Electrophoresis spreader for automatic paint removal

An electrophoresis spreader and paint film technology, applied in electrophoresis plating, manufacturing tools, electrolytic coatings, etc., can solve problems such as poor contact between hooks and parts to be electrophoresis, poor electrophoresis quality, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

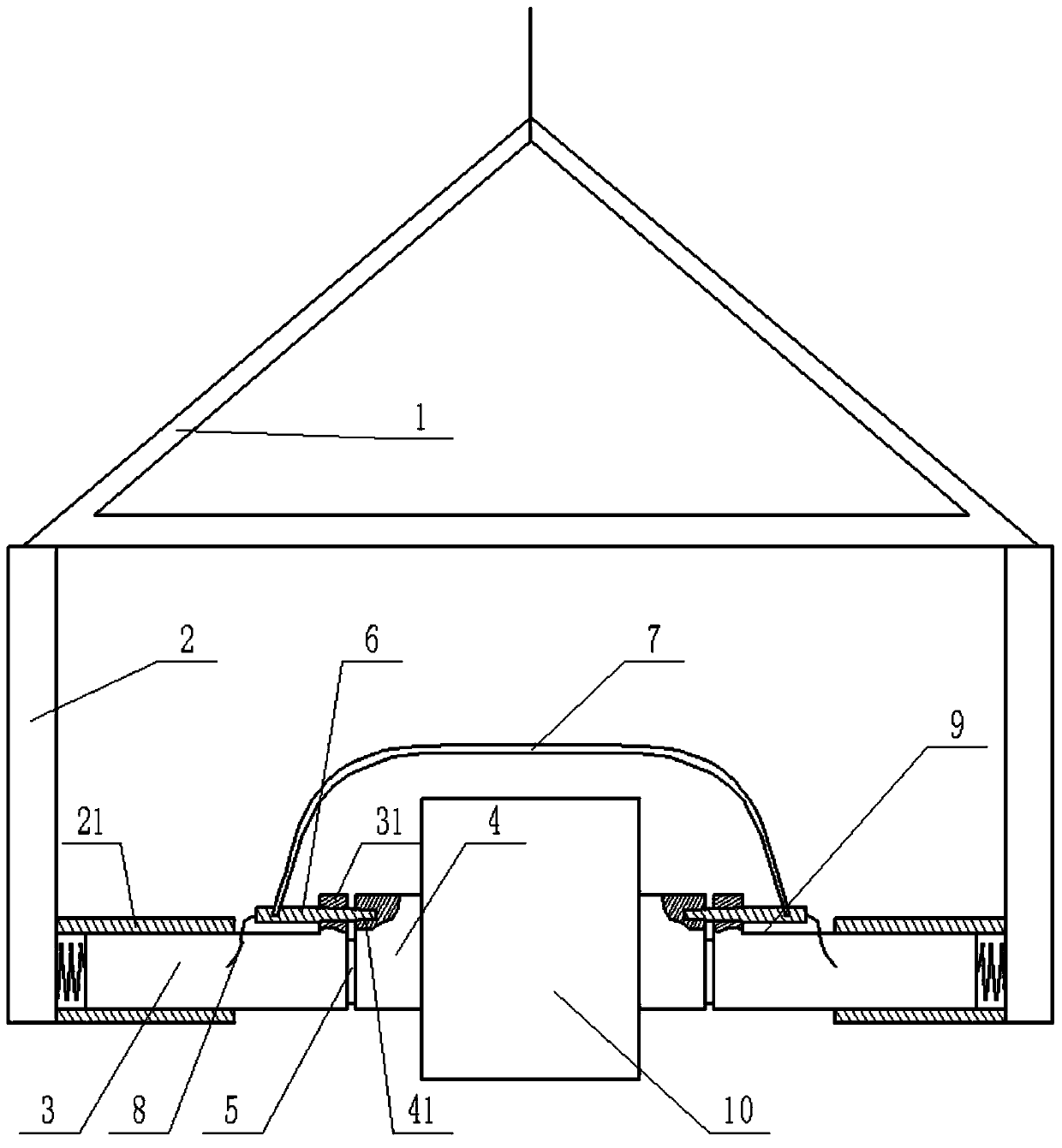

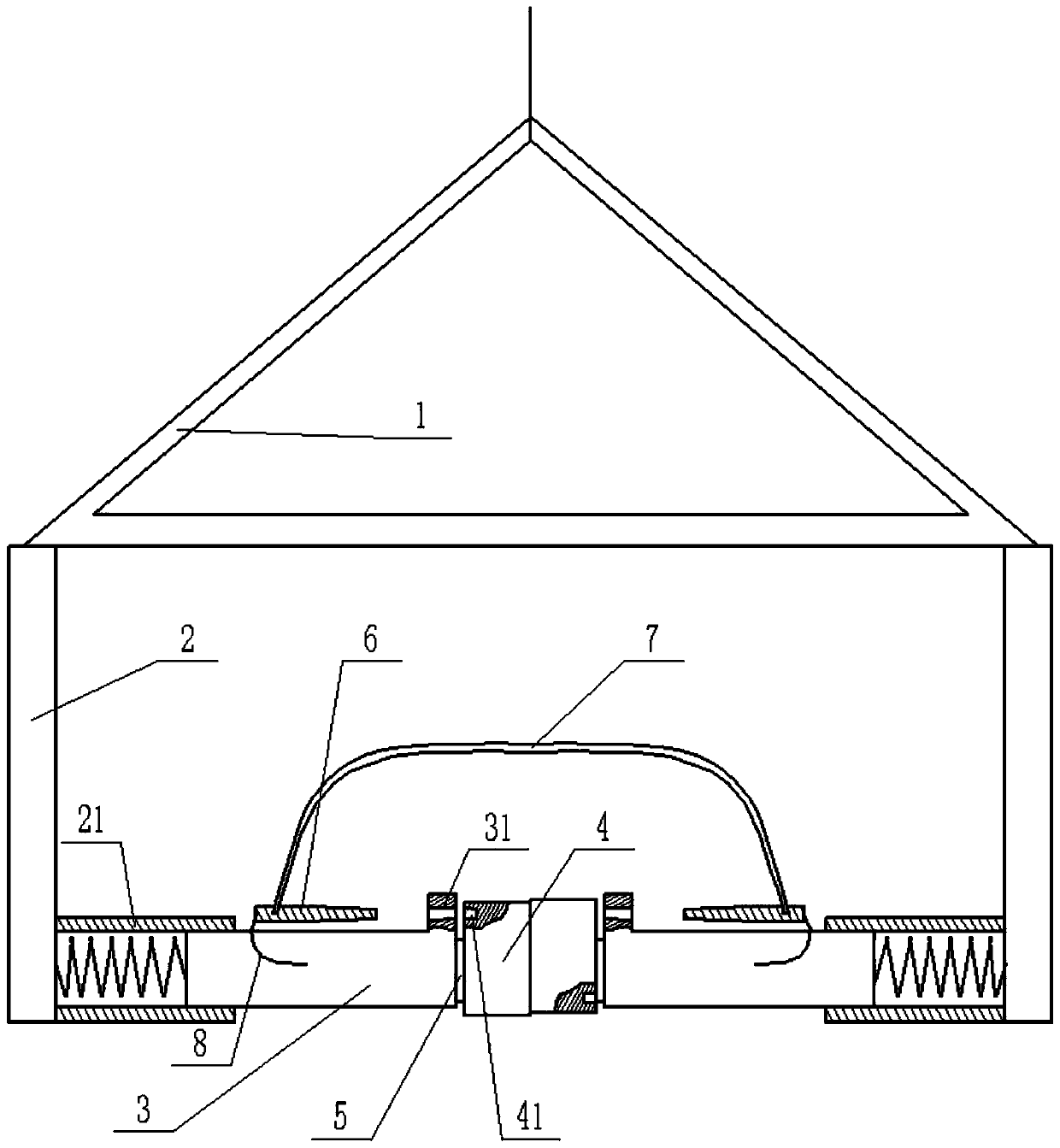

[0019] The reference signs in the drawings of the description include: triangular plate 1, frame rod 2, conduit 21, moving rod 3, bump 31, clamping block 4, matching hole 41, torsion spring 5, positioning pin 6, elastic sheet 7, thin Rope 8, clamping unit 9, parts 10.

[0020] The embodiment is basically as attached figure 1 Shown: The electrophoresis hanger for automatically removing the paint film, including a hanger and a clamping mechanism, the hanger includes two vertical poles 2 and a triangular plate 1 above the poles 2, the poles 2 are fixedly connected to the triangle plate 1 bottom end.

[0021] The clamping mechanism includes two mutually symmetrical clamping units 9, and the two clamping units 9 are respectively connected to the two frame rods 2. The clamping unit 9 includes a spring, a moving rod 3 and a clamping block 4, and the moving rod 3 is horizontal Arrangement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com