Polishing device for high-quality sheet metal processing

A plate processing, high-quality technology, applied in the direction of grinding drive device, grinding/polishing safety device, metal processing equipment, etc., can solve the problems affecting the efficiency and quality of grinding, leaving on the plate, etc., to achieve practical Strong performance, guaranteed grinding quality, and guaranteed grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

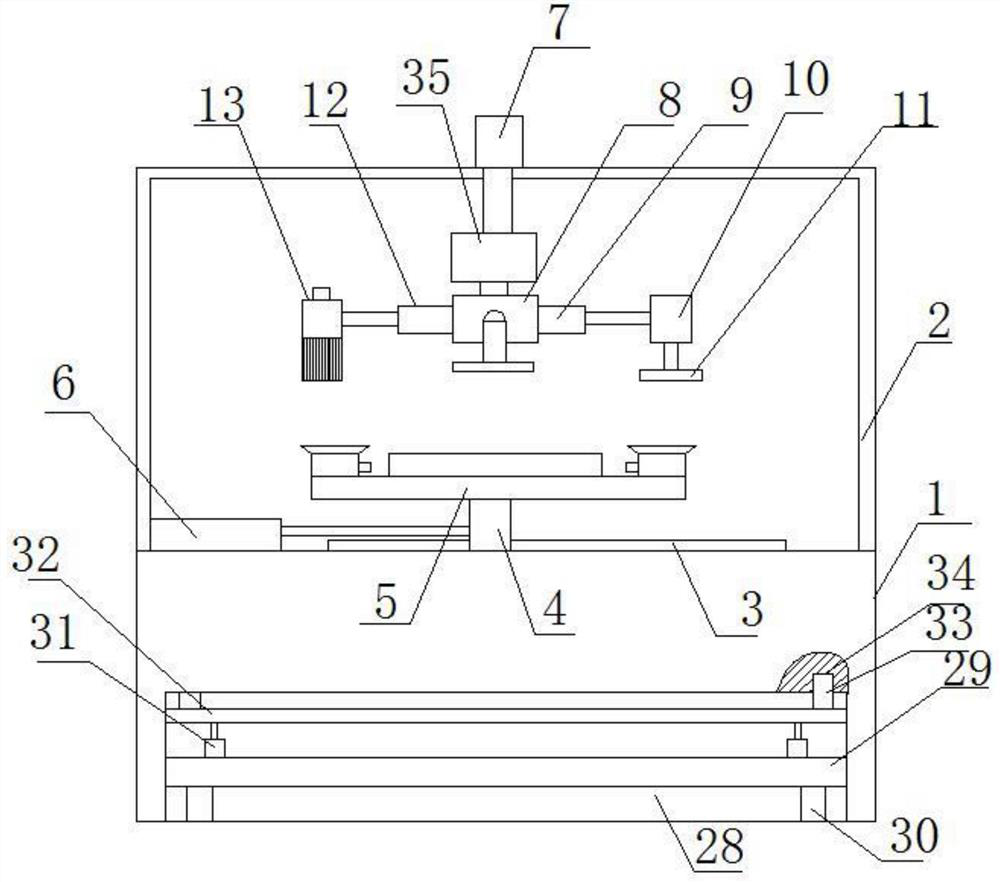

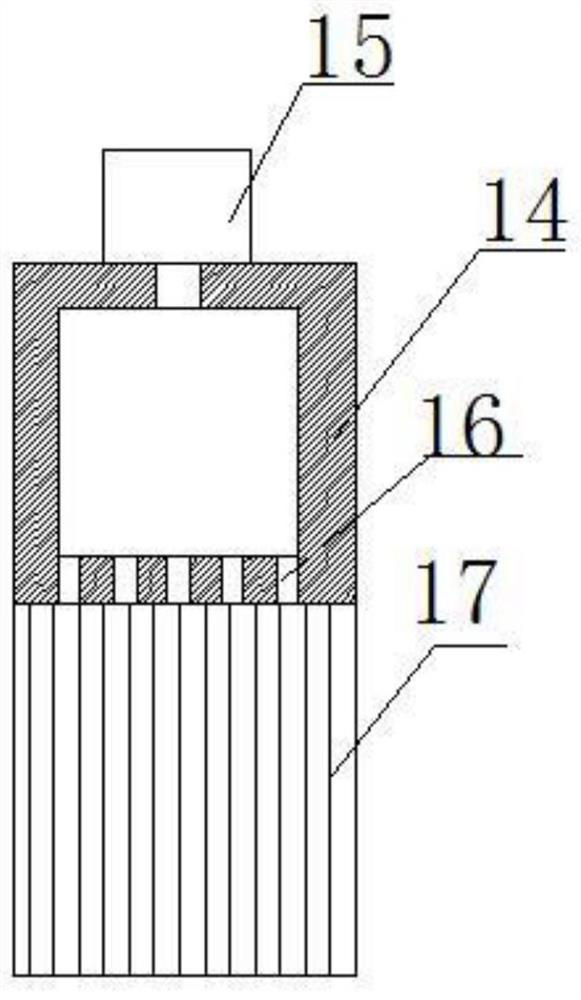

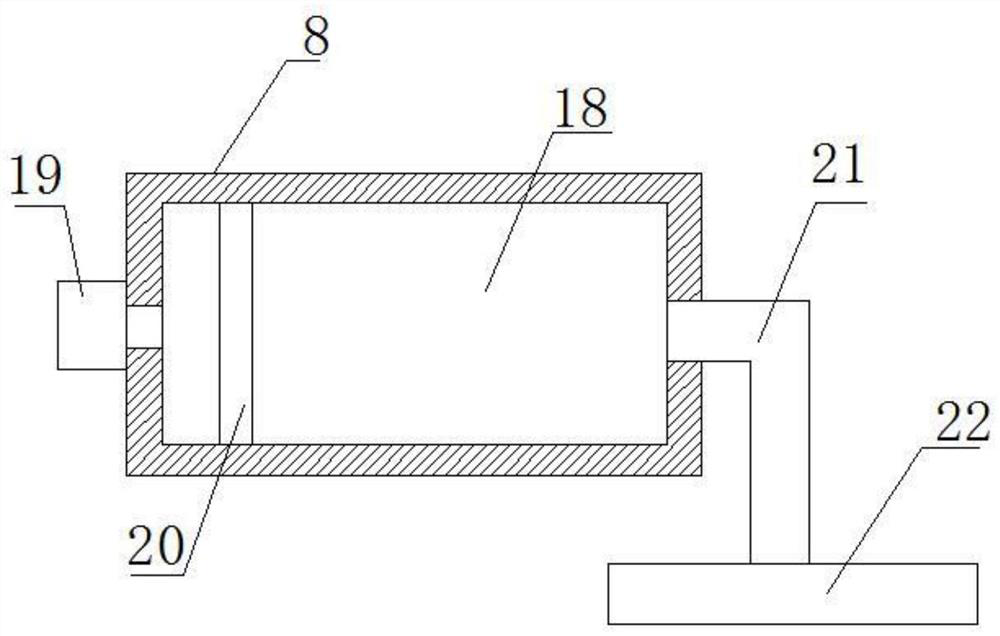

[0022] see Figure 1-4 , in an embodiment of the present invention, a high-quality plate processing grinding device includes a workbench 1, the upper end of the workbench 1 is provided with a machine cover 2, the upper end of the workbench 1 is provided with a plate fixing mechanism, and the inside of the machine cover 2 The upper end is provided with a first telescopic mechanism 7, and the lower end of the first telescopic mechanism 7 is provided with a rotating motor 35, and the output end of the rotating motor 35 is provided with a grinding mechanism, and the grinding mechanism includes a device installed at the lower end of the rotating motor 35. seat 8, the left and right ends of the mounting seat 8 are symmetrically provided with a second telescopic mechanism 9 and a third telescopic mechanism 12, the outer end of the second telescopic mechanism 9 is provided with a grinding motor 10, and the lower end of the grinding motor 10 is provided with There is a grinding disc 11...

Embodiment 2

[0025] On the basis of the first embodiment, the lower end of the workbench 1 is provided with a cavity 28, and the inside of the cavity 28 is provided with a standing mechanism, and the standing mechanism includes a slide plate 29, and the lower side of the slide plate 29 is provided with Several moving wheels 30, the upper side of the slide plate 29 are provided with some fifth telescopic mechanisms 31, the upper end of the fifth telescopic mechanism 31 is provided with a standing plate 32, and the upper left and right ends of the standing plate 32 are provided with limiting columns 33 , the inner upper end of the cavity 28 is provided with a limiting slot 34 that cooperates with the limiting column 33 . The setting of this structure can drive the fifth telescopic mechanism 31 when the device needs to move, so that the moving wheel 30 extends out of the cavity 28, which facilitates the movement of the device. After moving to a designated position, the moving wheel 30 can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com