A fully automatic wood processing device

A processing device, fully automatic technology, applied in the direction of grinding drive device, grinding/polishing safety device, metal processing equipment, etc., can solve the problems that affect the normal use of the grinder, reduce the aesthetics of the wood board, and affect the stability of the grinding performance. Achieve the effect of reducing the difficulty of sales, saving manpower, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

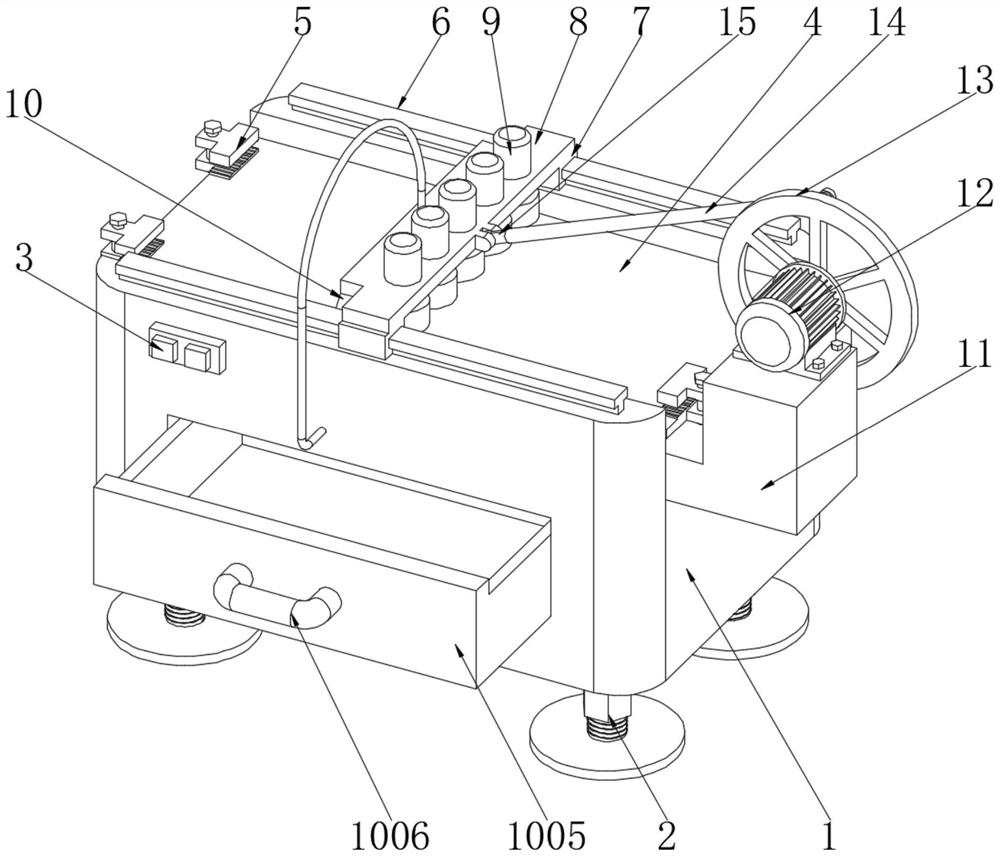

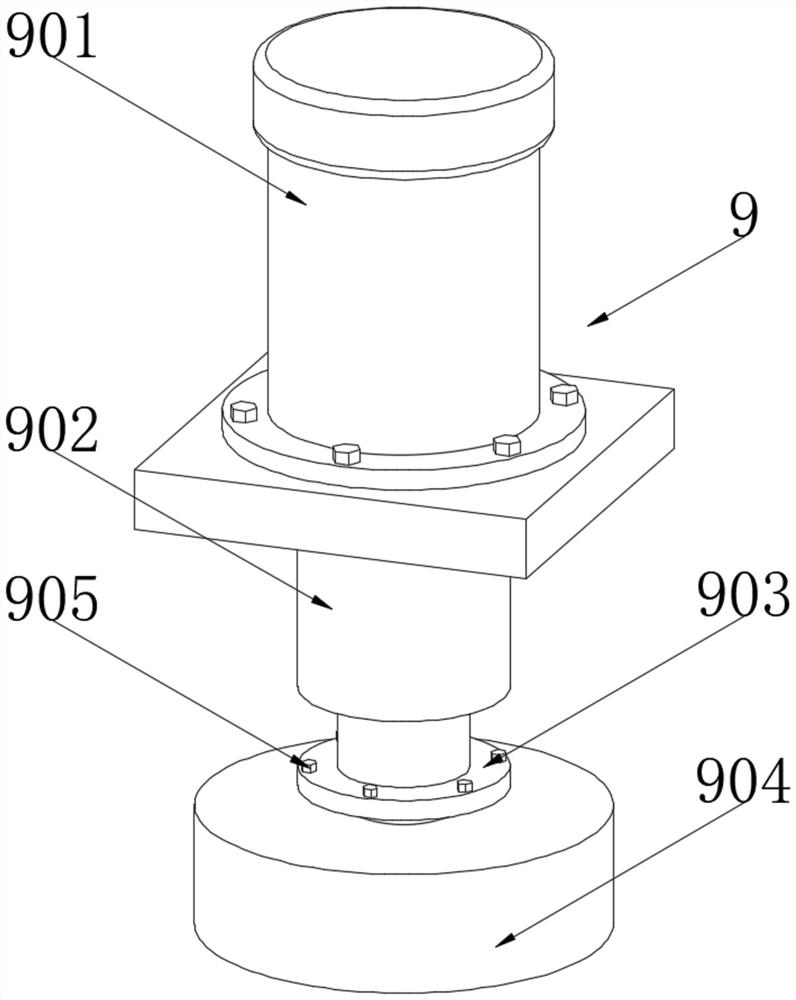

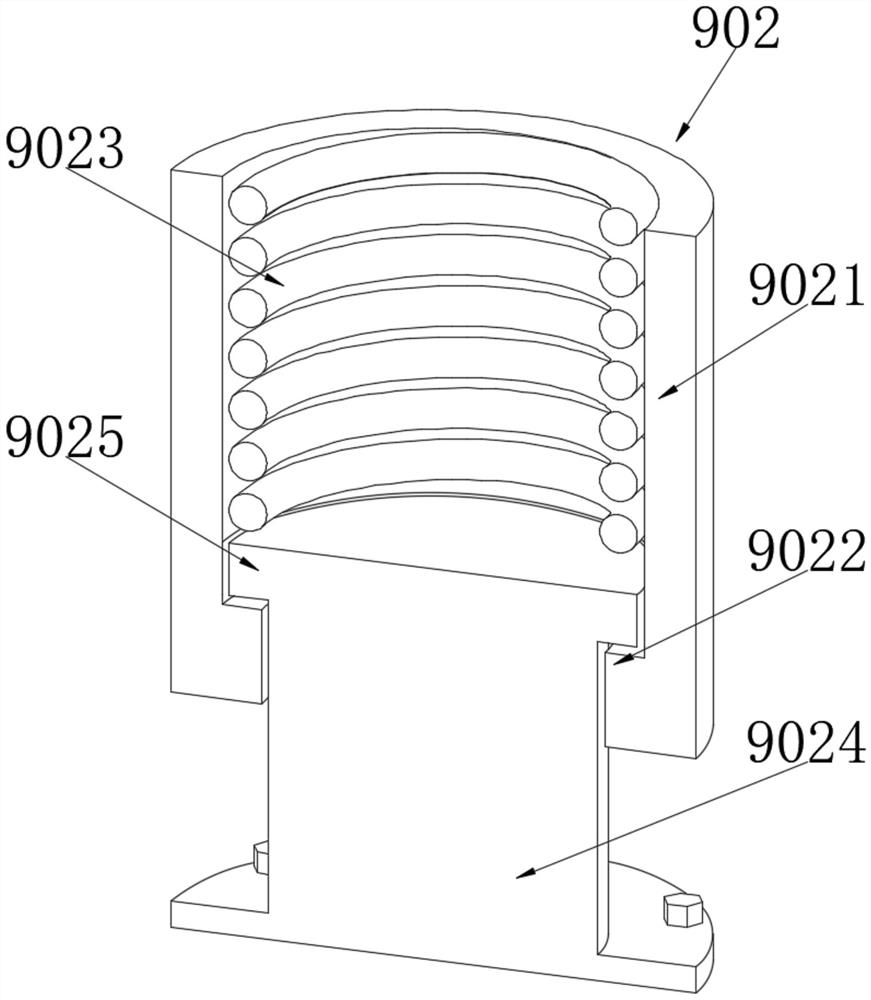

[0033] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a fully automatic wood processing device, including a processing table 1, in order to make the processing table 1 more stable by adjusting the support assembly 2 when the ground is uneven, during use Shaking will not occur in the middle of the processing table 1, each top corner of the bottom of the processing table 1 is equipped with a support assembly 2, the support assembly 2 includes a support rod 201, a first threaded rod 202, a hexagonal internal thread pipe 203, a second threaded rod 204, and a support base 205 , anti-slip rubber bump 206, the bottom end of the support rod 201 is welded with a first threaded rod 202, the outside of the bottom end of the first threaded rod 202 is sleeved with a hexagonal internal thread pipe 203, and the bottom end of the hexagonal internal thread pipe 203 is inserted with a second thread Rod 204, the bottom end of the second threaded rod 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com