Titanium welded tube forming section mould

A technology for forming sections and titanium welded pipes, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of different forming effects, uneven forming of titanium strips, insufficient roundness of pipes, etc., to achieve good surface smoothness, The effect of high uniformity and reduced production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045]

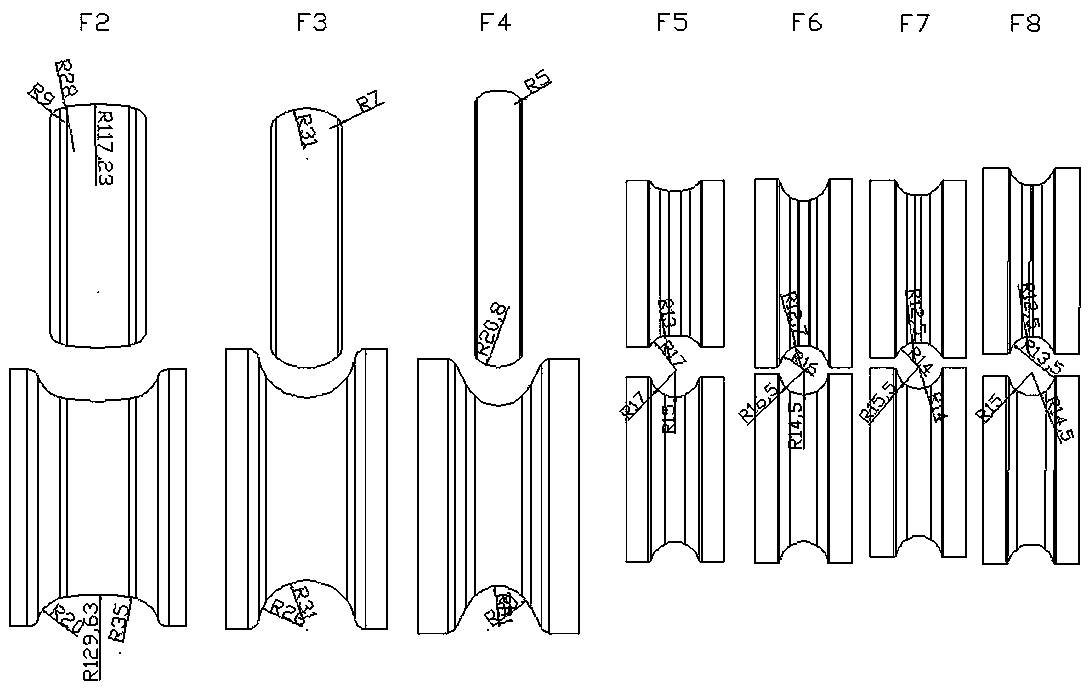

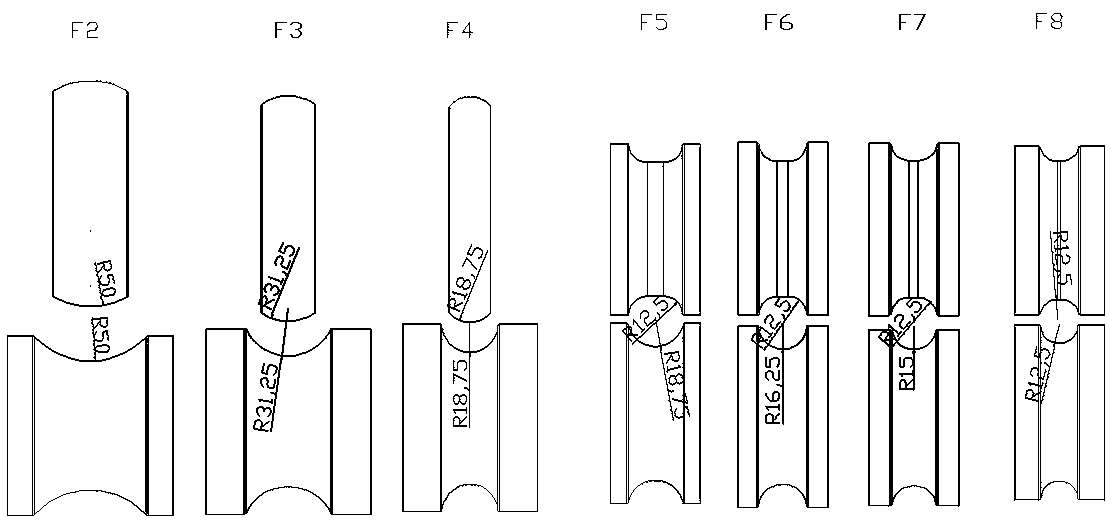

[0046] In the titanium welded pipe forming section mold used in this example, the upper rolls of the open rolls (F1~F4) in the flat rolls are made of mold steel Cr12MoV, and the rest of the flat rolls are made of bakelite.

[0047] Its processing flow is:

[0048] The first step, cleaning the titanium belt: the titanium belt enters the cleaning device before entering the forming mold, and uses a high-pressure air gun to remove the sundries and small titanium chips on its surface.

[0049] The second step, threading debugging: the front end of the titanium belt uses steel wire to make it pass through the mold of the forming section one by one, and the mold rollers are pressed down and formed in turn. Adjust the welding parameters to make it enter the rough sizing after the edge welding, and then enter the annealing furnace.

[0050] In the third step, the annealing temperature is set at 570°C, the annealing speed is consistent with the main line speed, and then ent...

Embodiment 3

[0054]

[0055] In the titanium welded pipe forming section mold used in this example, the upper rolls of the open rolls (F1~F4) in the flat rolls are made of mold steel Cr12MoV, and the rest of the flat rolls are made of bakelite.

[0056] Its processing flow is:

[0057] The first step, cleaning the titanium belt: the titanium belt enters the cleaning device before entering the forming mold, and uses a high-pressure air gun to remove the sundries and small titanium chips on its surface.

[0058] The second step, threading debugging: the front end of the titanium belt uses steel wire to make it pass through the mold of the forming section one by one, and the mold rollers are pressed down and formed in turn. Adjust the welding parameters to make it enter the rough sizing after the edge welding, and then enter the annealing furnace.

[0059] In the third step, the annealing temperature is set at 570°C, the annealing speed is consistent with the main line speed, and then ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com