Easily-torn wide medicinal composite bag forming device

A forming device and composite bag technology, applied in the direction of transportation and packaging, sending objects, winding strips, etc., can solve the problems of affecting hot pressing operation, misalignment, composite film can not be fully bonded, etc., to achieve the effect of avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

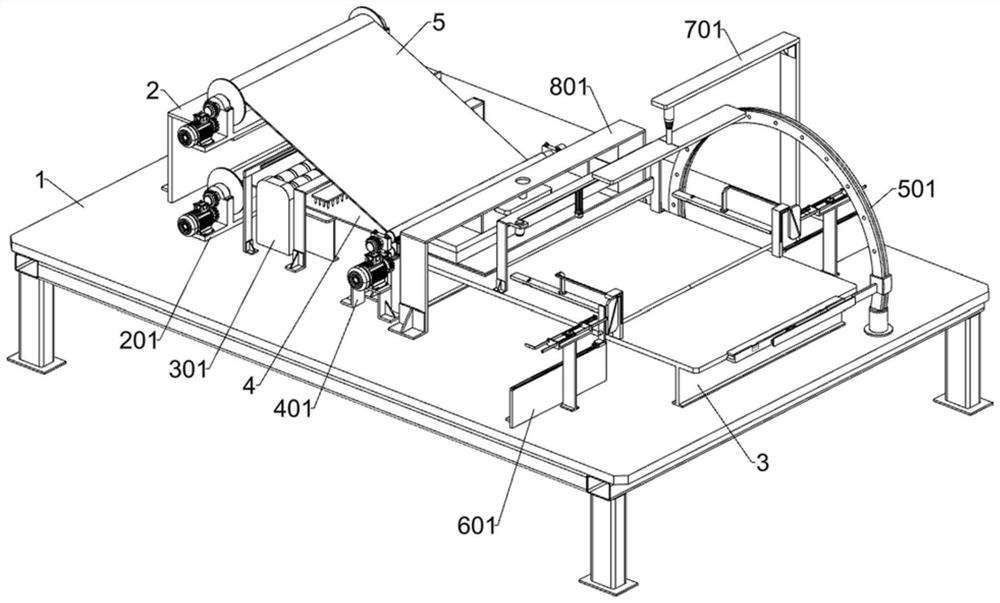

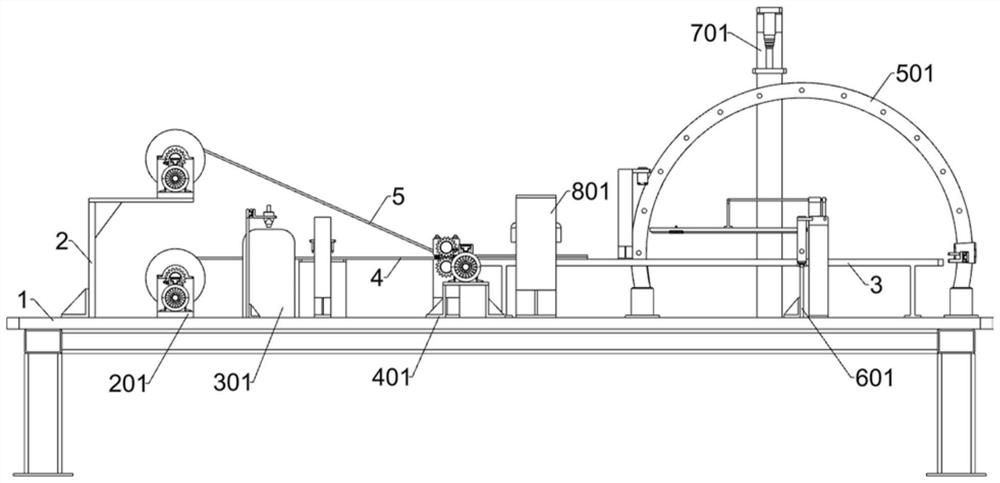

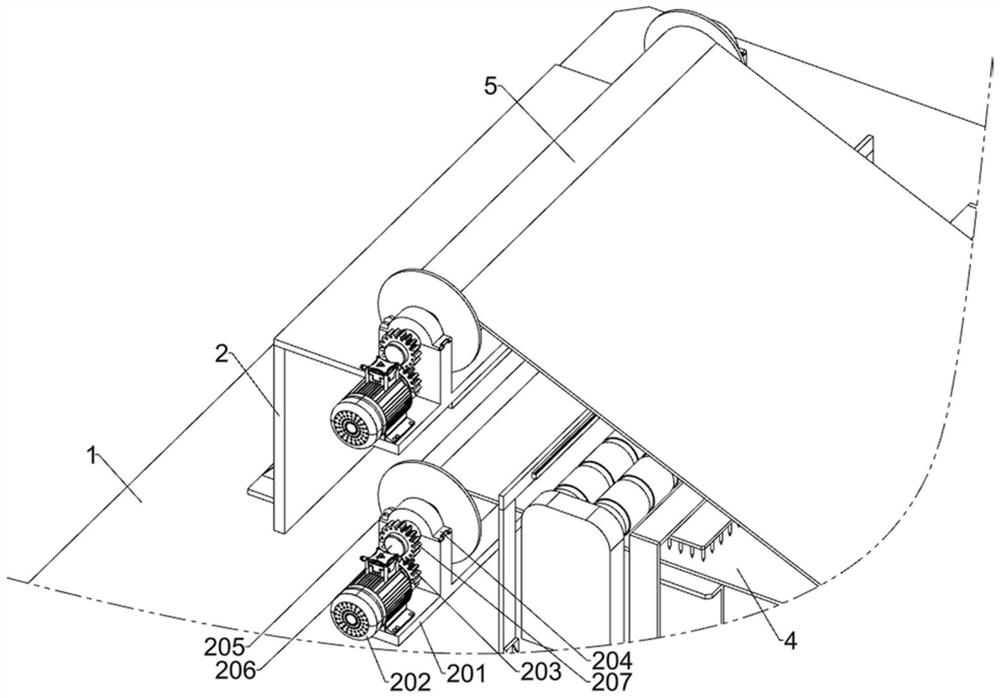

[0036] An easy-to-tear wide-width medicinal composite bag forming device, such as Figure 1-13 As shown, it includes a bottom frame 1, a first support frame 2, a support table 3, a bottom film 4, a top film 5, a feeding assembly, a gluing assembly, a transmission assembly, a folding assembly, a limit assembly, a pressing assembly and a cutting assembly The upper left part of the bottom frame 1 is connected with the first support frame 2 by bolts; the upper right part of the bottom frame 1 is connected with the support platform 3 by bolts; Another feeding assembly is installed on the upper side of the frame 1, and the two feeding assemblies are located on the same vertical plane; a bottom film 4 is installed on the bottom feeding assembly; the bottom right side of the bottom film 4 is in contact with the support platform 3; The top film 5 is installed on the feeding assembly; the lower part on the right side of the top film 5 is in contact with the bottom film 4; the upper side...

Embodiment 2

[0046] On the basis of Example 1, such as figure 1 and Figure 14-16As shown, it also includes two glue removal assemblies, two glue removal assemblies are installed on the transmission assembly, and the glue removal assembly at the front includes a connecting rod 901, a first collection compartment 902, a first cleaning plate 903, a funnel 904, Channel cylinder 905, second collection compartment 906, scraper 907, second cleaning plate 908, electric push rod 909, groove plate 9010 and sponge 9011; connecting rod 901 is fixedly connected to the upper right side of connecting block 404; behind connecting rod 901 The first collection cabin 902 is fixedly connected to the left side of the side; the first cleaning plate 903 is plugged into the lower side of the first collection cabin 902; the funnel 904 is fixedly connected to the middle of the first collection cabin 902; There is a channel cylinder 905; the upper part of the channel cylinder 905 is connected with the second colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com