Trimming machine for end faces of pins

A dressing machine and pin technology, which is applied in the direction of machine tools suitable for grinding workpiece planes, parts of grinding machine tools, and grinding feed movement, etc. It can solve the problem of reducing production efficiency and not removing the protruding end of the stop pin Partial, time-consuming and labor-intensive problems, to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

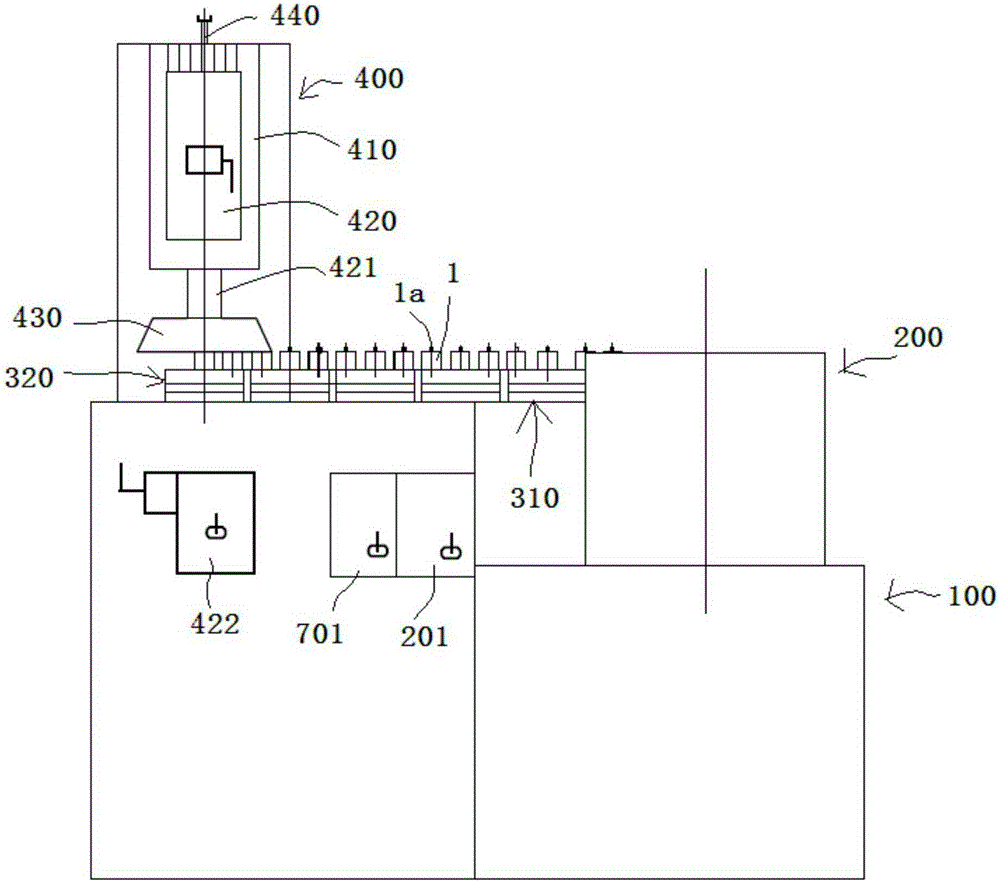

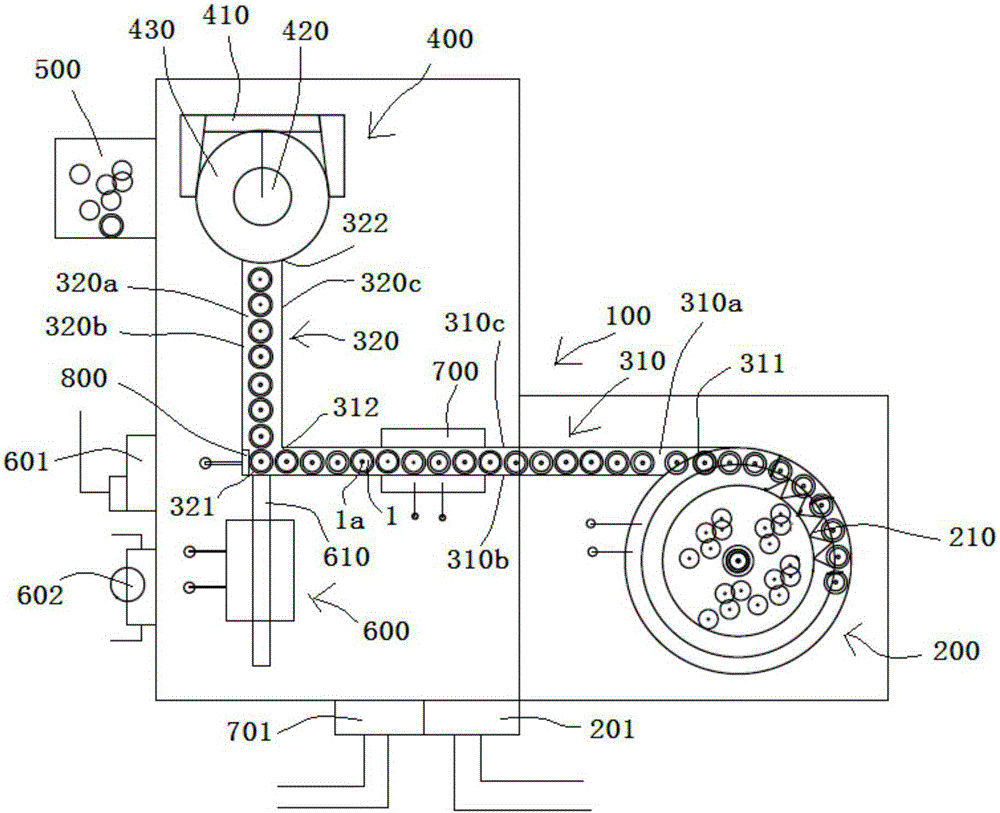

[0029] see figure 1 with figure 2 A pin end surface finishing machine shown includes a machine platform 100, which is provided with a graphite pin feeding device 200, a first feeding guide groove 310, a second feeding guide groove 320, a grinding device 400, and a receiving tray 500 , Linear pushing device 600.

[0030] The graphite pin feeding device 200 is a spiral magnetic feeder in the prior art, and the graphite pin feeding device 200 has a sorting device 210, so that the graphite pin 1 delivered by the discharge end of the graphite pin feeding device 200 is in a standing state, so that The protruding part 1a of the end surface of the graphite pin 1 faces upwards, which is convenient for grinding. The adjustment control switch 201 of the graphite pin feeding device 200 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com