A bamboo strip grinding device for processing bamboo weaving handicrafts

A technology for processing devices and handicrafts, applied in the direction of grinding/polishing safety devices, metal processing equipment, machine tools suitable for grinding the edge of workpieces, etc. Grinding and other problems on the surface of the strip to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

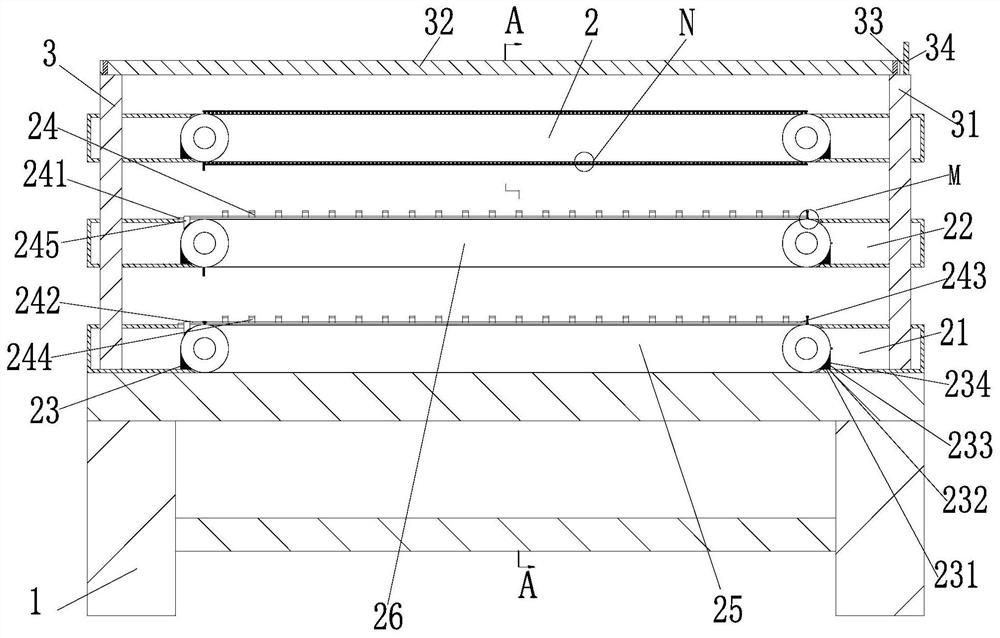

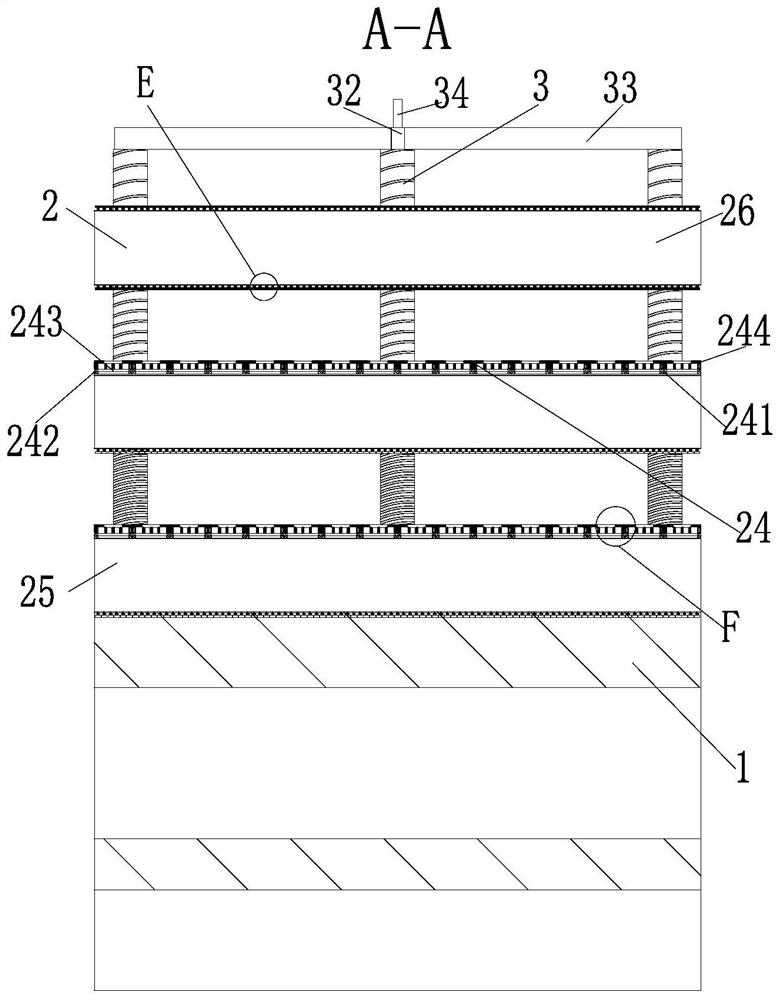

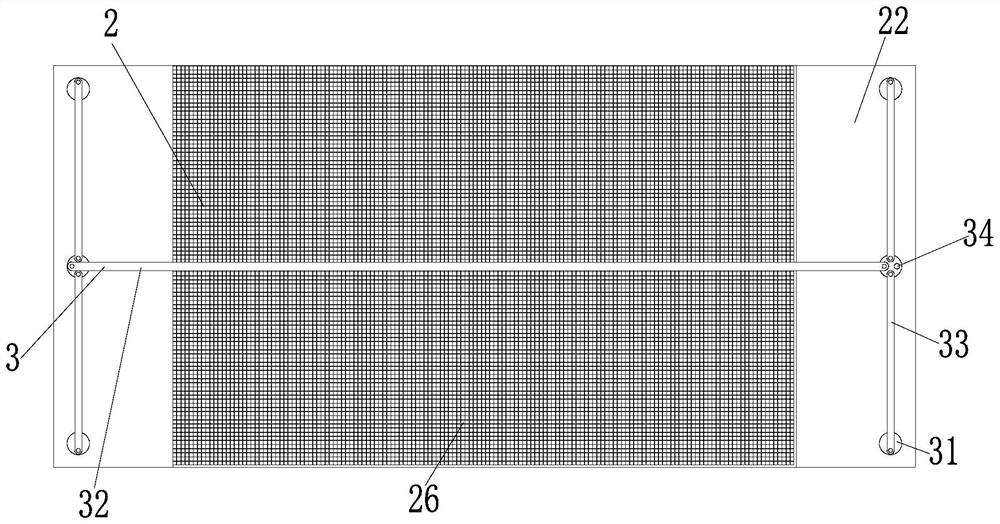

[0033]In order to make the technical means, the creation of the present invention, the purpose and energy is easy to understand, the following combinationsFigure 1 to 8Further, the invention is further illustrated.

[0034]A bamboo strip grinding device for processing for bamboo artwork, including a table 1, a processing apparatus 2 and a regulating apparatus 3, and the upper end of the working table 1 is fixedly mounted, and the upper end of the processing device 2 is mounted in the upper end; therein:

[0035]The processing apparatus 2 includes a fixing frame 21, a fixing frame 2 22, a cleaning plate 23, a clamping frame 24, a belt conveyor, one 25, and a belt conveyor 26, a table 1, and a fixed frame one is fixedly mounted. 21, the plurality of fixing frame 2 22 are vertically uniformly disposed on the upper end of the fixing frame 21, and the mounting frame 21 is opened in the middle of the mounting frame 2 22, and the rectangular vias are sided to have a cleaning plate 23 on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com