Bidirectional clamping and damping brake disc grinding mechanical equipment

A technology of mechanical equipment and brake discs, which is applied in the field of auto parts processing, can solve the problems of high operation requirements for grinding personnel, complicated grinding process, flying out, etc., and achieve the effect of convenient and fast clamping operation and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

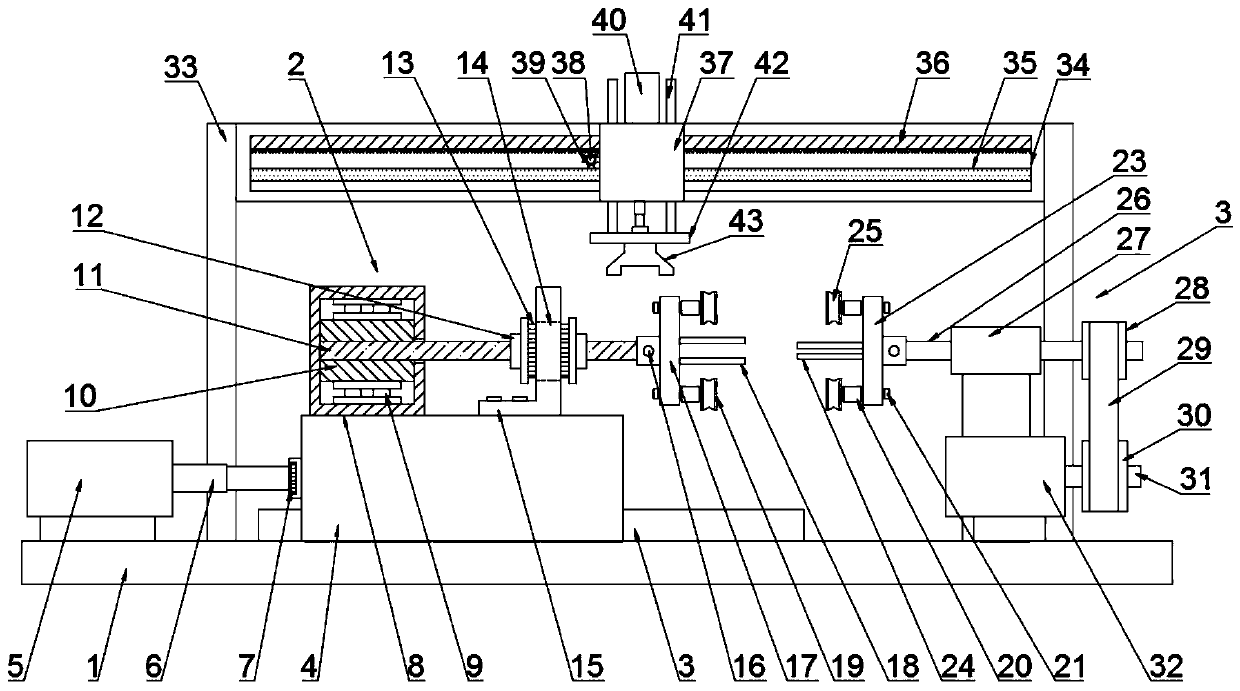

[0031] see Figure 1 to Figure 5 , a brake disc grinding mechanical equipment with two-way clamping and shock absorption, comprising a workbench 1, a sliding clamping mechanism 2, a fixed clamping mechanism 22 and a grinding mechanism, the sliding clamping mechanism 2 and the fixed clamping mechanism are arranged above the workbench 1 The clamping mechanism 22 and the grinding mechanism are arranged above the sliding clamping mechanism 2 and the fixed clamping mechanism 22. When the brake disc is polished, the sliding clamping mechanism 2 and the fixed clamping mechanism 22 are clamped on the brake disc in two directions. Both sides of the disc, and the grinding mechanism grinds the side of the brake disc to achieve the purpose of grinding the brake disc.

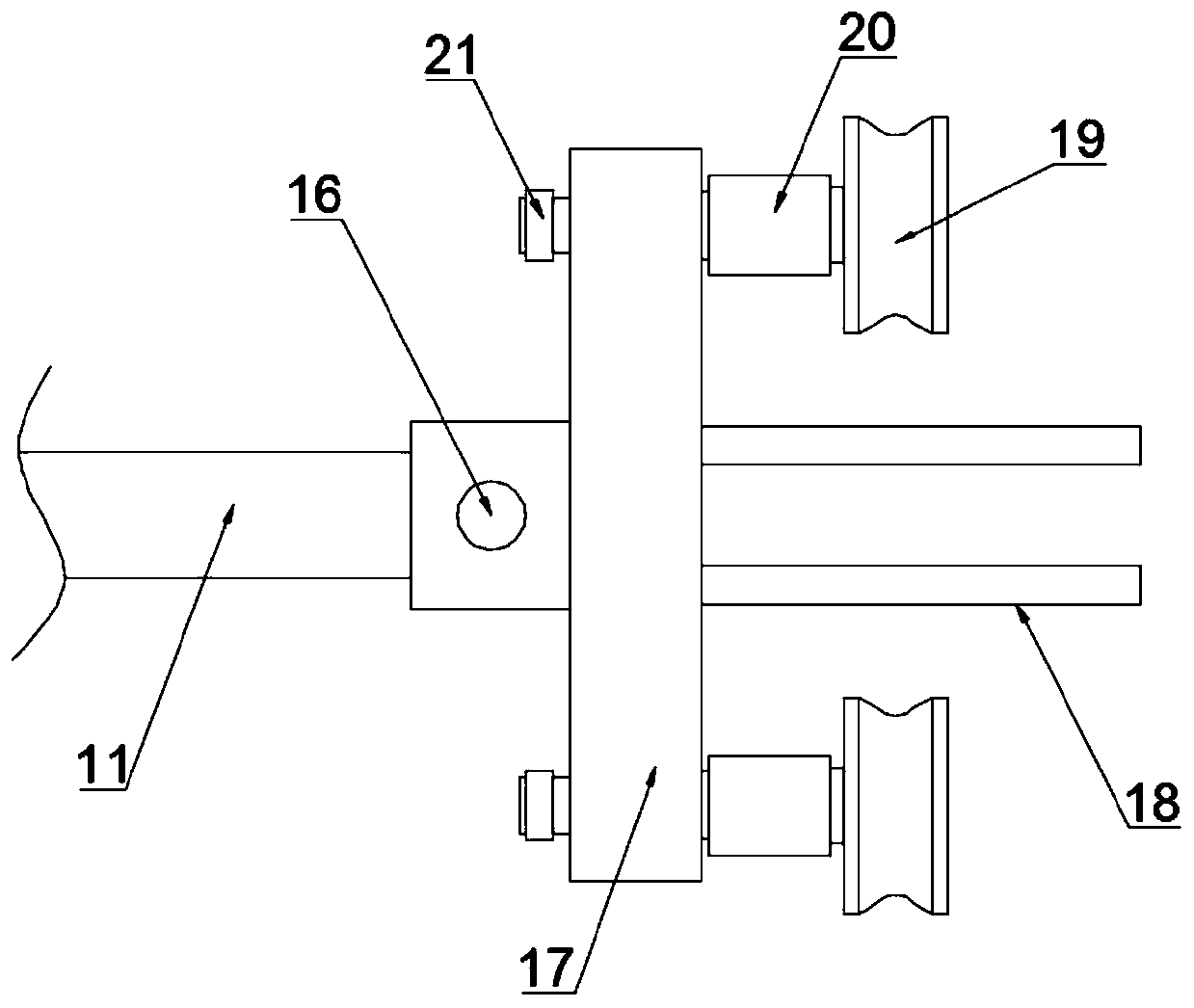

[0032] The sliding clamping mechanism 2 includes a transverse slide rail 3, a transverse slide seat 4, a driving cylinder 5, a rotating cylinder 8, a spline shaft 11, a fixed frame 15, a follower seat 17, a follower pin 18 ...

Embodiment 2

[0047] see Figure 2 ~ Figure 6 , a brake disc grinding mechanical equipment with two-way clamping and shock absorption, comprising a workbench 1, a sliding clamping mechanism 2, a fixed clamping mechanism 22 and a grinding mechanism, the sliding clamping mechanism 2 and the fixed clamping mechanism are arranged above the workbench 1 The clamping mechanism 22 and the grinding mechanism are arranged above the sliding clamping mechanism 2 and the fixed clamping mechanism 22. When the brake disc is polished, the sliding clamping mechanism 2 and the fixed clamping mechanism 22 are clamped on the brake disc in two directions. Both sides of the disc, and the grinding mechanism grinds the side of the brake disc to achieve the purpose of grinding the brake disc.

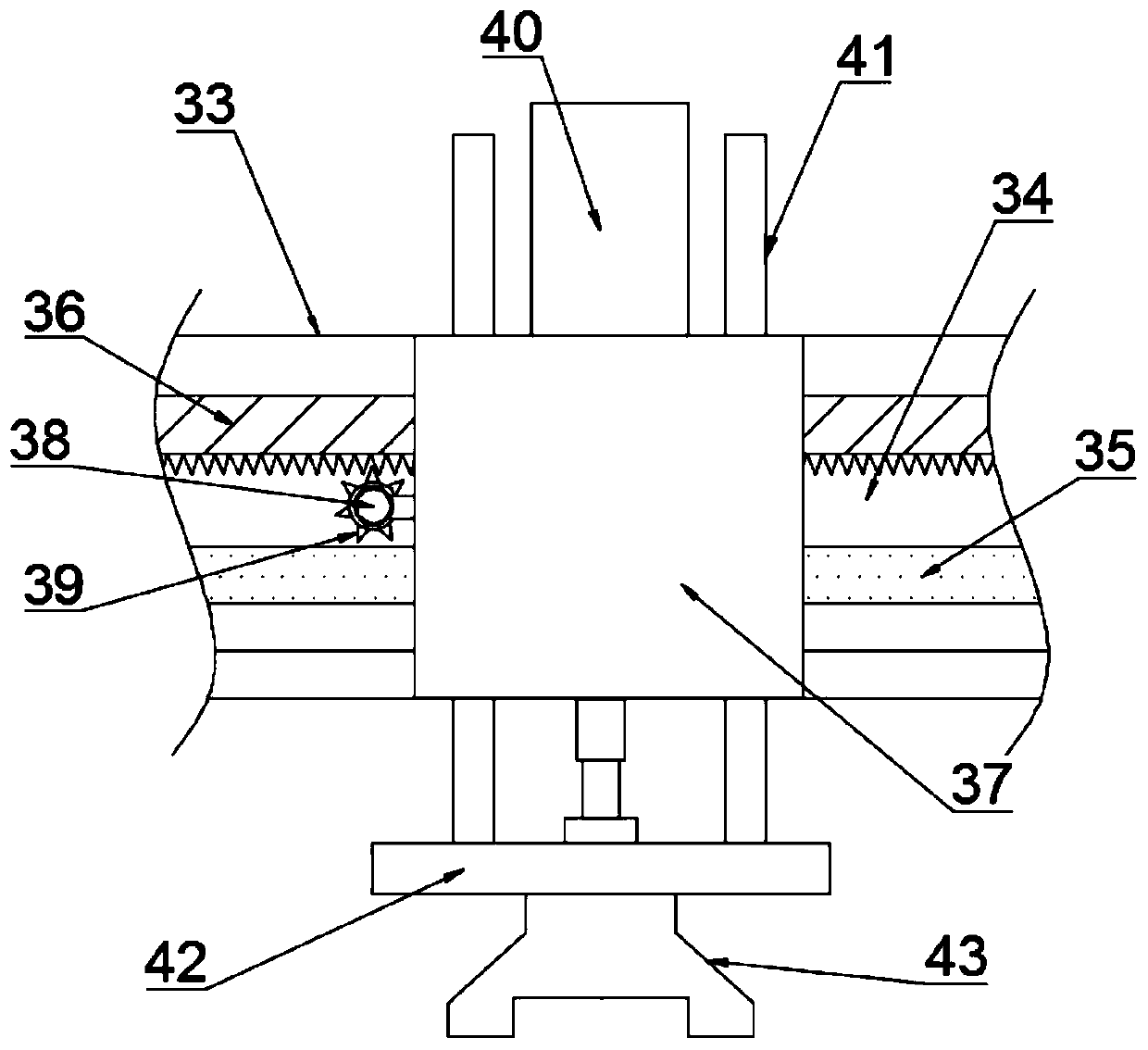

[0048] The grinding mechanism includes a gantry 33, a transverse slider 37, a grinding seat 42, and a grinding tool 43. In this embodiment, the structural parts of the workbench 1, the sliding clamping mechanism 2 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com