Bent pipe outer polishing device

A polishing device and pipe bending technology, which is applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of complex structure, large use limitations, and slow installation process of pipe bending parts, so as to improve the polishing quality, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

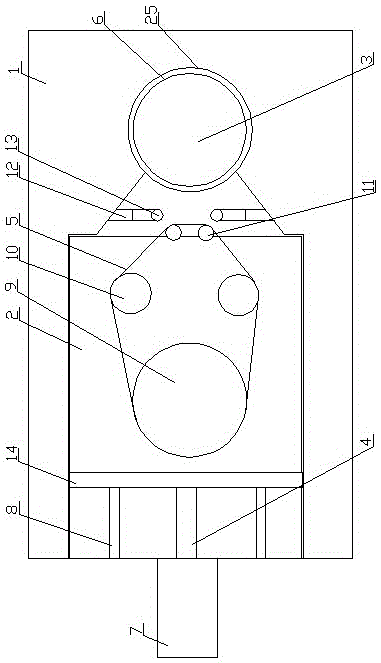

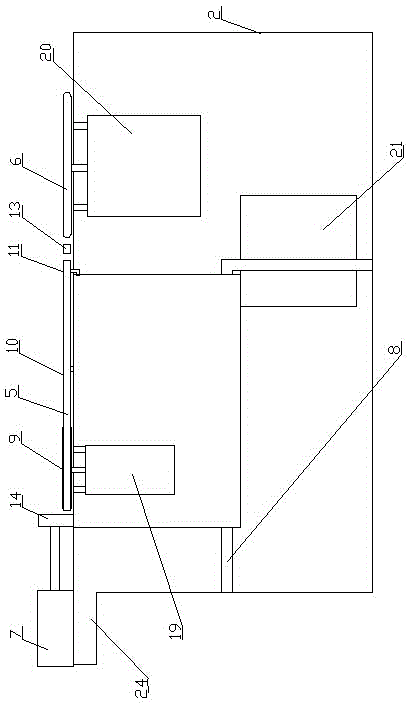

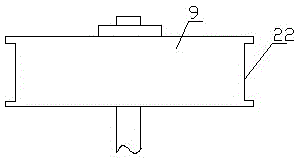

[0033] like Figure 1 to Figure 4 Shown: this embodiment provides a kind of curved pipe outer polishing device, including machine tool body 1, on which a grinding mechanism 2 and a reverse rotation mechanism 3 are arranged, and the grinding mechanism 2 includes a grinding drive mechanism and The polishing belt 5 provided on the grinding drive mechanism, the reverse rotation mechanism 3 includes a reverse drive mechanism 20 and the rotary disk 6 provided on the reverse drive mechanism 20, the polishing belt 5 is in phase with the rotary disk 6 In cooperation, the grinding mechanism 2 and the reverse rotation mechanism 3 are connected with the controller.

[0034] The grinding mechanism 2 is arranged on the machine tool body 1 through a horizontal movement mechanism 4 . The horizontal movement mechanism 4 includes a push plate 14 provided on the grinding mechanism 2, the push plate 14 is connected with the cylinder support 24 on the machine tool body 1 through the cylinder 7, a...

Embodiment 2

[0045] like Figure 1 to Figure 5 Shown: this embodiment provides a kind of curved pipe outer polishing device, including machine tool body 1, on which a grinding mechanism 2 and a reverse rotation mechanism 3 are arranged, and the grinding mechanism 2 includes a grinding drive mechanism and The polishing belt 5 provided on the grinding drive mechanism, the reverse rotation mechanism 3 includes a reverse drive mechanism 20 and the rotary disk 6 provided on the reverse drive mechanism 20, the polishing belt 5 is in phase with the rotary disk 6 In cooperation, the grinding mechanism 2 and the reverse rotation mechanism 3 are connected with the controller.

[0046] The grinding mechanism 2 is arranged on the machine tool body 1 through a horizontal movement mechanism 4 . The horizontal movement mechanism 4 includes a push plate 14 provided on the grinding mechanism 2, the push plate 14 is connected with the cylinder support 24 on the machine tool body 1 through the cylinder 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com