Abrasive for rapidly removing tampered burr and ring wear of riveted electrical contact, its preparation method and application

A technology of electrical contacts and abrasives, applied in chemical instruments and methods, machine tools suitable for grinding the edge of workpieces, grinding/polishing equipment, etc., can solve the problem of increased rivet processing costs, easy ring marks on the rivet working surface, and inability to Removal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

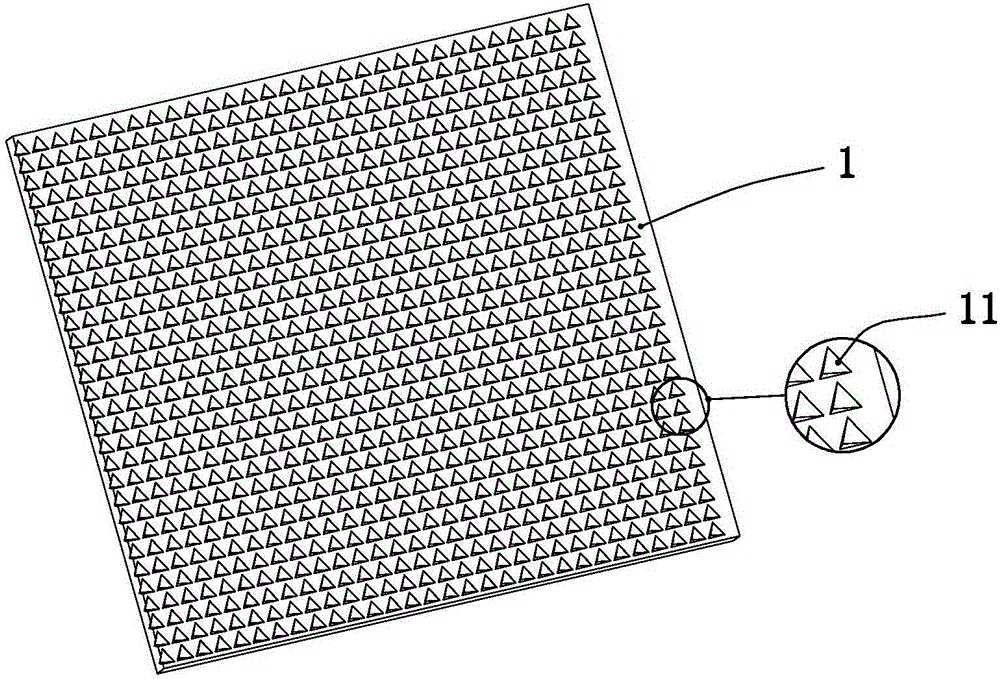

Embodiment 1

[0036] Contain mixed powder ferric oxide, ferrous oxide, magnesia, yttrium oxide, 10kg of mixed powder of zirconia, epoxy resin 15kg is placed in the blender, the epoxy resin described in the present embodiment is national designation E51 or E44, After stirring for 30 minutes, take out the colloid, put the colloid into the mold, put the mold in a refrigerator, control the temperature at 8°C, and refrigerate for 20 minutes. After taking out the mold, turn it over, pour out all 10,000 abrasives, and the side length is 15mm, the abrasive is put into the sizing agent, the sizing agent described in the present embodiment is sulfonic acid, a kind of organic acid, general formula R-SO3H, R represents hydrocarbon group, strong acidity, relatively large water solubility is arranged, is used for making dyestuff, Drugs, detergents, acidic, add water to 70%~80% of the volume of the grinding tank, put it into the centrifugal grinder, set the speed at 1200r / min, take it out after about 10min...

Embodiment 2

[0041] Put 5.9kg of ferric oxide, 2.9kg of ferrous oxide, 0.3kg of magnesia, 0.3kg of yttrium oxide, and 0.6kg of zirconia mixed powder into a total of 10kg, and place 15kg of epoxy resin with grade E44 in a mixer and stir for 10 minutes Finally, take out the colloid, put the colloid in the mold, put the mold in a refrigerator, control the temperature at 8°C, and refrigerate for 20 minutes. After taking out the mold, turn it over, pour out all 10,000 abrasives, and the side length is 12mm. Put the abrasive into the sizing agent, add water to the position of 70%~80% of the volume of the grinding tank, put it into the centrifugal grinder, set the speed at 1200r / min, take it out after about 10min, rinse and separate the product. Dry the product containing burrs and ring marks and put it into a vacuum furnace for annealing, set the temperature at 400°C, keep it for about 50 minutes, and then follow the furnace to room temperature and take it out. Use dilute sulfuric acid to pickle...

Embodiment 3

[0043]Put 6.1kg of ferric oxide, 3.1kg of ferrous oxide, 0.2kg of magnesia, 0.2kg of yttrium oxide, and 0.4kg of zirconia mixed powder into a total of 10kg, and place 15kg of E51 epoxy resin in a mixer and stir for 15 minutes Finally, take out the colloid, put the colloid in the mold, put the mold in a refrigerator, control the temperature at 5°C, and refrigerate for 15 minutes. After taking out the mold, turn it over, pour out all 10,000 abrasives, and the side length is 15mm. Put the abrasive into the sizing agent, add water to the position of 70%~80% of the volume of the grinding tank, put it into the centrifugal grinder, set the speed at 1200r / min, take it out after about 12min, rinse and separate the product. Dry the products containing burrs and ring marks and put them into a vacuum furnace for annealing. The temperature is set at 350 ° C, and the temperature is kept for about 60 minutes. After that, it is taken out with the furnace to room temperature. Use dilute sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com