Automatic pipeline polishing device for ocean engineering

A technology for marine engineering and pipelines, which is applied in the direction of grinding drive devices, grinding machines, manufacturing tools, etc. It can solve the problems of low grinding efficiency, difficulty in grinding the inner surface of pipelines, and poor grinding effect, so as to achieve high grinding efficiency and good grinding effect Good, even sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

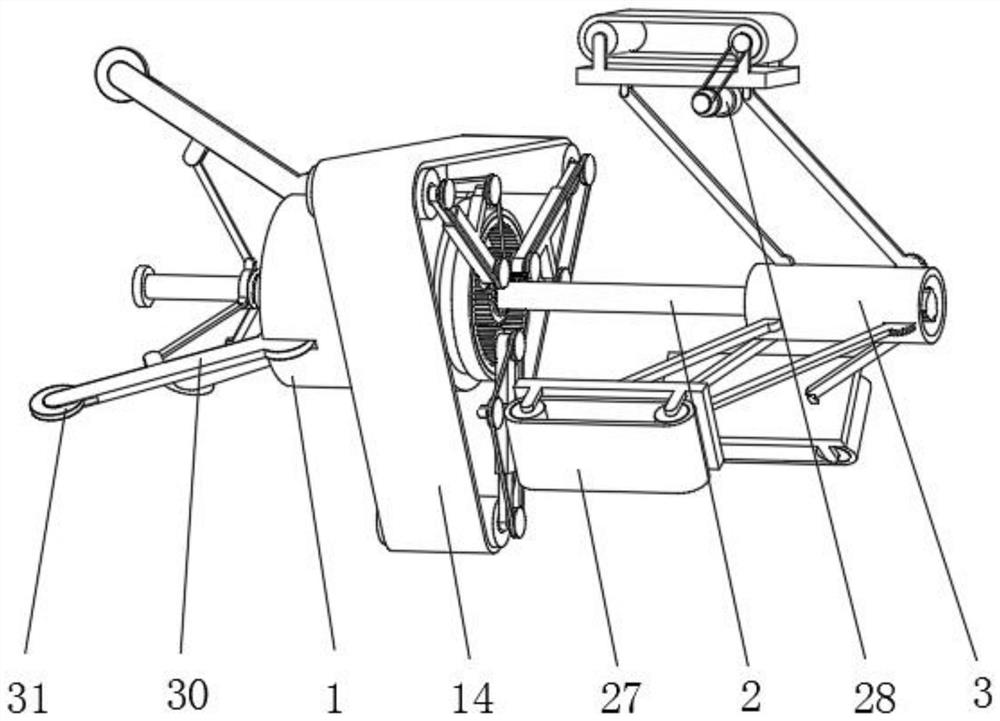

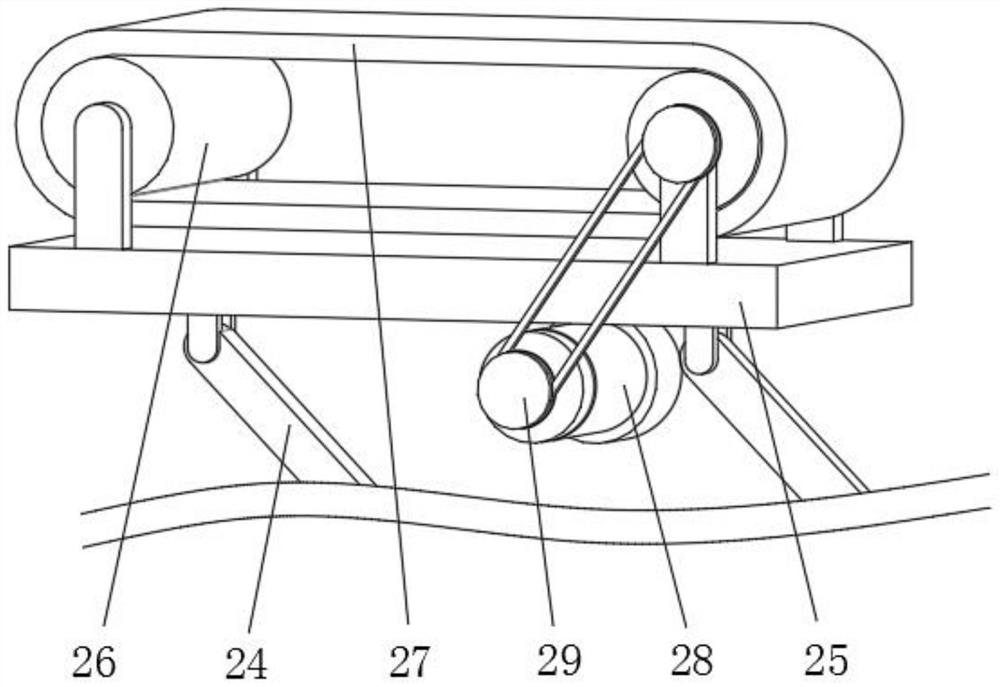

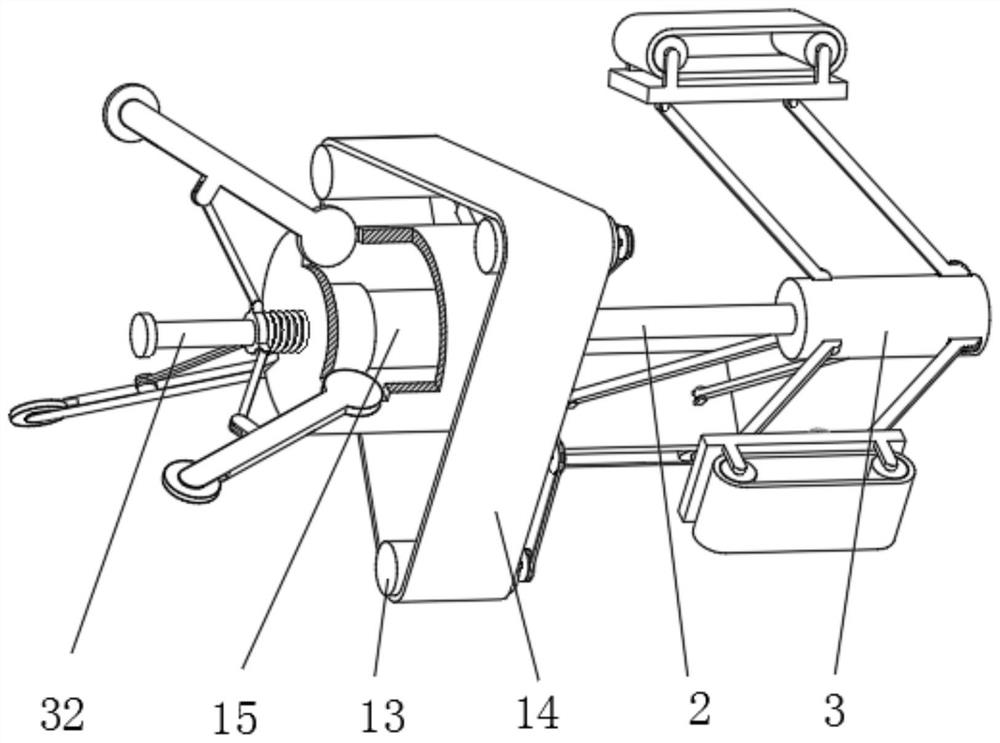

[0043] Example: Reference Figure 1-8 The shown automatic pipeline polishing device for marine engineering includes a main box body 1, a connecting cylinder 2 is fixedly installed on one side of the main box body 1, and a grinding mechanism is movably sleeved on the connecting cylinder 2, and one side of the connecting cylinder 2 The shaft core tube 3 is fixedly installed, and the peripheral side outer wall of the shaft core tube 3 is provided with a plurality of rotating holes, and a spreader gear 19 is rotated and installed in the plurality of rotation holes, and an electric motor is fixedly installed on the side inner wall of the shaft core tube 3 . Telescopic rod 23, the output end of electric telescopic rod 23 is fixedly equipped with strutting column 21, and the peripheral side outer wall of strutting column 21 is fixedly installed with a plurality of strutting tooth racks 22, and a plurality of strutting gears 19 are connected with multiple strutting gears respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com