Patents

Literature

61results about How to "Achieve the purpose of polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

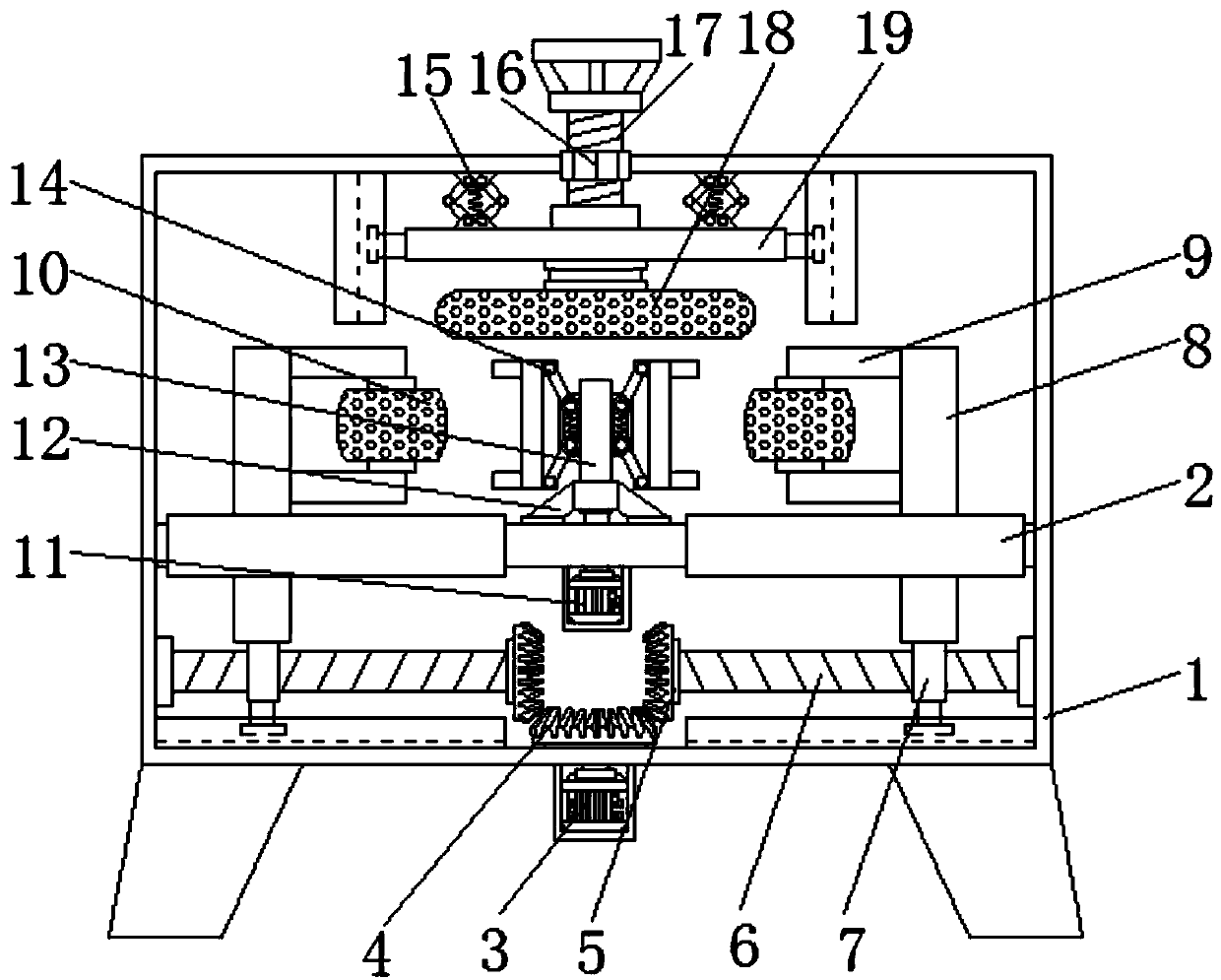

Grinding device for production of automobile brake disc

ActiveCN107649990AEasy to fixAvoid offsetGrinding carriagesGrinding drivesEngineeringGrinding process

The invention discloses a grinding device for production of an automobile brake disc, and relates to the technical field of automobile parts. The grinding device comprises an outer frame, and a transverse plate is fixedly connected between the two sides of the inner wall of the outer frame; a first motor is fixedly connected to the bottom of the outer frame, and one end of an output shaft of the first motor penetrates through the outer frame and extends to the interior of the outer frame; and a first conical gear is fixedly connected to the end, located at the interior of the outer frame, of the output shaft of the first motor, and second conical gears are engaged with the two sides of the first conical gear. According to the grinding device for production of the automobile brake discs, the purpose of convenient fixing of the brake disc is achieved, the grinding device is convenient to use for people, offset of the brake disc in the grinding process is prevented, the grinding effect isimproved, spacing of two grinding heads can be adjusted so that the grinding device can be suitable for the brake discs with different diameters; and the height of a grinding disc can be adjusted according to needs, controlling of the grinding thickness is facilitated, and different grinding effects can be obtained

Owner:烟台美丰机械集团有限公司

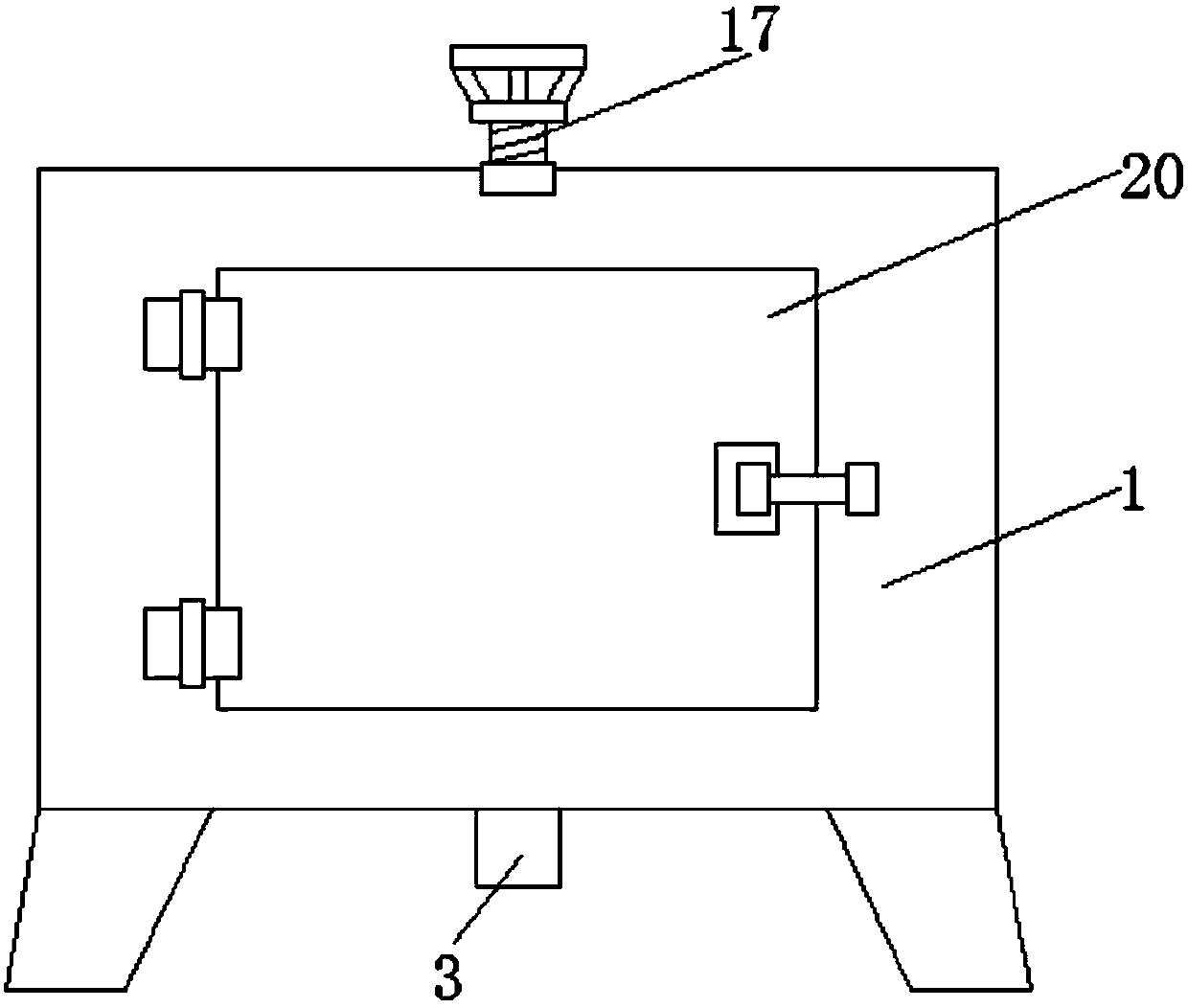

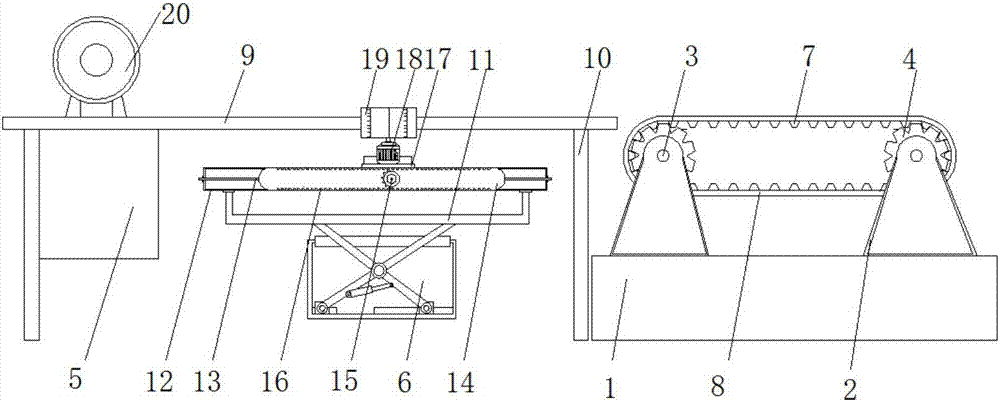

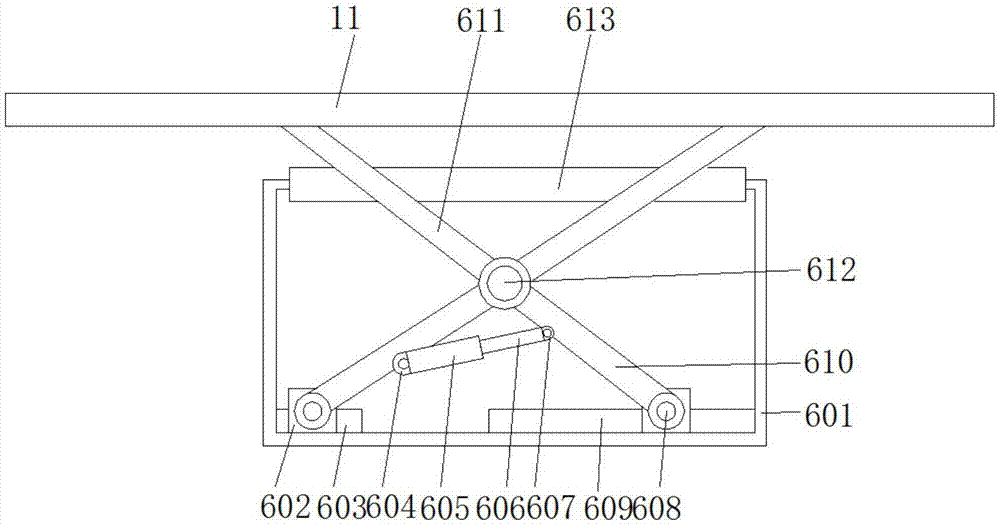

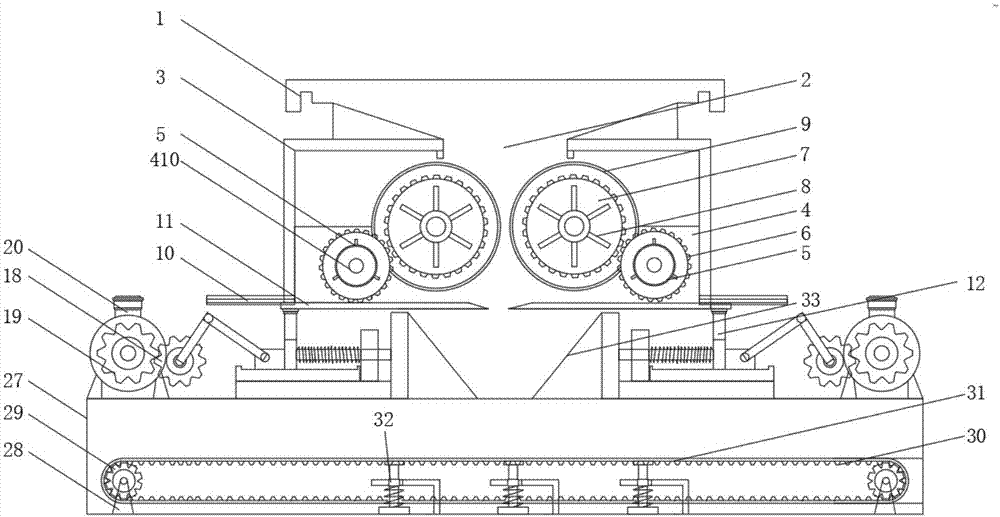

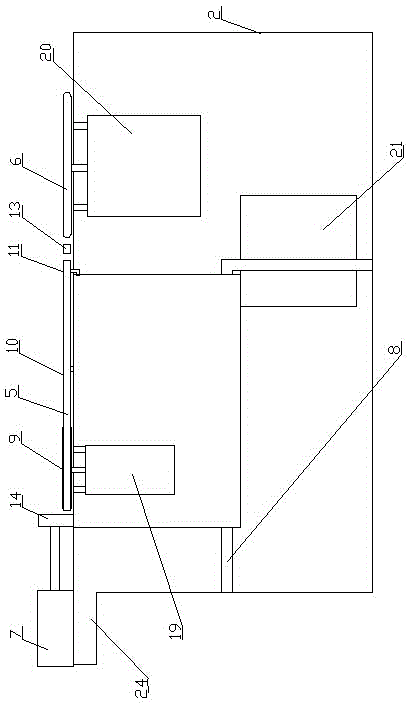

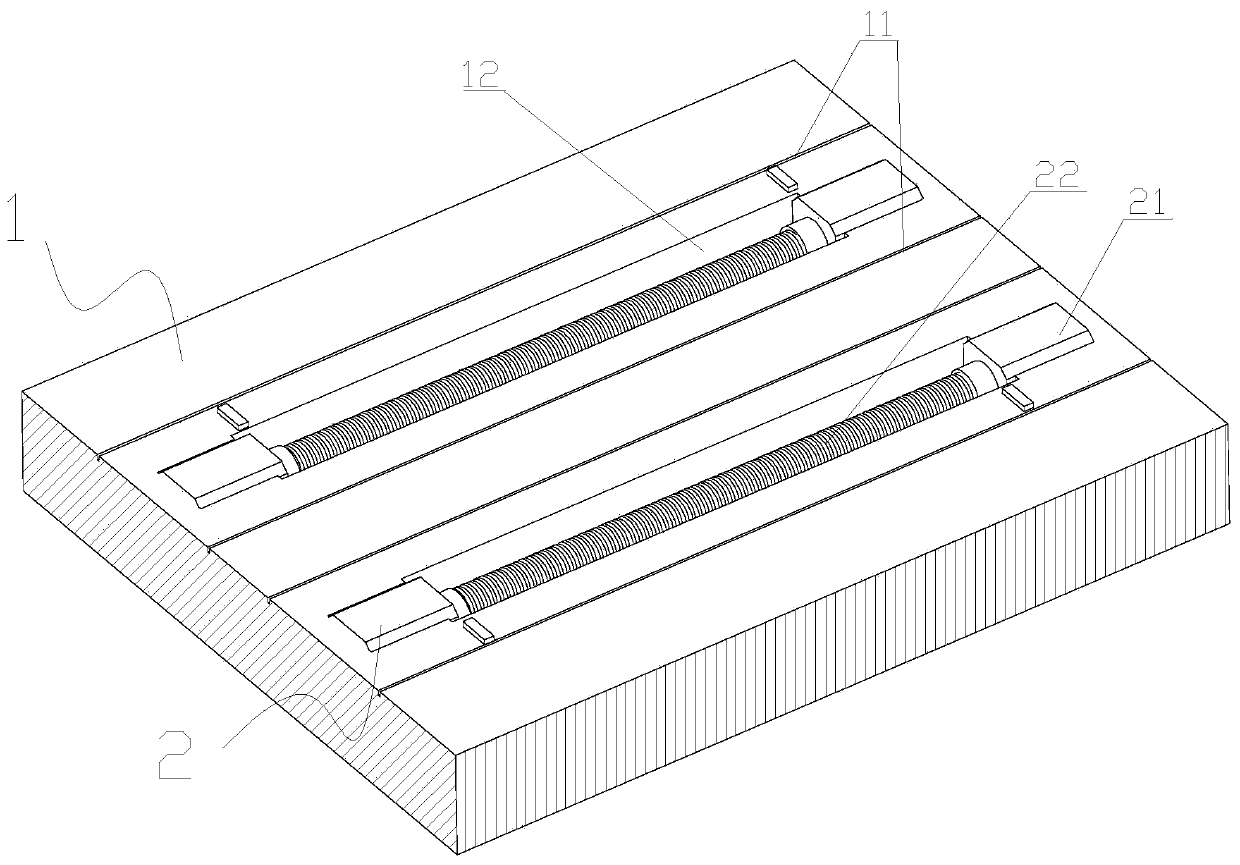

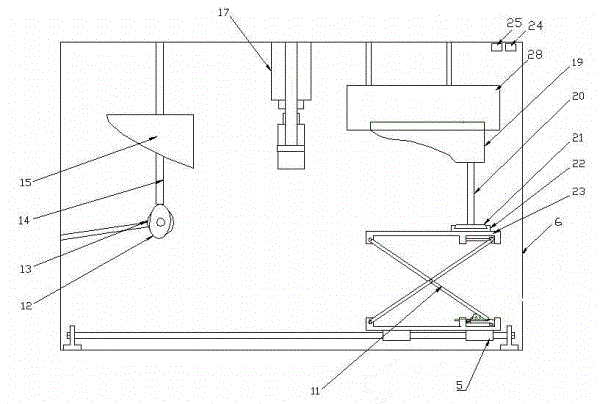

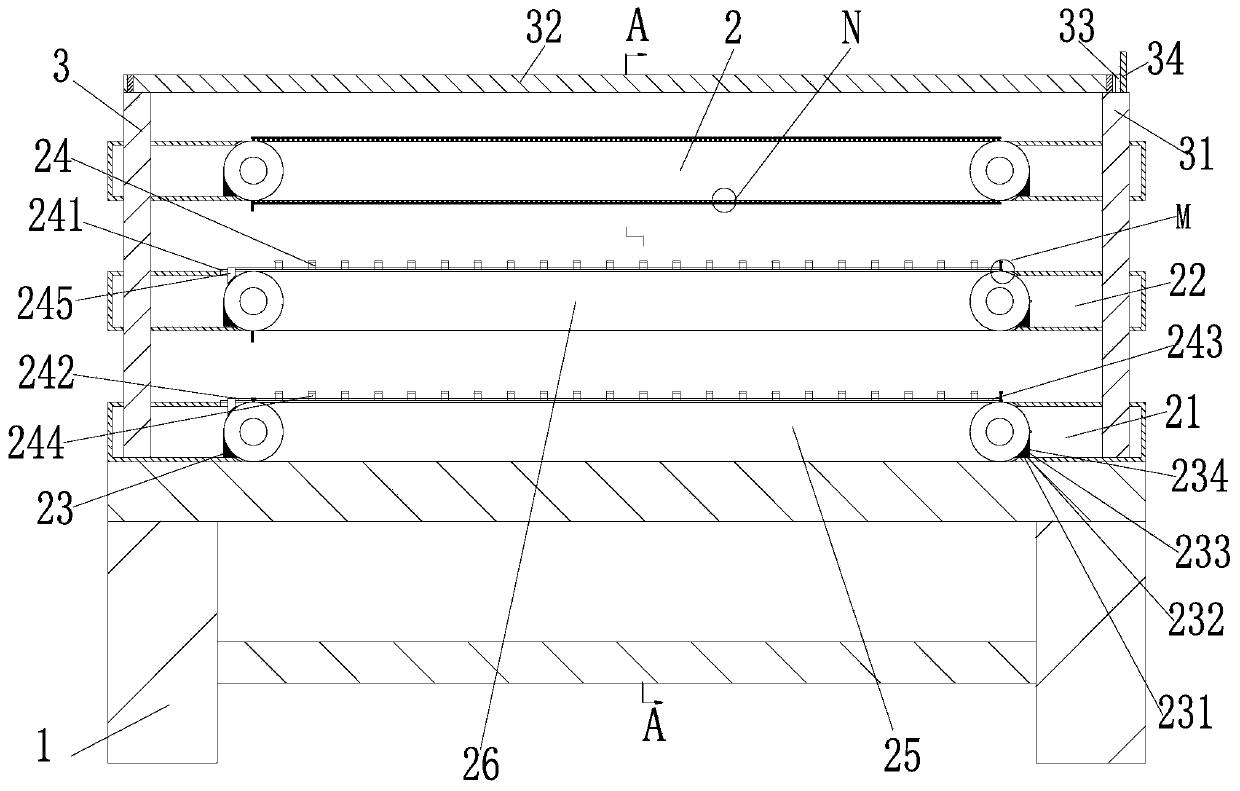

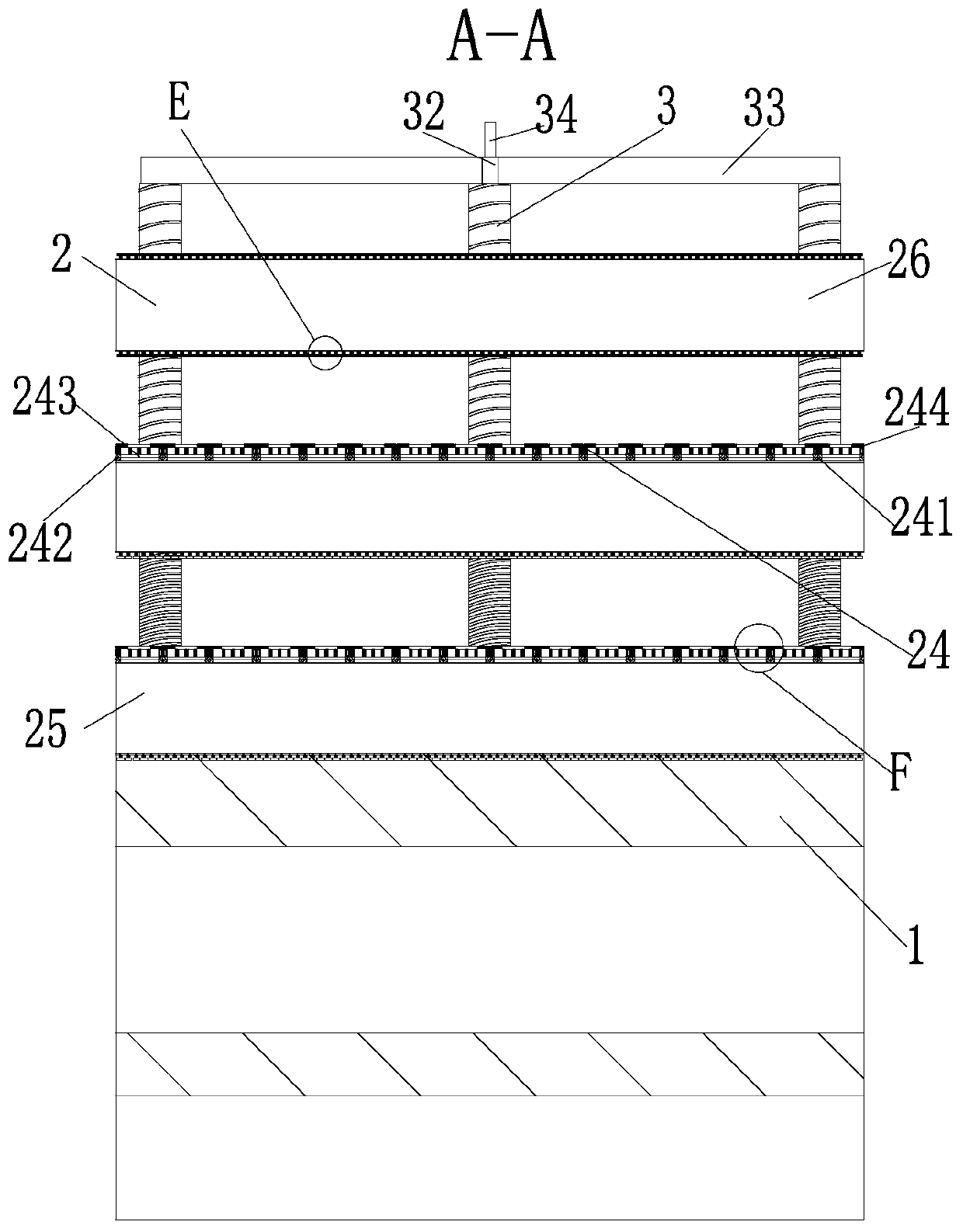

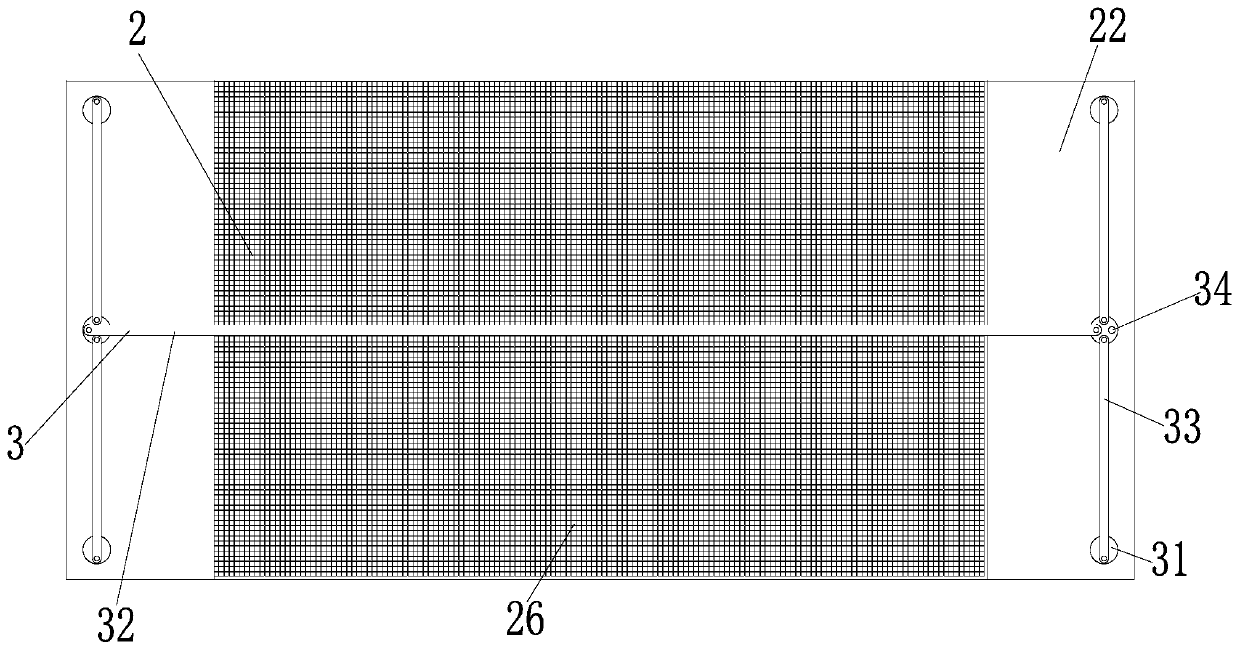

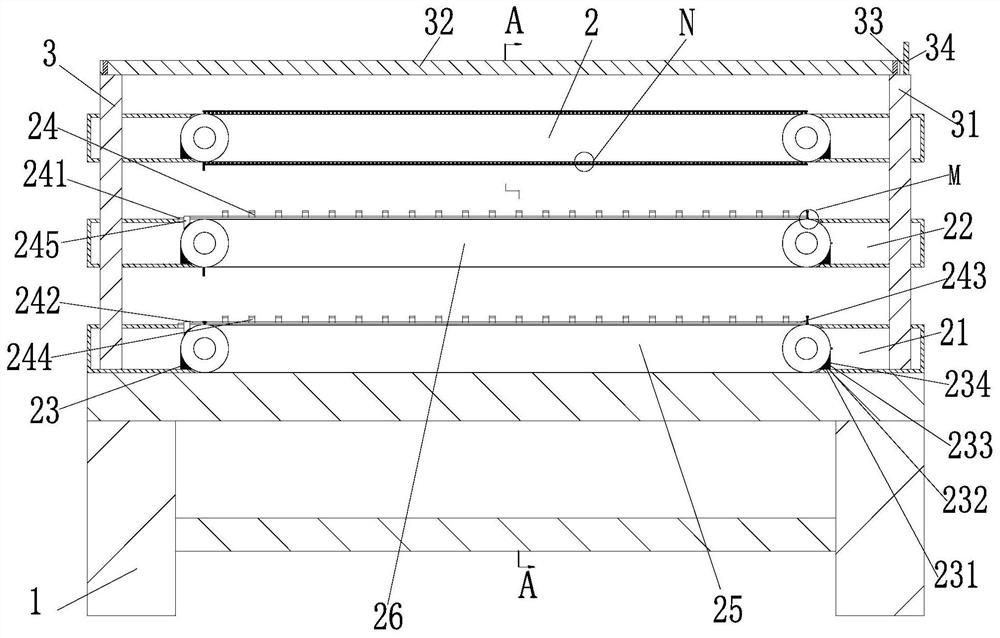

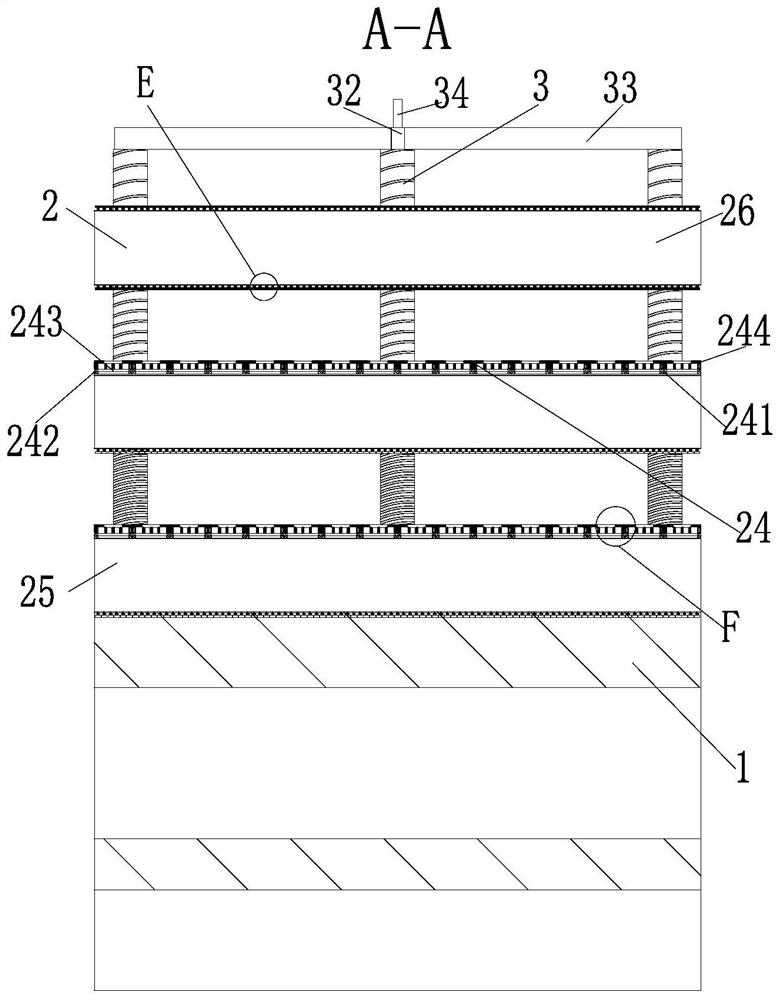

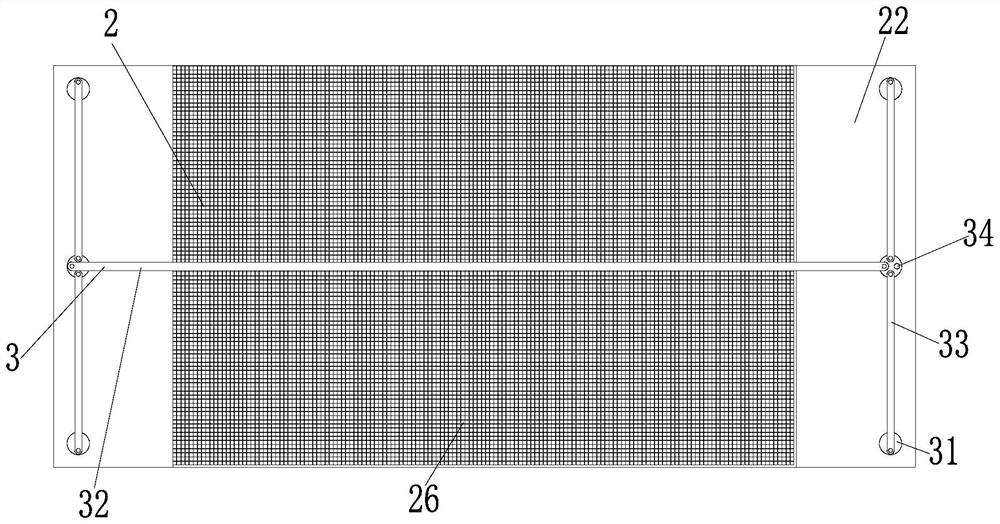

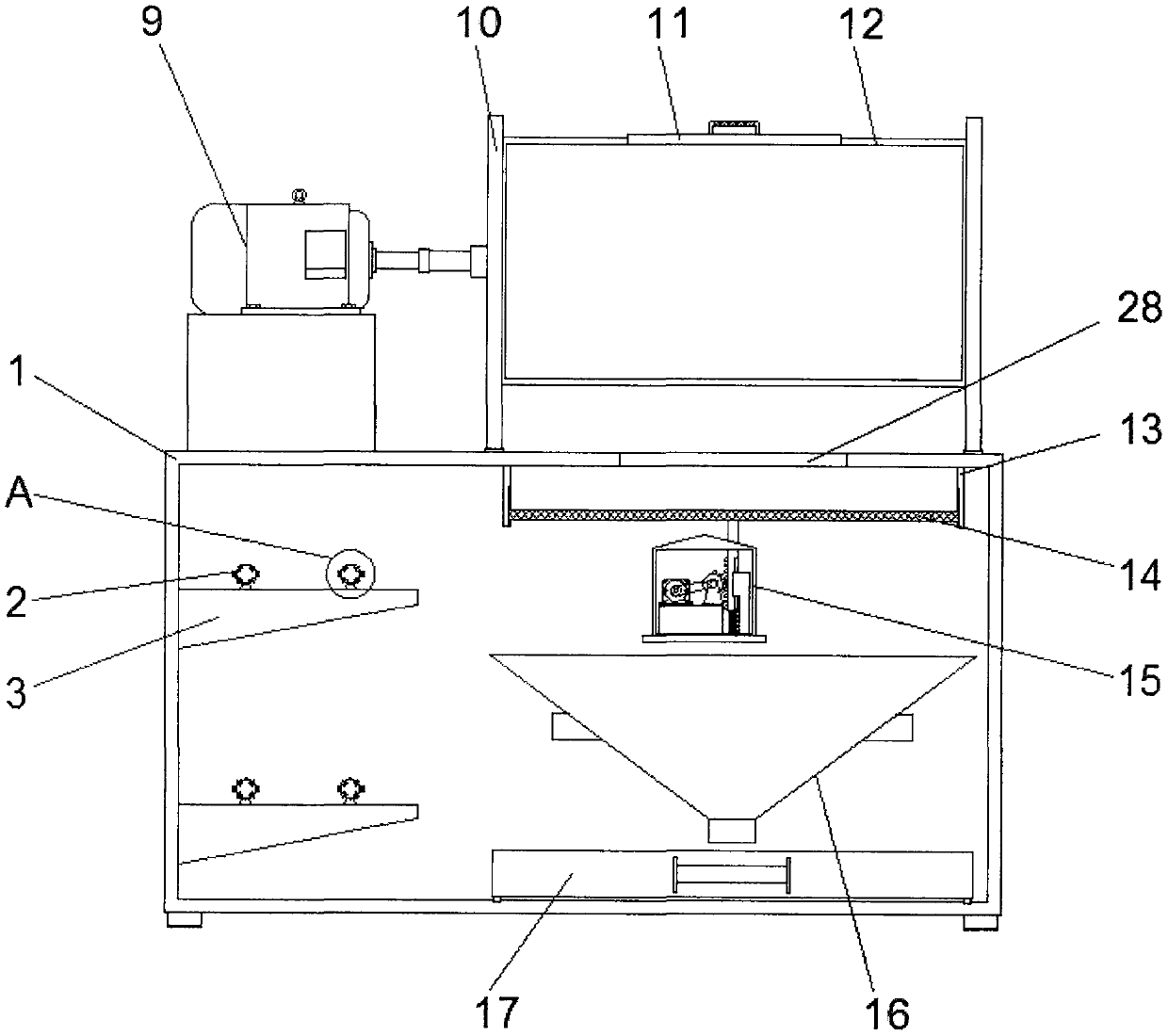

Automatic grinding machine for wood board processing

InactiveCN107263238AAchieve the purpose of moving up and downRealize moving up and downPlane surface grinding machinesEngineeringPulp and paper industry

The invention discloses an automatic grinding machine for wood board processing. The automatic grinding machine comprises a fixed installation base platform, wherein conveyor belt installation racks are fixedly connected to the top of the fixed installation base platform; a rotating shaft is rotatably connected to the top end of each of the conveyor belt installation racks; each of the rotating shafts is fixedly connected with a gear through a flat key; the gears are meshed and connected with a conveyor belt through a transmission toothed rack; a working platform is arranged on the left side of the fixed installation base platform; a grinding machine lifting device is arranged on one side of the inner wall of the working platform; and an up-down moving device is arranged at the position corresponding to the part below the middle of the working platform. The automatic grinding machine for wood board processing relates to the technical field of processing machinery. According to the automatic grinding machine for wood board processing, the following problems are solved: wood boards with different thicknesses can be ground by the grinding machine, the grinding quality and grinding efficiency are ensured, the production efficiency is improved, the production cost is reduced, the grinding efficiency and grinding quality are ensured through a reciprocating device, wood boards are prevented from improper grinding, and the life and property safety of workers is further ensured.

Owner:安吉县瑞旺竹木制品厂

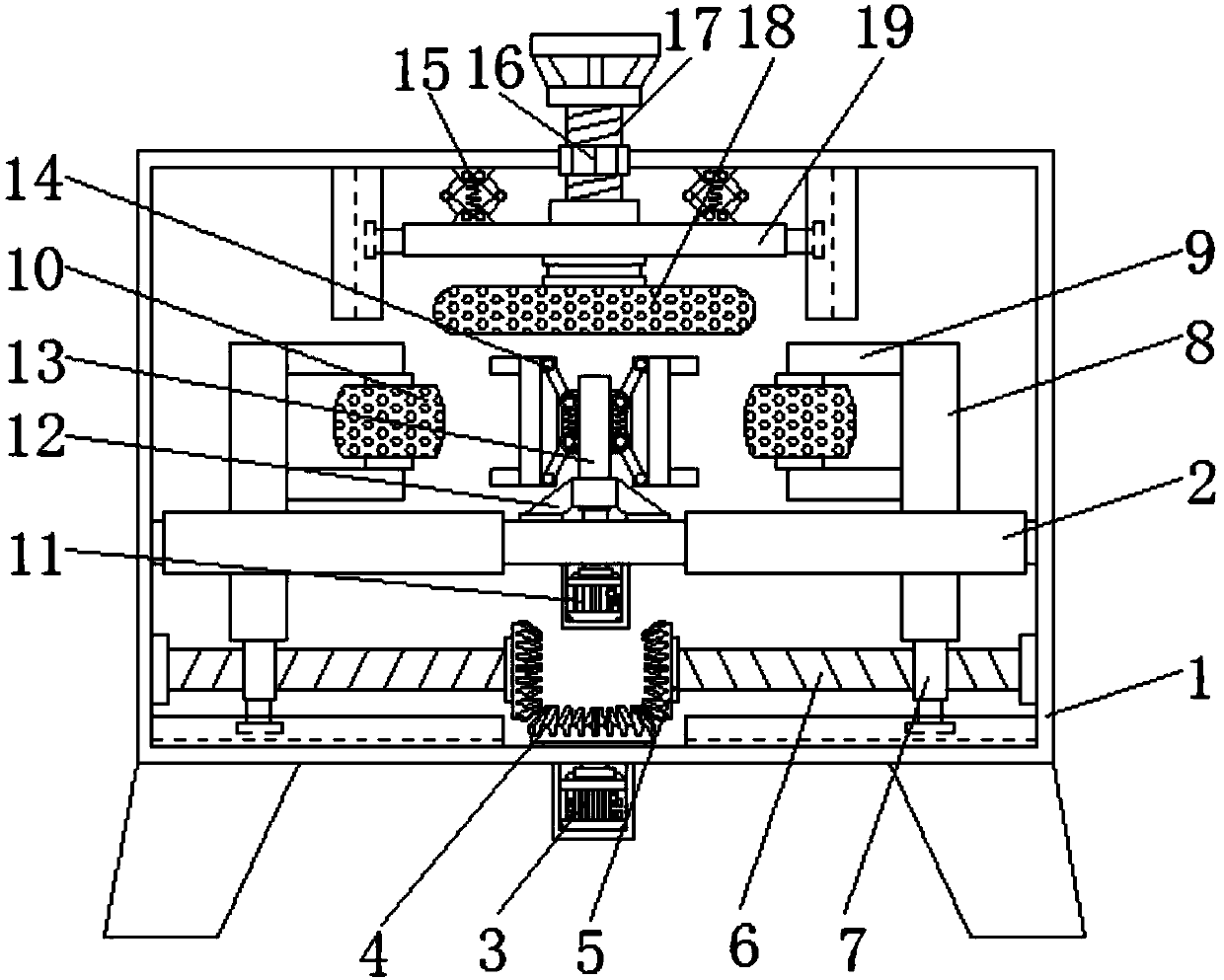

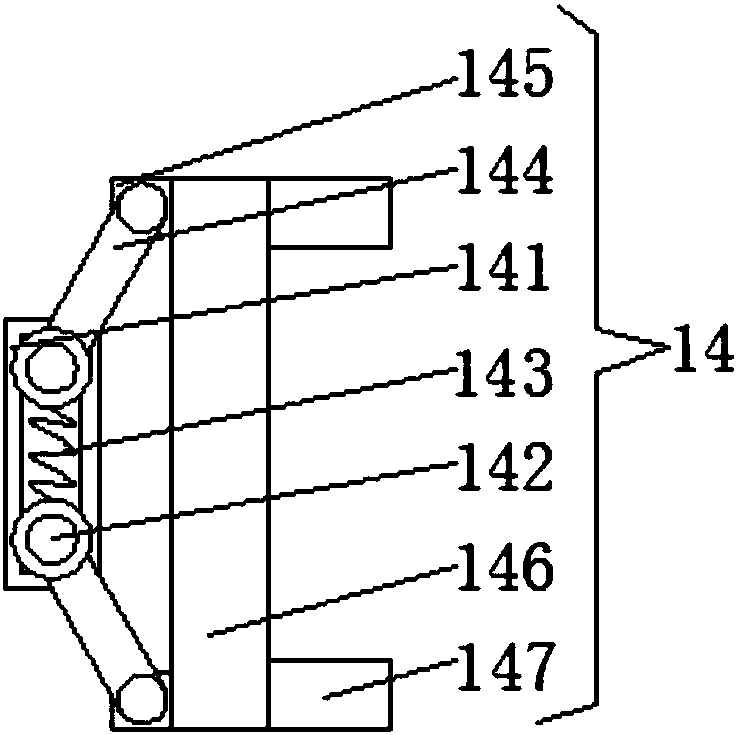

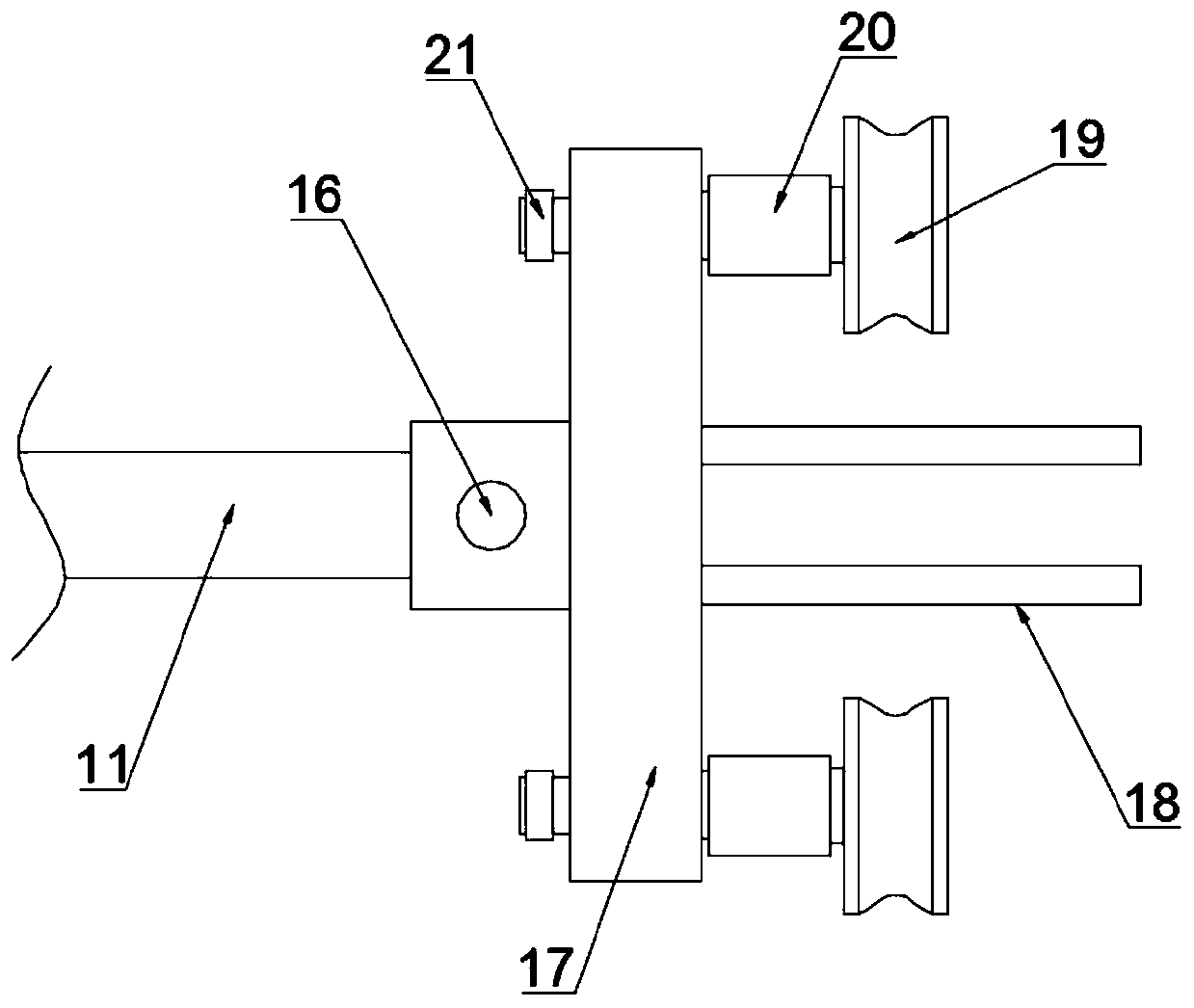

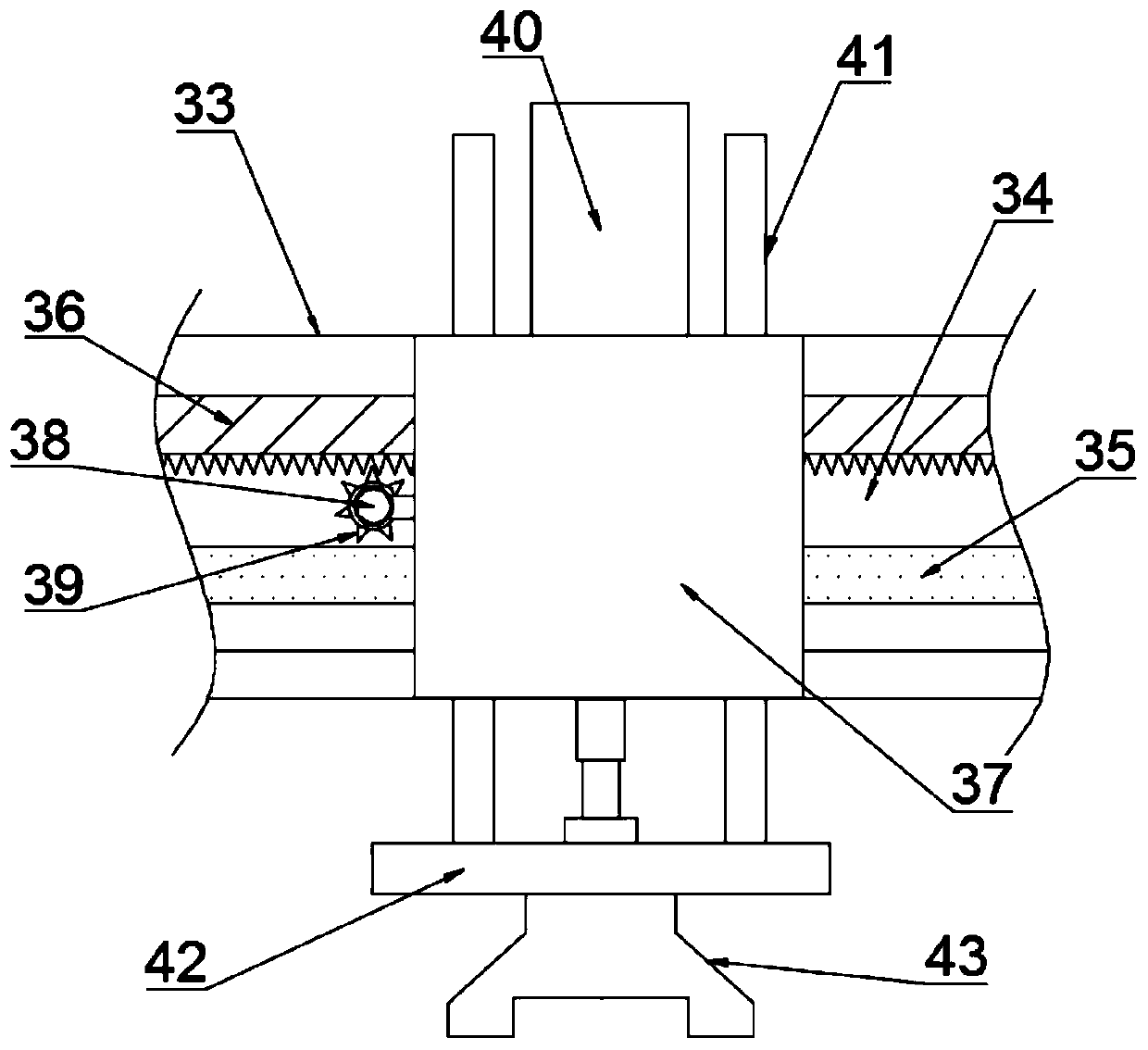

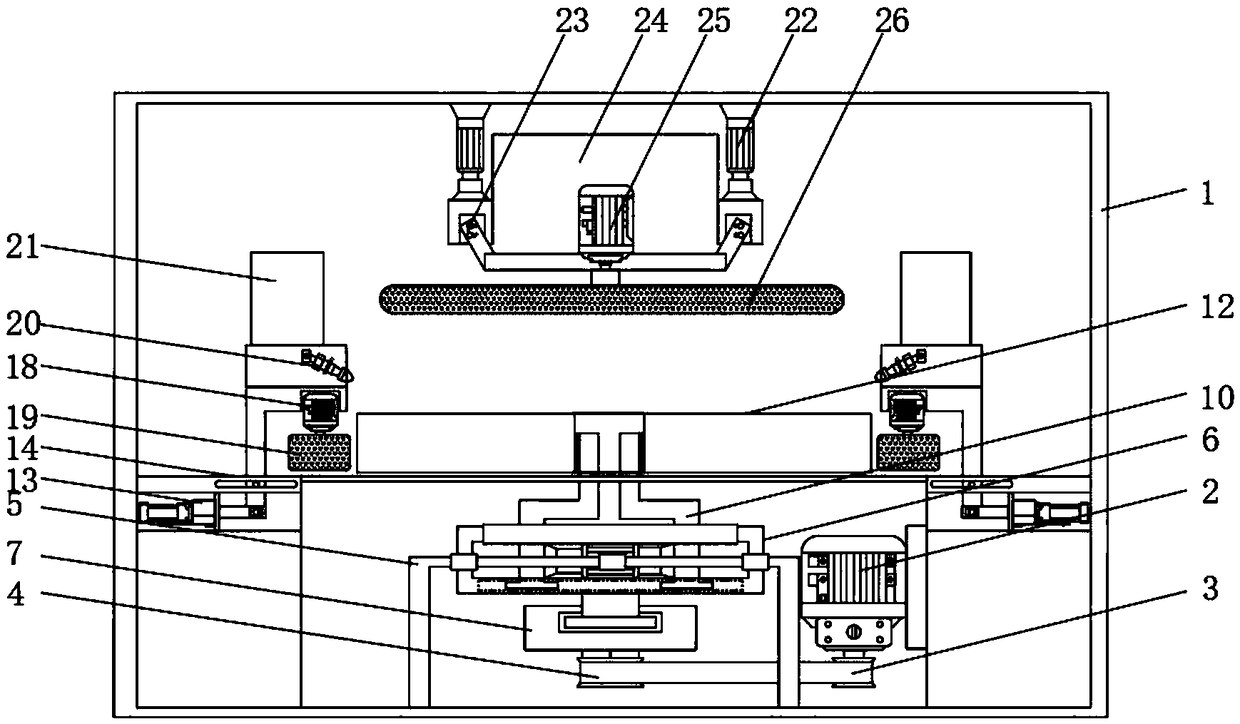

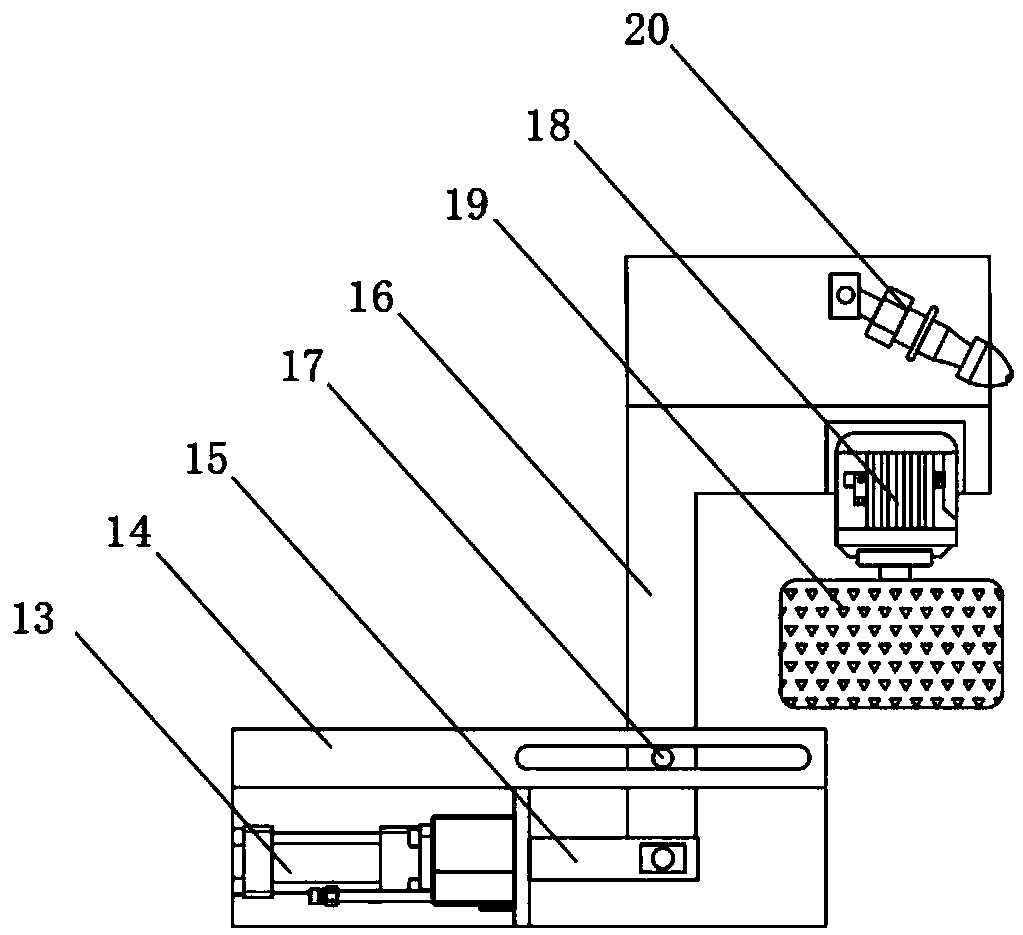

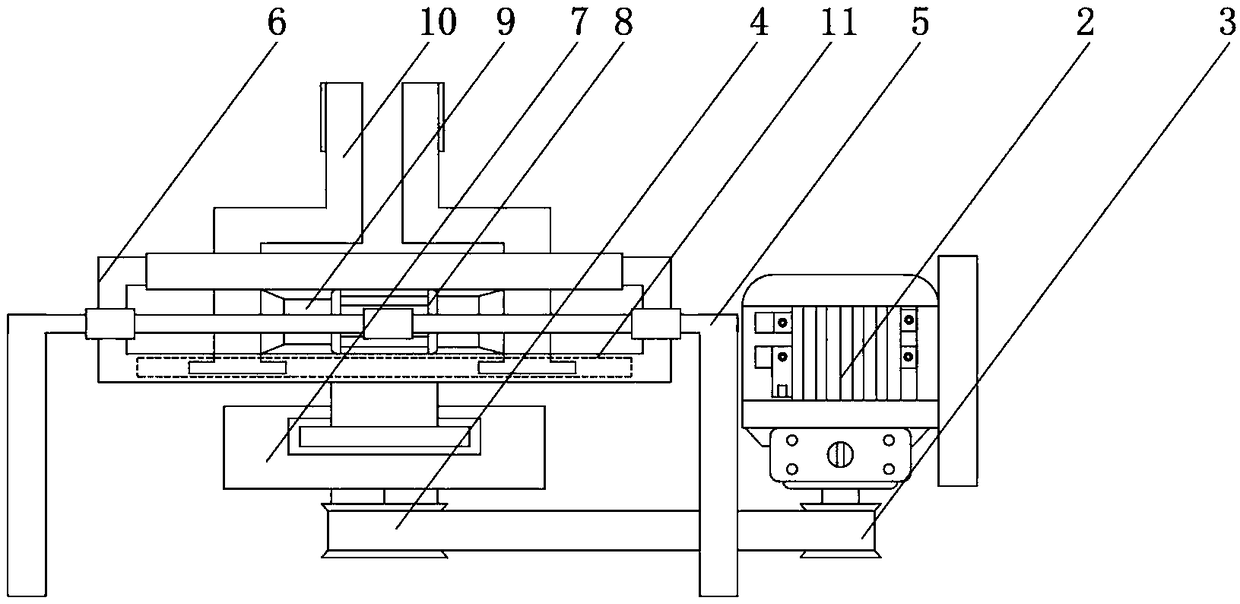

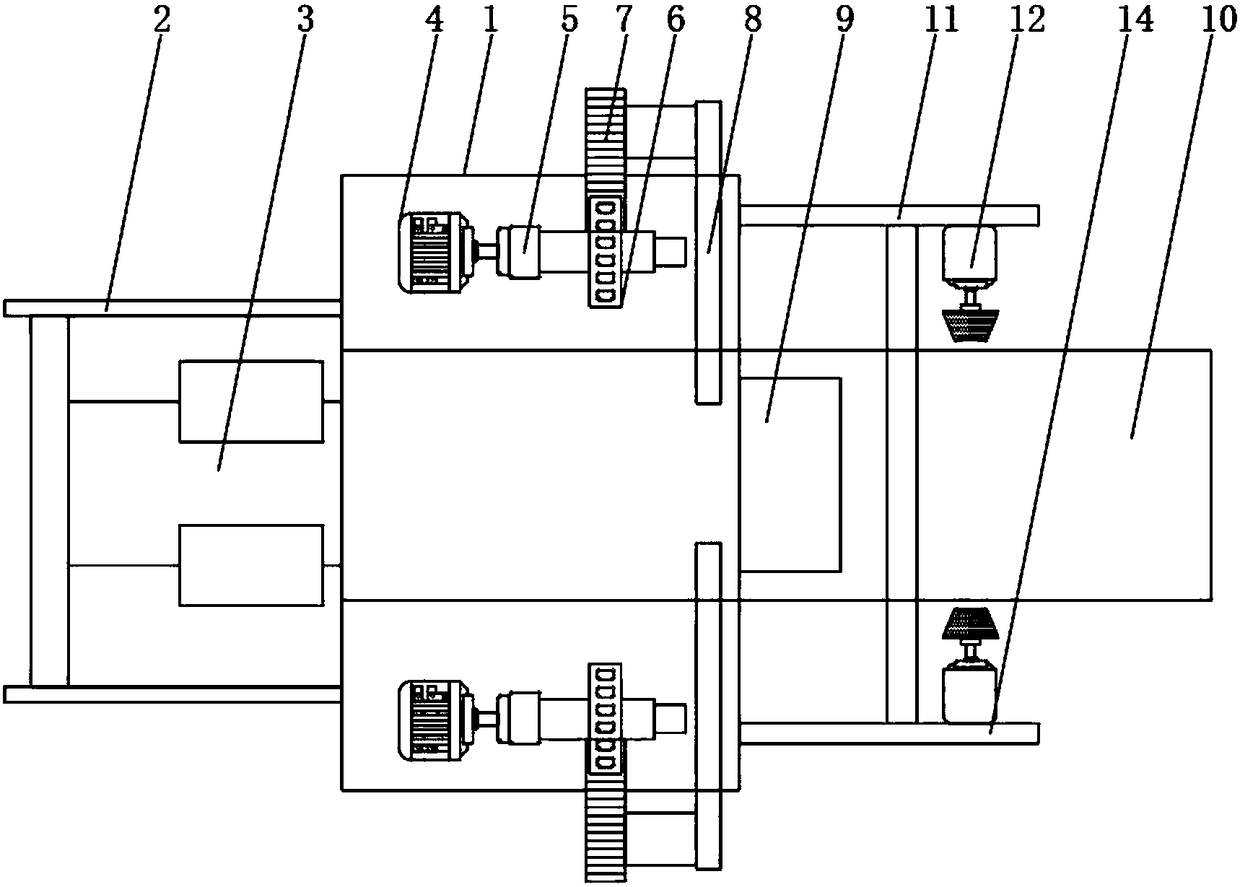

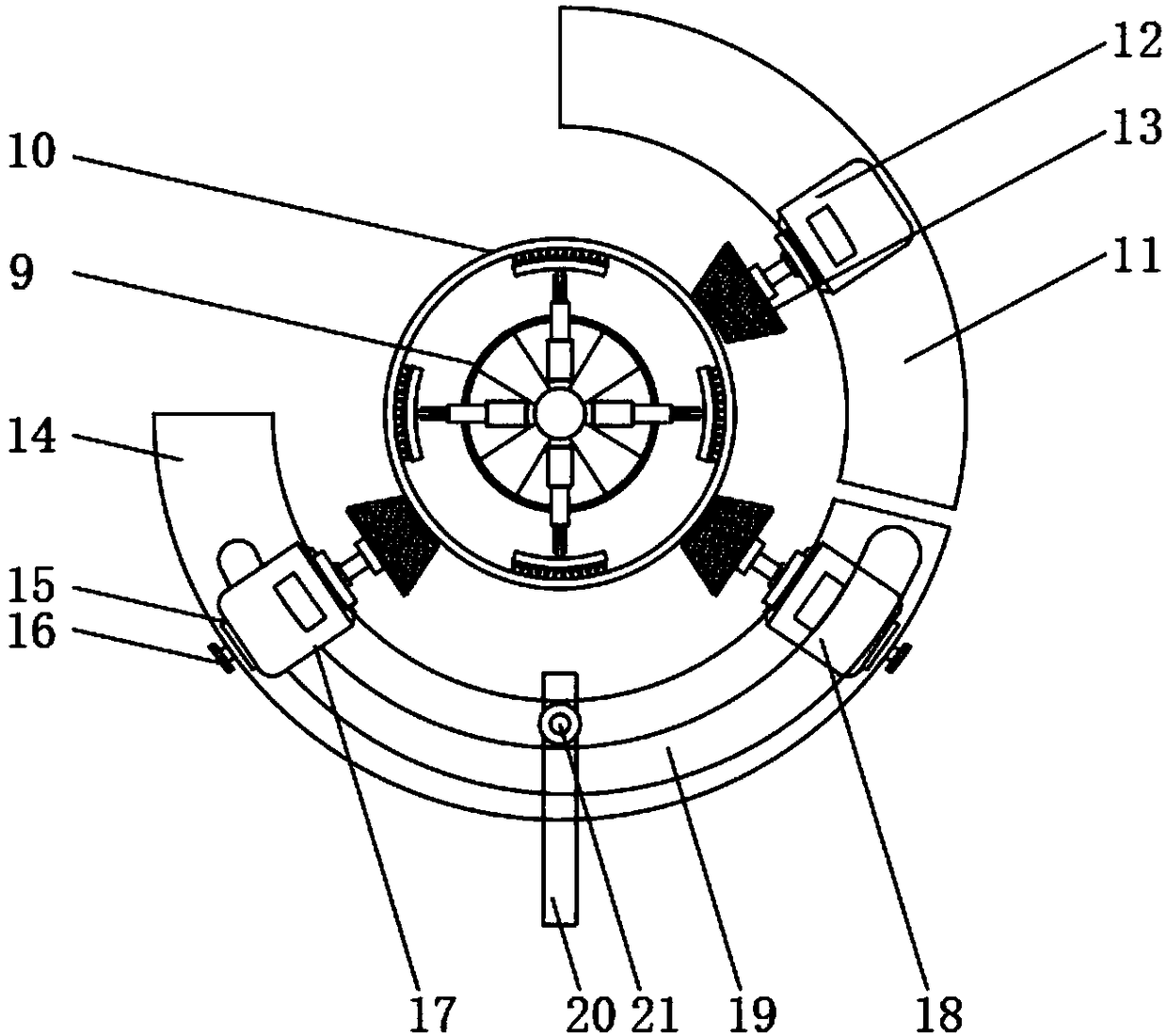

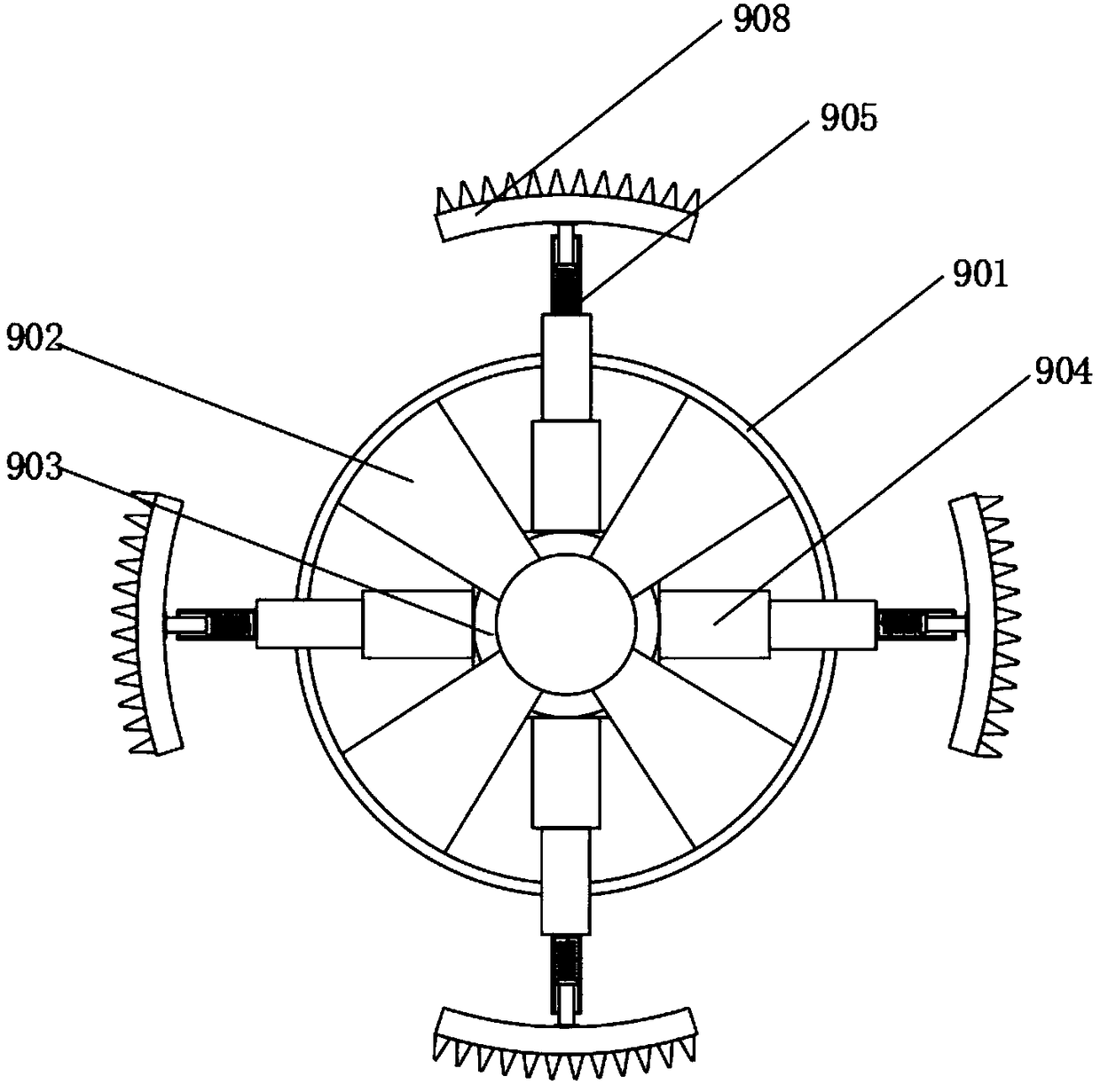

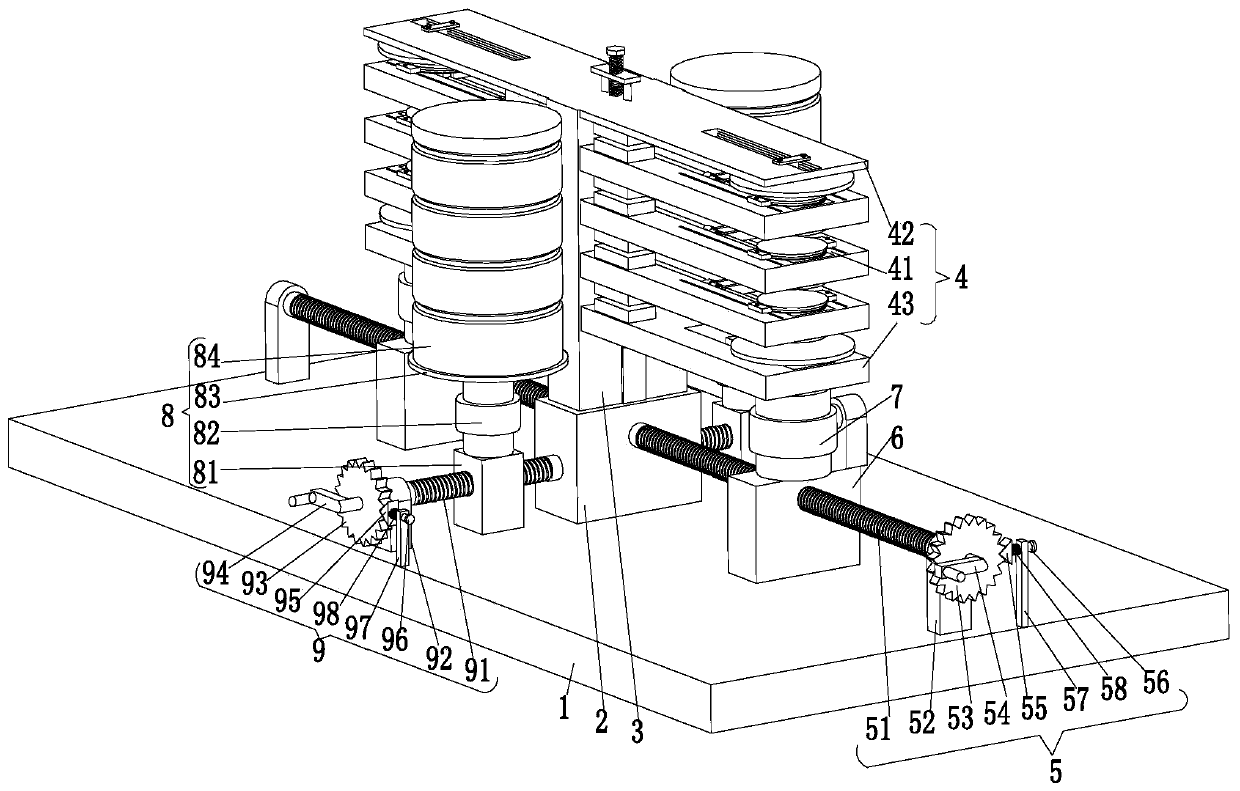

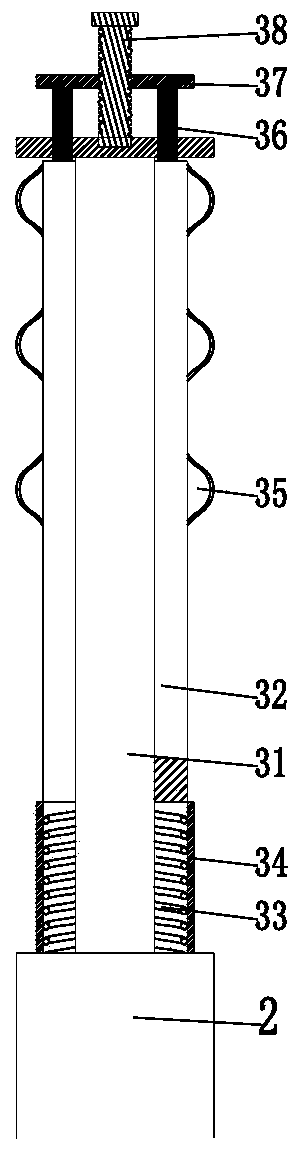

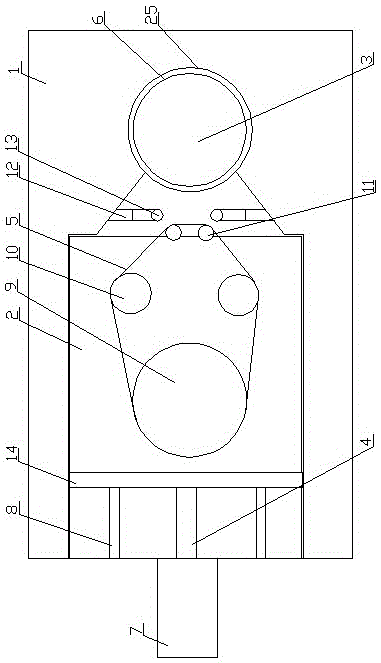

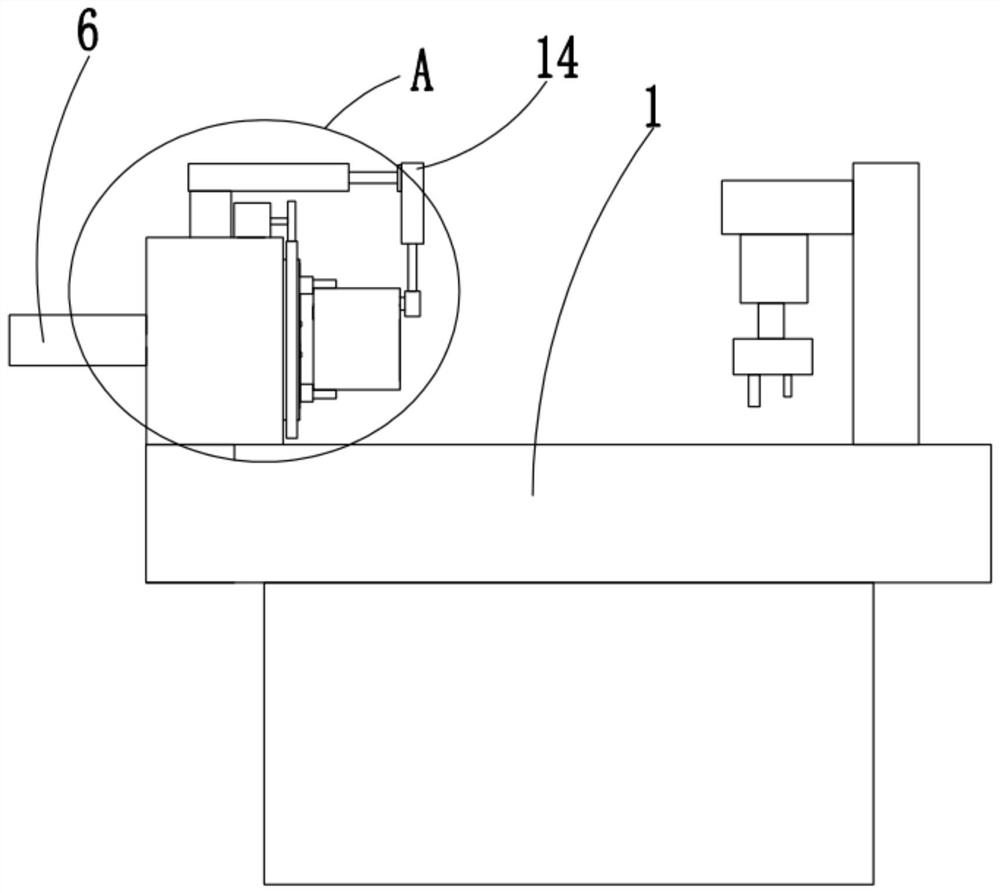

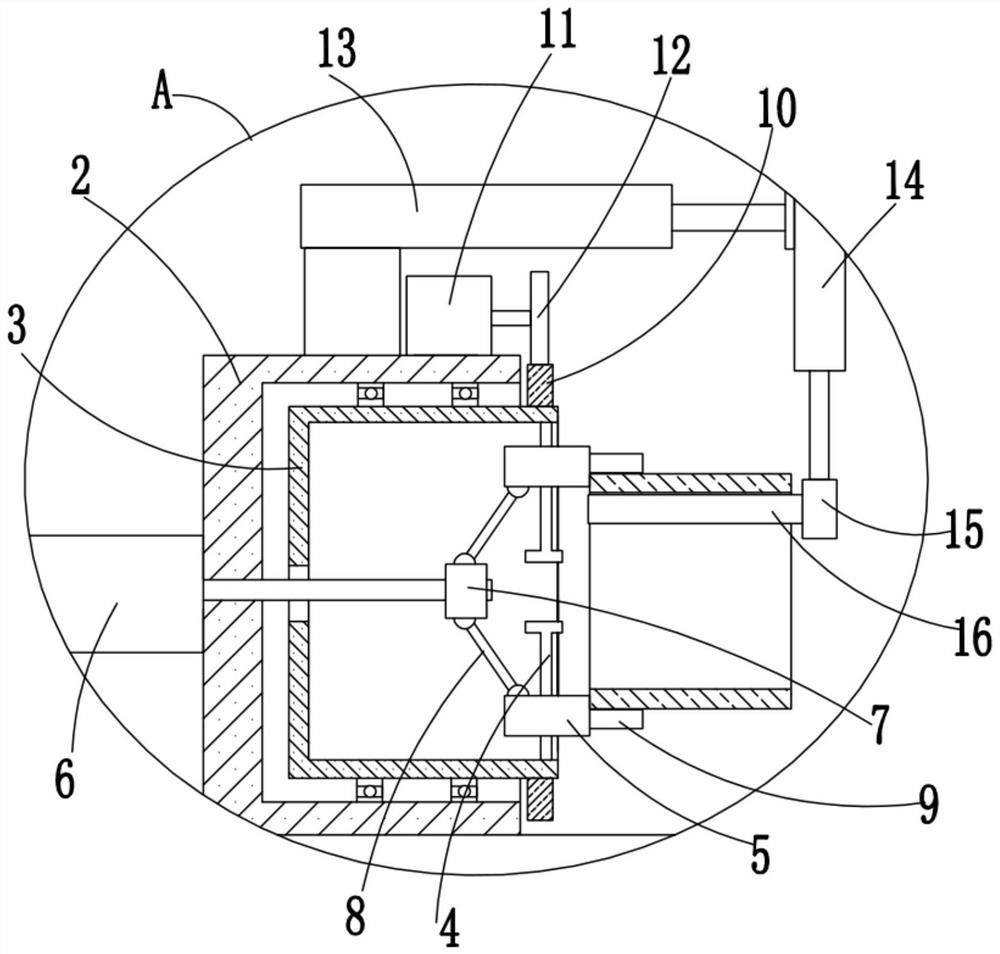

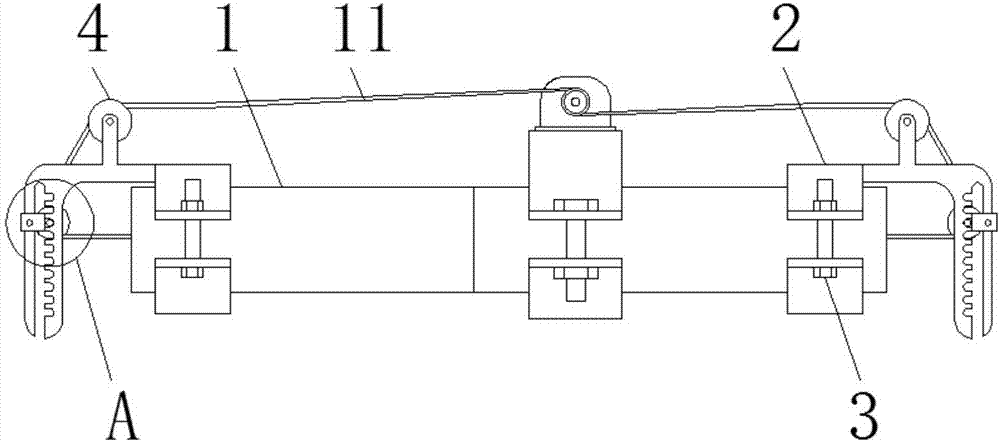

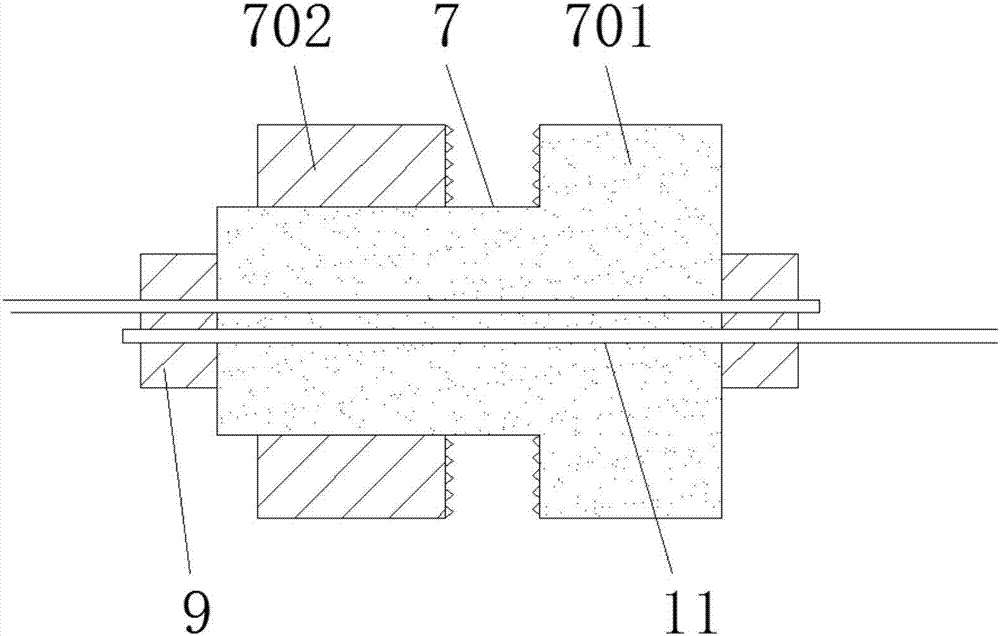

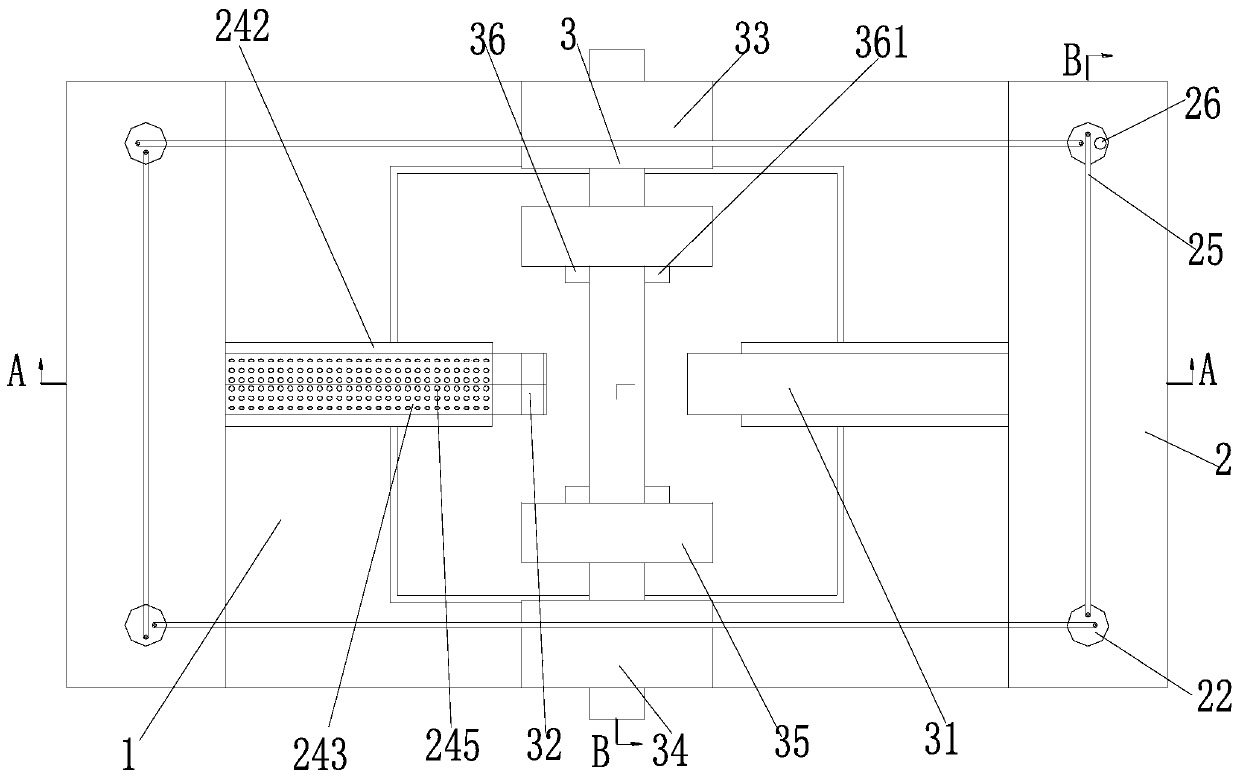

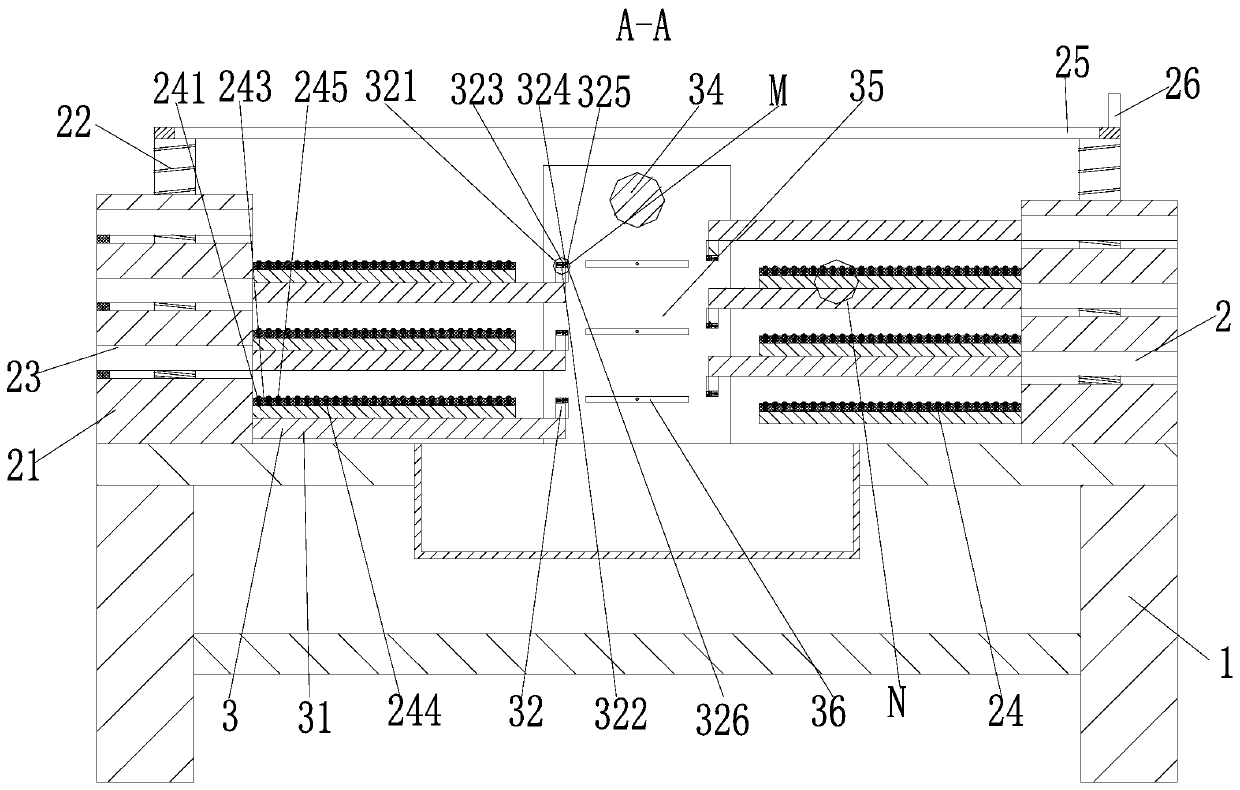

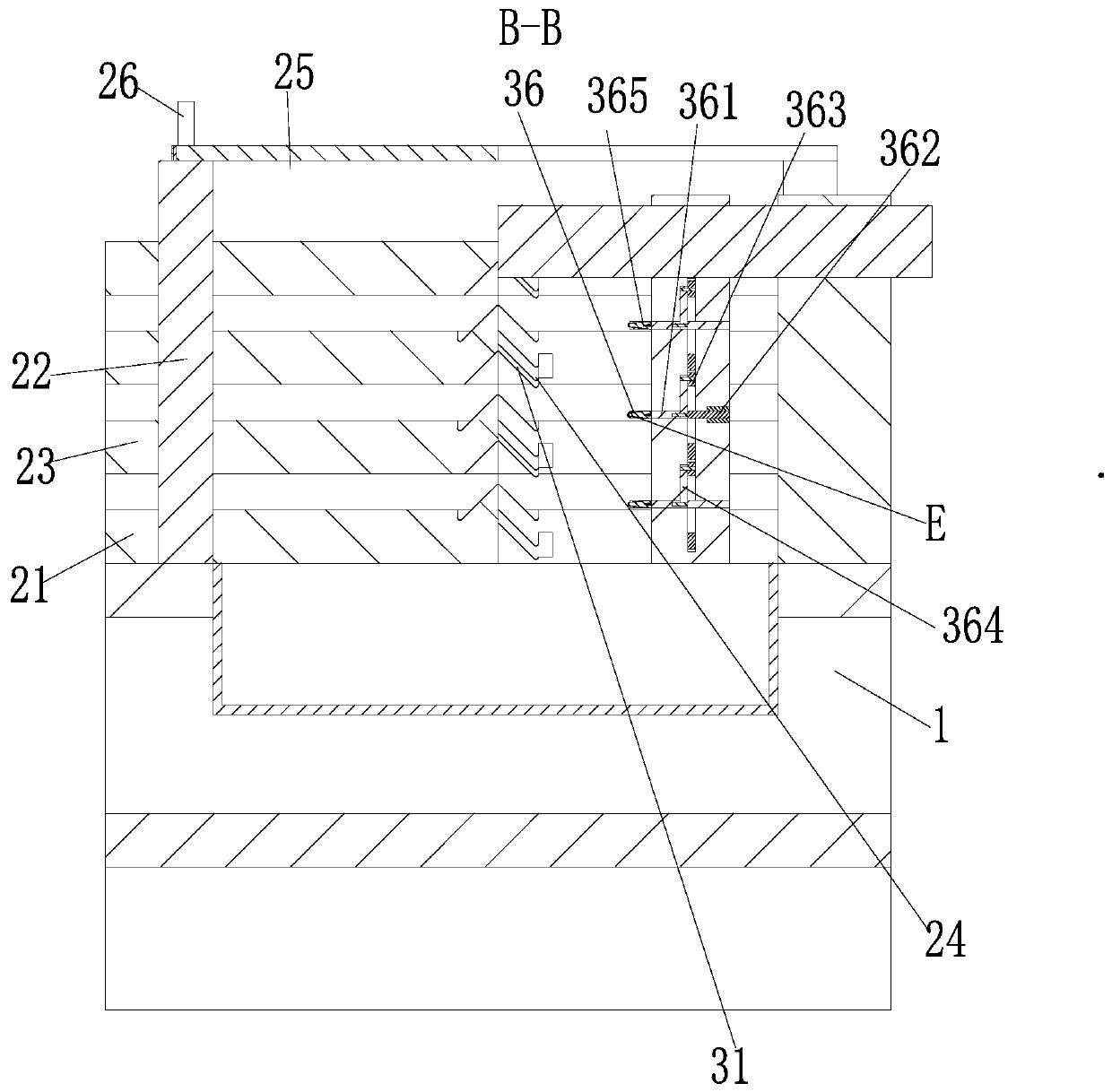

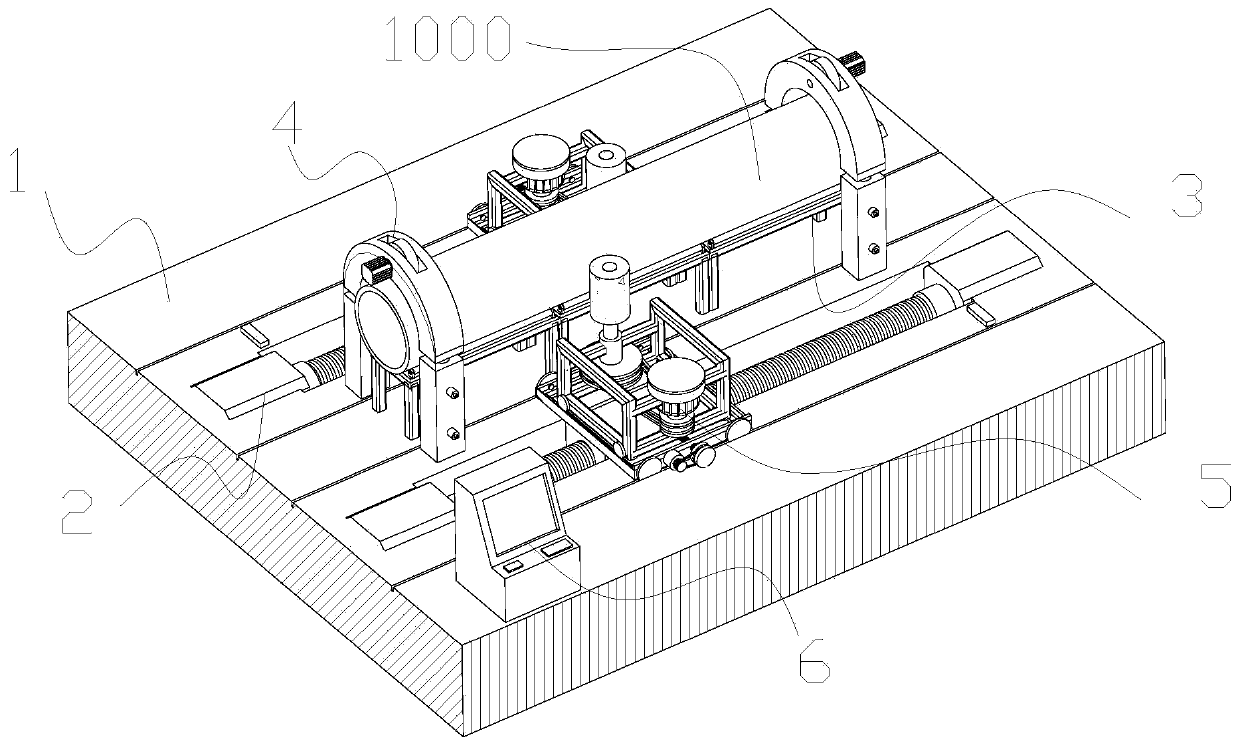

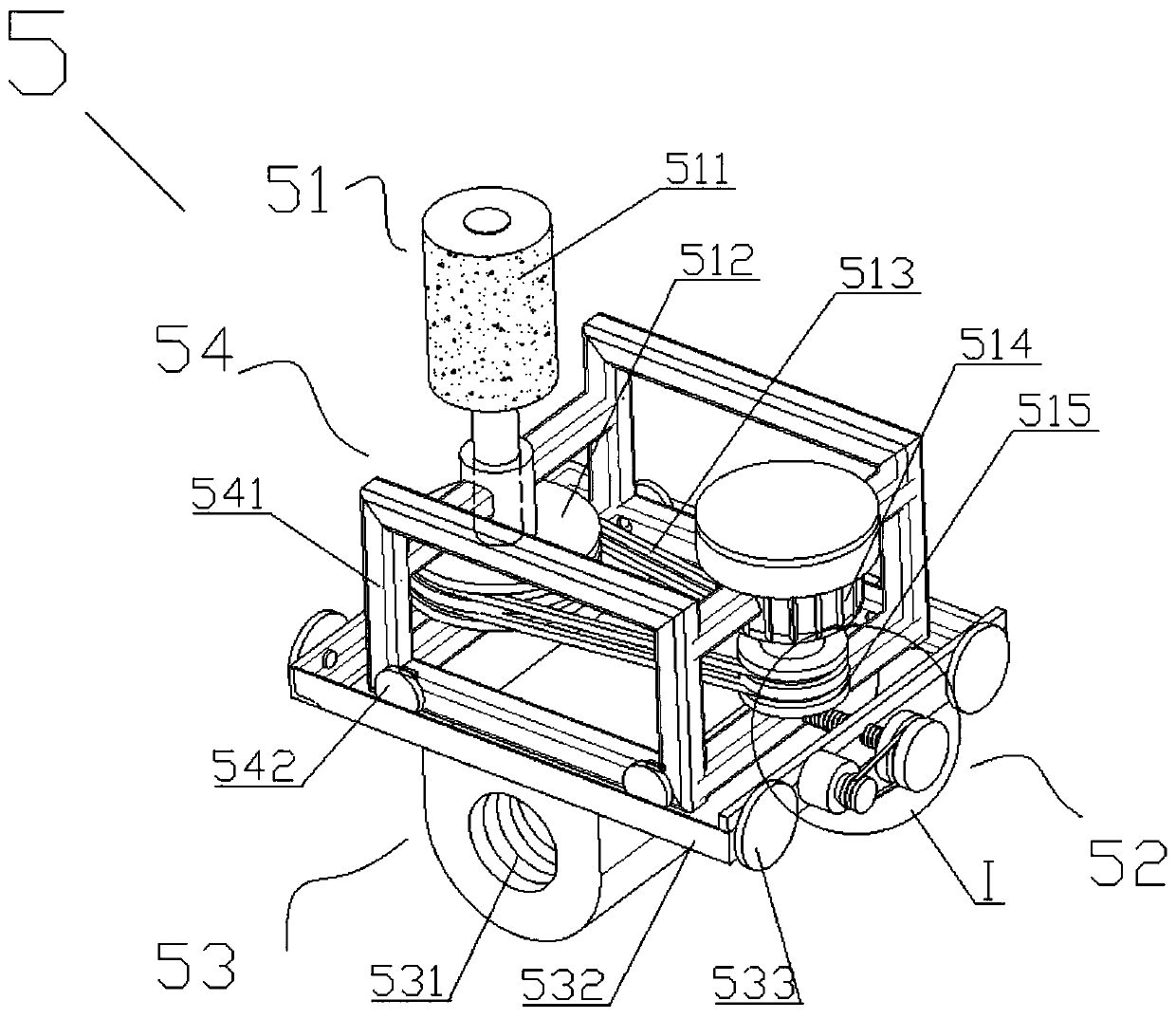

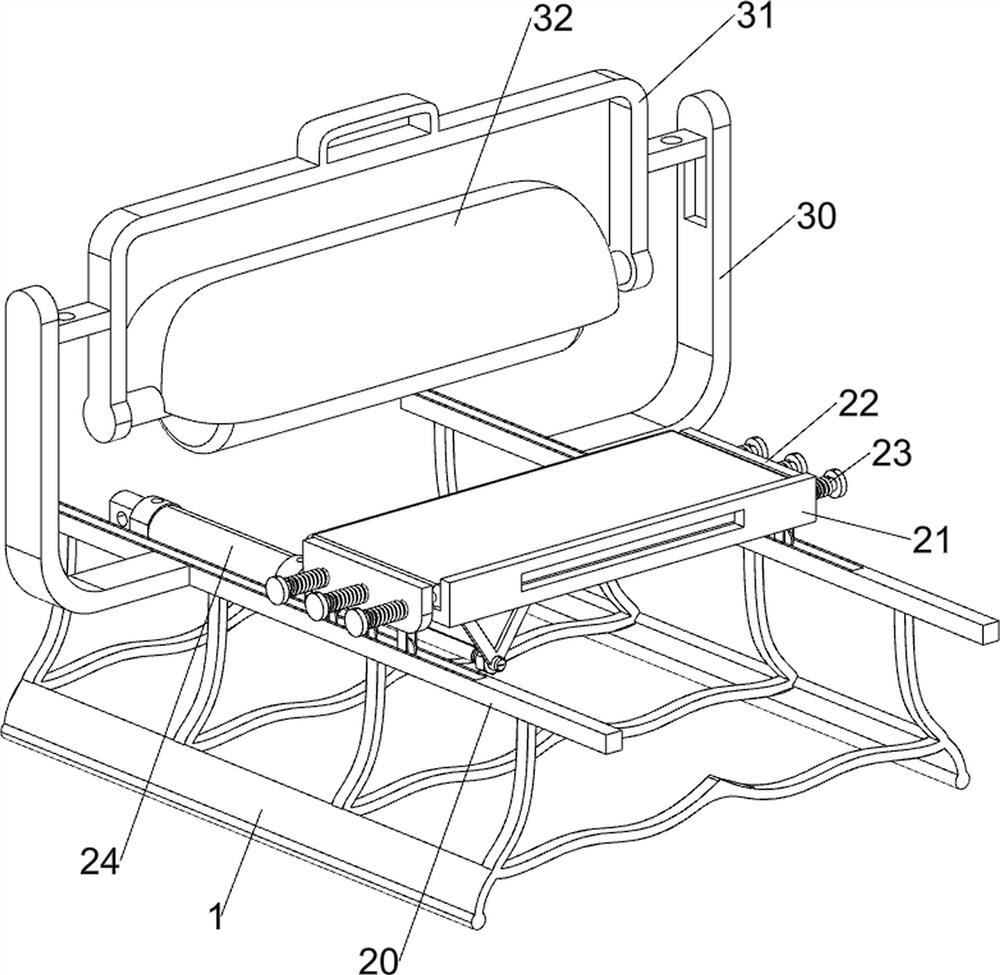

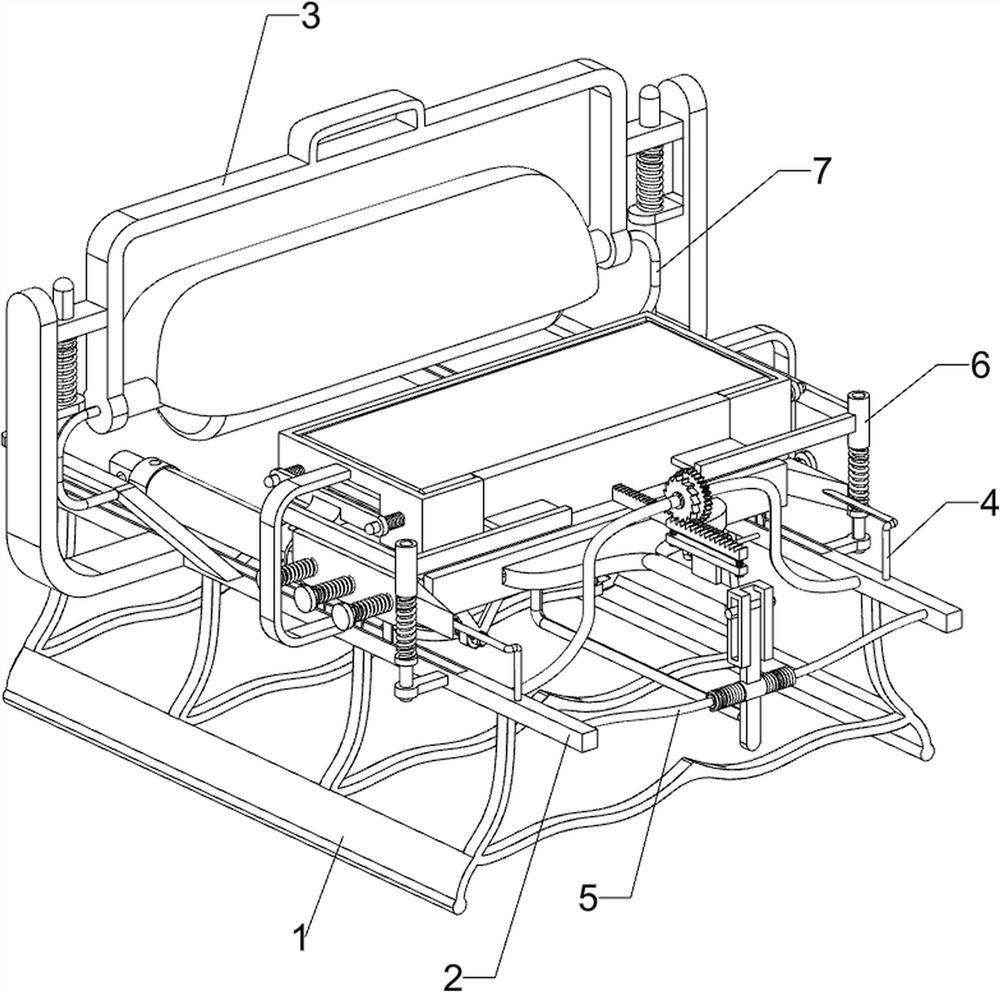

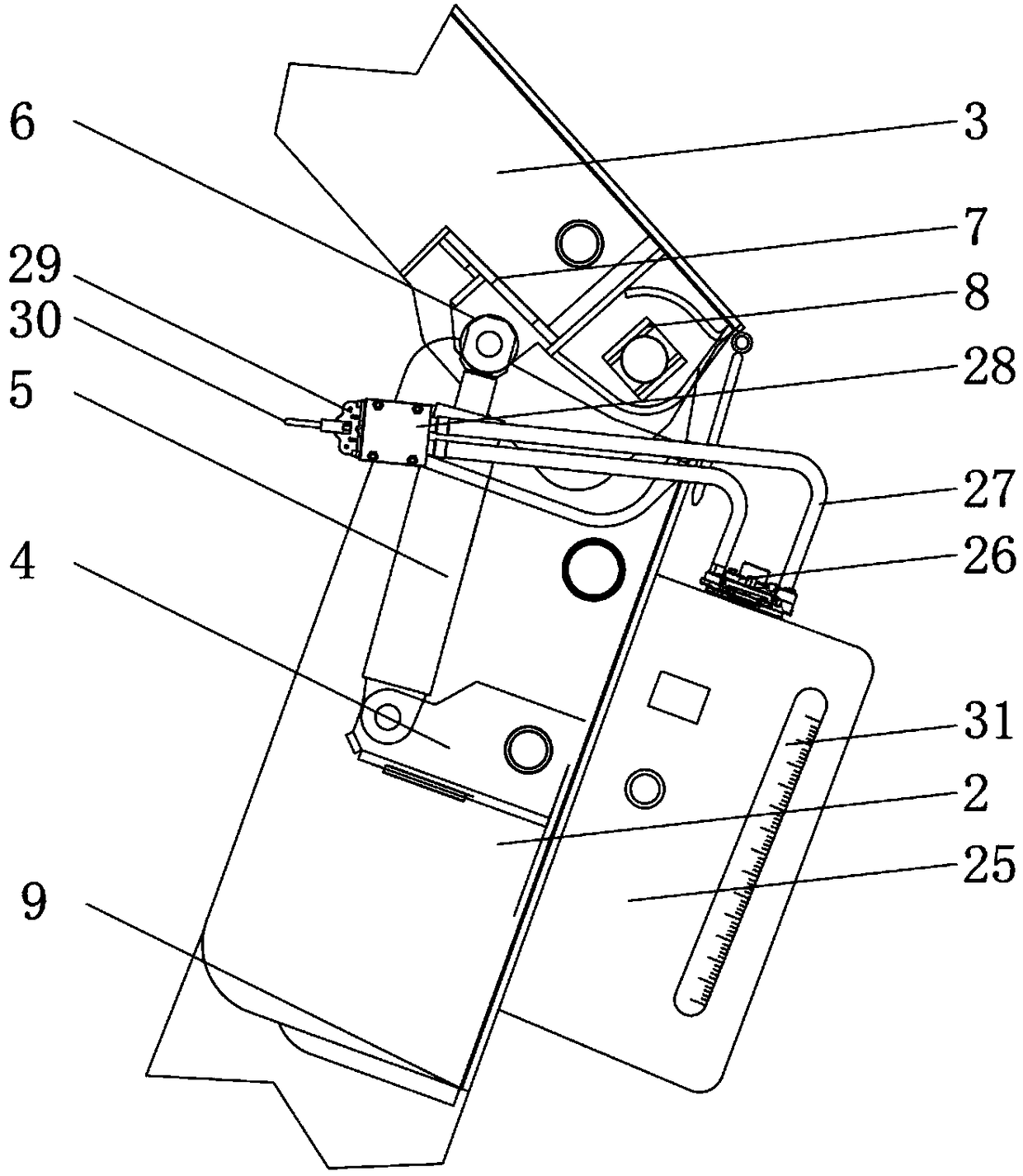

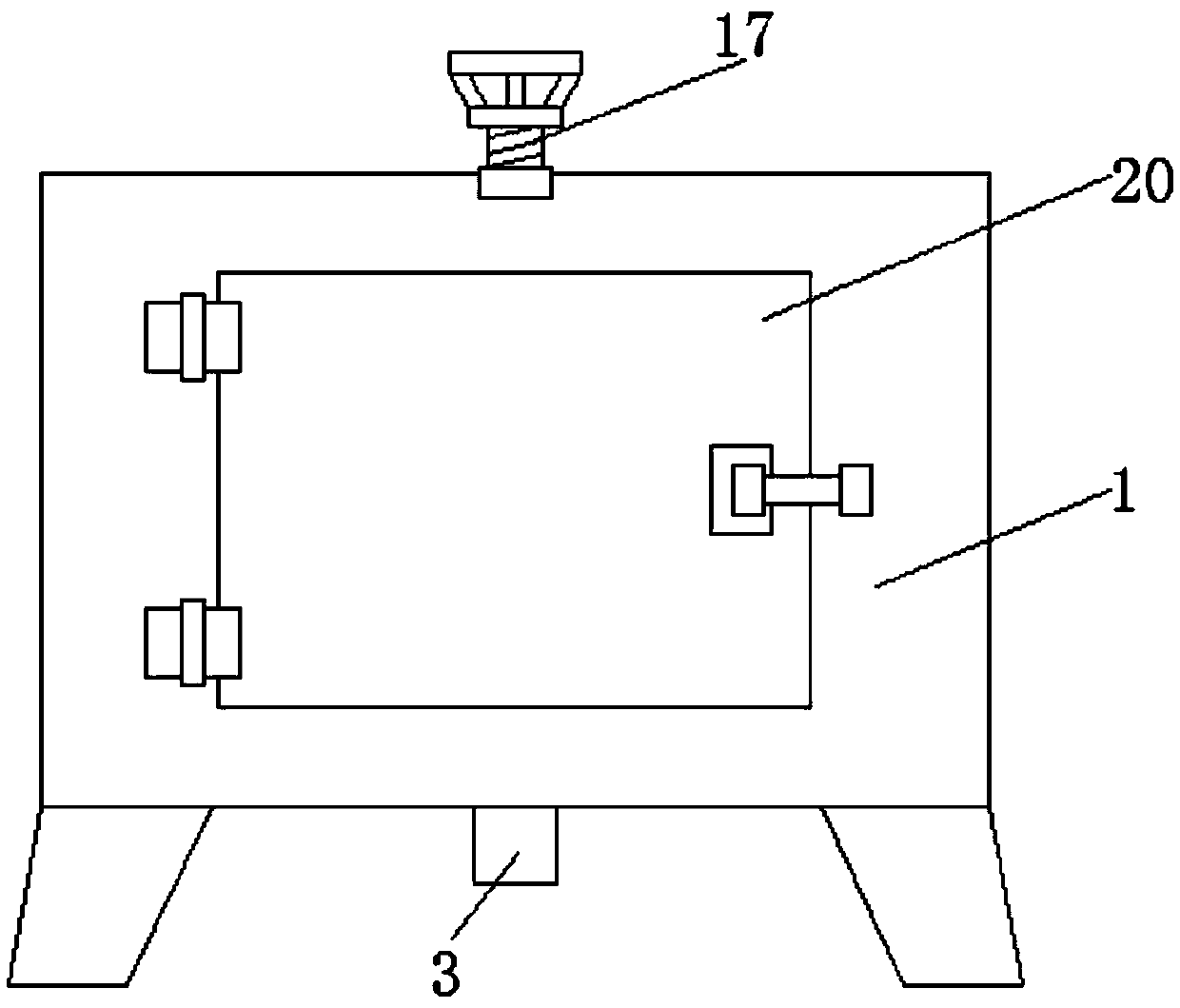

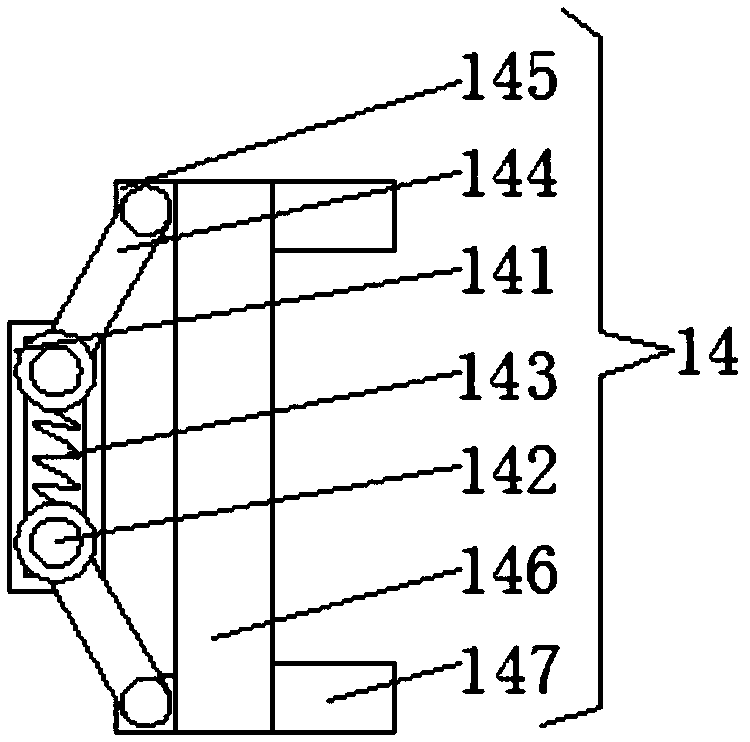

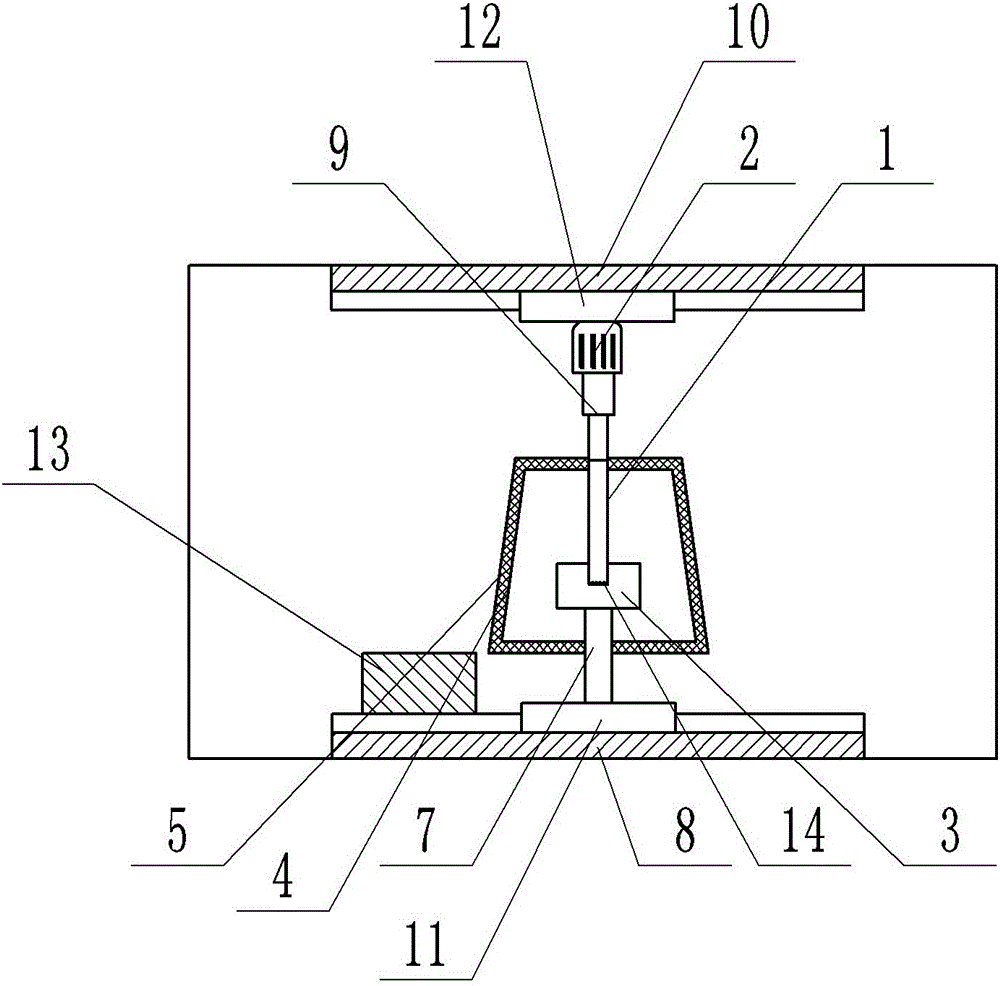

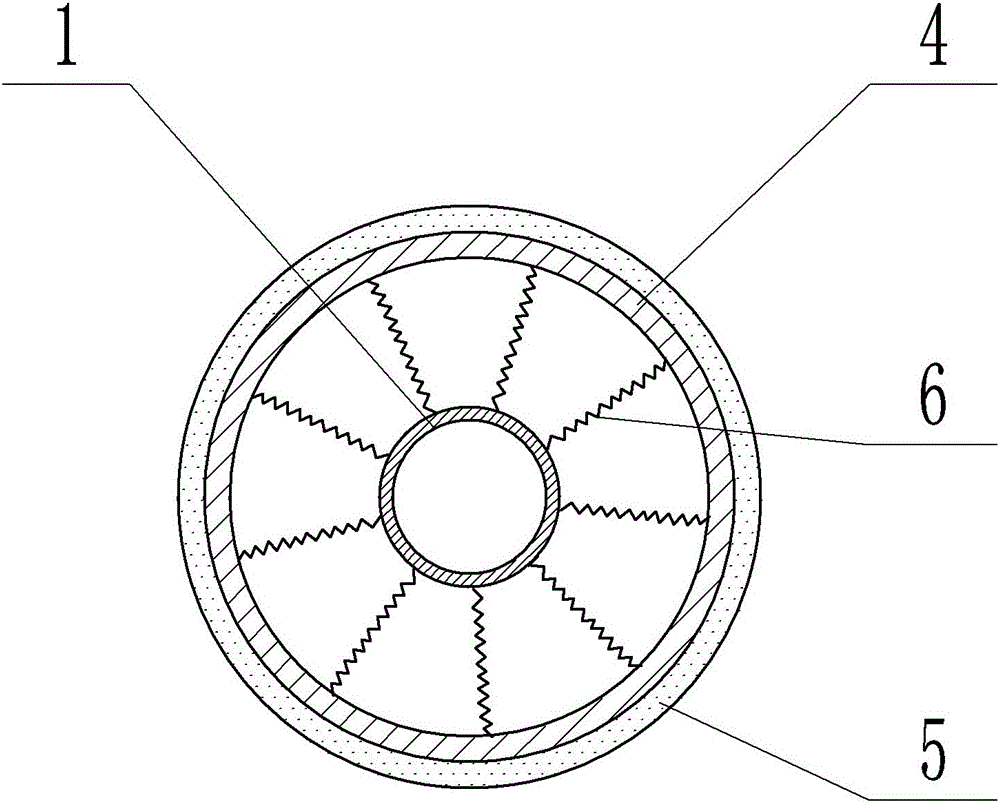

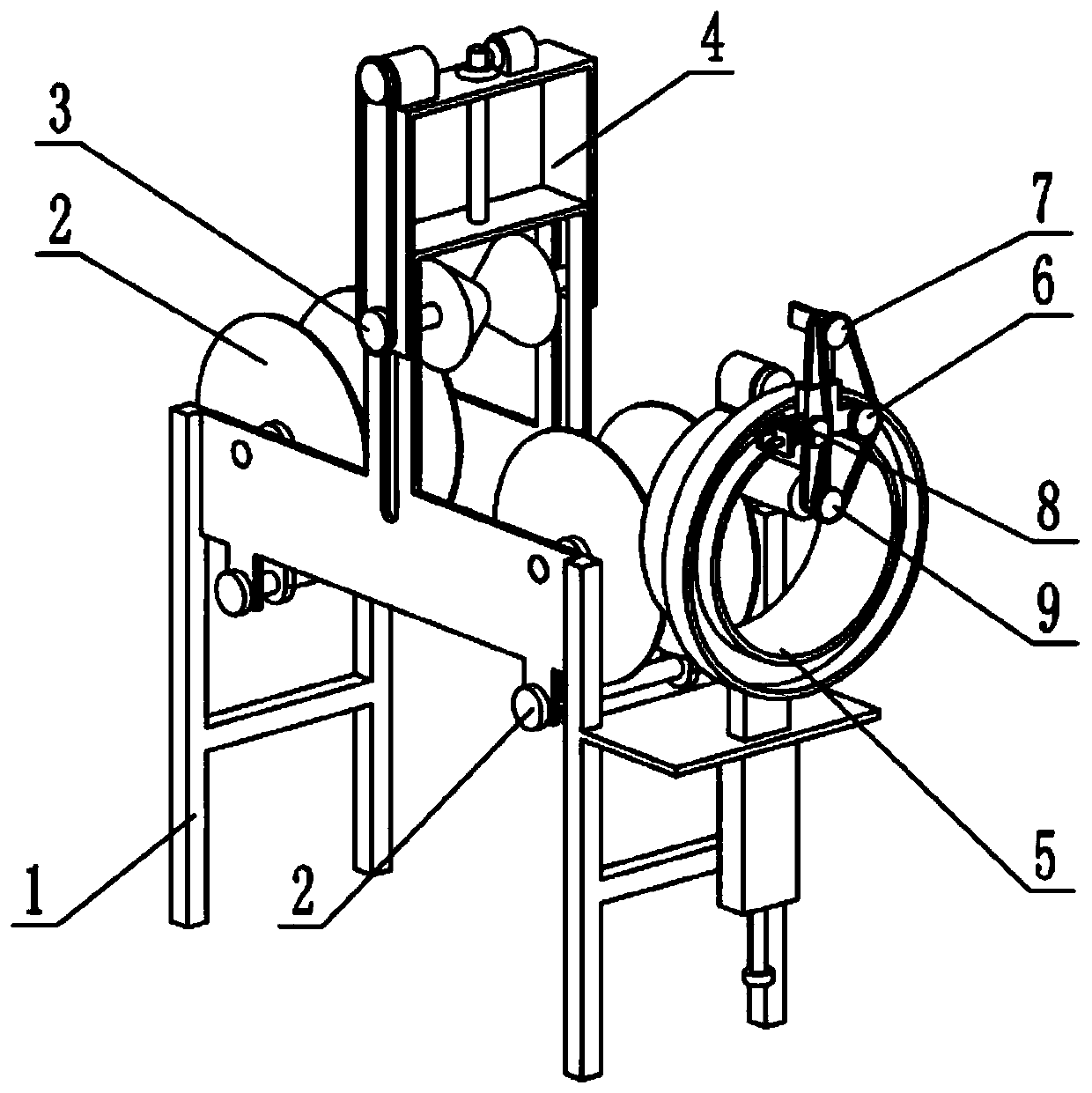

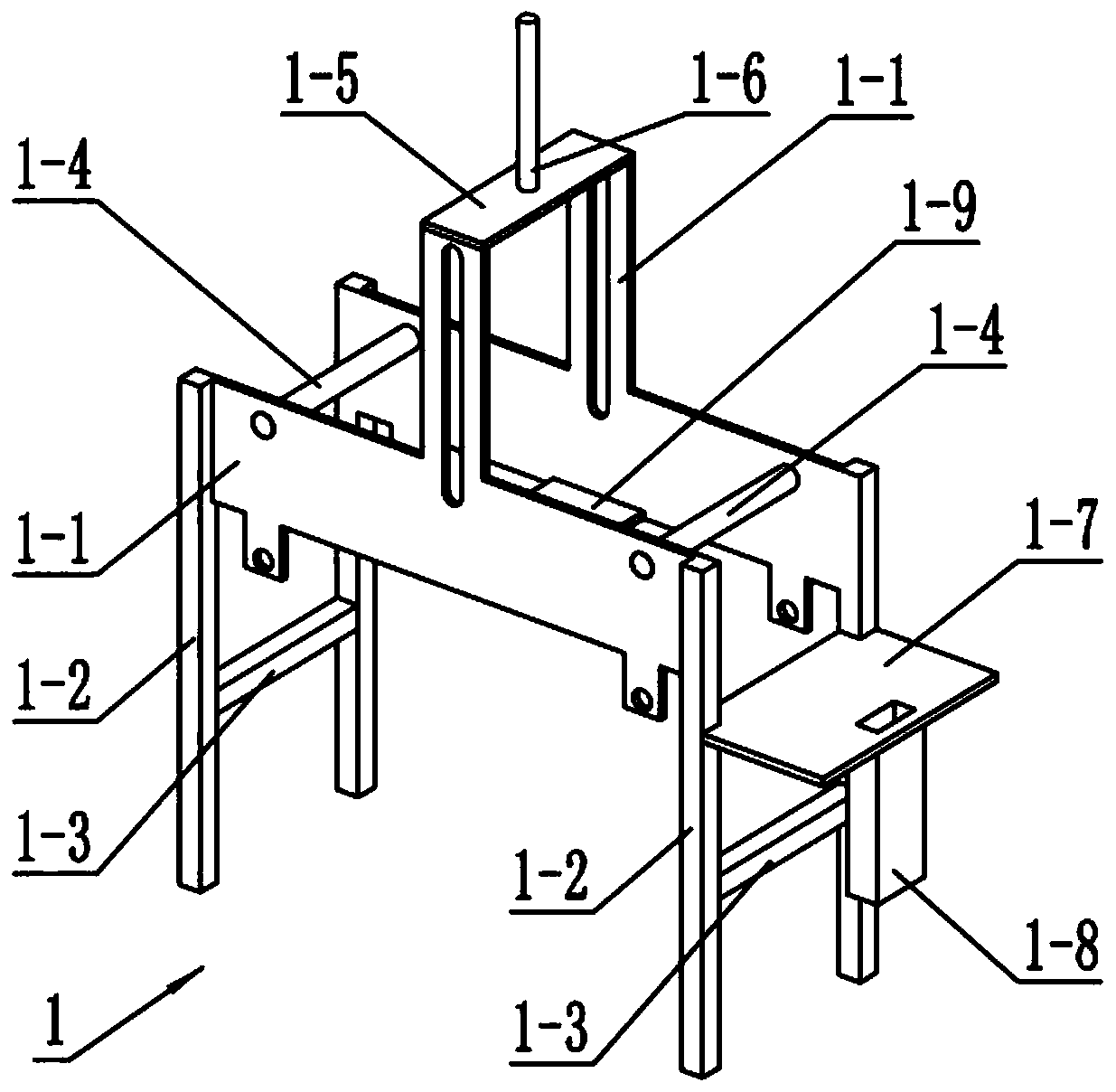

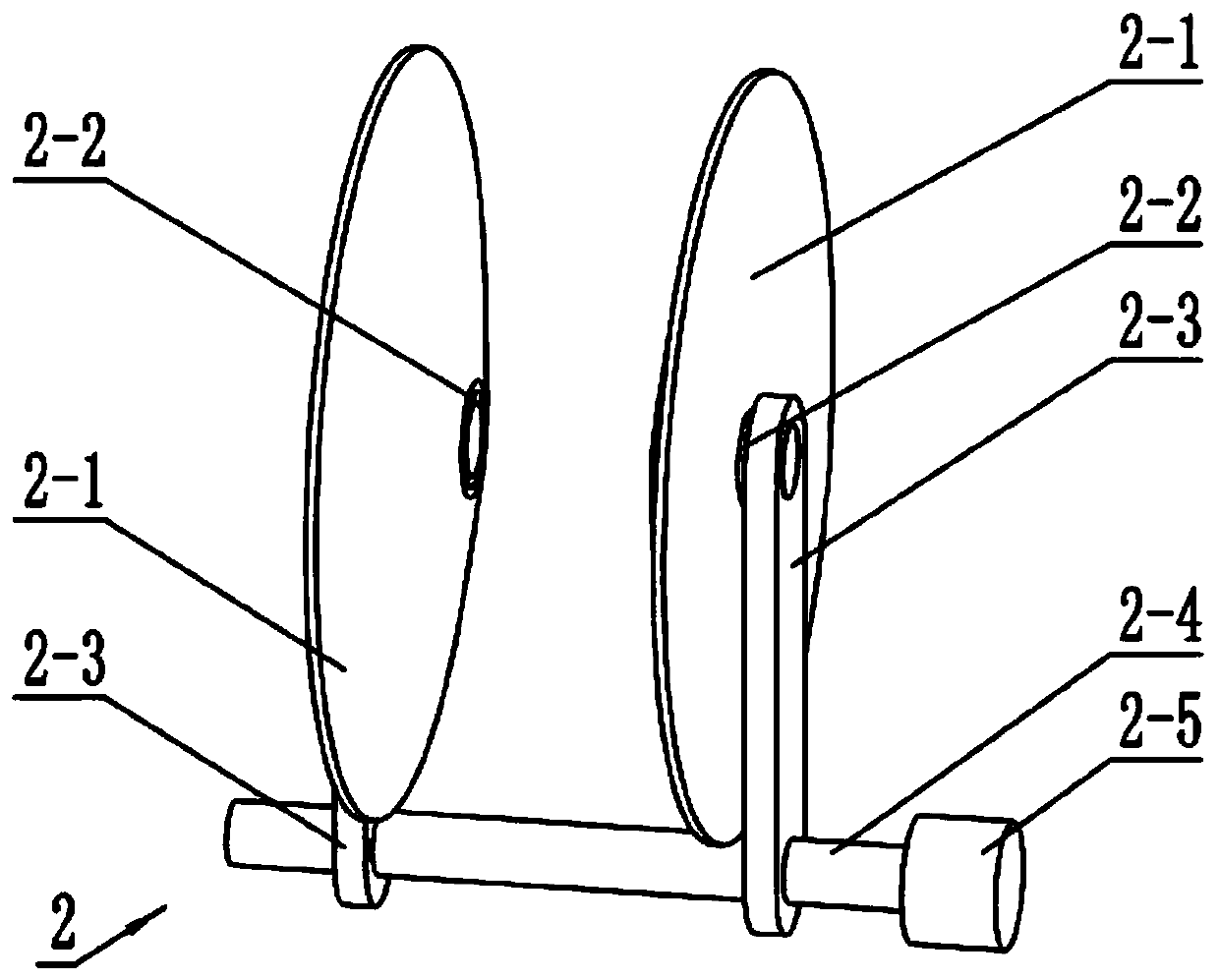

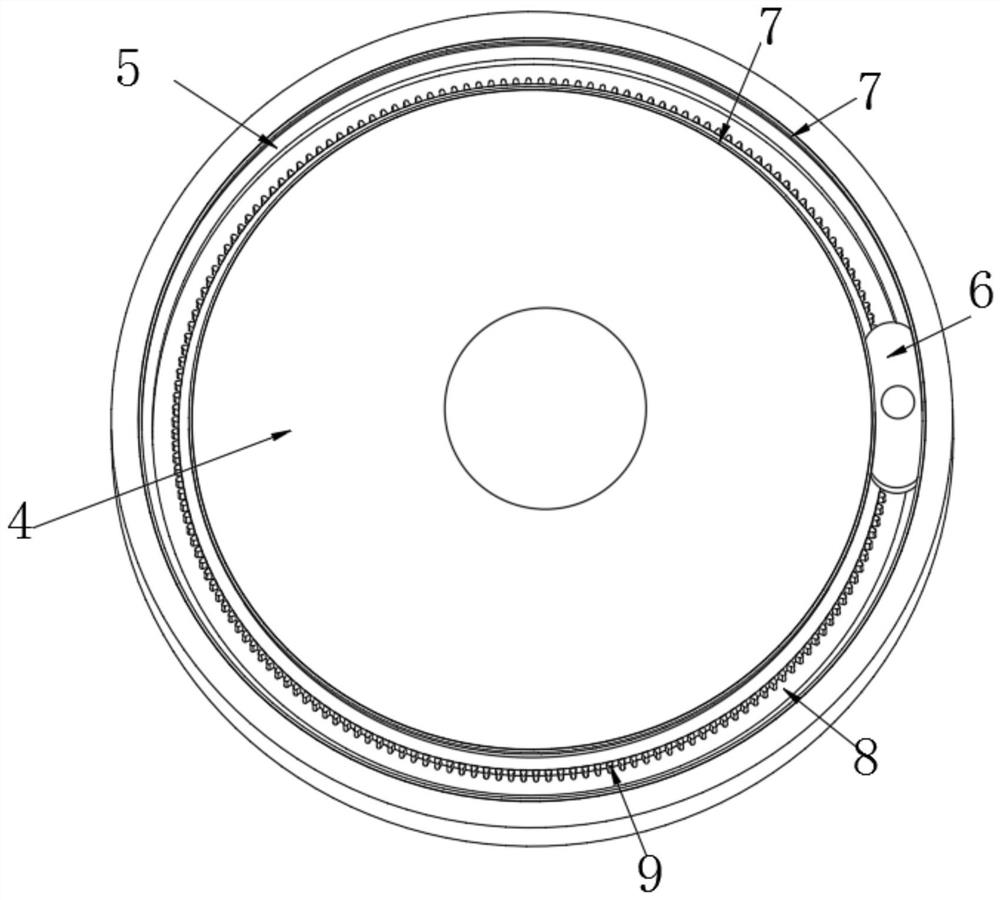

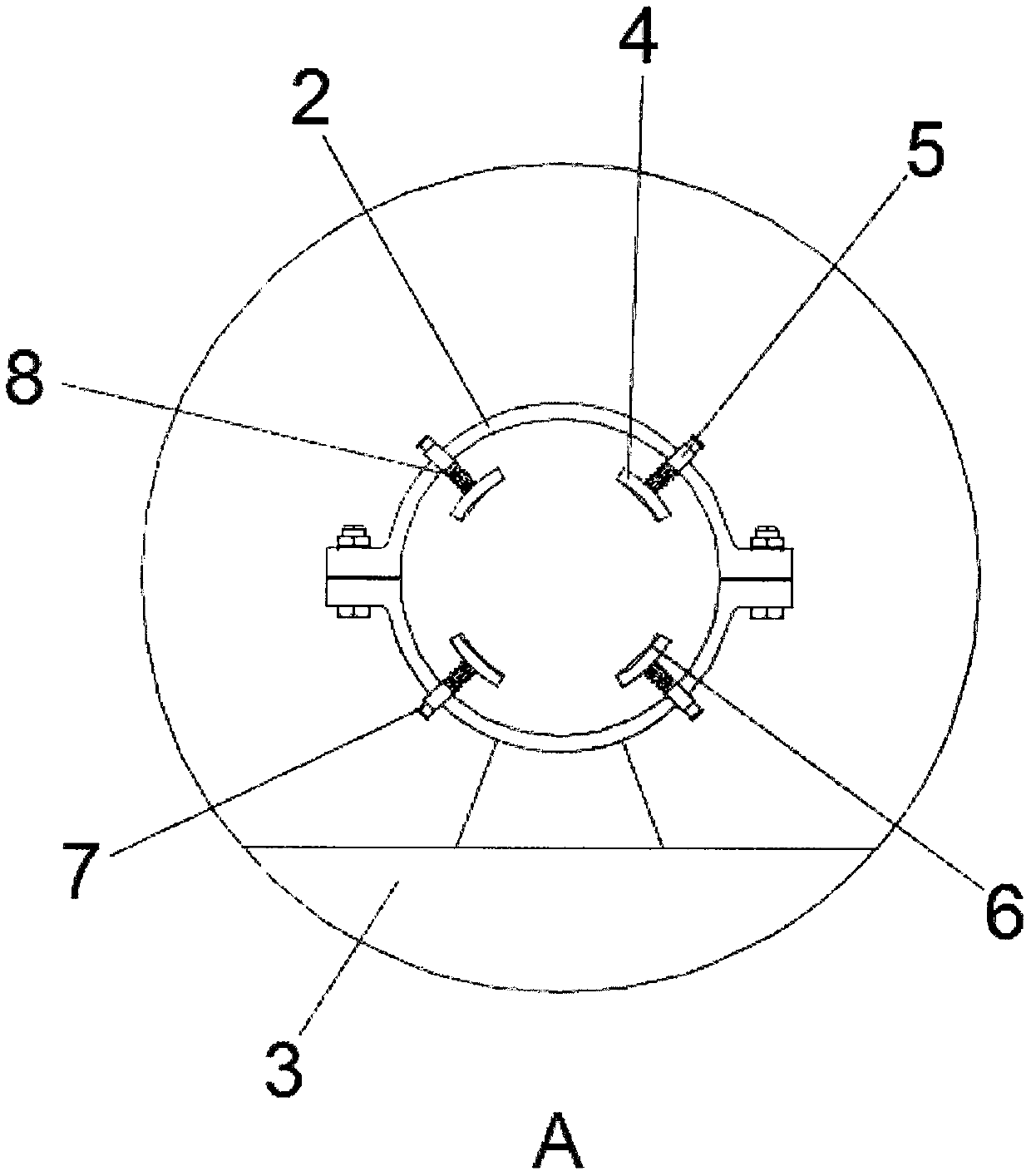

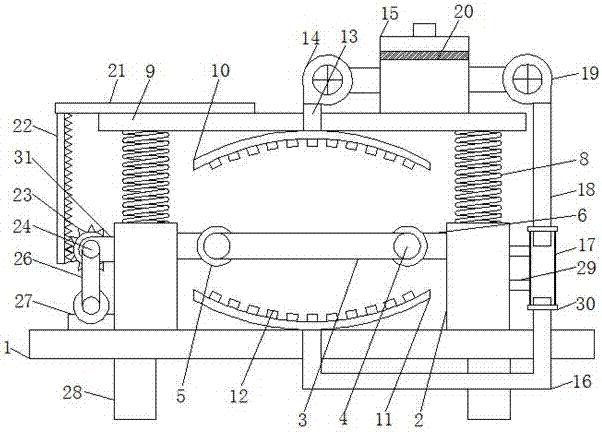

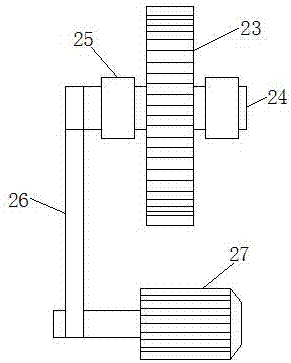

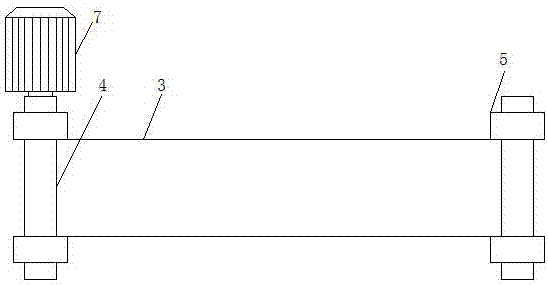

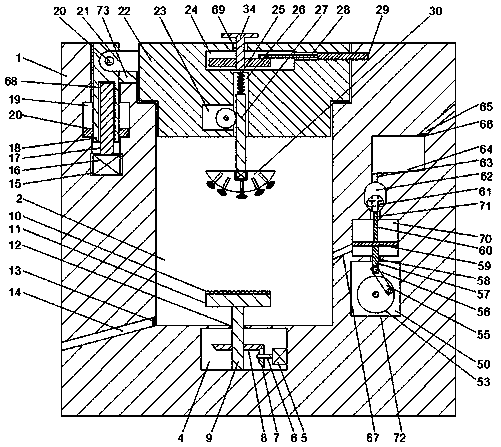

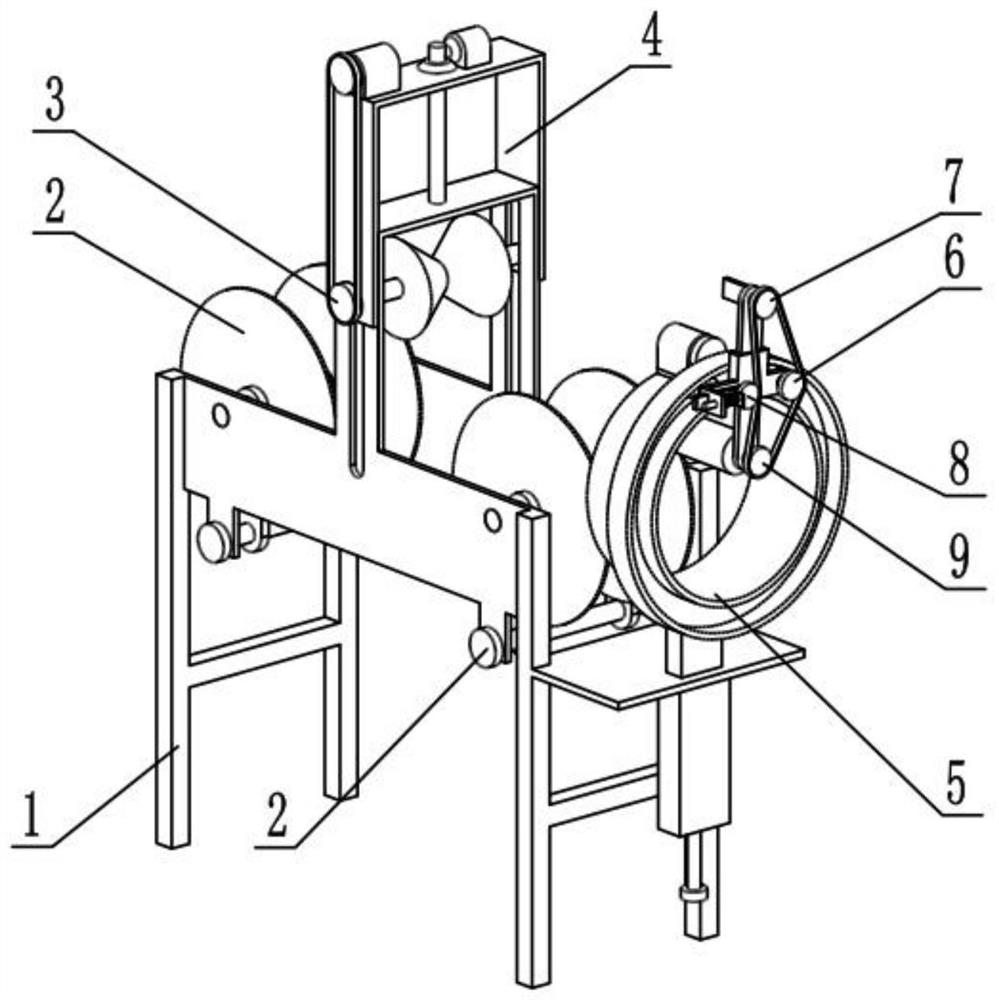

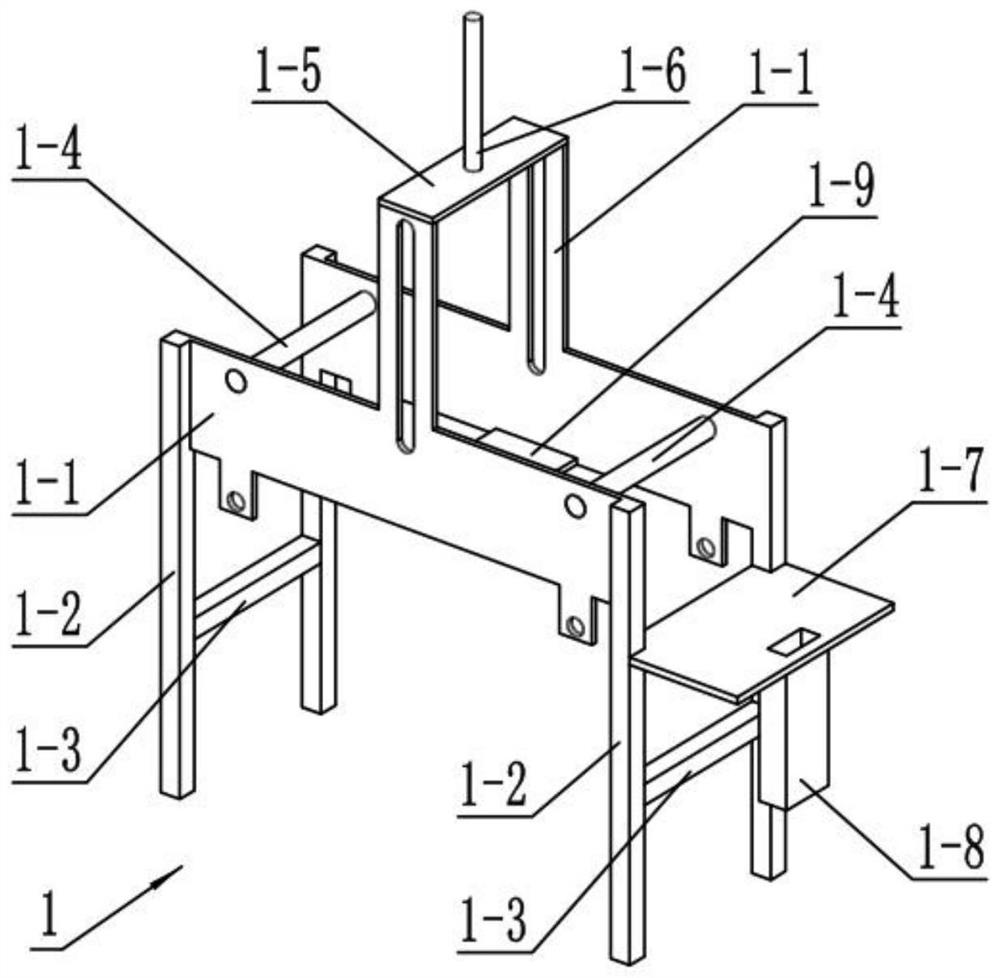

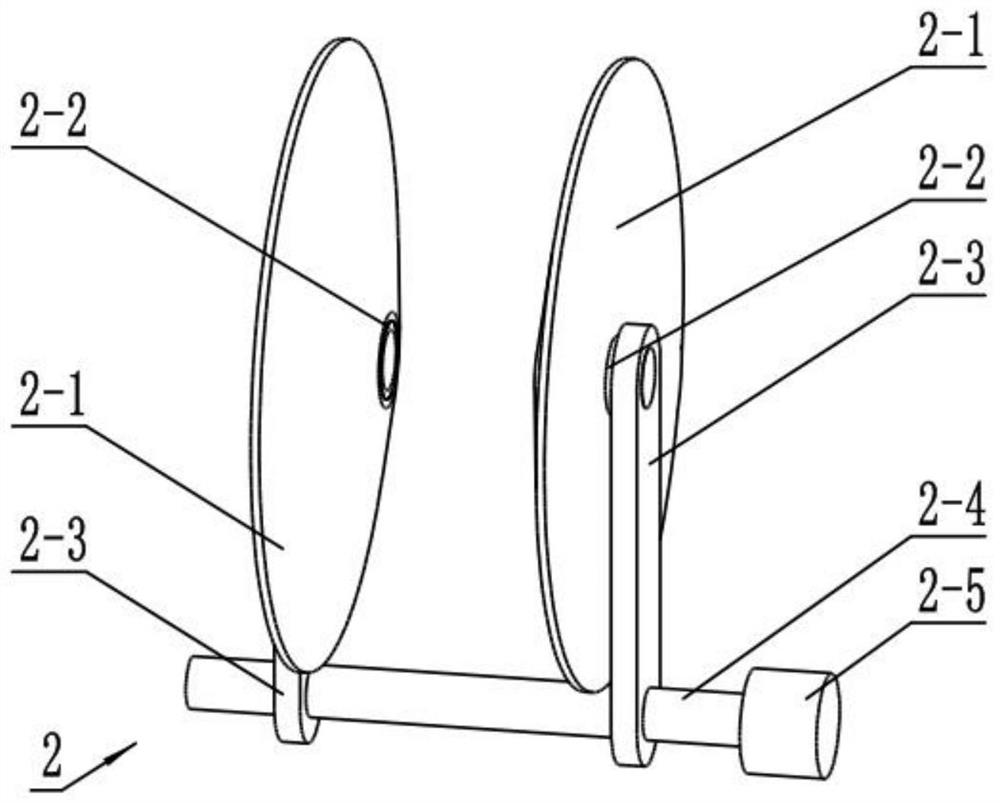

Bidirectional clamping and damping brake disc grinding mechanical equipment

ActiveCN110000693AAchieve the purpose of polishingReduce workloadEdge grinding machinesGrinding carriagesDrive shaftMechanical equipment

The invention discloses bidirectional clamping and damping brake disc grinding mechanical equipment, and belongs to the technical field of automobile part machining. The problems that clamping is notstable when the side surface of a brake disc is ground, the brake disc cannot be ground through a tool, and damping cannot be realized under the high-speed rotation of the brake disc can be solved. The equipment is technically characterized by comprising a workbench, a sliding clamping mechanism, a fixed clamping mechanism and a grinding mechanism, the brake disc is fixed through the sliding clamping mechanism and the fixed clamping mechanism which are arranged on the workbench, under driving of a servo motor, a driving shaft, a driving seat, a clamped brake disc, a follow-up seat, a spline shaft and a rotating block are jointly rotated, a grinding tool moves to the position above the brake disc, falls down to be contact with the side face of the brake disc and grinds the side face of thegrinding disc, so that the purpose of grinding the brake disc is achieved, the workload of workers is reduced, brake pad clamping operation is convenient and rapid, and a follow-up pressing disc and adriving pressing disc can also be used for effectively mitigating vibration in the grinding process.

Owner:蓬莱市鑫泰铸造有限公司

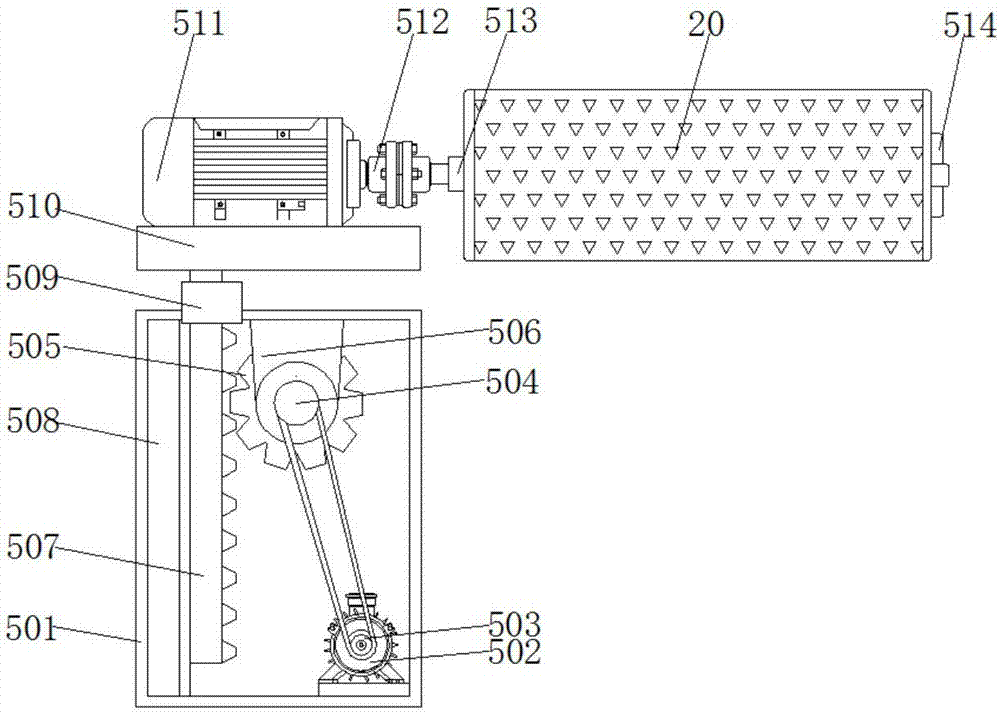

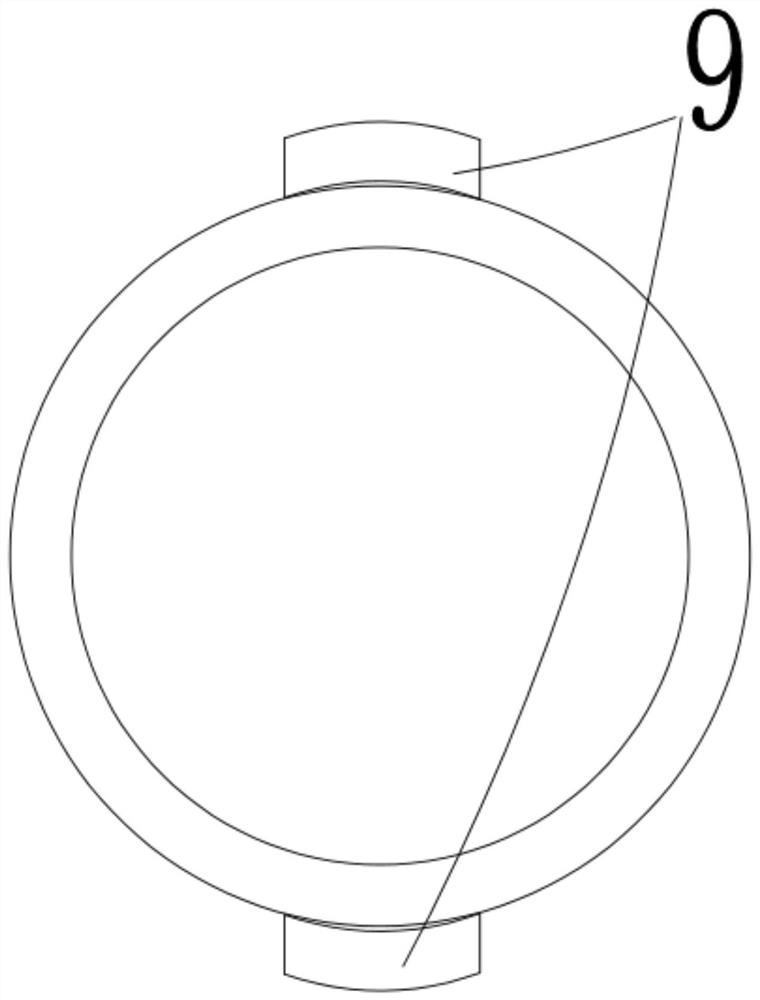

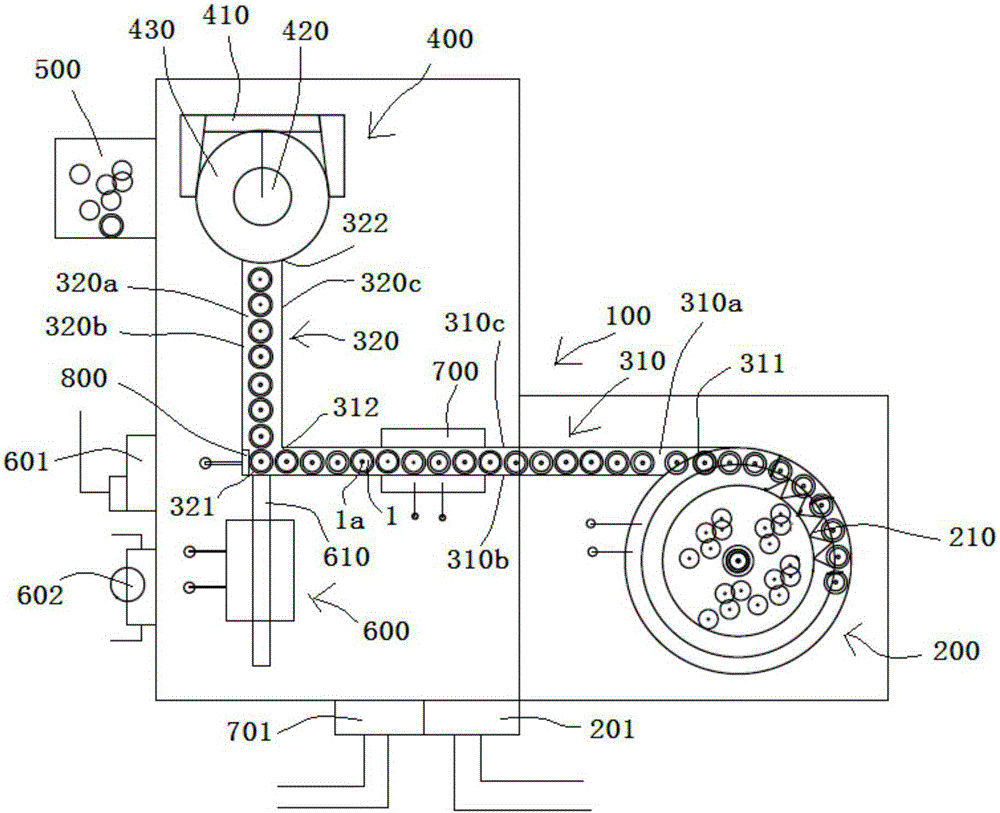

Steel ball polishing and transporting device

ActiveCN107877348AAchieve the purpose of polishingAchieve work uniformityPolishing machinesGrinding drivesGear wheelSteel ball

The invention discloses a steel ball polishing and transporting device, which comprises a feeding top cover. A feeding inlet is formed in the bottom part of the feeding top cover; a polishing work boxis fixedly connected to the bottom part of the feeding top cover; power devices are fixedly connected to two sides of the bottom part of an inner wall of the polishing work box and are fixedly connected with power rotating wheels; each power rotating wheel is rotatably connected with a first gear through an output shaft; each first gear is located on the upper part of the inner side of the polishing work box and is engaged with a second gear; each second gear is rotatably connected with a polishing roller wheel through a rotary shaft; and a detachable fixing handle is arranged on the surfaceof each second gear. The invention relates to the technical field of steel ball polishing transporters. The steel ball polishing and transporting device can be used for polishing, discharging and transporting steel balls, the stability of the rotating speed and the working evenness are ensured, the polishing quality and the polishing efficiency are ensured, the possible problems occurred during work are reduced, the transportation efficiency is ensured, and the automatic process is improved.

Owner:临沂临港经济开发区合顺物流有限公司

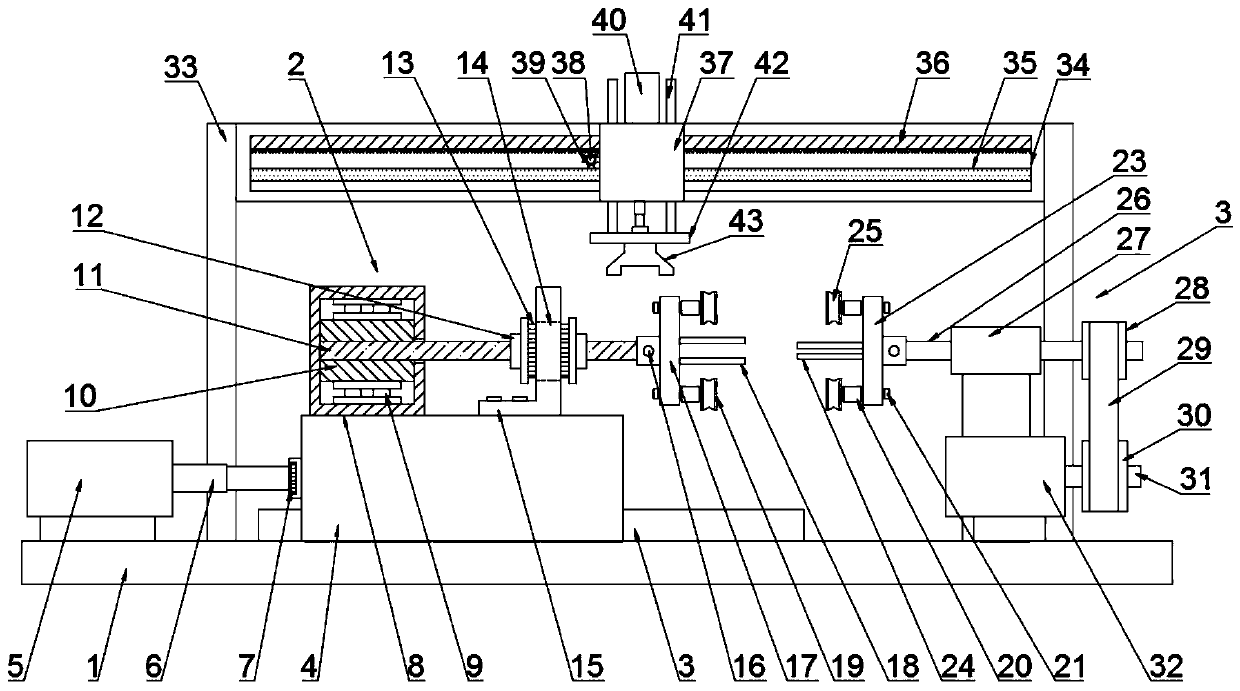

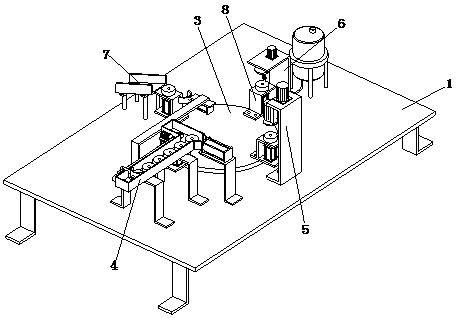

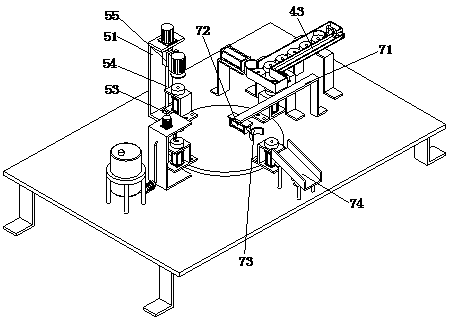

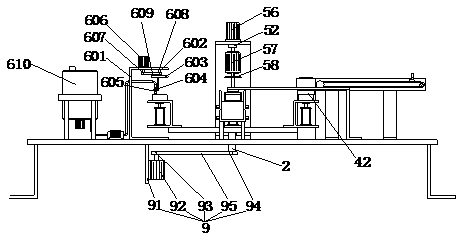

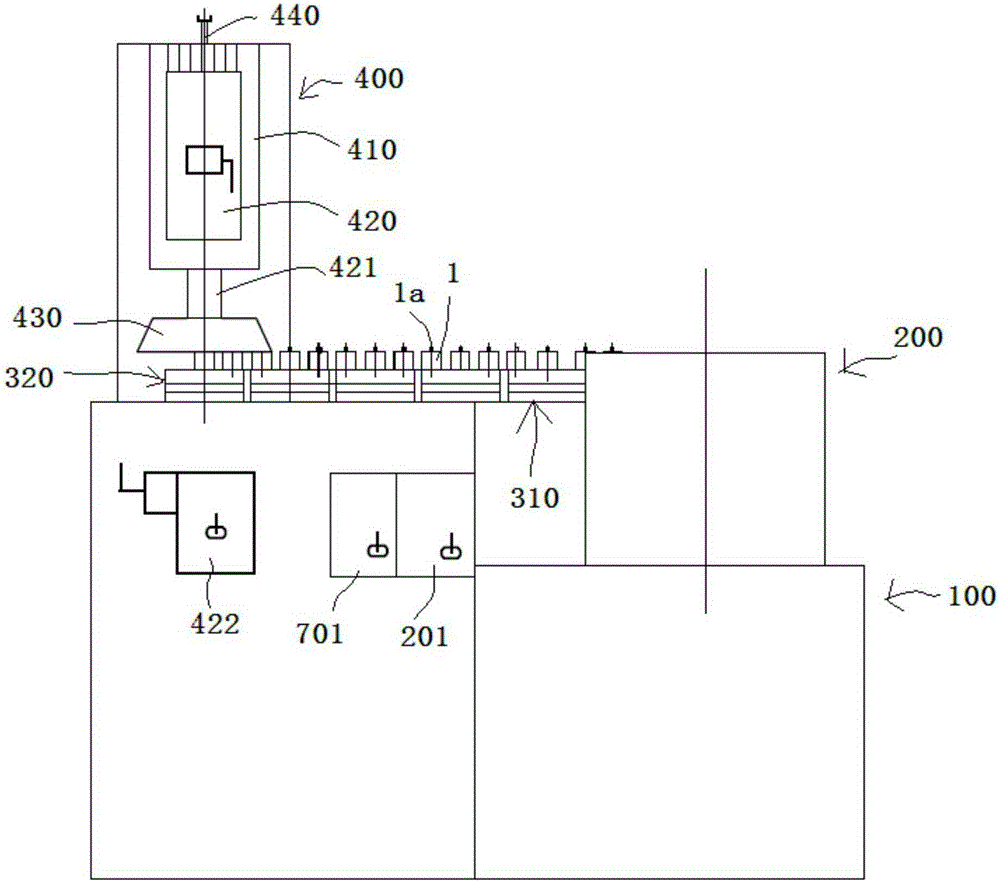

Automobile part integrated processing equipment

InactiveCN110227988ATo achieve the purpose of integrated processing of auto partsShorten the timeGrinding drivesGrinding machinesEngineeringIntegrated processing

The invention discloses automobile part integrated processing equipment, and belongs to the technical field of automobile part processing. The automobile part integrated processing equipment comprisesa pedestal, a first rotary shaft, a rotary disc, a loading assembly, a grinding assembly, a paint spraying assembly, an unloading assembly and four positioning assemblies, wherein the first rotary shaft is vertically arranged on the pedestal; the first rotary shaft is rotatably matched with the pedestal; the bottom end of the first rotary shaft extends to a position below the pedestal; the rotarydisc is fixedly connected to the top end of the first rotary shaft; a drive assembly for driving the first rotary shaft to rotate is arranged below the pedestal; the loading assembly, the grinding assembly, the paint spraying assembly and the unloading assembly are mounted on the pedestal; the loading assembly, the grinding assembly, the paint spraying assembly and the unloading assembly are arranged in a peripheral direction of the rotary disc; and the four positioning assemblies are arranged on the rotary disc. The automobile part integrated processing equipment disclosed by the invention solves the problems that automobile parts need to separately process on multiple pieces of processing equipment, manual multi-time dismounting positioning is required, operation is complex, time and labor are wasted, and processing efficiency is low.

Owner:李义飞

Abrasive for rapidly removing tampered burr and ring wear of riveted electrical contact, its preparation method and application

ActiveCN106281223AQuick removalAchieve the purpose of polishingEdge grinding machinesPolishing machinesEpoxyLow voltage

The invention discloses an abrasive for rapidly removing tampered burr and ring wear of a riveted electrical contact, its preparation method and an application. The preparation method comprises the following steps of placing the mixed powder and epoxy resin in a blender after being mixed at a ratio; after blending for a period of time, taking out a colloid; placing the colloid in a mould and refrigerating; taking out the abrasive after a period of time. The abrasive can rapidly remove tampered burr and ring wear of the riveted electrical contact. The abrasive can remove tampered burr and ring wear of the riveted electrical contact; meanwhile, the abrasive shortens the grinding time, saves the testing cost and provides technical support for the development of low-voltage appliance industry.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

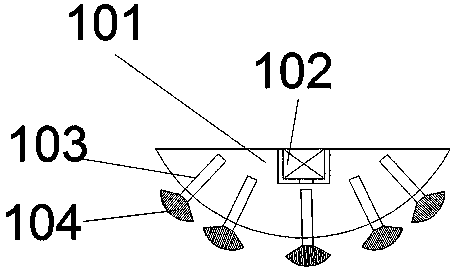

Automobile brake disc grinding device

InactiveCN108942525AEasy to fixEasy side grindingGrinding machinesGrinding/polishing safety devicesEngineeringRotating disc

The invention discloses an automobile brake disc grinding device. The grinding device comprises a working frame, the lower part of the interior of the working frame is fixedly connected with a rotating motor, the rotating motor is connected with a belt wheel I in the rotating mode through an output shaft, the belt wheel I is connected with a belt wheel II in the rotating mode through a belt, the bottom of the inner wall of the working frame is fixedly connected with a rotating frame, a rotating mounting disc is connected with the inner side of the rotating frame in a rotating mode, a rotatingdisc is arranged at the bottom of the rotating mounting disc, the bottom of the rotating disc is fixedly connected with the belt wheel II, and the inner side of the rotating mounting disc is connectedwith a brake disc mounting base in a sliding way. The grinding device relates the technical field of automobile part machining. According to the automobile brake disc grinding device, the purpose ofgrinding the brake disc is achieved, grinding efficiency of the brake disc can be improved due to multi-azimuth grinding at the same time; a controllable pushing device is used, so movement of the grinding machine is convenient; material changing can be carried out rapidly when the grinding work is stopped, and workload of workers is reduced.

Owner:ANHUI TIANYU AUTO PARTS MFG

Novel environment-friendly cyclic derusting and grinding device

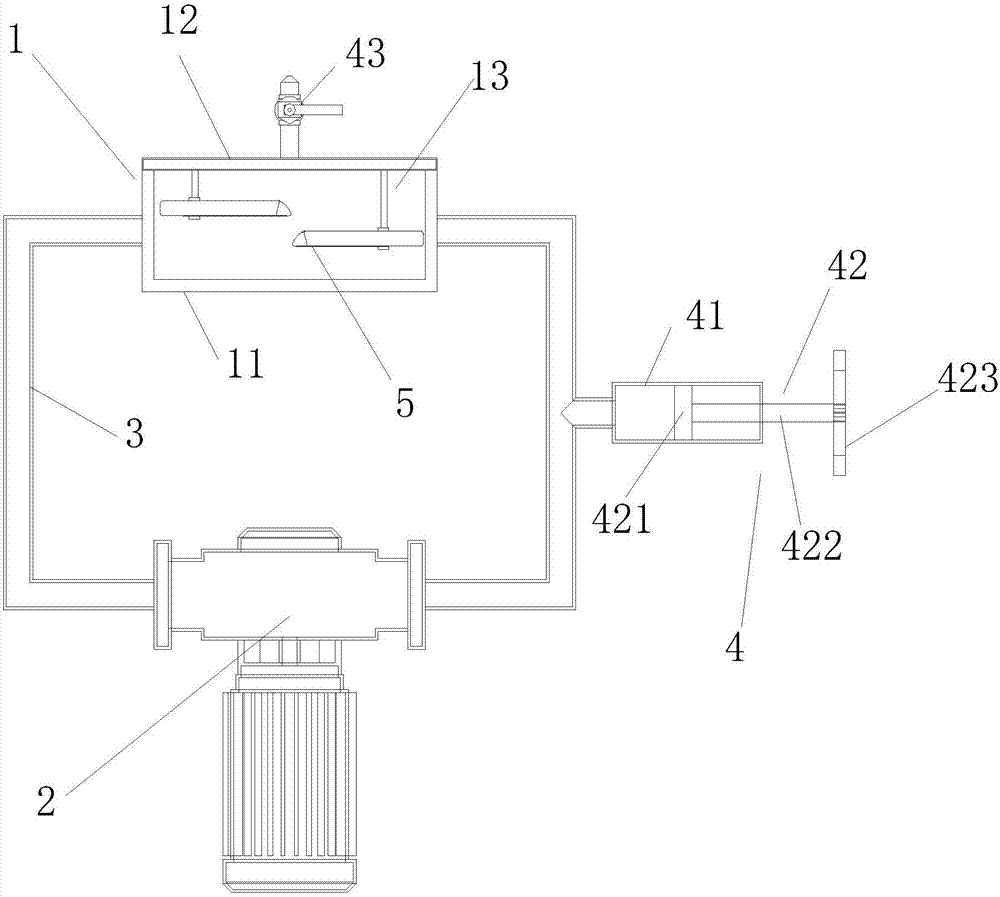

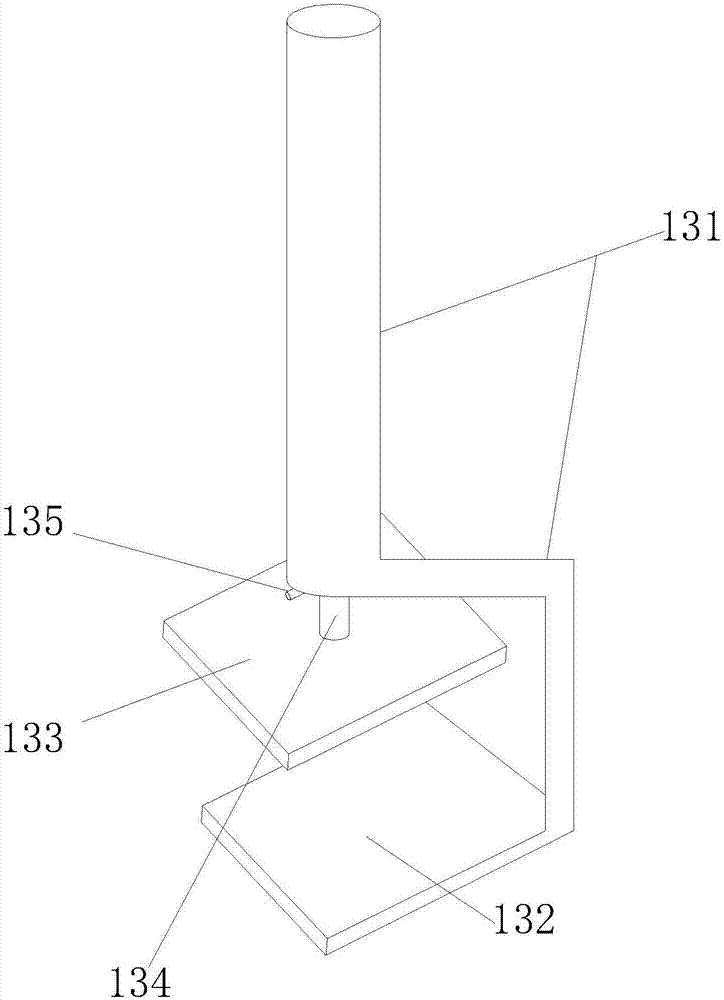

InactiveCN108356619AGuaranteed efficiencyReduce energy consumptionRevolution surface grinding machinesGrinding work supportsSteel tubeLawn mower

The invention discloses a novel environment-friendly cyclic derusting and grinding device and relates to the technical field of agricultural machines. The device comprises a work frame. One side of the work frame is fixedly connected with a power frame. A power motor is arranged in the middle of the power frame. Rotating motors are fixedly connected into the work frame. An output shaft of each rotating motor is rotationally connected with a power rotary shaft through a coupler. The end, away from the rotating motor, of each power rotary shaft is rotationally connected with a rotating gear. Theouter side of each rotating gear is in engaged connection with a movable rack bar. The end, away from the rotating gear, of each movable rack bar is fixedly connected with a clamp plate through an adapting arm. A steel pipe is arranged in the middle of the work frame. According to an agricultural convenient and fast hay mower, the purposes that the steel pipe is ground and derusted when being rotated and the inner wall of the steel pipe is ground are achieved, the positions of grinding motors are adjusted conveniently, the grinding quality and derusting efficiency are guaranteed, energy consumption is low, the structure is simple, and the labor intensity is relieved.

Owner:佛山杰致信息科技有限公司

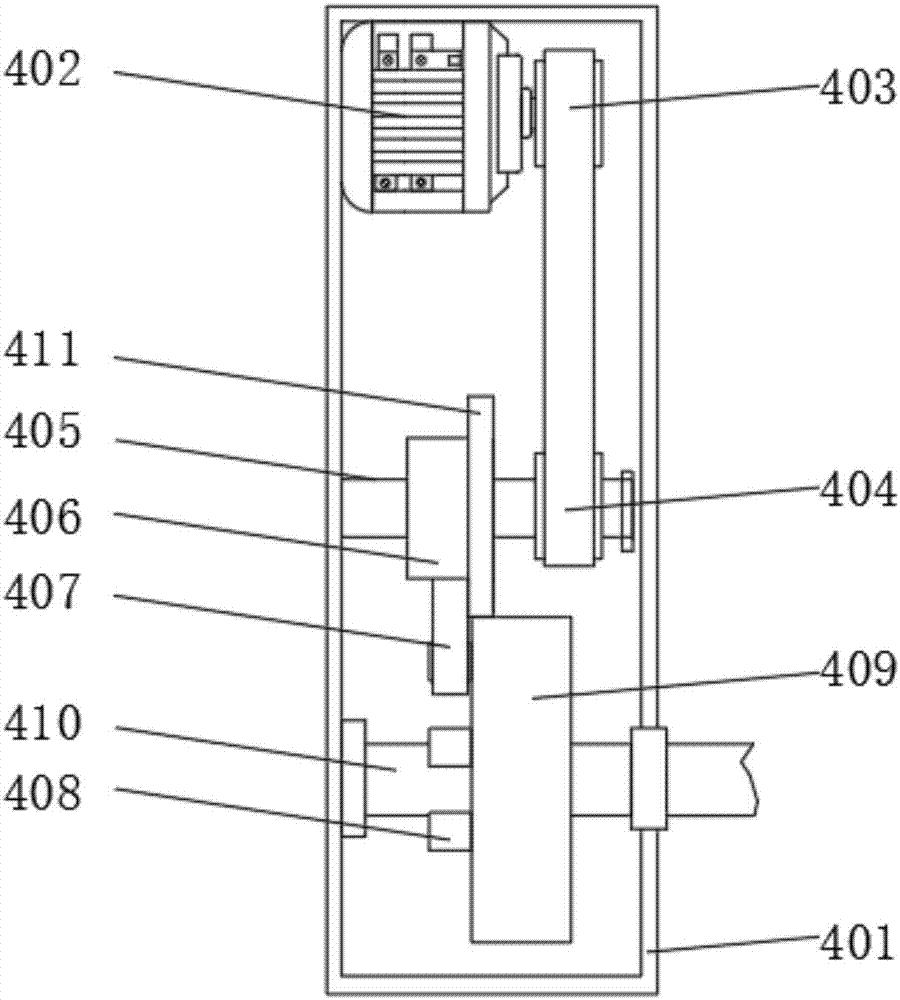

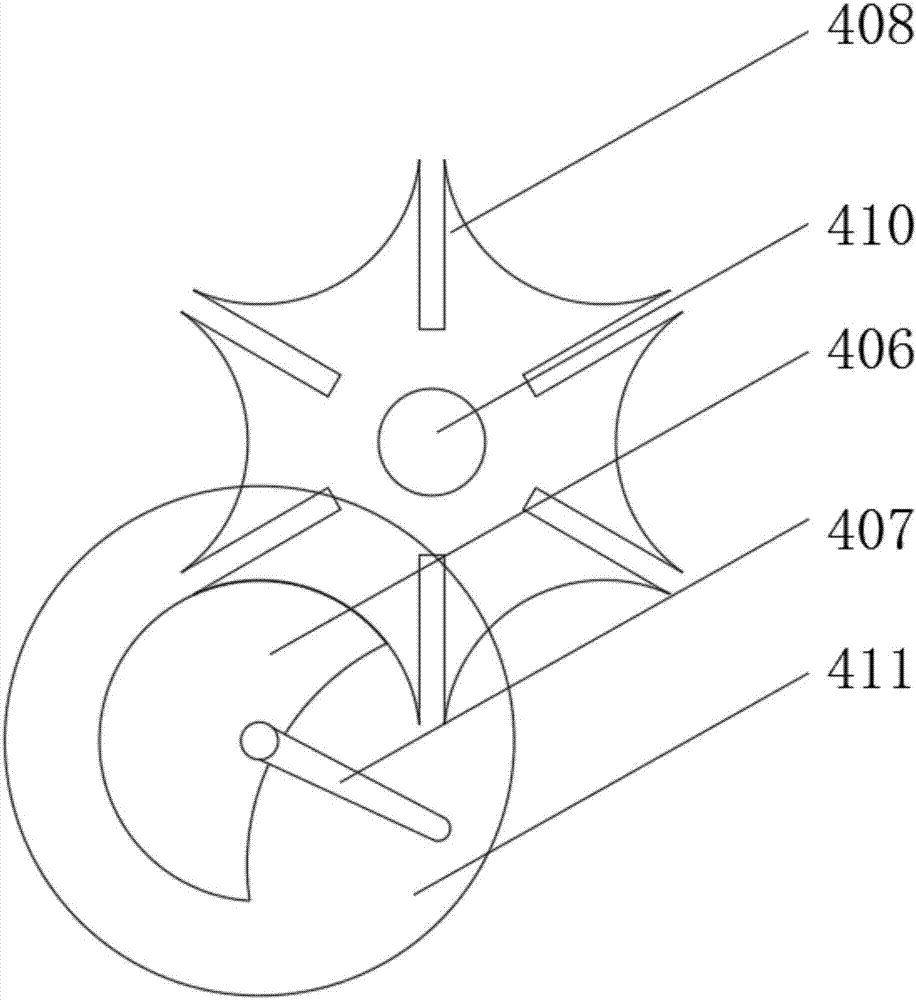

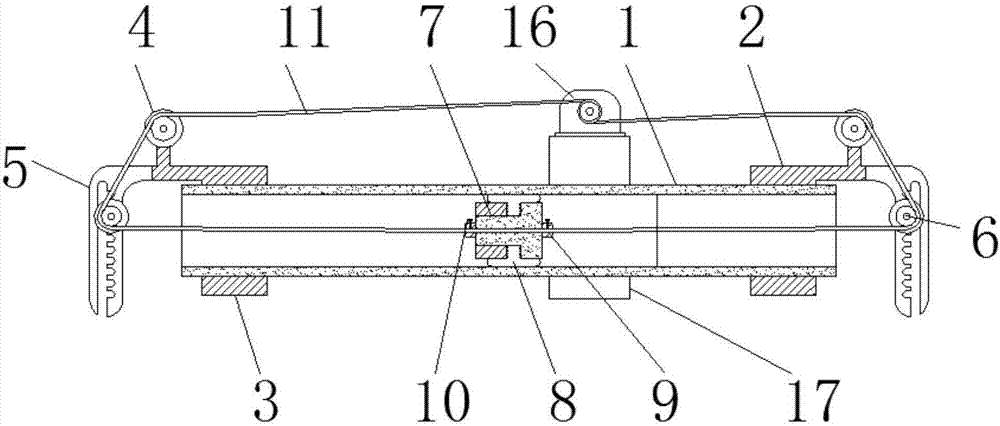

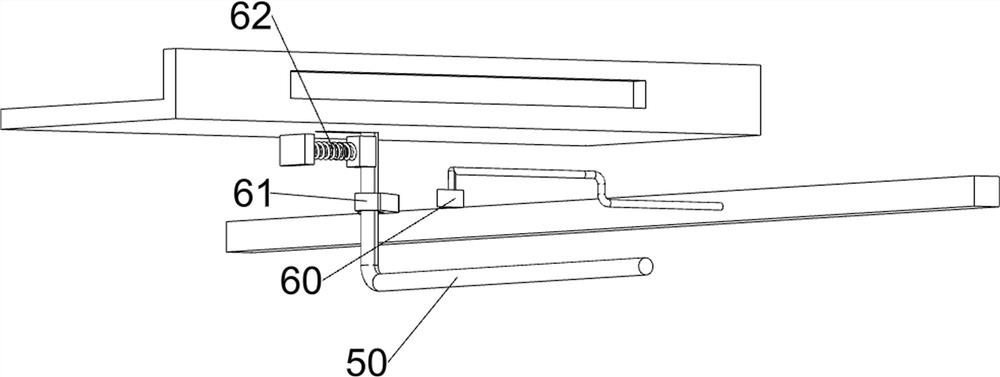

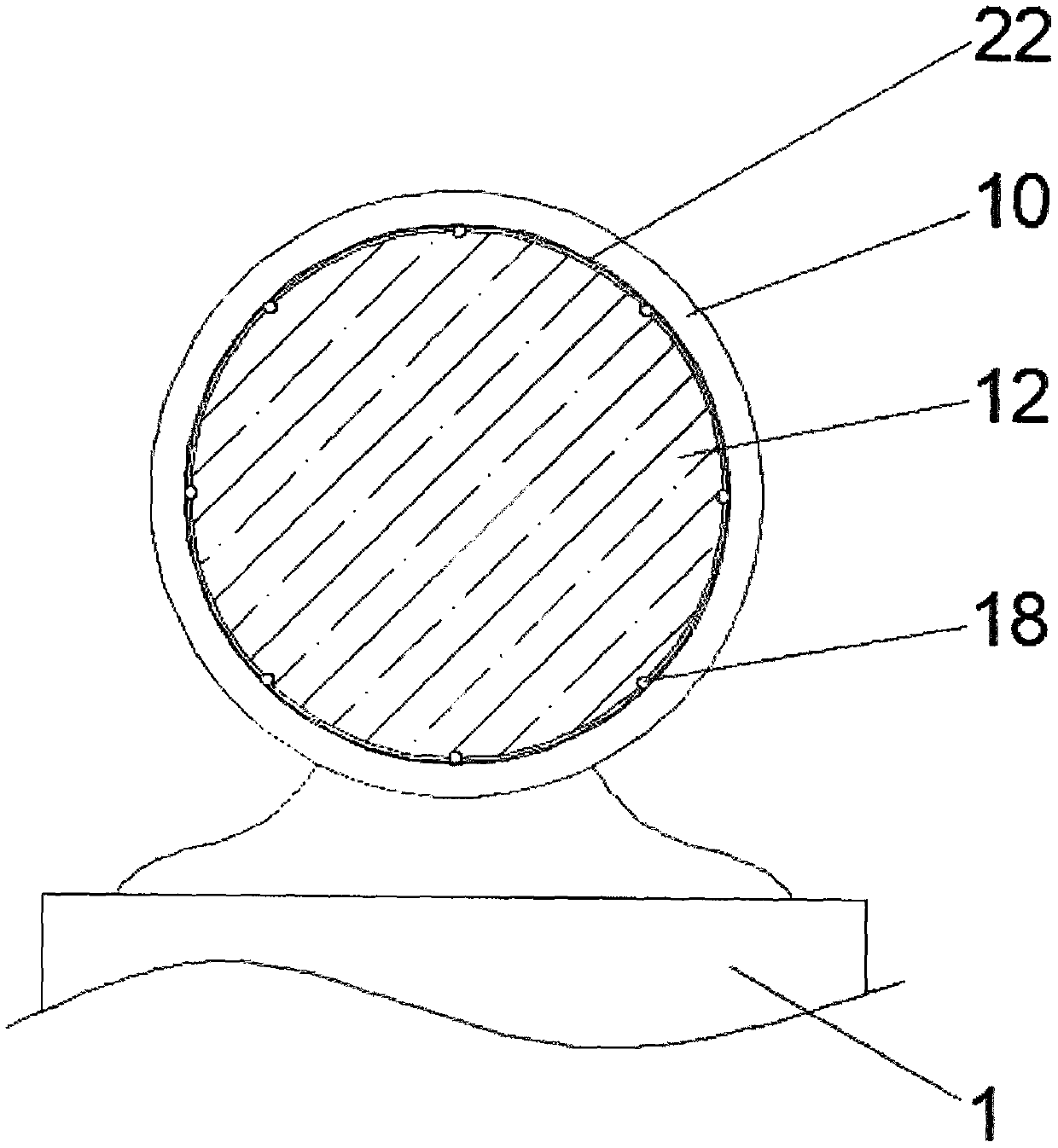

Automatic edge grinding machine for tempered glass after shaping and cutting

ActiveCN111390697AImprove edging efficiencyEasy to cleanEdge grinding machinesGrinding drivesElectric machineryStructural engineering

The invention relates to an automatic edge grinding machine for tempered glass after shaping and cutting. The automatic edge grinding machine for the tempered glass after shaping and cutting comprisesa base, a supporting seat, a supporting mechanism, locking mechanisms, a driving adjustment mechanism, driving sliding blocks, driving motors, grinding mechanisms and grinding adjustment mechanisms.The supporting seat is arranged on the upper end surface of the middle of the base, the supporting mechanism is installed on the upper end surface of the supporting seat, the locking mechanisms are installed at the front end and the rear end of the supporting mechanism, the driving adjustment mechanism is located under the locking mechanisms, the driving sliding blocks are installed at the front end and the rear end of the driving adjustment mechanism, the driving motors are arranged on the upper end surfaces of the driving sliding blocks, output shafts of the driving motors are connected withthe lower parts of the outer ends of the locking mechanisms, the grinding mechanisms are arranged on the left side and the right side of the supporting seat, and the grinding adjustment mechanisms are arranged at the lower ends of the grinding mechanisms. The problems that when round glass is subjected to edge grinding, only one piece can be ground at a time, and the residue on the glass needs tobe cleaned twice after edge grinding are solved; when round glass of different specifications is subjected to edge grinding, a fixture is required to be replaced.

Owner:恩迪(山东)智能装备有限公司

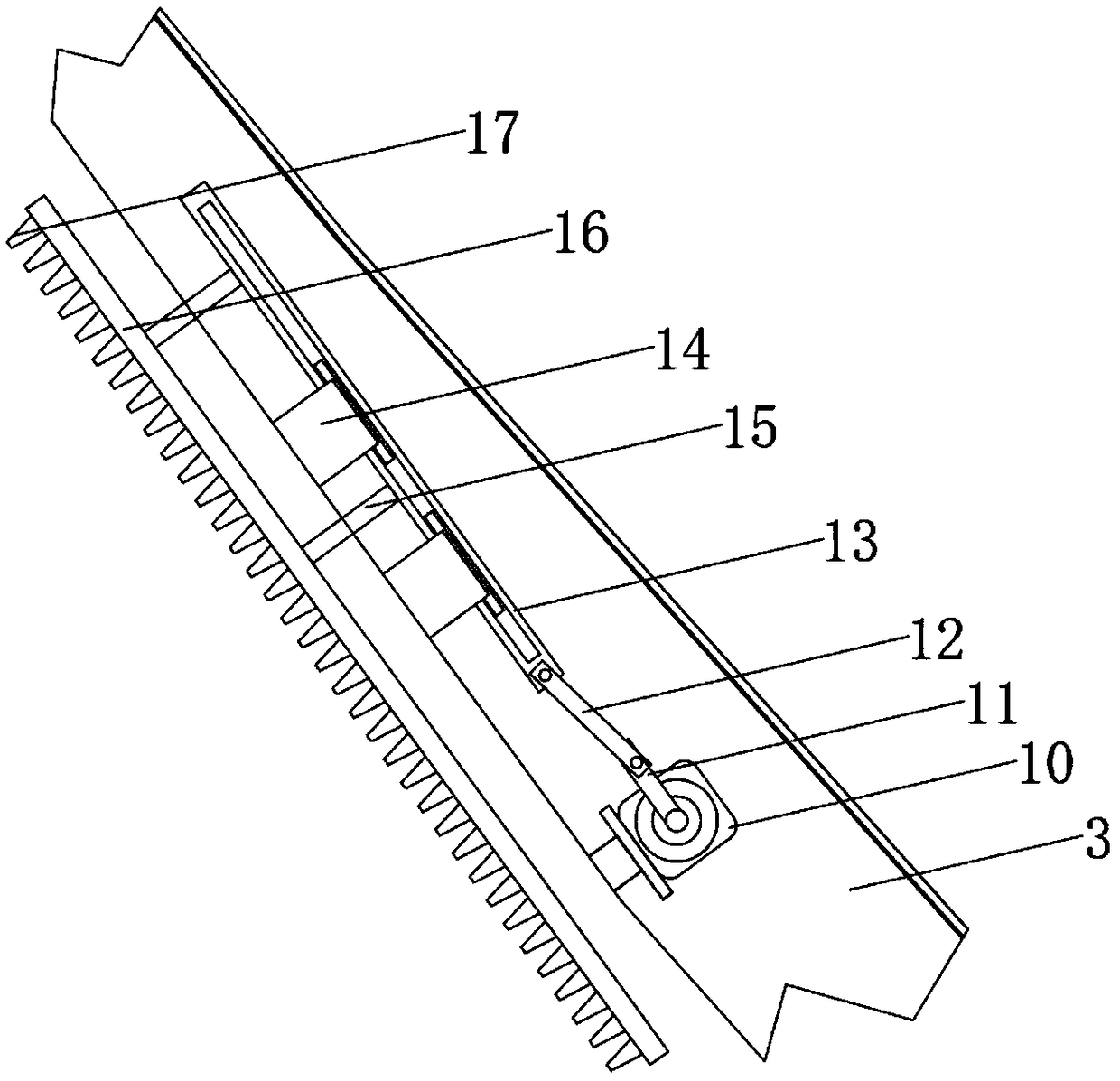

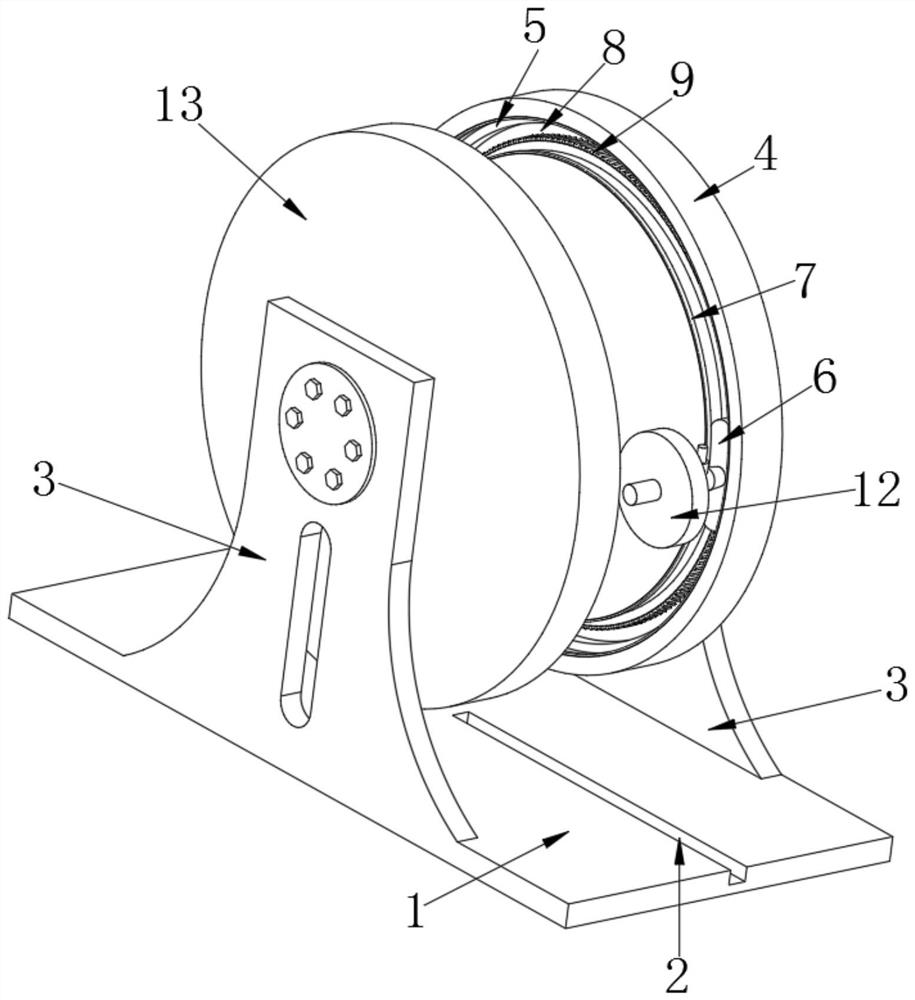

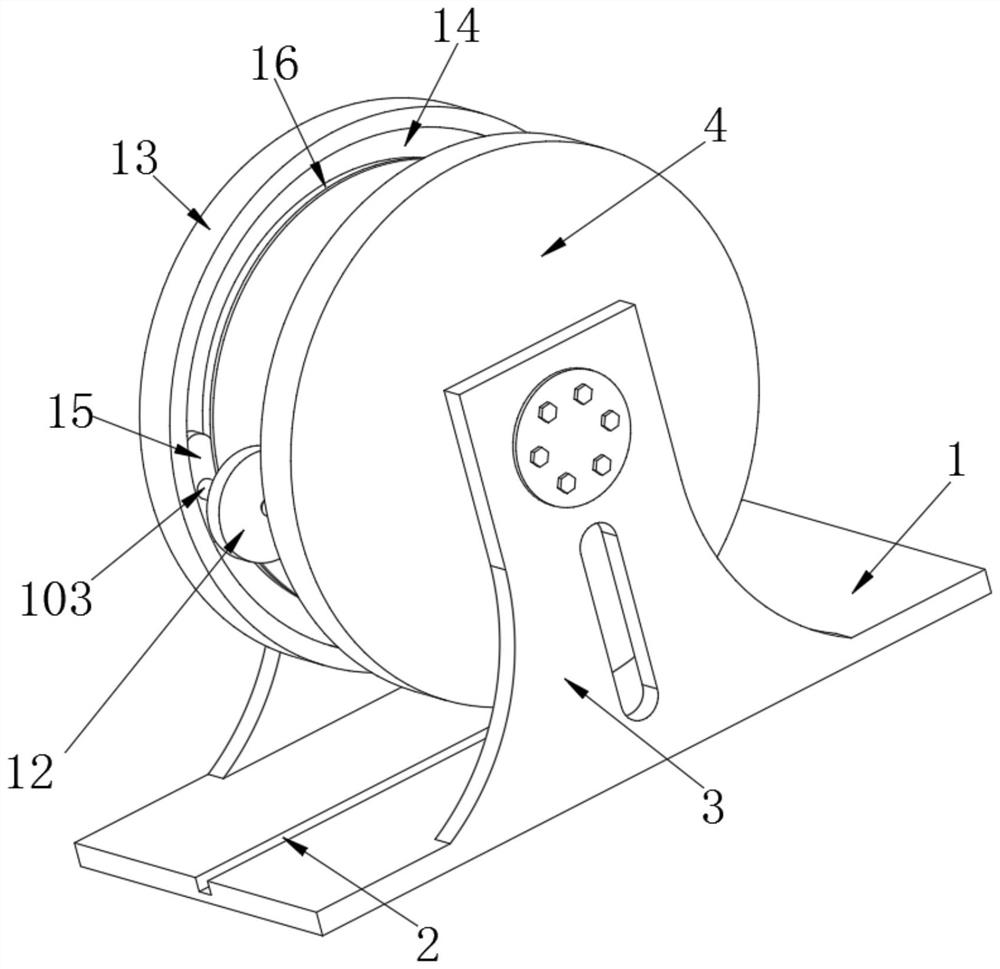

Bent pipe outer polishing device

ActiveCN105108614AImprove polishing qualityAchieve the purpose of polishingBelt grinding machinesMachine toolAutomation

The invention discloses a bent pipe outer polishing device. The bent pipe outer polishing device comprises a machine tool body which is provided with a grinding mechanism and a reverse rotating mechanism. The grinding mechanism comprises a grinding driving mechanism and a polishing strap arranged on the grinding driving mechanism. The reverse rotating mechanism comprises a reverse driving mechanism and a rotating plate arranged on the reverse driving mechanism. The polishing strap is matched with the rotating plate. The grinding mechanism and the reverse rotating mechanism are connected with a controller. The bent pipe outer polishing device can automatically polish the outer surfaces of a bent pipe and a straight pipe. A supporting and moving mechanism of the bent pipe is omitted due to the fact that the grinding mechanism is horizontally arranged, the complexity of a traditional outer polishing device is greatly simplified, the automation degree for outer polishing is improved, and all-face dead-angle-free polishing is performed on the surface of the bent pipe.

Owner:HENAN YONGFUDE SCI & TECH CO LTD

Polishing mechanism

PendingCN107052980AAvoid damageEffectively respond to surface polishing operationsEdge grinding machinesPolishing machinesCirculating pumpWasher

The invention discloses a polishing mechanism. The polishing mechanism comprises a containing box, a circulating pump and a circulating pipeline, wherein the containing box is used for containing objects to be polished, and the circulating pipeline communicates with the circulating pump and the containing box; a pressurizing and exhausting device is arranged on the circulating pipeline; the circulating pipeline is filled with a polishing solution; the containing box comprises a box body and a box cover, wherein the box cover is covered on the box body in a sealed mode through a sealing washer; a clamping structure used for clamping the objects to be polished is arranged on the inner wall of the box cover; the pressurizing and exhausting device comprises a hollow barrel body and an exhaust ball valve, wherein one end of the cylinder communicates with the circulating pipeline, and a movable part which can move and is used for enhancing or reducing the internal pressure of the barrel body is arranged in the barrel body; and the movable part comprises a piston head, a piston rod and a piston handle, wherein a through hole is formed in the end, far away from the circulating pipeline, of the barrel body, one end of the piston rod is connected to the piston head, and the other end of the piston rod extends out of the barrel body through the through hole and is connected to the piston handle. Compared with the prior art, the polishing mechanism has the advantages that the damage to the surfaces of the objects to be polished is small, and the surface polishing operation of precise parts can be effectively realized.

Owner:合肥瑞硕科技有限公司

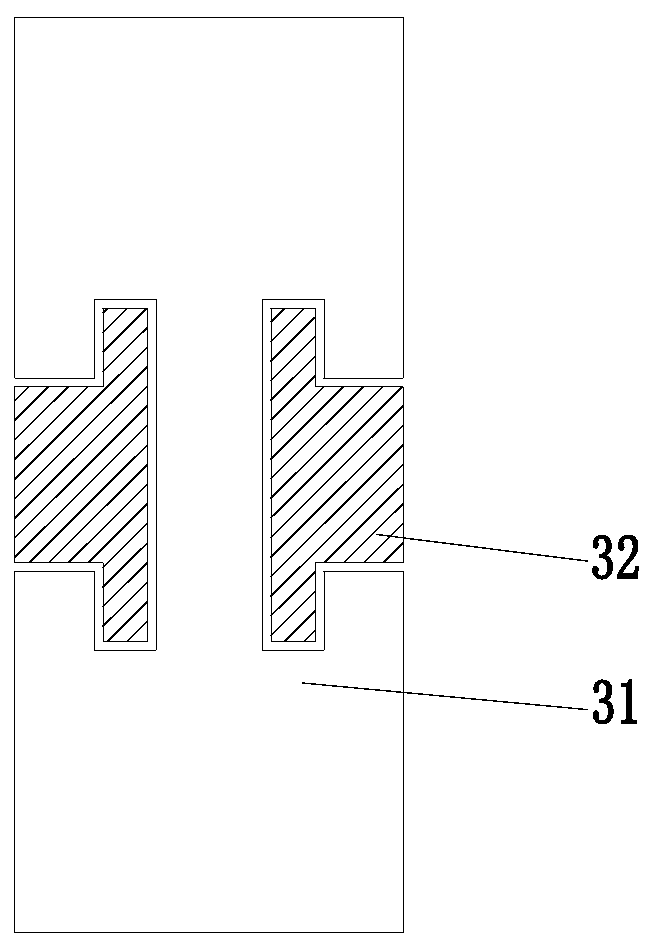

Production equipment for precision bearing ring or bearing

InactiveCN112518452AEasy to fixReasonable designGrinding carriagesRevolution surface grinding machinesWorkbenchIndustrial engineering

The invention discloses production equipment for a precision bearing ring or a bearing. The production equipment comprises an equipment body, the equipment body comprises a workbench, one side of thetop of the workbench is fixedly connected with a shell with an opening formed in one side, and a cylinder with an opening formed in one side is rotatably arranged in the shell in a sleeving mode; andT-shaped positioning rods are fixedly connected to the inner wall of the top and the inner wall of the bottom of the cylinder correspondingly, the two T-shaped positioning rods are symmetrically arranged, the T-shaped positioning rods are slidably sleeved with movable bases, a first electric extendable rod is fixed to the other side of the shell in a threaded mode, and the output end of the firstelectric extendable rod extends into the cylinder. The production equipment is reasonable in design and convenient to use, product inner rings of different specifications can be conveniently, rapidlyand stably fixed, the inner side and the outer side of a product ring can be ground, applicability is high, other grinding tools do not need to be replaced when inner side grinding and outer side grinding are changed, time and labor are saved, the use requirement is met, and use is convenient.

Owner:常州鼎森传动科技有限公司

Polishing device for inner surface of steel pipe

InactiveCN107263229AEasy to fixEasy to polishRevolution surface grinding machinesGrinding drivesArchitectural engineeringEngineering

The invention discloses a steel pipe inner surface grinding device, which comprises a steel pipe, movable clips and steel wires. First clips are arranged at both ends of the steel pipe, and a second clip is arranged below the first clip. Above the first clip, a The first wire wheel, and the adjustment frame is installed on the first clip, the second wire wheel is arranged on the adjustment frame, the movable card is arranged in the middle of the steel pipe, and the rigid brush is installed on the movable card, and the movable card has two The end is provided with a fixed card, and a compression bolt is installed above the fixed card, and the middle surface of the steel pipe is provided with a motor fixed card, and a servo transmission motor is installed above the motor fixed card. The steel pipe inner surface grinding device can drive the clamp shaft to move back and forth inside the steel pipe through the servo drive motor, so as to achieve the purpose of grinding the inside of the steel pipe. In addition, it can adapt to the diameter of the steel pipe by moving the second wire wheel, which is more convenient to clean the inside of the steel pipe. The grinding makes the device more widely applicable.

Owner:HEFEI YONGWEI MACHINERY EQUIP

Post-welding treatment process for steel structural profile steel

InactiveCN111215798APrevent affecting sanding qualityReduce frictionWelding/cutting auxillary devicesOther manufacturing equipments/toolsFriction forceThreaded rod

The invention relates to a post-welding treatment process for steel structural profile steel. Post-welding treatment equipment comprises a workbench, a fixing device and a grinding device, wherein thefixing device is fixedly arranged at the upper end of the workbench, and the grinding device is arranged at the lower end of the fixing device; and the fixing device comprises fixing plates, screw rods, supporting plates, positioning plates, connecting plates and rotating rods, and the grinding device comprises right-angle frames, grinding heads I, fixing blocks, threaded rods, movable plates andgrinding heads II. According to the post-welding treatment process for the steel structural profile steel, multiple pieces of welded angle steel are fixed at the same time through the fixing device,and therefore the friction force between the angle steel and the positioning plates is increased through rubber plates with rough surfaces, so that the angle steel is further positioned; and the surfaces of ground angle steel are cleaned while the welding positions of the angle steel is completely ground through the grinding device, so that the purpose of preventing excessive debris accumulation from affecting the grinding quality is achieved.

Owner:刘秀娟

Special flexible adapter tube 3PE polishing device for manufacturing photosensitive glass fiber reinforced plastics protecting layer

ActiveCN111546146AAchieve the purpose of polishingGuaranteed grinding qualityGrinding carriagesRevolution surface grinding machinesFiberPolishing

The invention discloses a special flexible adapter tube 3PE polishing device for manufacturing a photosensitive glass fiber reinforced plastics protecting layer. The device comprises a substrate assembly for carrying a pipeline and a polishing module configured on one side of the pipeline, wherein the polishing mechanism is arranged on the polishing module. The polishing module is in feeding transmission connection to the feeding assembly and is driven by the feeding assembly to feed linearly. Matched with the polishing mechanism, the complete cycle of the pipeline can be polished. During use,clamping modules can be further configured at two ends of the substrate to fix the pipeline, and rotatable guide wheels can be configured to the clamping modules to drive the pipeline to rotate on the substrate. Matched with the polishing motion and the linear feeding motion, the polishing efficiency is further improved. In a word, the invention discloses the special polishing device for polishing a large pipeline, so that purposes of improving the polishing efficiency and guaranteeing the peripheral polishing quality are achieved, and the special flexible adapter tube 3PE polishing device has very good promotional value.

Owner:WUXI CHINA RESOURCES GAS

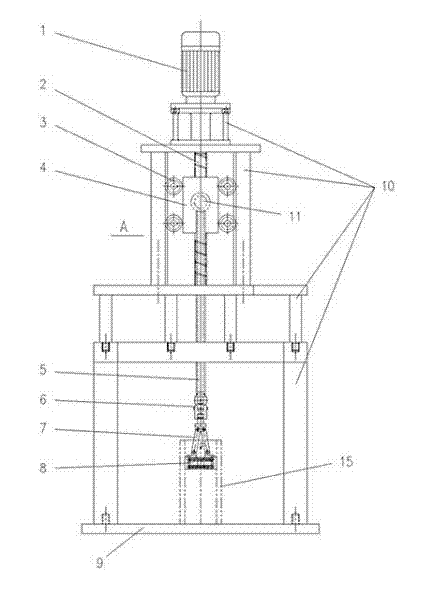

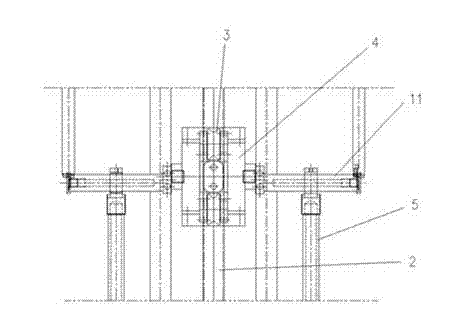

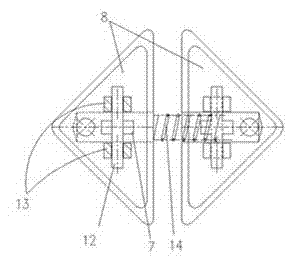

Polishing machine for copper pipe of crystallizer

InactiveCN102398204AAchieve the purpose of polishingSimple structurePolishing machinesEngineeringCopper

The invention relates to a polishing machine for a copper pipe of a crystallizer. In the polishing machine, a motor is fixedly arranged on the topmost side of a machine frame; an output shaft of the motor is downward and is connected with a lead screw; a screw nut matched with the lead screw is fixed in a movable trolley; rollers are symmetrically arranged on two sides of the movable trolley and are matched with a rail in the vertical direction on the machine frame; beams are symmetrically and fixedly arranged on the other two sides of the movable trolley; the beams are connected with the upper end of a connecting rod; the lower end of the connecting rod is connected with a horn grinding head by a cross joint and a connecting arm; the horn grinding head consists of two triangular parts, and a butted spring is arranged in the middle of the horn grinding head; and a bottom plate of a support workpiece is arranged at the bottom of the machine frame. The polishing machine has a simple integral structure and high polishing efficiency and is convenient to operate, polishing textures are consistent with the continuous casting throwing direction, and operators can be far away from the polished workpieces and are not influenced by dust.

Owner:大连百合氧枪喷头有限公司

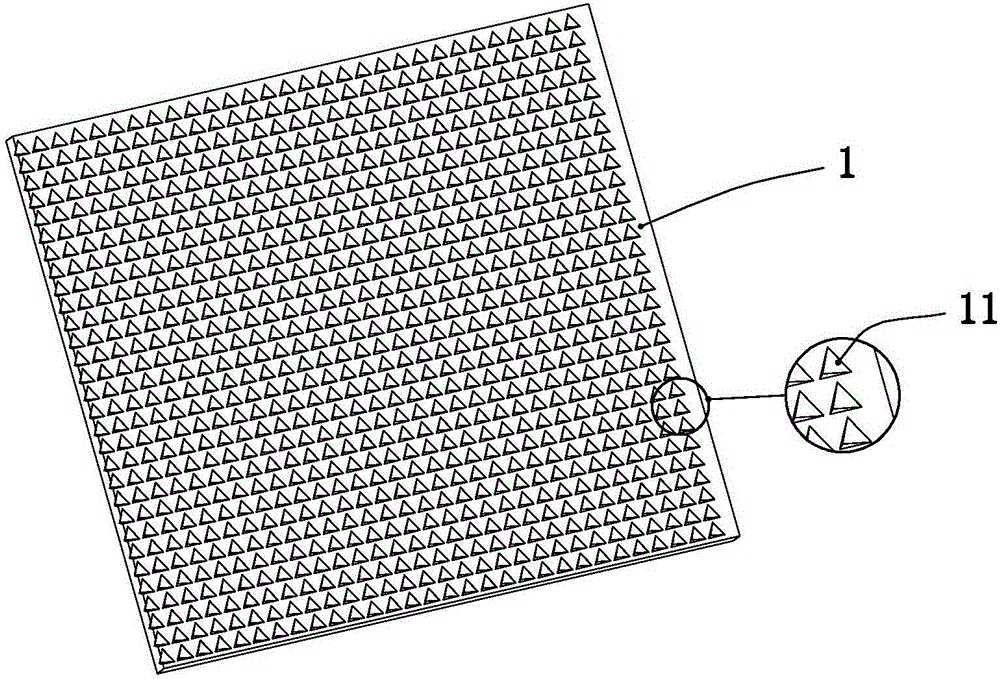

Grinding equipment for mounting plastic plate at bottom of mounting seat

ActiveCN113211219AAchieve the purpose of polishingEasy to operateGrinding carriagesGrinding drivesEngineeringStructural engineering

The invention relates to grinding equipment, in particular to grinding equipment for mounting a plastic plate at the bottom of a mounting seat. According to the grinding equipment for mounting the plastic plate at the bottom of the mounting seat, the danger coefficient of workers is reduced, the operation process is automated and simplified, and the grinding smoothness is improved. The grinding equipment for mounting the plastic plate at the bottom of the mounting seat comprises a base, clamping mechanisms and grinding mechanisms, and the clamping mechanisms are connected to the two sides of the top of the base; and the outer sides of the clamping mechanisms are connected with the grinding mechanisms. According to the grinding equipment, through cooperation of a discharging plate, clamping blocks, first springs and an air cylinder, the purpose of grinding the plastic plate is achieved.

Owner:郭涵沫

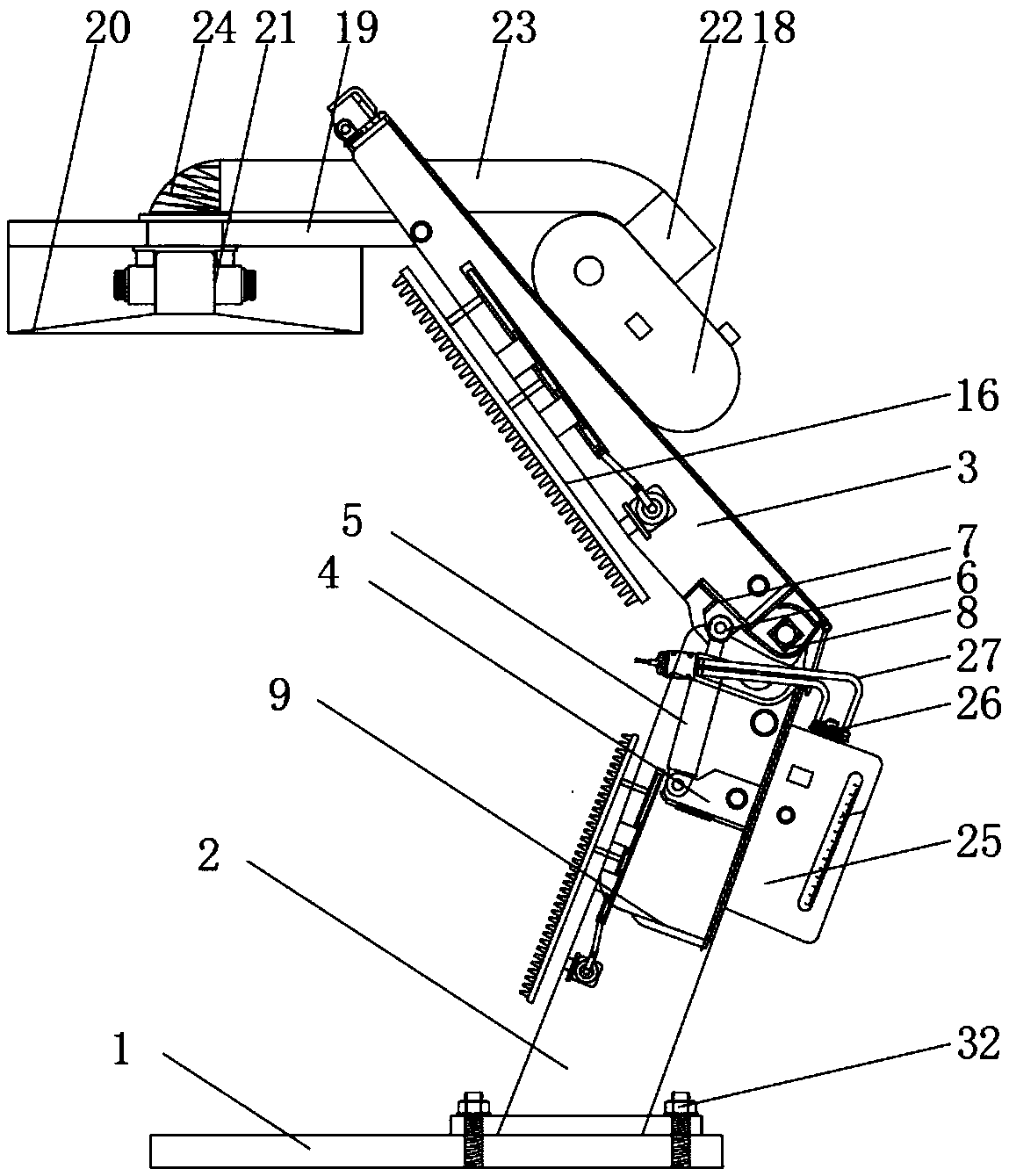

Operating table board angle grinding device

ActiveCN109262404AAdjustable angleEasy to processEdge grinding machinesGrinding carriagesEngineeringOperating table

The invention discloses an operating table board angle grinding device comprising a base. A bottom grinding arm is fixedly connected to the top right side of the base, a rotating shaft is arranged onthe top of the bottom grinding arm, and the top of the bottom grinding arm is connected with a top grinding arm by a rotating shaft in the rotating mode. The inner walls of the top grinding arm and the bottom grinding arm are both fixedly connected with a moving grinding motor, an output shaft of the moving grinding motor is provided with a rotating rod, and one end of the rotating rod away from the moving grinding motor is in rotating connection with a driving rod. One end of the driving rod away from the rotating rod is in rotating connection with a reciprocating sliding frame. The grindingdevice relates to the technical field of table board grinding. The operation table board angle grinding device solves the problem that the cutting angle cannot be guaranteed in the cutting work, and the angle and the roundness are not attractive in appearance after the cutting, and a large amount of dust is generated during the cutting process and endangers the health of workers. The table board is more attractive in overall appearance during edge grinding, and the harm of dust to the human body is reduced.

Owner:滁州市朝友精密制造有限公司

Grinding device for automobile brake disc production

ActiveCN109676485AEasy to fixAvoid offsetGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention discloses a grinding device for automobile brake disc production. The grinding device comprises an outer frame, wherein a cross plate is fixedly connected between two sides of the innerwall of the outer frame; the bottom of the outer frame is fixedly connected with a first motor; one end of the output shaft of the first motor penetrates through the outer frame and extends into the outer frame; one end, which is positioned inside the outer frame, of the output shaft of the first motor is fixedly connected with a first bevel gear; and the two sides of the first bevel gear are engaged with second bevel gears. The invention relates to the technical field of automobile fittings. The grinding device for automobile brake disc production achieves the purpose of conveniently fixing abrake disc, facilitates use of people, prevents the brake disc from deviating in a grinding process, improves the grinding effect, can adjust spacing between two grinding heads, is convenient for adapting to brake discs of different diameters, can adjust the height of a grinding disc according to the needs, conveniently controls a grinding thickness, and obtains different grinding effects.

Owner:孔江君

Multi-purpose type glass mold cavity polishing machine

ActiveCN106312755AAchieve the purpose of polishingVersatilityGrinding machine componentsGrinding machinesEngineeringMechanical engineering

The invention discloses a multi-purpose type glass mold cavity polishing machine. The multi-purpose type glass mold cavity polishing machine comprises a rotating shaft, a motor, a plurality of springs and a support, wherein the rotating shaft is hollow and is driven by the motor; the motor is connected onto the support; an air outlet hole is formed in the upper part of the rotating shaft; the lower end of the rotating shaft is glidingly connected with a box body in the axial direction; a hydrochloric acid solution is contained in the box body; calcium carbonate solids are accommodated in the rotating shaft; a plurality of small round holes are formed in the bottom surface of the rotating shaft; a closed air bag is connected outside the rotating shaft; an abrasive material layer is arranged on the outer surface of the air bag; the rotating shaft and the air bag are connected through the springs. With the adoption of the scheme, the air bag is expanded until the size is matched with that of a glass mold cavity according to the specific size of a glass mold, and the machine can be used for polishing glass molds of various sizes and has universality.

Owner:重庆市笙建玻璃有限公司

Multifunctional leather shoe maintenance machine

The invention provides a technical scheme of a multifunctional leather shoe maintenance machine. The multifunctional leather shoe maintenance machine comprises a shoe tree, a sprayer, a shoe brush and a framework, and is characterized in that the shoe tree is fixedly arranged on a sliding plate through a fixing rod; the lower part of the sliding plate is provided with a movable lifting device; a connecting plate with a chute is fixedly arranged on the lifting device; the front part of the framework is provided with the shoe brush which is matched with the shoe tree; the shoe brush is fixedly arranged on a vertical rod; the lower part of the vertical rod is connected with a cam; the cam is connected with an output shaft of a motor; the sprayer is fixedly arranged on the top of the framework; a cotton brush connected with the framework is fixedly arranged at the upper part of the shoe tree; and an infrared lamp and an ultraviolet lamp are fixedly arranged on the top of the framework. With the adoption of the multifunctional leather shoe maintenance machine, not only can the purposes that the leather shoes are decontaminated, dedusted and polished be achieved, but also the effects of sterilizing, disinfecting, warming the cavities of the shoes and smoothing the surfaces of the shoes are achieved. The multifunctional leather shoe maintenance machine is simple in structure and convenient to maintain, and is suitable for popularization and use.

Owner:王阔 +1

Bamboo cane grinding device for bamboo weaving handicraft processing

ActiveCN111185815AAchieve the purpose of polishingExtended service lifeEdge grinding machinesGrinding feedersIndustrial engineeringBelt conveyor

The invention relates to a bamboo cane grinding device for bamboo weaving handicraft processing. The bamboo cane grinding device for bamboo weaving handicraft processing comprises a working table, a processing device and an adjusting device. The processing device is fixedly arranged at the upper end of the working table, the adjusting device is arranged at the upper end of the processing device, the processing device comprises a fixing frame I, a fixing frame II, a cleaning plate, a clamping frame, a belt conveyor I and belt conveyors II. A plurality of bamboo canes are ground by the processing device, and through cooperation of the clamping frame, the belt conveyor I and the belt conveyors II, the purpose of completely grinding the surfaces of the bamboo canes is achieved. The distances between the belt conveyor I and the belt conveyors II and the distance between the belt conveyors II are controlled simultaneously through the adjusting device, and the elasticity of a spring is used to enable a rubber plate to be in close contact with the bamboo canes so as to grind the surfaces of the bamboo canes; and a cylindrical block is used for changing the clamping positions of the bamboocanes by a right-angle plate to achieve the purpose of completely grinding the surfaces of the bamboo canes.

Owner:新宁县小军竹木制品有限公司

Round steel polishing machining device

ActiveCN111496645AAchieve the purpose of polishingGuaranteed normal transmissionPolishing machinesGrinding drivesPolishingStructural engineering

The invention relates to the field of machining equipment, in particular to round steel polishing machining device. The round steel polishing machining device comprises a bracket, guide wheel mechanisms, a moving mechanism, an adjusting lifting mechanism, a polishing power rack, a rotating mechanism, an jacking and tightening mechanism, a tensioning mechanism and a polishing mechanism, wherein thetwo guide wheel mechanisms are both connected onto the bracket; the adjusting lifting mechanism is connected to the upper end of the bracket; the moving mechanism is connected onto the adjusting lifting mechanism and is in sliding connection with the bracket; the polishing power rack is connected to the upper end of the bracket; the rotating mechanism is in transmission connection with the polishing power rack; the jacking and tightening mechanism is connected onto the rotating mechanism; the tensioning mechanism is in sliding connection with the rotating mechanism; the polishing mechanism isrotationally connected onto the jacking and tightening mechanism; and the rotating mechanism, the jacking and tightening mechanism, the tensioning mechanism and the polishing mechanism are in transmission connection. The round steel polishing machining device can polish round steel, and the condition that the quality of a workpiece is affected due to the fact that the round steel wobbles with adoption of manual pressing is avoided.

Owner:抚州市圣航洁具有限公司

A bamboo strip grinding device for processing bamboo weaving handicrafts

ActiveCN111185815BAchieve the purpose of polishingExtended service lifeEdge grinding machinesGrinding feedersStructural engineeringWorkbench

The invention relates to a bamboo strip grinding device for processing bamboo weaving handicrafts, which comprises a workbench, a processing device and an adjusting device. Frame one, fixed frame 2, cleaning board, clamping frame, belt conveyor 1 and belt conveyor 2, the present invention polishes a plurality of bamboo strips through processing device, and through clamping frame, belt conveyor 1 Cooperate with the second belt conveyor to achieve the purpose of completely grinding the surface of the bamboo strips, and simultaneously control the distance between the first belt conveyor and the second belt conveyor and between the second belt conveyor through the adjustment device , make use of the elasticity of the spring to make the rubber plate and the bamboo strips closely contact, polish the surface of the bamboo strips, change the clamping position of the bamboo strips by the right-angle plate through the cylindrical block, so as to achieve the purpose of completely polishing the bamboo strip surface.

Owner:新宁县小军竹木制品有限公司

Machining equipment for large-radius arc surface on piano rib

PendingCN113798967AIncrease the range of specificationsAchieve the purpose of polishingGrinding carriagesGrinding drivesPhysicsEngineering

The invention relates to machining equipment for a large-radius arc surface on a piano rib. The machining equipment comprises a machining table, a first circular plate fixedly connected to the top of a mounting plate located on the rear side, a second circular plate fixedly connected to the top of a mounting plate located on the front side, and a grinding wheel movably connected between the first circular plate and the second circular plate. The grinding wheel slides along a first annular sliding rail while rotating. A servo motor drives an input shaft to rotate forwards and backwards, the grinding wheel connected with a second output shaft is driven to rotate at a high rotating speed, and meanwhile, a gear connected with a first output shaft rotates at a low rotating speed, and meshing of the gear and an annular gear is matched, so that the gear moves back and forth along the surface of the annular gear; and therefore, when the grinding wheel is controlled to rotate at a high rotating speed, the axis of the grinding wheel slides in a reciprocating mode along an arc-shaped track a, then the piano rib slides from right to left along a feeding groove till the piano rib abuts against the left end surface of the feeding groove, and the purpose of polishing the arc-shaped surface of the piano rib is achieved.

Owner:张牧春

Easy-to-clamp grinding device for go chess piece machining

InactiveCN110370154AFacilitates polishing stepsGuaranteed polishing effectEdge grinding machinesPolishing machinesCouplingEngineering

The invention discloses an easy-to-clamp grinding device for go chess piece machining, and relates to the field of go chess piece manufacturing. The grinding device comprises a shell, a plurality of abreast support seats are fixedly connected to one inner side surface of the shell from top to bottom, a plurality of clamping mechanisms used for clamping go chess pieces are connected to the upper surface of each support seat through supports, and an output shaft of a rotating motor is connected to one end of a dry grinding roller through a coupler; and the peripheral edges of the two ends of thedry grinding roller are correspondingly provided with a plurality of rolling grooves which are distributed in equal intervals and are used for rolling a ball, an annular rolling groove for rolling and connecting the ball is formed in the inner circumferential surface, corresponding to fixing rings, of the ball, and meanwhile, and both the two fixing rings are fixedly connected with the upper surface of the shell through supports. According to the easy-to-clamp grinding device for the go chess piece machining, after primarily grinding, the go chess pieces are placed into the clamping mechanisms, and further polishing treatment is carried out, so that the two-step processes of grinding and polishing of the go chess pieces are realized; and the go chess pieces and sand grains are fully vibrated for separating through a vibration mechanism, so that the next polishing effect is ensured.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

Polishing equipment used for mechanical part

InactiveCN106863079AAchieve the purpose of polishingPromote absorptionBelt grinding machinesGrinding/polishing safety devicesMechanical componentsTransmission belt

The invention discloses a polishing device for mechanical parts, which comprises a fixed seat, a polishing belt is arranged between two pillars, roller shafts are arranged on both sides of the inside of the polishing belt, and the bottom of the receiving plate is The middle part is provided with a first dust suction plate, the middle part of the top of the fixed seat is provided with a second dust suction plate, and the bottom of the first dust suction plate is equidistant from the top of the second dust suction plate. The right side of the first suction fan is connected to the collection box, the left side of the second suction fan is connected to the collection box, the inner cavity of the collection box is provided with a filter screen, and the left side of the top of the receiving plate is connected to a fixed plate, The left side of the bottom of the fixed plate is connected with a gear bar, the right side of the gear bar is engaged with a transmission gear, and the front of the rotating shaft is connected with a lifting motor through a transmission belt. The invention has the advantages of improving the dust-proof efficiency and effect when polishing mechanical parts, and solves the problem that poor dust-proof effect and efficiency will reduce the practicability of polishing equipment.

Owner:于浩

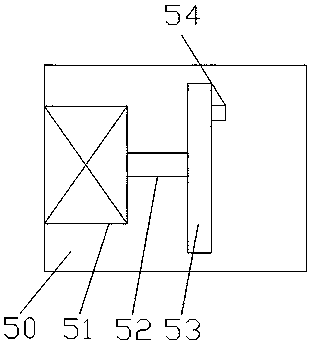

Trimming machine for end faces of pins

ActiveCN105252360AAchieve the purpose of polishingFully automated working processGrinding feedersPlane surface grinding machinesButt jointGraphite

The invention discloses a trimming machine for the end faces of pins. The trimming machine comprises a machine table, a graphite pin feeding device arranged on the machine table, a first feeding guide trough, a second feeding guide trough, a polishing device, a receiving disc and a linear pushing device. The first feeding guide trough and the second feeding guide trough are arranged on the machine table. The first end of the second feeding guide trough is in butt joint with the second end of the first feeding guide trough. The polishing device is arranged above the second end of the second feeding guide trough. The receiving disc is arranged on the machine table. The linear pushing device is arranged on the outer side of the first end of the second feeding guide trough. A conductive block electrically connected with a driving switch of the linear pushing device is arranged on the inner side wall and the inner bottom wall of the first end of the second feeding guide trough. According to the trimming machine, through connection achieved when the graphite pins are in contact with the conductive block and disconnection achieved when the graphite pins are not in contact with the conductive block, the pushing end of the linear pushing device is driven to push the graphite pins on the second feeding guide trough to forwards move, and then the aim of polishing the graphite pins is achieved. The whole working process is full automatic, manual polishing is avoided, and working efficiency is greatly improved.

Owner:SHANGHAI HONGFENG IND

Polishing device

The invention discloses a polishing device. The polishing device comprises a work box, wherein a polishing cavity is formed in the work box; a steering cavity is formed in the lower end wall of the polishing cavity; a platform is arranged on the upper end surface of a rotating shaft B in the steering cavity; a plurality of fixedly connected adhesion plates are arranged on the upper end surface ofthe platform; a separation cover is arranged at the upper end of the polishing cavity; a pull rod is arranged in the separation cover; the lower end of the pull rod is in screwed fit and connection with a detachable polishing device; and a pushing device is arranged in the right end wall of the polishing cavity. During working, the polishing device disclosed by the invention is fixed on the platform through the adhesion plates so as to prevent a container from separating during polishing.

Owner:马礼艳

A round steel polishing processing device

ActiveCN111496645BAchieve the purpose of polishingGuaranteed normal transmissionPolishing machinesGrinding drivesPolishingMachine

The invention relates to the field of mechanical processing equipment, in particular to a round steel polishing processing device, which includes a bracket, a guide wheel mechanism, a moving mechanism, an adjusting lifting mechanism, a polishing power frame, a rotating mechanism, a top tightening mechanism, a tensioning mechanism and a polishing mechanism , the guide wheel mechanism is provided with two, the two guide wheel mechanisms are connected to the bracket, the adjusting lifting mechanism is connected to the upper end of the bracket, the moving mechanism is connected to the adjusting lifting mechanism, the moving mechanism is slidingly connected with the bracket, and the polishing power The frame is connected to the right end of the bracket, the rotating mechanism is connected to the polishing power frame through transmission, the tensioning mechanism is connected to the rotating mechanism, the tensioning mechanism is slidably connected to the rotating mechanism, the polishing mechanism is connected to the top tightening mechanism in rotation, the rotating mechanism, The jacking mechanism, the tensioning mechanism and the polishing mechanism are connected by transmission, and the invention can polish the round steel, avoiding shaking caused by manual pressing and affecting the quality of the workpiece.

Owner:抚州市圣航洁具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com