Patents

Literature

136results about How to "Guaranteed grinding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

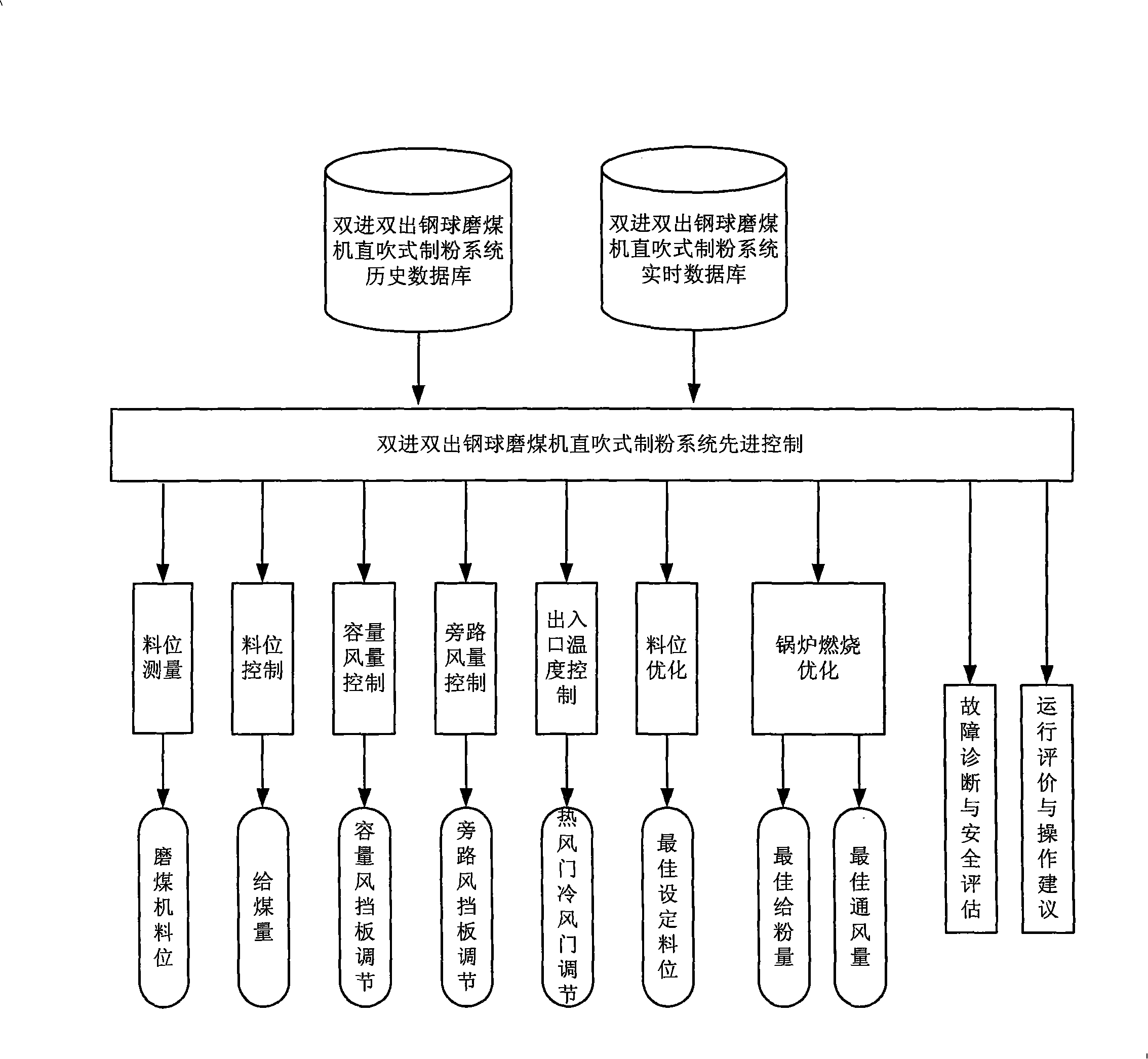

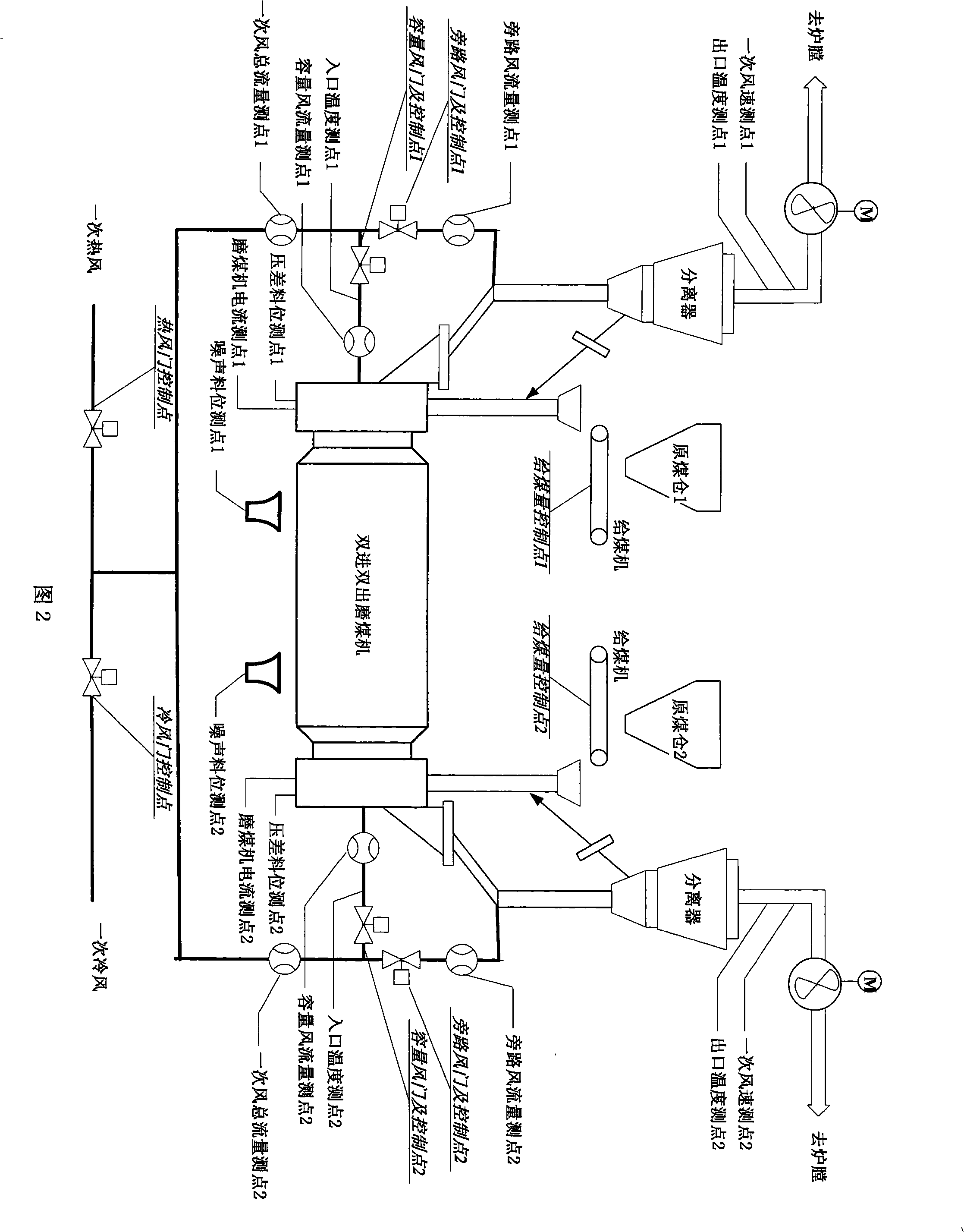

Double-inlet double-outlet steel ball coal mill straight blowing type milling system optimized control method

ActiveCN101334666AImprove combustion efficiencyGuaranteed uniformityGrain treatmentsProgramme total factory controlTemperature controlCombustion

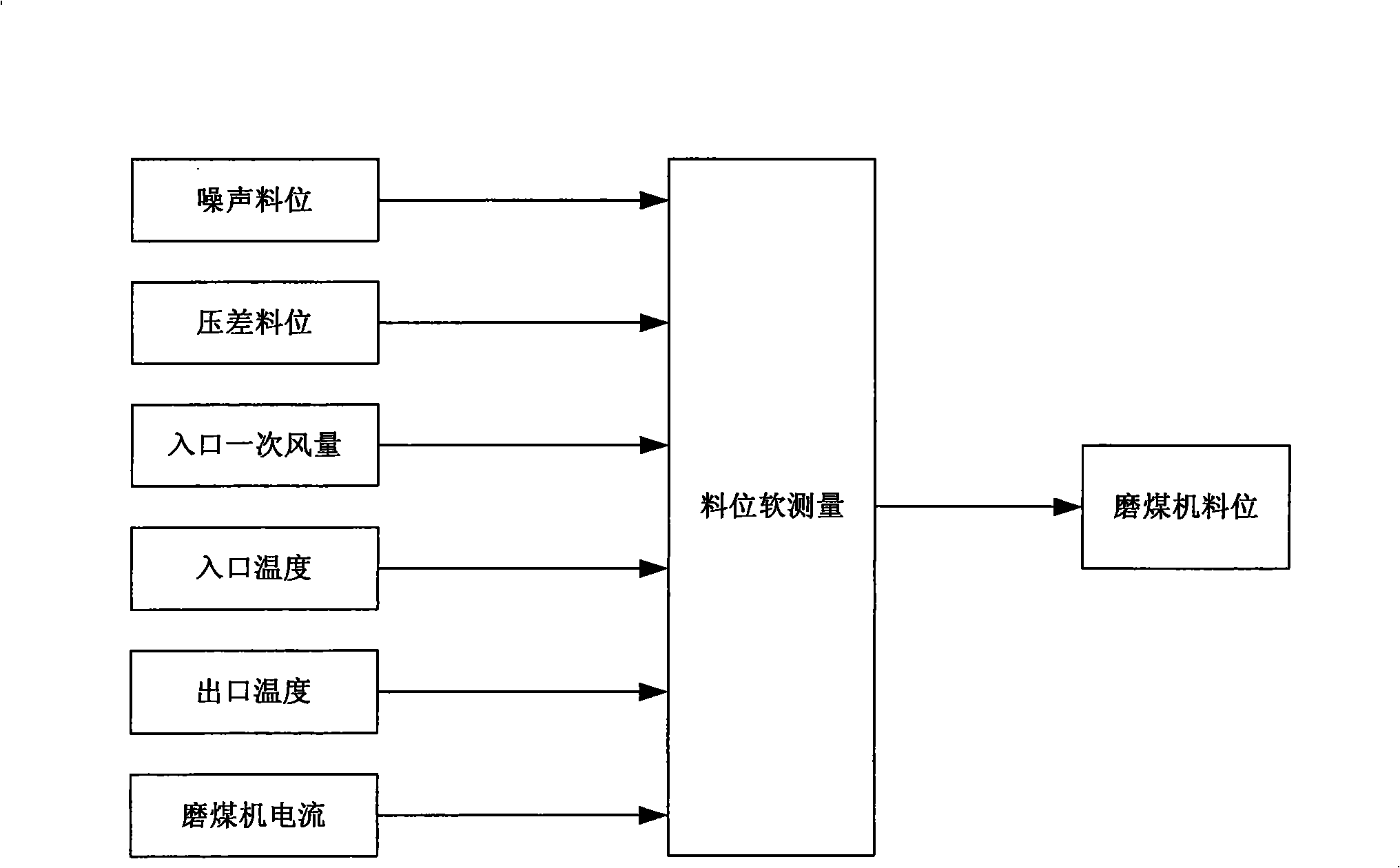

The invention discloses an optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method. The method obtains the material position of the coal grinding machine after carrying out soft-measurement processing by collecting the noise material position of the coal grinding machine, the material position of pressure difference, the current of the coal grinding machine, one-time air quantity, one-time opening of the hot wind door and the cold wind door of an inlet, inlet temperature and outlet temperature; the control comprises material position control, air quantity capacity control, bypass air quantity control and the temperature control of the inlet and the outlet; the material position is optimized and the best material position of the coal grinding machine is searched online so as to ensure the combustion safety of the boiler and coal powder supply quantity when the load of the boiler is adjusted. The boiler combustion is optimized: according to the boiler technology, the load and the running working conditions, the powder supply quantity and the ventilation quantity of each coal grinding machine are optimized and the combustion efficiency of the boiler is improved. Malfunction diagnosis, running evaluation and analysis are carried out to the system and reasonable suggestions are provided so as to ensure the system to run continuously, stably, safely and economically; the optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method is widely applied to the dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation system or industrial similar systems in other industries.

Owner:西安蓝海机械仪表成套有限责任公司

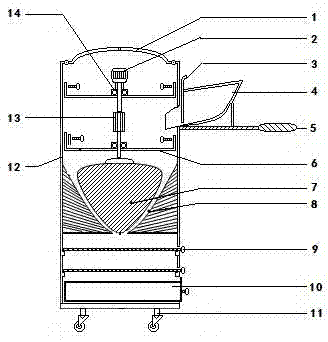

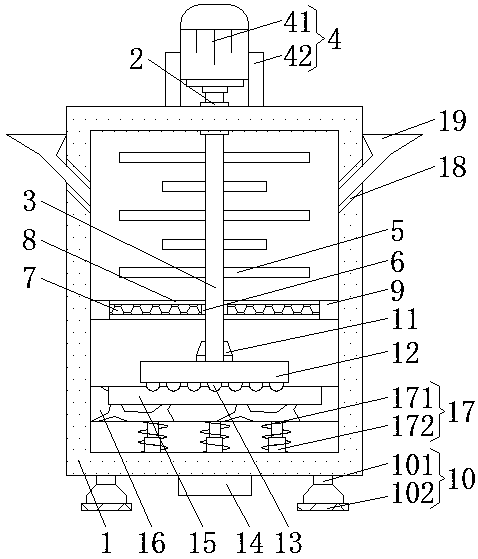

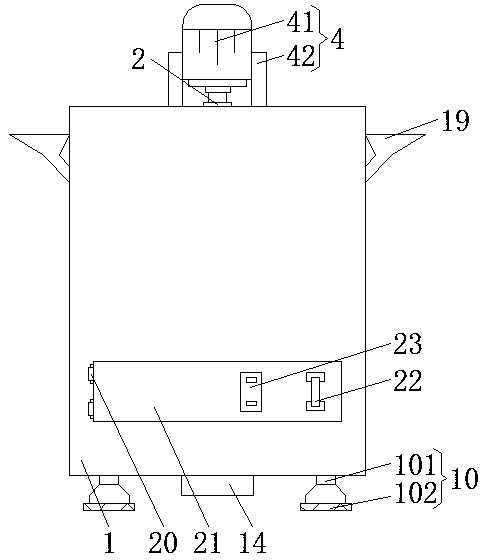

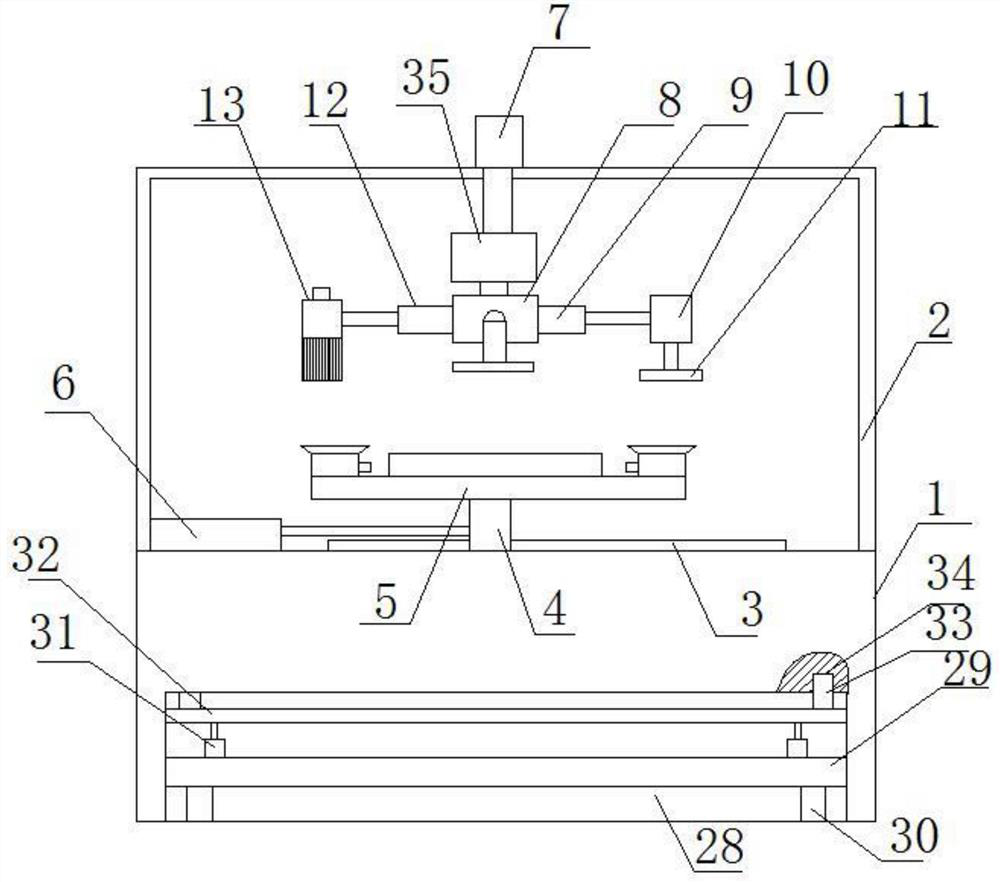

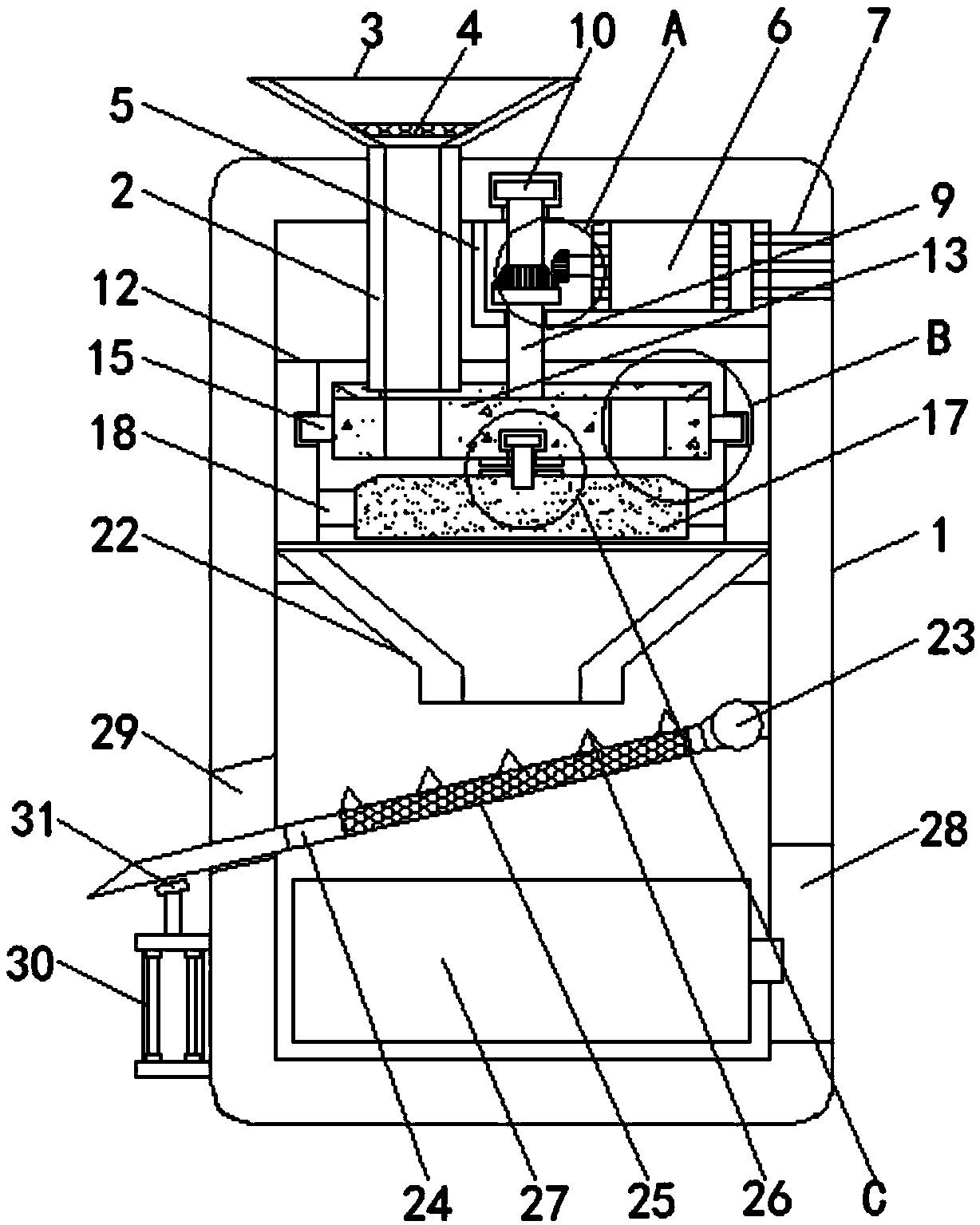

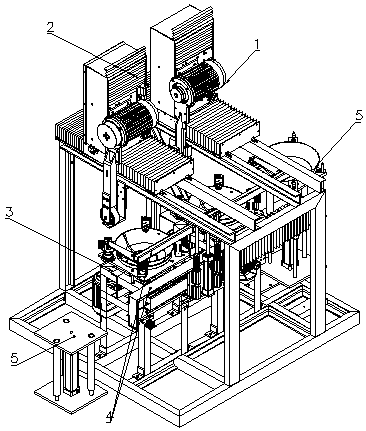

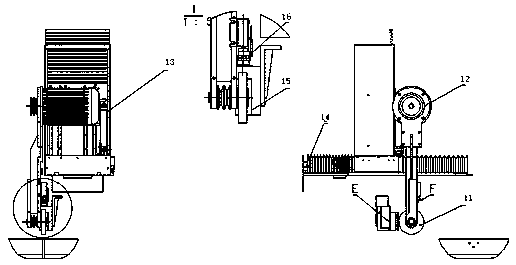

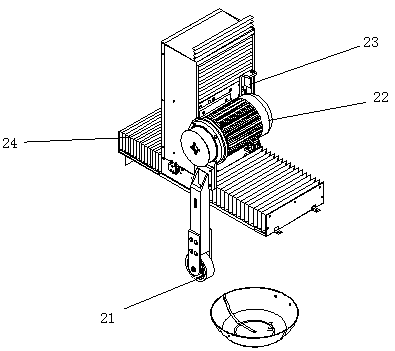

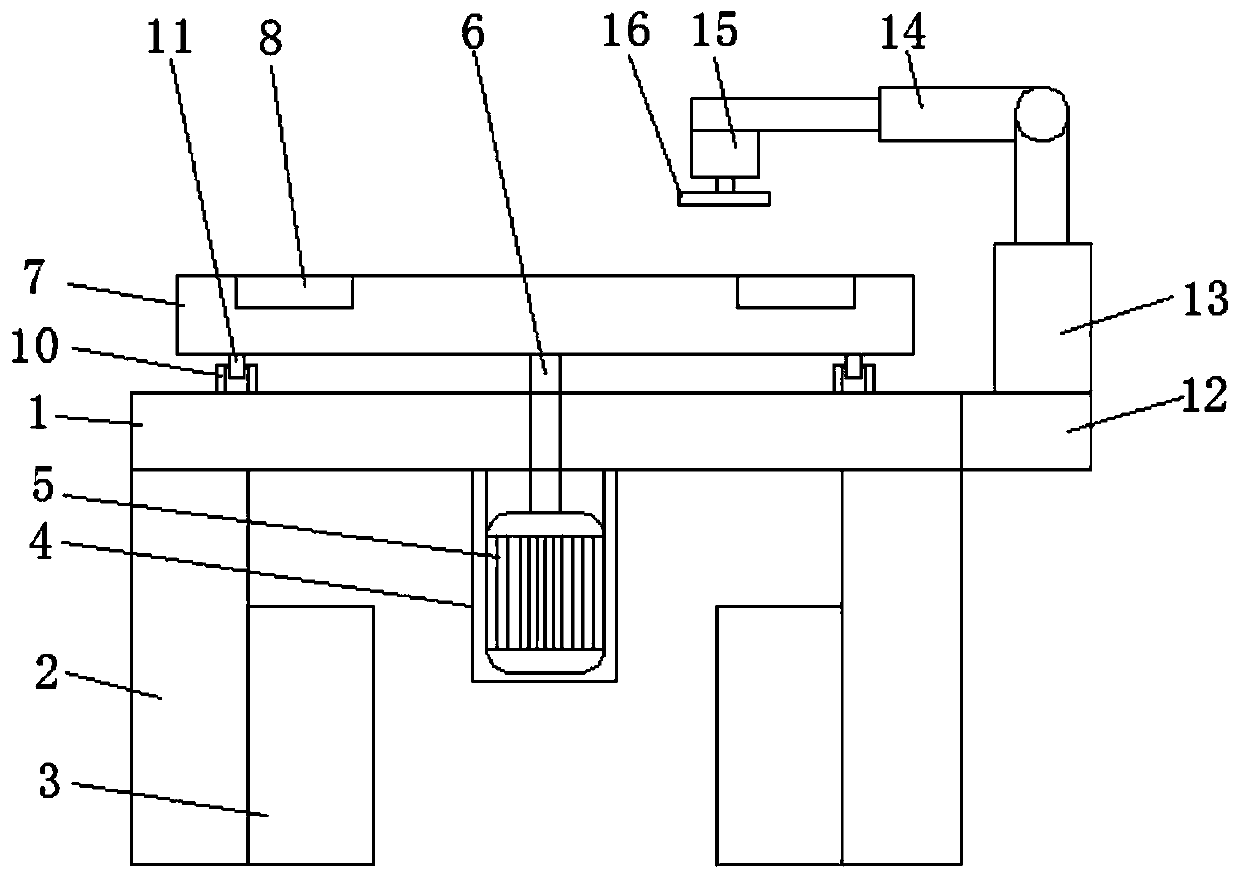

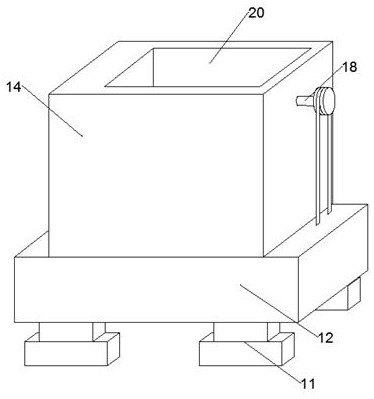

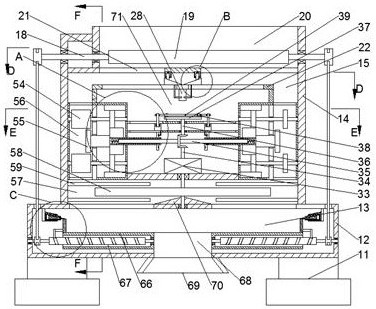

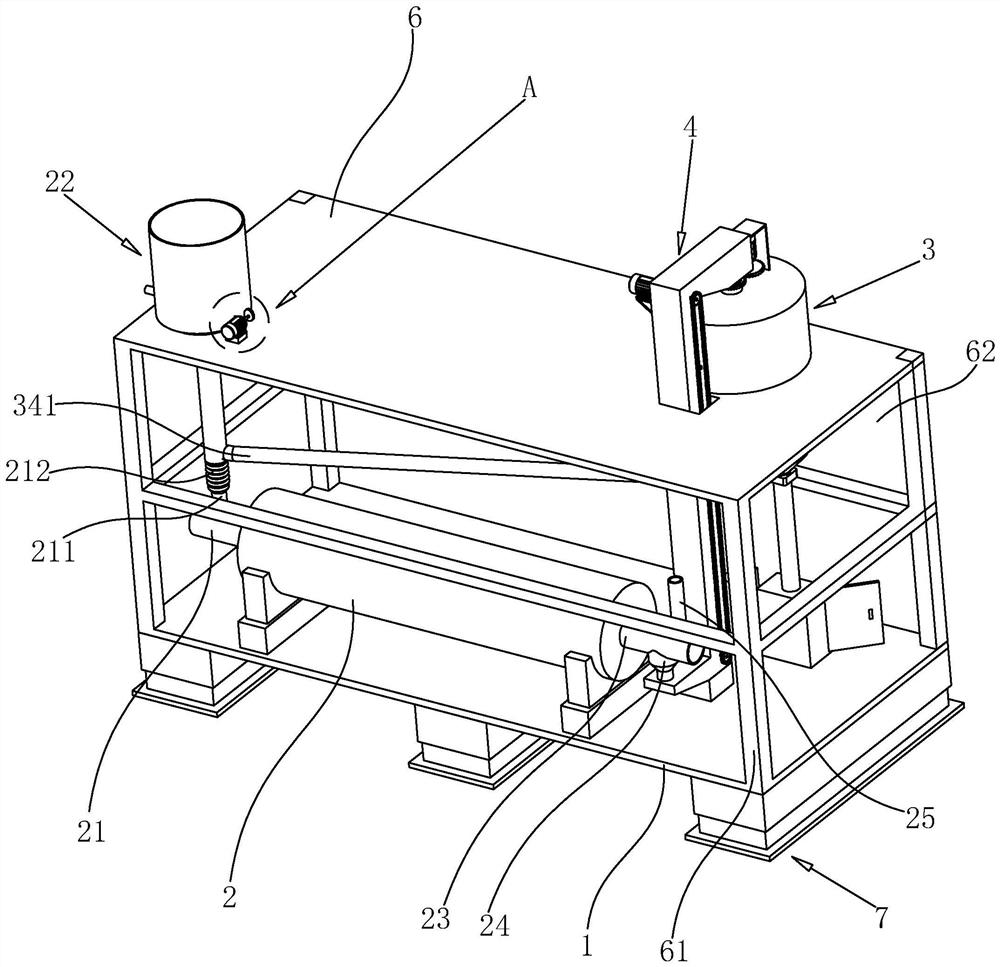

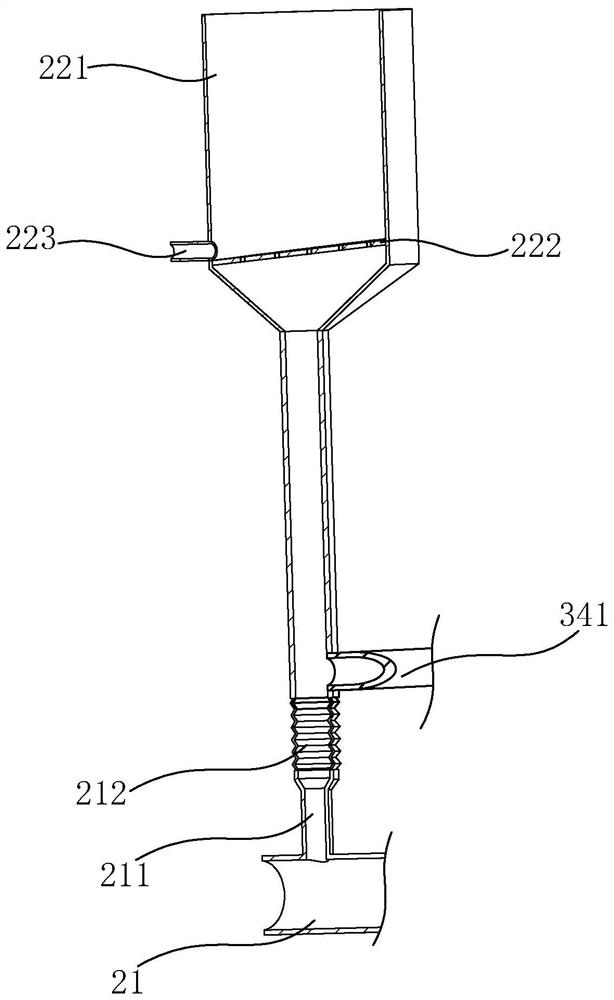

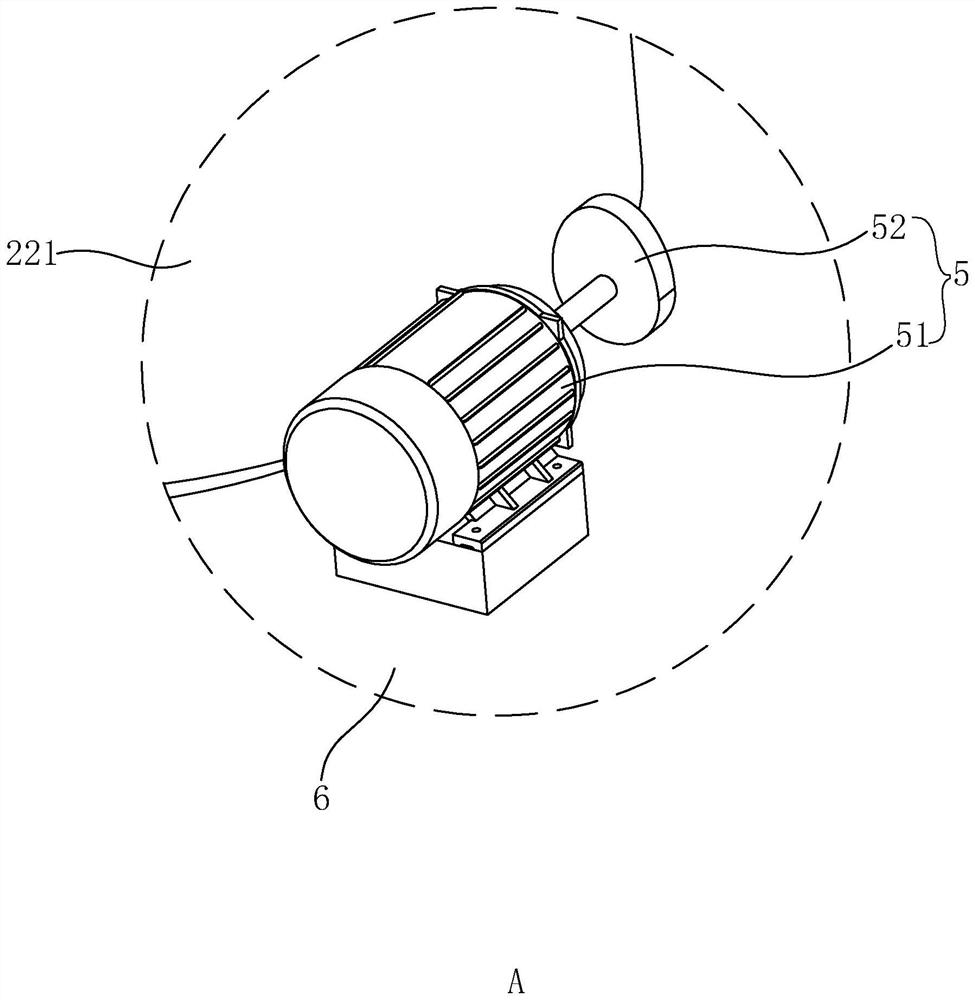

Soil analysis sample screening-grinding movable all-in-one machine

ActiveCN103487301AReduce workloadLow pricePreparing sample for investigationSoil scienceAgricultural engineering

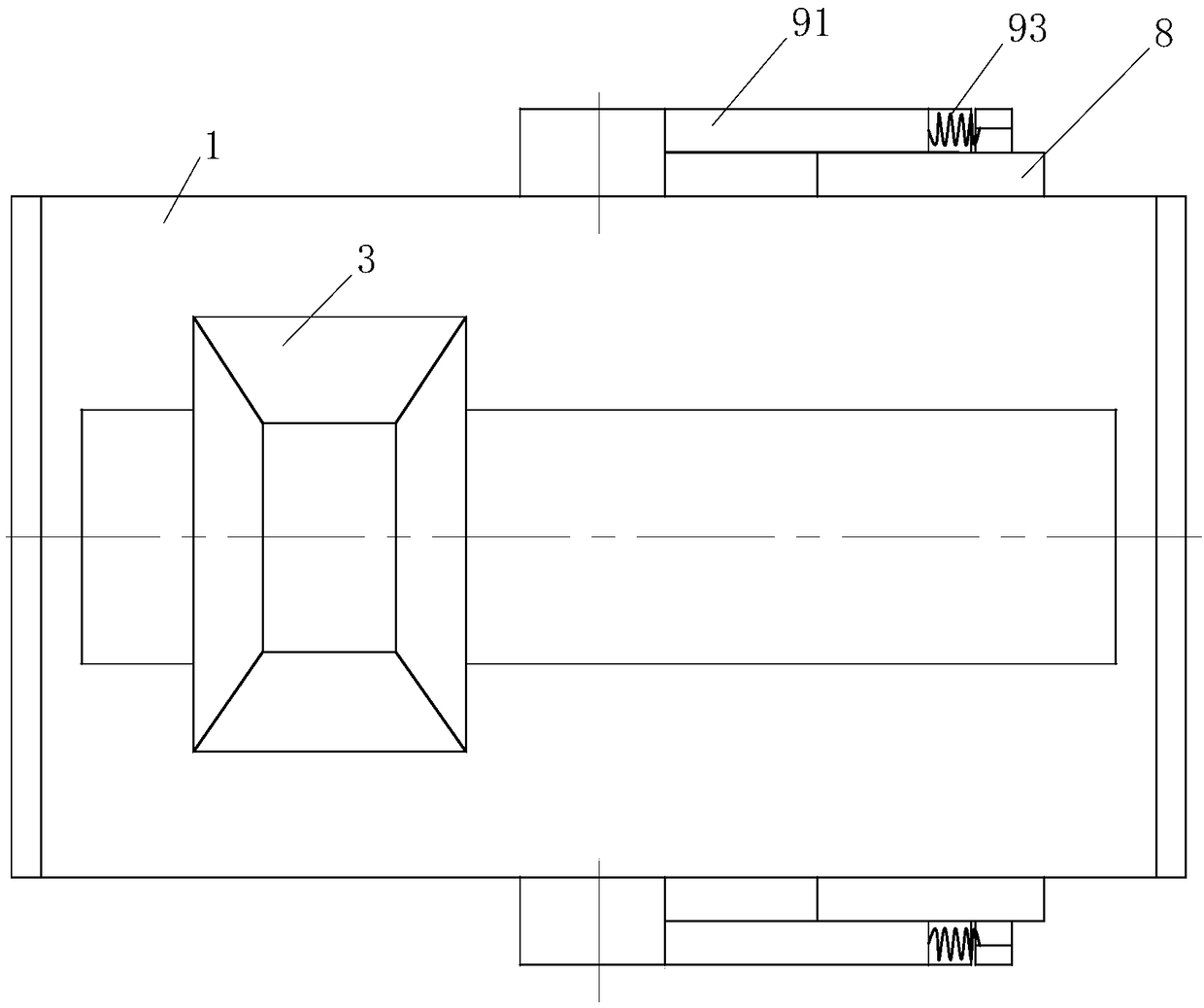

The invention relates to the technical field of soil sample screening-grinding equipment, particularly to a soil analysis sample screening-grinding movable all-in-one machine for laboratory analysis. The technical scheme of the machine is that the movable all-in-one machine includes a machine body, a feeding treatment system, a grinding system and a classified screening system, wherein the machine body is formed by a cuboid box body; a feeding treatment system is arranged at the upper part of the side wall of the box body; the classified screening system is positioned at the middle lower part of the box body; the grinding system is positioned at the middle upper part of the box body and is arranged in the middle part. Tests show that the all-in-one machine can one-step pulverize soil into particles not larger than 2 mm in diameter and counting for 85% above, and one-step pulverize soil into particles not larger than 0.15 mm in diameter and counting for 65% above, and the screening yield is 100%. The machine has the advantages that the obtained materials are common, the operation is simple, high quality and efficiency are realized, no pollution to a soil sample is caused, and the result is reliable.

Owner:FUJIAN NORMAL UNIV

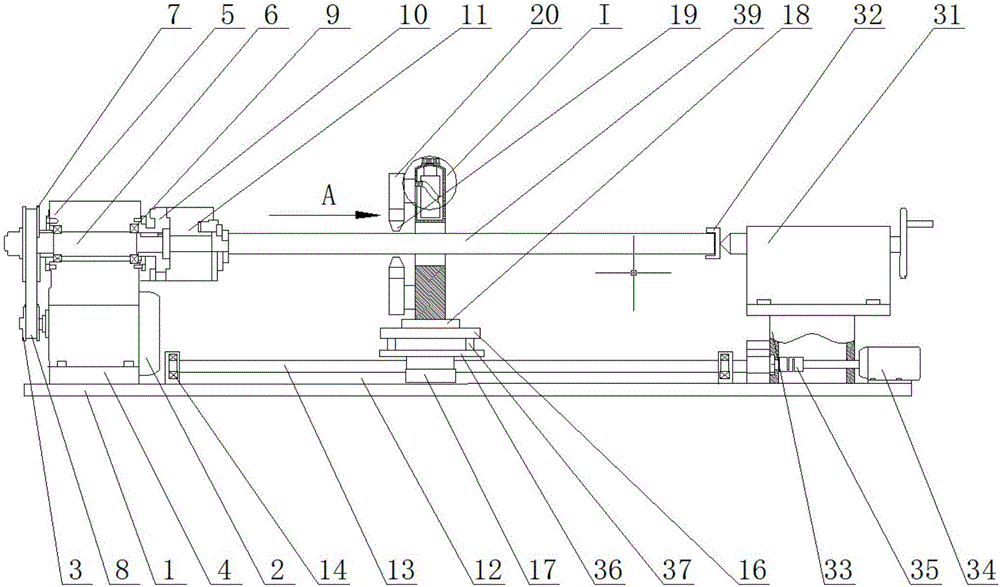

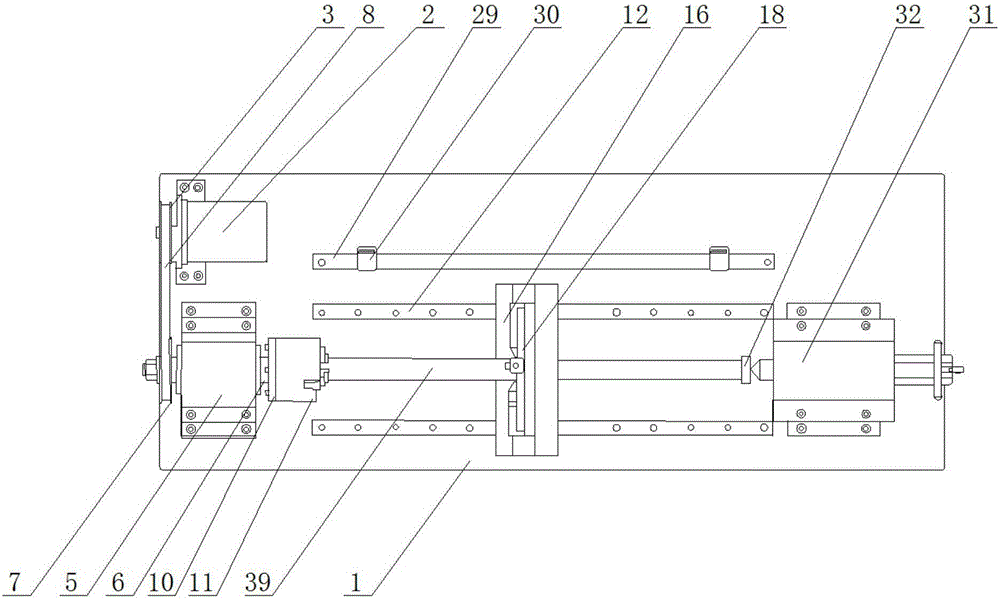

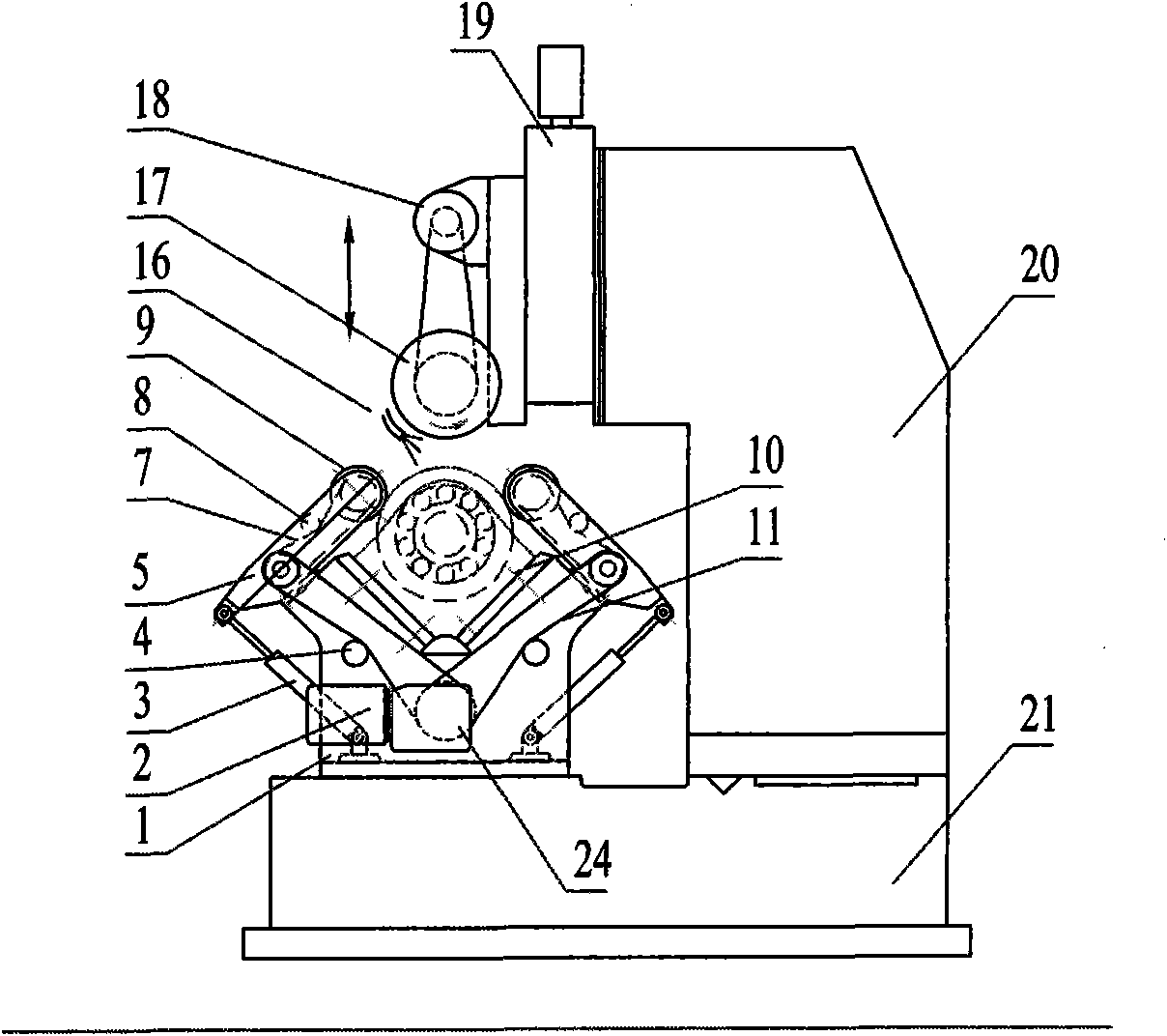

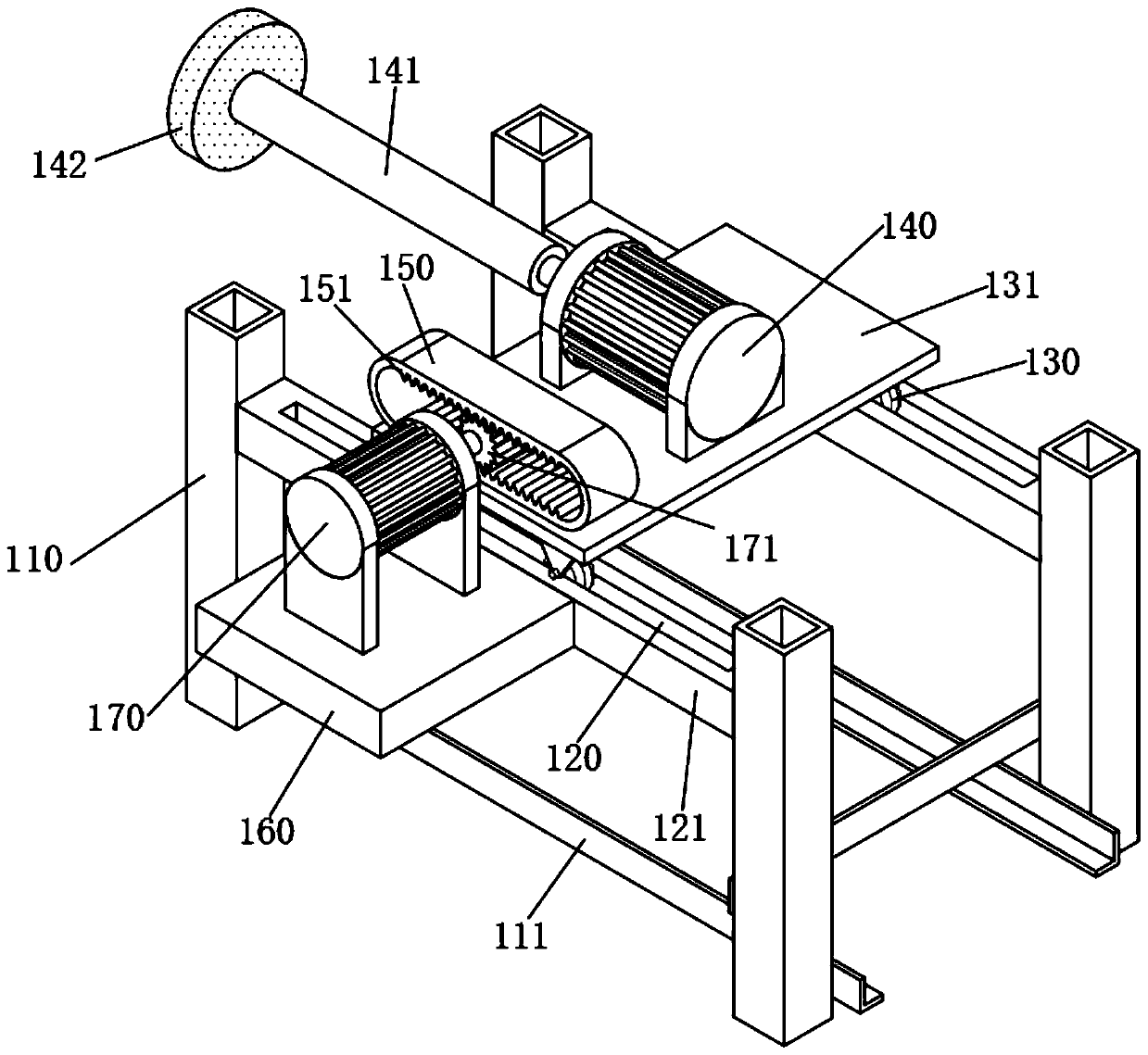

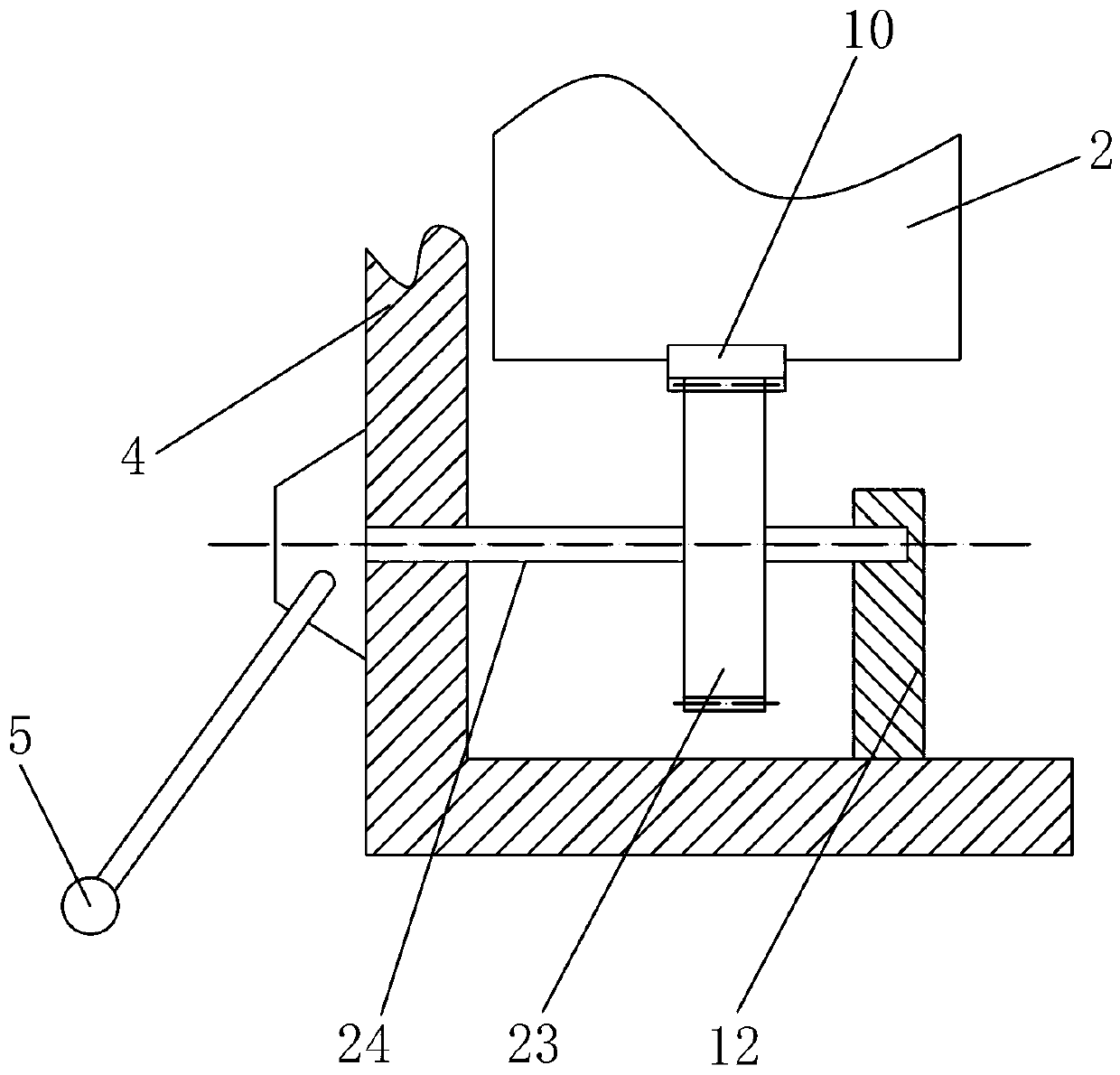

Automatic precision grinding device for outer surfaces of shaft type workpieces

InactiveCN106826403AEasy to operateLow costRevolution surface grinding machinesGrinding drivesDrive wheelCoupling

The invention discloses an automatic precision grinding device for the outer surfaces of shaft type workpieces and relates to the technical field of magnetic grinding. The device comprises a baseplate, a heel block, a driving wheel, a driven wheel, a transmission belt, a main shaft end cover, a first transmission box, a positioning seat, a flange plate, a three-jaws self-centering chuck, a grinding device, a connecting block, a grinding support base, a workpiece positioning base, a tailstock, a second motor, a coupling, a screw positioning seat, a screw, a supporting plate, a nut, a sensor positioning seat, a limit sensor, a slide way, the nut and a sliding block. A punched hole is formed in the top and / or the side of the grinding support base, a cylindrical cam is arranged on a connecting rod, the cylindrical cam is provided with a rotating rod, the grinding support base is provided with an arc block, a rotary knob is installed on the arc block, and the rotating rod is sleeved with the rotary knob. The automatic precision grinding device for the outer surface of shaft type workpieces has the beneficial effects that the device is simple in operation, low in cost, capable of adapting to shaft type workpieces of different specifications , capable of improving the machining efficiency and capable of improving the precision and quality of the outer surface of the shaft workpieces.

Owner:NANJING INST OF RAILWAY TECH

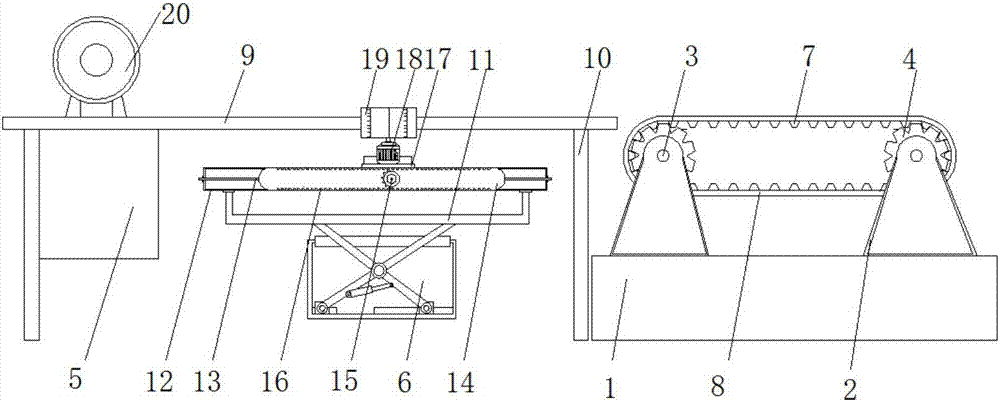

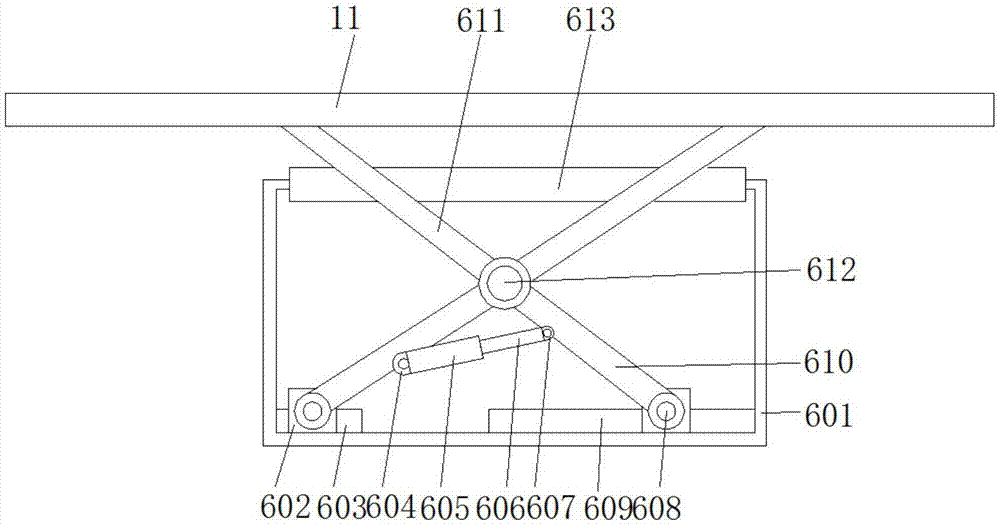

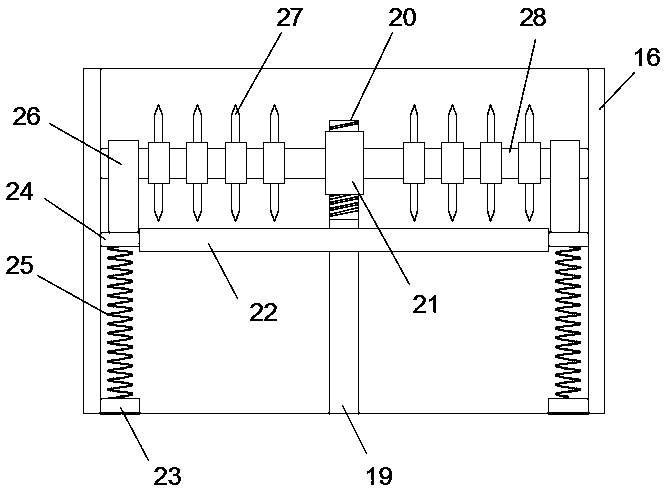

Automatic grinding machine for wood board processing

InactiveCN107263238AAchieve the purpose of moving up and downRealize moving up and downPlane surface grinding machinesEngineeringPulp and paper industry

The invention discloses an automatic grinding machine for wood board processing. The automatic grinding machine comprises a fixed installation base platform, wherein conveyor belt installation racks are fixedly connected to the top of the fixed installation base platform; a rotating shaft is rotatably connected to the top end of each of the conveyor belt installation racks; each of the rotating shafts is fixedly connected with a gear through a flat key; the gears are meshed and connected with a conveyor belt through a transmission toothed rack; a working platform is arranged on the left side of the fixed installation base platform; a grinding machine lifting device is arranged on one side of the inner wall of the working platform; and an up-down moving device is arranged at the position corresponding to the part below the middle of the working platform. The automatic grinding machine for wood board processing relates to the technical field of processing machinery. According to the automatic grinding machine for wood board processing, the following problems are solved: wood boards with different thicknesses can be ground by the grinding machine, the grinding quality and grinding efficiency are ensured, the production efficiency is improved, the production cost is reduced, the grinding efficiency and grinding quality are ensured through a reciprocating device, wood boards are prevented from improper grinding, and the life and property safety of workers is further ensured.

Owner:安吉县瑞旺竹木制品厂

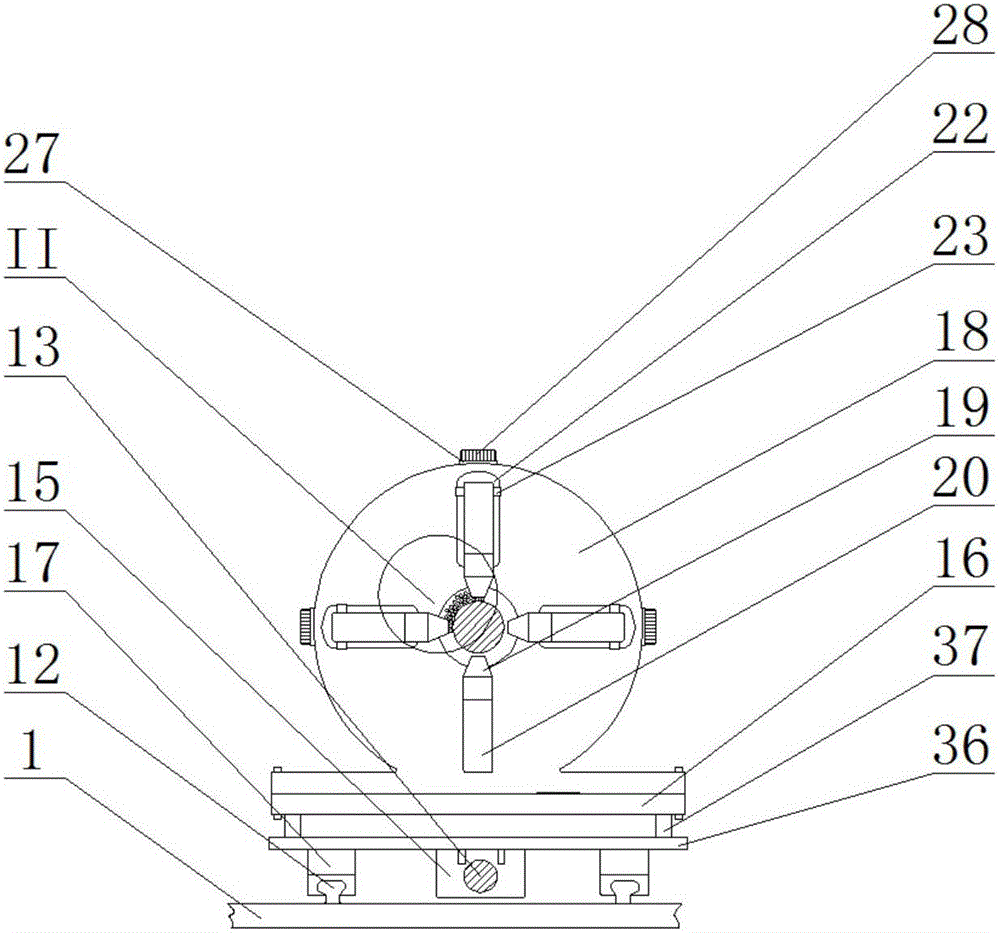

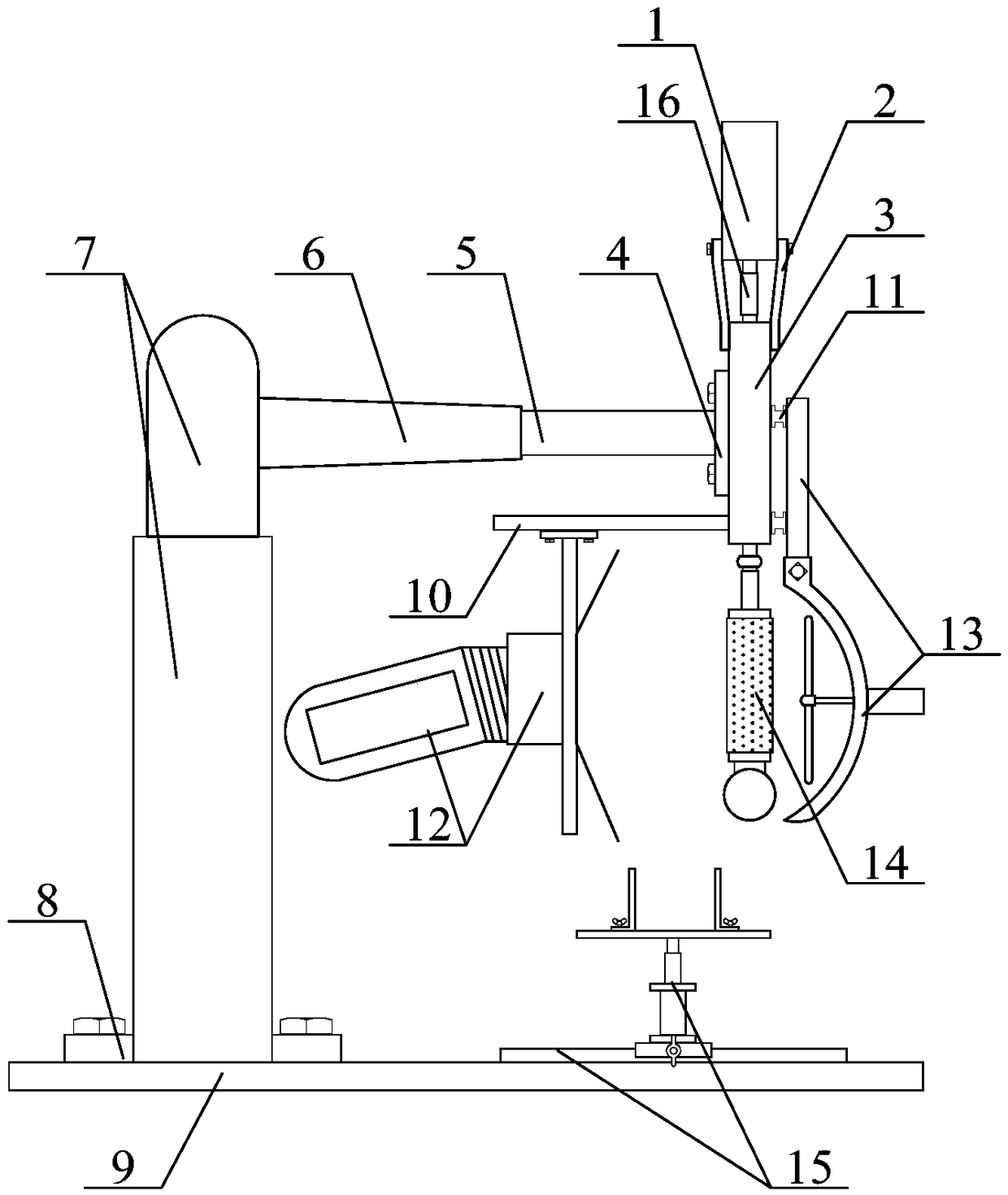

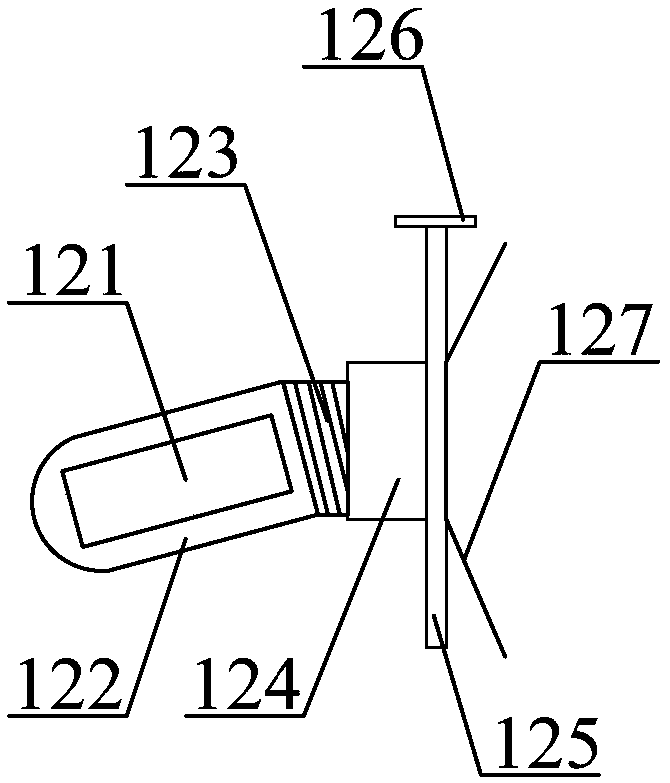

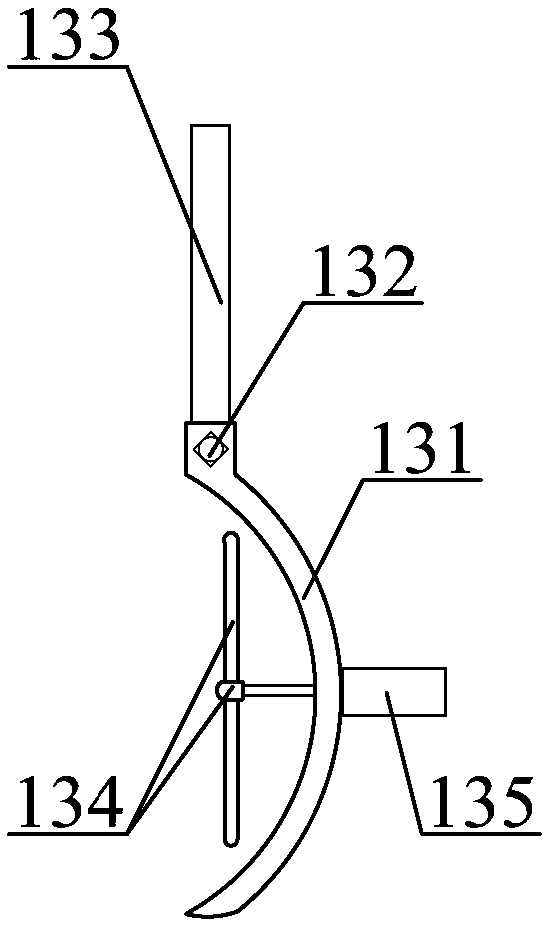

Multifunctional robot polishing equipment

ActiveCN108655911ATimely collectionAdd collection functionGrinding carriagesGrinding machinesCouplingEngineering

The invention provides multifunctional robot polishing equipment. The multifunctional robot polishing equipment comprises a polishing motor, a fixed plate, a fixed sleeve, a connecting plate, a robotpower arm, a robot extension arm, an ER50-3200 six-axle robot, a fixed clamping base, a base, a support plate, an I-shaped frame, a waste chip and dust collecting environmental-protection barrel structure, an adjustable dust and waste chip blowing machine structure, a quick polishing replacement rod structure, a height-adjustable clamping plate structure and a sleeve coupling. Through arrangementof a collecting barrel, a metal hose, a dust guide pipe, a joint base, a support lining base and a dust guide hopper, dust and waste chips generated by polishing are timely collected, the collecting function is added, the pollution is prevented, and the environment is protected; through arrangement of a transparent piece, the collecting condition of the dust and the waste chips in the collecting barrel can be timely determined to achieve replacement or cleaning; and through arrangement of fan blades and a blowing motor, the waste chips and the dust generated by polishing are timely blown out to guarantee the polishing efficiency.

Owner:柳州中科机器人自动化股份有限公司

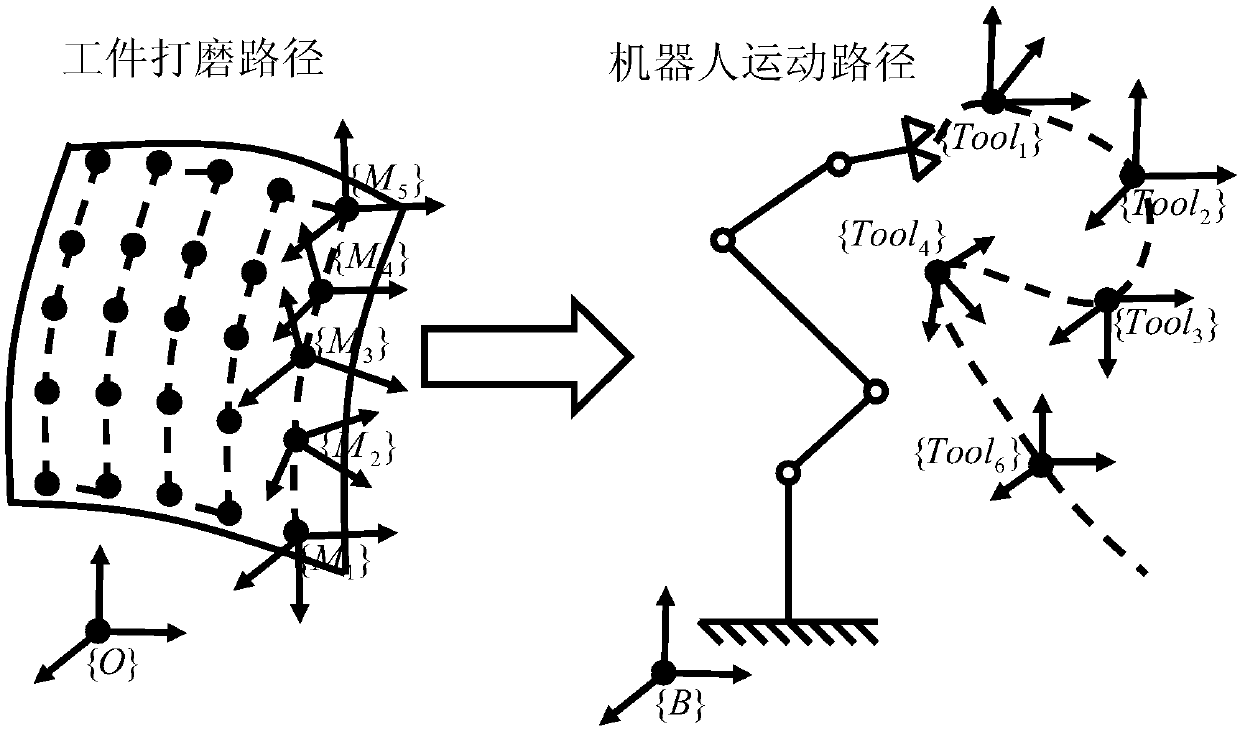

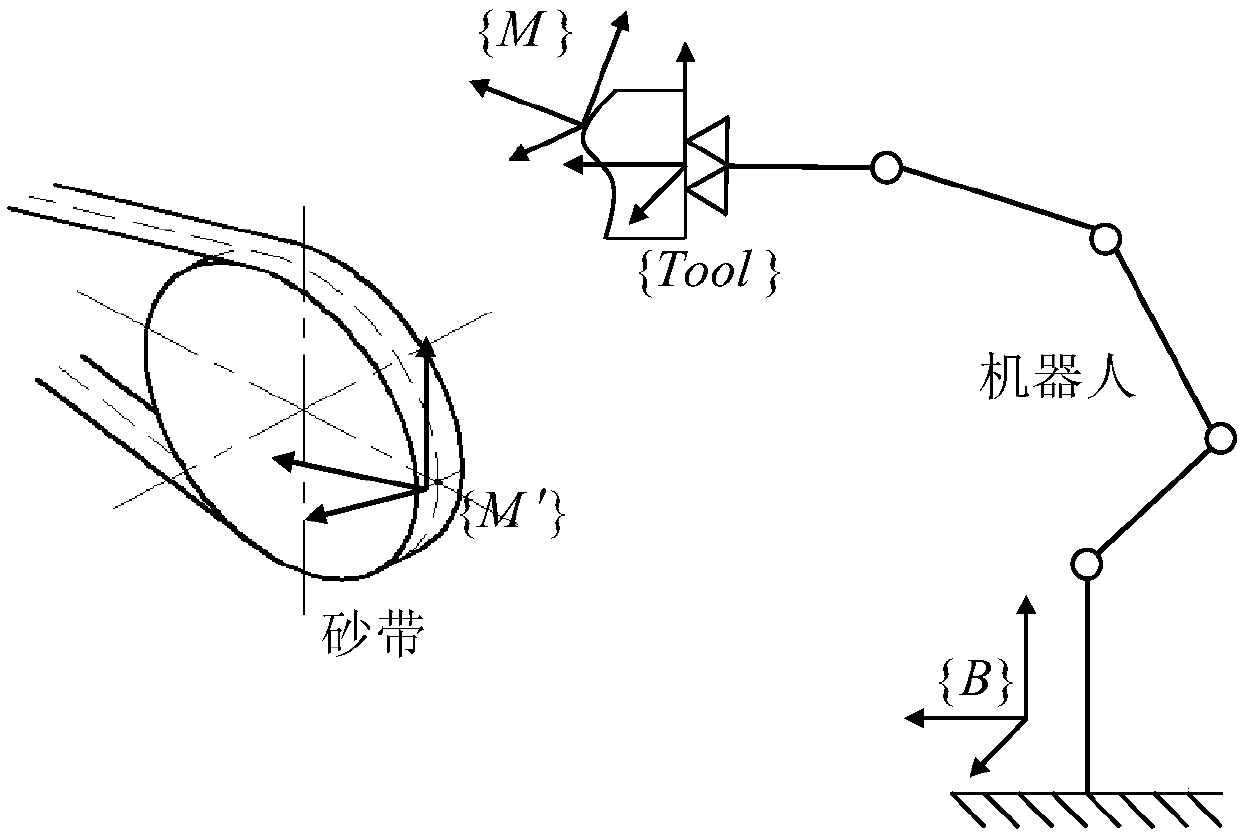

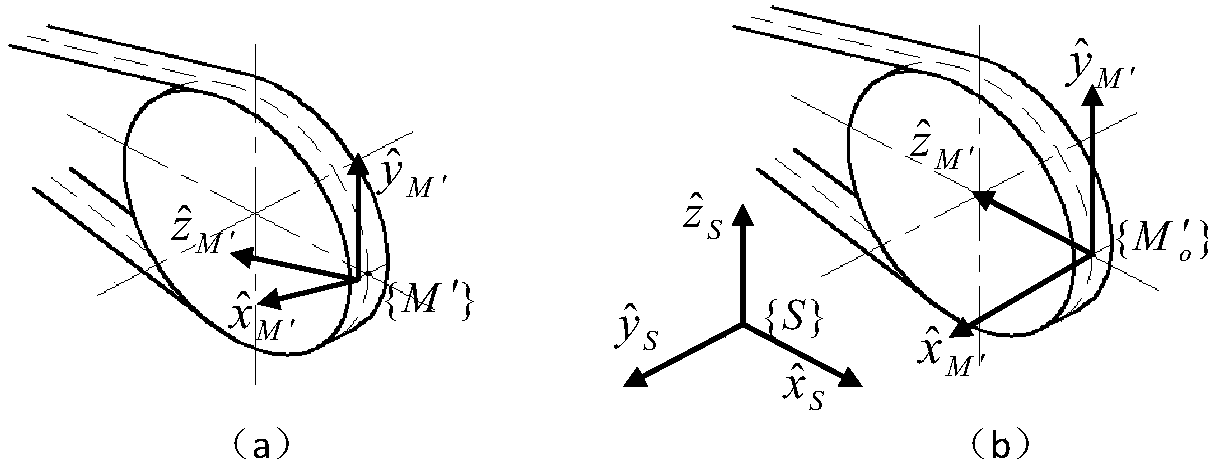

Motion path anticollision adjustment method for grinding of robot belt

ActiveCN107414860AAvoid collisionGuaranteed grinding accuracyProgramme-controlled manipulatorSimulationMachining process

The invention discloses a motion path anticollision adjustment method for grinding of a robot belt. The motion path anticollision adjustment method comprises the steps of (1) generating a robot motion path: converting a workpiece grinding path into the robot motion path; (2) adjusting the anticollision of the robot motion path: changing the position and posture of each cutter contact point on the motion path when grinding is performed by a robot, so that the robot is prevented from colliding during machining. The motion path anticollision adjustment method has the characteristics of flexibility and practicability, a three-dimensional problem is simplified into a two-dimensional problem for searching an optimized curve in a reliable area in a collision layer, the robot can be effectively prevented from colliding when a workpiece is ground by the belt, and additionally, the grinding accuracy and efficiency can be guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

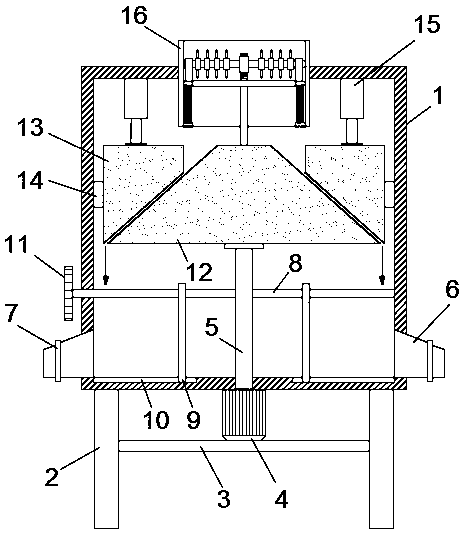

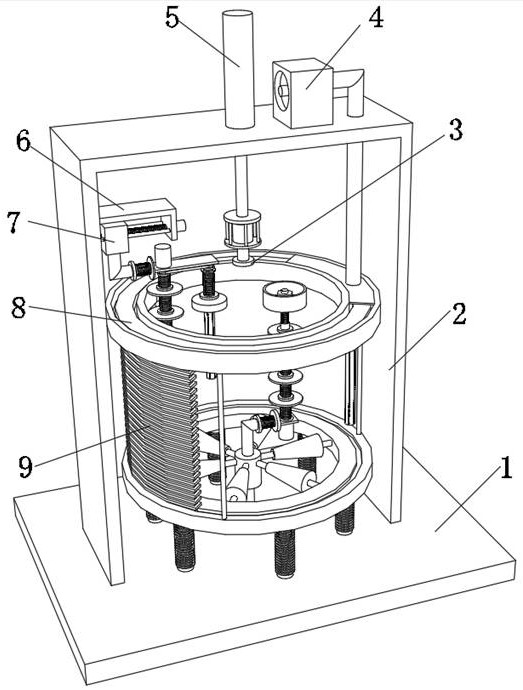

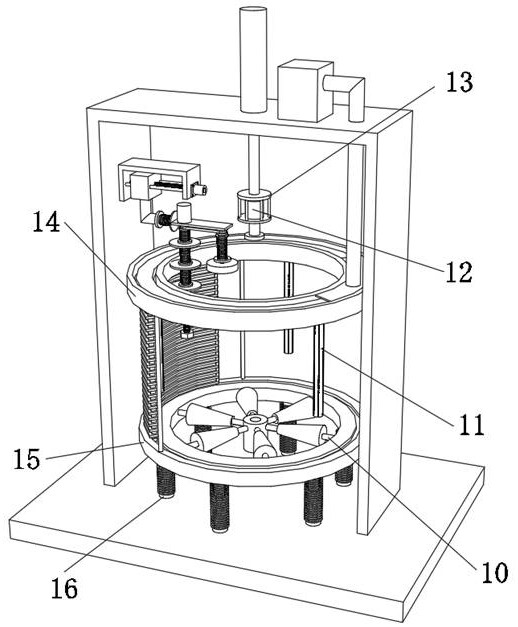

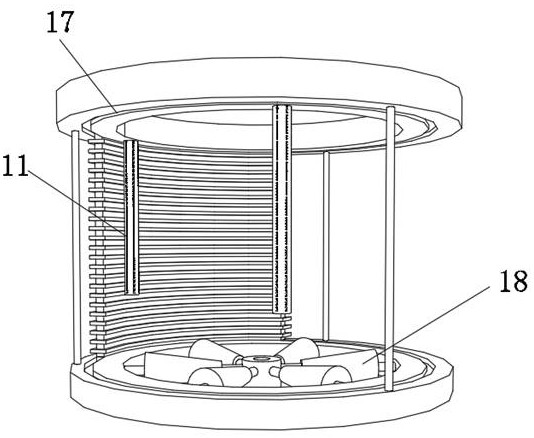

Grinding device for finish machining of ores

InactiveCN108993682AImprove work efficiencyIncrease grinding rateCocoaGrain treatmentsEngineeringMachining

The invention discloses a grinding device for finish machining of ores. The grinding device for finish machining of the ores comprises a grinding box body; a bearing is clamped in the middle part of the upper surface of the grinding box body; a rotating shaft is sleeved with the bearing; the top of the rotating shaft is fixedly connected with an output shaft of a driving device; the lower surfaceof the driving device is fixedly connected to the upper surface of the grinding box body; a plurality of crushing blades are fixedly connected to the left and right side surfaces of the rotating shaft; and the crushing blades are positioned in the grinding box body. The grinding device for finish machining of the ores, disclosed by the invention, has the advantages that ore raw materials penetratethrough small holes in a screening plate to fall into a grinding groove by arranging the driving device when the ore raw materials are small to a certain degree; a grinding disc can also be driven torotate at a high speed in the rotating process of the rotating shaft so that the ore raw materials in the grinding groove can be ground and machined; the ore raw materials entering the grinding box body are crushed and ground in sequence so that the grinding effect and the grinding efficiency of the grinding disc can be both guaranteed.

Owner:周佩龙

Polishing device for high-quality sheet metal processing

InactiveCN111633490AAchieve rotary grindingAchieve cleanupGrinding drivesPlane surface grinding machinesPolishingEngineering

The invention relates to the field of sheet metal processing, in particular to a polishing device for high-quality sheet metal processing. A cleaning mechanism comprises a box body, the upper end of the box body is provided with a first fan, the lower end of the box body is provided with a plurality of air outlets, the lower end of the box body is also provided with a cleaning brush, the inside ofa mounting seat is provided with a dust suction chamber, the rear side of the mounting seat is provided with a second fan communicating with the dust suction chamber, the inside of the dust chamber is provided with a filter screen, the front side of the mounting seat is provided with a dust suction pipe communicating with the dust suction chamber, and the lower end of the dust suction pipe is provided with a dust suction cover. The structure arrangement of the device realizes the cleaning of a sheet metal, so that debris do not remain on the sheet metal to affect the polishing, thereby ensuring the polishing quality and polishing efficiency of the sheet metal, and therefore, the polishing device has strong practicability.

Owner:陈二凤

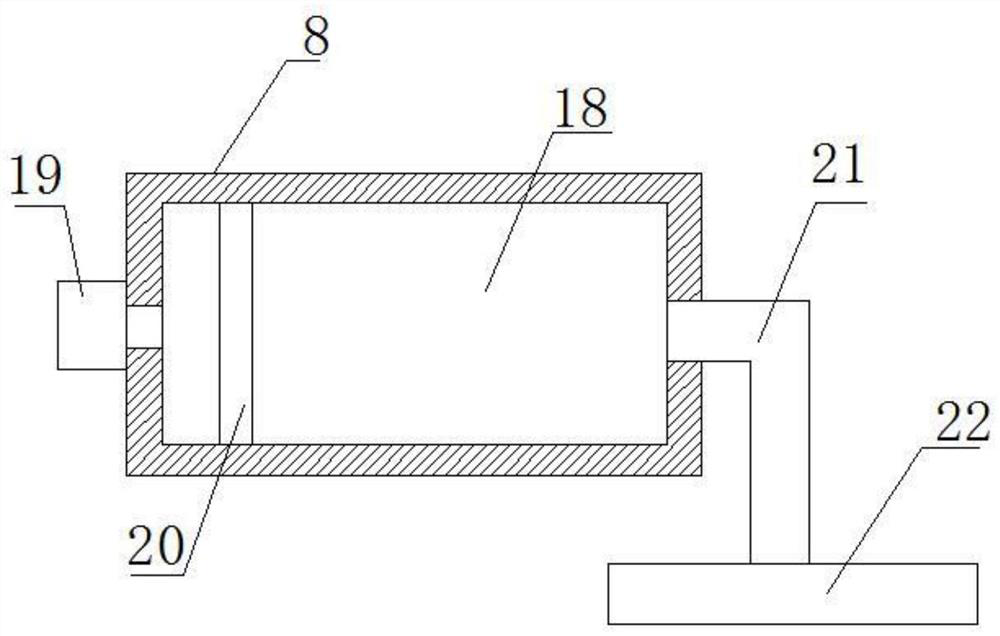

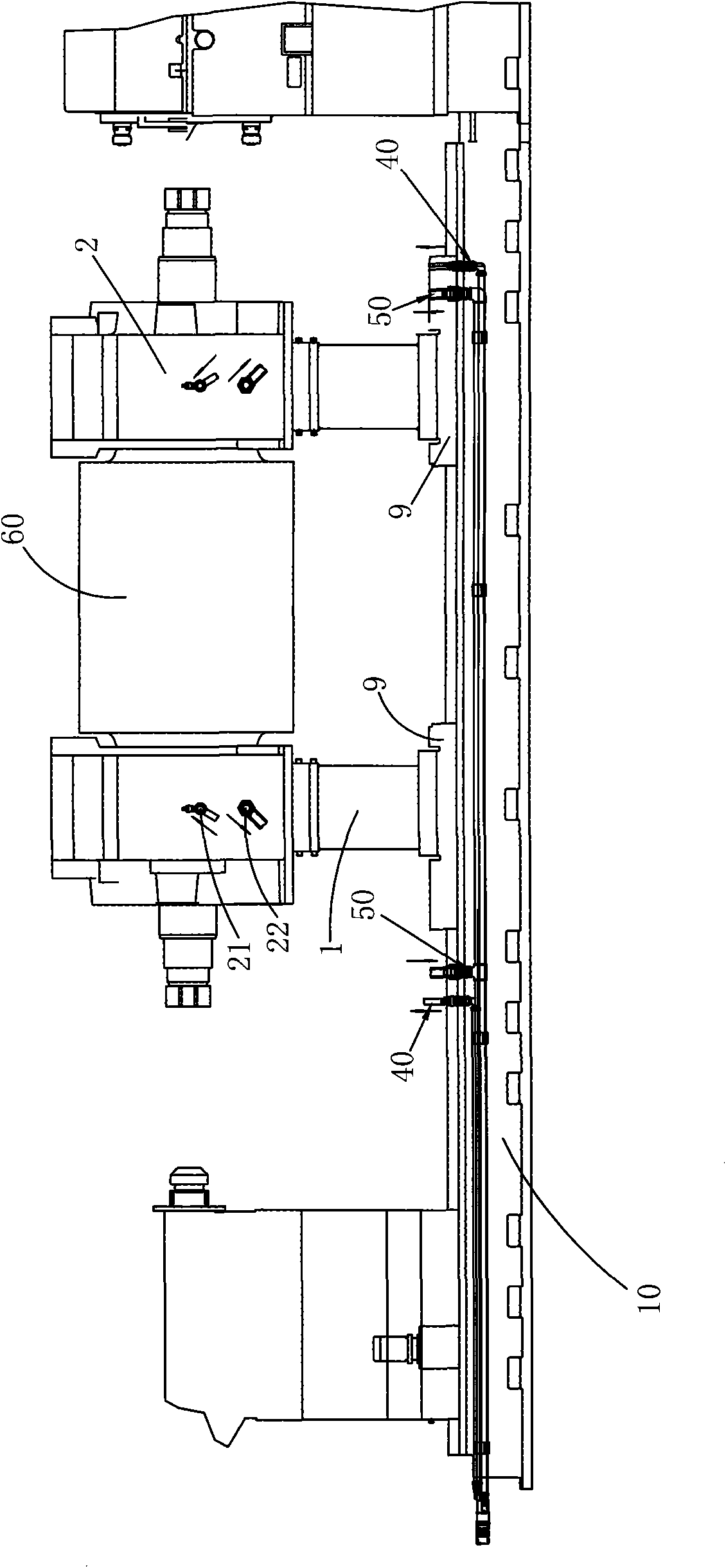

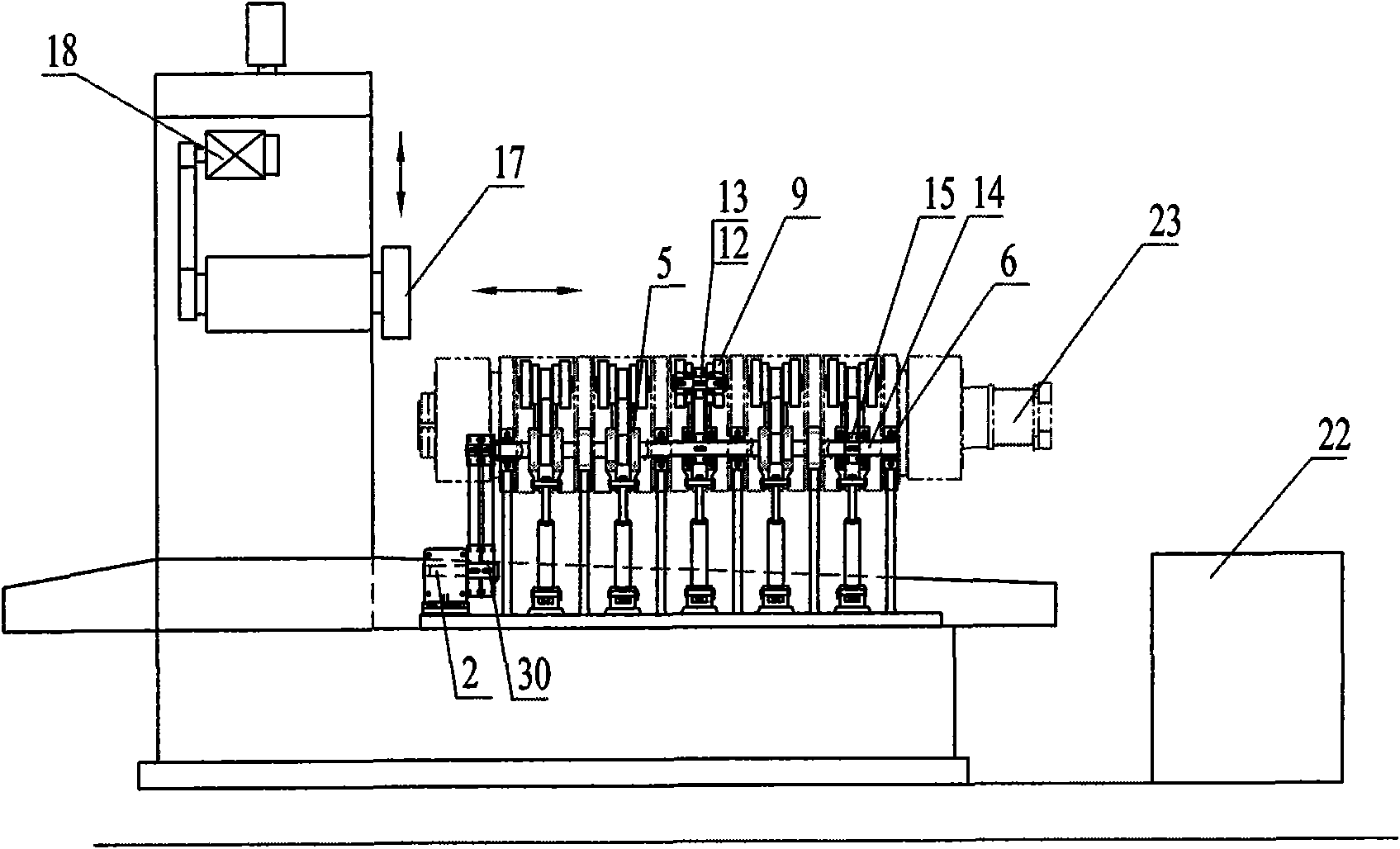

Full-automatic digital control roll grinder backup roll belt box grinding device

ActiveCN101856795AAvoid injury hazardGuaranteed grinding accuracyRevolution surface grinding machinesRadial positionFuel tank

The invention discloses a full-automatic digital control roll grinder backup roll belt box grinding device, comprising an installation precision regulating device, an oil supplying device and an oil temperature controlling device, wherein the installation precision regulating device comprises a bearing box pushing cylinder, limit blocks, an inching device and a clamping plate, the bearing box pushing cylinder and the limit blocks are arranged on the box seat and used for locating the position of the bearing box relative to the box seat, the clamping plate is used for driving the box seat to slide in a radial direction relative to a bed body of a workpiece, and the inching device and the lamping plate are used for regulating the radial position of the box seat at one end of the bed body of the workpiece so as to parallel a space axial line between the two box seats with the axial line of a grinding wheel, thereby ensuring grinding precision; the oil temperature controlling device comprises a temperature sensor and an oil temperature controller, which is used for ensuring that the temperature of the supplied oil in the oil supplying device is proper; and the oil supplying device comprises an oil inlet pipeline, a cylinder and an oil outlet pipeline with an overflow valve and a throttle valve, which is used for supplying the oil meeting the requirements of temperature, oil pressure and flow to a bearing box so as to ensure that a oil film bearing forms an effective dynamic pressure, thereby effectively avoiding hidden troubles of damaging a bearing and ensuring grinding efficiency. In all, the invention ensures grinding, and can be convenient and reliable in use.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

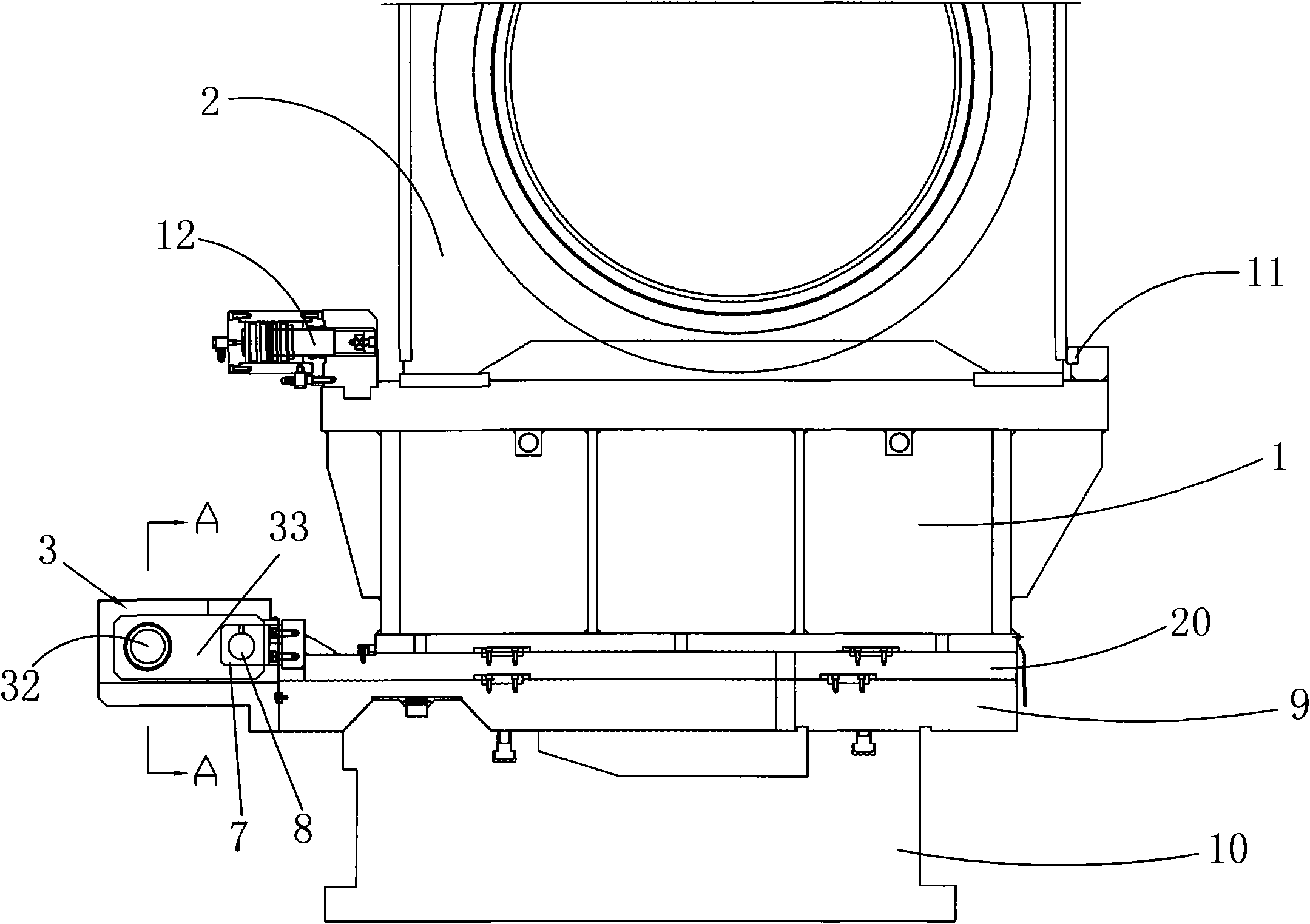

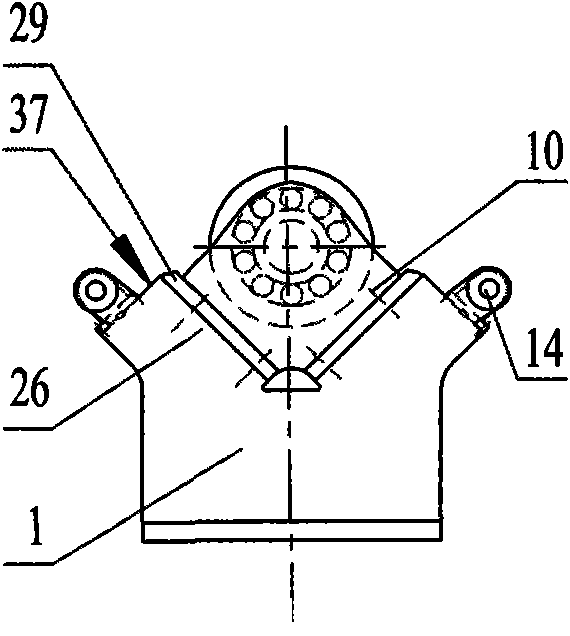

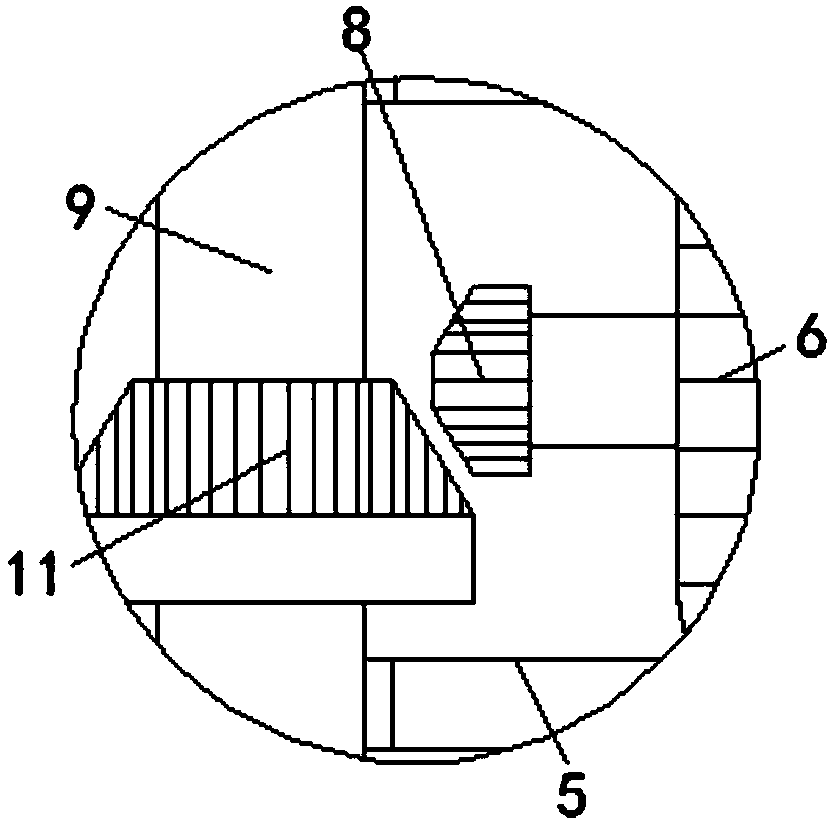

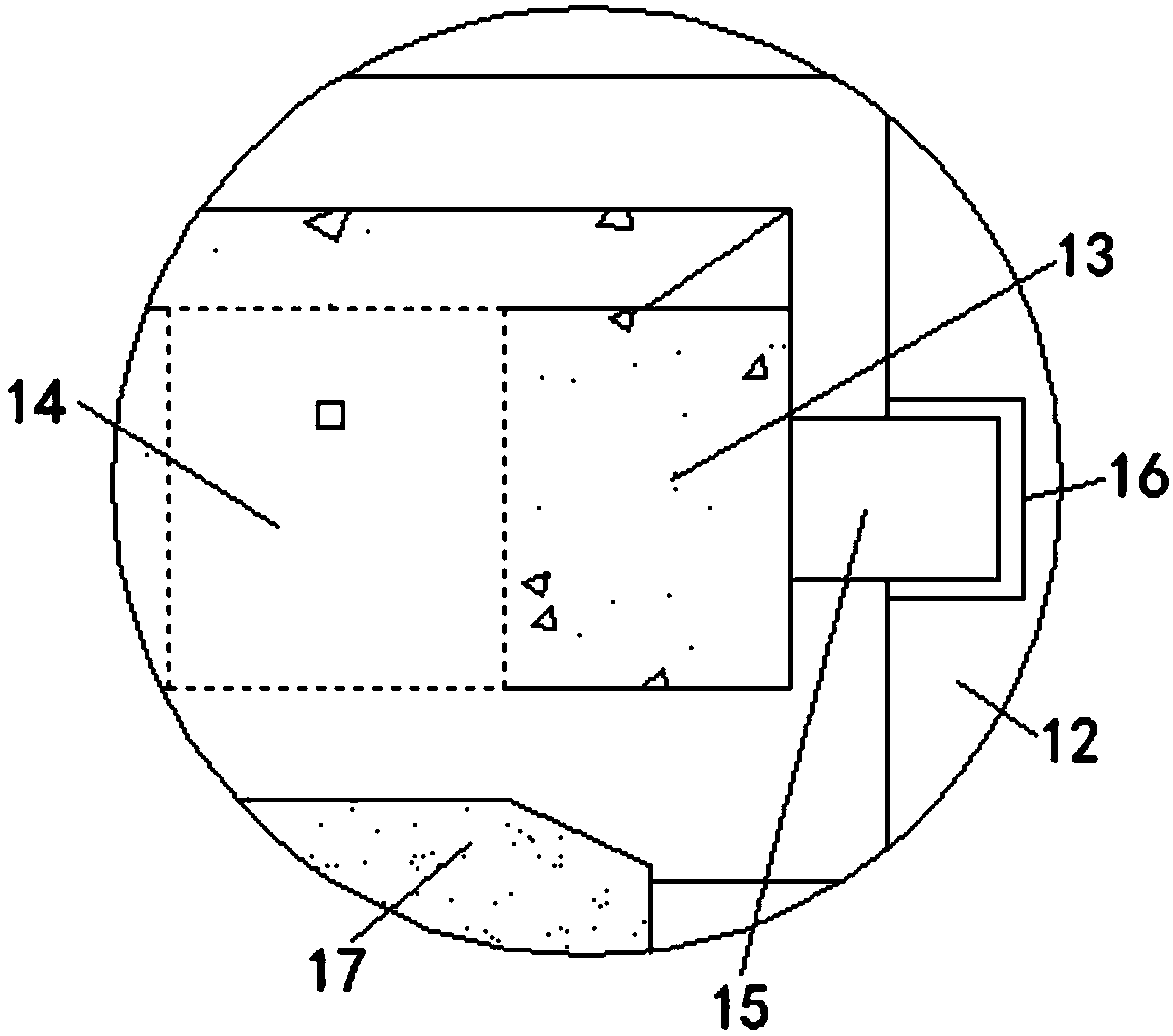

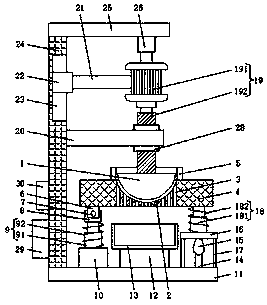

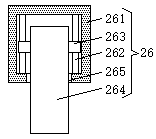

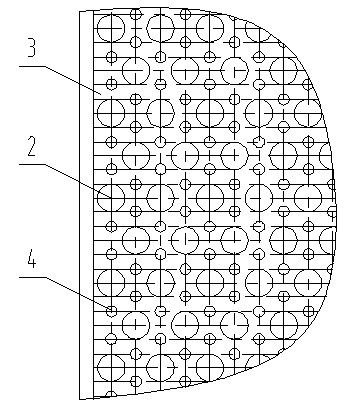

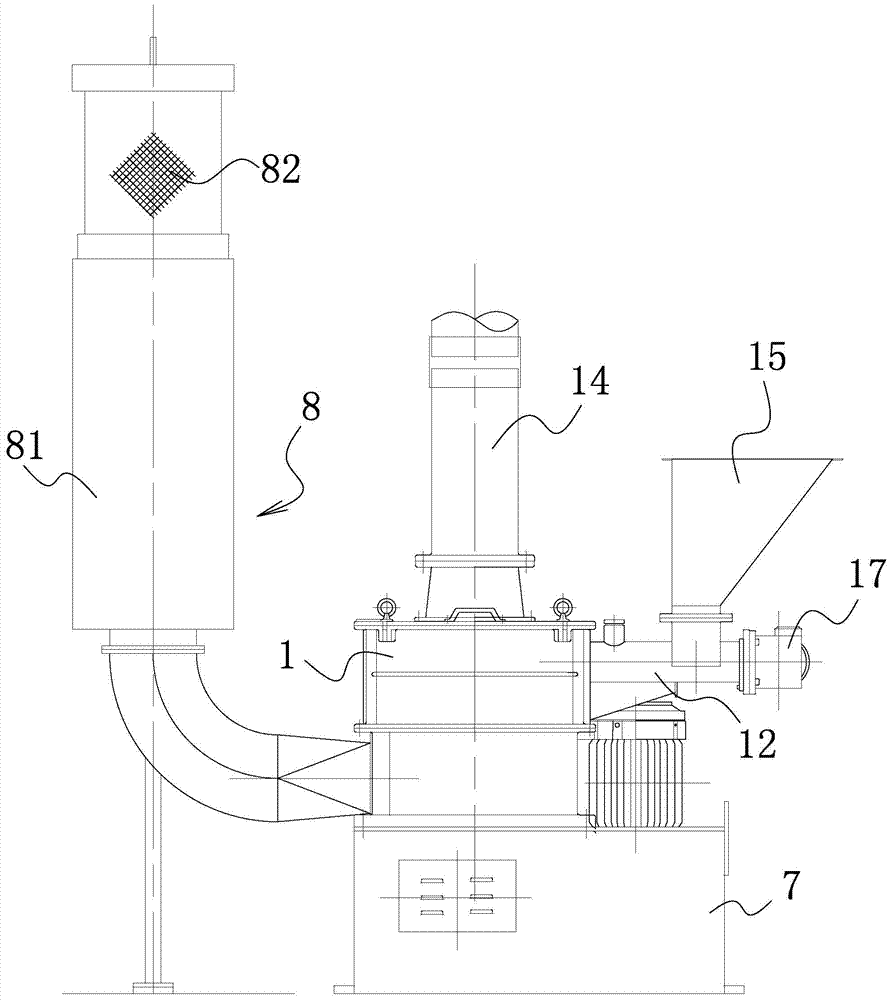

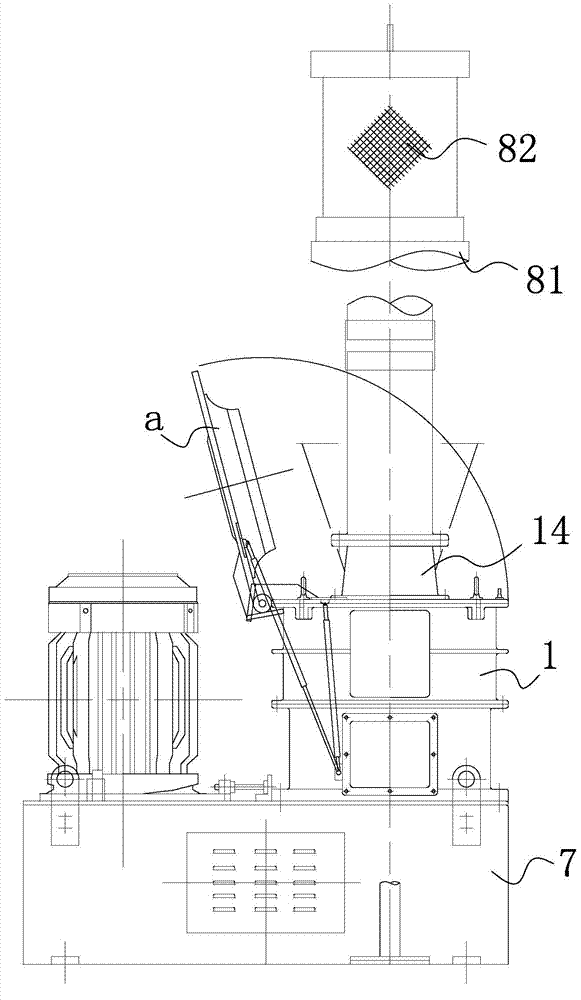

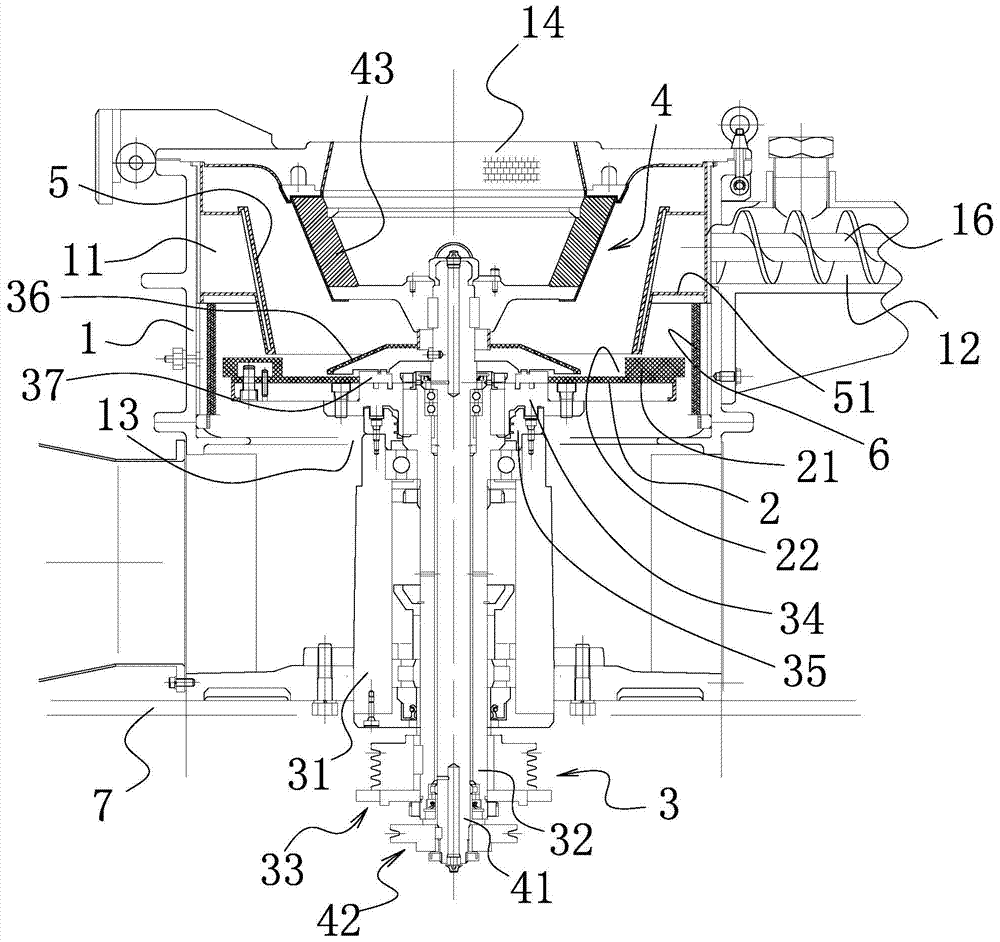

Multi-roller mill backing roller integral gapless repairing method and repairing device thereof

The invention relates to a multi-roller mill backing roller integral repairing method, which includes steps of: selecting, assembling and grinding, wherein bottom surface of a base plate (26) of a backing roller is used as installation standard, the backing roller to be repaired is integrally installed on a grinding processing standard surface of a reconditioning mold. The invention also relates to a multi-roller mill backing roller integral repairing device, which includes a mold arranged on a workbench (21). The mold comprises a fixed base (1) for supporting the backing roller to be repaired, the fixed base is provided with a compaction roller driving device with a power machine and a transmission mechanism and compaction devices which has same number with bearing roller on the backing roller and are arranged at one side or two sides of the backing roller to be repaired, a groove (29) which is adapted with shape of the base plate of the backing roller is arranged at upper end of the fixed base (1), and the groove is in V shape or circular arc shape. The invention can carry out integral gapless grinding for the backing roller to be repaired, realizes integral moulding grinding, and has advantages of simple process, high precision and low cost.

Owner:CERI TECH

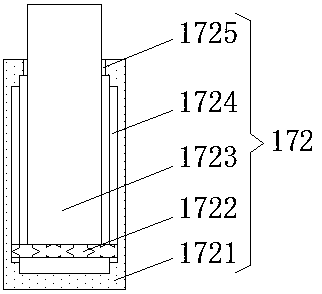

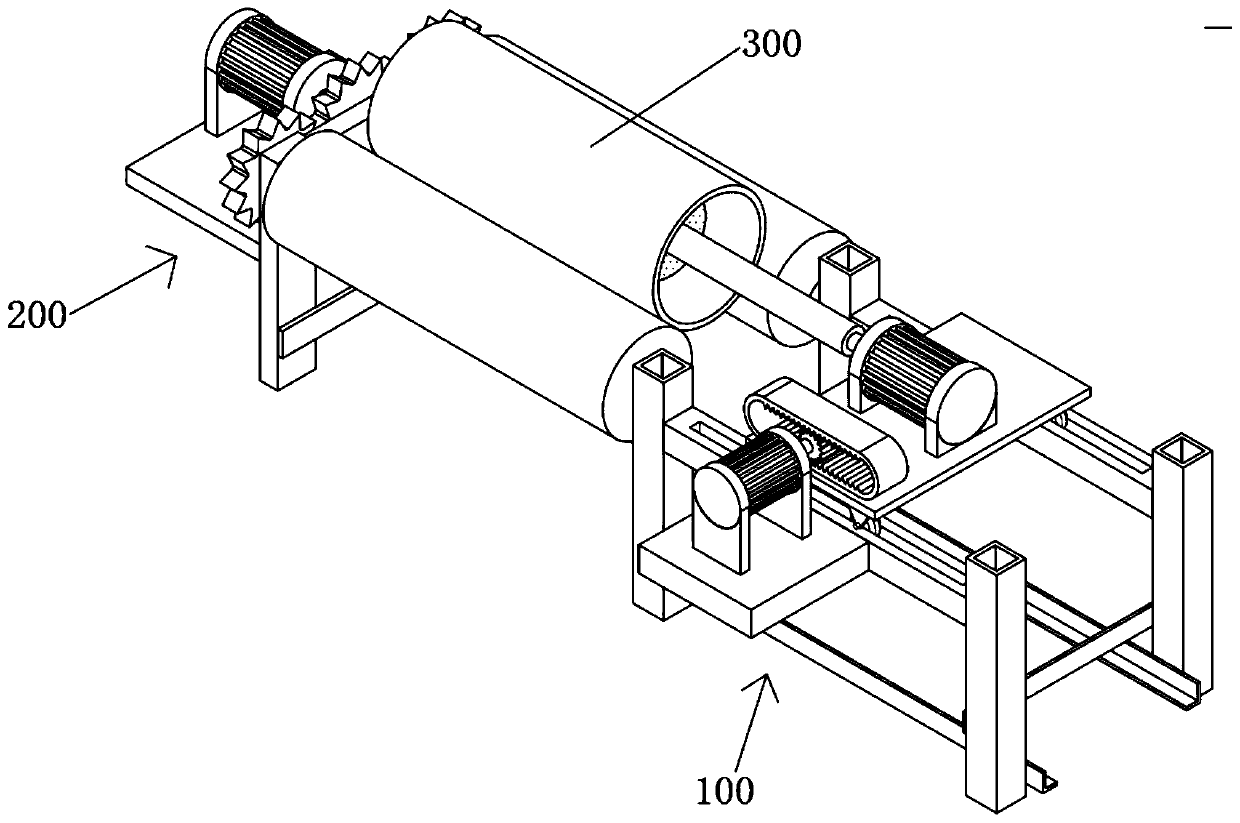

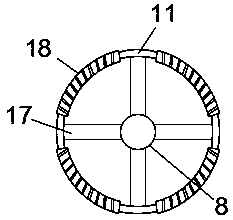

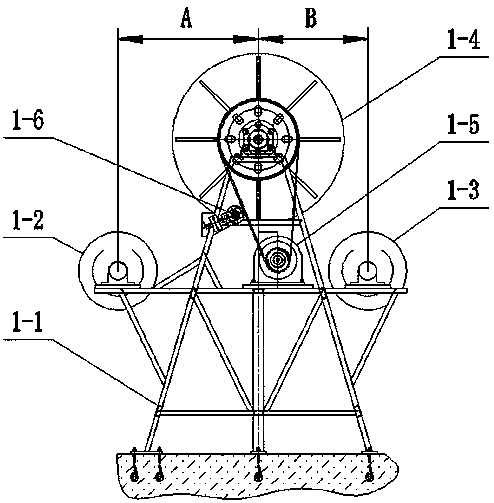

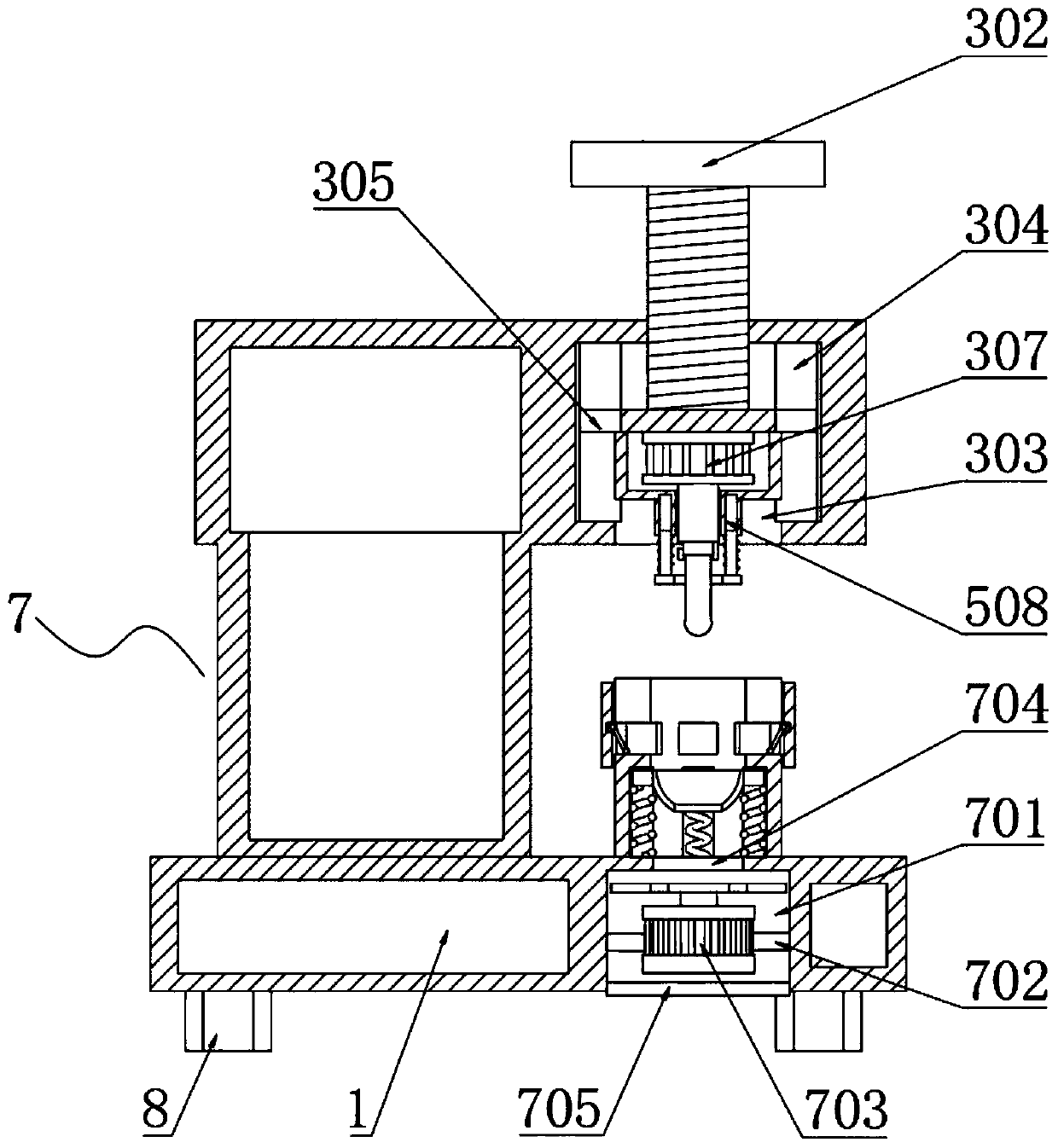

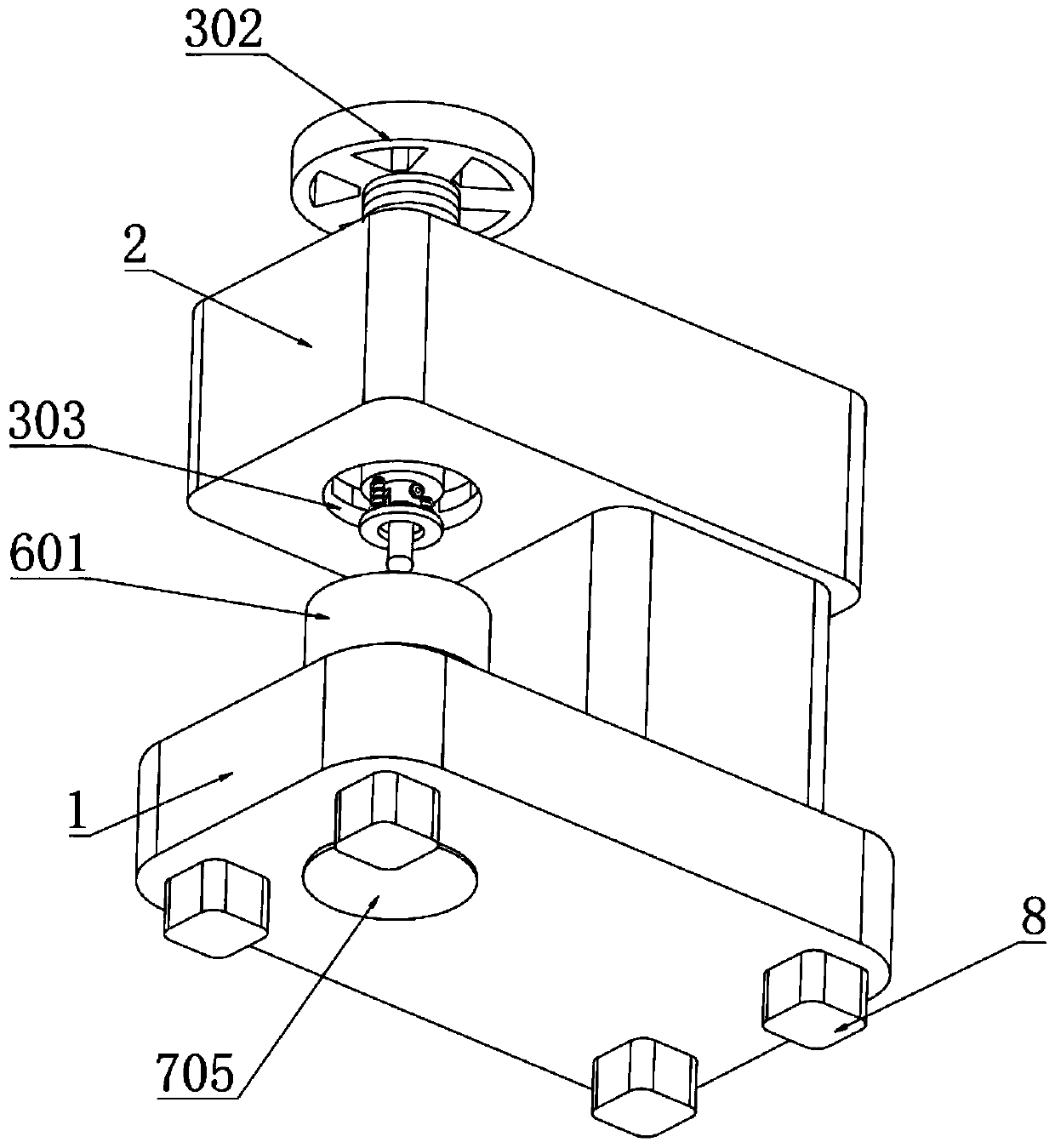

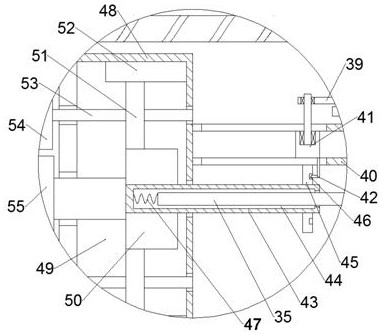

Pipeline inner and outer wall treating device for nodular cast iron pipe fitting

InactiveCN111409003ASolve the problem of fast sandingGuaranteed grinding efficiencyGrinding carriagesGrinding drivesElectric machineryEngineering

The invention belongs to the technical field of cast iron pipe treating, and particularly relates to a pipeline inner and outer wall treating device for a nodular cast iron pipe fitting. The device comprises an inner wall treating mechanism and an outer wall treating mechanism, wherein the outer wall treating mechanism is arranged outside the inner wall treating mechanism, the inner wall treatingmechanism comprises four supporting legs and two transverse plates, the supporting legs are fixed to the outer walls of the two sides of each of the two transverse plates, the outer wall treating mechanism comprises a left square bracket-shaped plate, and a second reinforcing plate is fixed between the inner walls of the vertical sections of the two sides of the bottom end of the left square bracket-shaped plate. According to the pipeline inner and outer wall treating device for the nodular cast iron pipe fitting, a first motor is started to drive a grinding disc to rotate, a second motor is started to enable an incomplete gear to drive the first motor to reciprocate front and back through a transmission plate, and a third motor is started to enable two grinding cylinders to rotate under the transmission of a first gear, so that the problem that the inner wall and the outer wall of an existing nodular cast iron pipe need to be rapidly ground after the nodular cast iron pipe is annealedis solved, and the grinding efficiency of the inner wall and the outer wall of the nodular cast iron pipe after the inner wall and the outer wall of the nodular cast iron pipe are annealed is guaranteed.

Owner:马鞍山冠成科技信息咨询有限公司

Waste plastic grinder for producing PVC building template, and using method

InactiveCN110614735AGuaranteed cutting efficiencyGuaranteed grinding efficiencySievingScreeningArchitectural engineeringMixing chamber

The invention discloses a waste plastic grinder for producing a PVC building template. The waste plastic grinder for producing the PVC building template comprises a shell; support legs is symmetrically and fixedly connected to the bottom side of the shell; a mounting plate is fixedly connected to the support legs; a driving device is arranged on the mounting plate; a lower grinding roller is arranged in the shell; telescopic cylinders are symmetrically and fixedly connected to the inner wall of the shell; an upper grinding roller is fixedly connected to output ends of the telescopic cylinders,a mixing chamber is fixedly connected to the shell; a connecting shaft is fixedly connected to the lower grinding roller; a rotating shaft is rotatably connected to the inner wall of the mixing chamber; and a plurality of cutting blades are symmetrically and fixedly connected to the rotating shaft. According to the waste plastic grinder for producing the PVC building template, a worm rotates andthen drives a worm wheel to rotate, so that the rotating shaft rotates, the cutting blades shred plastic, the cutting efficiency is guaranteed through the high dense distribution of the cutting blades, the waste plastic is subjected to fragmentation treatment before grinding, and the later grinding efficiency is guaranteed.

Owner:欧阳春洲

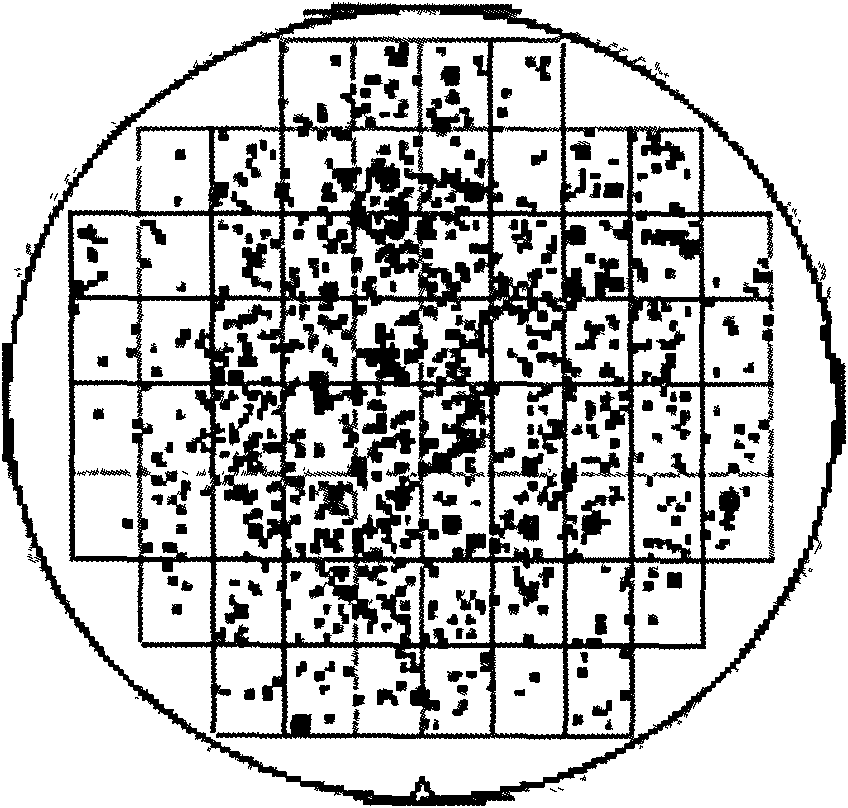

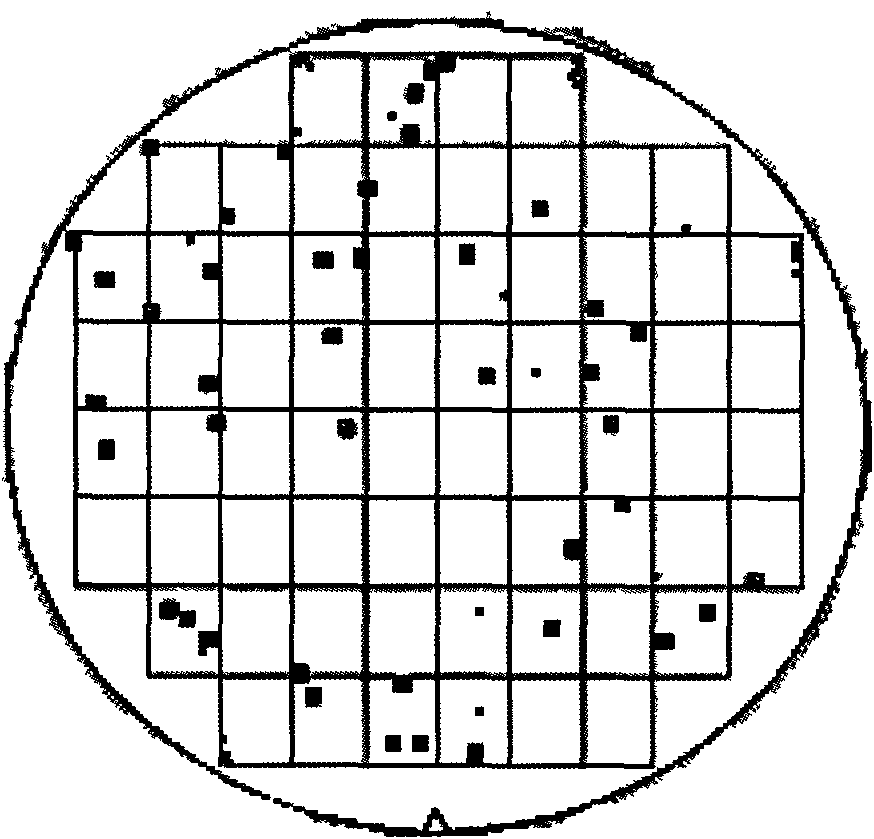

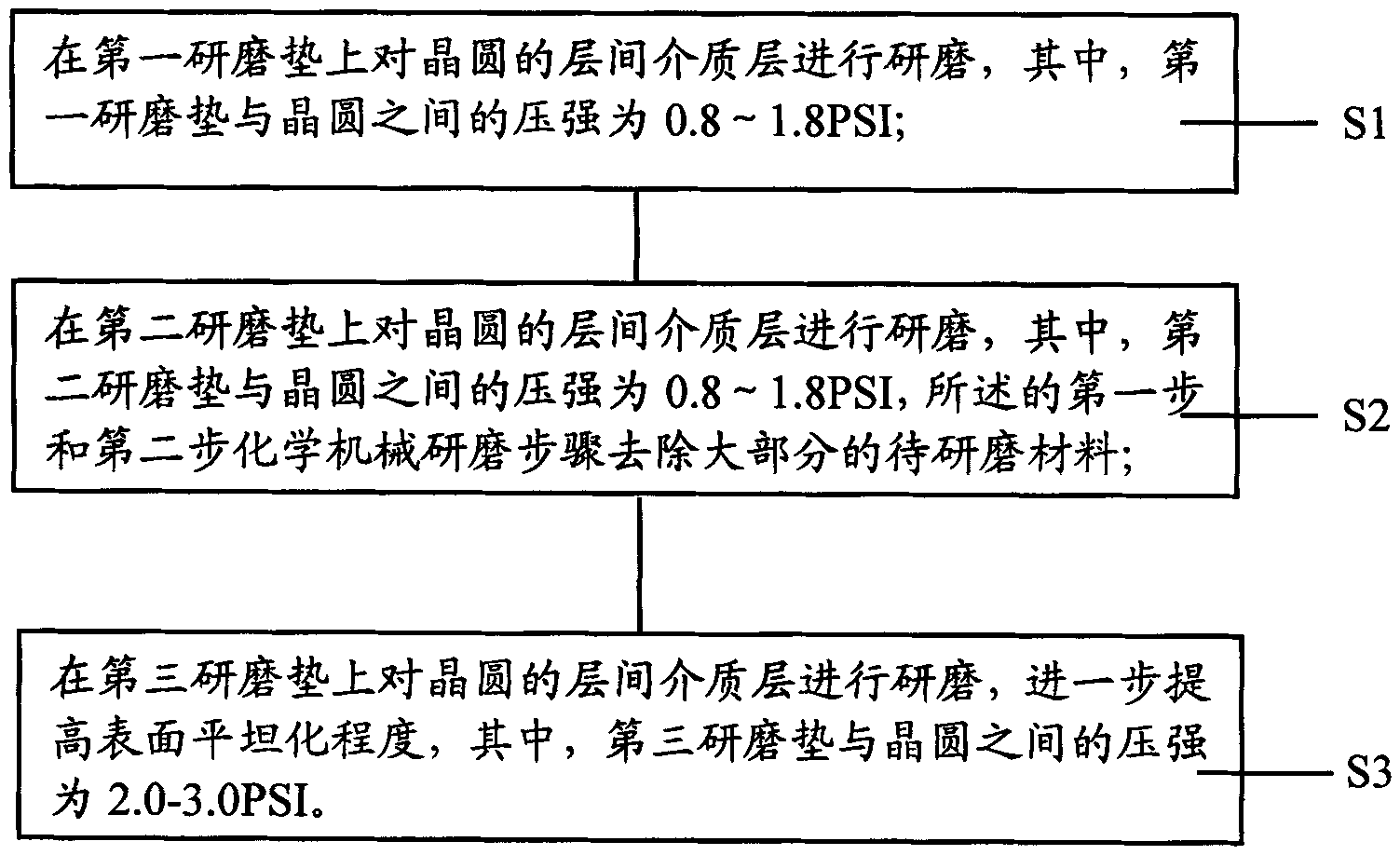

Chemical mechanical grinding method for interlayer dielectric layer

InactiveCN101961852AReduce grinding rateIncrease grinding rateSemiconductor/solid-state device manufacturingLapping machinesPolymer chemistryMaterials science

The invention relates to a chemical mechanical grinding method for an interlayer dielectric layer, which comprises the following steps of: 1. grinding an interlayer dielectric layer of a wafer on a first grinding pad, wherein pressure between the first grinding pad and the wafer is 0.8-1.8PSI; 2. grinding the interlayer dielectric layer of the wafer on a second grinding pad, wherein pressure between the second grinding pad and the wafer is 0.8-1.8PSI, and most materials to be ground are removed in the first and second chemical mechanical grinding steps; and 3. grinding the interlayer dielectric layer of the wafer on a third grinding pad so as to further improve surface flat degree, wherein pressure between the third grinding pad and the wafer is 2.0-3.0PSI. The method can effectively reduce chemical mechanical grinding scratches of the interlayer dielectric layer and improve product yield.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Cleaning device capable of conveniently cleaning wheat bran

The invention relates to the technical field of agriculture and discloses a cleaning device capable of conveniently cleaning wheat bran. The cleaning device comprises a mounting shell. A feeding pipeis arranged at the left side of the top of the mounting shell in a penetrating manner, and a feeding funnel is fixedly arranged at the top of the feeding pipe. According to the cleaning device capableof conveniently removing the wheat bran, ground wheat leaks into a wheat bran discharging plate through a gap between a fixed grinding disc and a mounting ring, and then the wheat bran is continuously pushed up and down through a driving cylinder, so that the wheat bran discharging plate shakes up and down, and finally flour leaks into a flour collecting box through a wheat bran filtering net; and meanwhile, because the wheat bran filtering net is provided with strip-shaped limiting blocks, the speed of the wheat bran sliding out of a mounting shell can be slowed down, and the residence timeof the wheat bran can be prolonged, so that the flour in the wheat bran can be effectively shaken off, the wheat bran in the wheat flour can be effectively removed by the adoption of the method, and thus the wheat flour fineness is improved effectively.

Owner:NINGXIA JINBOLE FOOD TECH CO LTD

Medicinal material grinding device convenient to use

The invention discloses a medicinal material grinding device convenient to use. The medicinal material grinding device comprises a grinding block, wherein the lower surface of the grinding block is inlap joint with the lower surface of an inner wall of a placement groove; the placement groove is formed in the upper surface of a placement plate; a plurality of first through holes are formed in thelower surface of the inner wall of the placement groove; the upper surface of the placement plate is fixedly connected with the lower surface of a baffle plate; the lower surface of the placement plate is fixedly connected with the upper surfaces of two first connecting blocks; and the back sides of the first connecting blocks are movably connected with the front side of a second connecting block. According to the medicinal material grinding device convenient to use disclosed by the invention, through cooperation of a second motor, a threaded column, a threaded cap, the grinding block, the placement groove, a first elastic device, a second elastic device and the first through holes, the grinding quality of medicinal materials is better, so that a drug effect of the medicinal materials isensured; through arrangement of a fixed plate, the threaded cap is fixed, so that the medicinal materials also can be ground while being extruded at the same time, so that the grinding quality of themedicinal materials is ensured.

Owner:张孝法

Novel full-automatic iron pan polishing machine

InactiveCN107662143AGuaranteed grinding efficiencyNo action requiredGrinding carriagesGrinding drivesEngineeringGrinding wheel

The invention discloses a novel full-automatic iron pan polishing machine which comprises a machine frame. The machine frame is provided with a cross beam. An autorotation device and pan feeding and replacing devices are arranged below the cross beam. An abrasion wheel polishing device and an abrasive band polishing device are arranged above the cross beam. A pan feeding lifting platform and a pandischarging lifting platform are arranged on the side portion of the machine frame.

Owner:夏晓军 +1

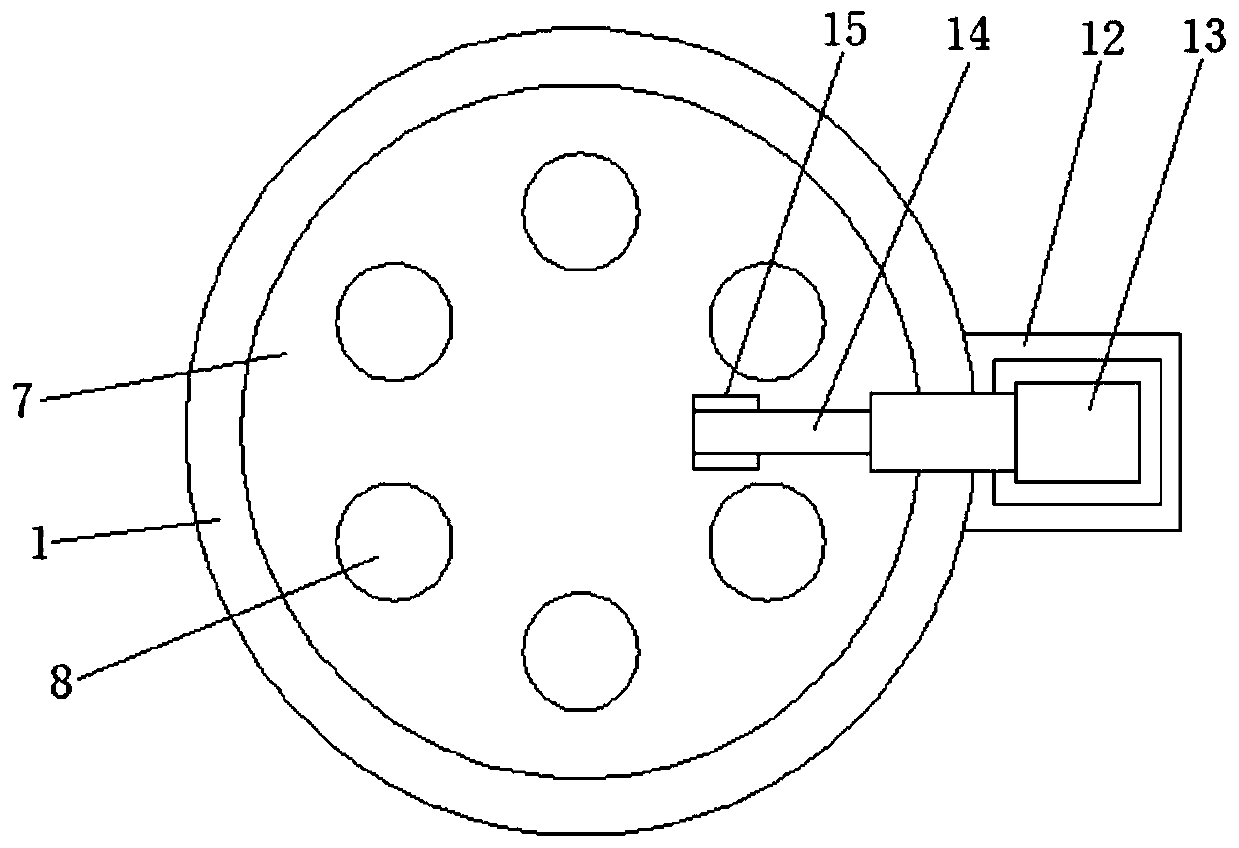

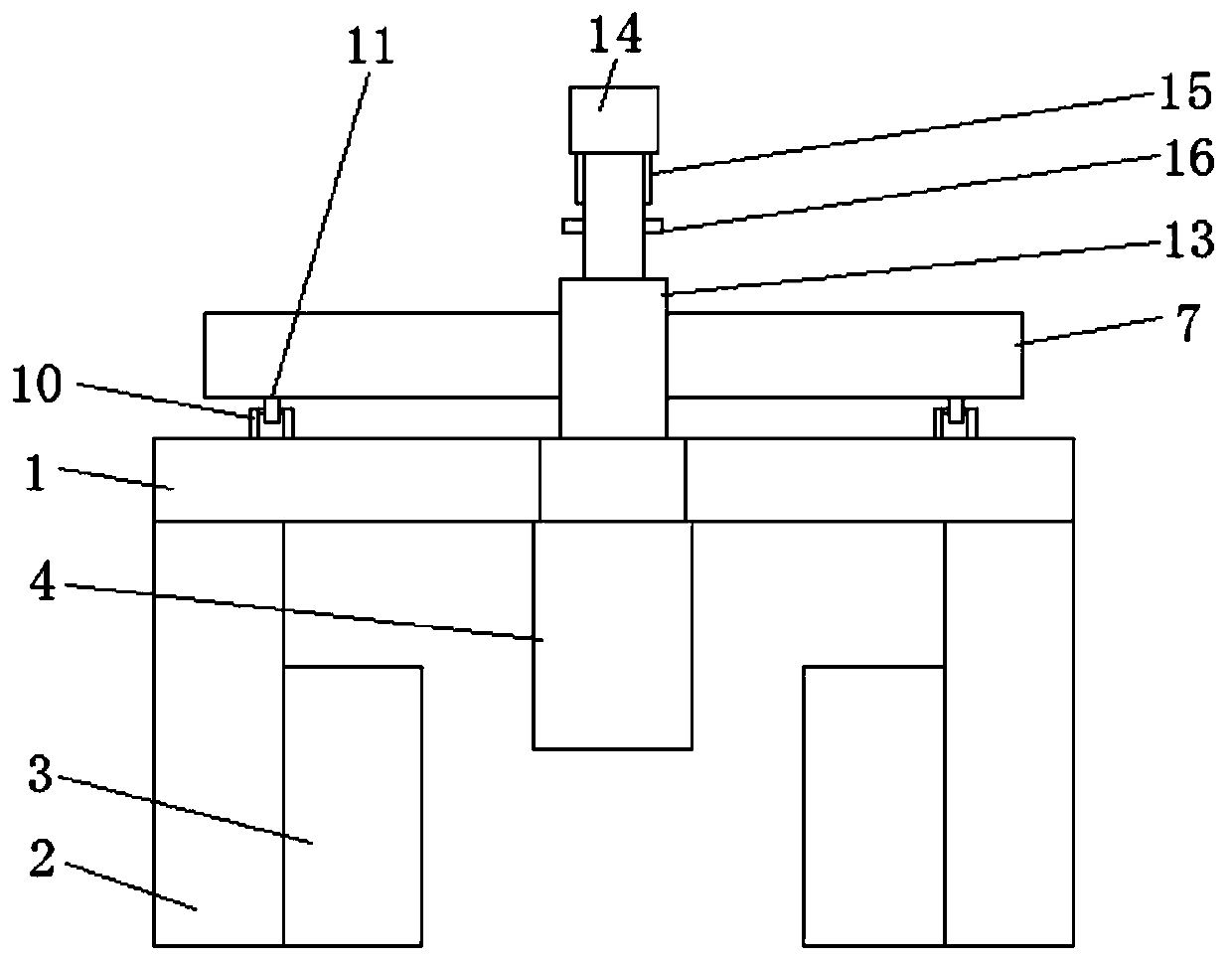

Polishing workbench

InactiveCN110385623AEasy to polishGuaranteed grinding efficiencyGrinding drivesGrinding machinesArchitectural engineeringMachining

The invention belongs to the technical field of machining, in particular to a polishing workbench. The polishing workbench comprises an operation table, wherein the operation table is connected with amotor box. The cavity of the motor box is connected with a rotating motor, wherein the top of the rotating motor is connected with a rotating shaft, the top of the rotating shaft is connected with aturntable, and circular grooves are formed in the top of the turntable. The operation table is fixedly connected with a supporting plate, wherein the top of the supporting plate is fixedly connected with a vertical telescopic rod, the top of the vertical telescopic rod is connected with a transverse telescopic rod, and the transverse telescopic rod is connected with a polishing motor. According tothe polishing workbench, through arranging fixing devices, the cavities of the circular grooves are matched with external fixing devices in structure, in this way, to-be-polished pieces are fixed through the different fixing devices, which is convenient for the different pieces to be polished; and in addition, through arranging the telescopic rods, the polishing motor is controlled by the vertical telescopic rod to move up and down and controlled by the transverse telescopic rod to move left and right, which is convenient for a polishing disc to be controlled, and the polishing for specific locations of the pieces can be realized.

Owner:安徽建发电气设备有限公司

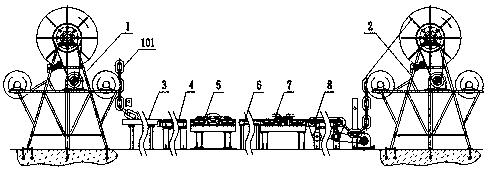

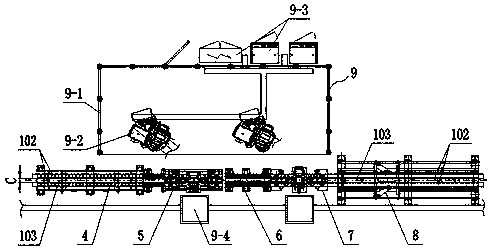

Automatic anchor chain polishing device

InactiveCN107900844AGuaranteed grinding efficiencyGuaranteed YieldGrinding feed controlGrinding machinesEngineeringMechanical engineering

The invention discloses an automatic anchor chain polishing device comprising a first cone wheel conveying device and a second cone wheel conveying device which are arranged at the two ends correspondingly. An anchor chain support, an anchor chain feeding rail, a vertical chain clamping device, an adjusting transition device, a flat chain clamping device and an anchor chain discharging rail are arranged sequentially between the first cone wheel conveying device and the second cone wheel conveying device; the automatic anchor chain polishing device further comprises a robot assembly matched with the vertical chain clamping device and the flat chain clamping device for polishing anchor chains; and the first cone wheel conveying device, the second cone wheel conveying device, the anchor chainsupport, the anchor chain feeding rail, the vertical chain clamping device, the adjusting transition device, the flat chain clamping device and the anchor chain discharging rail are located on the same straight line. Intelligent control is achieved, so that the polishing efficiency and the finished product rate are guaranteed, in addition, energy saving and environmental friendliness are achieved, and manual work is saved.

Owner:JIANGSU ASIAN STAR ANCHOR CHAIN +1

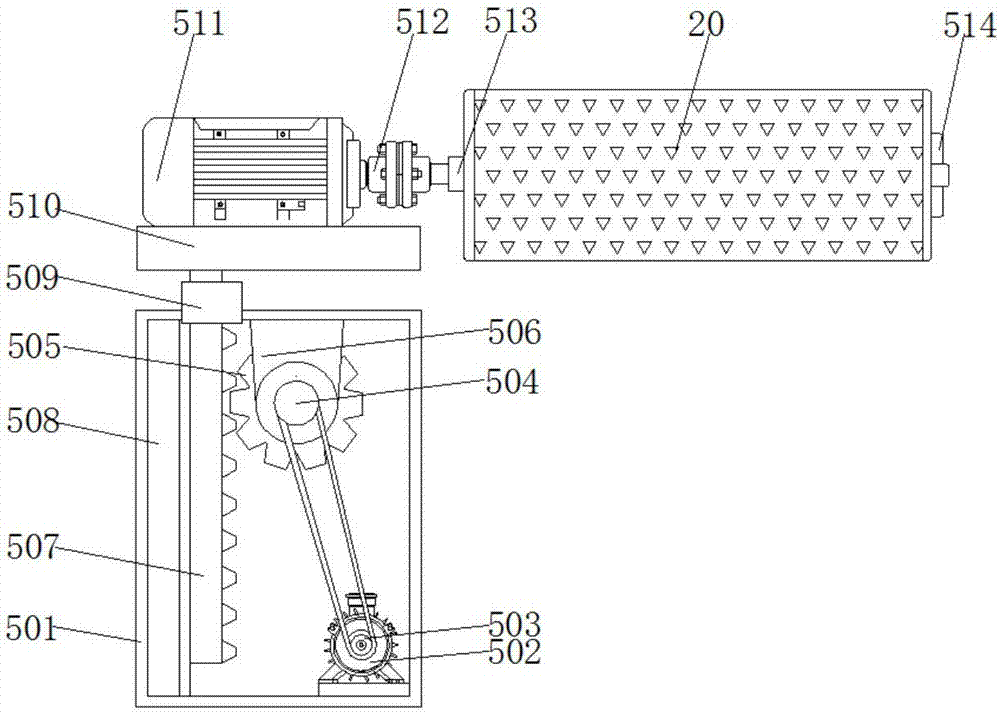

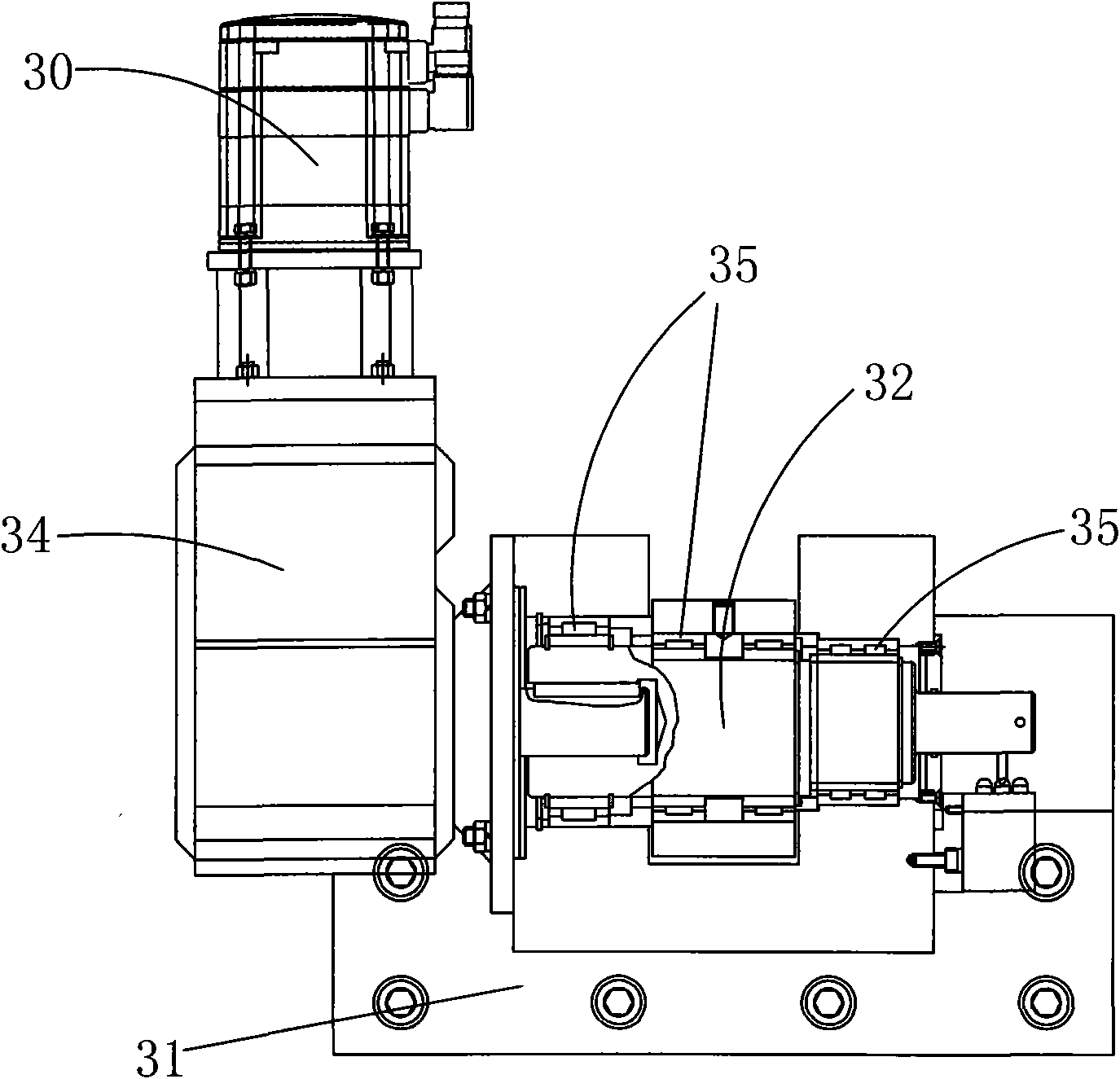

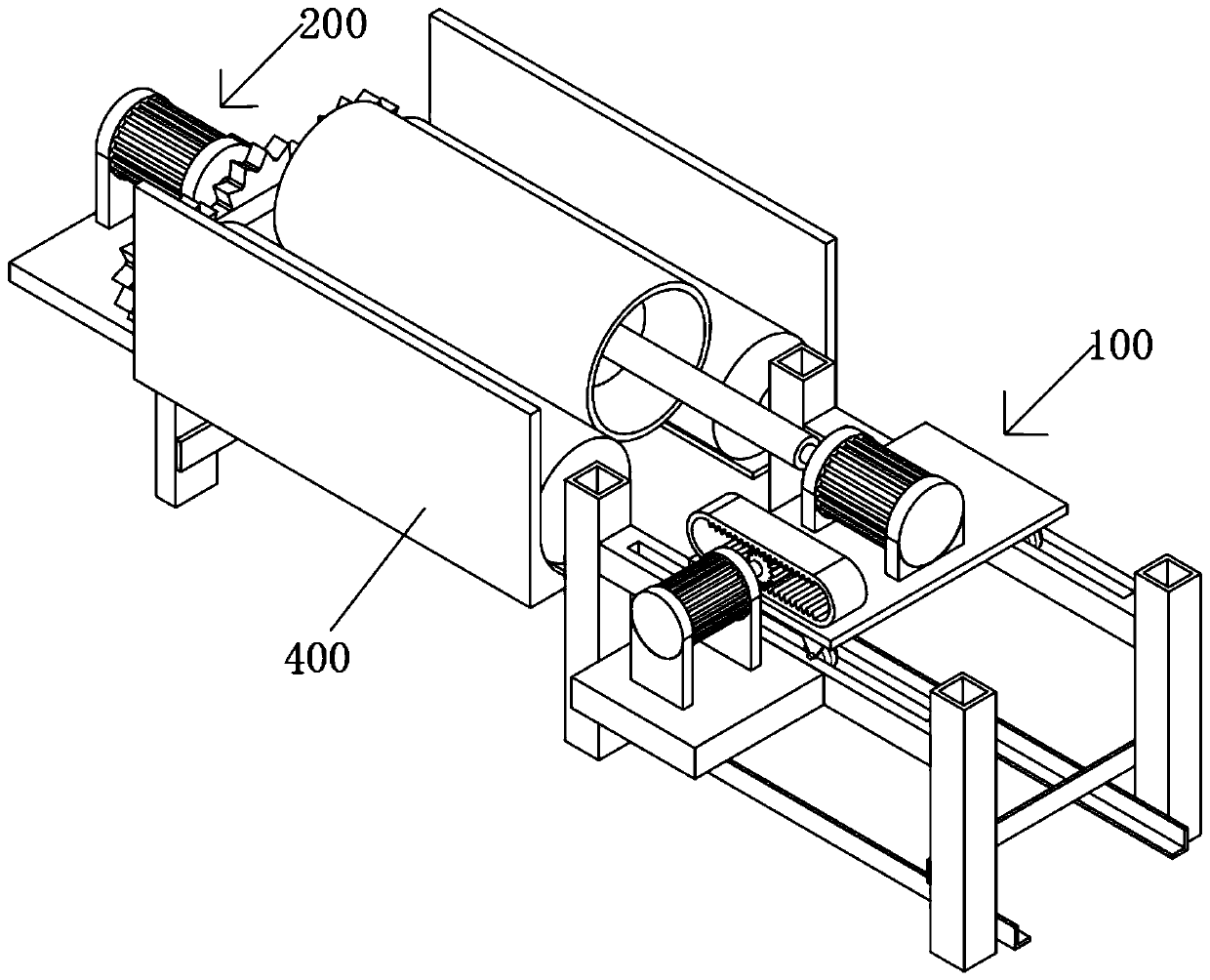

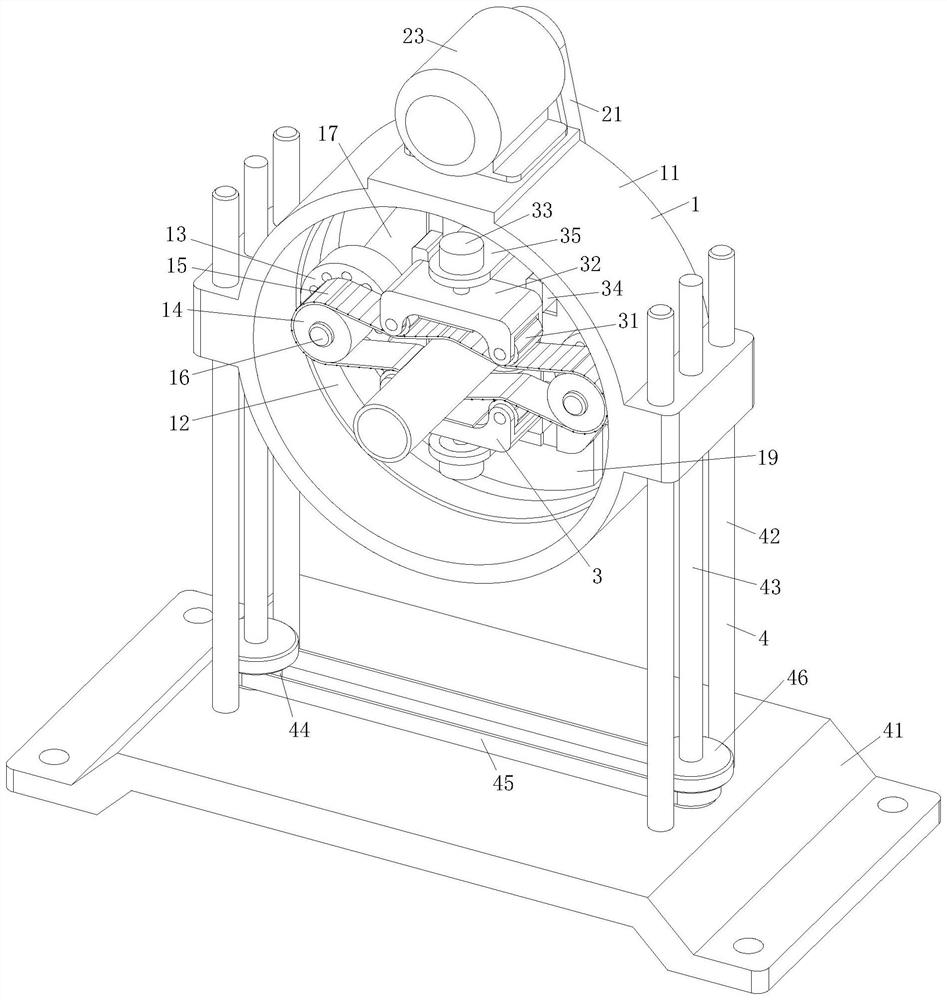

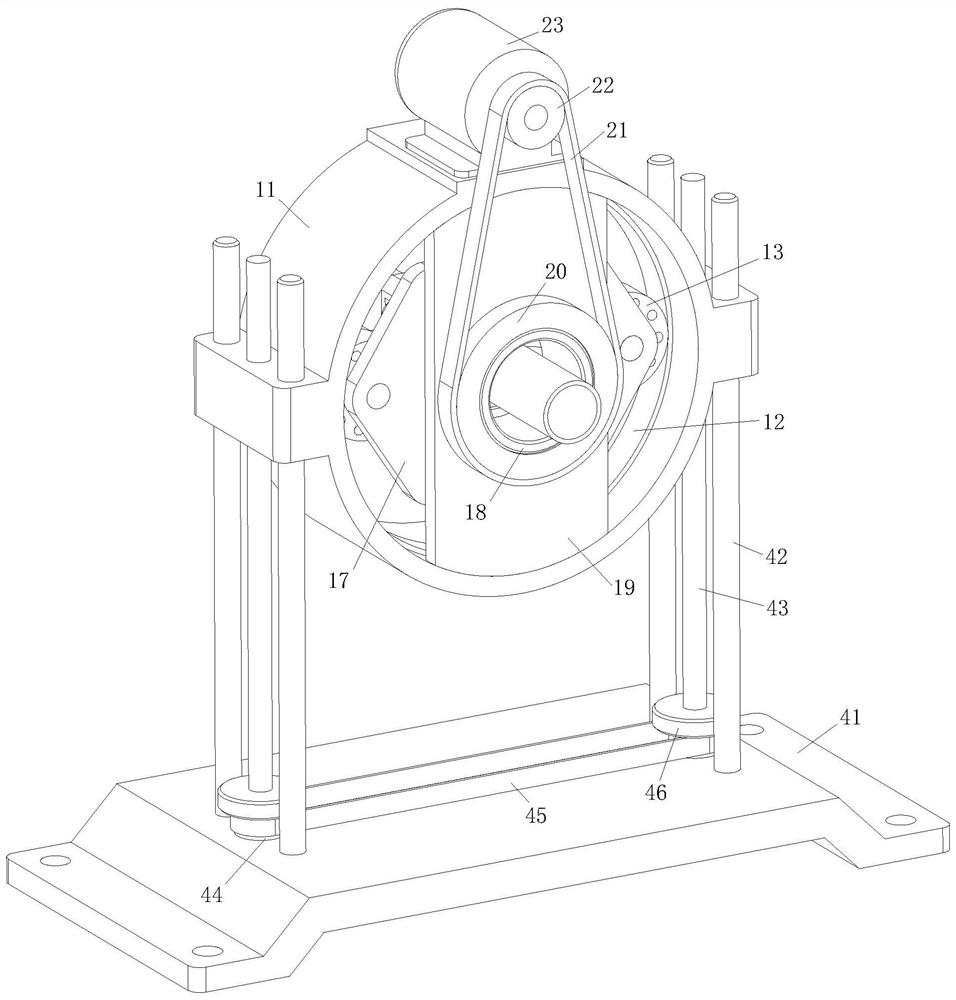

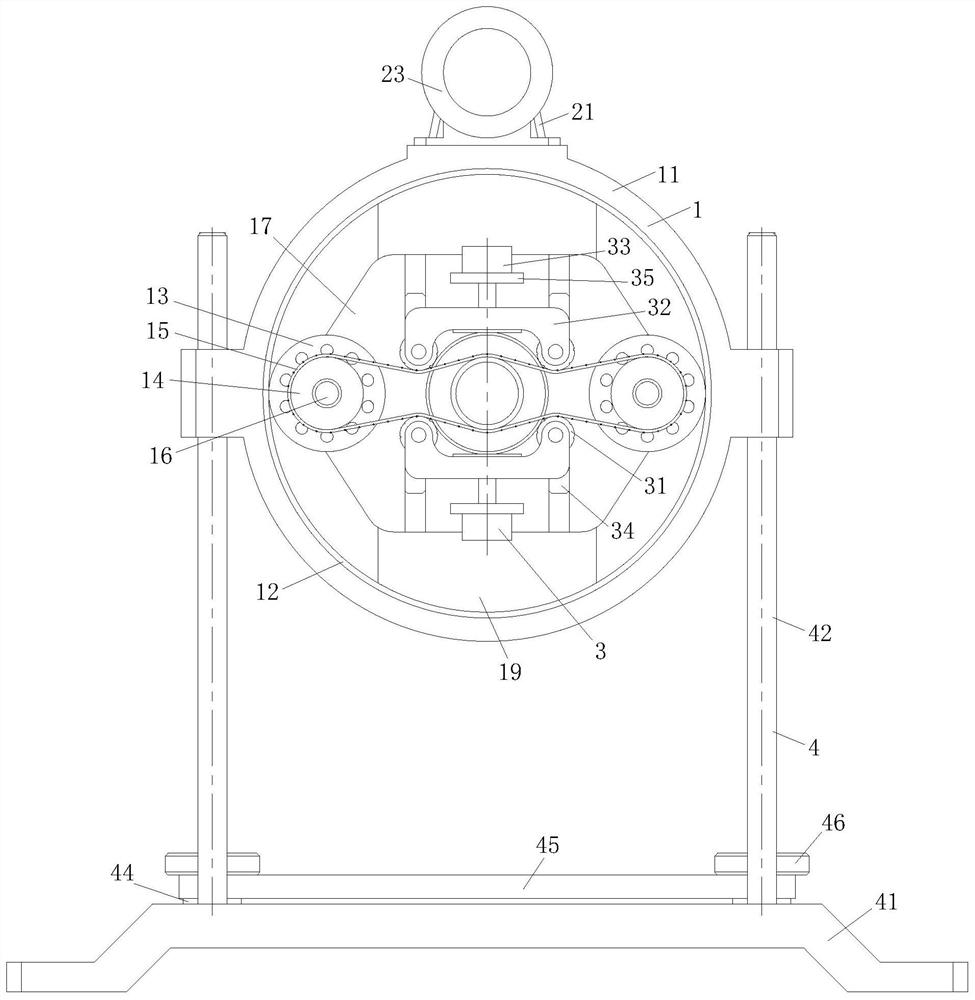

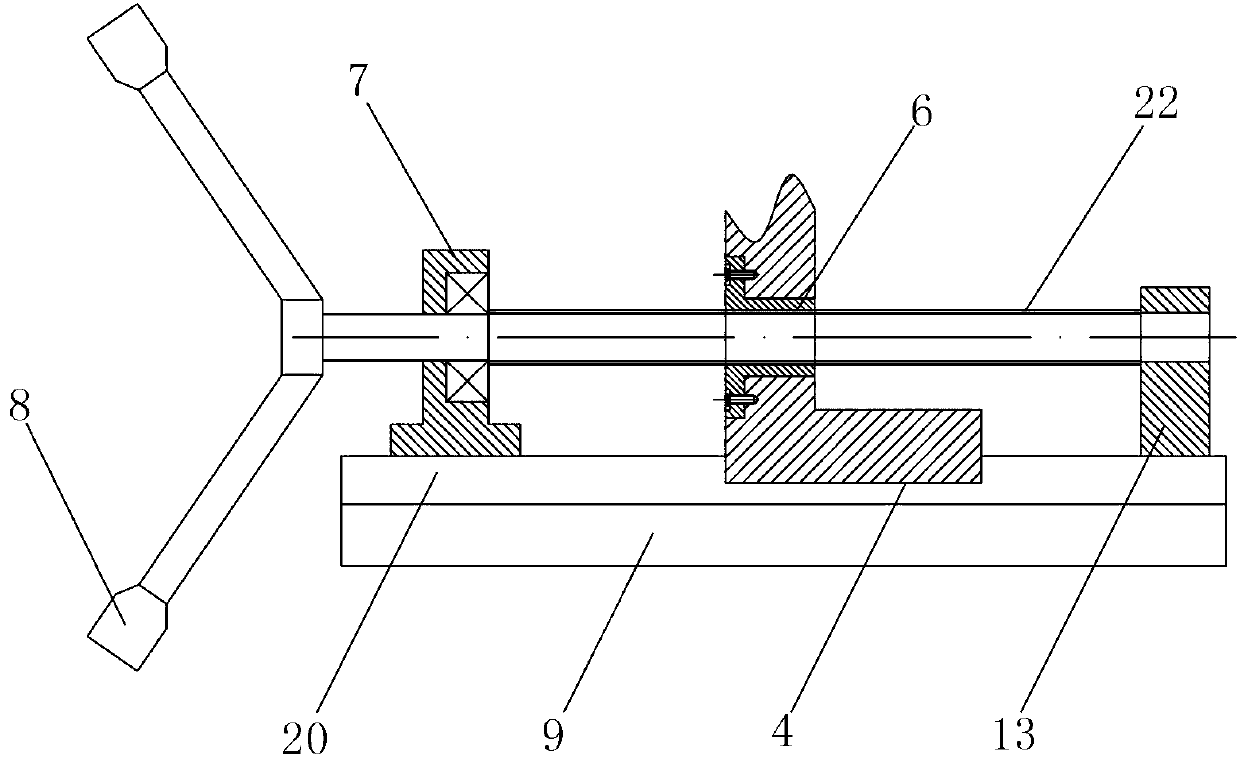

Portable uniform grinding device for welds of stainless steel tube

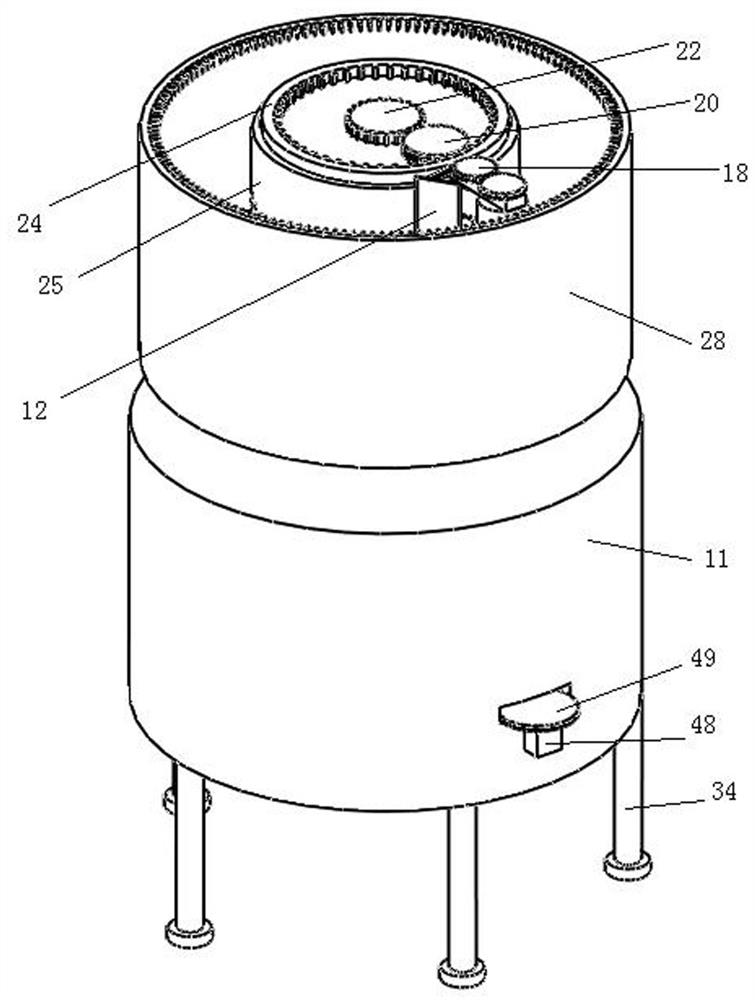

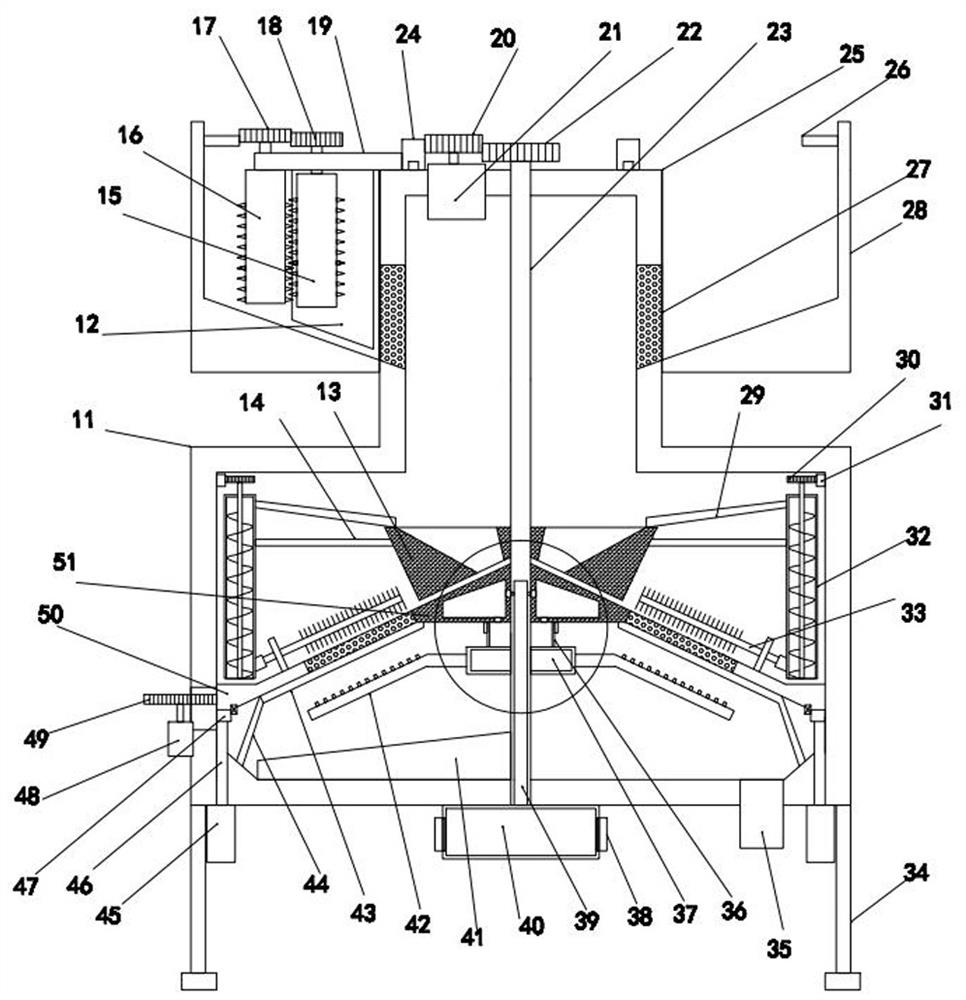

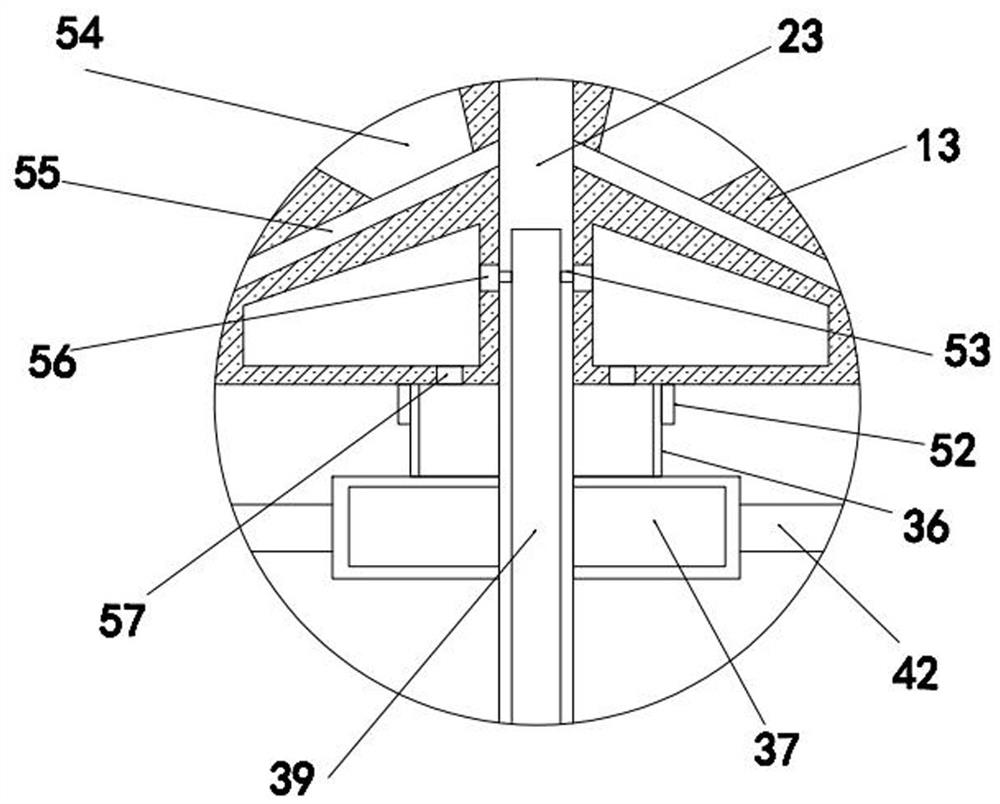

ActiveCN112247772AExtended service lifeGuaranteed grinding efficiencyBelt grinding machinesGrinding/polishing safety devicesGear wheelElectric machinery

The invention belongs to the technical field of grinding equipment, and particularly relates to a portable uniform grinding device for welds of a stainless steel tube. The portable uniform grinding device comprises a planet grinding component, a tensioning feeding component and a height adjusting component. The planetary grinding part comprises a cylindrical base, an annular gear ring, a planetarygear, a grinding belt wheel, a grinding belt, a first rotating shaft, a rotating plate, a hollow rotating shaft, a supporting plate, a first belt wheel, a first belt, a second belt wheel and a driving motor. According to the invention, the rotating plate is driven by the hollow rotating shaft to rotate, and the rotating plate drives the planetary gear and the grinding belt wheel to rotate aroundthe hollow rotating shaft through the first rotating shaft; meanwhile, the planetary gear meshes with the annular gear ring, so that the grinding belt wheel drives the grinding belt to rotate; and thegrinding belt driven by the grinding belt wheel rotates around the hollow rotating shaft at the same time, so that polishing points, which are in contact with the surface of the stainless steel tube,of the polishing belt can cover the surface of the whole stainless steel tube, and the moving speeds of the polishing points are uniform, thereby realizing uniform grinding for the welds on the surface of the stainless steel tube.

Owner:佛山市维通金属制品有限公司

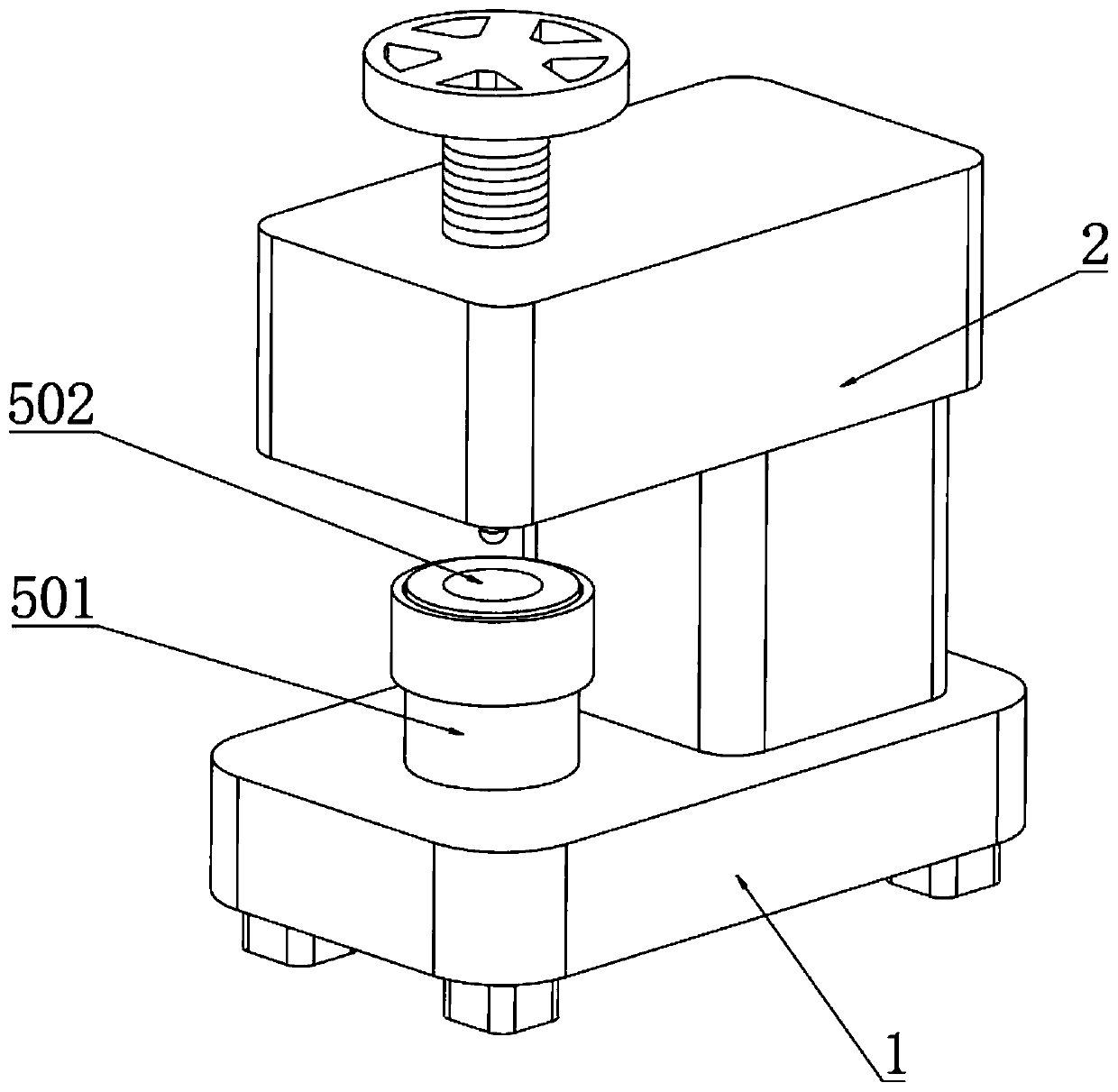

Anti-loss molecular biology experimental sample grinder

ActiveCN111530536AScientific and reasonable structureEasy to useGrain treatmentsRotational axisElectric machine

The invention discloses an anti-loss molecular biology experimental sample grinder. The anti-loss molecular biology experimental sample grinder comprises a base. A supporting frame is fixedly connected with the lateral side of the top end of the base. A lifting mechanism is movably connected with the lateral side of the top end of the supporting frame. The lifting mechanism comprises a rotating rod, a rotary disc, a round groove, a slide groove, a slider, a fixed base, rotating motor and a rotating shaft base. The rotating rod is screwed in and rotationally connected with the top end of the supporting frame. The rotary disc is cast at the top end of the rotating rod. The anti-loss molecular biology experimental sample grinder is scientific and reasonable in structure and safe and convenient to use; and the lifting mechanism is arranged and the rotary disc is rotated to drive the rotating rod to rotate, and the fixed base is pushed to slide up and down along the round groove through thecooperation of the slide groove and the slider, so that the heights of the fixed base, the rotating motor and the rotating shaft base are adjusted, then the gap between a grinding rod and a grindingpipe is adjusted according to needs, the grinding effect is improved, and biological experimental samples can be ground more sufficiently.

Owner:QINGDAO AGRI UNIV

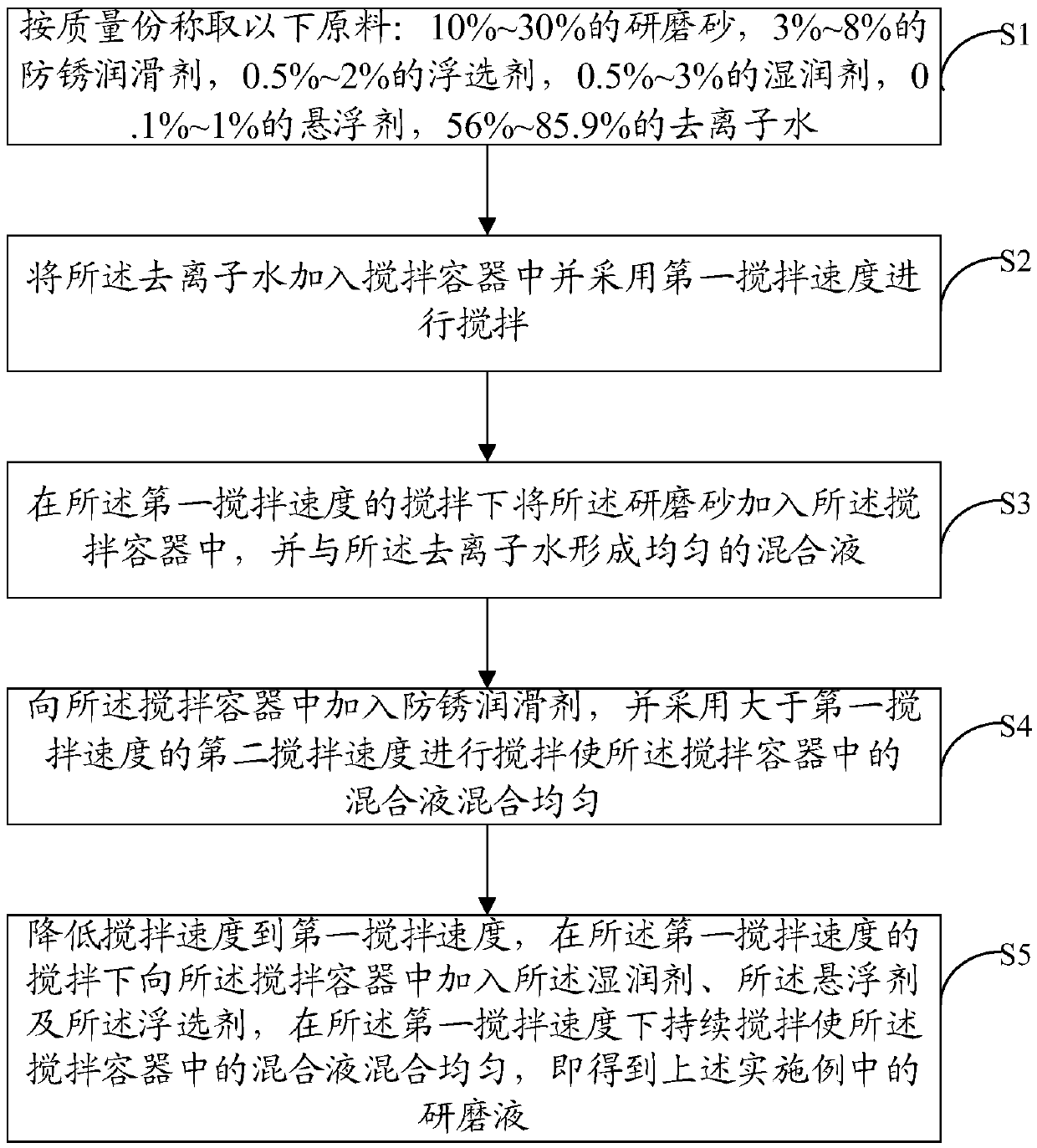

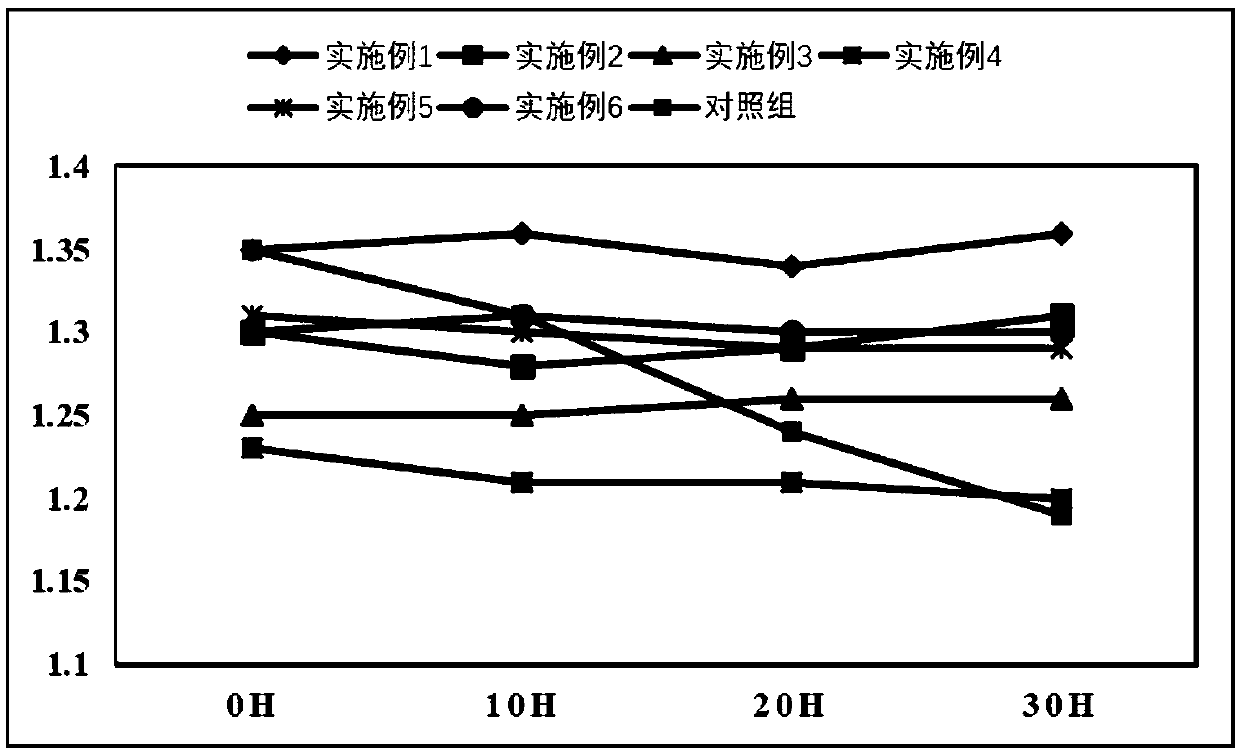

Grinding solution and preparation method thereof

InactiveCN109628064ALow efficiencySolve easy rustOther chemical processesSemiconductor materialsBatch processing

The invention discloses a grinding solution and a preparation method thereof. The grinding liquid is used for batch processing of semi-conductor material chips of novel silicon wafers, silicon chips and the like. The grinding solution comprises, by weight, 10%-30% of grinding sands, 3%-8% of an anti-rusting lubricant, 0.5%-2% of a flotation reagent, 0.5%-3% of a moistening agent, 0.1%-1% of a suspending agent and 56%-85.9% of deionized water. The grinding liquid and the preparation method have the advantages that inorganic alkali is not needed, which is safe and protects the environment, the grinding efficiency is maintained under the condition that the performance of the grinding solution is not reduced, the grinding sands can uniformly act on the surfaces of the silica wafers or the silica chips in the grinding process, and therefore the long-term use of the grinding solution is achieved while the efficiency is not reduced.

Owner:东莞市希尔金属材料有限公司

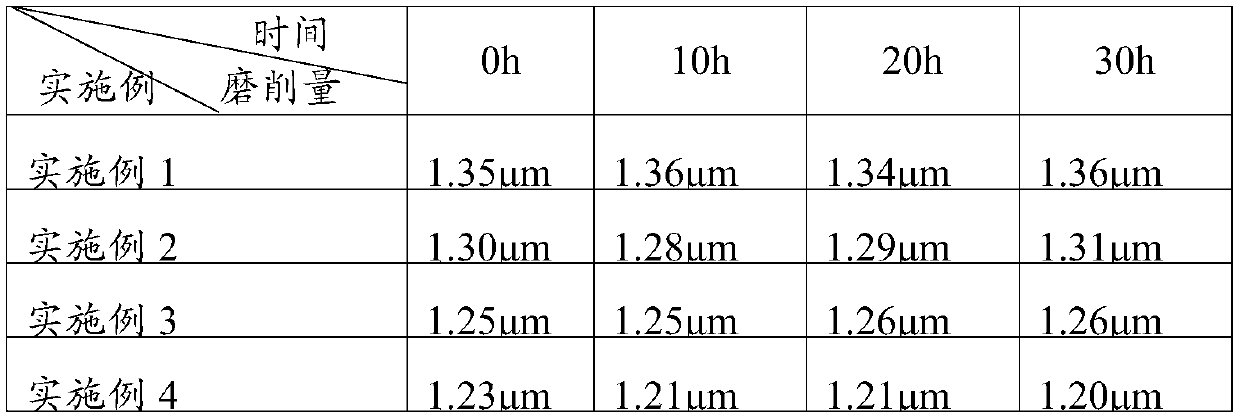

Powder coating production technology

The invention belongs to the technical field of coating production, in particular to a powder coating production technology. The grinding equipment in the technology comprises an upper shell, a lowershell, a feeding hopper, a grinding roller, a rolling roller, a grinding linear, an outer grinding cylinder, a connecting plate, a stay cord and a swing arm. A driving motor is arranged to drive the swing arm to quickly swing, the swing arm drives the connecting plate to move through the stay cord so as to drive the grinding roller and the rolling roller on the connecting plate to move to grind granular coating on the inner wall of the grinding linear, meanwhile, the breaking effect of the grinding roller is good, and grinding efficiency is improved; the coating which is grinded into small particles falls to the inner wall of the outer grinding cylinder from a No.1 baiting hole on the grinding linear; and the rolling roller on the outer wall of the outer grinding cylinder extrudes the outer grinding cylinder, the outer grinding cylinder deforms, meanwhile, the coating on the inner wall of the outer grinding cylinder is rolled, the rolling roller extrudes the outer grinding cylinder toenable the outer grinding cylinder to deform, and then, the coating is grinded. Since a contact area with the coating is large, grinded coating powder is fine.

Owner:永康市辰马工贸股份有限公司

Traditional Chinese medicine nursing smashing device and method for hypertension treatment

ActiveCN114733601AAvoid cloggingImprove grinding efficiencySievingScreeningMedicinal herbsNursing care

The traditional Chinese medicine nursing smashing device comprises a first box body and a plurality of supporting legs arranged at the lower end of the first box body, a second box body communicating with an inner cavity of the first box body is arranged in the middle of the upper end of the first box body, and a feeding groove used for feeding is formed in the outer side of the second box body; a feeding groove is formed in the outer side of the first box body, the feeding groove is annularly formed, a filtering ring net used for conducting preliminary screening on medicine is distributed on the outer side of the second box body, a smashing shaft is arranged between the first box body and the second box body, a fourth gear is arranged at the upper end of the smashing shaft, and a steering ring plate is rotationally arranged on the outer side of the upper end of the second box body; the screening device is designed according to existing requirements, medicinal materials can be pre-crushed so that the medicinal materials can be in a state suitable for grinding, the grinding efficiency can be improved, the surface of a screening face can be disturbed while grinding is conducted, reverse blowing operation can be conducted on the lower portion of the screening face, screening blockage is effectively avoided, and the screening efficiency is guaranteed.

Owner:THE CHINESE TRADITIONAL HERB MEDICINE RES INST HENAN PROV

Polishing device for battery protection shell of reconnaissance robot

InactiveCN113043089AIncrease flexibilityReduce dead angleGrinding wheel securing apparatusGrinding carriagesElectrical batteryElectric machinery

The invention discloses a polishing device for a battery protection shell of a reconnaissance robot, and relates to the technical field of battery protection shell polishing devices. The polishing device is used for conveniently polishing battery protection shells of different shapes. The polishing device specifically comprises a base and a supporting mechanism; a supporting frame is fixed to the outer wall of the top of the base through bolts, an electric lead screw sliding rail is fixed to the inner wall of one side of the supporting frame through bolts, a sliding block is slidably connected to the output end of the electric lead screw sliding rail, and a first telescopic frame is fixed to the outer wall of one side of the sliding block through bolts; and the same fourth spring is clamped to the inner wall of one side of the sliding block and the inner wall of one side of the first telescopic frame, a first polishing motor is fixed to the outer wall of the top of the first telescopic frame through bolts, and a first mounting column is rotationally connected to the outer wall of the bottom of the first telescopic frame. By arranging the electric lead screw sliding rail, the sliding block can be driven to move in the horizontal direction, and the supporting mechanism can be used for containing a cylindrical protection shell.

Owner:章余

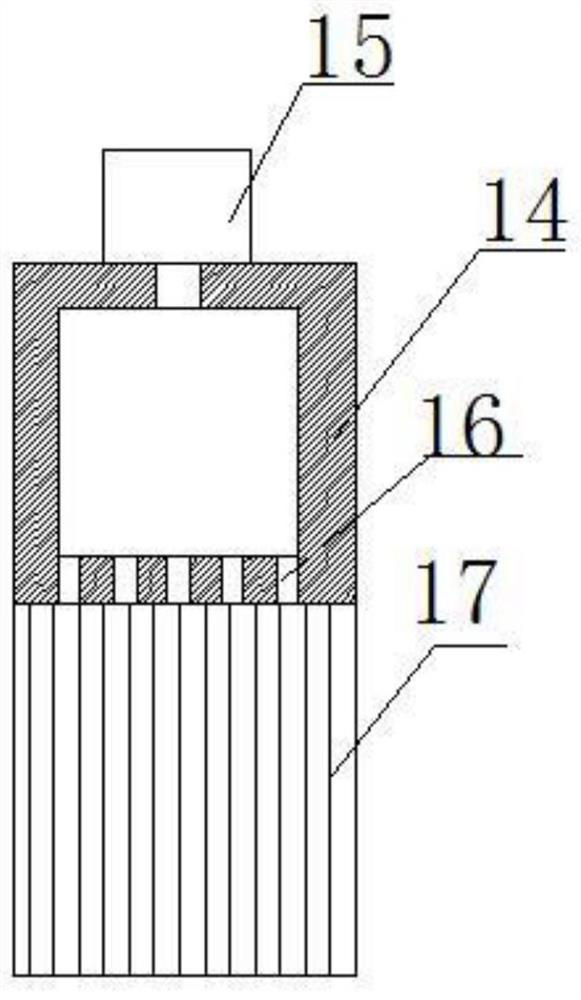

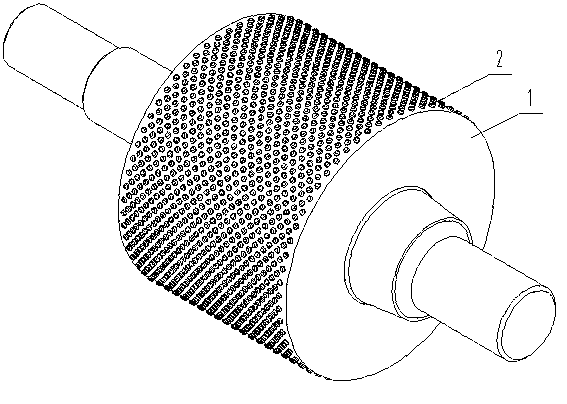

Magnetism column pin roller

InactiveCN103008051AReduce wearGuaranteed grinding efficiencyGrain treatmentsPulp and paper industryMagnetism

The invention discloses a magnetism column pin roller, and belongs to the technical field of roller grinding equipment. The magnetism column pin roller provided by the invention comprises a magnetism roller body and column pins, and the plurality of column pins are uniformly distributed on the surface of the magnetism roller body. Through the magnetism column pin roller provided by the invention, materials form a material gasket automatically on the surface of the roller body, meanwhile, materials with magnetism also are absorbed on the surface of the roller body among the column pins so as to form a material gasket; and when the material gasket on the surface of the roller body slides off and the magnetism materials passes by the region again, the magnetism materials automatically fill and are absorbed on the surface of the roller body in the region, automatically fills the region in which the material gasket slides off and forms the material gasket, thus the roller body abrasion is reduced, the device maintaining expense is lowered, the device running efficiency is improved, and the roller press grinding efficiency is ensured.

Owner:CHENGDU LEEJUN IND

Pulverizing mill for producing activated carbon

InactiveCN104492550AGuaranteed grinding efficiencyShorten the production cycleGrain treatmentsActivated carbonEngineering

The invention belongs to the technical field of mechanical production equipment, and particularly relates to a pulverizing mill for producing activated carbon. The technical problems of low pulverizing efficiency and the like of the prior art are solved. The pulverizing mill for producing activated carbon comprises a base with a cavity, wherein a material feeding hole is formed in the base, an air inlet hole communicated with the cavity is formed in the bottom of the base, an air outlet and material discharging hole is formed in the top of the base, a main millstone capable of rotating relative to the base is arranged in the cavity of the base, the main millstone is connected with a millstone drive mechanism capable of driving the main millstone to rotate, and a grading and sieving mechanism capable of grading and sieving ground materials so as to discharge the ground materials which are graded and sieved out from the air outlet and material discharging hole is arranged above the main millstone when air enters into the cavity from the air inlet hole. Compared with the prior art, the pulverizing mill has the advantages of high pulverizing efficiency and excellent practicability.

Owner:ZHEJIANG XINGDA ACTIVATED CARBON

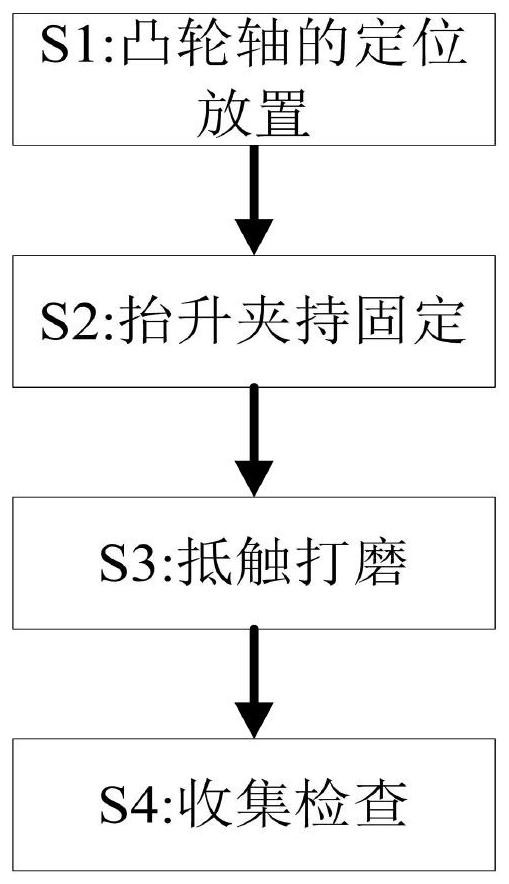

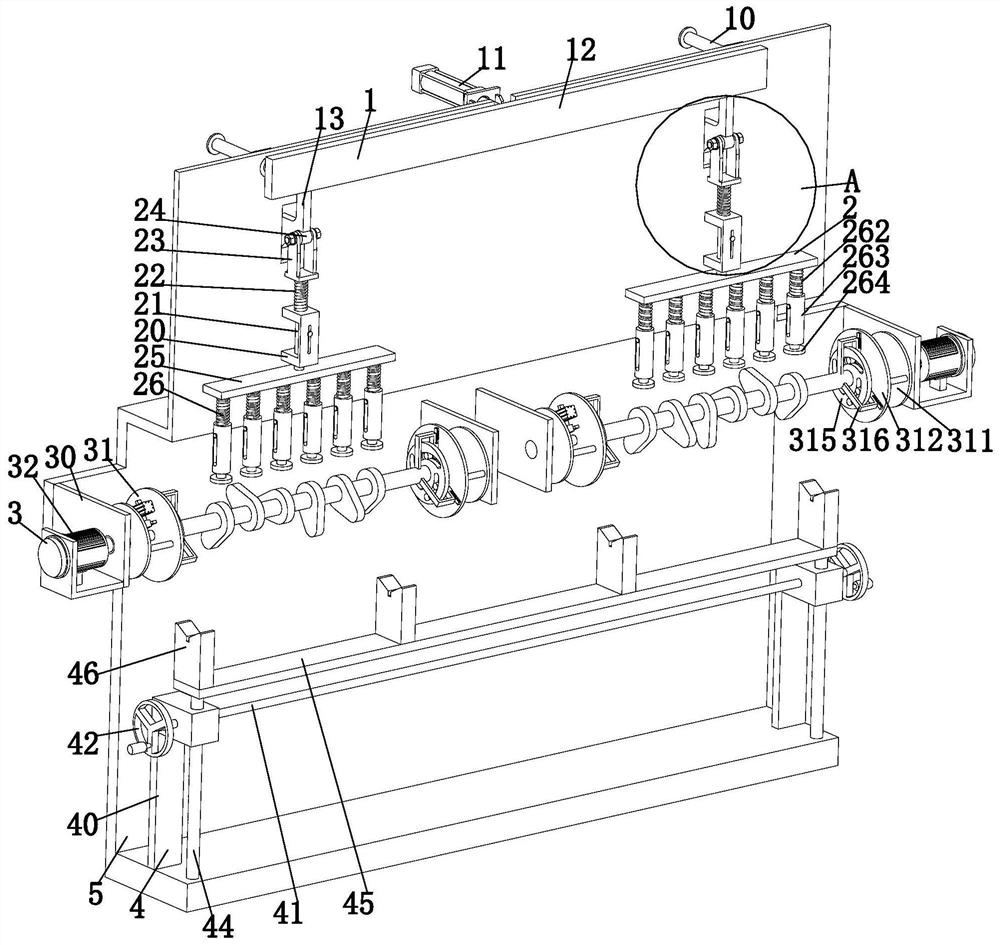

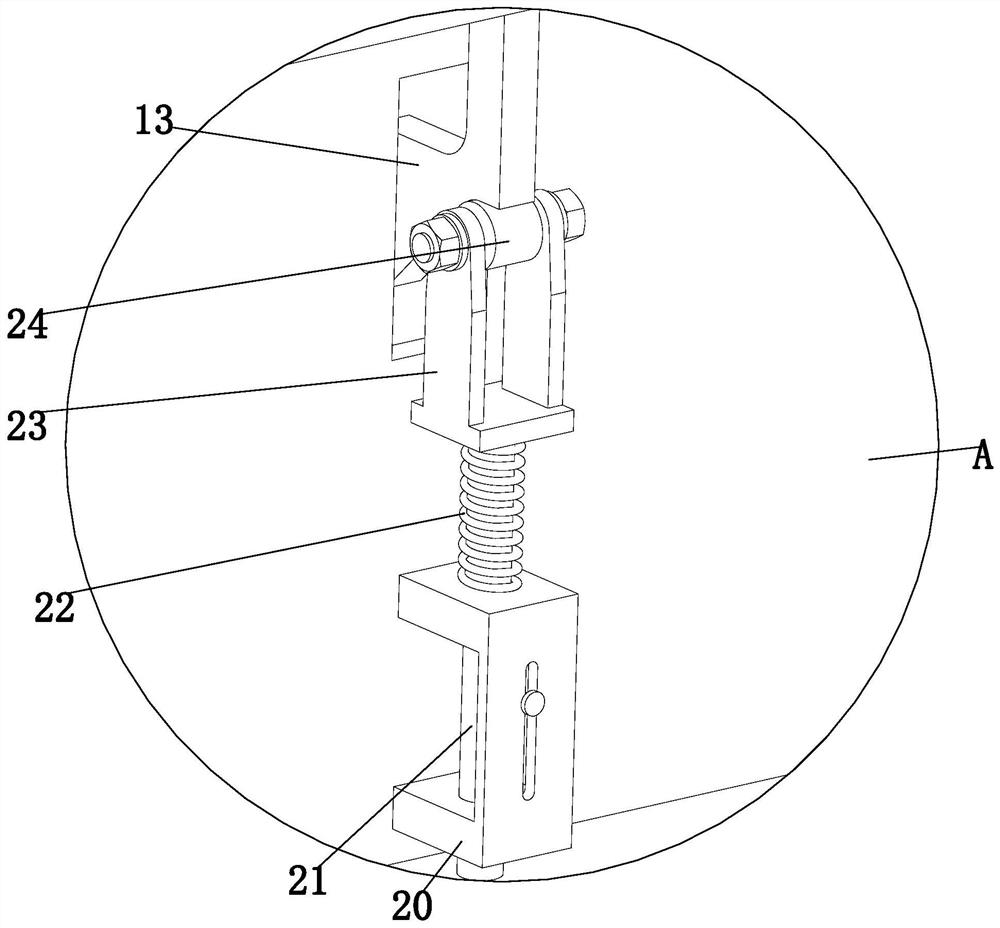

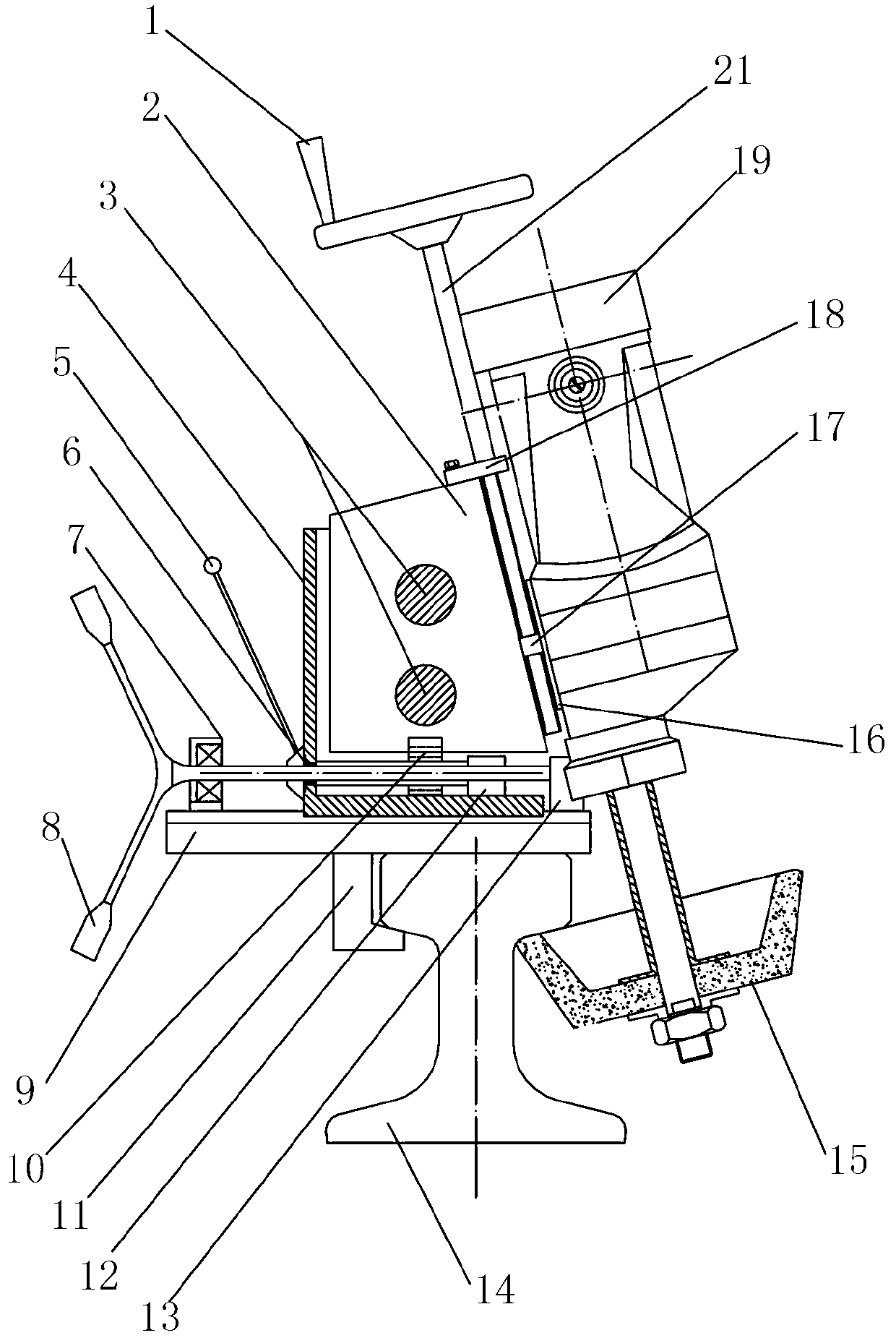

Engine camshaft manufacturing and machining process

InactiveCN112476068ATimely replacementEfficient removalGrinding carriagesGrinding drivesMachining processCamshaft

The invention provides an engine camshaft manufacturing and machining process which comprises pushing mechanisms, polishing mechanisms, clamping mechanisms, lifting mechanisms and a main beam verticalplate frame. The pushing mechanisms are installed on the main beam vertical plate frame, the polishing mechanisms are arranged under the pushing mechanisms, and the polishing mechanisms are symmetrically installed on the outer wall of the main beam vertical plate frame; and the polishing mechanisms are connected with the pushing mechanisms in a rolling manner, the clamping mechanisms are arrangedunder the polishing mechanisms and symmetrically installed on the outer wall of the main beam vertical plate frame, and the lifting mechanisms are arranged under the clamping mechanisms and installedon the bottom end face of the main beam vertical plate frame. According to the engine camshaft manufacturing and machining process, the problems of high operation difficulty, low polishing efficiency, low polishing precision, easy generation of burrs, incapability of normal operation of the whole mechanical system due to existence of the burrs, reduced reliability and stability, influence on product quality and the like caused by polishing by adopting a manual manner in general factories are solved.

Owner:杭州佳顿智能科技有限公司

Rail jaw refiner of rocket sled sliding rail welding connector

ActiveCN103128616ASimple structureNovel and reasonable designPlane surface grinding machinesBench grinderRocket

The invention discloses a rail jaw refiner of a rocket sled sliding rail welding connector. The rail jaw refiner comprises a fixed base fixedly installed on the rocket sled sliding rail welding connector and a straight-direction grinding machine arranged on one side of a rocket sled sliding rail and used for grinding a rail jaw of the rocket sled sliding rail welding connector. The upper surface of a grinding wheel of the straight-direction grinding machine is bonded to the rail jaw of the rocket sled sliding rail welding connector, a transverse adjusting mechanism capable of moving transversely along the rocket sled sliding rail is installed on the fixed base and is connected with a vertical adjusting mechanism used for driving the straight-direction grinding machine to move vertically along the rocket sled sliding rail, and the vertical adjusting mechanism is connected with the straight-direction grinding machine through a height adjusting mechanism used for driving the straight-direction grinding machine to move vertically. The rail jaw refiner of the rocket sled sliding rail welding connector is high in automation degree, simple to process and convenient to use, saves cost and has wide popularization and application value in laying of rocket sled sliding rail jointless tracks.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

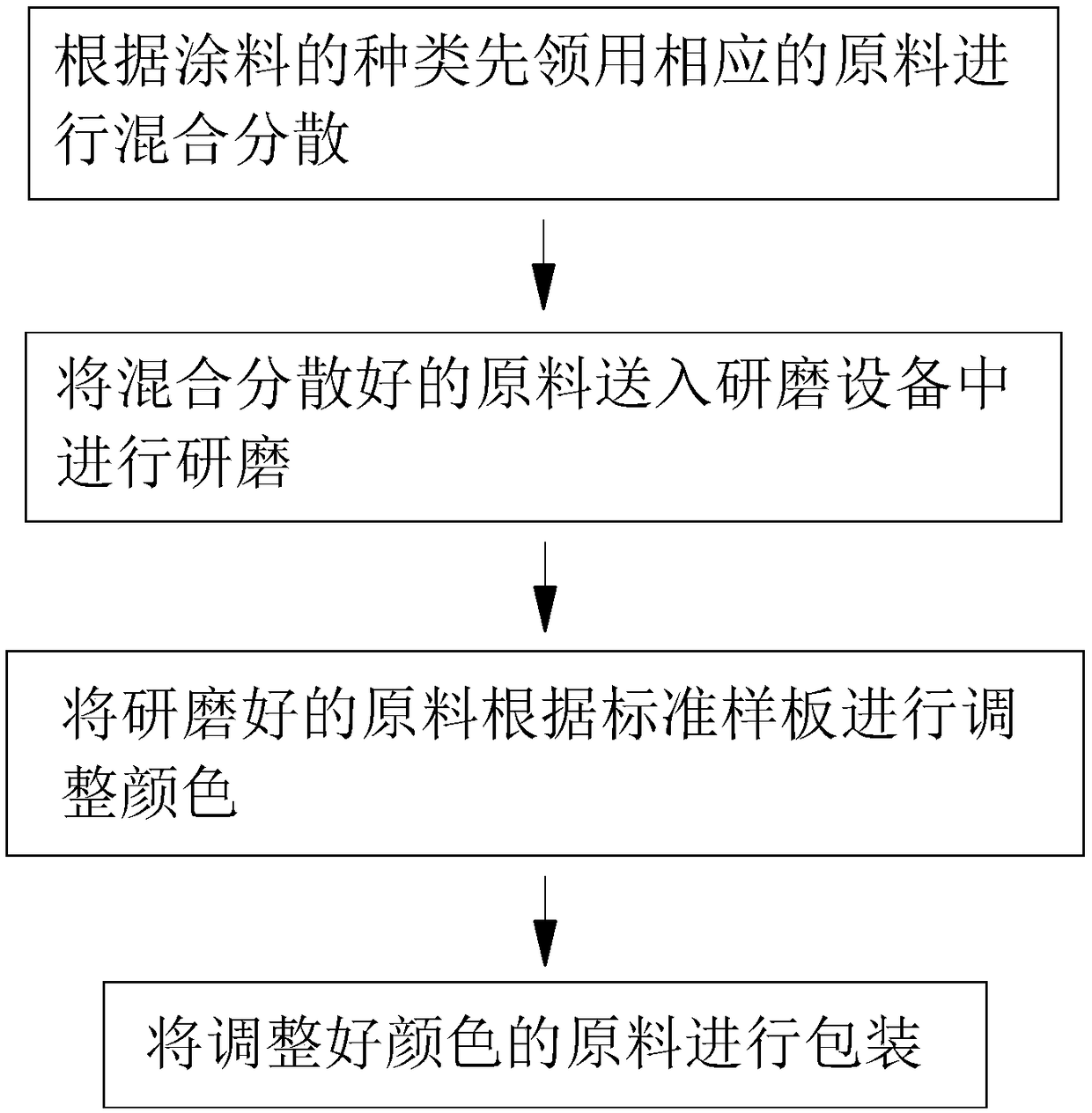

Macromolecular water-based paint grinding device

ActiveCN113368947AImprove efficiencyGuaranteed grinding efficiencyGrain treatmentsReciprocating motionProcess engineering

The invention discloses a macromolecular water-based paint grinding device which comprises a base. A collecting base plate is arranged on the base, a machine body shell is arranged on the collecting base plate, a machine body cavity with an upward opening is formed in the machine body shell, and a mashing mechanism is arranged on the machine body shell. According to the macromolecular water-based paint grinding device, a mashing roller is used for grinding raw materials for the first time, then the mashed raw materials are divided into two parts, mashed chippings are smashed again through a planetary gear structure and a reciprocating motion structure, the smashing efficiency is extremely high, then the fully-smashed materials are ground for the third time, and the raw materials to be treated are ground for the third time, so that the grinding efficiency is greatly guaranteed, grinding is more thorough, the product quality is improved, and waste caused by unqualified raw materials is prevented.

Owner:广东升百年新材料科技有限公司

Ball mill

InactiveCN111744609AUniform material diameterGuaranteed grinding efficiencyGrain treatmentsEngineeringPipe

The invention relates to the field of smashing devices, and discloses a ball mill. The ball mill comprises a supporting seat, a ball mill body, an air inlet pipe, a first feeding pipe, a discharging pipe, a discharging hopper and an air outlet pipe. A rough filtration feeding hopper is arranged at the top of the first feeding pipe in a communicating mode, and a refined filtration detection deviceis arranged on one side of the ball mill body. The refined filtration detection device comprises a shell, a rotating pipe and a screening barrel, an unqualified material recovery pipe is rotatably arranged at the bottom of the screen barrel in a communicating mode, qualified material discharging hoppers are arranged at the positions, located on the two sides of the unqualified material recovery pipe, of the bottom of the shell in a communicating mode, a power device for driving the rotating pipe to rotate is arranged at the position, located on one side of the rotating pipe, of the top of theshell, a second feeding pipe is rotatably arranged in the rotating pipe, one end of the second feeding pipe is stretched into the rotating pipe, and a material-lifting and feeding device is arranged at the end, away from the screen barrel, of a discharging opening of the discharging hopper and the second feeding pipe in a communicating mode. The ball mill can improve the insufficient grinding of materials, so that the ground materials are more uniform, and thus the product quality is ensured.

Owner:SHAANXI ZHENGYUAN QINDIAN ENVIRONMENTAL PROTECTION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com