Special flexible adapter tube 3PE polishing device for manufacturing photosensitive glass fiber reinforced plastics protecting layer

A technology of glass fiber reinforced plastics and protective layers, applied in the direction of grinding drive devices, grinding machines, manufacturing tools, etc., can solve the problems of large diameter, unguaranteed efficiency, and poor clamping and fixing of machine tools, so as to improve grinding efficiency, good promotion value, Guarantee the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

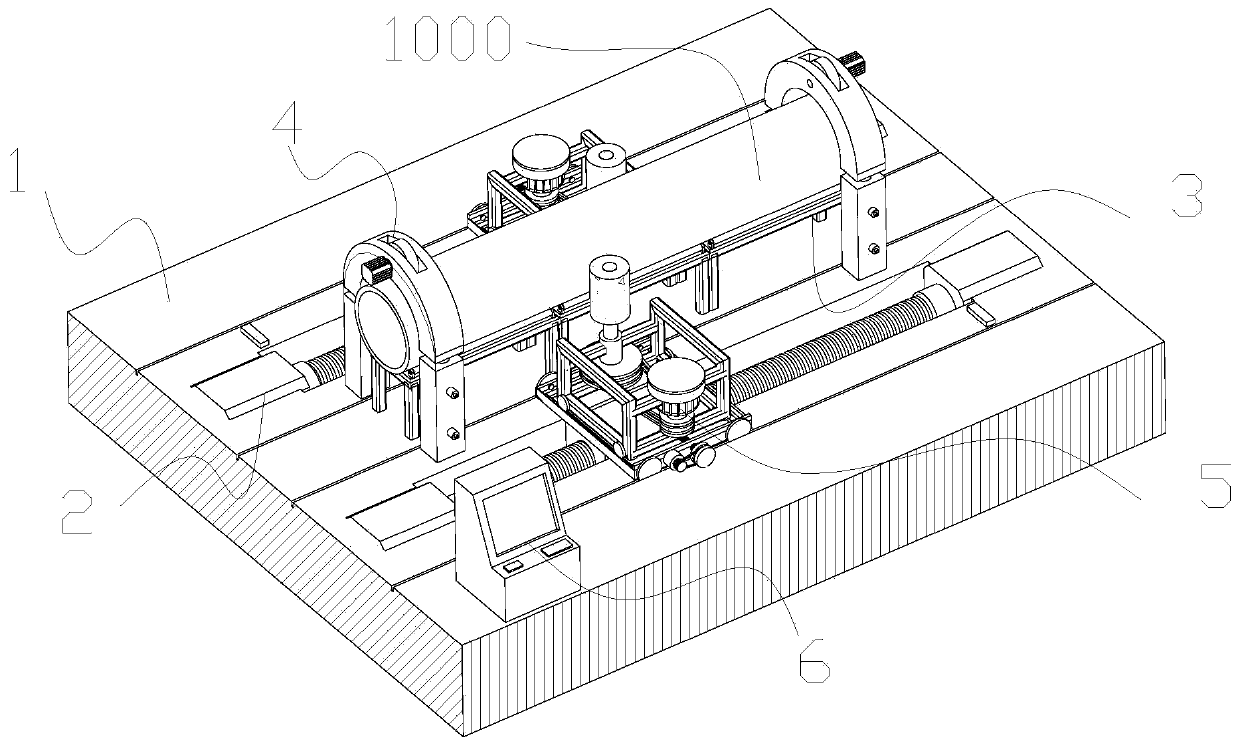

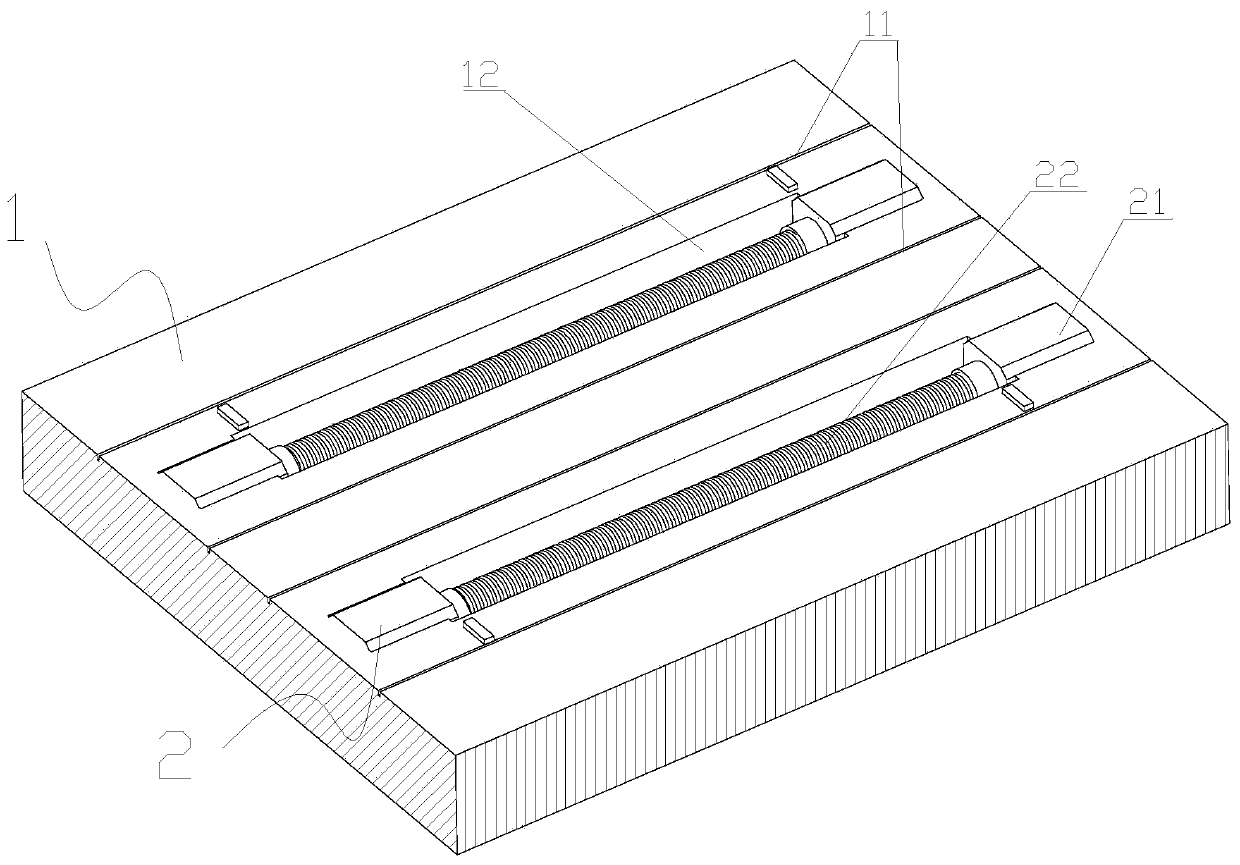

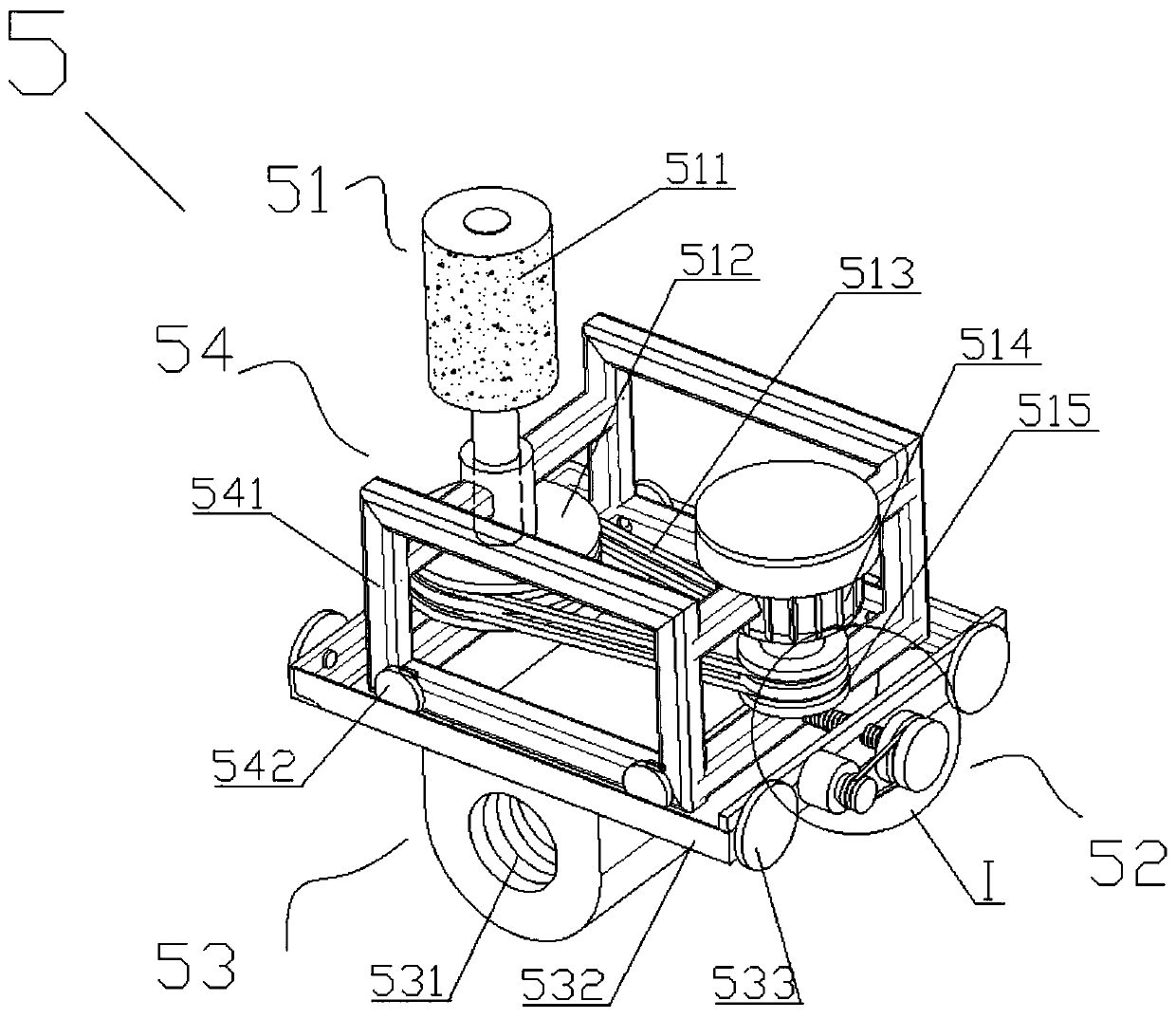

[0034] In some embodiments, such as figure 1 The shown flexible adapter pipe 3PE grinding device dedicated to making a photosensitive FRP protective layer is used for grinding a pipe 1000 , and includes a base assembly 3 positioned below the pipe 1000 for carrying. The pipe 1000 can rotate around its own axis on the base assembly 3 . It also includes a grinding module 5 located on one side of the pipeline 1000; the grinding module 5 includes a grinding mechanism 51; the grinding mechanism 51 is capable of grinding. It also includes a feed assembly 2 connected with the grinding module 5 for feed transmission. The feeding assembly 2 enables the grinding module 5 to perform a linear feeding motion along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com