Polyethylene/wood powder composite wire for fused deposition modeling, and preparation method thereof

A technology of fused deposition molding and polyethylene, which is applied in the field of 3D printing technology and plastic processing, to achieve the effects of reducing costs, improving molding accuracy, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

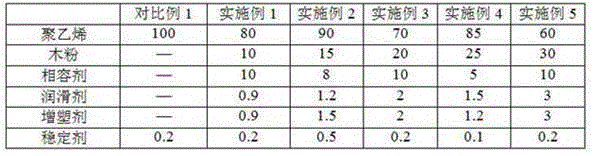

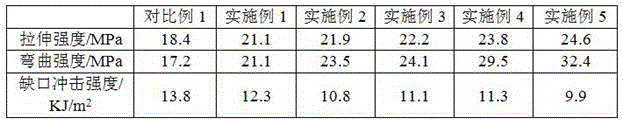

Embodiment 1

[0033] The polyethylene / wood flour composite wire material for fused deposition molding in this embodiment is made of the following raw materials: polyethylene (high-density polyethylene) 80g, wood flour (straw) 10g, maleic anhydride grafted Polyethylene 10g, lubricant (polyethylene glycol) 0.9g, plasticizer (dioctyl phthalate) 0.9g, stabilizer (antioxidant 1010 and tetrakis[β-(3,5-di-tert-butyl base-4-hydroxyphenyl)propionic acid]pentaerythritol ester) 0.2g.

[0034] The preparation method of the polyethylene / wood flour composite wire material for fused deposition molding of the present embodiment comprises the following steps:

[0035] (1) Processing of raw materials: Prepare each raw material, and the wood powder is processed into powder by a milling machine. The water remaining in polyethylene and wood flour evaporates, and the moisture content of polyethylene and wood flour is controlled below 10%;

[0036] (2) Mixing of reagents and raw materials: first put polyethylen...

Embodiment 2

[0040] The polyethylene / wood powder composite wire material for fused deposition molding in this embodiment is made of the following raw materials: polyethylene (high-density polyethylene and linear low-density polyethylene) 90g, wood powder (straw and rice bran) 15g, maleic anhydride grafted polyethylene 8g, lubricant (polyolefin and polyethylene glycol) 1.2g, plasticizer (dioctyl phthalate and synthetic vegetable ester) 1.5g, stabilizer (antioxidant mixture of agent 168 and tris[2.4-di-tert-butylphenyl]phosphite) 0.5g.

[0041] The preparation method of the polyethylene / wood powder composite wire material for fused deposition molding of the present embodiment is the same as that of embodiment 1.

Embodiment 3

[0043] The polyethylene / wood flour composite wire material for fused deposition molding in this embodiment is made of the following raw materials: polyethylene (linear low-density polyethylene) 70g, wood flour (straw and sawdust) 20g, maleic anhydride Grafted polyethylene 10g, lubricant (polyolefin and stearamide lubricant) 2g, plasticizer (dioctyl phthalate and glycerin) 2g, stabilizer (antioxidant 1010 and four [β- (3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester mixture) 0.2g.

[0044] The preparation method of the polyethylene / wood flour composite wire material for fused deposition molding in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com