Post-welding treatment process for steel structural profile steel

A processing process and post-welding technology, applied in the field of post-welding processing of steel structural steel, can solve the problems of increased processing cost, low work efficiency, low equipment work efficiency, etc., and achieve the effect of increasing friction and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

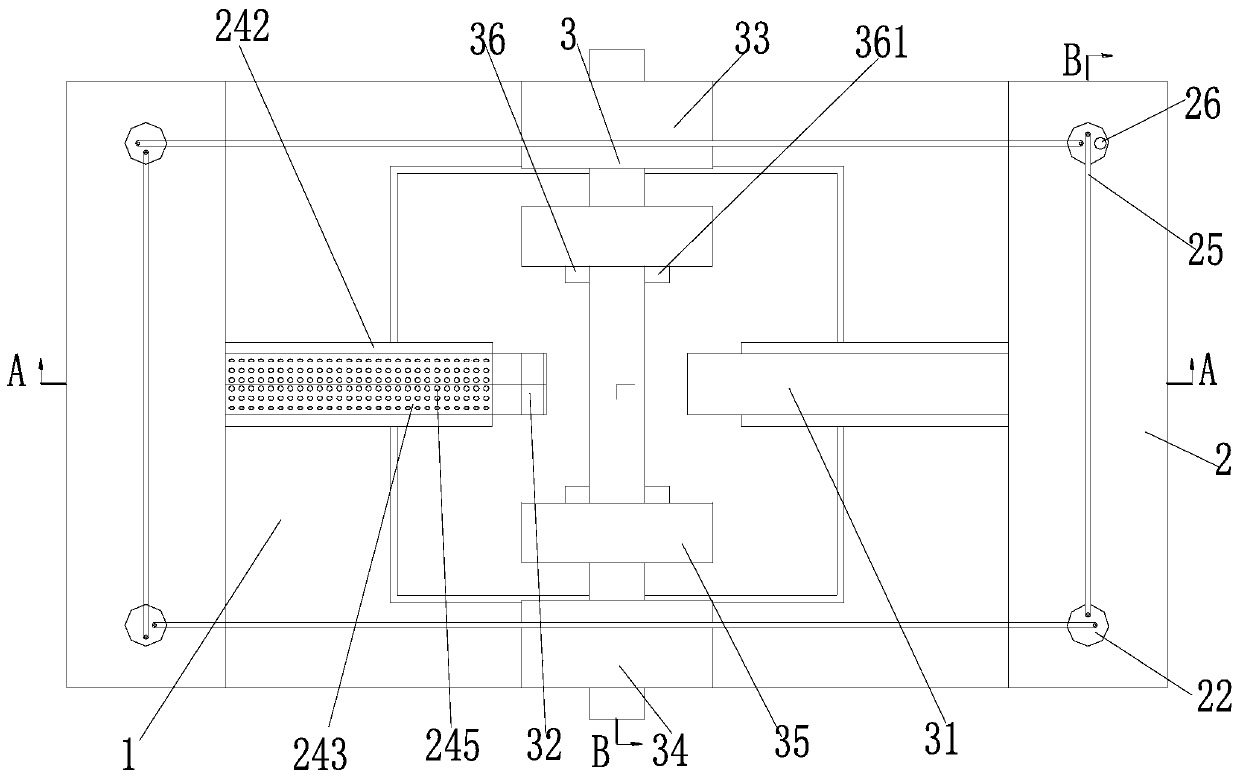

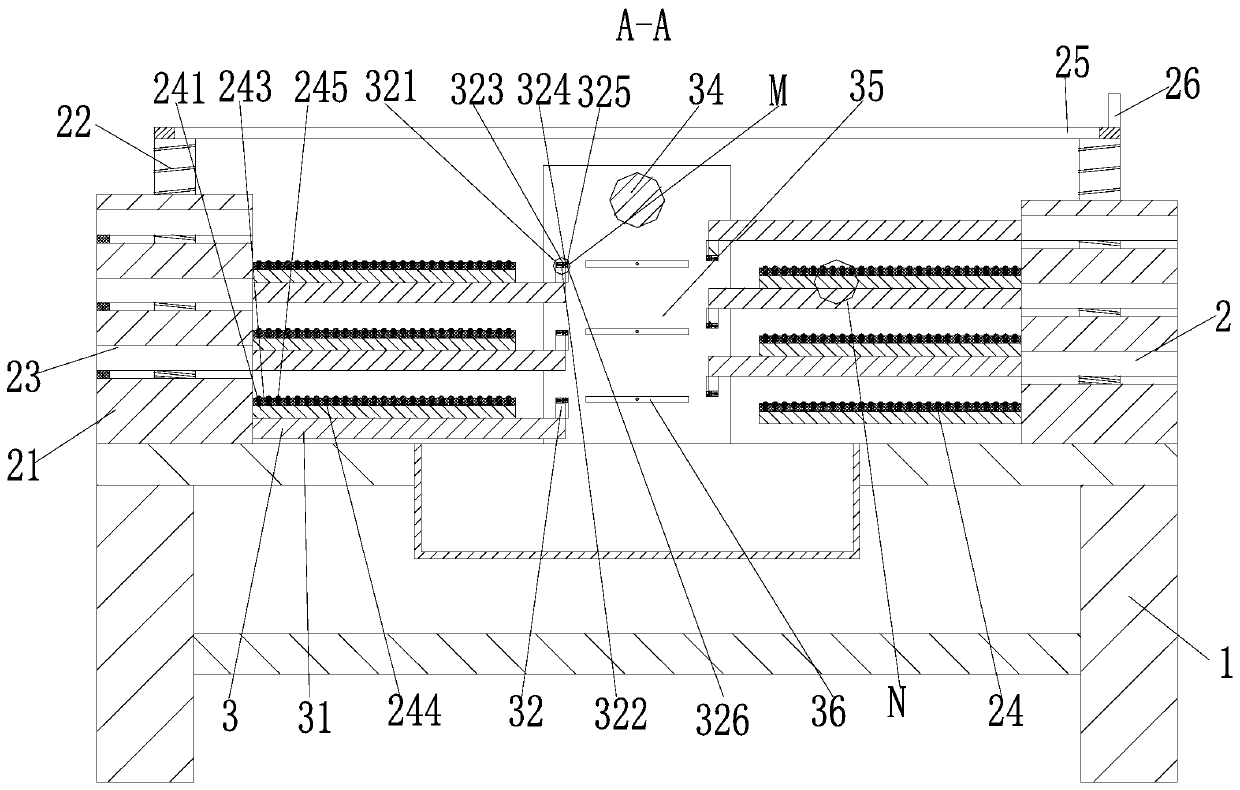

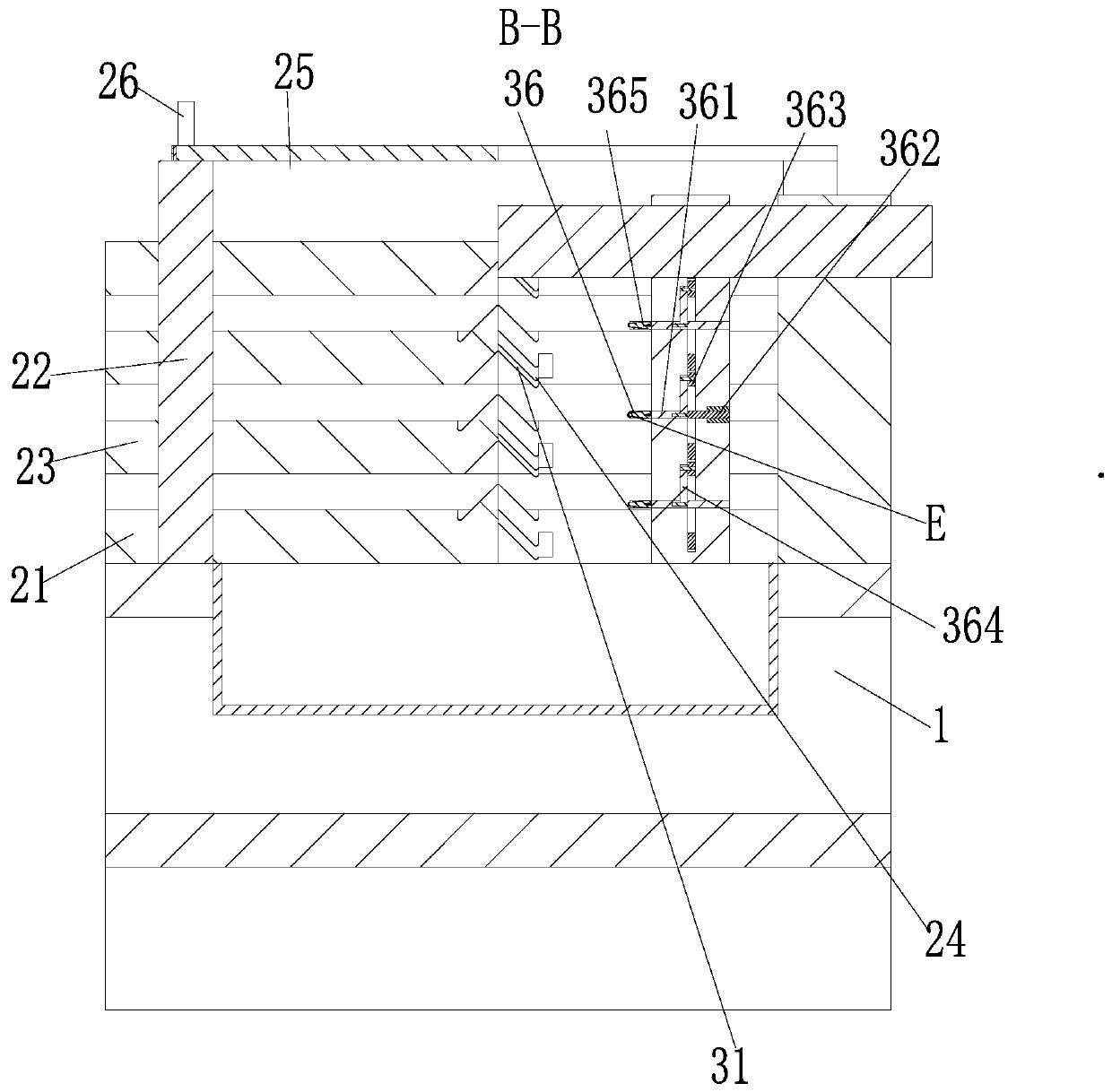

[0039] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0040] A steel structure section steel welding post-processing process, which uses section steel welding post-processing equipment. The specific method of processing is as follows:

[0041] S1. Take out the weldment: take out the welded section steel;

[0042] S2. Fixing the weldment: Fix the two ends of the weldment taken out by S1 through the fixing device 2;

[0043] S3. Grinding the weldment: the weldment fixed by S2 is polished by the grinding device 3 on its welding spot;

[0044] S4. Cleaning the surface of the weldment: the surface of the weldment polished by S3 is cleaned by the grinding device 3;

[0045] S5. Collect weldments: collect the weldments cleaned in S4.

[0046] A fixing device 2 is fixedly installed on the upper end of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com