A grinding module and a grinding device

A technology of modules and grinding discs, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding slides, etc., can solve the problems of low manual grinding efficiency, achieve the effects of reducing grinding processing costs, reducing scrap rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

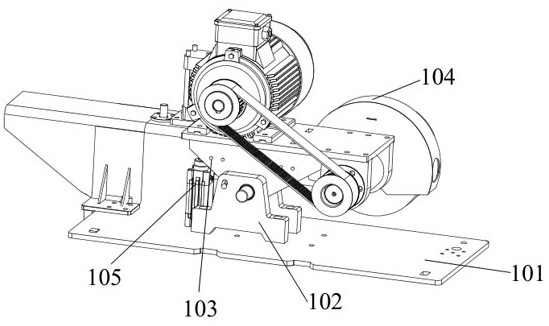

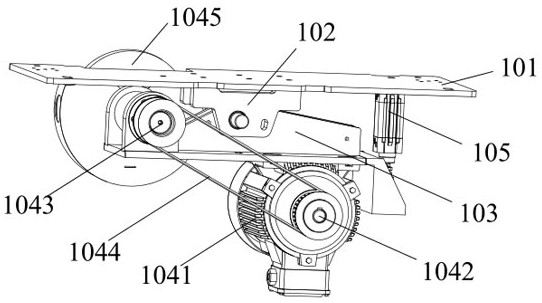

[0041] see Figure 1-7 , the present embodiment provides a grinding module 10, comprising a base 101, a grinding assembly 104, a deflection seat 103 and a driver 105, wherein a part of the surface of the base 101 forms a walking path of the workpiece 30 to be polished, and the grinding assembly 104 rotates Assembled on the base 101, specifically, the grinding assembly 104 includes a grinding motor 1041 and a grinding disc, the first synchronous pulley 1042 is installed on the output shaft of the grinding motor 1041, the grinding disc is connected with the second synchronous pulley 1043, the first The synchronous pulley 1042 and the second synchronous pulley 1043 are connected by a synchronous belt 1044, and the grinding assembly 104 is arranged on the deflection seat 103, and the grinding assembly 104 is located on one side of the walking path. In this embodiment, the middle part of the deflection seat 103 is hinged to The seat 102 is hinged, and the hinged seat 102 is fixed o...

Embodiment 2

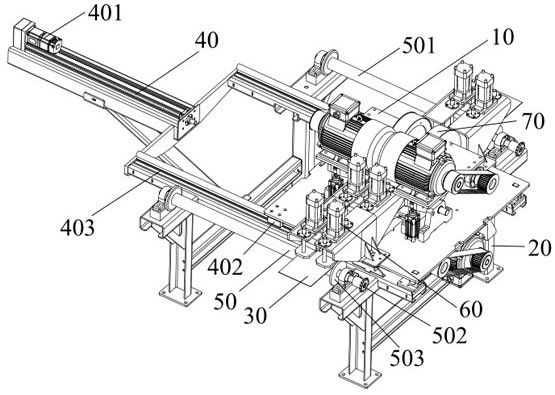

[0044] This embodiment provides a kind of grinding device, comprises two groups of aforementioned grinding modules 10, two groups of grinding modules 10 share the base 101, and the grinding components 104 of the two groups of grinding modules 10 are arranged on two parts of the workpiece 30 to be polished. The surface is polished on both sides.

[0045] Specifically, two groups of grinding modules 10 constitute a grinding unit, and there are two grinding units, at least one of which is configured for sliding installation, and two grinding units are configured on both sides of the object to be polished 30 for double-sided grinding. In this embodiment, the two grinding units are a first grinding unit and a second grinding unit, wherein the base 101 of the first grinding unit is slidably mounted on the frame 20 and driven by the drive module 40, and the second grinding unit The base 101 of the base 101 is fixed on the frame 20. In this embodiment, the drive module 40 includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com