Electric grinding machine for manufacturing cable joints

A cable head and grinding machine technology, which is applied in the direction of grinding racks, grinding machine parts, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve the problems of slow construction progress, affecting cable safety and service life, and grinding quantity. And the speed is not ideal, etc., to achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

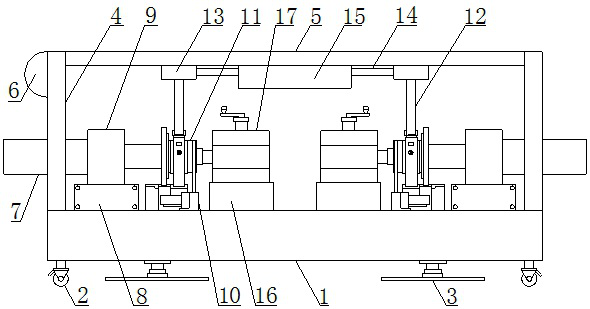

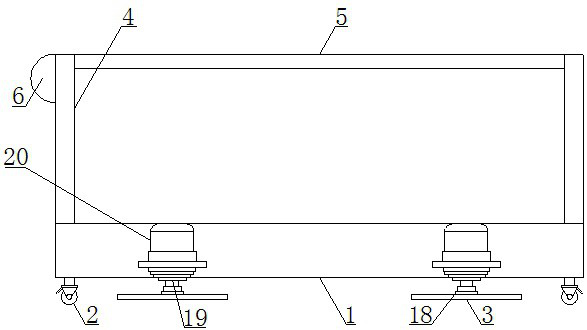

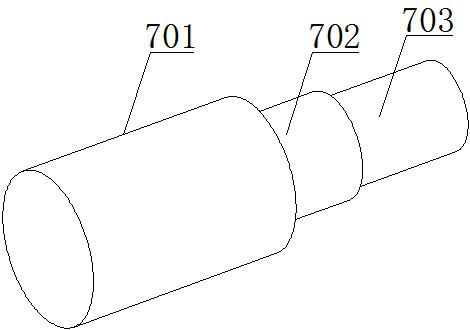

[0025] like Figure 1-10 As shown, an electric grinder is used to make a cable head, which includes a bottom plate 1 and a cable head 7, universal wheels 2 are arranged on the left and right sides below the bottom plate 1, and the universal wheels 2 on both sides are evenly spaced. Two foot supports 3 are provided, and connecting sleeves 18 are arranged above the above described foot supports 3, telescopic rods 19 are arranged above the described connecting sleeves 18, and cylinders 20 are arranged above the telescopic rods 19. , the cylinders 20 are all arranged inside the base plate 1, the left and right sides above the base plate 1 are provided with gantry frames 4, and the left side of the gantry frame 4 on the left side is provided with handrails 6 on the left side. A top plate 5 is arranged above the gantry 4 on the side, and a cable head 7 is arranged in the middle of the gantry 4 on the left and right sides, and the cable head 7 includes a sheath 701, an insulating lay...

Embodiment 2

[0031] like Figure 1-10 As shown, an electric grinder is used to make a cable head, which includes a bottom plate 1 and a cable head 7, universal wheels 2 are arranged on the left and right sides below the bottom plate 1, and the universal wheels 2 on both sides are evenly spaced. Two foot supports 3 are provided, and connecting sleeves 18 are arranged above the above described foot supports 3, telescopic rods 19 are arranged above the described connecting sleeves 18, and cylinders 20 are arranged above the telescopic rods 19. , the cylinders 20 are all arranged inside the base plate 1, the left and right sides above the base plate 1 are provided with gantry frames 4, and the left side of the gantry frame 4 on the left side is provided with handrails 6 on the left side. A top plate 5 is arranged above the gantry 4 on the side, and a cable head 7 is arranged in the middle of the gantry 4 on the left and right sides, and the cable head 7 includes a sheath 701, an insulating lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com