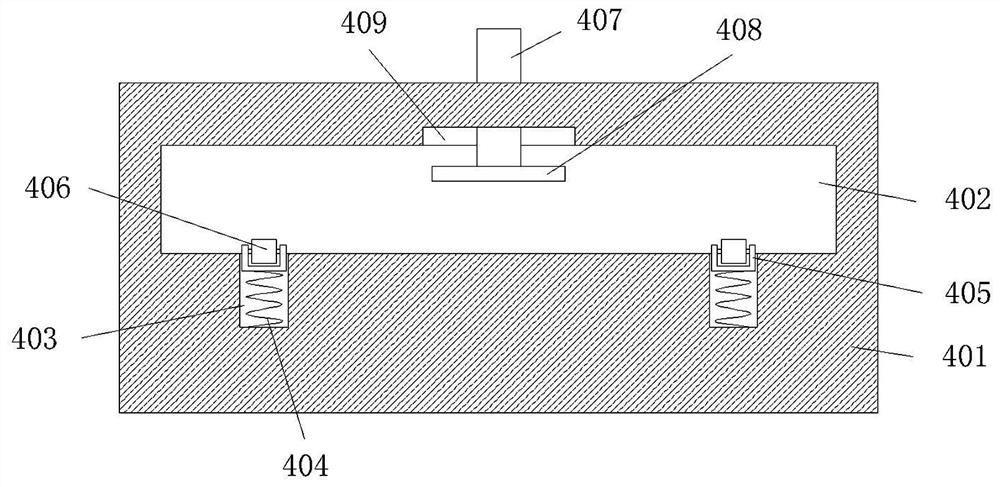

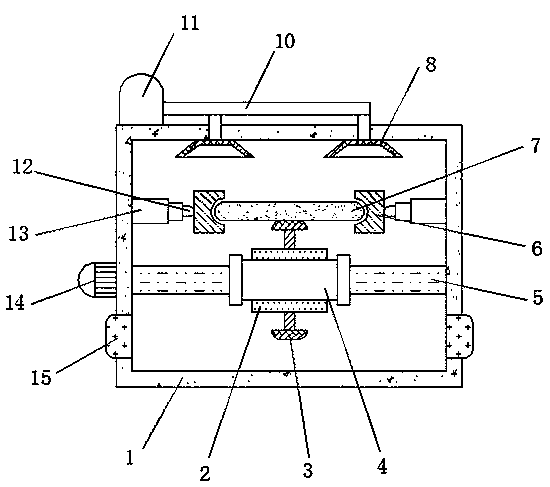

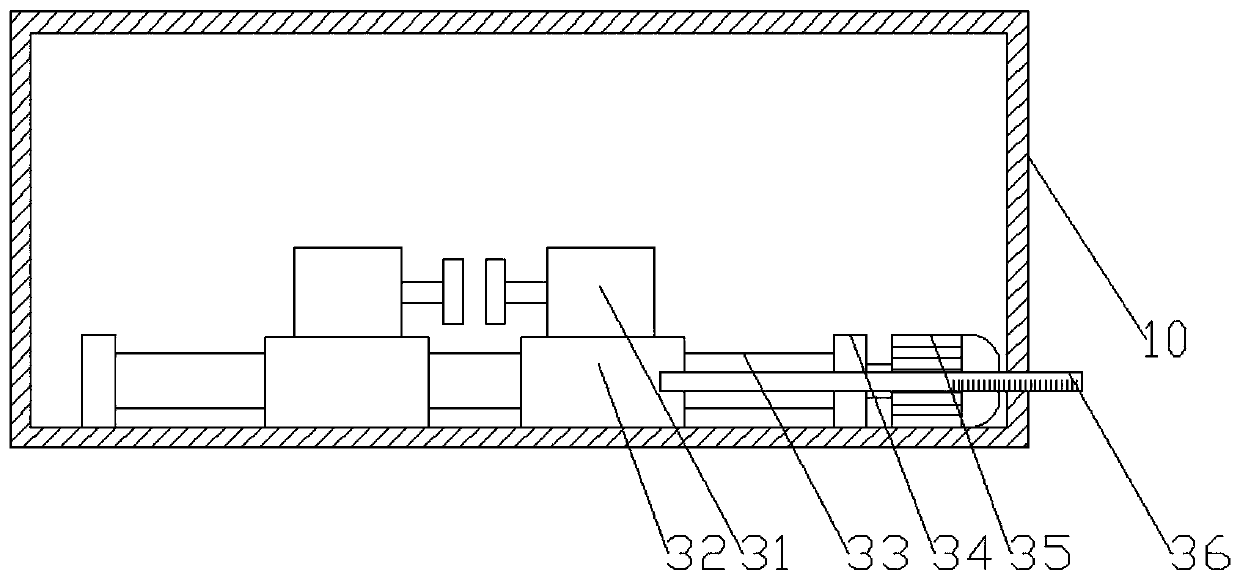

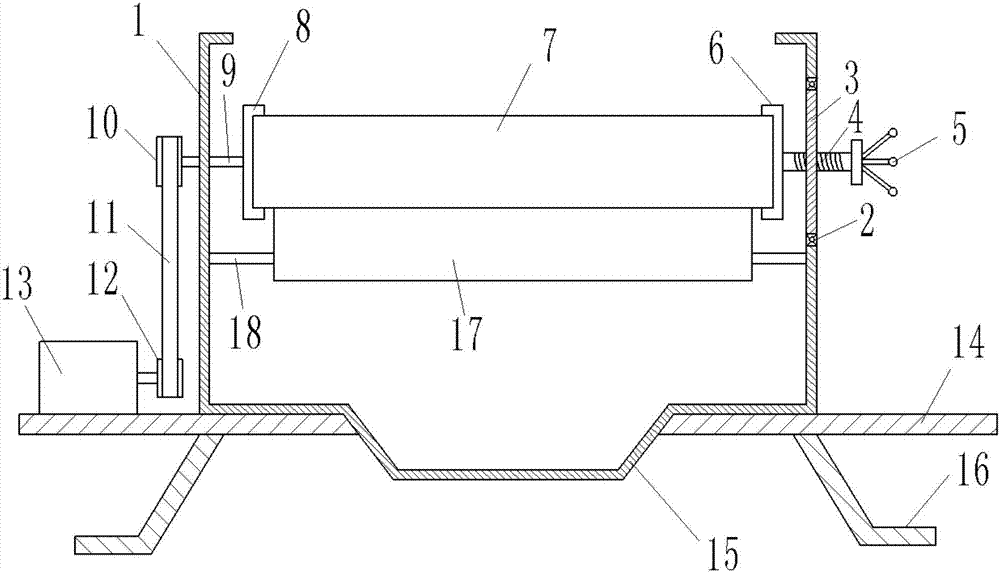

Polishing device of scraper

ActiveCN110421416ACreate pollutionNo need for manual grindingGrinding carriagesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a polishing device of a scraper. The polishing device comprises a cuboid box body. A feeding hole is formed in the front end of the box body, a U-shaped first supporting grooveis formed in the end, facing the inner side of the box body, of the feeding hole, a discharging hole aligned with the feeding hole is formed in the back end of the box body, a U-shaped second supporting groove is formed in the end, facing the inner side of the box body, of the discharging hole, the first supporting groove and the second supporting groove are located in a same straight line, and afirst absorbing conveying assembly, a polishing assembly and a second absorbing conveying assembly are successively arranged in the box body from the first supporting groove to the second supportinggroove. The polishing assembly clamps the scraper and guides the scraper to move through the first absorbing conveying assembly and the second absorbing conveying assembly and polishes the scraper through the polishing assembly without manual polishing, so that the polishing efficiency is high. The polishing device is uniform to polish and good in polishing effect, and polishing work is carried out in the box body, so that a working environment is not polluted.

Owner:MAANSHAN WISDOM NEW NANOMETER MATERIALS

Automatic grinding device for vehicle intelligent curtain motor rotor

ActiveCN110900370ATo achieve the effect of automatic controlFully automatedGrinding drivesGrinding machinesElectric machineryAutomation

The invention belongs to the technical field of motor manufacturing equipment, and particularly relates to an automatic grinding device for a vehicle intelligent curtain motor rotor. The device comprises supporting plates, wherein the lower surfaces of the two supporting plates are fixedly connected with supporting legs, the surfaces of one sides of the two supporting plates are provided with rotating holes, the inner walls of the rotating holes are slidably provided with rotating shafts in a sleeve mode, the supporting plates are symmetrically distributed with axes of the rotating shafts as the symmetrical centers, one end of one rotating shaft is fixedly connected with a geneva wheel mechanism, the upper surfaces of the two supporting plates are fixedly connected with supporting blocks,and the inner side faces of the supporting blocks are provided with grinding mechanisms. According to the automatic grinding device for the vehicle intelligent curtain motor rotor, by arranging the grinding mechanisms on the inner side faces of the supporting blocks, the effects that grinding on the motor rotor is uniform and short in time, manpower consumption grinding is not needed, and the automation degree is high are achieved, and the problems that existing grinding needs to be manually conducted, the time is too long, manual grinding is tedious, physical strength is easy to consume and the grinding efficiency is low are solved.

Owner:NANJING SHILAIER AUTOMOTIVE ELECTRONICS CO LTD

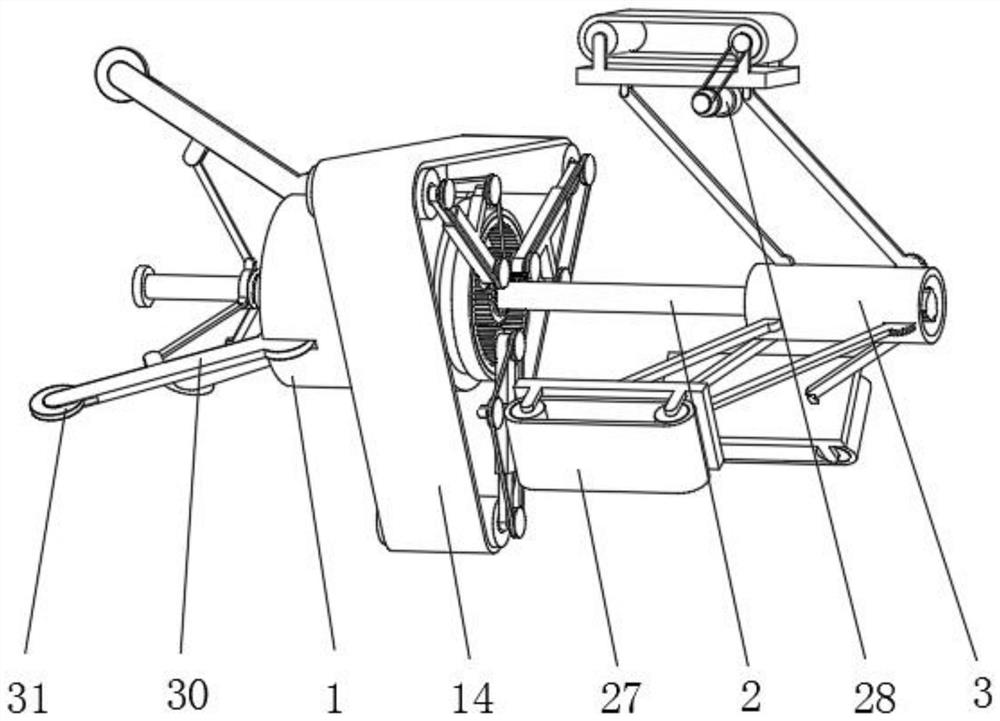

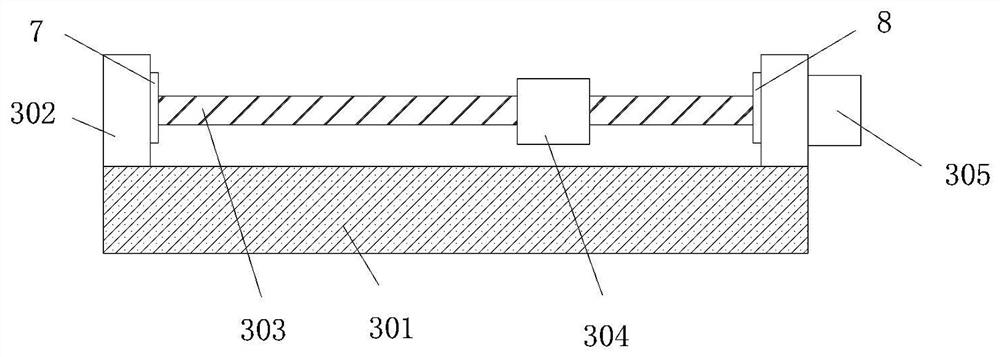

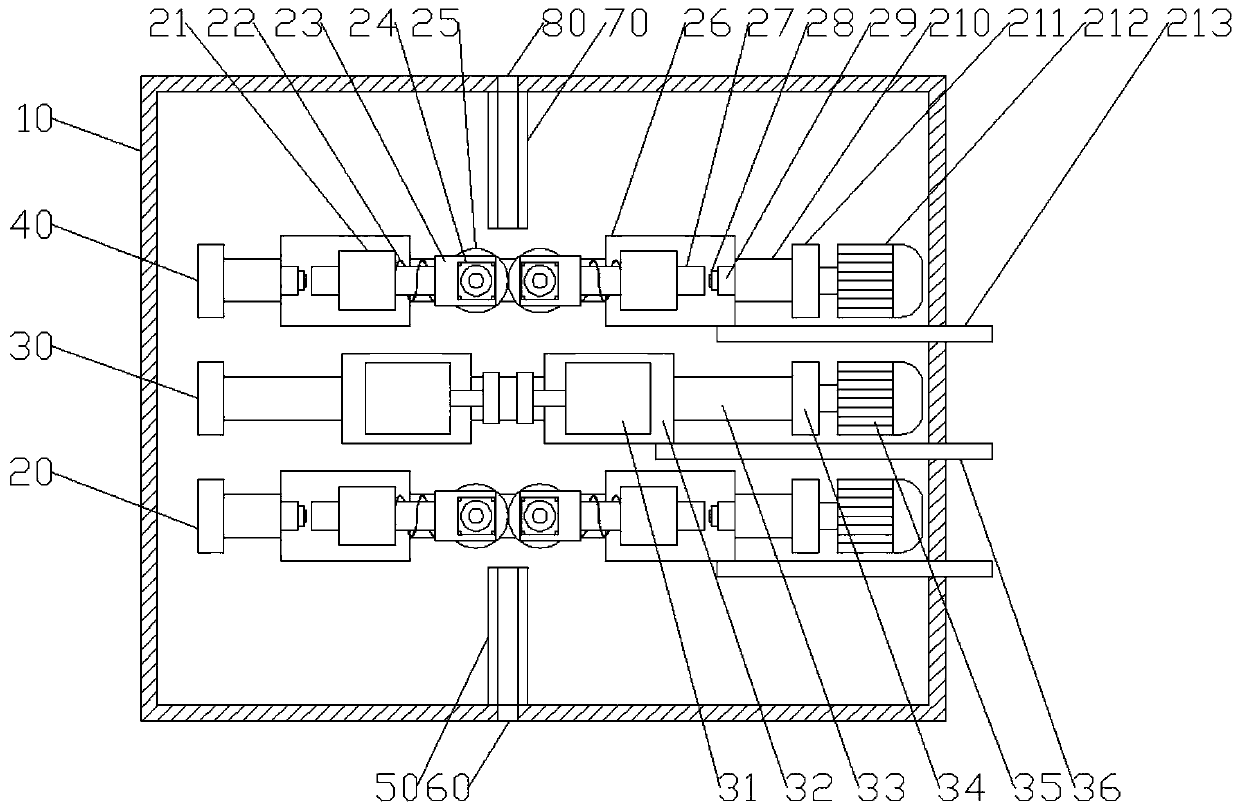

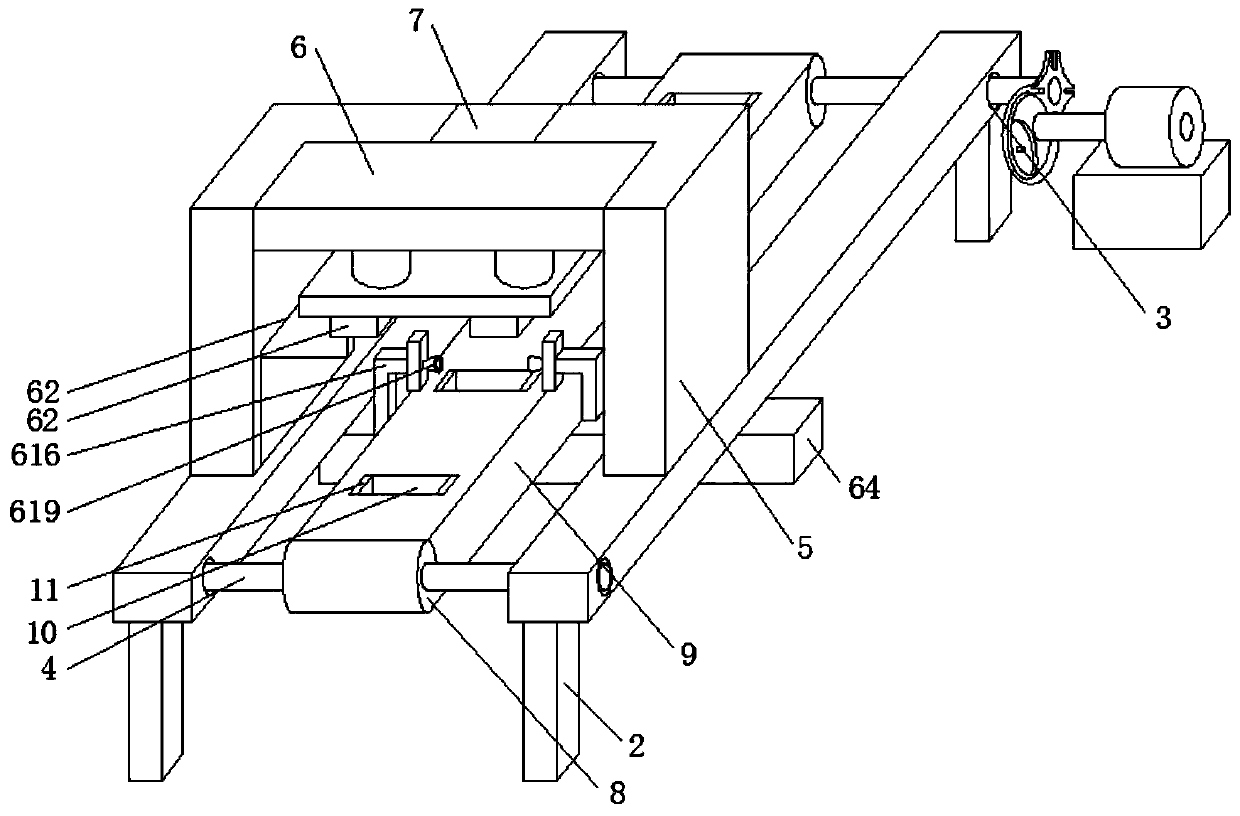

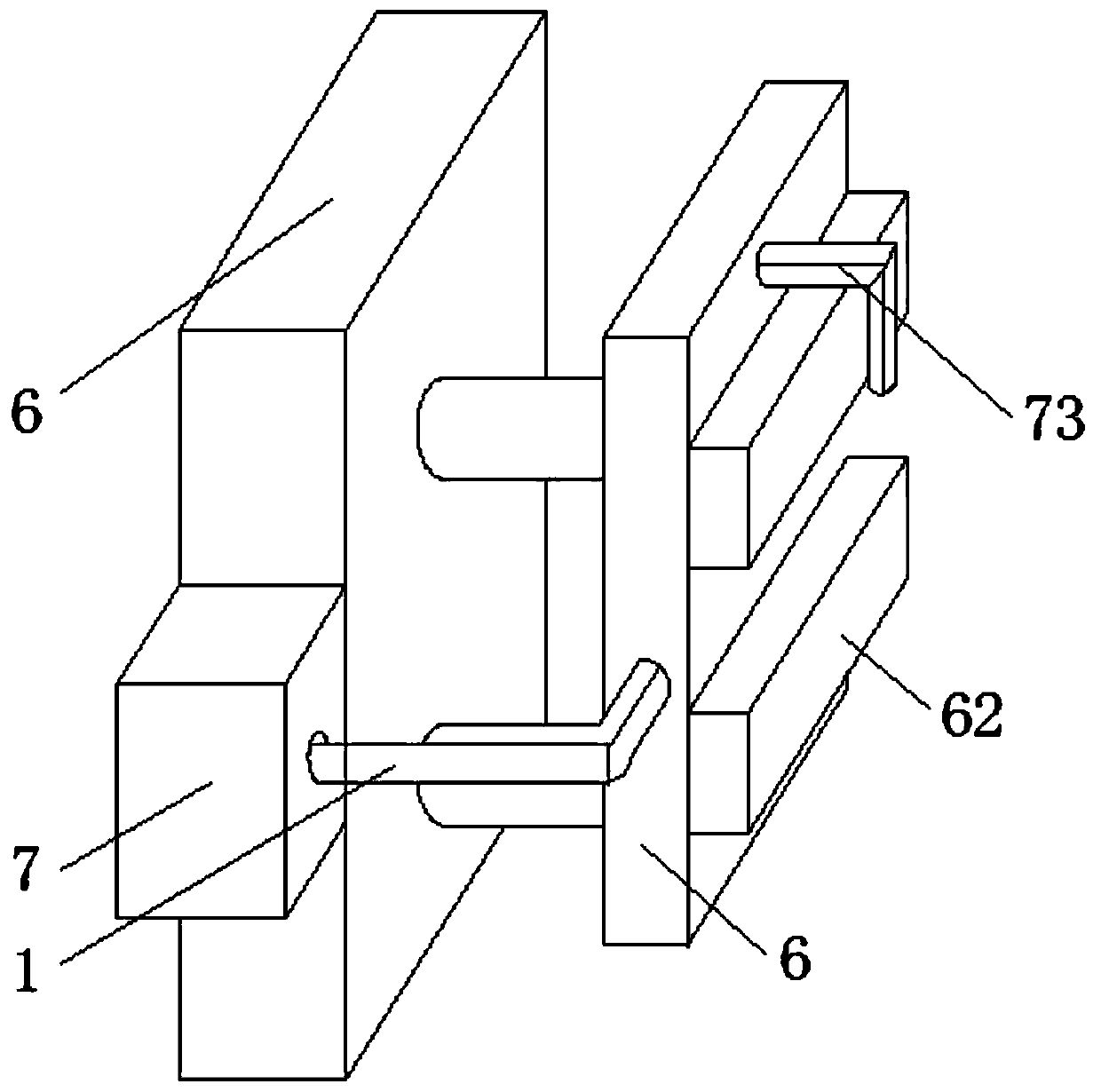

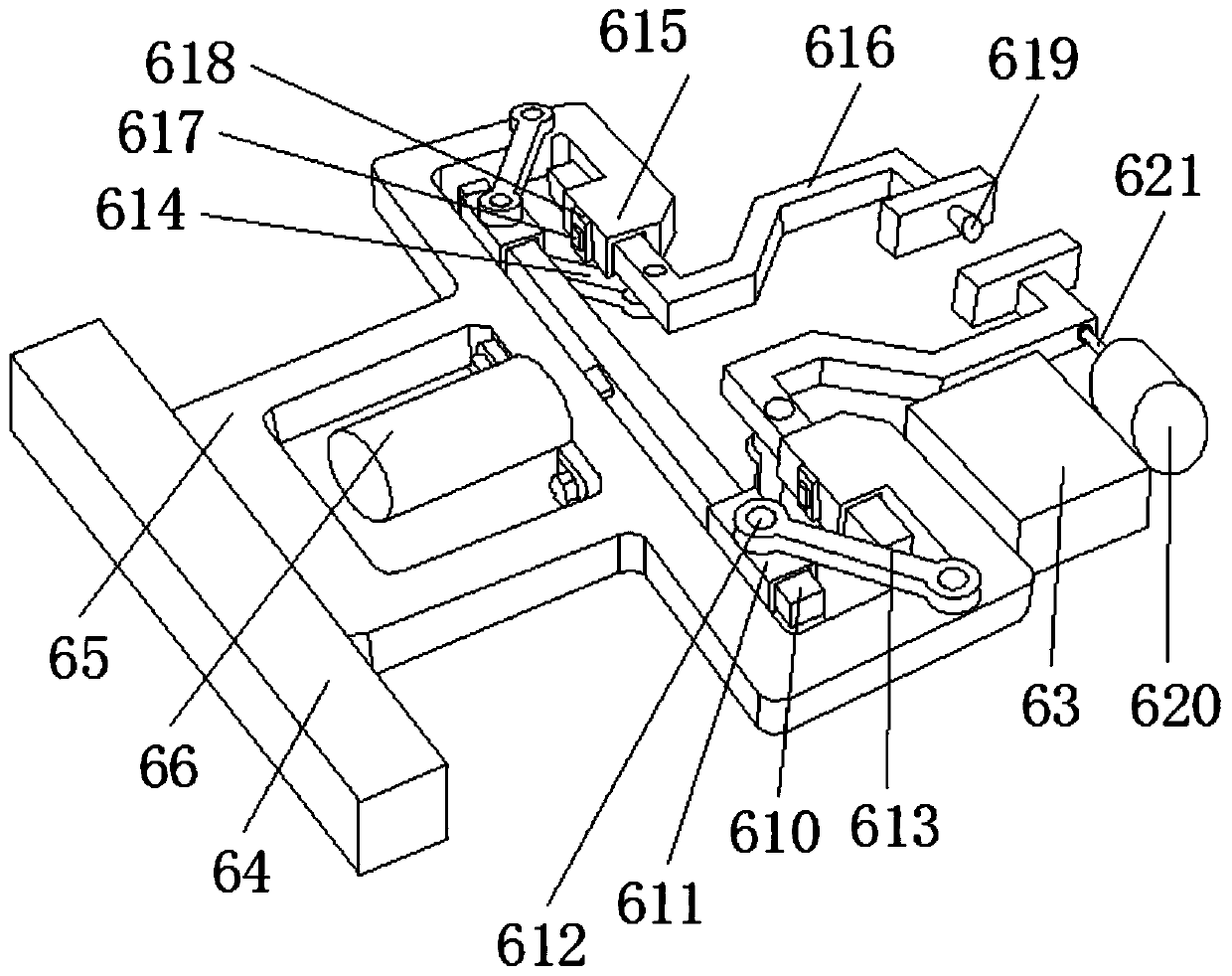

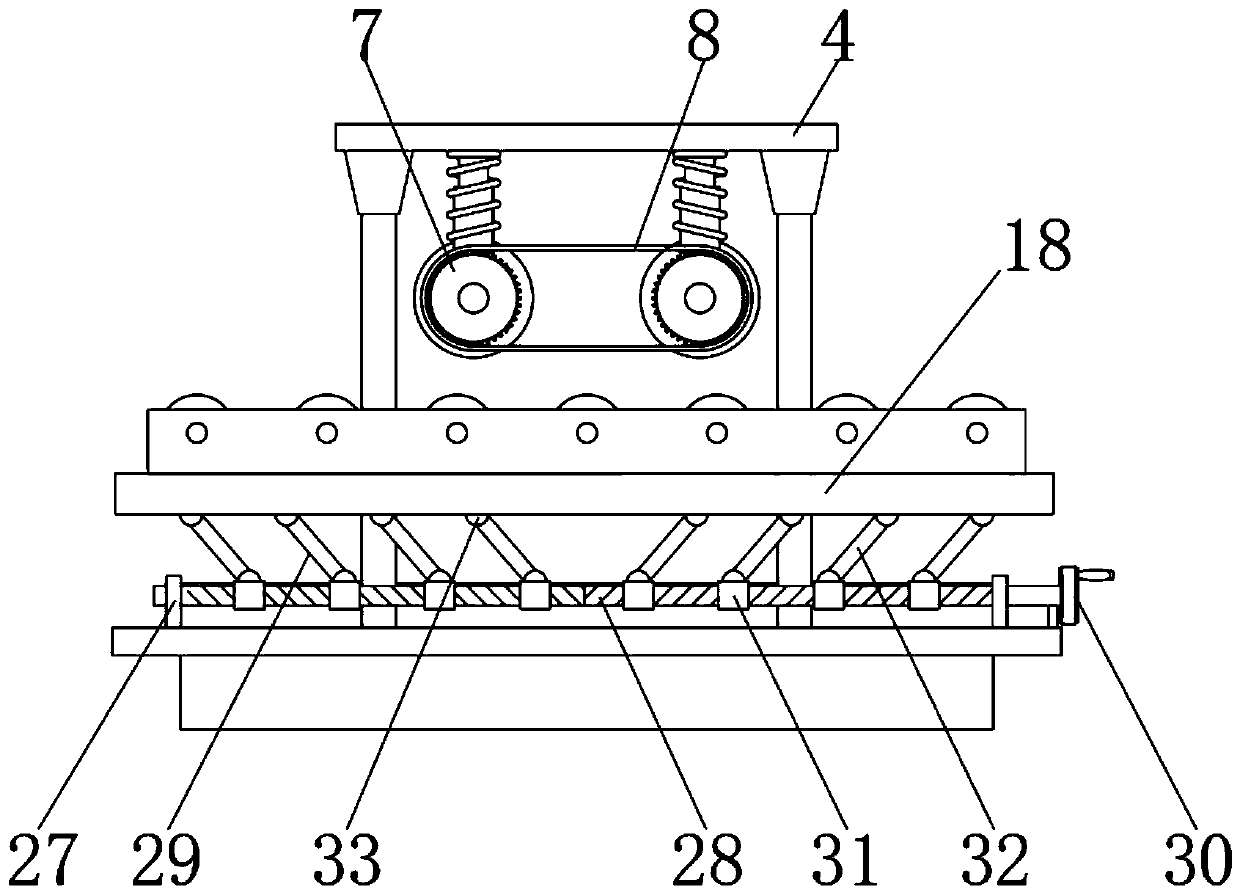

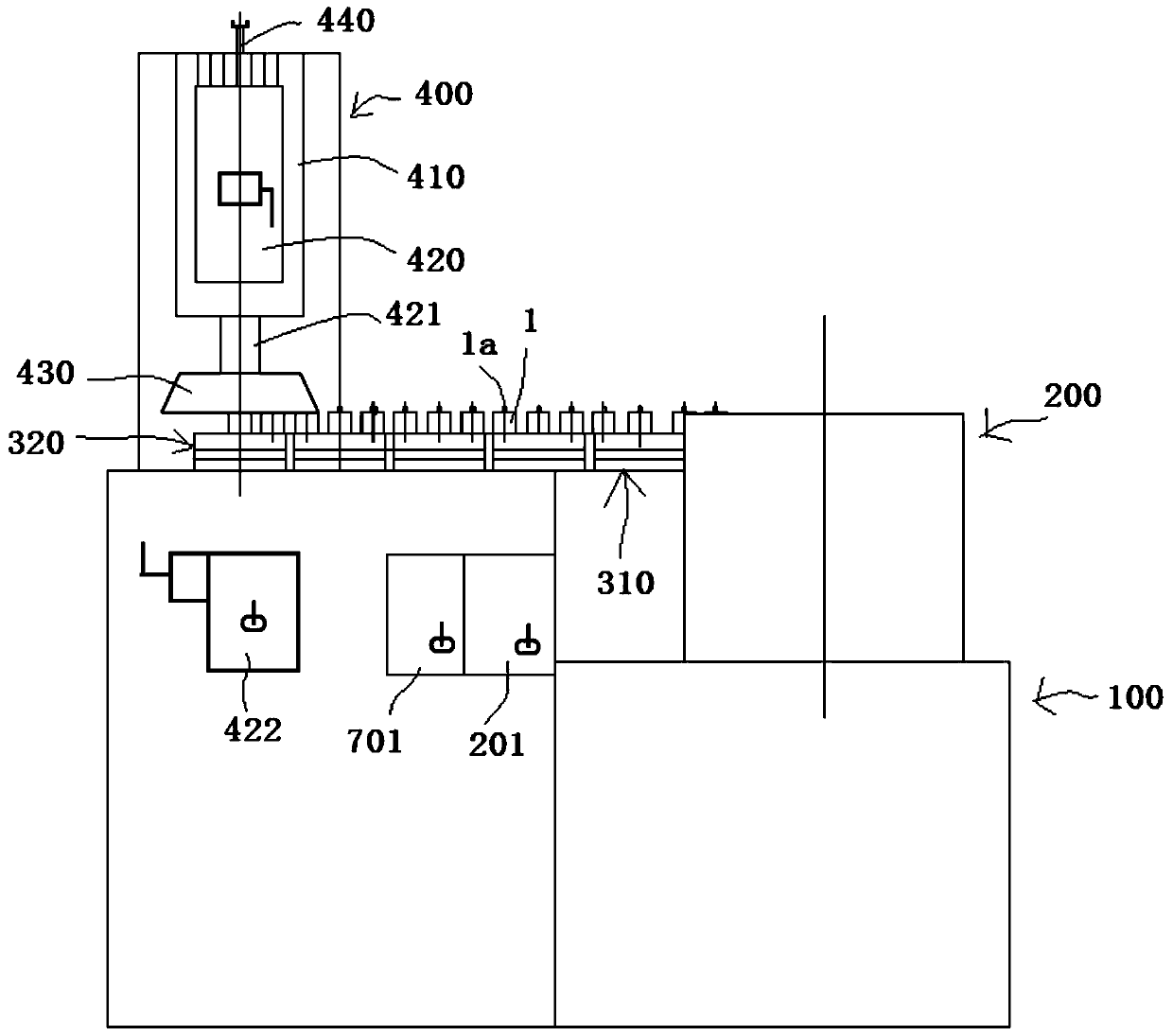

Automatic production line for knife and sword

PendingCN110125740AAdjust contactAdjustable distanceGrinding carriagesOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses an automatic production line for a knife and sword. The automatic production line comprises a grinding device, a moving device and a supporting device, the moving device is fixed to the top of the supporting device, the moving device is located on the bottom of the grinding device, through the grinding device and the supporting device, adjusting of the distance between theknife and sword surface and the grinding roller is achieved, grinding and polishing of knives and swords of different thickness specifications can be met, meanwhile, through an extrusion part in the grinding device, the contact between a grinding roller and the surface of the knife and sword can be adjusted in a small scale manner, grinding of the sunken arc surface in the knife and sword surfaceafter forging can be met, manual grinding is not needed, production efficiency is increased, and meanwhile, the ground knife and sword surface is uniform and smooth.

Owner:龙泉市陈栋剑铺

Candle polishing equipment

InactiveCN107538284AReduce labor intensityNovel structureRevolution surface grinding machinesGrinding work supportsCandleSlide plate

The invention discloses candle polishing equipment, which comprises a main frame, a bearing is installed on the upper right side of the main frame, a center wheel is connected inside the bearing, a threaded rod is threaded in the middle of the center wheel, and a lock is installed at the right end of the threaded rod. Tighten the turntable, the left end of the threaded rod is equipped with a right splint, the left end of the right splint is connected to the candle, the left side of the candle is connected to the right end of the left splint, the left side of the left splint is equipped with a rotating shaft, and the rotating shaft is connected to the left side of the main frame. The side plate is slidingly connected, the left end of the rotating shaft is connected to the large pulley through the key, the large pulley is connected to the belt, and the small pulley is connected to the bottom of the belt, and the small pulley is connected to the motor through the key, and the motor is installed on the left side of the bottom plate. The upper end face of the present invention is novel in structure, scientific in design, simple in structure, and does not need manual grinding, which reduces the labor intensity of users and improves work efficiency.

Owner:荣昌区昌州街道全福蜡烛加工厂

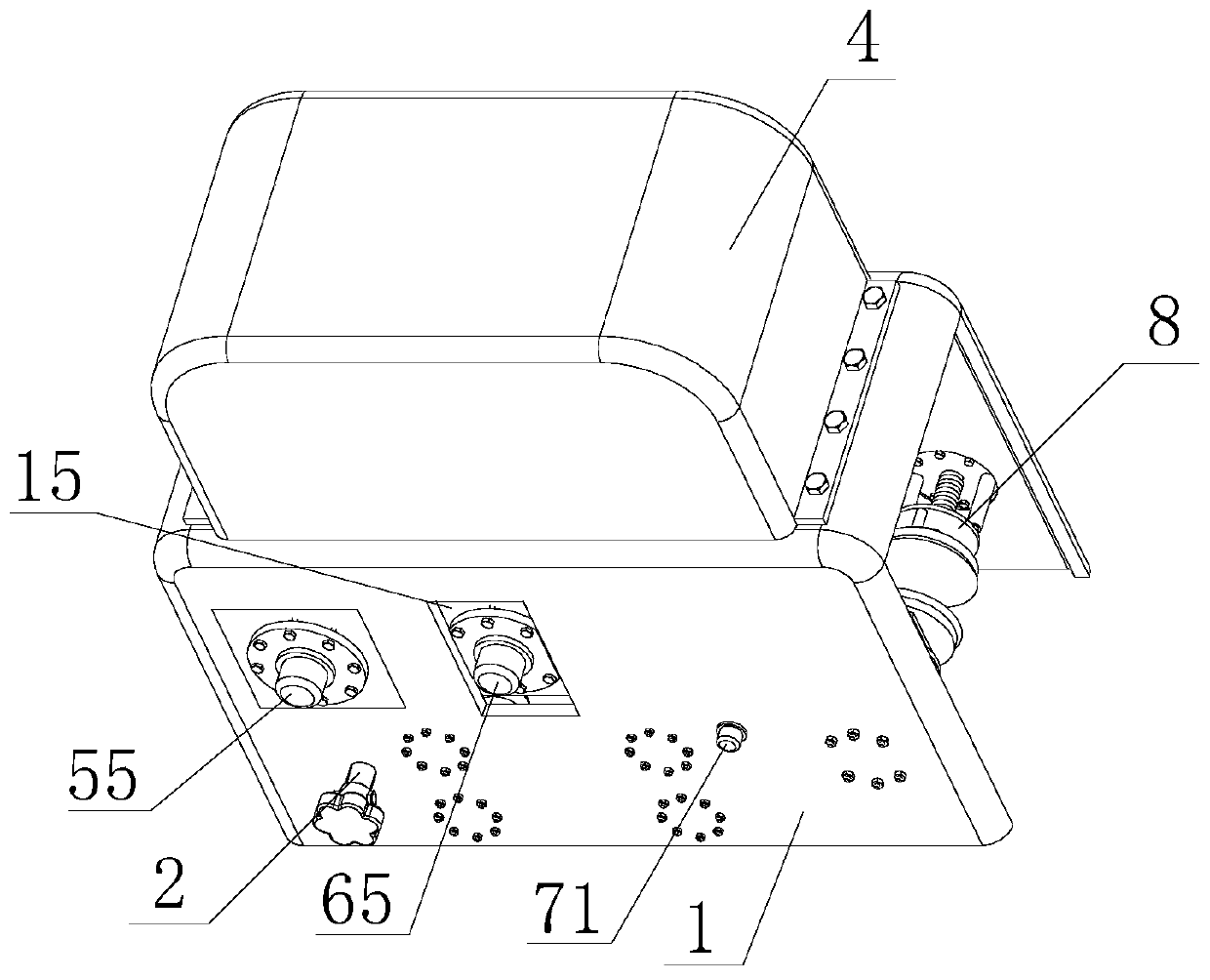

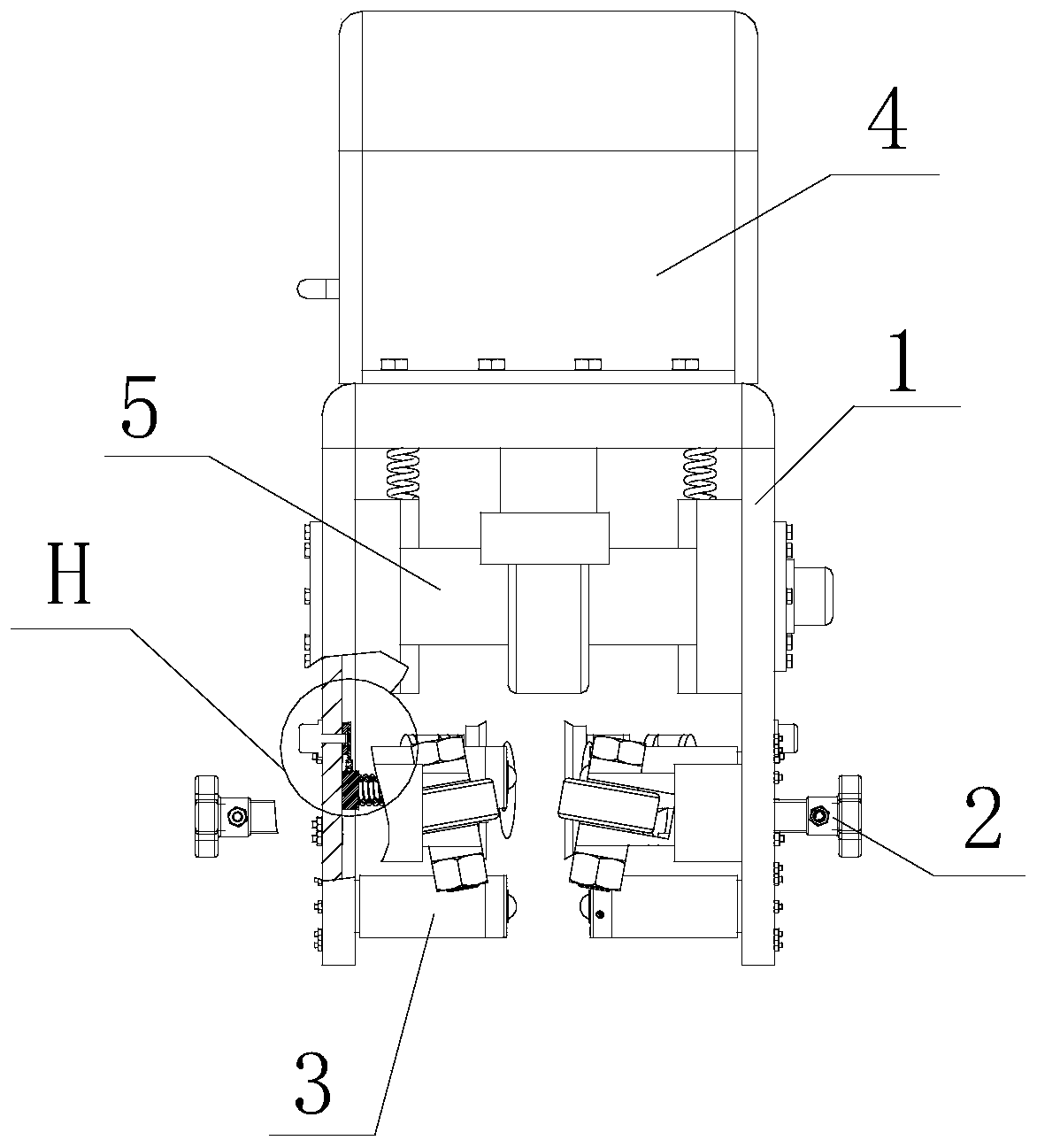

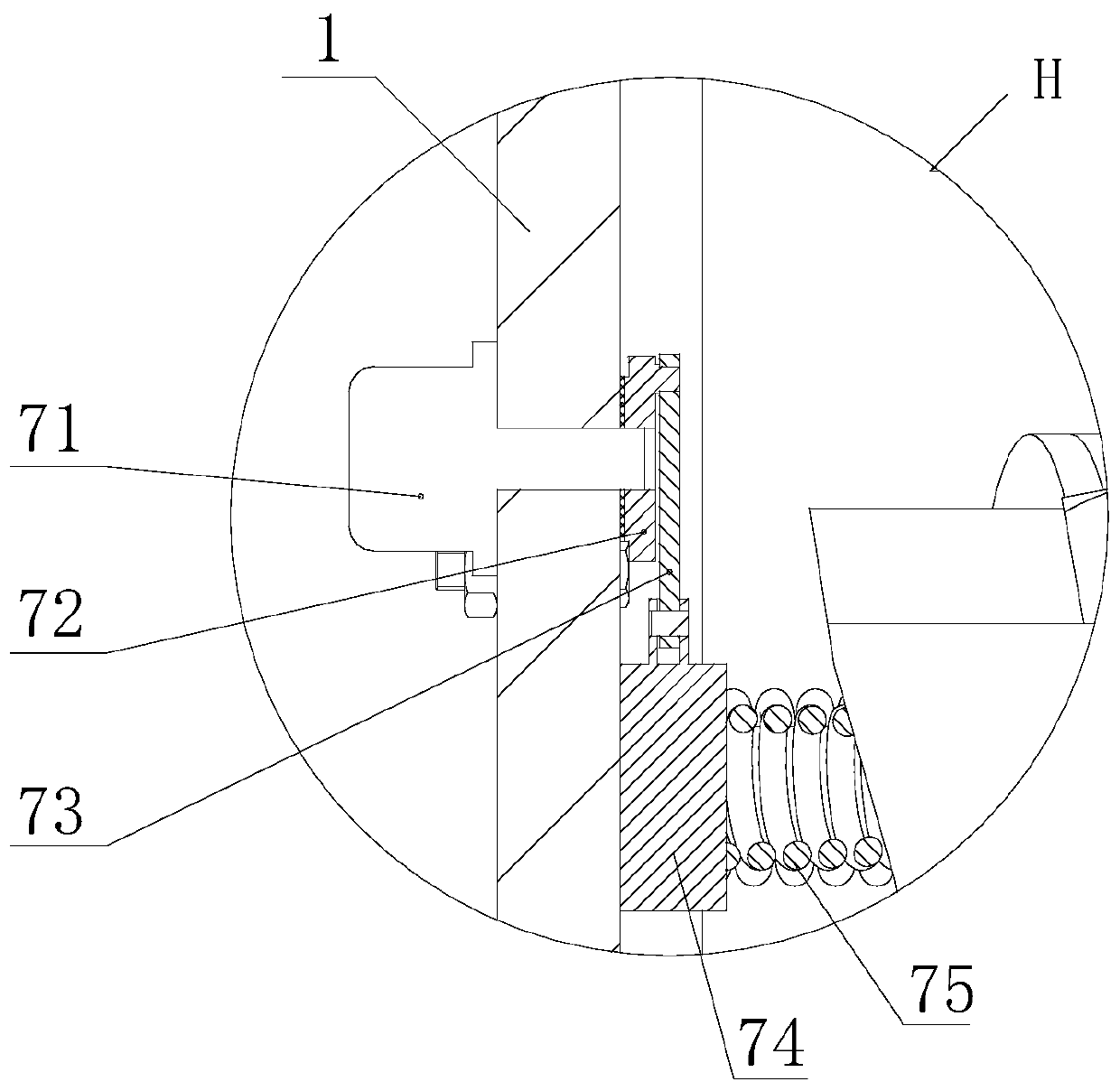

An automatic, safe and environmentally friendly dust removal robot for grinding the side of the steel drum intersecting line

ActiveCN108890299BNo need for manual grindingLabor savingEdge grinding machinesGrinding wheel securing apparatusDrive wheelDust control

The invention discloses an automatic, safe and environmentally-friendly dust-removing robot for steel drum intersection line side face polishing. The robot comprises a housing with a U-shaped cross section, a first driving mechanism, a second driving wheel mechanism and a cutting cutter disc mechanism which are sequentially installed from front to back in the U-shaped cavity of the housing, multiple magnetic blocks are fixedly distributed on the top wall of the interior of the U-shaped cavity of the housing from front to back, a group of branching splayed wheel mechanisms which roll and abut the outer surface and inner surface of a steel drum are arranged on the part, below the first driving wheel mechanism, of the interior of the housing, and multiple rolling bead mechanisms which roll and abut the outer surface and inner surface of the steel drum are fixedly distributed on the two side walls of the interior of the housing. By means of the robot, cutting and polishing on the side faceof a cutting port of an intersection line of the steel drum can be automatically completed, the inner and outer side faces of the intersection line cross section of the steel drum are smooth, manualpolishing is not needed, labor force is saved, and the production efficiency is improved.

Owner:扬州耐盾桶业有限公司

Pin End Finishing Machine

ActiveCN105252360BAchieve the purpose of polishingFully automated working processGrinding feedersPlane surface grinding machinesButt jointGraphite

The invention discloses a trimming machine for the end faces of pins. The trimming machine comprises a machine table, a graphite pin feeding device arranged on the machine table, a first feeding guide trough, a second feeding guide trough, a polishing device, a receiving disc and a linear pushing device. The first feeding guide trough and the second feeding guide trough are arranged on the machine table. The first end of the second feeding guide trough is in butt joint with the second end of the first feeding guide trough. The polishing device is arranged above the second end of the second feeding guide trough. The receiving disc is arranged on the machine table. The linear pushing device is arranged on the outer side of the first end of the second feeding guide trough. A conductive block electrically connected with a driving switch of the linear pushing device is arranged on the inner side wall and the inner bottom wall of the first end of the second feeding guide trough. According to the trimming machine, through connection achieved when the graphite pins are in contact with the conductive block and disconnection achieved when the graphite pins are not in contact with the conductive block, the pushing end of the linear pushing device is driven to push the graphite pins on the second feeding guide trough to forwards move, and then the aim of polishing the graphite pins is achieved. The whole working process is full automatic, manual polishing is avoided, and working efficiency is greatly improved.

Owner:SHANGHAI HONGFENG IND

An intelligent curtain motor rotor automatic grinding device

ActiveCN110900370BTo achieve the effect of automatic controlFully automatedGrinding drivesGrinding machinesElectric machineryEngineering

The invention belongs to the technical field of motor manufacturing equipment, in particular to an automatic grinding device for an intelligent curtain motor rotor, which includes a support plate, the lower surfaces of the two support plates are fixedly connected with support legs, and one side surface of the two support plates is provided with a rotating hole , the inner wall of the rotating hole is slidingly sleeved with a rotating shaft, and the support plates are symmetrically distributed with the axis of the rotating shaft as the symmetric axis. The inner side of the block is provided with a grinding mechanism. The intelligent curtain motor rotor automatic grinding device, by setting the inner surface of the support block with a grinding mechanism, achieves the effect of uniform grinding of the motor rotor, short time, no need to consume manpower and high degree of automation, and solves the existing problems. Grinding requires manual grinding, which takes too long, and the manual grinding is cumbersome, easy to consume physical strength, and the grinding efficiency is low.

Owner:NANJING SHILAIER AUTOMOTIVE ELECTRONICS CO LTD

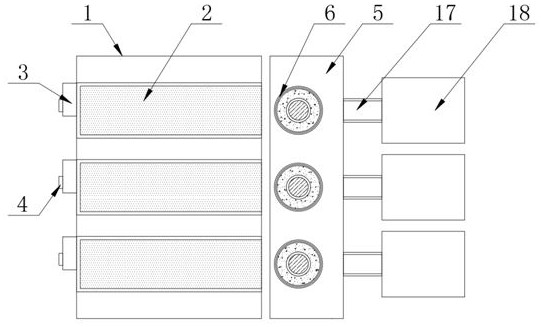

A construction steel pipe surface grinding and transportation device

ActiveCN112223044BEasy to transportImprove grinding efficiencyBelt grinding machinesAbrasive surface conditioning devicesGear wheelElectric machinery

The invention relates to a construction steel pipe surface grinding and transportation device. The construction steel pipe surface grinding and transportation device includes a transportation assembly and a cover assembly. The transportation assembly includes a transportation frame, a driving roller, a driven roller, a grinding belt and a driving motor, and a plurality of partition plates are fixed in the transportation frame, adjacent to each other. A grinding space is formed between the two partition plates, and each grinding space is used to accommodate a construction steel pipe. The driving roller and the driven roller are respectively rotatably installed at the bottom of the opposite ends of the transport frame. The opposite ends of the moving roller are respectively equipped with tires, the middle part of the driving roller is recessed with a ring groove, and the peripheral surface of the ring groove is fixed with a driving gear. The driving motor is installed at the bottom of the transport frame and meshed with the driving gear through a reduction gear set. . The construction steel pipe surface grinding and transportation device can save manpower and improve grinding efficiency.

Owner:安徽贵宏建工集团有限公司

A mold grinding device

ActiveCN109514417BAdsorption effectNo need for manual grindingEdge grinding machinesPolishing machinesElectric machineryEngineering

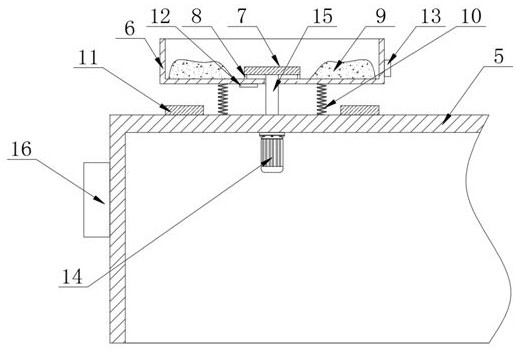

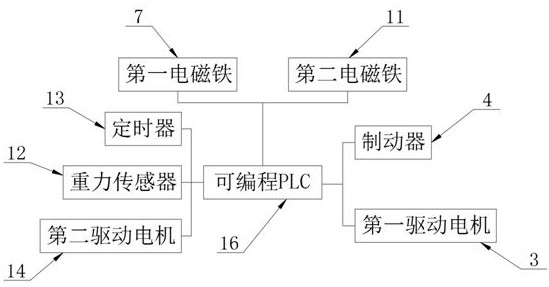

The invention discloses a mold grinding device which comprises a feeder. A grinding rack is arranged on one side of the feeder. Grinding discs are arranged at the top of the grinding rack. A first electromagnet is arranged in each grinding disc. A deformation mat is arranged between each first electromagnet and the inner wall of the correspondingly grinding disc. Grinding sand is arranged on the outer portion of each first electromagnet. First reset springs are arranged between each grinding disc and the grinding rack. Second electromagnets are arranged at the top of the grinding rack. A gravity sensor is arranged at the bottom of each grinding disc. A timer is arranged on the outer wall of each grinding disc. A second drive motor is arranged in an inner cavity of the grinding rack. A PLCis arranged on one side of the grinding rack. According to the mold grinding device, through the arrangement of the grinding rack and the grinding discs, after the PLC controls the first electromagnetto be powered on to attract a mold and controls the second electromagnet to drive the positions of the grinding discs to be lifted under the action of resilience force of the first reset springs after the second electromagnets are powered off, the second drive motors work to drive molds to rotate through transmission rods and the first electromagnets, and grinding is carried out.

Owner:佛山市南海镕信金属制品有限公司

A composite material for artificial teeth and its preparation method and application

ActiveCN103976883BMeet needsSolve the mechanical strengthImpression capsDentistry preparationsSelective laser sinteringMicrocrystalline wax

The invention discloses a composite material for artificial teeth and a selective laser sinter molding method and an application thereof. The method includes raw materials, a powder preparation method and a material molding method. The raw materials contain polymethyl methacrylate, hydroxyapatite nano-particles, an emulsifier, microcrystalline wax and paraffin. The powder preparation method comprises the following steps: firstly carrying out lipophilic modification on the hydroxyapatite nano-particles by a wax emulsification method and then preparing a polymethacrylate powder material doped with the hydroxyapatite nano-particles by hot-melting mechanical agitation and crushing ball milling. According to the molding method, a polymethacrylate powder is molded by a selective laser sintering technology. By the adoption of the artificial teeth dedicated composite material with a composite bioactivity, the problem that traditional artificial teeth have insufficient mechanical strength and poor compatibility can be solved effectively. In addition, as the selective laser sinter molding technology is provided, preparation time of artificial teeth is shortened greatly, teeth replacement cycle is minimized for patients, and requirements of doctors and patients on artificial teeth are met.

Owner:INST OF CHEM CHINESE ACAD OF SCI

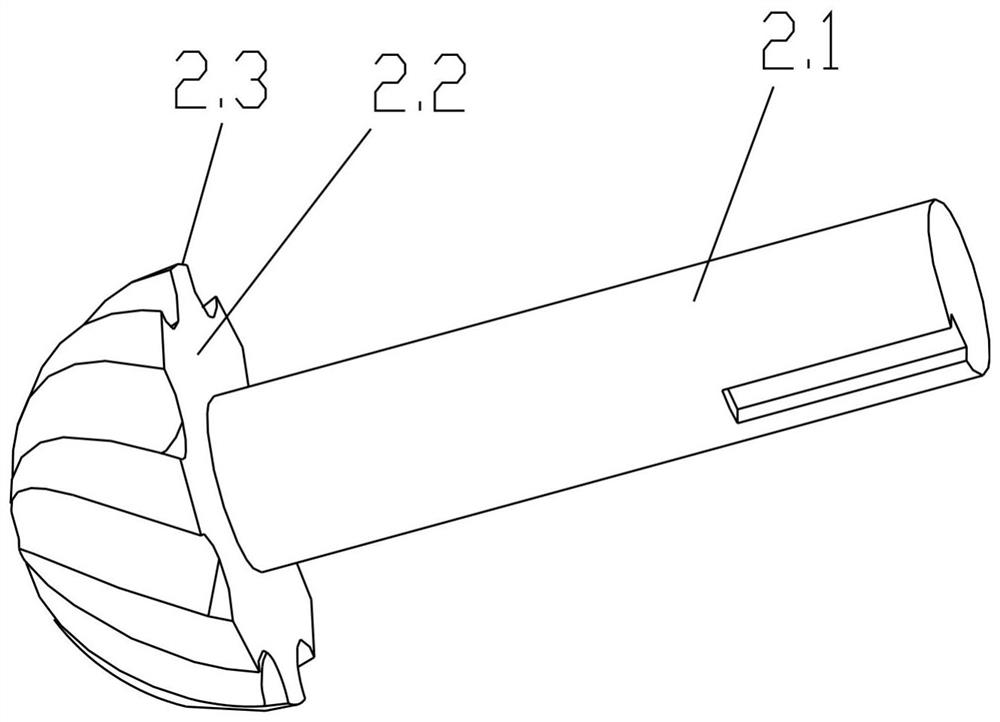

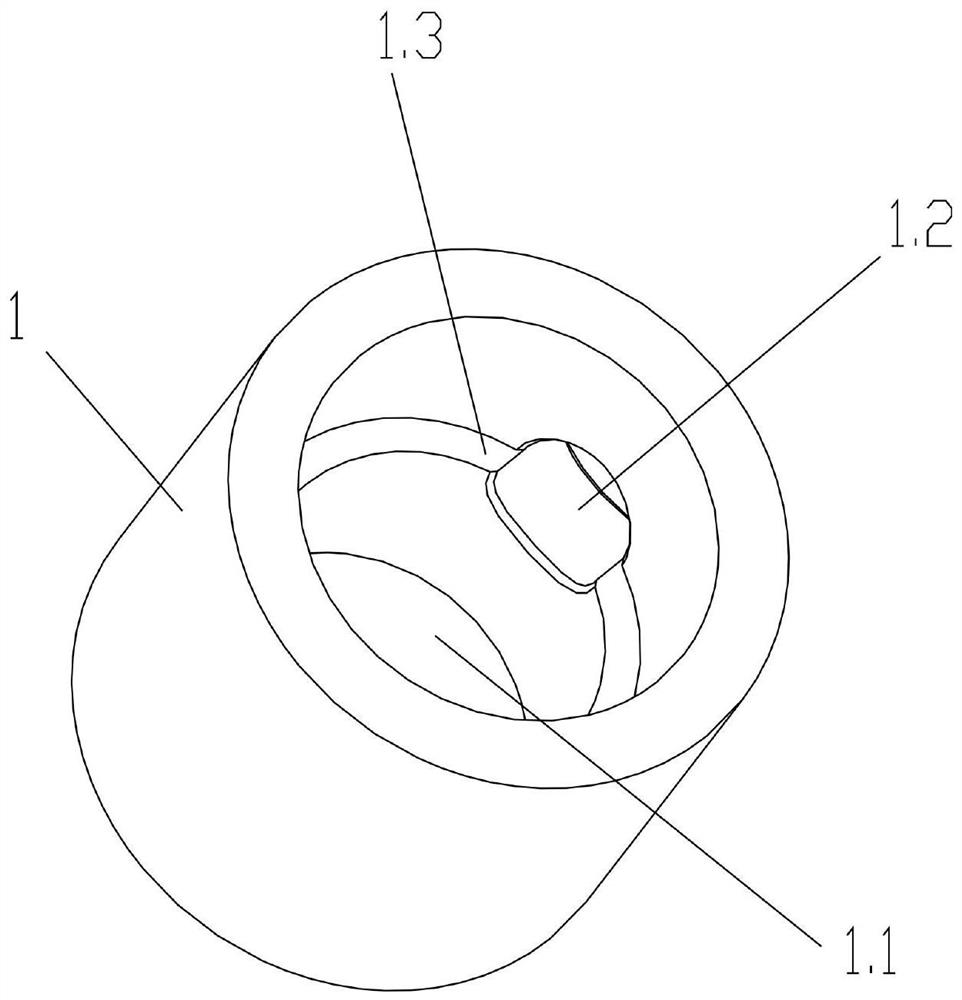

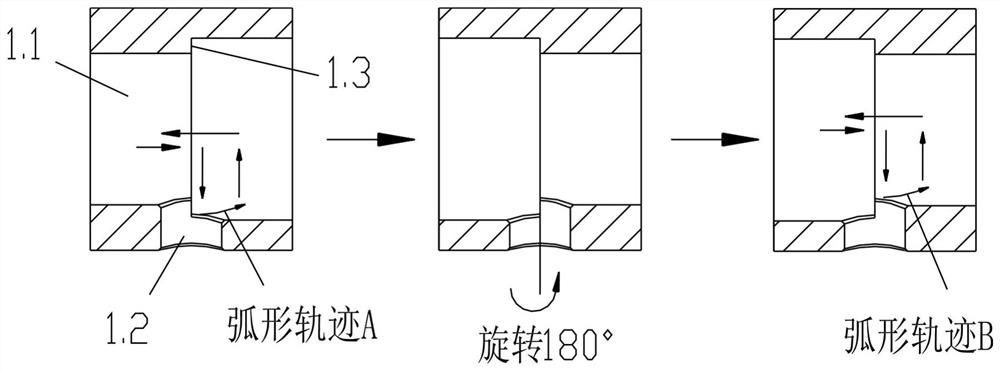

Spherical milling cutter for machining stepped hole chamfer and machining method for machining stepped hole chamfer

The invention discloses a spherical milling cutter for machining a stepped hole chamfer and a machining method for machining the stepped hole chamfer. According to the spherical milling cutter, a spherical cutter head is smaller than or equal to a half spherical surface, the diameter of a cutter handle is smaller than the outer diameter of the widest part of a maximum cutting edge, and the axis ofthe cutter handle is perpendicular to the end face of the spherical cutter head, so that a stepped hole can be chamfered. During machining, the axis of the spherical milling cutter is parallel to a center hole of a workpiece, the end face of the spherical cutter head can be attached to the interface due to the fact that the axis of the cutter handle is perpendicular to the end face of the spherical cutter head, the plane where the interface is located serves as a cutting feed starting point, and the inner wall face of the center hole can be prevented from being cut. Therefore, the stepped hole is chamfered through the feeding route, chamfering of the stepped hole can be accurately and automatically completed on machining equipment, manual polishing is not needed, labor intensity is reduced, and production efficiency is improved.

Owner:HONDA FOUNDRY (FOSHAN) CO LTD

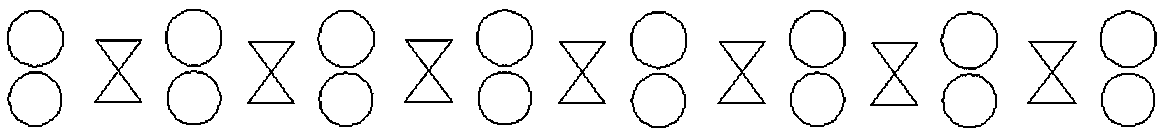

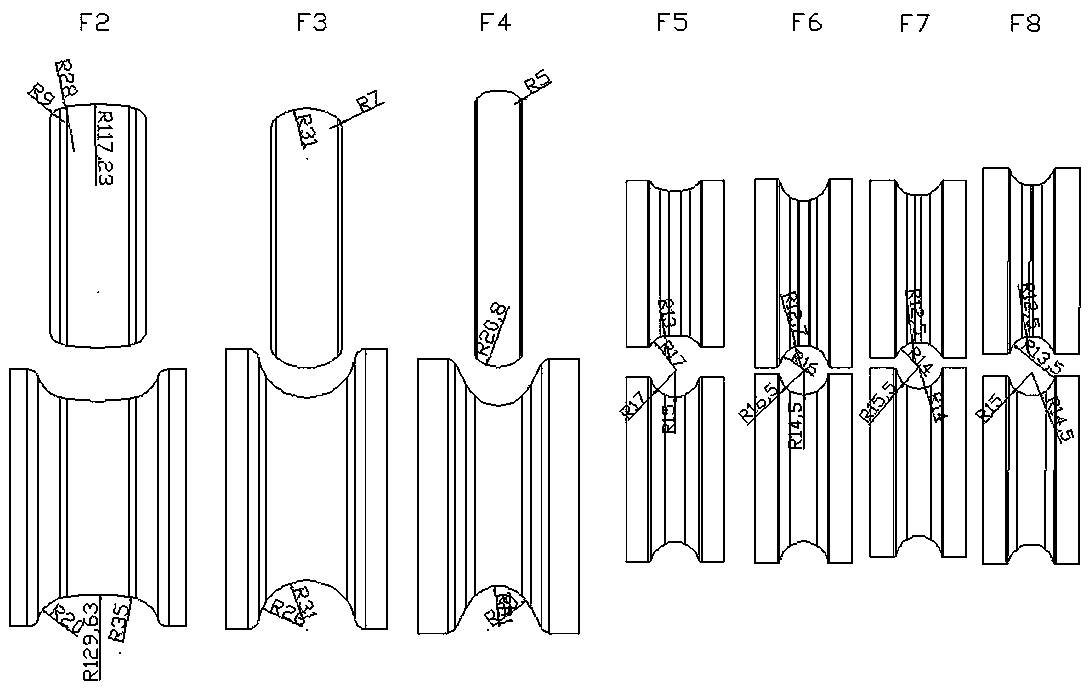

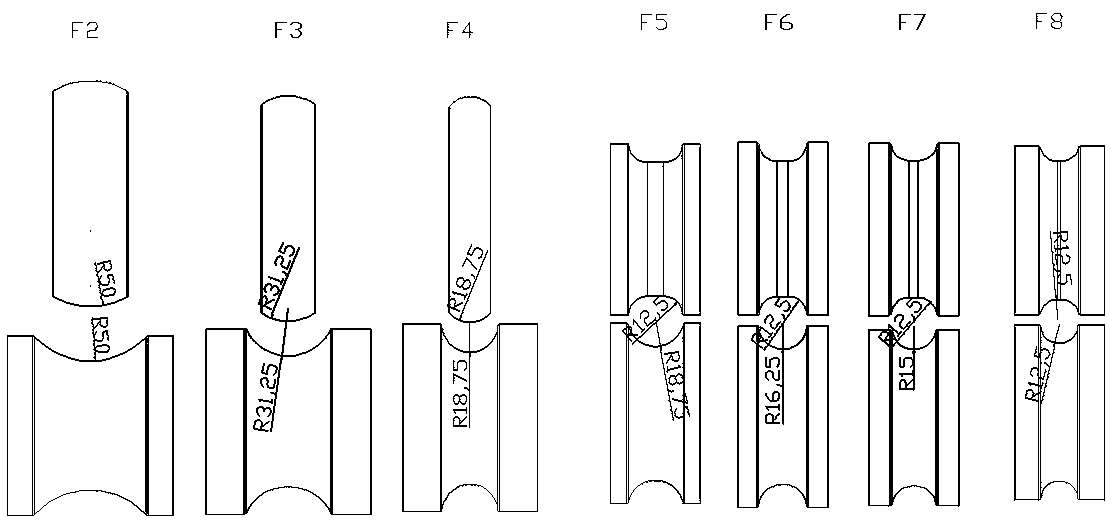

Titanium welded tube forming section mould

InactiveCN108296326ALow requirements for production equipmentReduce manufacturing costShaping toolsSurface roughnessTitanium

The invention discloses a titanium welded tube forming section mould. The titanium welded tube forming section mould comprises an odder number of pressing roller groups which are sequentially arrangedleft and right, wherein the pressing roller groups comprises flat roller groups and vertical roller groups; a raw material titanium belt is formed into a titanium welded tube after being sequentiallypressed through the odder number of pressing roller groups; the flat roller groups and the vertical roller groups are arranged in a spaced mode; front and tail ends of the forming section mould are equipped with the flat roller groups; each flat roller groups comprises an opening roller group and a closed roller group, wherein flat rollers positioned at the lower side in the opening roller groupand flat rollers in the closed roller group are made of bakelite; except from the flat roller group at the front end of the forming section mould, each of matched parts of upper and lower flat rollerholes of the rest of the roller groups is formed by a section of a circular arc. The titanium welded tube forming section mould can adopt a titanium belt which is low in surface roughness and has an acid-pickled or grinded surface as a raw material, can effectively avoid grinding crack defects on a formed surface, is good in wear resistance, is long in service life, and is high in production efficiency; and the processed finished product titanium welded tube is good in uniformity, is high in dimension precision and is excellent in quality.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Electrophoresis spreader for automatic paint removal

ActiveCN108251883BAutomatic removalNo need for manual grindingGrinding drivesElectrophoretic coatingsElectrophoresisTorsion spring

The invention relates to the technical field of electrophoresis coating hanging devices, in particular to an electrophoresis hanging device for automatically removing a paint film. The electrophoresishanging device comprises a hanging frame and a clamping mechanism; the hanging frame comprises two vertical frame rods; the clamping mechanism comprises two symmetrical clamping units which are connected to the two frame rods; each clamping unit comprises a spring, a moving rod and a clamping block; the moving rods are horizontally arranged, the clamping blocks are rotatably connected to the endsof the moving rods by adopting torsion springs, and the ends, away from the torsion springs, of the moving rods are connected with the frame rods by adopting the springs; the frame rods are providedwith guiding tubes, and the end, connected with the springs, of the moving rods are slidably matched with the interiors of the guiding tubes; the moving rods are further provided with positioning pinsused for limiting relative rotating of the clamping blocks and the moving rods; and arc-shaped elastic pieces are further included. The electrophoresis hanging device aims to solve the problem that in the prior art, an electrophoresis paint film is required to be removed manually.

Owner:重庆广福科技有限公司

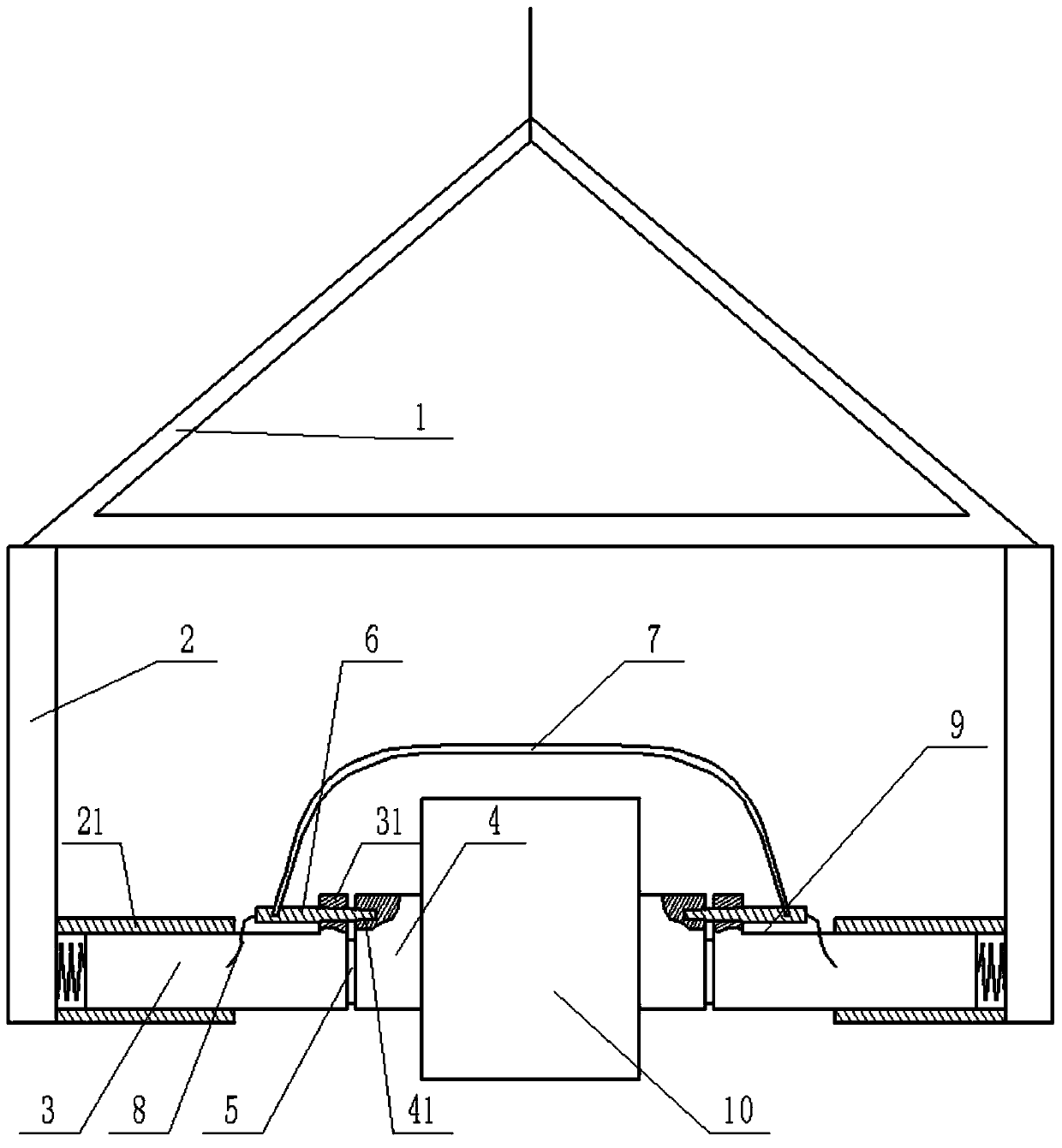

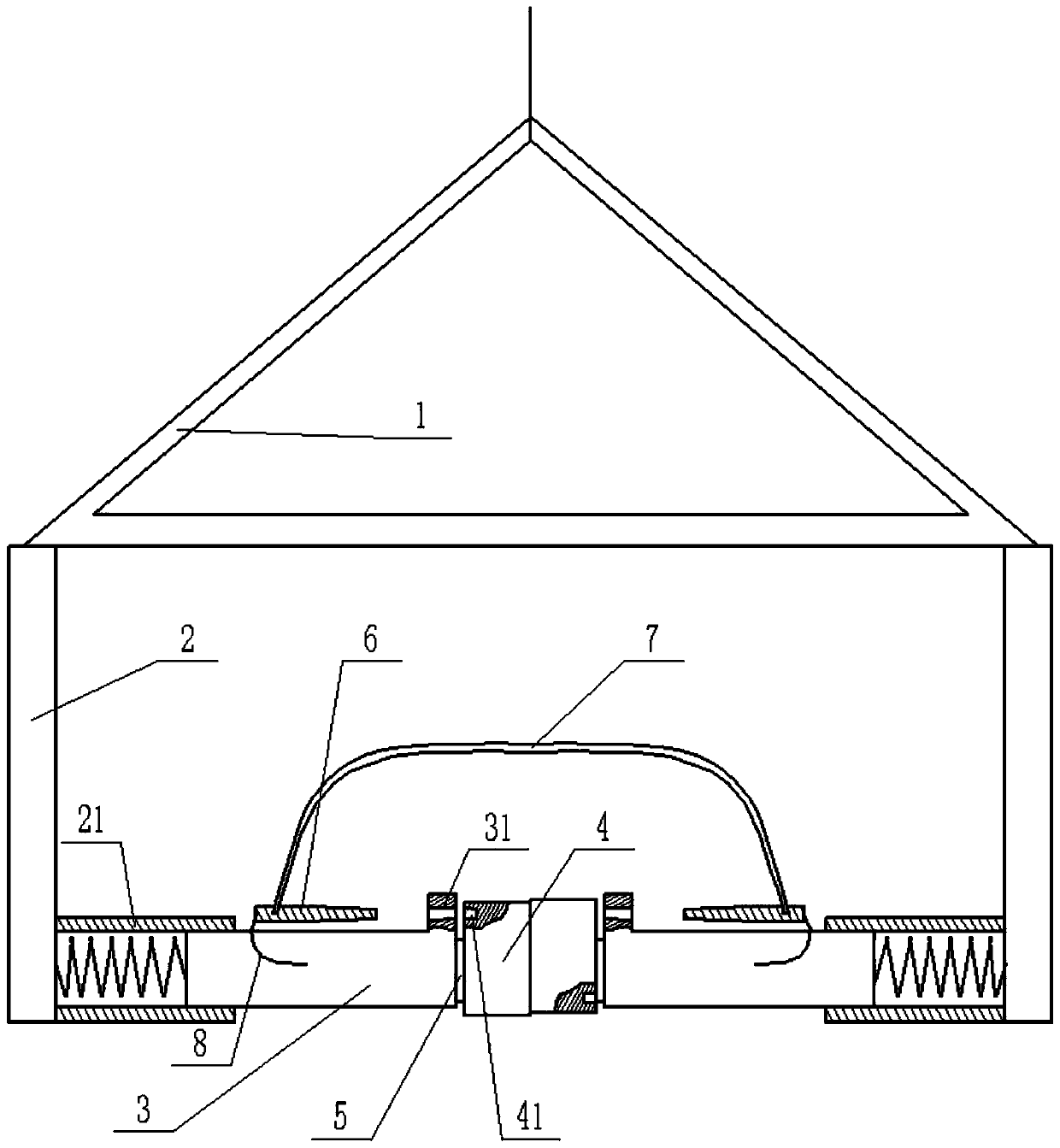

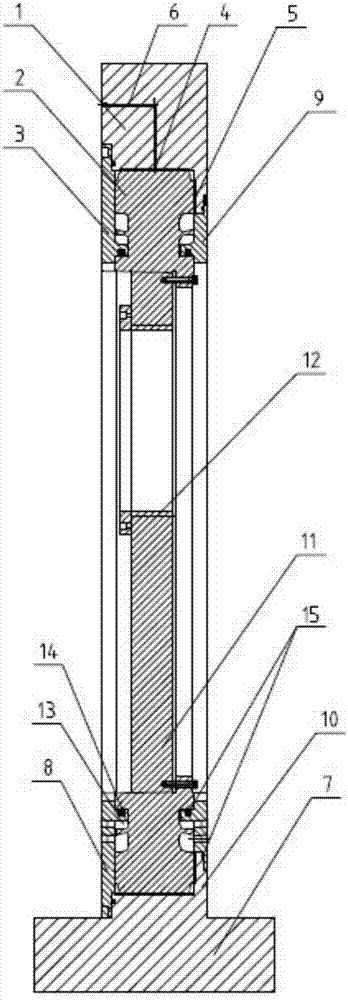

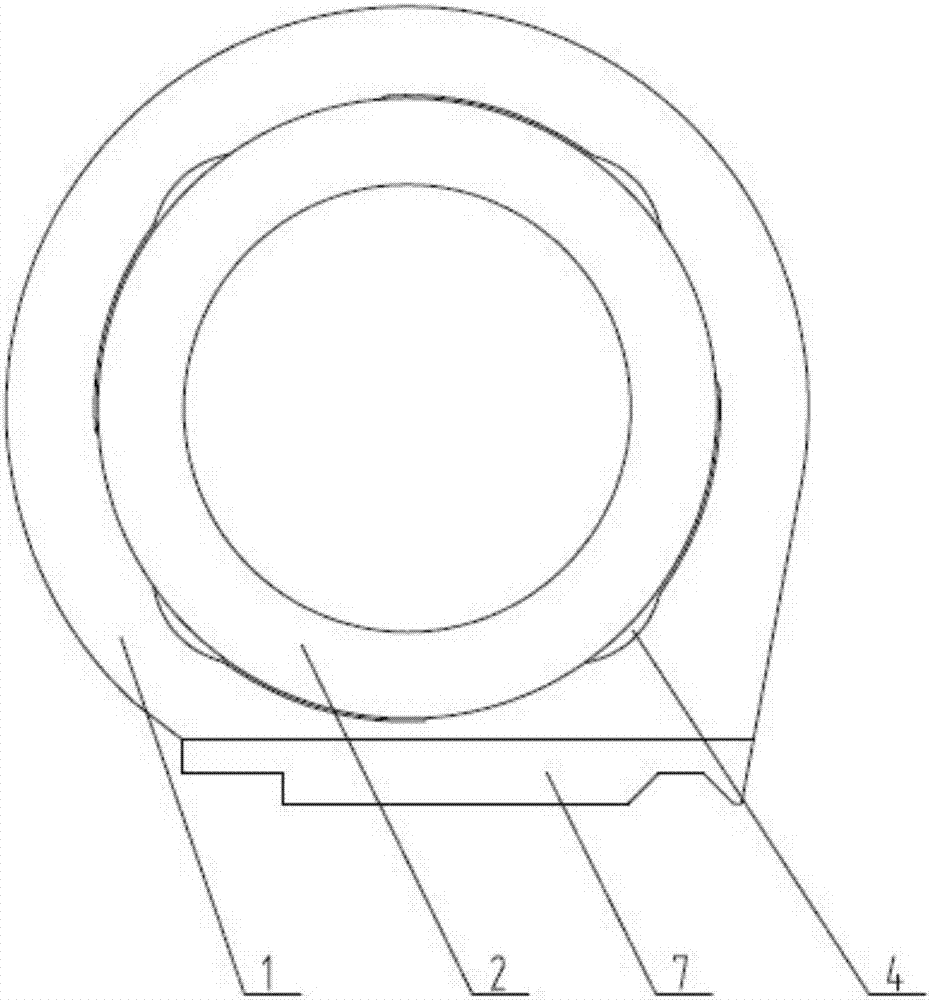

Static-pressure center frame

PendingCN107097152AImprove machining accuracyImprove processing efficiencyGrinding work supportsOil filmCrankshaft

The invention discloses a static-pressure center frame which comprises a frame body, a rotor and static-pressure covers. The static-pressure covers are connected with the outer end faces of the two sides of the frame body. The rotor is arranged in a cavity composed of the frame body and the static-pressure covers. An oil film clearance is arranged between the rotor and the inner wall of the frame body, and an oil film clearance is arranged between the inner walls of the static-pressure covers. Radial oil cavities are formed in the positions, opposite to the circumferential outer wall of the rotor, on the circumferential inner wall of the frame body. End face oil cavities are formed in the end faces, in contact with the rotor, of the static-pressure cover and the frame body. The frame body is provided with an oil injection channel communicating with the radial oil cavities and the end face oil cavities. By means of the static-pressure center frame, the rotor can bear external force to conduct high-precision rotation movement, the machining precision of a crankshaft is high, manual coping is not needed, and the machining efficiency is improved.

Owner:GUNAI HEAVY IND SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com