A grinding test equipment

A test equipment, grinding ring technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems such as the inability to observe the grinding efficiency, the inability to fine-tune the amplitude, and the short vibration grinding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

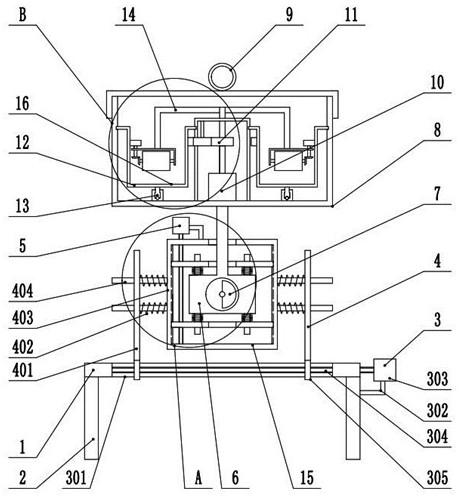

[0033] see Figure 1-7 , a grinding test equipment, including a mounting base 1 and a support leg 2 fixed on the bottom of the mounting base 1;

[0034] The mounting base 1 is provided with a vibration assembly 15, and the vibration assembly 15 includes a horizontal adjustment mechanism 3, a horizontal vibration mechanism 4, a vertical adjustment mechanism 5, a vertical vibration mechanism 6 and a vibration mechanism 7, and the horizontal adjustment mechanism 3 is used for Adjust the horizontal vibration mechanism 4, the vertical adjustment mechanism 5 is used to adjust the vertical vibration mechanism 6, and the vibration mechanism 7 is used to drive the horizontal vibration mechanism 4 and the vertical vibration mechanism 6 to vibrate;

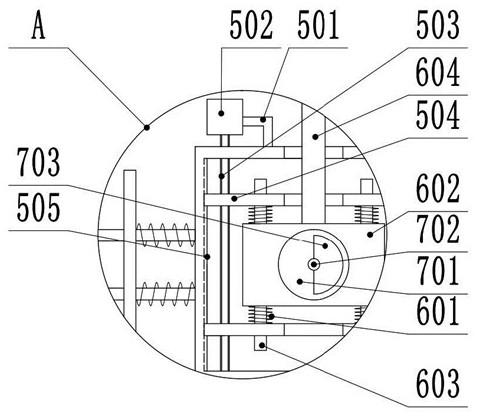

[0035] The horizontal adjustment mechanism 3 is arranged on the mounting base 1, the horizontal vibration mechanism 4 is fixed on the horizontal adjustment mechanism 3, the vertical adjustment mechanism 5 is arranged on the horizontal vibrat...

Embodiment 2

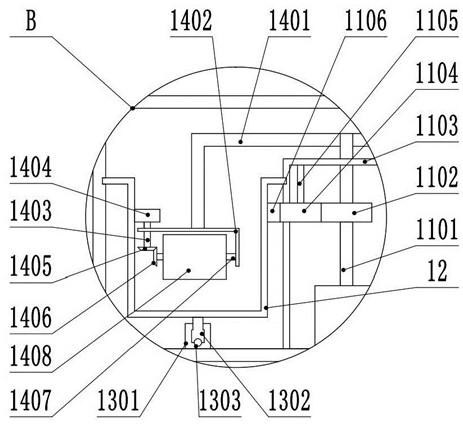

[0048] see image 3 The other content of this embodiment is the same as that of Embodiment 1, except that the rotating mechanism 13 includes a rotating outer tank 1301 fixed at the bottom of the box body 8, and the rotating outer tank 1301 is connected to the rotating ring 1302 in rotation, and the rotating ring 1302 and Several balls 1303 are arranged between the rotating outer grooves 1301, and the rotating ring 1302 is fixedly connected with the grinding ring groove 12. Specifically, when the grinding ring groove 12 rotates, the rotating ring 1302 will rotate around the rotating outer groove 1301.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com