Round steel polishing machining device

A processing device and round steel technology, which is applied to grinding drive devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of surface roughness reduction, reduction of workpiece surface smoothness, workpiece traces, etc., to improve polishing The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

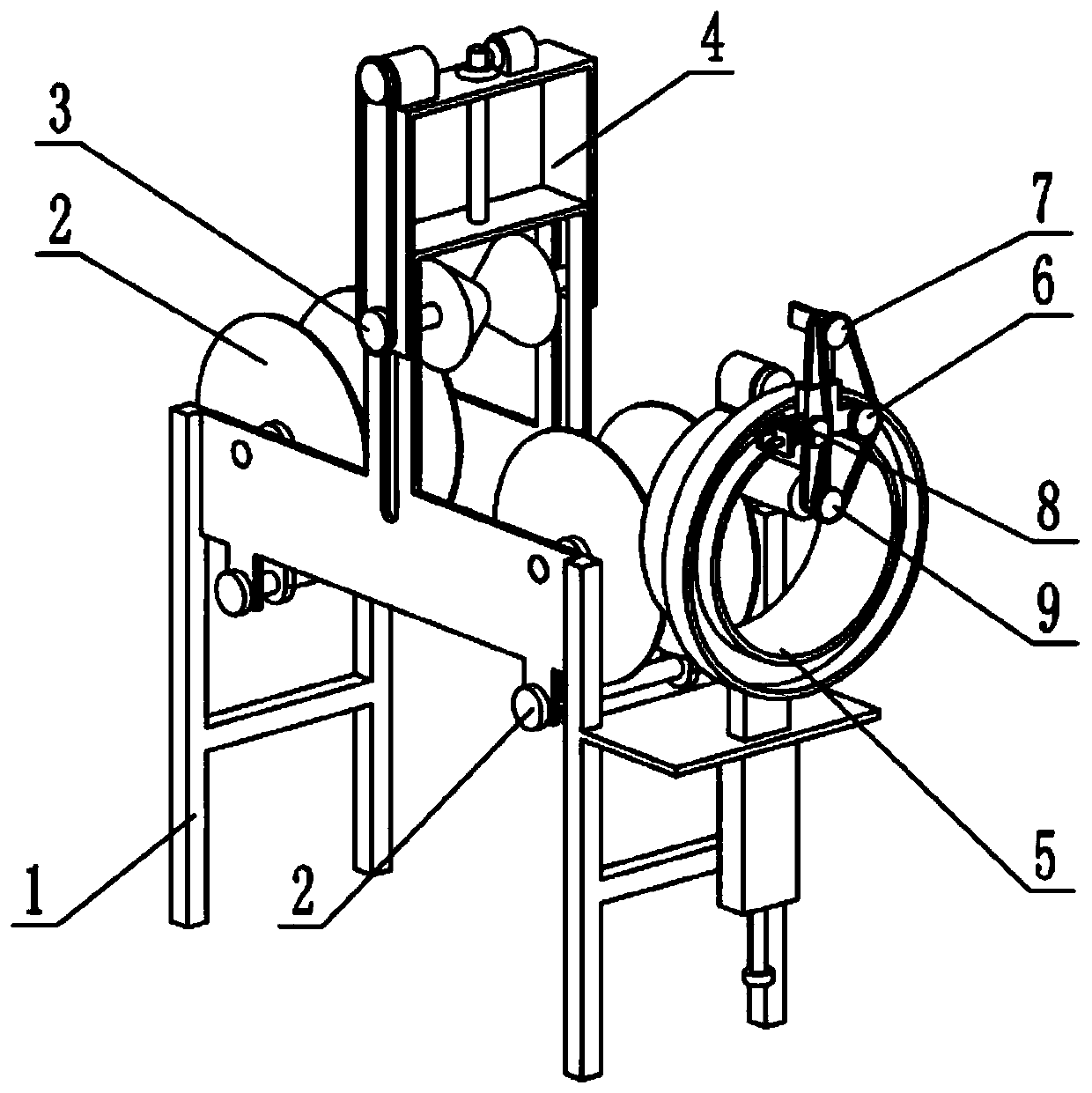

[0030] Such as Figure 1-11 As shown, a round steel polishing processing device includes a bracket 1, a guide wheel mechanism 2, a moving mechanism 3, an adjusting lift mechanism 4, a polishing power frame 5, a rotating mechanism 6, a tightening mechanism 7, a tensioning mechanism 8 and a polishing mechanism 9. The guide wheel mechanism 2 is provided with two, the two guide wheel mechanisms 2 are both connected to the bracket 1, the adjusting lifting mechanism 4 is connected to the upper end of the bracket 1, and the moving mechanism 3 is connected to the adjusting On the lifting mechanism 4, the moving mechanism 3 is slidably connected to the bracket 1. The moving mechanism 3 is located between the two guide wheel mechanisms 2, the polishing power frame 5 is connected to the right end of the bracket 1, and the rotating mechanism 6 is connected in transmission On the polishing power frame 5, the tightening mechanism 7 is connected to the rotating mechanism 6, the tensioning mec...

specific Embodiment approach 2

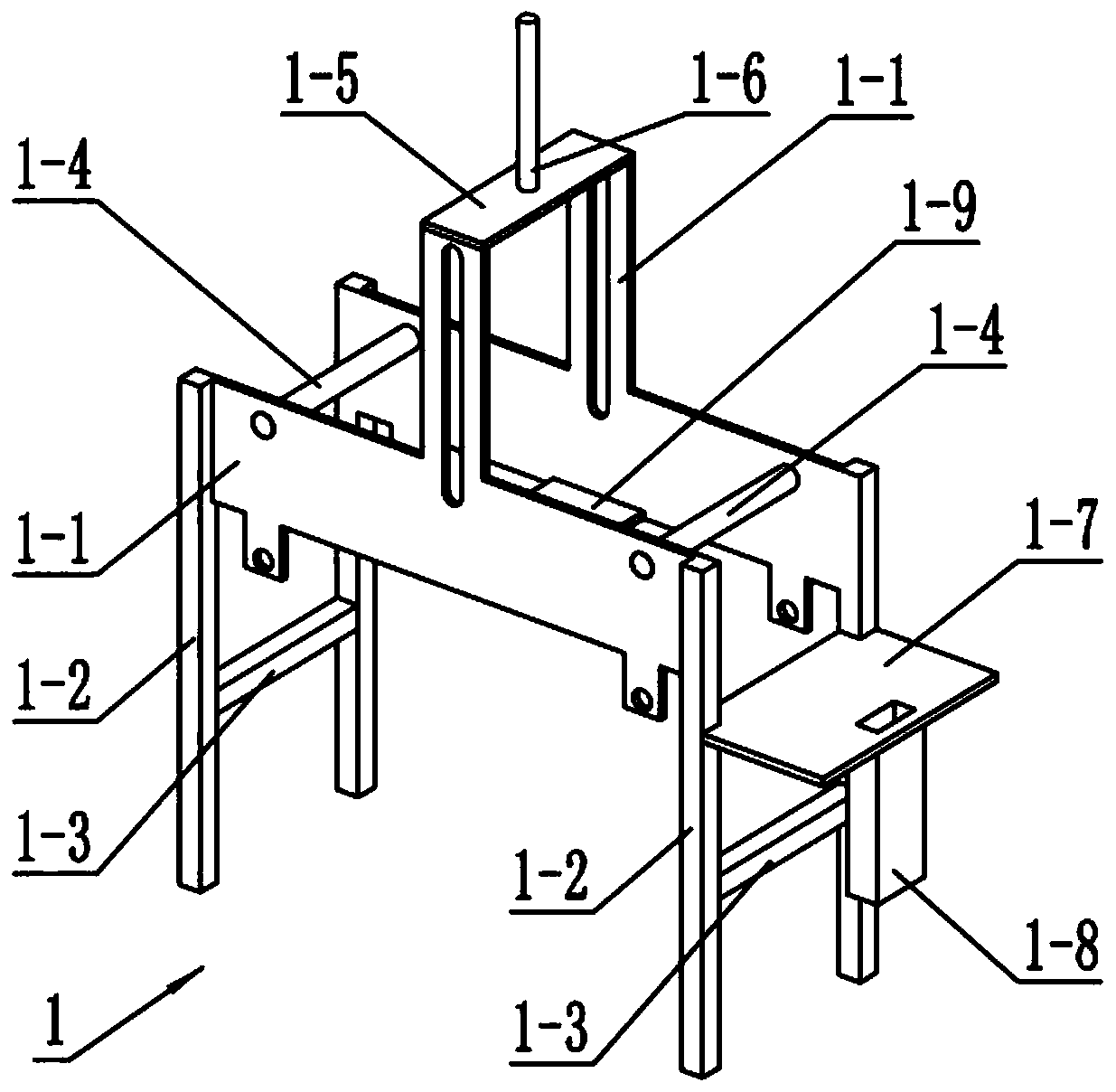

[0033] Such as Figure 1-11 As shown, the bracket 1 includes side plates 1-1, legs 1-2, cross bars 1-3, sliding shafts 1-4, upper cross plates 1-5, threaded rods 1-6, and mounting plates 1- 7. Fix the box tube 1-8 and the connecting plate 1-9. There are two side plates 1-1. Both ends of the two side plates 1-1 are fixedly connected with legs 1-2, two at the left end. A crossbar 1-3 is fixedly connected between the leg 1-2 and the two legs 1-2 at the right end. There are two sliding shafts 1-4, and the two sliding shafts 1-4 are rotatably connected to the two Between the two side plates 1-1, the upper horizontal plate 1-5 is fixedly connected to the upper ends of the two side plates 1-1, the connecting plate 1-9 is fixedly connected to the lower ends of the two side plates 1-1, and the threaded rod 1- 6 is fixedly connected to the upper horizontal plate 1-5, the mounting plate 1-7 is fixedly connected to the two legs 1-2 at the right end, and the fixed box pipe 1-8 is fixedly c...

specific Embodiment approach 3

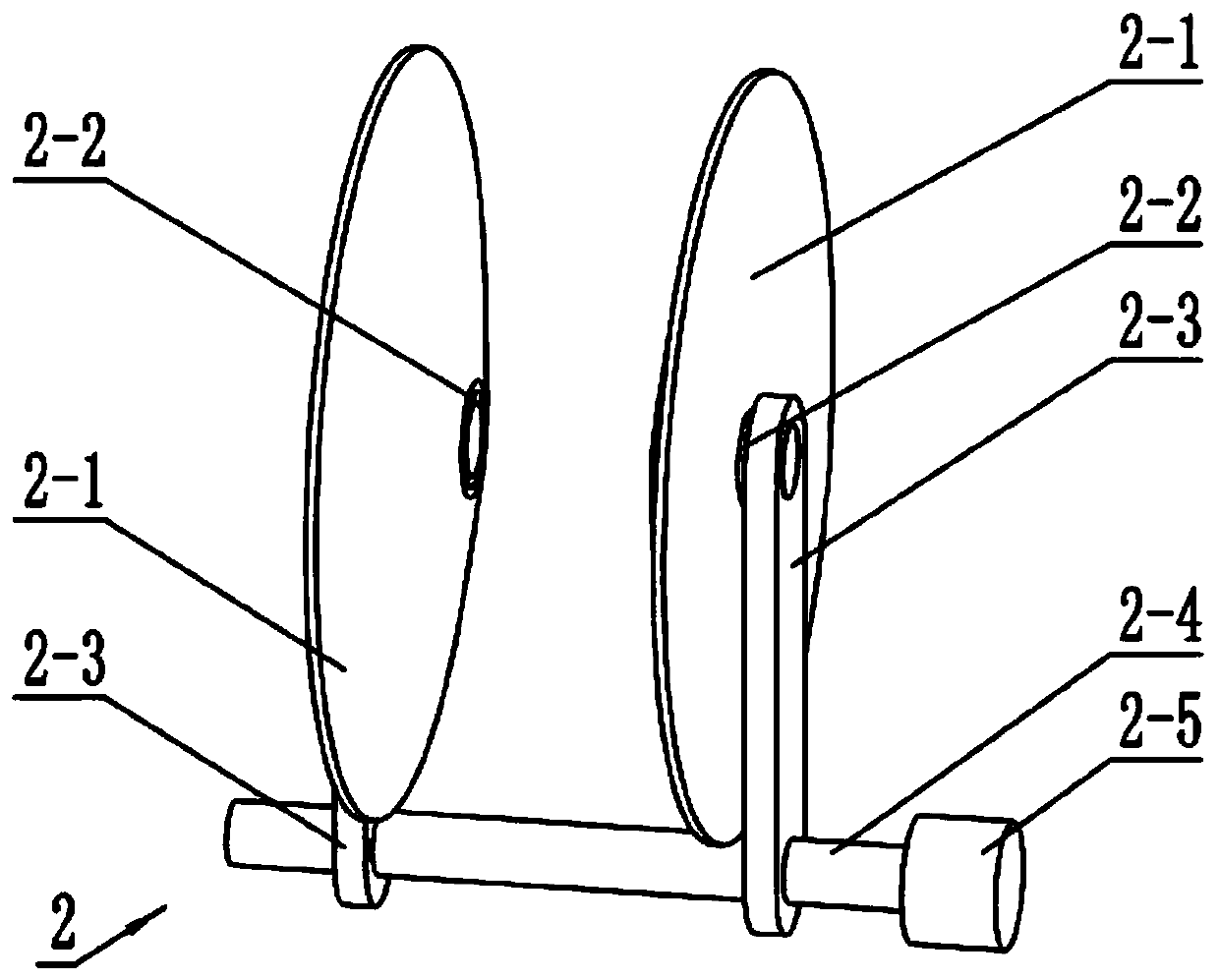

[0036] Such as Figure 1-11 As shown, the guide wheel mechanism 2 includes a tapered side wheel 2-1, a wheel sleeve 2-2, a threaded plate 2-3, a double threaded rod 2-4, and a guide wheel adjustment motor 2-5. The tapered side wheel There are two 2-1, the two tapered side wheels 2-1 are rotatably connected to the wheel sleeve 2-2, the two tapered side wheels 2-1 are arranged oppositely, and the two wheel sleeves 2-2 are both fixed Connected to the threaded plate 2-3, the two threaded plates 2-3 are connected to the two ends of the double-threaded rod 2-4 by threads, the threads of the two ends of the double-threaded rod 2-4 are opposite to each other. The output shaft of the guide wheel adjustment motor 2-5 is fixedly connected, the guide wheel mechanism 2 is provided with two, the two double threaded rods 2-4 are both rotatably connected to the two side plates 1-1, two sets of wheel sets 2-2 They are slidably connected to the two sliding shafts 1-4, and the two guide wheel ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com