Patents

Literature

58results about How to "Avoid injury hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

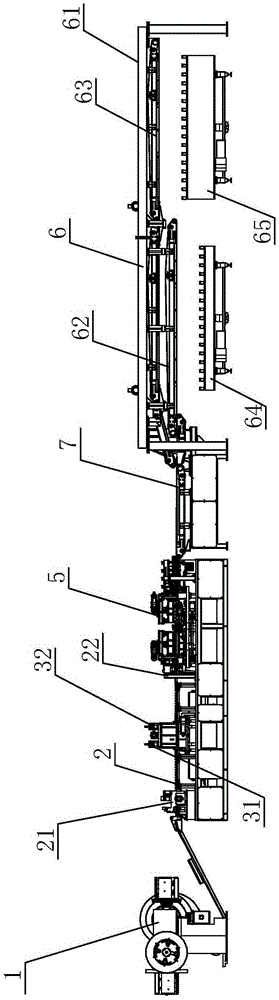

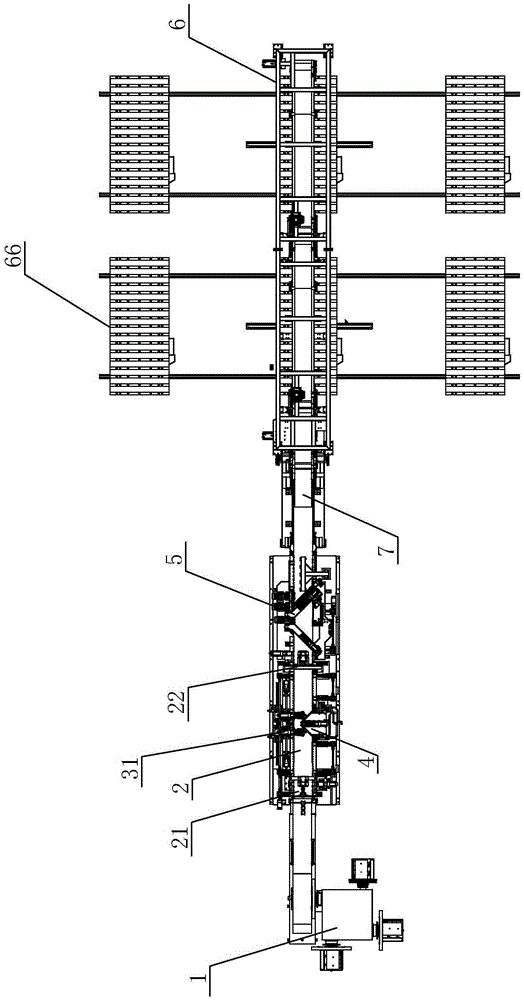

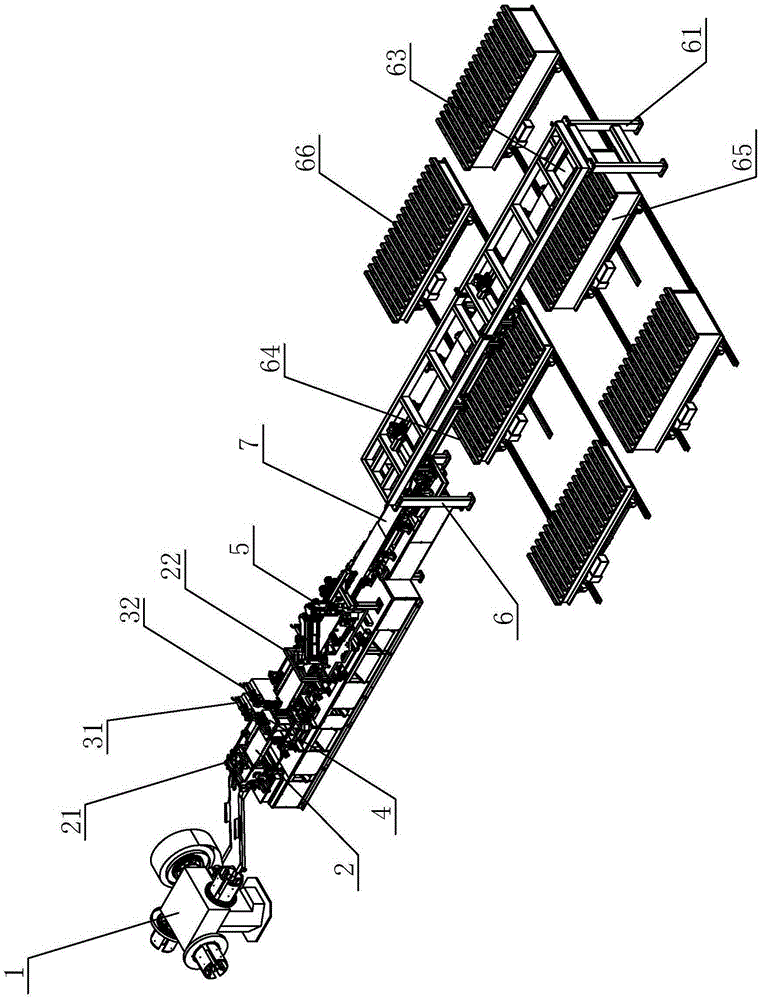

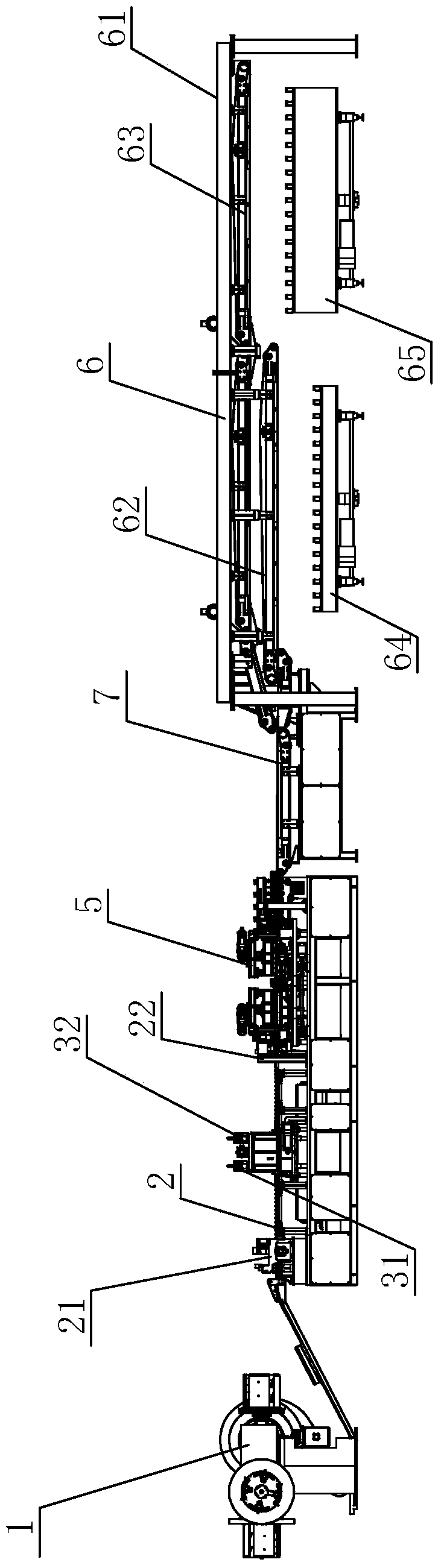

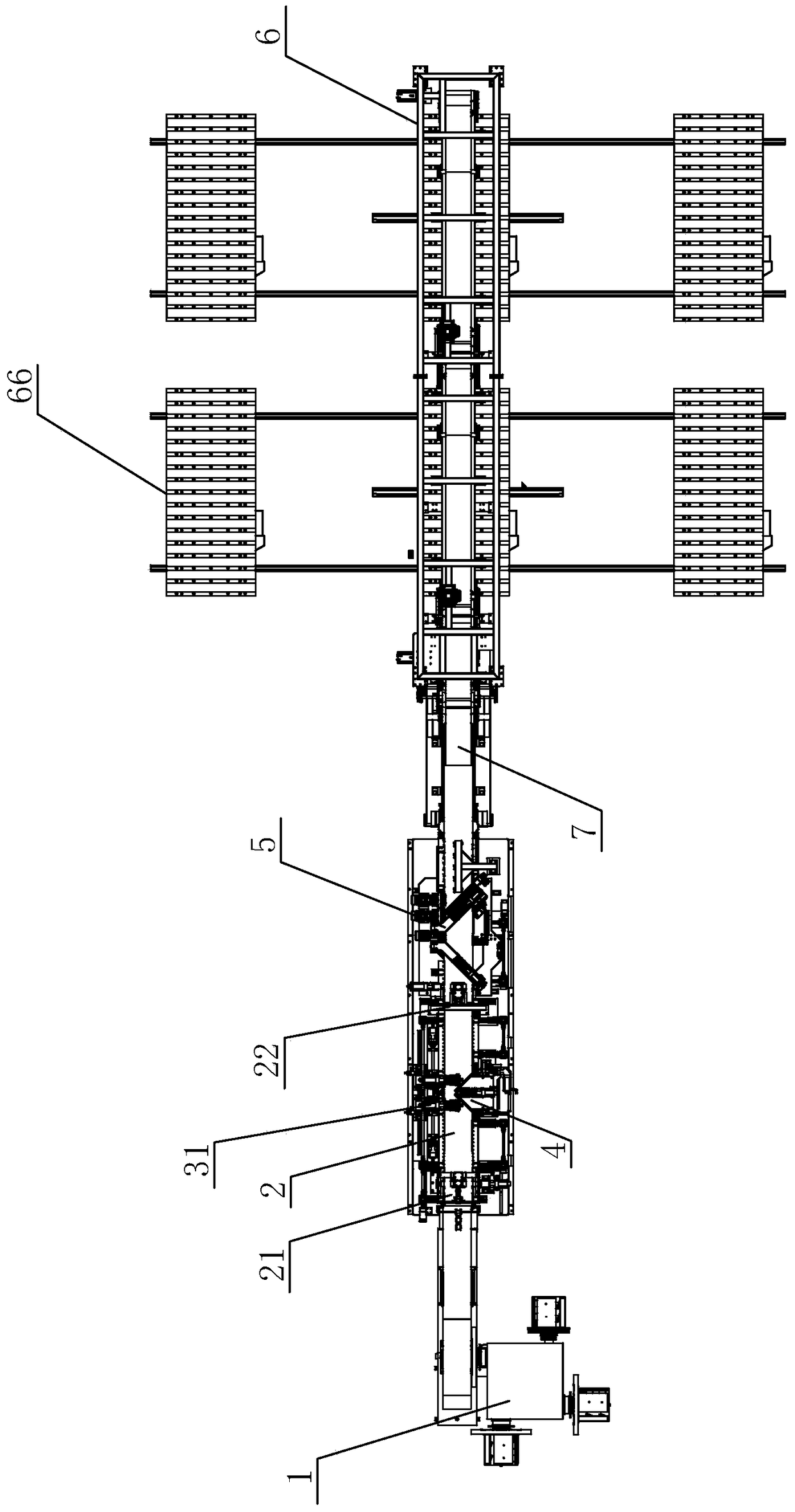

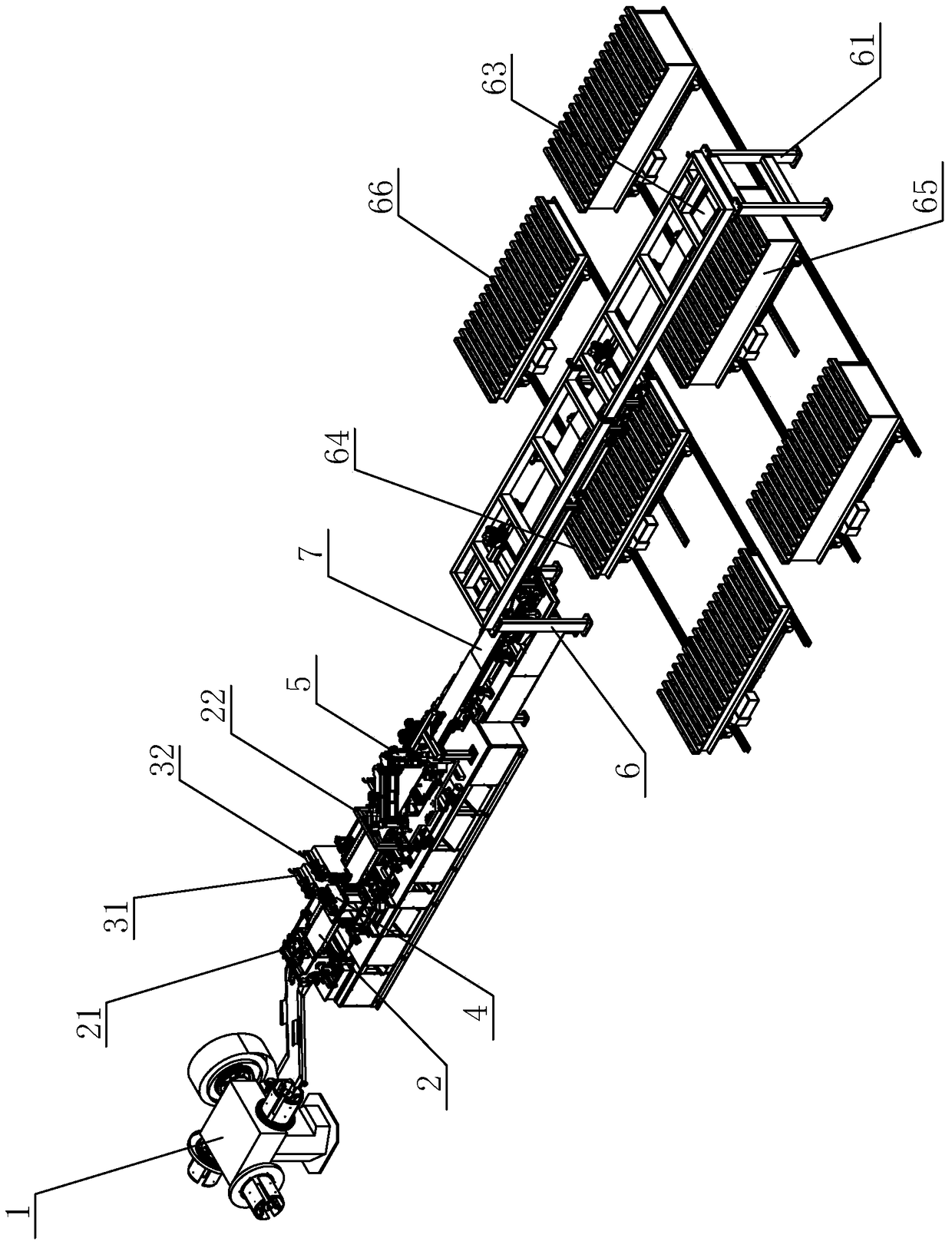

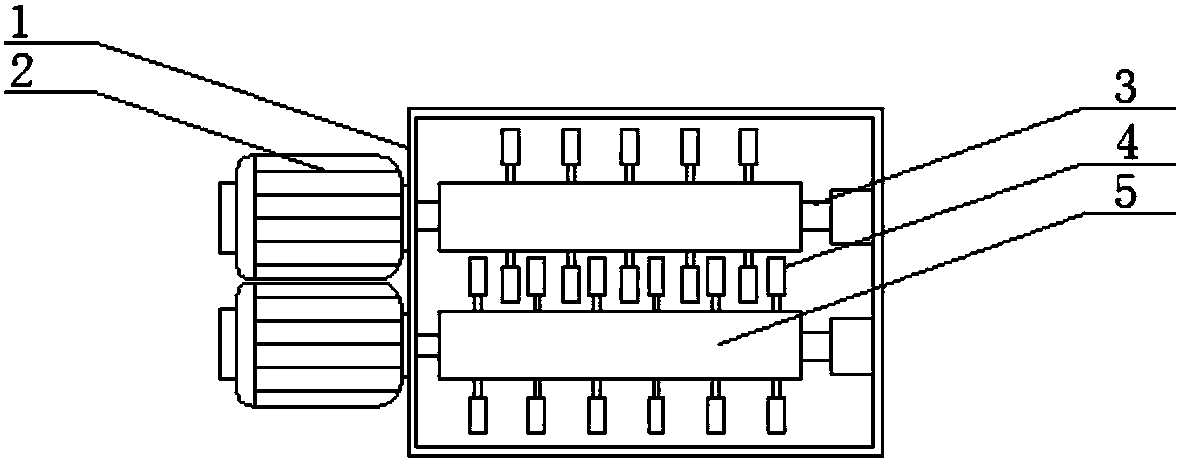

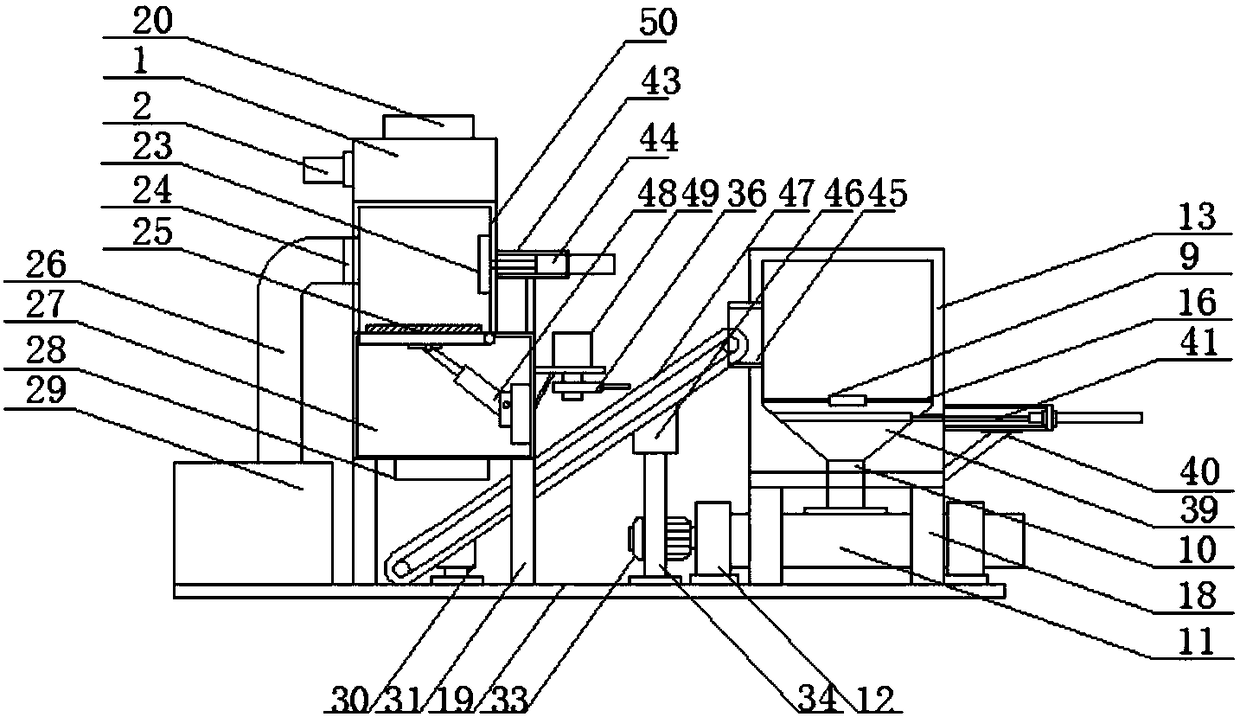

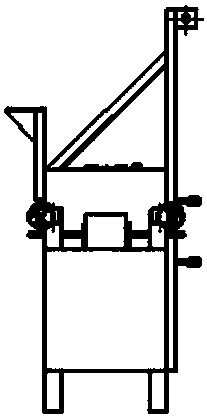

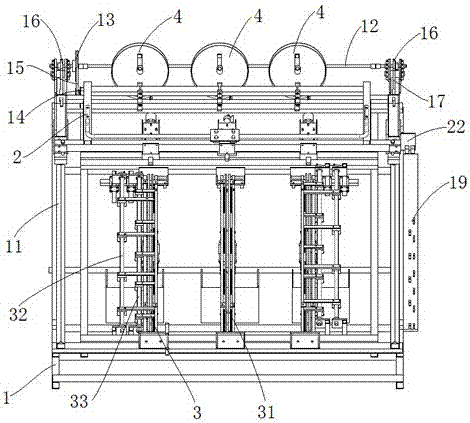

Novel numerical control silicon steel sheet transverse shearing line device

ActiveCN105397495AReduce distanceShorten the lengthOther manufacturing equipments/toolsShearing machine accessoriesNumerical controlPunching

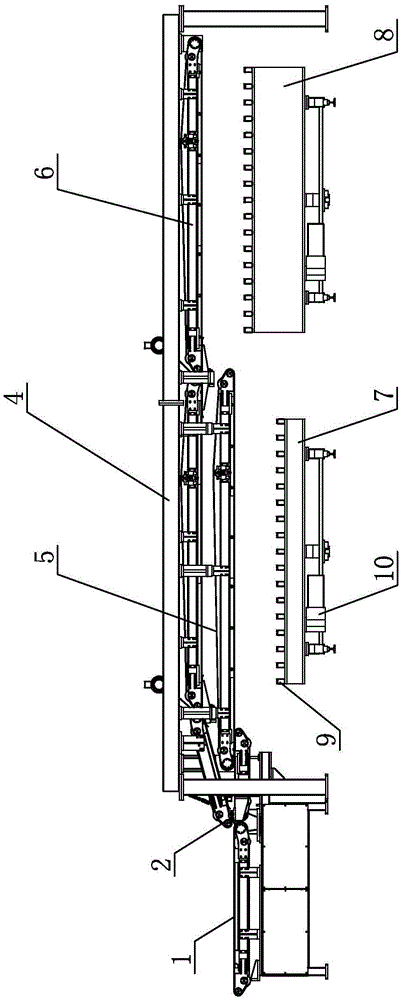

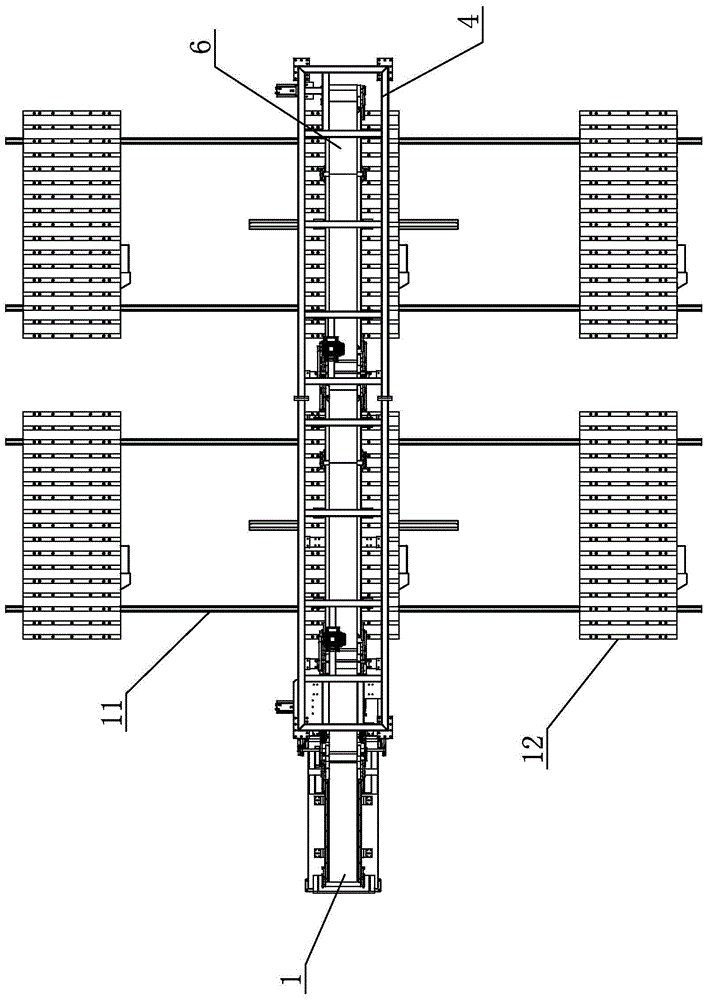

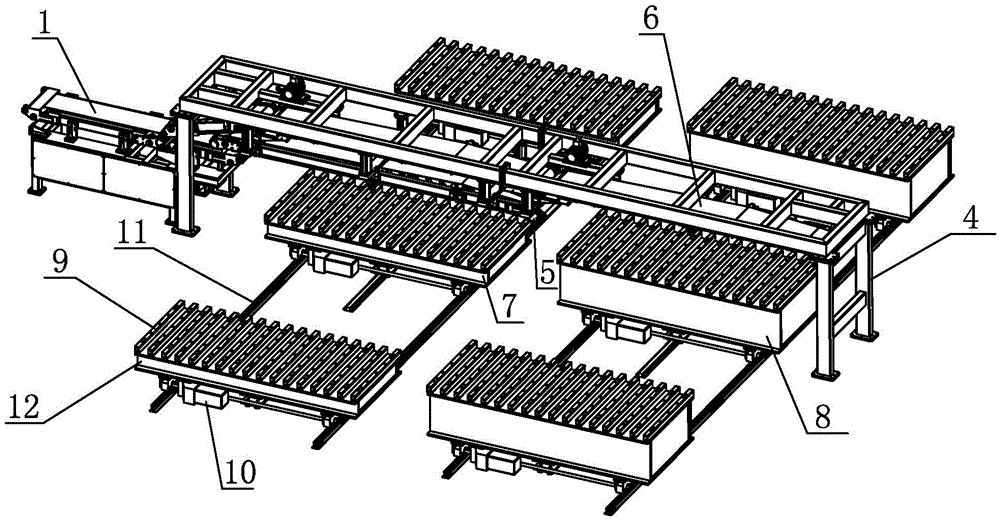

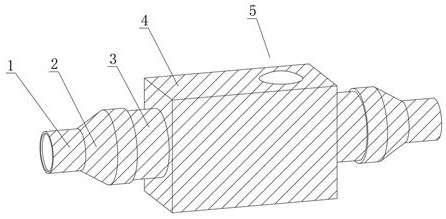

The invention discloses a novel numerical control silicon steel sheet transverse shearing line device. The novel numerical control silicon steel sheet transverse shearing line device comprises a control center, a discharging device and a feeding channel. The feeding channel is sequentially provided with a front feeding device, a first punching device, a V-shaped opening shearing device, a second punching device, a rear feeding device, a swing shearing device and a discharging table. A material collecting device is arranged behind the discharging table. The material collecting device comprises a magnetic conveying belt and a sheet stacking table. The numerical control silicon steel sheet transverse shearing line device has the beneficial effects that the front feeding device and the rear feeding device are arranged, waste of sheets is reduced, and the shearing precision is improved; twisting and bulging of silicon steel sheets are avoided, and high-speed conveying of the silicon steel sheets is achieved; the first punching device and the second punching device are symmetrically distributed on the front side and the rear side of the V-shaped opening shearing device, one-step punching is achieved, time is saved, and the production efficiency is improved; and according to the material collecting device, the magnetic conveying belt is matched with the sheet stacking table, shorn silicon steel sheets are automatically stacked in order, operation of workers is reduced, human resources are saved, and efficiency is improved.

Owner:CANWIN AUTOMATIC EQUIP CO LTD

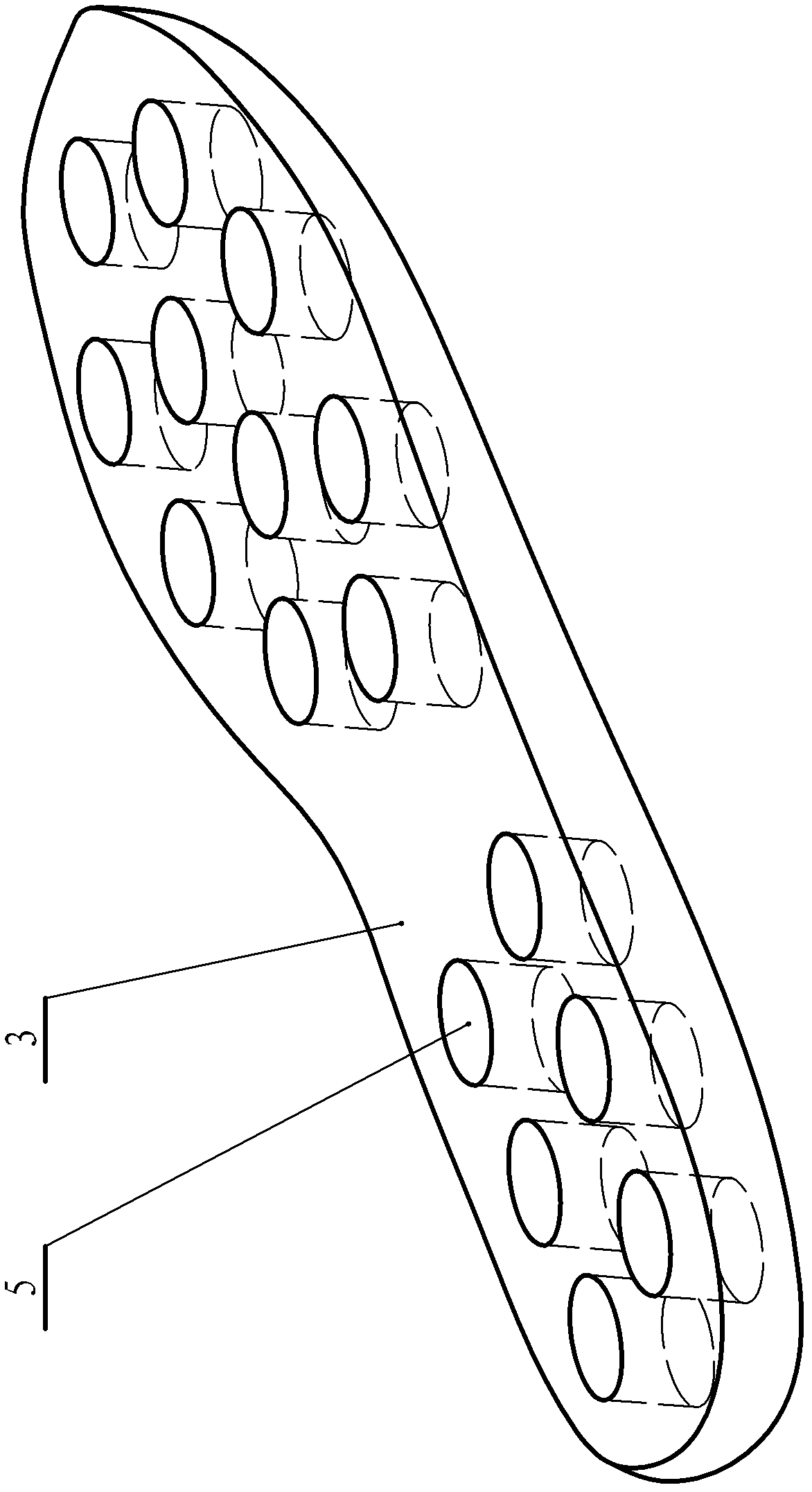

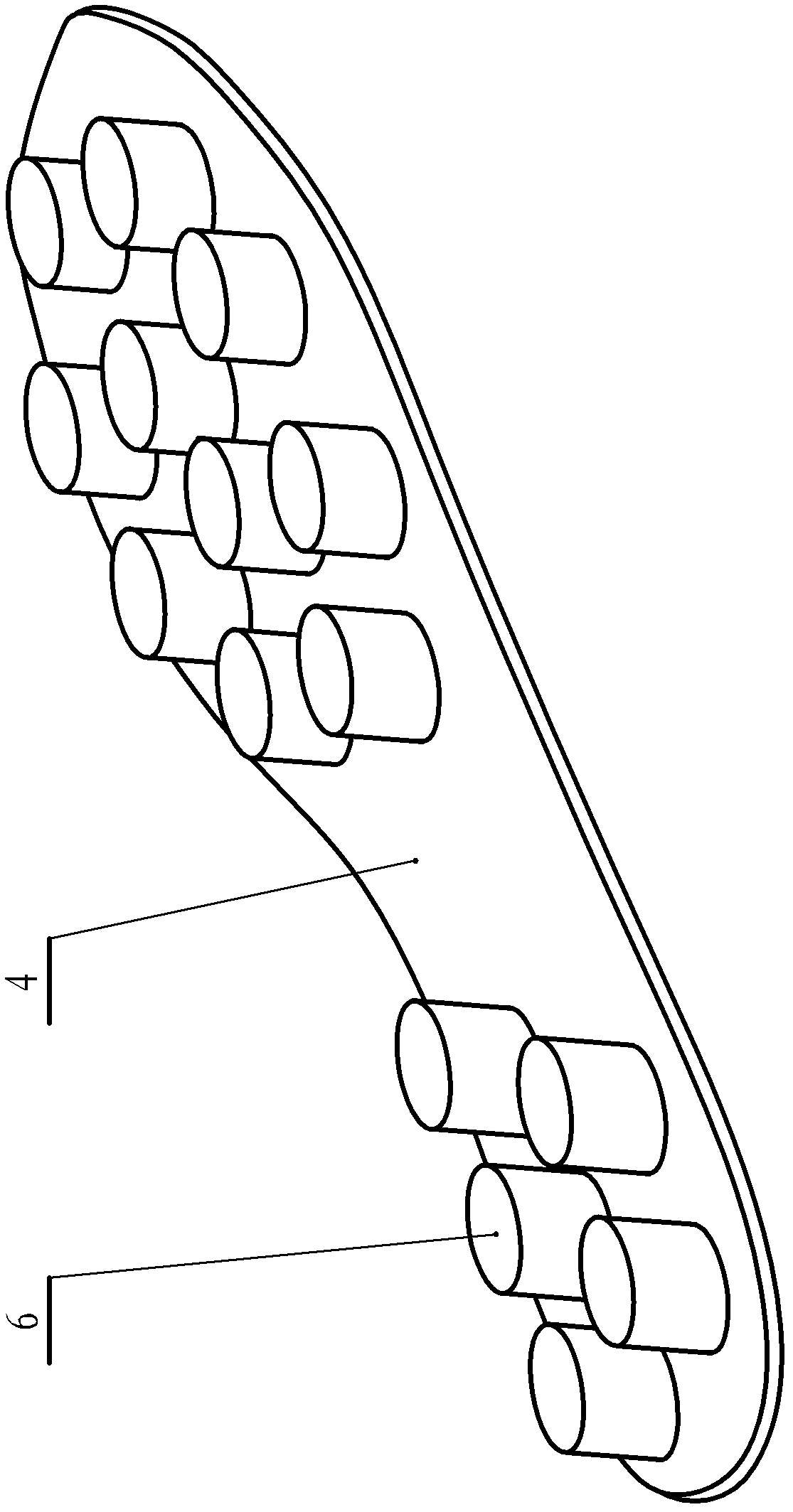

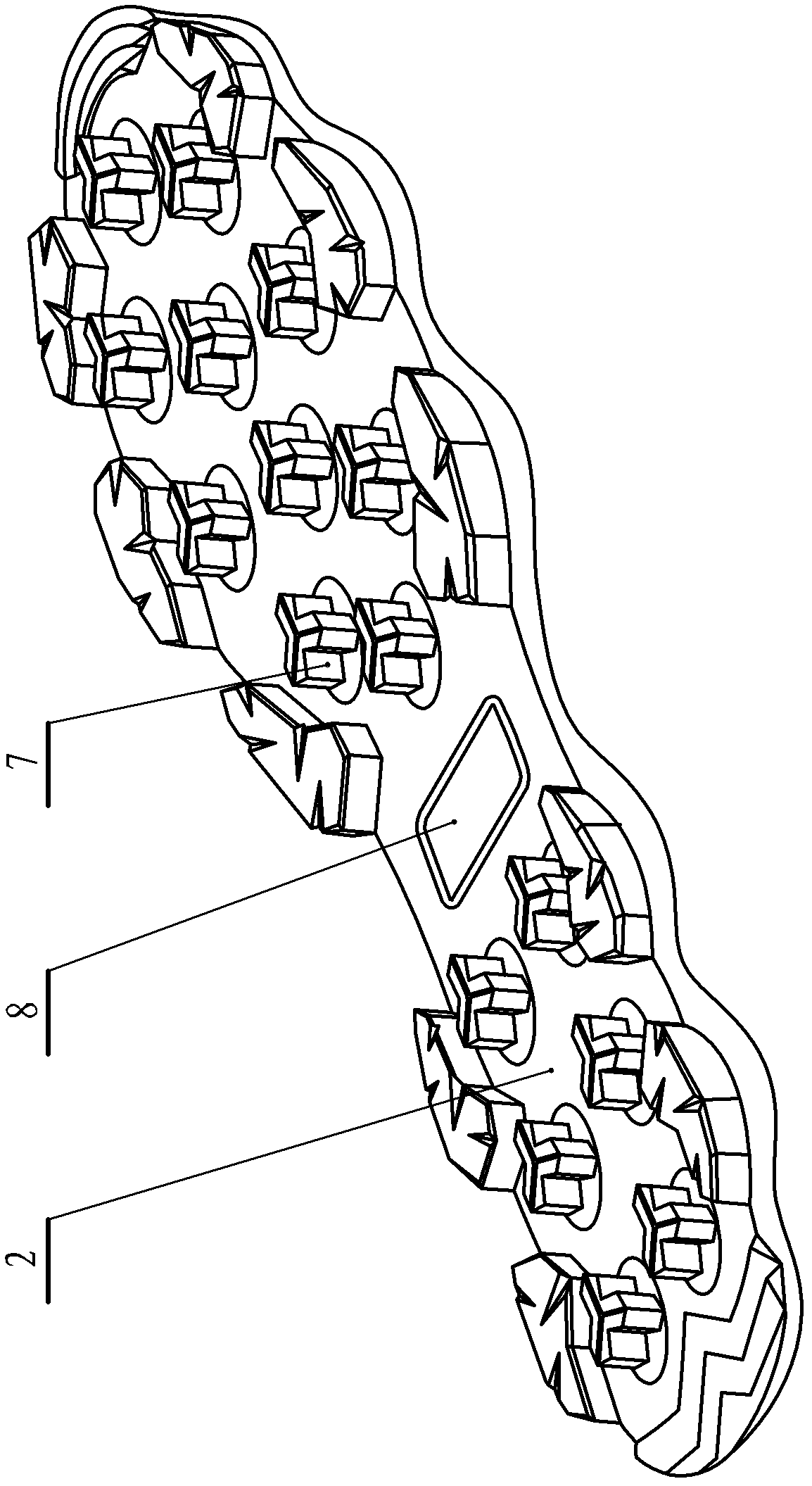

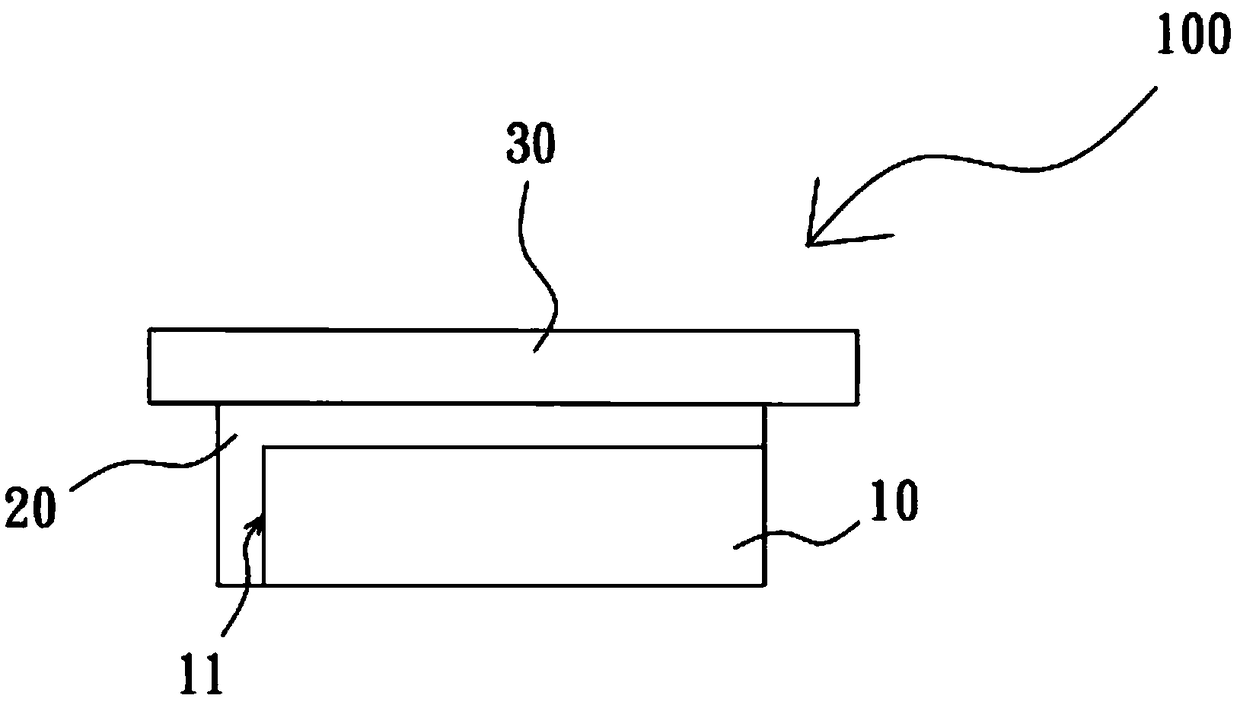

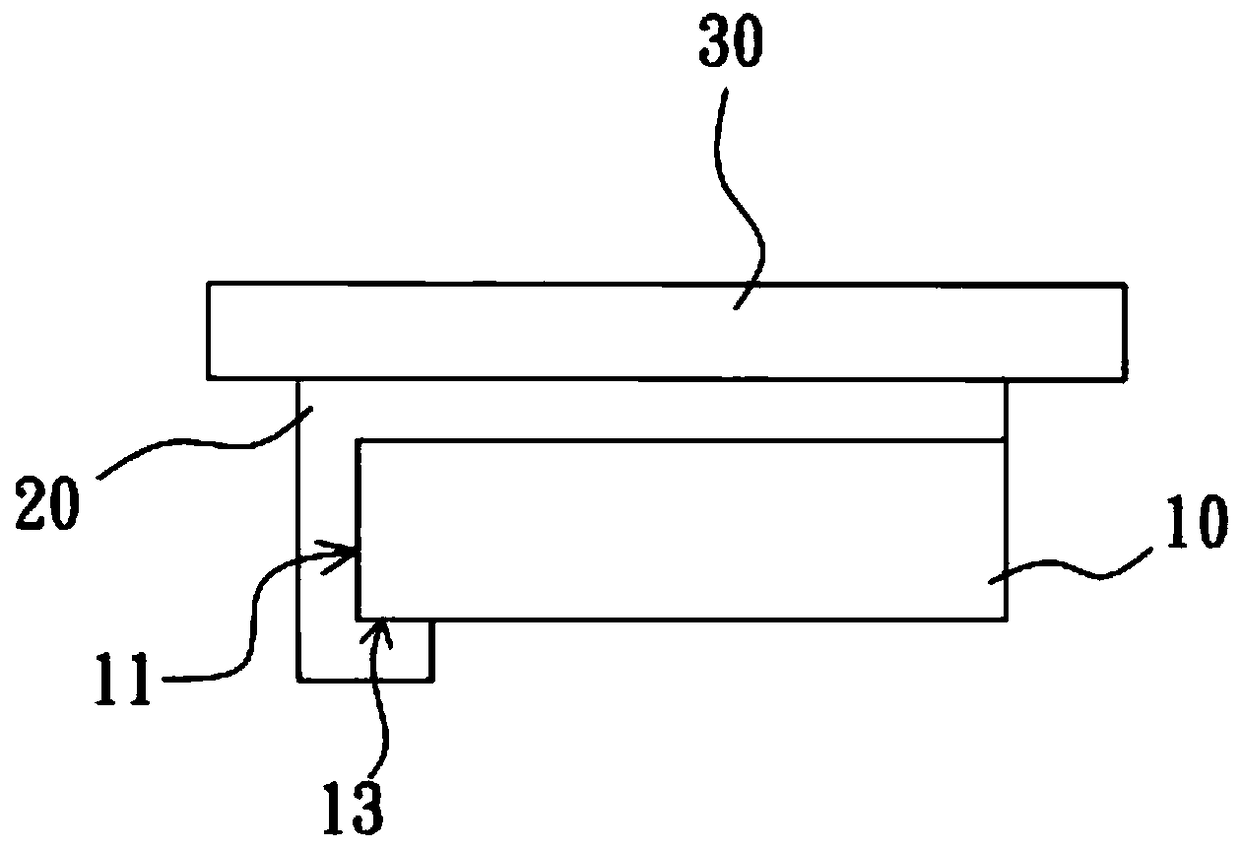

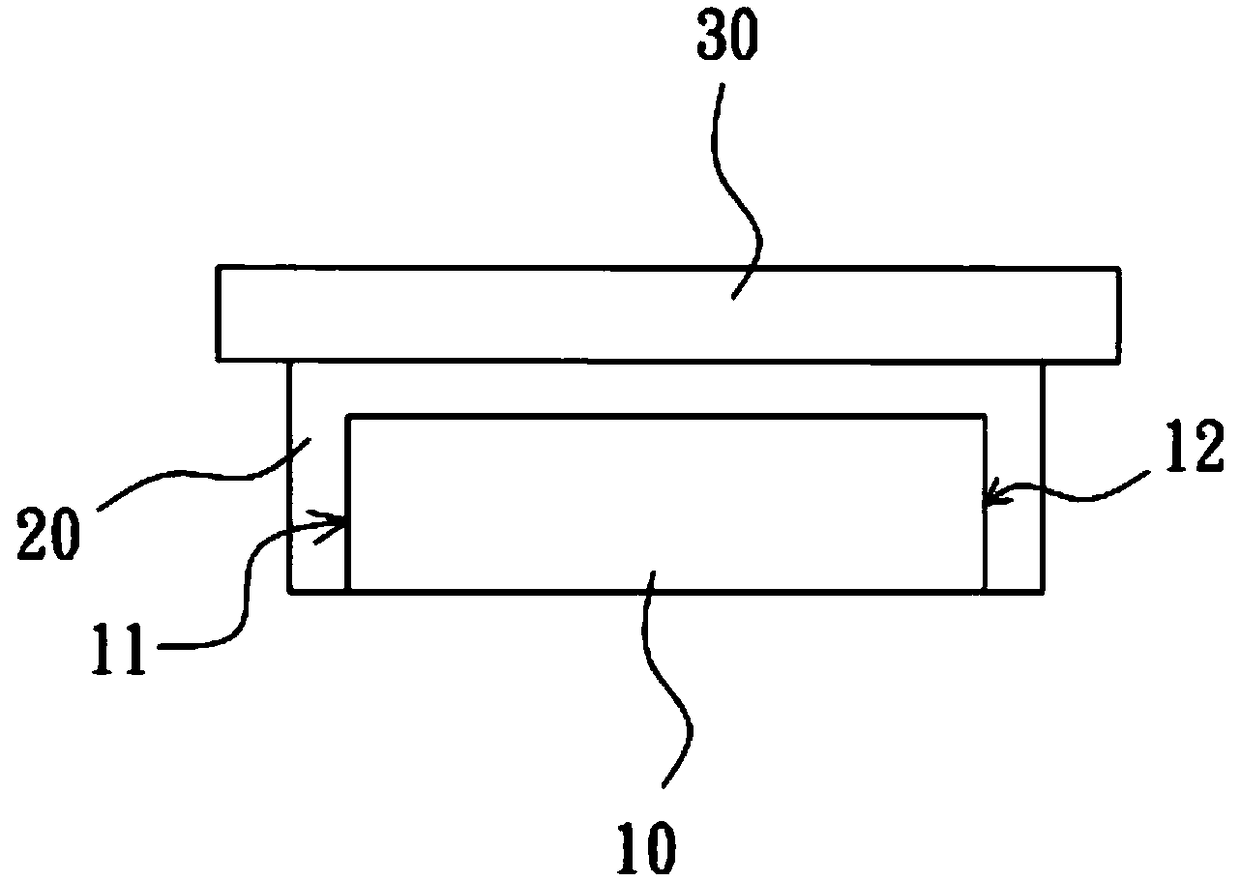

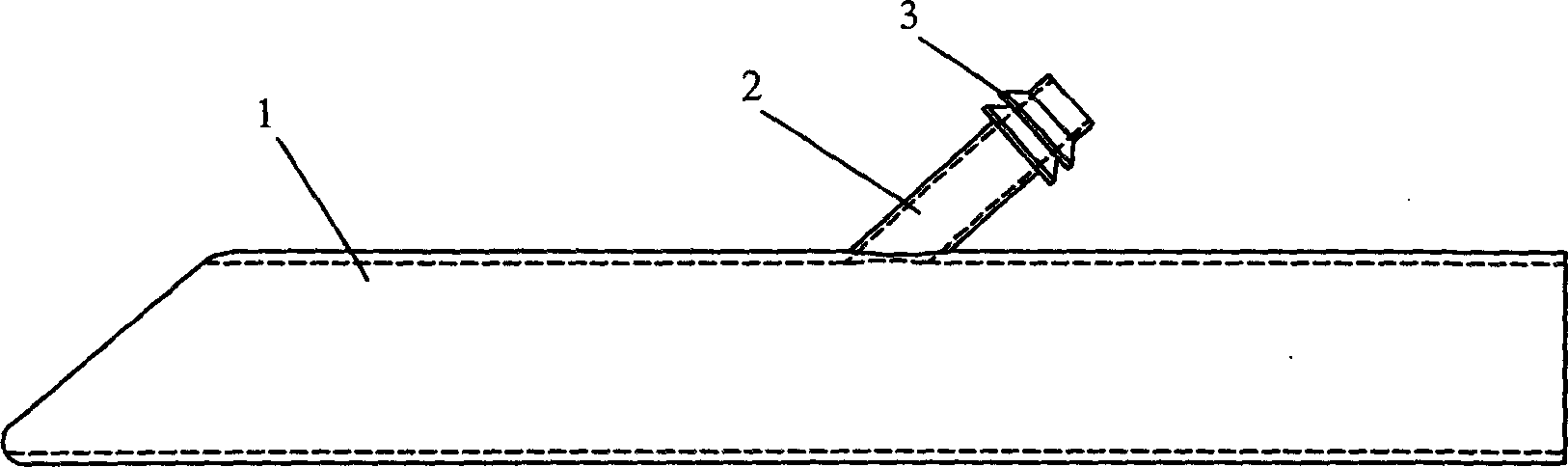

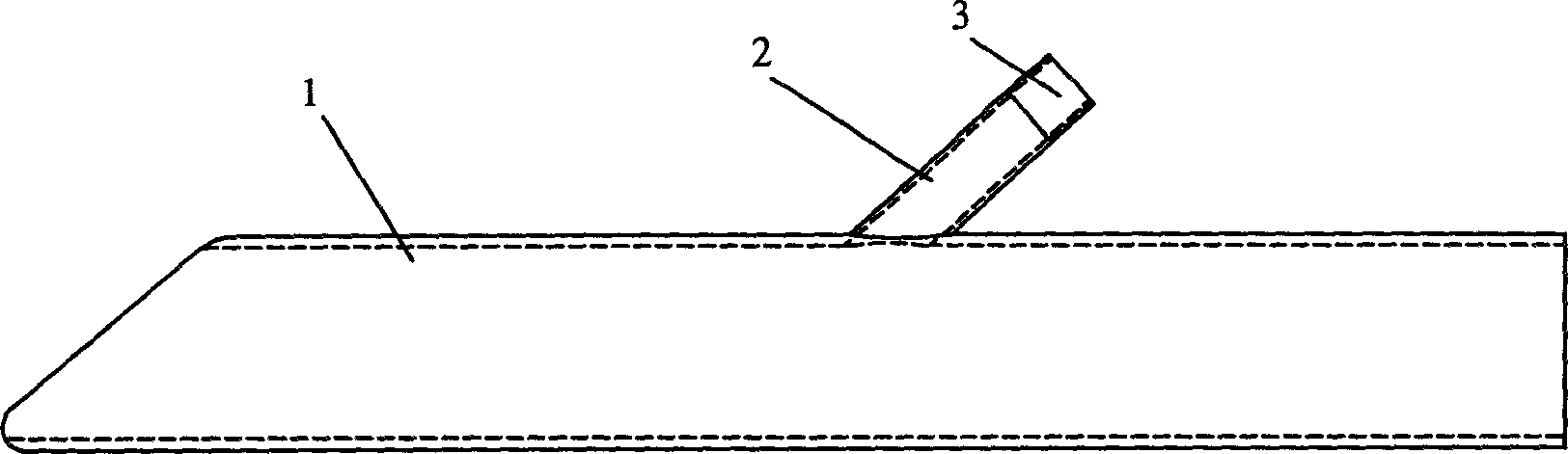

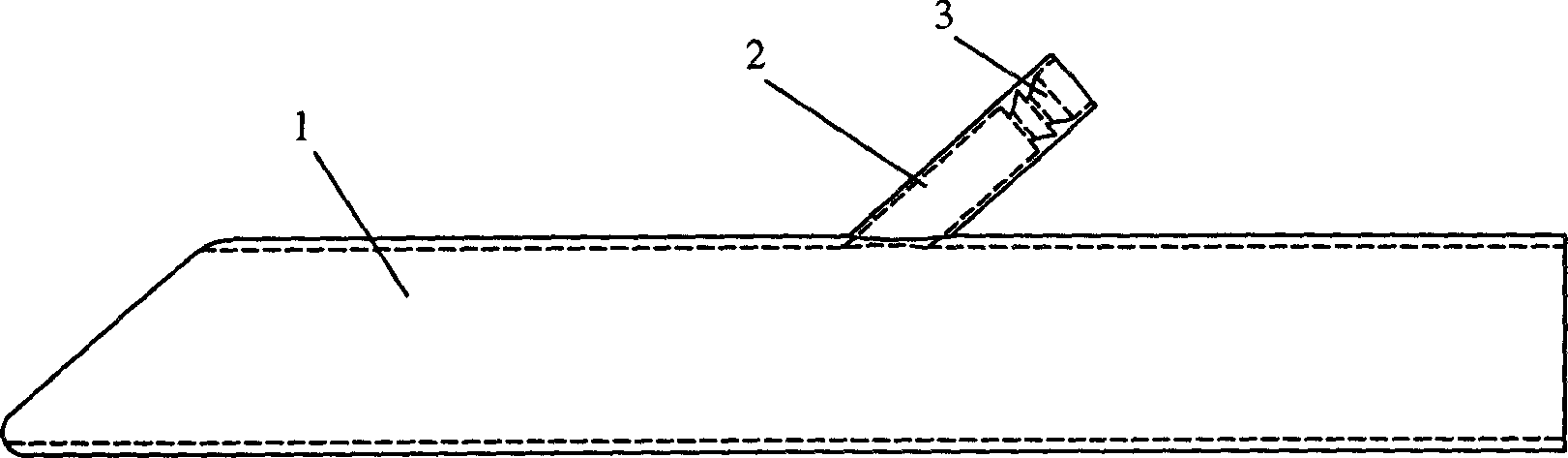

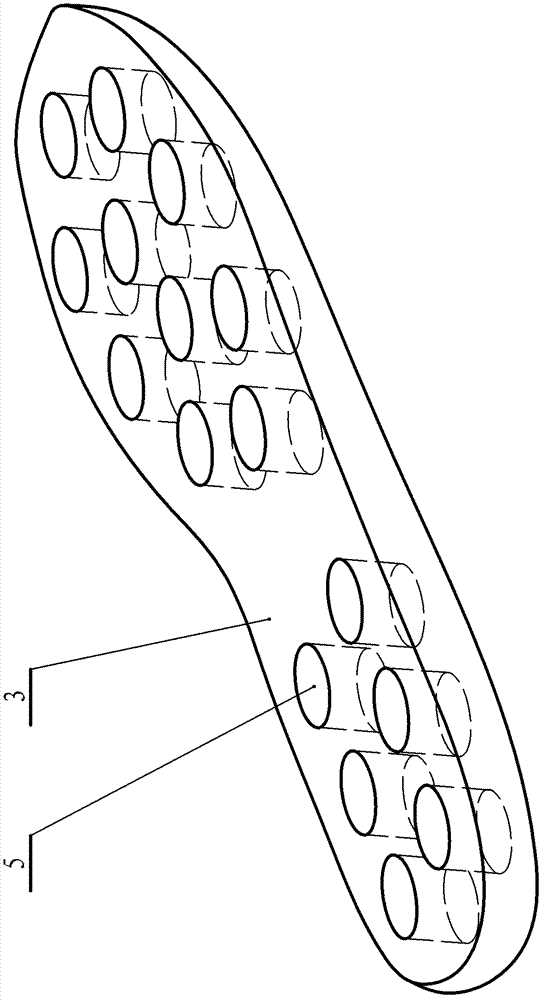

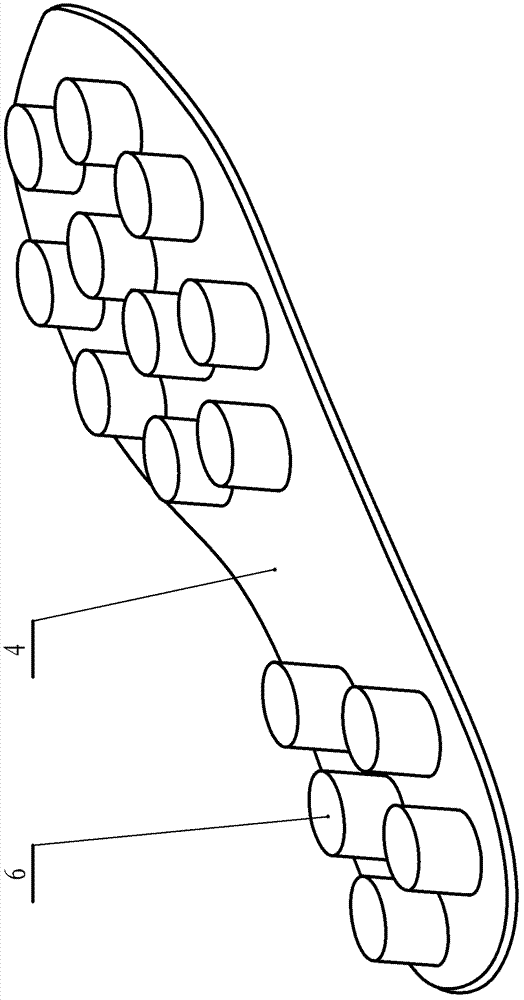

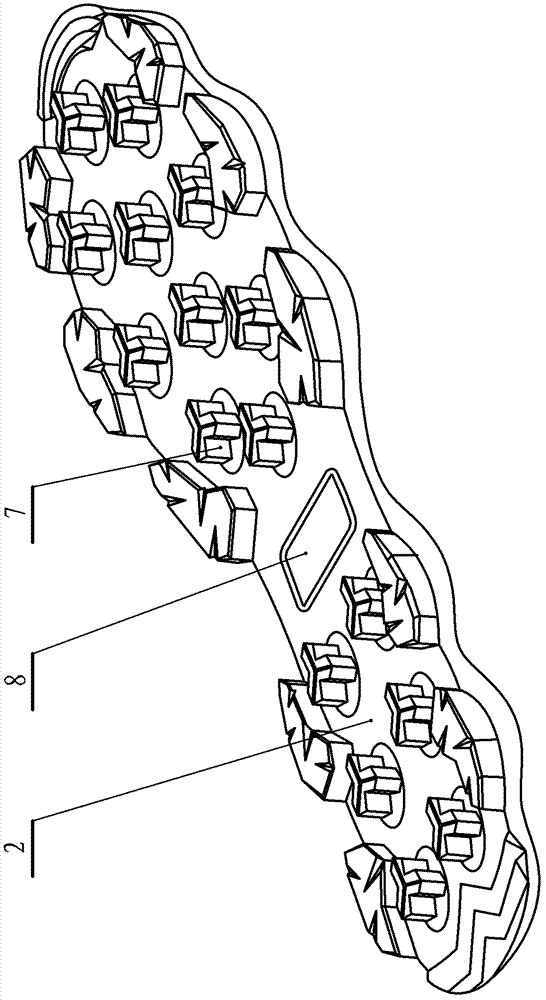

Shock-absorbing comfortable sole

A shock-absorbing comfortable sole comprises an outsole in contact with the ground and a midsole fixed on the upper surface of the outsole. The midsole comprises an upper layer and a lower layer. One or a plurality of through holes penetrating through the midsole in the thickness direction are respectively reserved on a heel, a rear sole and / or a front sole of the upper midsole. Projections corresponding to the through holes on the upper midsole are arranged on the upper surface of the lower midsole. The projections on the lower midsole are connected with the through holes on the upper midsole respectively in an embedded manner. Bottom grains protruding the lower surface of the outsole and corresponding to the projections on the lower midsole in position are arranged on the lower surface of the outsole. The upper midsole is hard, the lower midsole is soft, and when the surface of the upper midsole is stepped by a foot in walking, the upper surfaces of the soft projections are recessed highly and the upper surface of the hard upper midsole is recessed lowly, so that the upper surface of the upper midsole is flat or slightly uneven alternately, a foot sole of a wearer can be massaged, walking fatigue can be relieved, and the effect is evident.

Owner:MAOTAI FUJIAN SOLES CO LTD

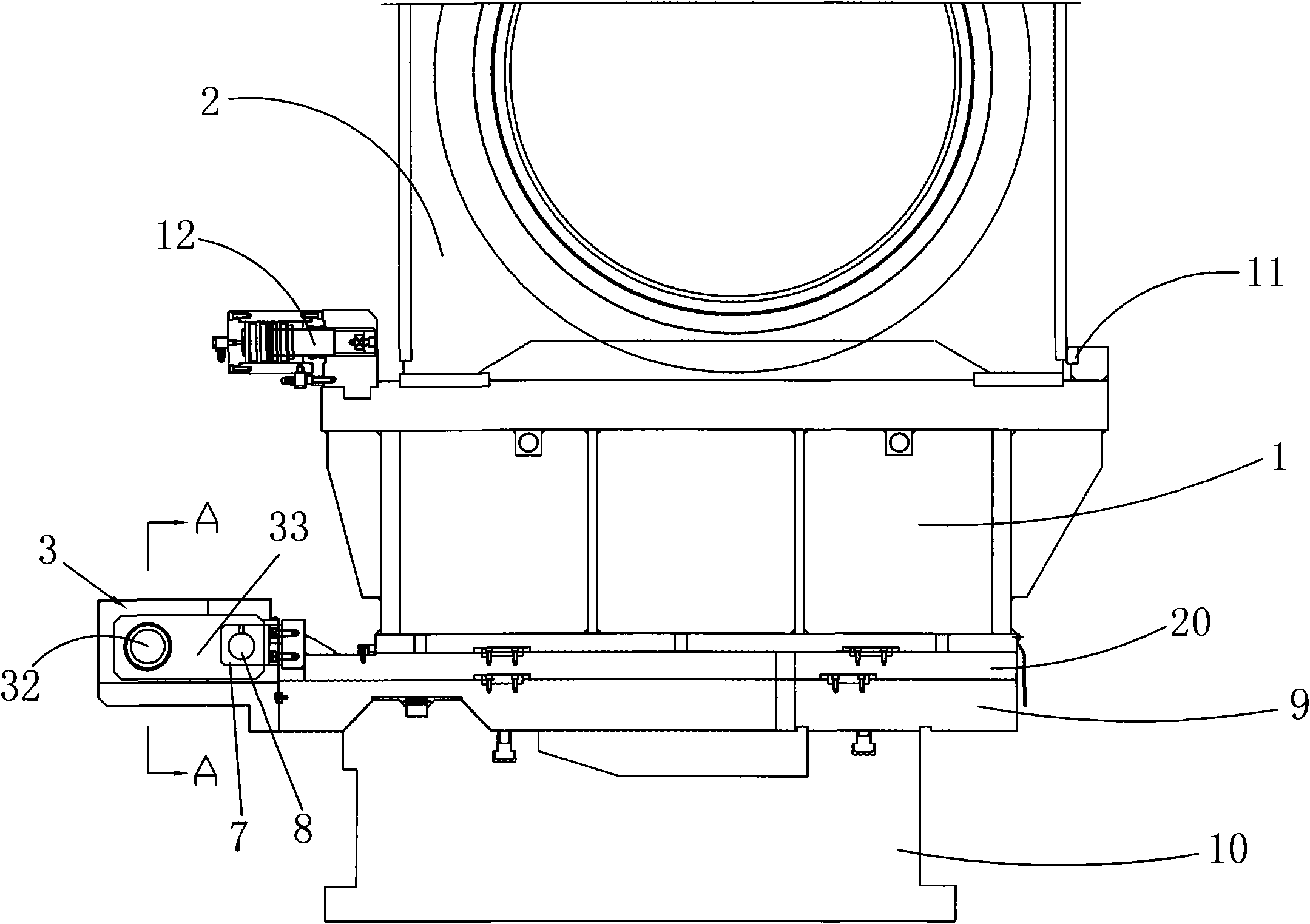

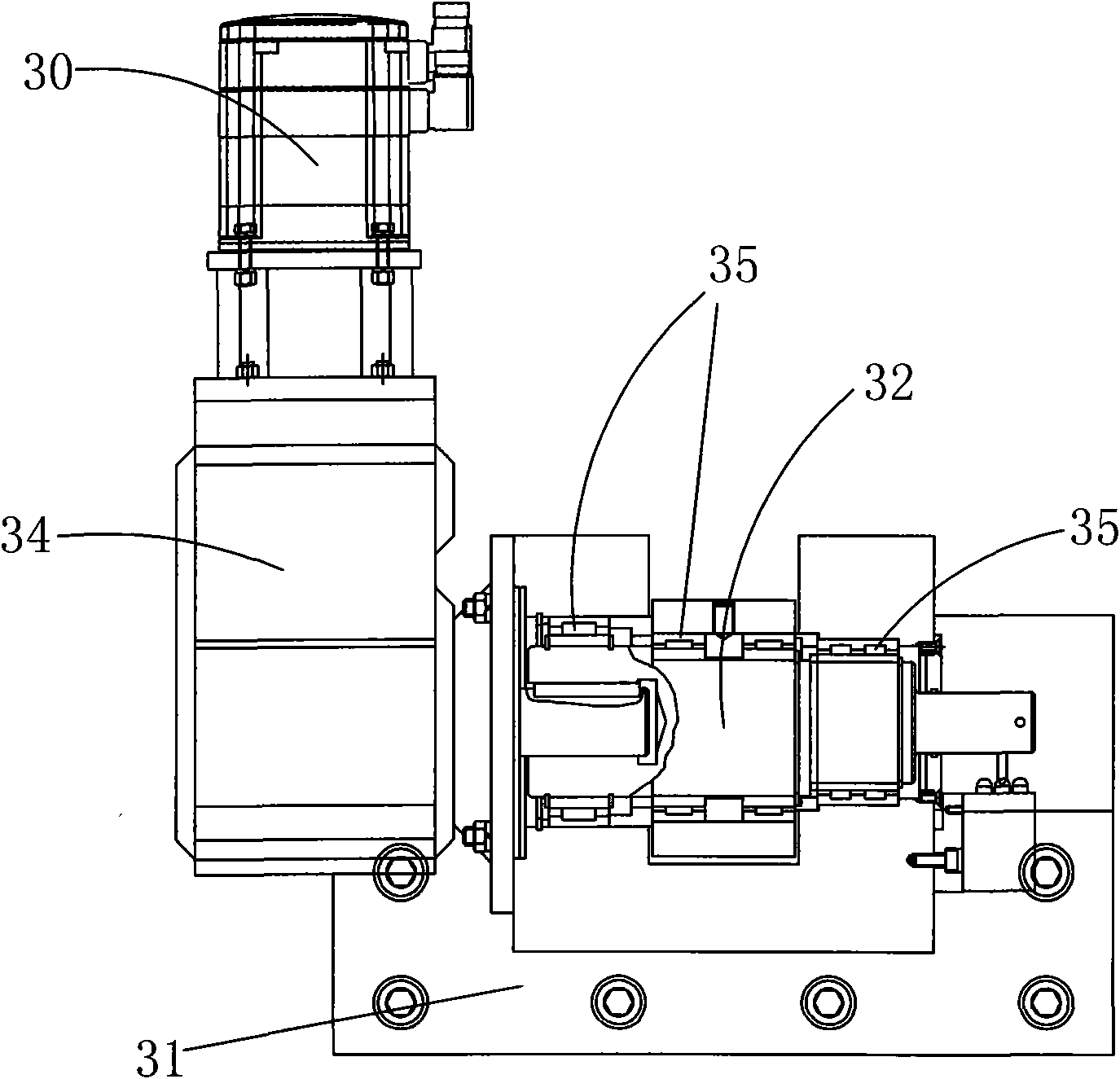

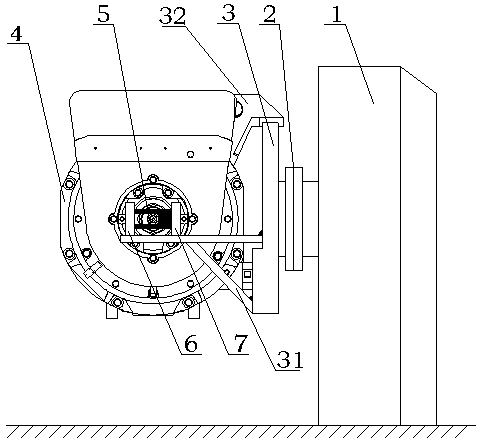

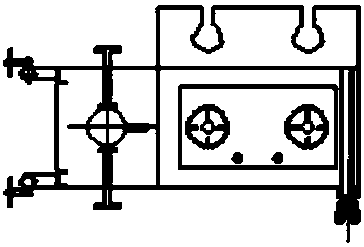

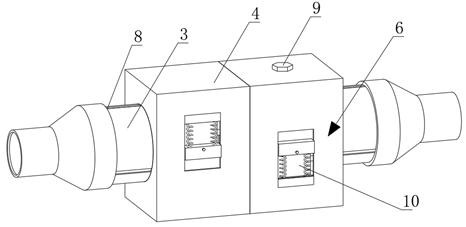

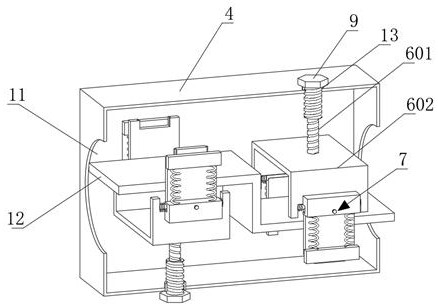

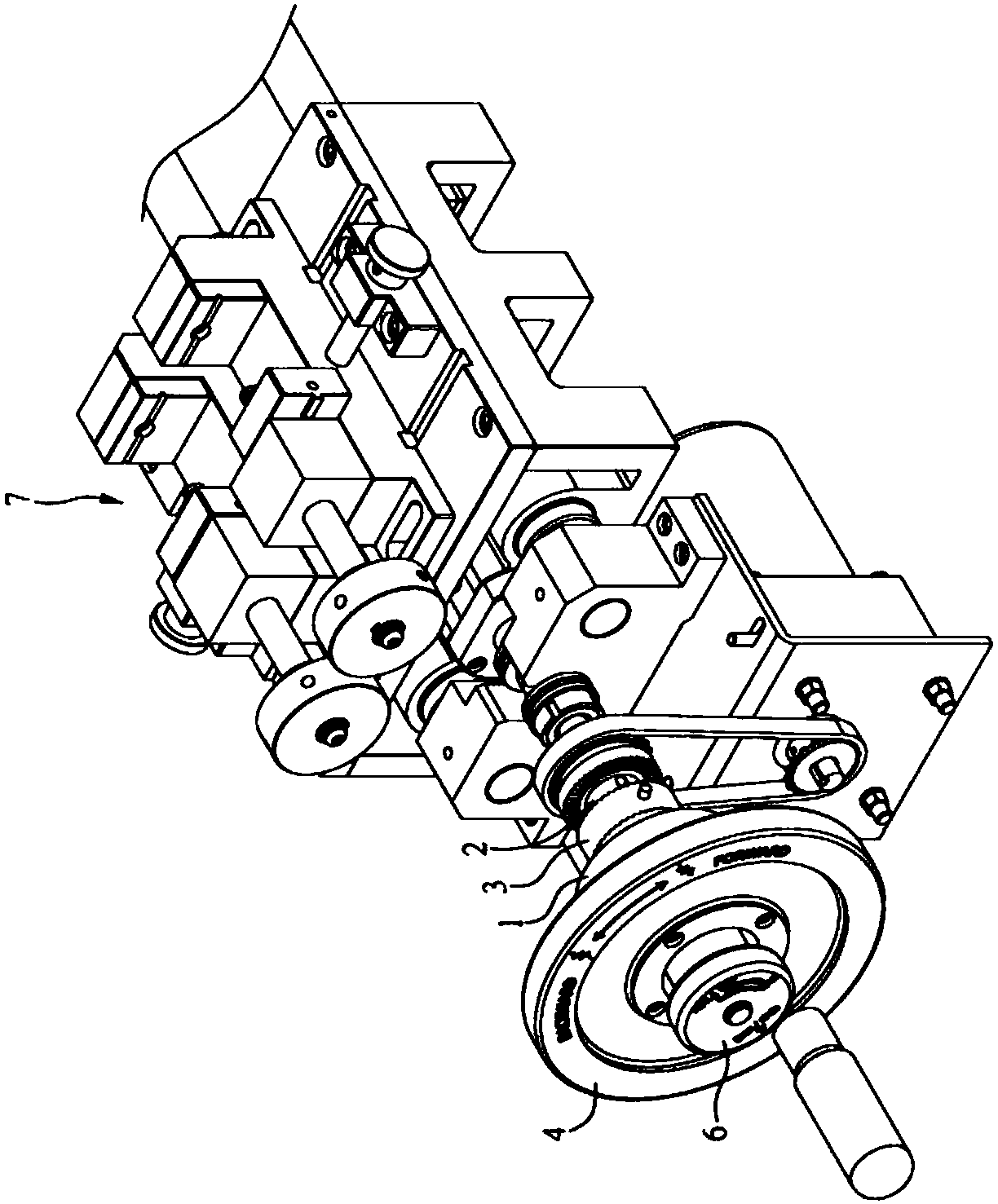

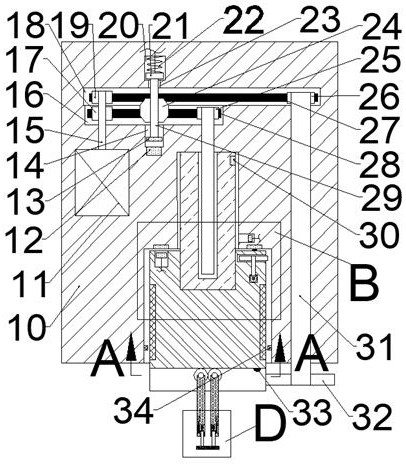

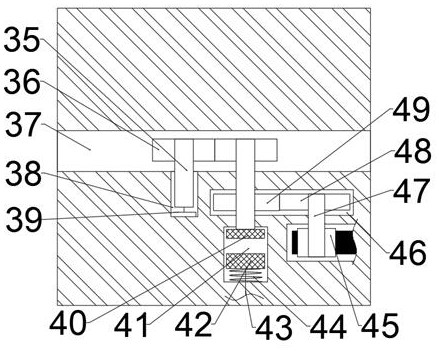

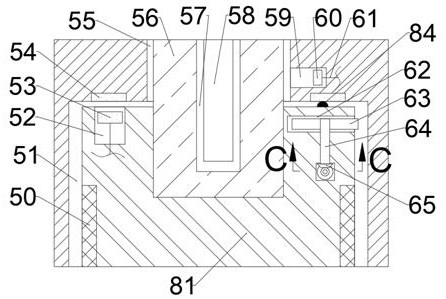

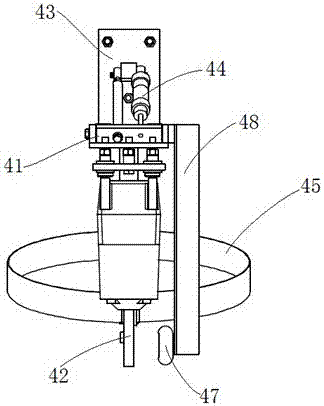

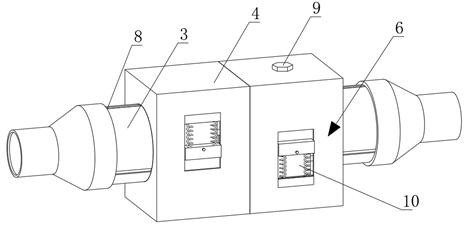

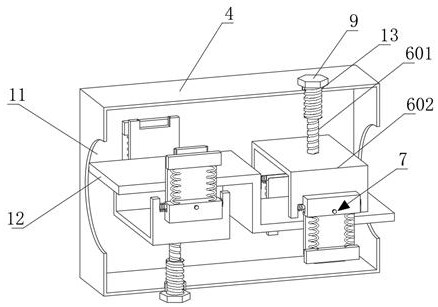

Full-automatic digital control roll grinder backup roll belt box grinding device

ActiveCN101856795AAvoid injury hazardGuaranteed grinding accuracyRevolution surface grinding machinesRadial positionFuel tank

The invention discloses a full-automatic digital control roll grinder backup roll belt box grinding device, comprising an installation precision regulating device, an oil supplying device and an oil temperature controlling device, wherein the installation precision regulating device comprises a bearing box pushing cylinder, limit blocks, an inching device and a clamping plate, the bearing box pushing cylinder and the limit blocks are arranged on the box seat and used for locating the position of the bearing box relative to the box seat, the clamping plate is used for driving the box seat to slide in a radial direction relative to a bed body of a workpiece, and the inching device and the lamping plate are used for regulating the radial position of the box seat at one end of the bed body of the workpiece so as to parallel a space axial line between the two box seats with the axial line of a grinding wheel, thereby ensuring grinding precision; the oil temperature controlling device comprises a temperature sensor and an oil temperature controller, which is used for ensuring that the temperature of the supplied oil in the oil supplying device is proper; and the oil supplying device comprises an oil inlet pipeline, a cylinder and an oil outlet pipeline with an overflow valve and a throttle valve, which is used for supplying the oil meeting the requirements of temperature, oil pressure and flow to a bearing box so as to ensure that a oil film bearing forms an effective dynamic pressure, thereby effectively avoiding hidden troubles of damaging a bearing and ensuring grinding efficiency. In all, the invention ensures grinding, and can be convenient and reliable in use.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

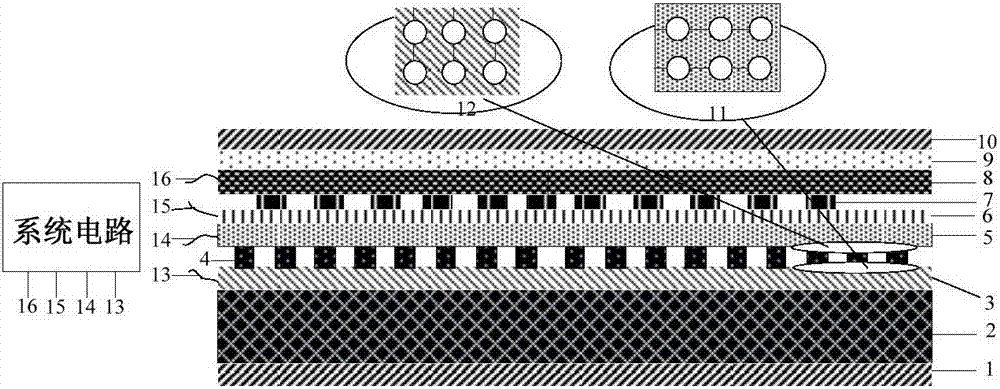

Liquid crystal display device with narrow side frame

ActiveCN108254962AGood for anti-foldingAvoid injury hazardStatic indicating devicesNon-linear opticsTouch SensesEngineering

The invention discloses a liquid crystal display device with a narrow side frame. A touch sensing film is made of a flexible material, and is arranged between an upper transparent substrate and a liquid crystal display module. The liquid crystal display module is arranged on the lower side of the touch sensing film. The liquid crystal display device has the advantages that the flexible touch sensing film is formed by extending along at least one lateral side of the liquid crystal display module, and is attached to cover at least one lateral side or bottom surface of the liquid crystal displaymodule after reverse folding, so that a narrow frame and a high screen occupation ratio of a display panel are achieved; a circuit layer on the panel is designed to contract on the lateral side of theliquid crystal display module, and a signal circuit does not need to be arranged on the reverse side of the liquid crystal display module, so that damage to circuits on the reverse side during assembly is avoided, and the touch sensing film on the reverse side is maintained to facilitate reverse folding and adhesion.

Owner:INTERFACE TECH CHENGDU CO LTD +2

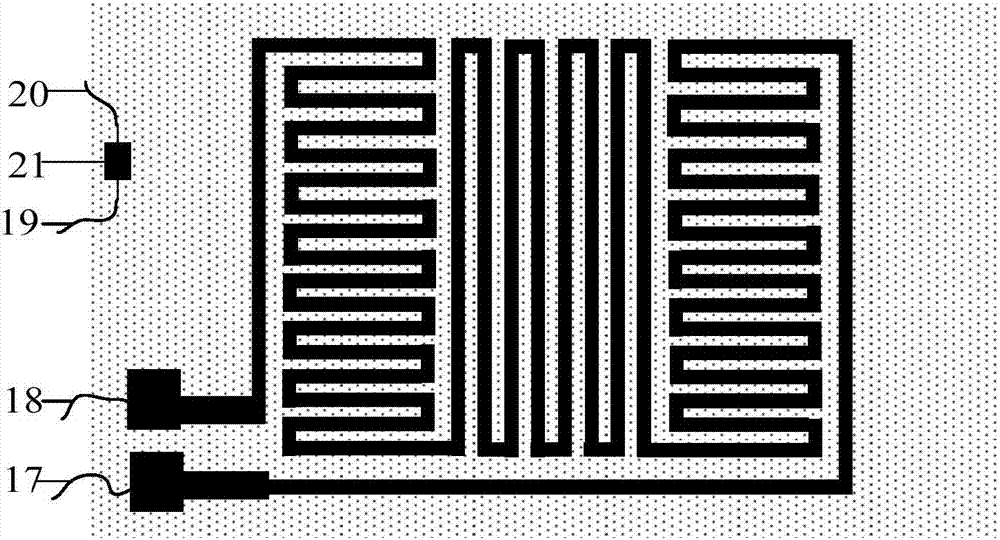

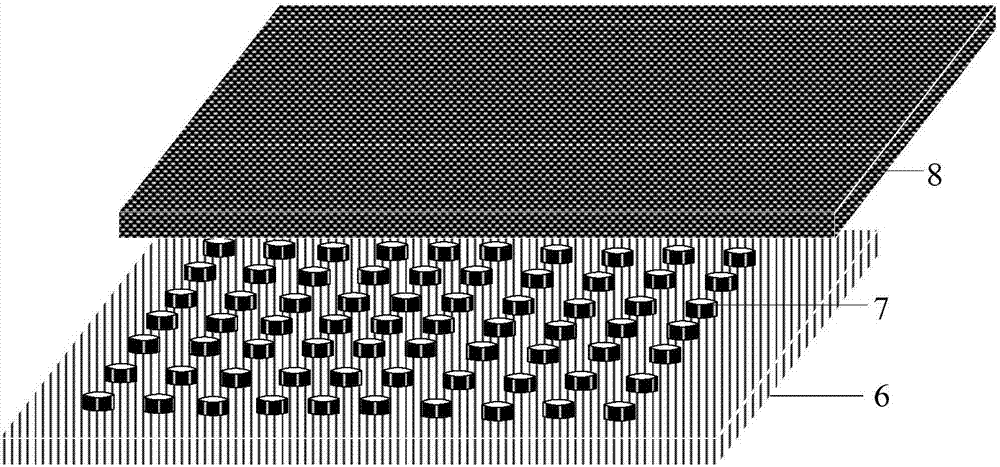

Intelligent mattress and system for infant monitoring and remote automatic adjustment method

PendingCN106901549AWaterproof and breathableImprove comfortChildren furnitureSimultaneous control of multiple variablesHuman bodyEngineering

The invention discloses an intelligent mattress and system for infant monitoring and a remote automatic adjustment method. A giant-piezoelectricity zinc oxide nanoarray with high sensitivity and measuring precision is used for measuring the heart rate value and the body motion, a capacitive film array of the mattress can measure the human body stress distribution, and if an infant sleeps beyond a safe area, the system can give an alarm. The mattress is further provided with a radiation-proof heating part. The intelligent mattress system has the advantages of adjusting the sleep environment by itself and adjusting the sleep environment by an APP. Sleep analysis can be carried out through the APP, and when the human body is uncomfortable and the environment exceeds a set range, the APP gives an alarm; the APP can issue instruction information through WIFI and transmit feedback information to an MCU, and the MCU controls a control device to work or not by controlling on / off of a relay. A guardian using the mattress can carry out remote monitoring and adjustment; besides, a remote video function can be started to relieve the pressure of the guardian.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

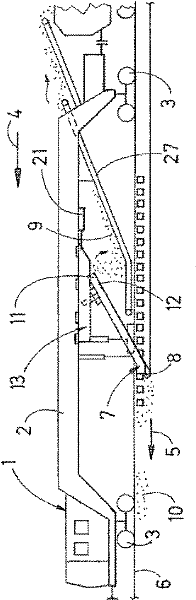

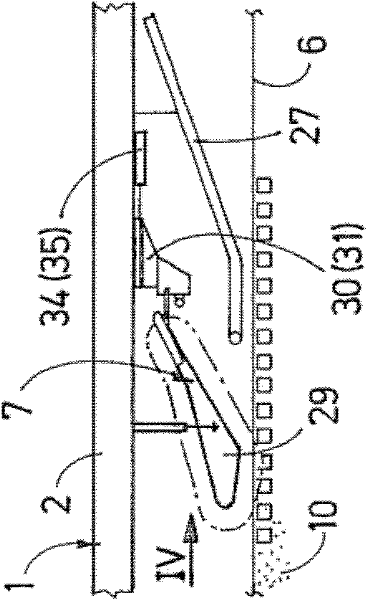

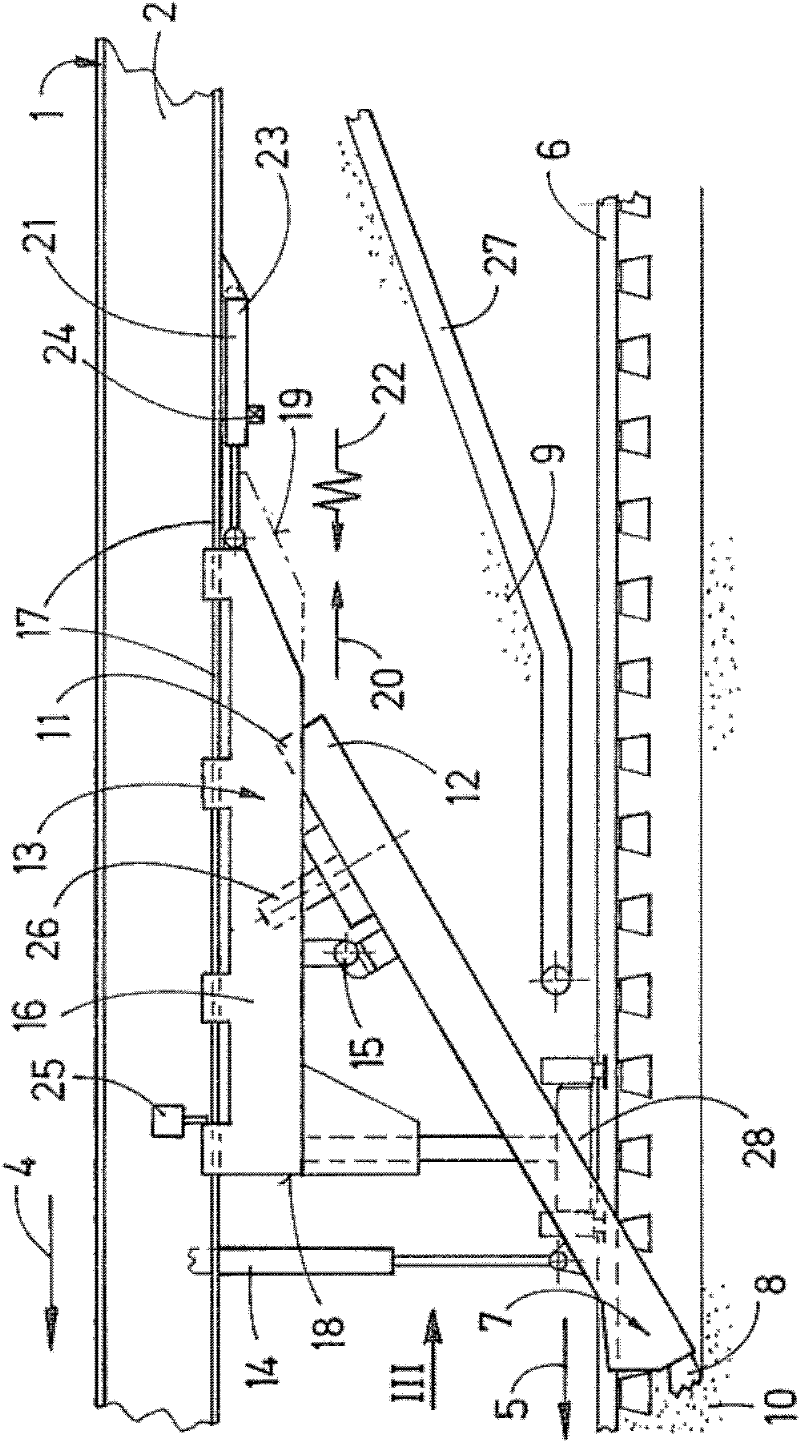

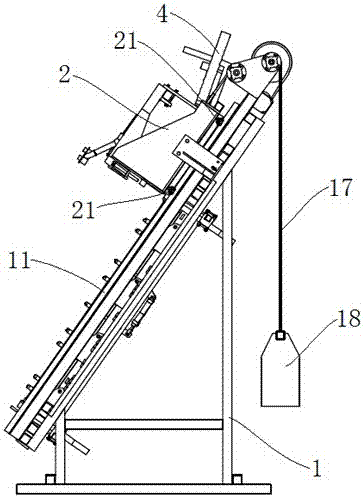

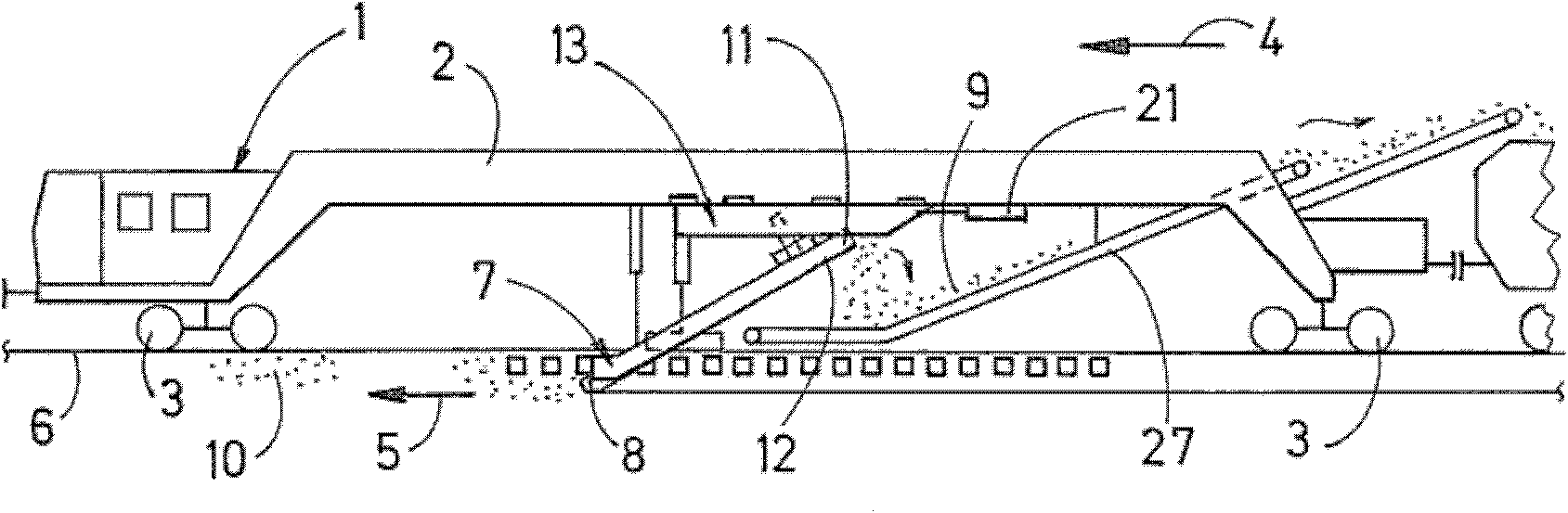

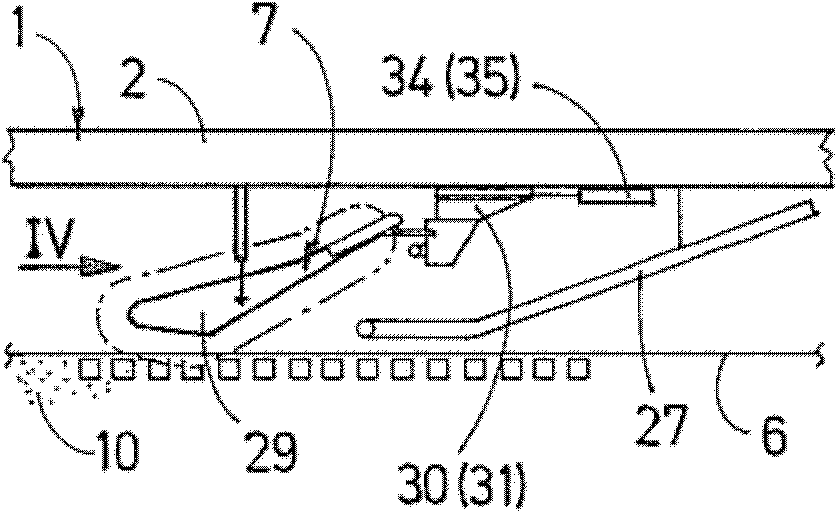

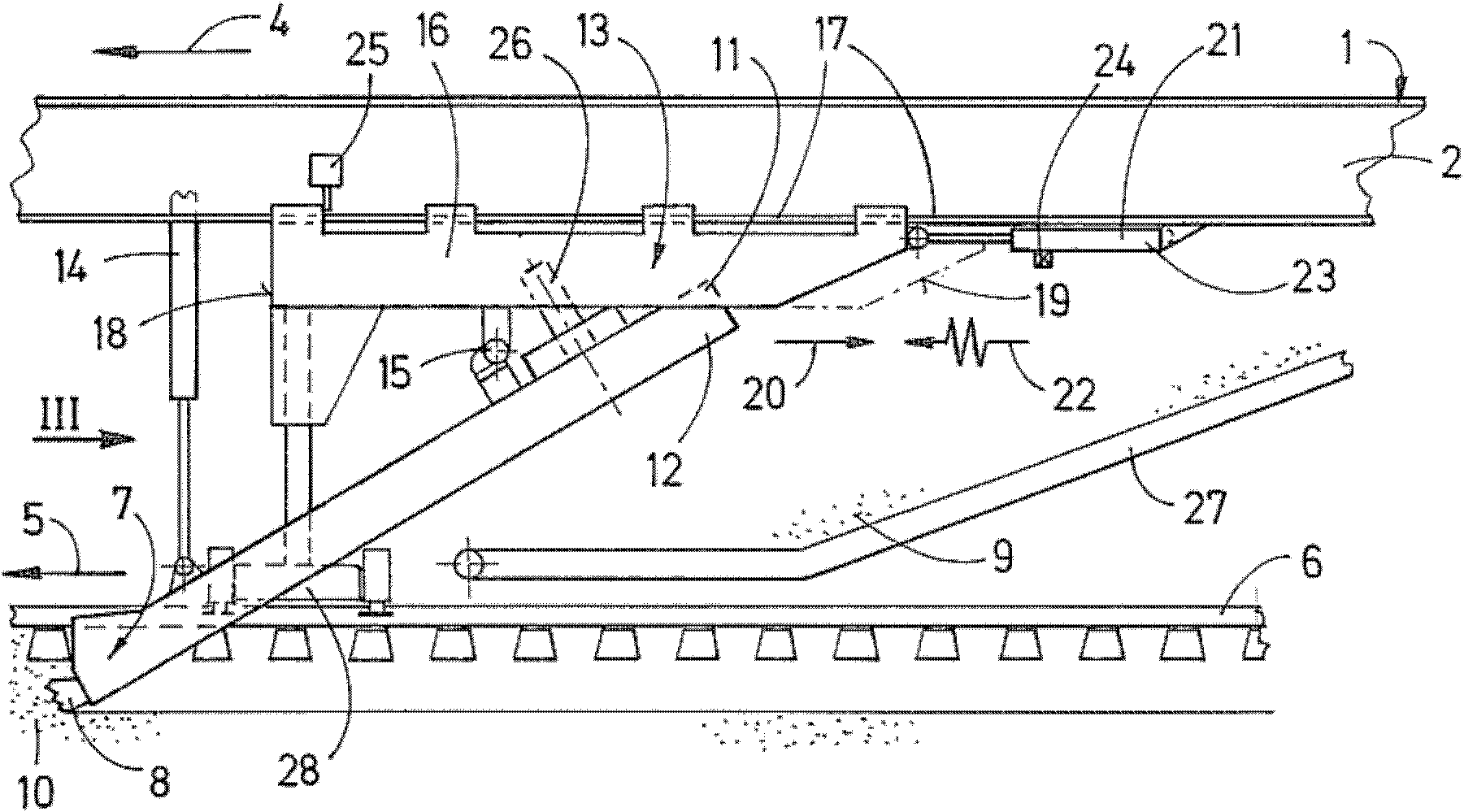

Machine comprising a lifting device for receiving bulk material of a track bed

A lifting device (7) with a rotatable, endless conveyor-chain (8) for receiving bulk material (9) of a track bed (10) is associated with a machine (1) comprising a machine frame (2) that can be moved on a track (6) during a working advancement (5). A discharging device (12) for discharging the received bulk material (9) and a mounting (13) for connecting the lifting device (7) to the machine frame (2) in an articulated manner are provided in the region of an upper conveyor-chain deflection (11). The mounting (13) is movably supported on the machine frame (2) relative to same in a longitudinal direction of the machine, said mounting moving in a displacing motion (20) that is limited by a front working position (18) with respect to a working direction (4) and by a rear end position (19). The mounting is also connected to a buffering element (21) that is fixed on the machine frame (2), said buffering element enabling a displacement of the mounting (13) together with the lifting device (7) to the end position (19) after a target resistance (22) acting against the displacing motion (20) is exceeded. A switch (25) that detects the displacing motion (20) and the exceeding of the target resistance (22) is designed to interrupt the working advancement (5) of the machine (1).

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

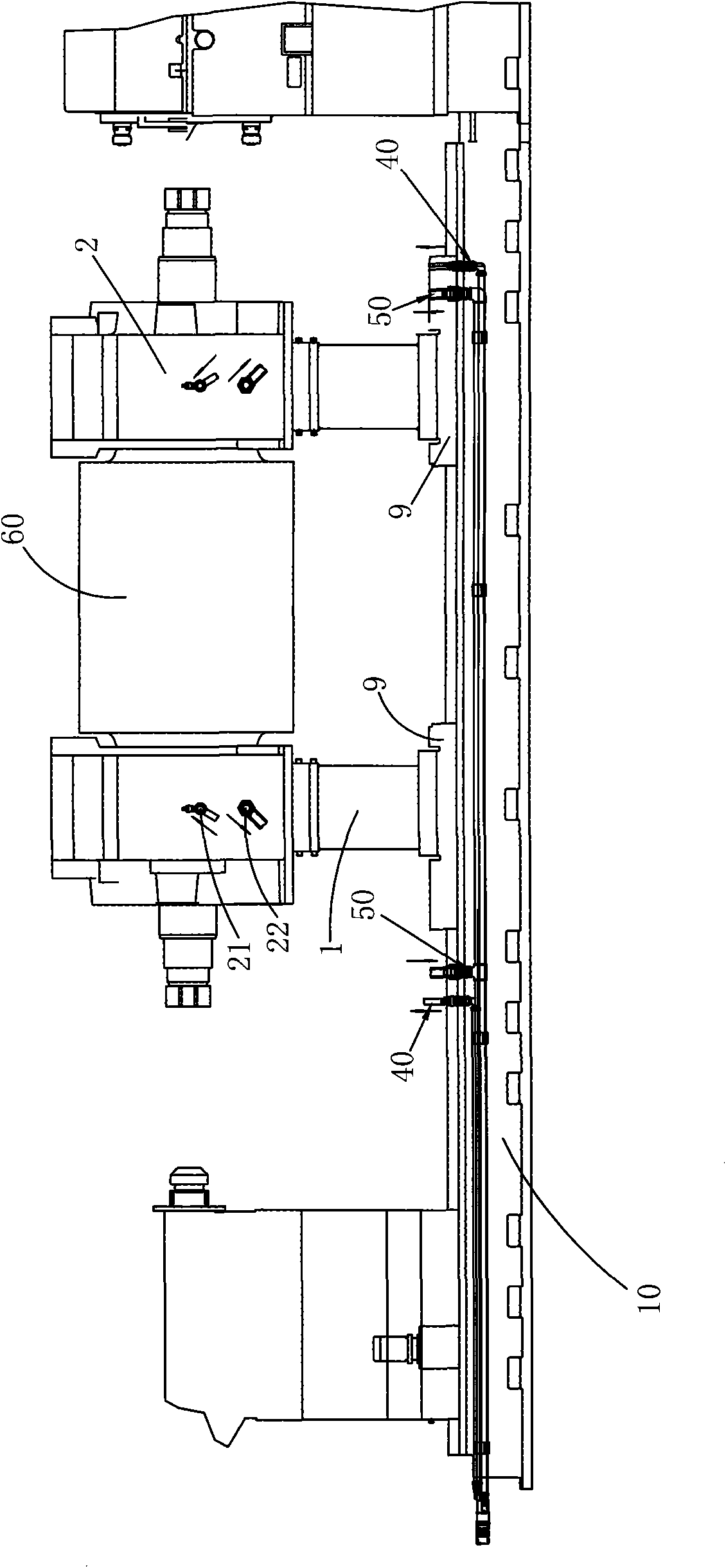

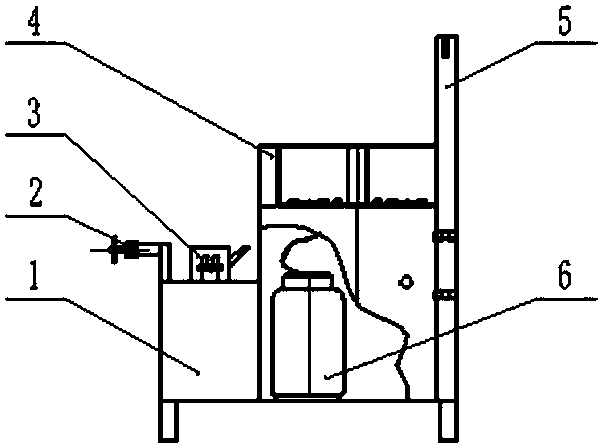

Automatic sheet stacking method and device for cut-to-length lines of silicon steel sheets

InactiveCN105540188AAvoid injury hazardReduce stepsConveyor partsMechanical conveyorsEngineeringHigh velocity

The invention discloses an automatic sheet stacking method and device for cut-to-length lines of silicon steel sheets. The device comprises a front-arrangement conveying belt, a magnetic conveying belt and a material collection cart. The magnetic belt is used for attracting the silicon steel sheets for conveying, and when the silicon steel sheets reach the position above the material collection cart, the magnetic belt is demagnetized, and the silicon steel sheets freely descend; and under the effect of a limiting device of the material collection cart, the silicon steel sheets are rapidly stacked in order, the danger that the silicon steel sheets fly out at the high speed to hurt a person is avoided, rapid in-order stacking can be achieved, worker operation is reduced, and manpower resources are saved.

Owner:CANWIN AUTOMATIC EQUIP CO LTD

High and low dual-position charging and discharging tube for colon dialysis and application method thereof

ActiveCN1883725ARelieve painSimplify the management processEnemata/irrigatorsDialysis systemsLiquid wasteEngineering

Provided is a high / low position colon dialysis irrigation and drainage tube comprising a liquid inlet tube and a waste liquid separation tube having a connection means for inserting the liquid inlet tube into the inner chamber thereof, which is characterized in that the liquid inlet tube connects with the inner chamber of the waste liquid separation tube by the connection means on the body thereof and can further infuse liquid thereto. Meanwhile, an application method for applying the high / low position colon dialysis irrigation / drainage conduit is provided. The invention has simple structure, quick and convenient application and reduced pain in operation for patients.

Owner:BEIJING SUNNY MEDICAL

A new CNC silicon steel sheet cutting line equipment

ActiveCN105397495BReduce distanceShorten the lengthOther manufacturing equipments/toolsShearing machine accessoriesNumerical controlPunching

Owner:CANWIN AUTOMATIC EQUIP CO LTD

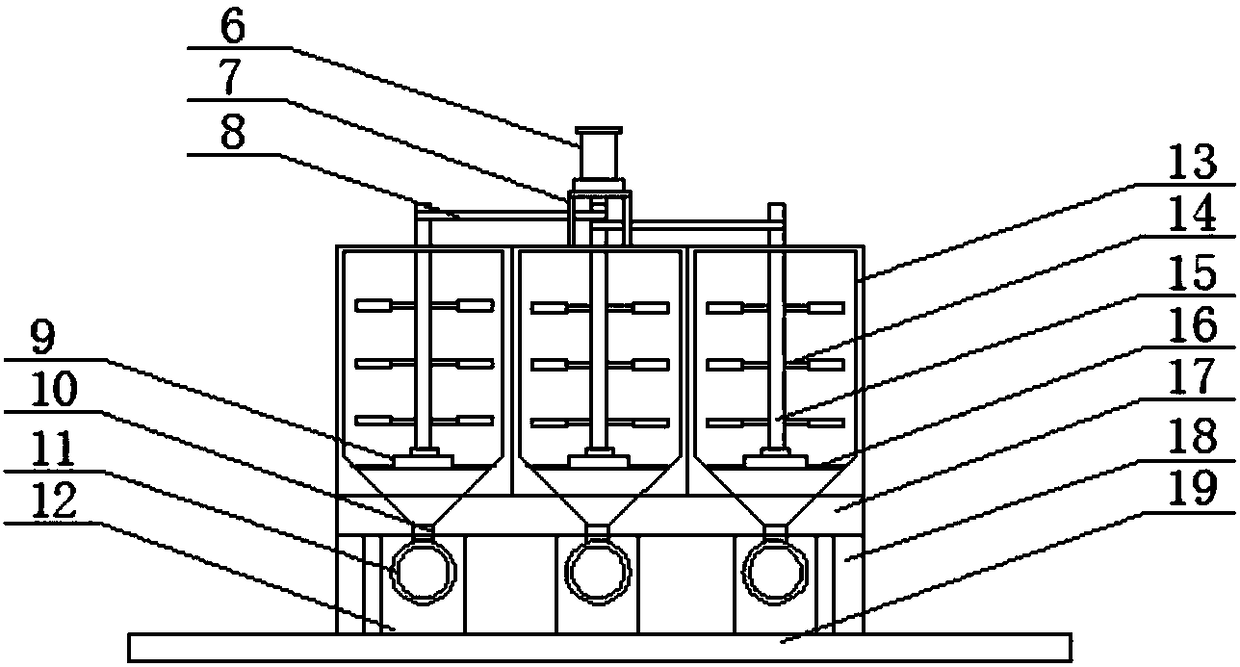

Quantitative proportioning type fodder mixing machine for animal husbandry

InactiveCN108554295AIt takes a long time to solveAvoid injury hazardFeeding-stuffRotary stirring mixersEngineeringAnimal husbandry

The invention discloses a quantitative proportioning type fodder mixing machine for the animal husbandry. The quantitative proportioning type fodder mixing machine comprises a base, three fixed boxesare arranged at the upper end of the base, four supporting rods are fixed to the four corners of the lower end of each fixed box, and the lower ends of the four supporting rods of each fixed box are fixed to the upper end of the base. An automatic sealing device is arranged on one side of the each fixed box, a second bearing rod is fixed to the lower end of each automatic sealing device, one end of each second bearing rod is fixed to one side of the corresponding fixed box, a second fixed block is fixed to the side wall of one end in each fixed box, one side of each second fixed block is rotationally connected with a second oil cylinder, and a first opening is formed in the upper end of each fixed box. According to the quantitative proportioning type fodder mixing machine, the function ofreplacing manual stirring with mechanical stirring is achieved, the problem that due to manual stirring, the consumed time is long, a large amount of manpower is wasted, and stirring is uneven is solved, meanwhile, the hidden danger of possible harm to the human body in the manual stirring process is avoided, operation is easy, and the quantitative proportioning type fodder mixing machine is suitable for popularization.

Owner:朱利松

Motor bearing assembly radial clearance measuring method and device

ActiveCN110986809ARealize 360° rotation and displacement requirementsAchieving rotational displacement requirementsMachine bearings testingUsing optical meansElectric machineEngineering

The invention discloses a motor bearing assembly radial clearance measuring method and device. The method comprises the steps of: fixing a motor housing on a motor displacement apparatus, setting a laser measurement apparatus on the motor displacement apparatus, and starting the laser measurement apparatus to carry out first vertical measurement on the position at a rotating shaft of a motor, starting the motor displacement apparatus to enable the motor to rotate by 180 degrees around a direction perpendicular to the axial direction of the motor, then carrying out second vertical measurement on the position at the rotating shaft of the motor through the laser measurement apparatus, and working out the difference value of the two values measured in the vertical direction, thus obtaining theradial clearance of motor bearing assembly. The method and device provided by the invention adopt the laser measurement apparatus to scan the positions of the rotating shaft before and after rotationand calculate the radial assembly clearance, and have the advantages of high precision, high efficiency, no damage to the bearing and the like.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

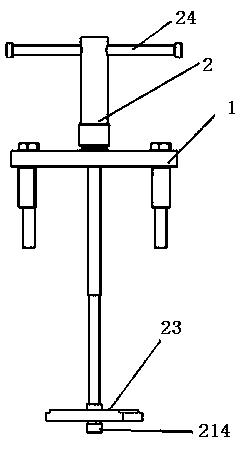

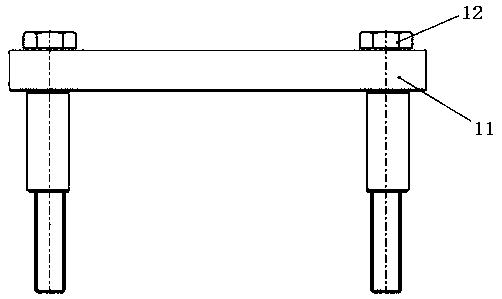

Engine cylinder sleeve dismounting device

InactiveCN110815123AEnough operating spacePlay a supporting roleMetal-working hand toolsEngineeringStructural engineering

The invention provides an engine cylinder sleeve dismounting device which comprises a bracket assembly and a drawing assembly, wherein the bracket assembly comprises a bracket and a plurality of mounting bolts; the bracket can be connected with a cylinder cover bolted hole on a body through the mounting bolts; the drawing assembly comprises a spiral driving mechanism and a pulling plate; the spiral driving mechanism comprises a driving rod and a rotating component; the driving rod penetrates through the bracket; the upper end of the driving rod is engaged with the rotating component; the lowerend of the driving rod is connected with the pulling plate; the pulling plate can be propped against the lower end of the engine cylinder sleeve to be dismounted; the rotating component and the bracket can relatively rotate and not move downwards; and the rotating component can rotate under the action of an external force to further drive the driving rod and the pulling plate to move upwards. A cylinder sleeve can be drawn out from a line engine and a V-type engine, the operation is simple, and a cylinder cover mounting surface of the engine body cannot be scratched when the engine cylinder sleeve dismounting device.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

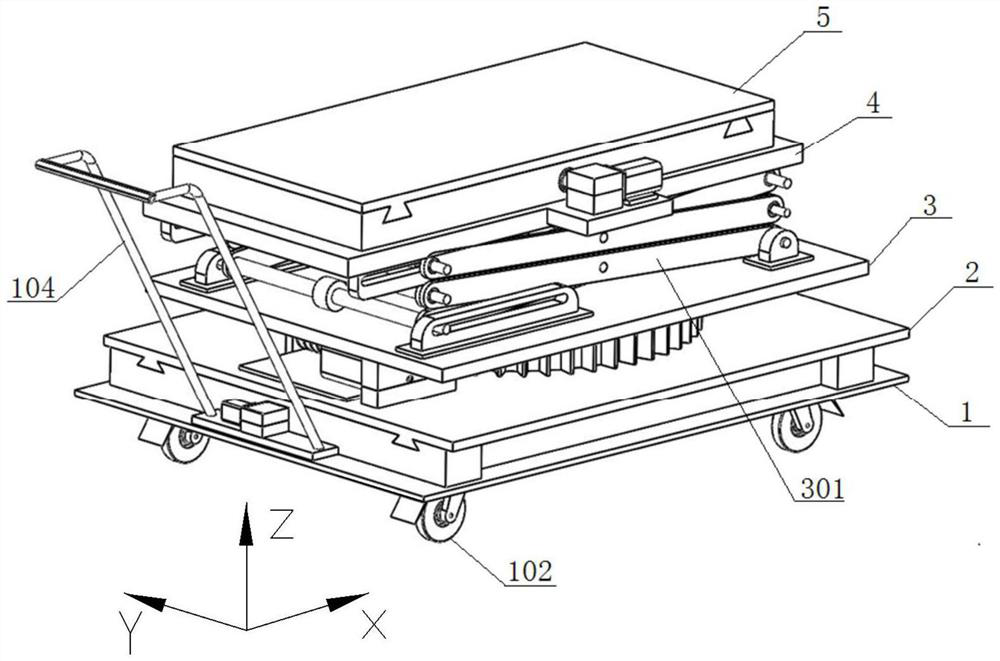

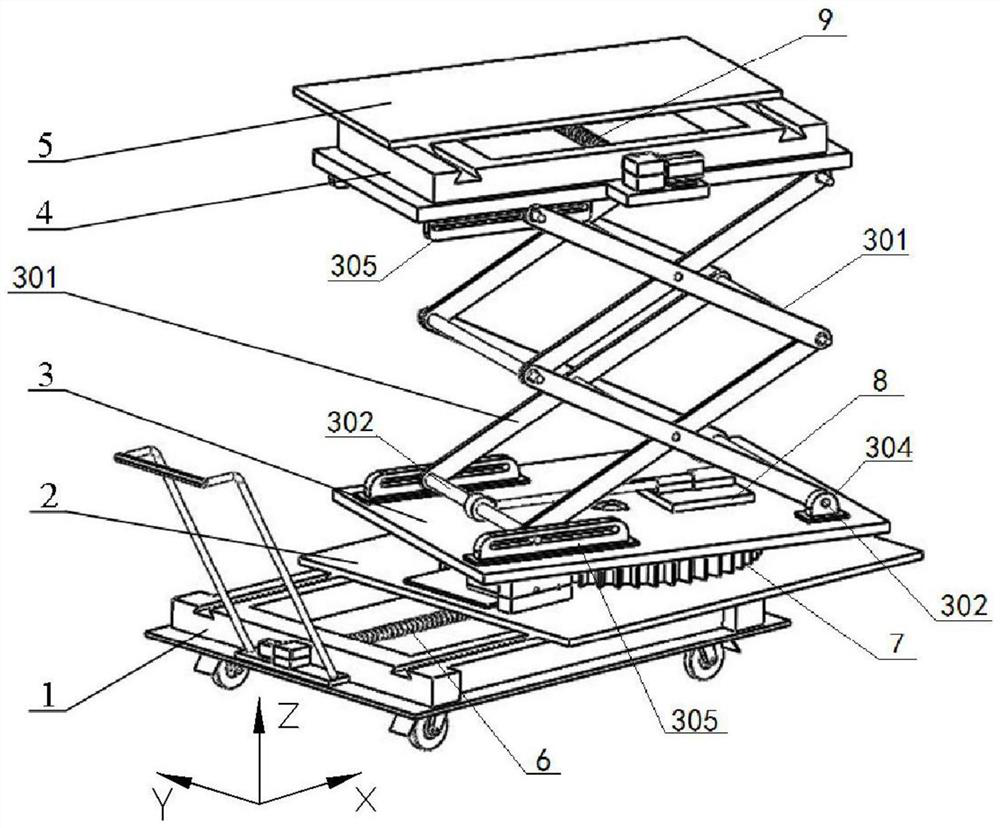

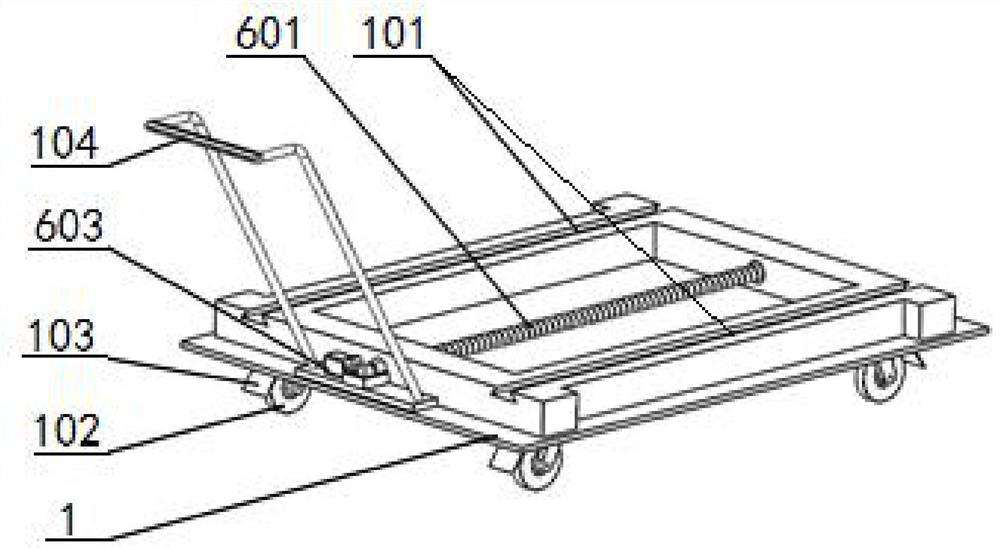

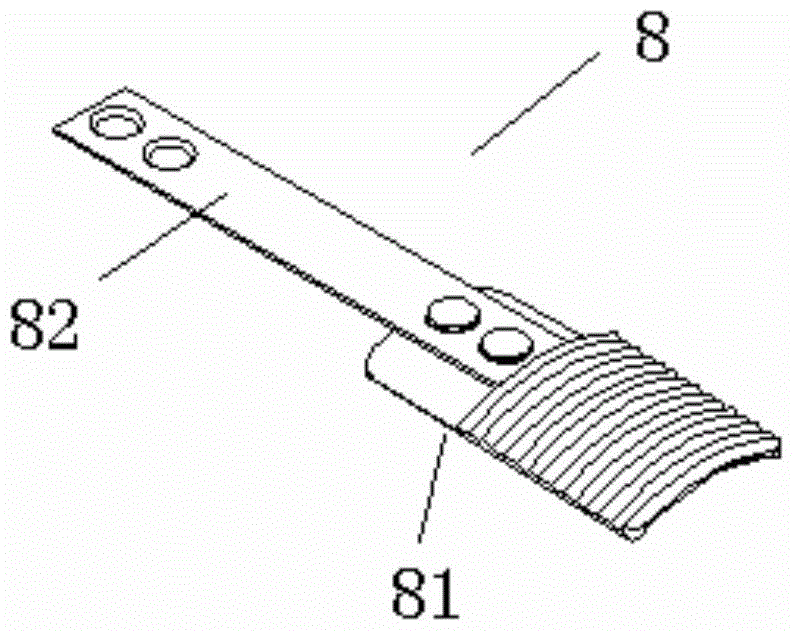

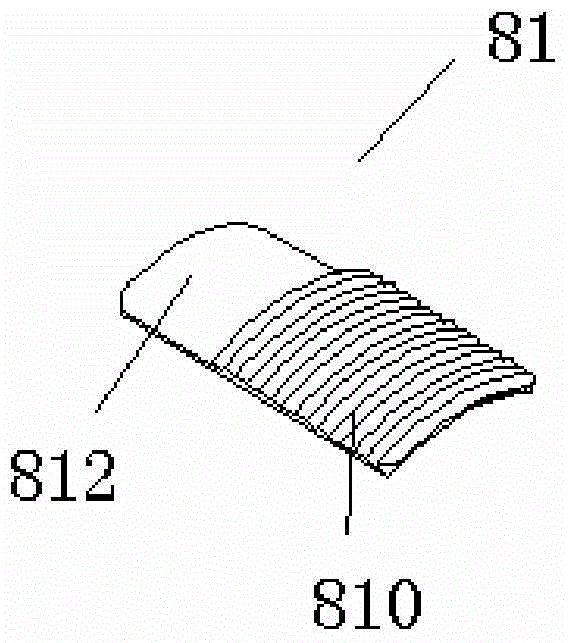

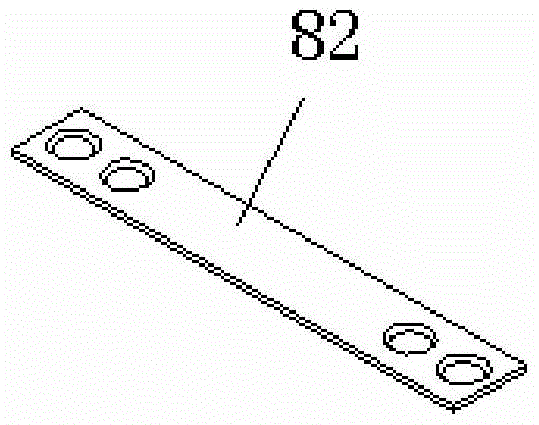

Four-degree-of-freedom accurate hoisting carrier loader for under-train parts of motor train unit

PendingCN112706809AAccurate adjustment positionEasy to assembleHand carts with multiple axesHand cart accessoriesControl engineeringControl theory

The invention discloses a four-degree-of-freedom accurate hoisting carrier loader for under-train parts of a motor train unit, and belongs to the technical field of under-train part carrying equipment in the rail transit vehicle assembling stage. The four-degree-of-freedom accurate hoisting carrier loader is provided with a bottom frame; a bearing platform is arranged above the bottom frame; a movable layer comprises a movable layer, a rotating layer and a lifting layer; the lower part of the movable layer is in sliding connection with the bottom frame, and the upper part is rotationally connected with the rotating layer; the upper part of the rotating layer supports the lifting layer to lift along the Z-axis through a bracket; a bearing table is slidably connected to the lifting layer; the movable layer further comprises transmission mechanisms distributed between the bottom frame and the movable layer, between the movable layer and the rotating layer and between the rotating layer and the bearing platform, and the transmission mechanisms are used for enabling the bearing platform to move along the X axis, rotate and move along the XY plane, ascend and descend along the Z axis and move along the Y axis. The four-degree-of-freedom accurate hoisting carrier loader can realize accurate adjustment on vehicle lower part positions in four freedom degrees, the structure is simple, operation is stable and reliable, time and labor are saved, and the working efficiency can be improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

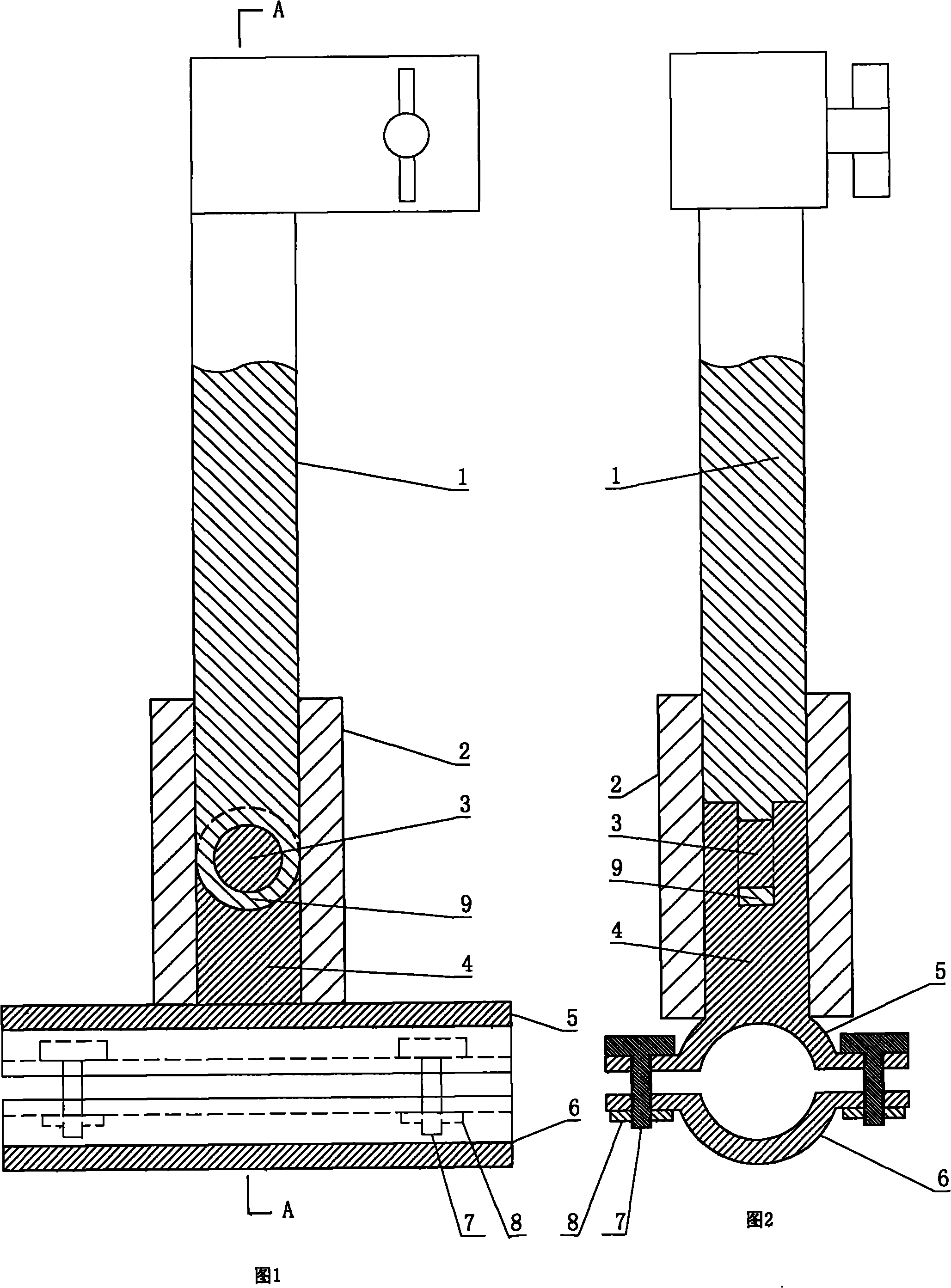

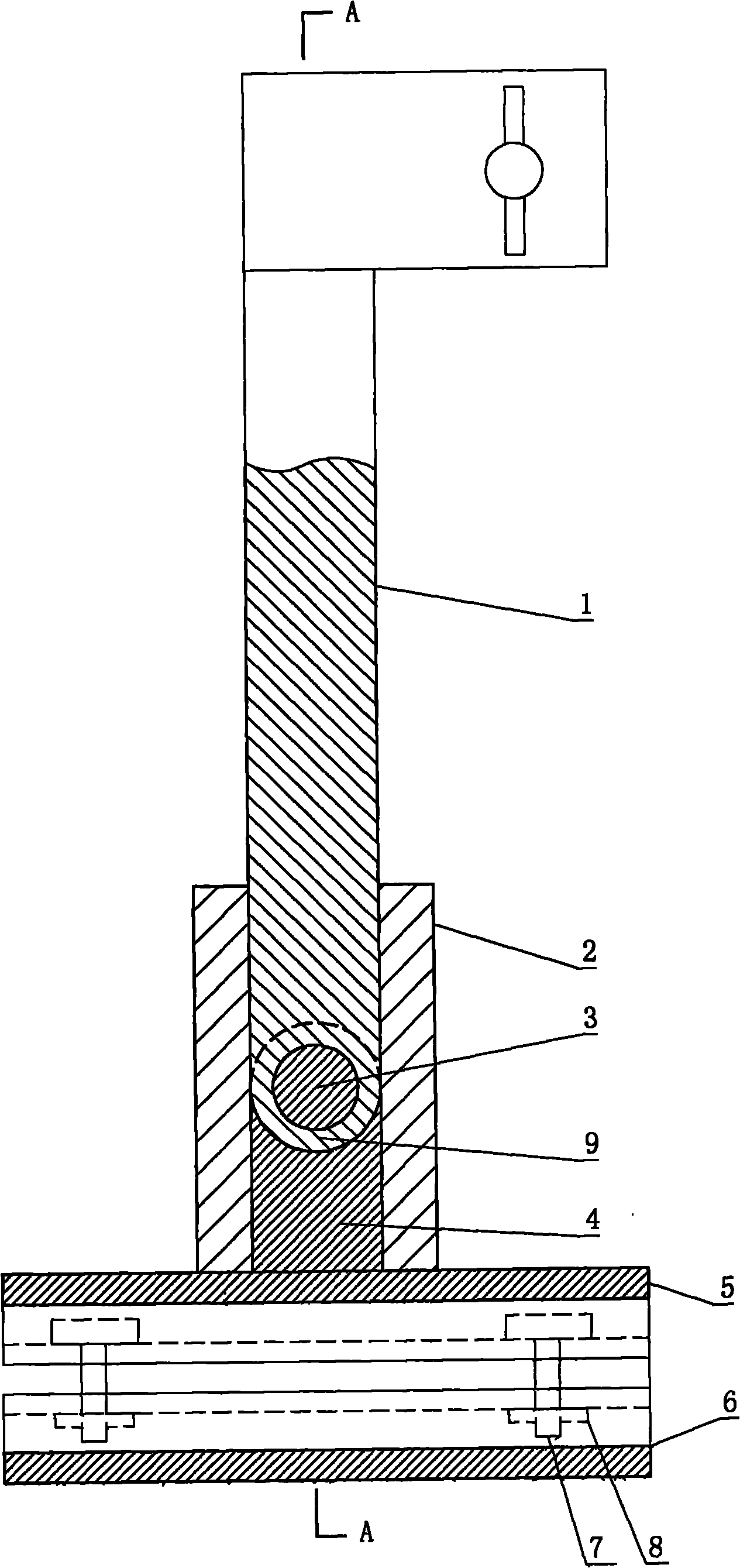

Oil filter tube sleeve hanger welding fixture

ActiveCN104097011BReduce manufacturing costSmall size errorWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMachining

The invention discloses a welding jig for a petroleum filter pipe sleeve hanger. The welding jig comprises a V-shaped push block, a hanging arm fixing block, a jig body, a push block guide pillar and a guide pillar positioning block, wherein one end of the V-shaped push block is provided with a V-shaped opening made of tooth-shaped metal plate for fixing the hanger while the other end of the V-shaped push block is connected to the guide pillar positioning block through the push block guide pillar; the hanging arm fixing block is provided with a groove for containing the hanging arm of the hanger; the hanging arm fixing block, the V-shaped push block and the guide pillar positioning block are sequentially arranged on the jig body; the jig body is arranged on the welding arm of a spot-welder. The welding jig provided by the invention has the advantages of novel structure, rapid machining speed, high welding quality and capable of adapting to different types of welding parts.

Owner:TAICANG UNION TECH PRECISION MACHINERY

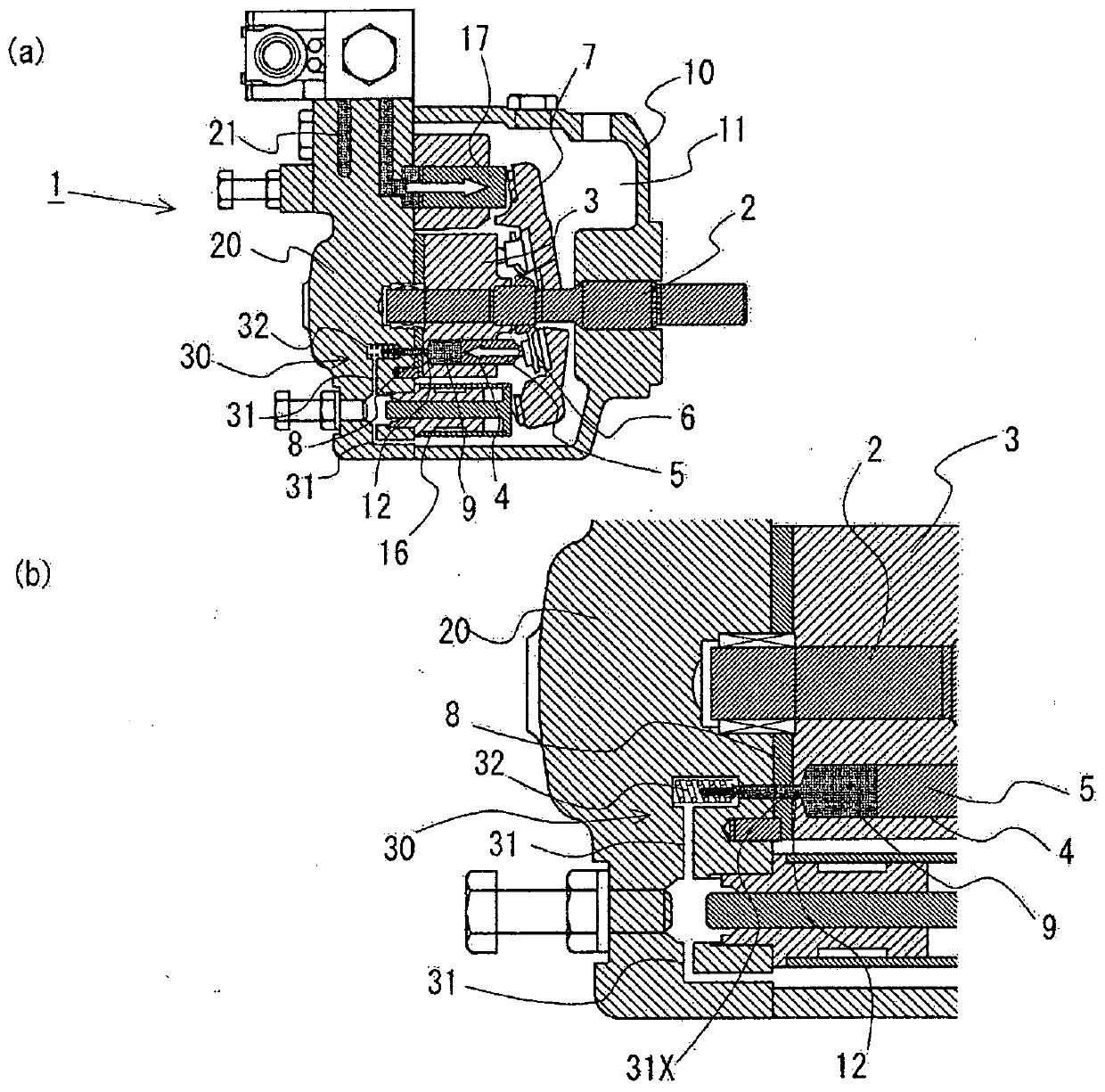

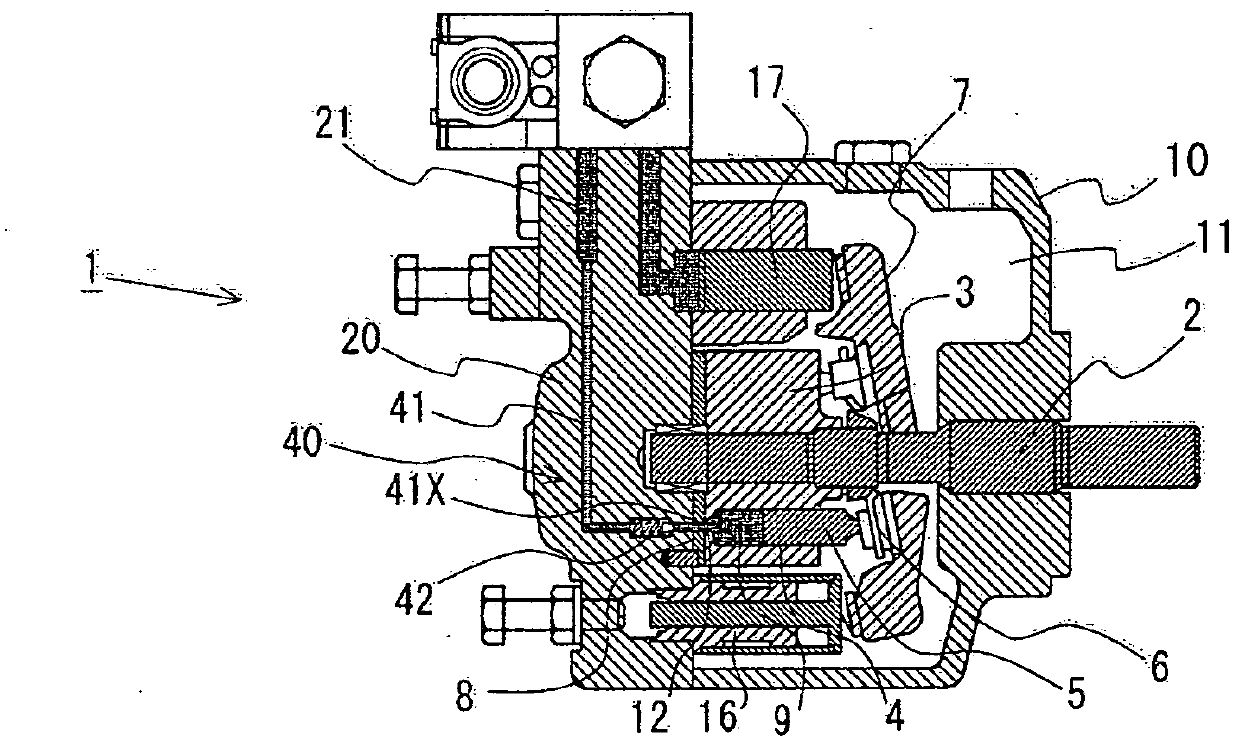

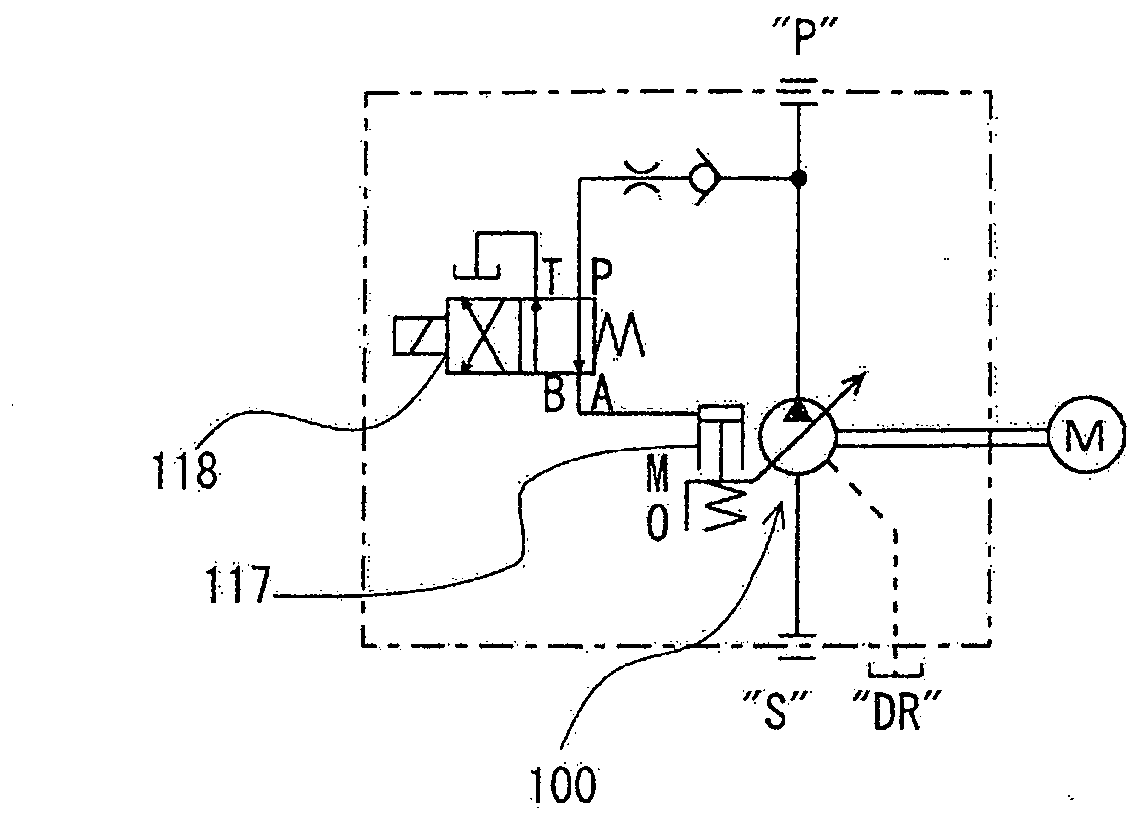

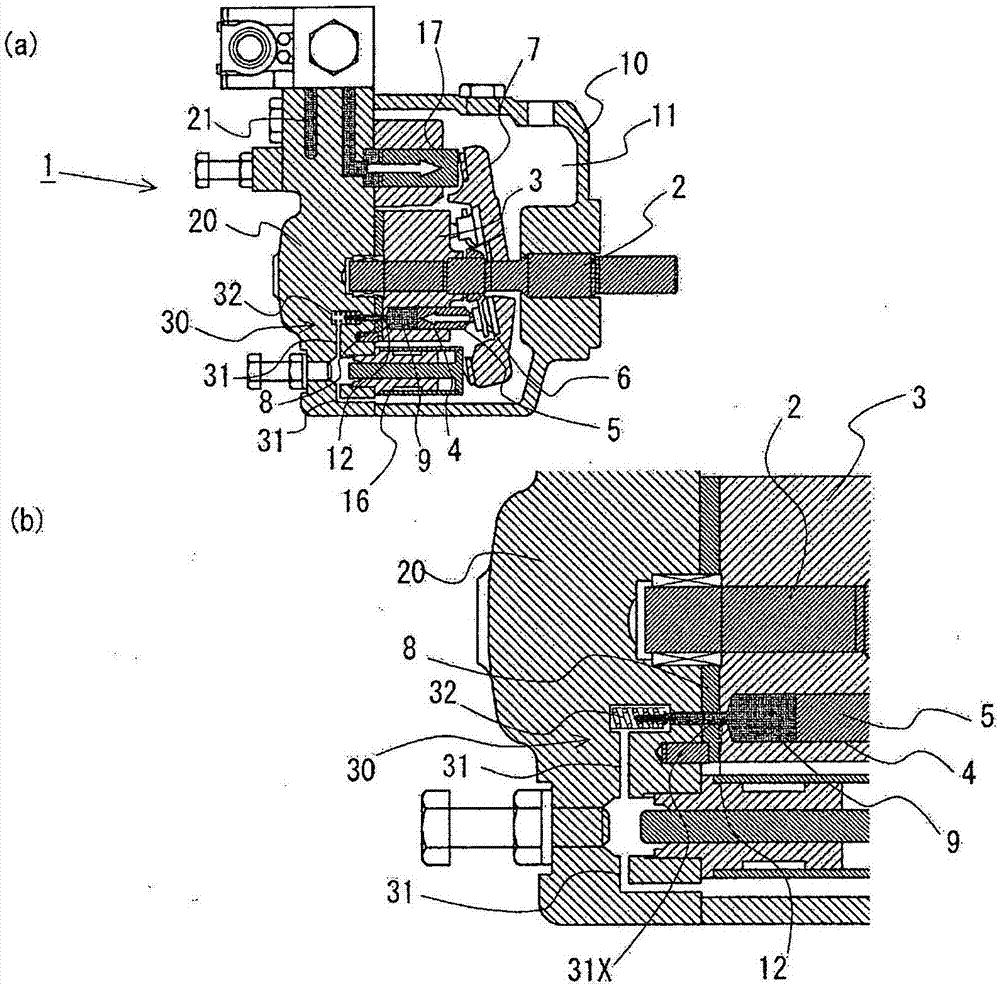

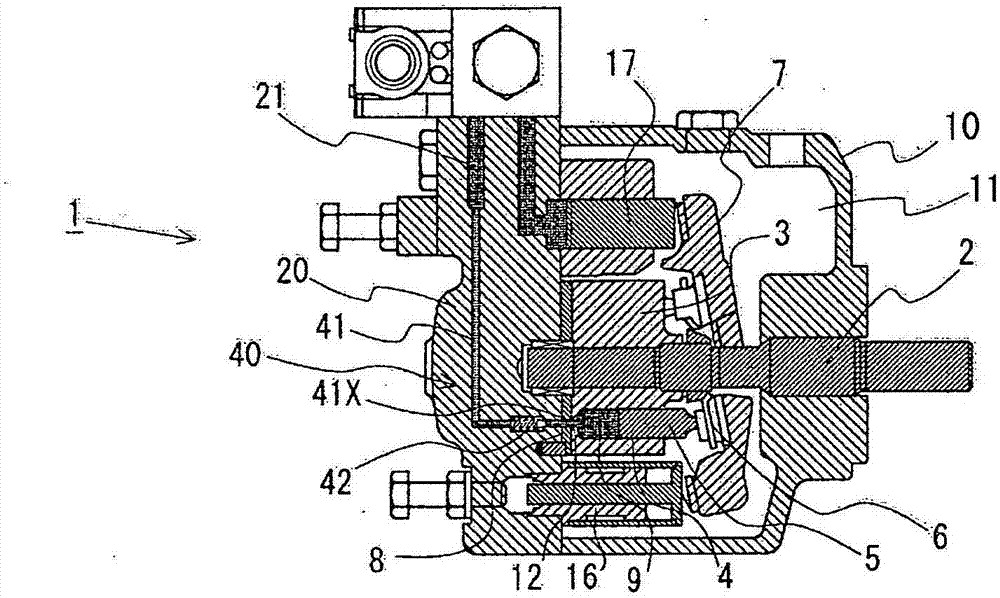

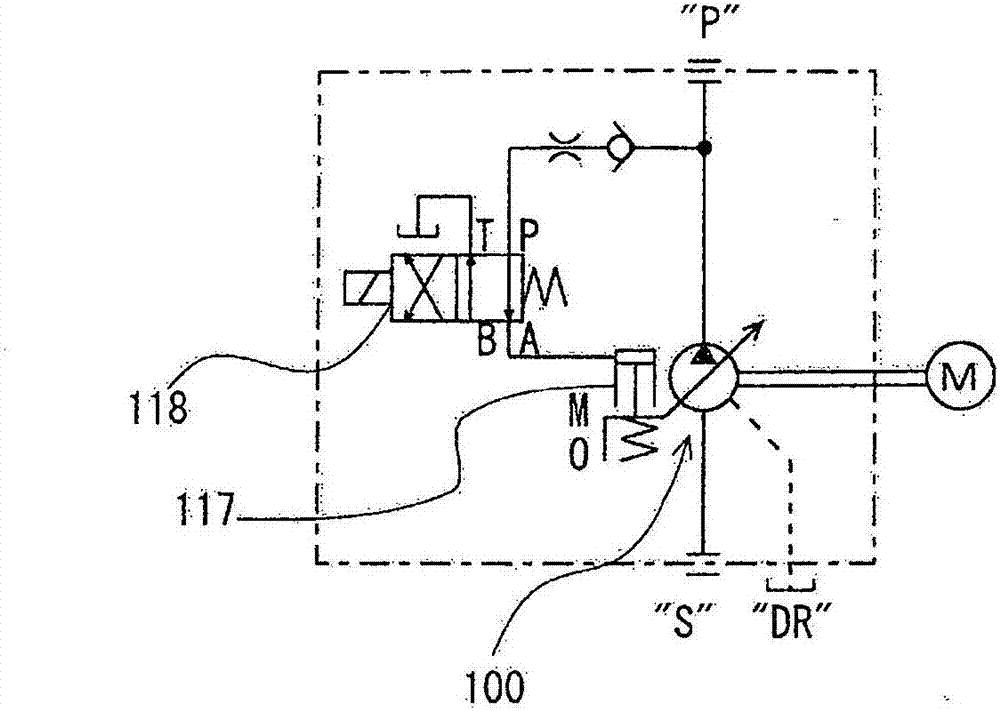

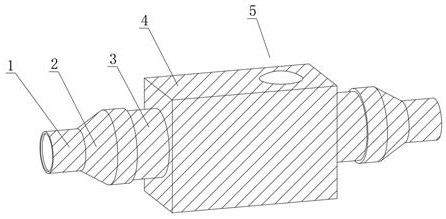

Variable displacement piston pump for speed control

ActiveCN107407263BAvoid injury hazardPump controlPositive-displacement liquid enginesRadial piston pumpHydraulic circuit

Provided is a rotational-speed-controlling variable piston pump with which it is possible to satisfactorily avoid abnormal pressures in the bore chamber of a cylinder block with a simple configuration, without causing loss of pump efficiency or increases in cost. The present invention provides a rotational-speed-controlling variable piston pump in which pistons move back and forth within a bore at a stroke suited to the angle of inclination of a swash plate along with the rotation of a cylinder block, whereby hydraulic oil is drawn into a bore chamber from an intake oil passage formed in a casing, via an intake port of a port plate against which the cylinder block slides, and the hydraulic oil is discharged to a discharge oil passage formed in the casing, via a discharge port of the port plate; wherein an abnormal-pressure-avoiding oil pressure circuit, which releases the hydraulic oil in the bore chamber out of the bore chamber when the pressure in the bore chamber positioned between the intake port and the discharge port of the port plate exceeds a predetermined pressure, is provided as being incorporated in the same unit structure within the same casing.

Owner:YUKEN KOGYO

Indwelling needle

The invention relates to an indwelling needle which is safe to use and is not liable to break; the indwelling needle comprises a conduit seat, a protecting tube and a jacket. The conduit seat is provided with a sealing plug; an upper end of the conduit seat is provided with a conduit; a connecting pipe is arranged on the external side of the conduit seat; one end, provided with an opening, of the protecting tube is detachably installed at the bottom end of the conduit seat; the external surface of the protecting tube is provided with a linear slideway extending in the axial direction of the protecting tube; the bottom of an inner side surface of the protecting tube is provided with a circle of flange; the protecting tube is provided with a needle seat; the upper surface of the needle seat is fixedly provided with a needle core; the outer side surface of the needle seat is provided with a connecting rod; one end, protruding from the outer side surface of the protecting tube, of the connecting rod is fixedly connected with a handle; the external side surface of the needle seat is provided with an accommodating groove; the accommodating groove is provided with a connecting plate therein; the top end of the connecting plate is arranged on an inner side surface, close to the needle core, of the accommodating groove; the bottom end of the connecting plate is fixedly provided with a protruding part; the bottom of the jacket is detachably arranged on the top end of the protecting tube.

Owner:曹宇

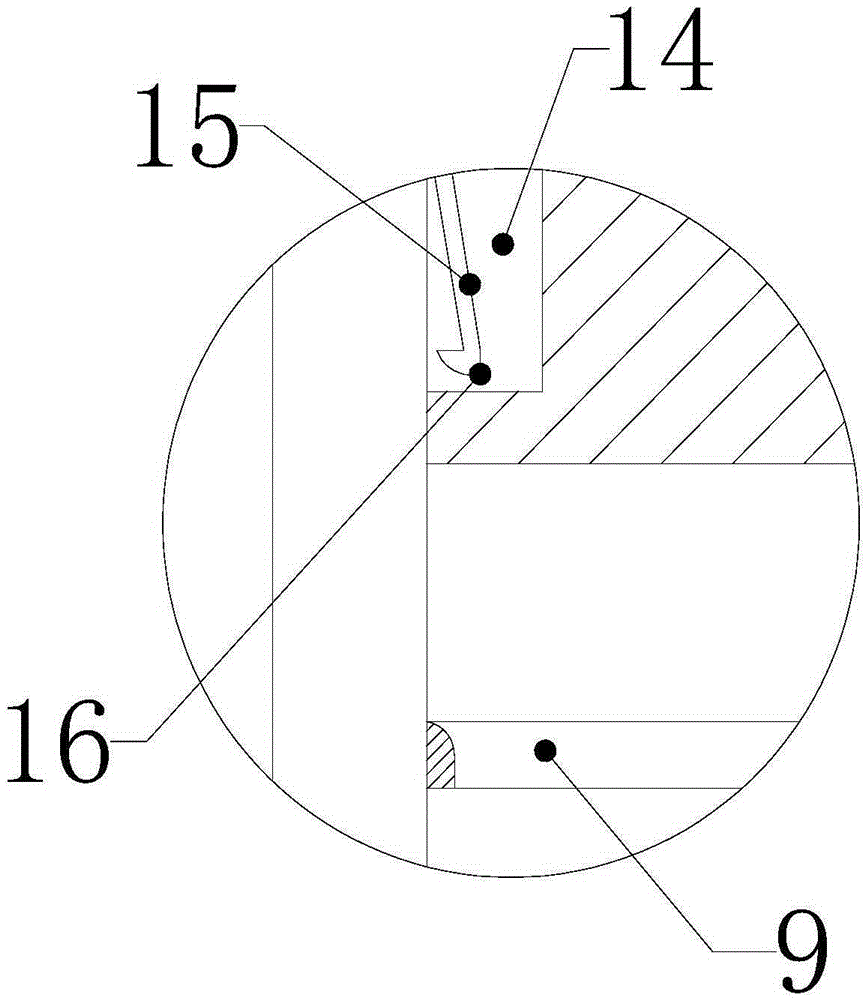

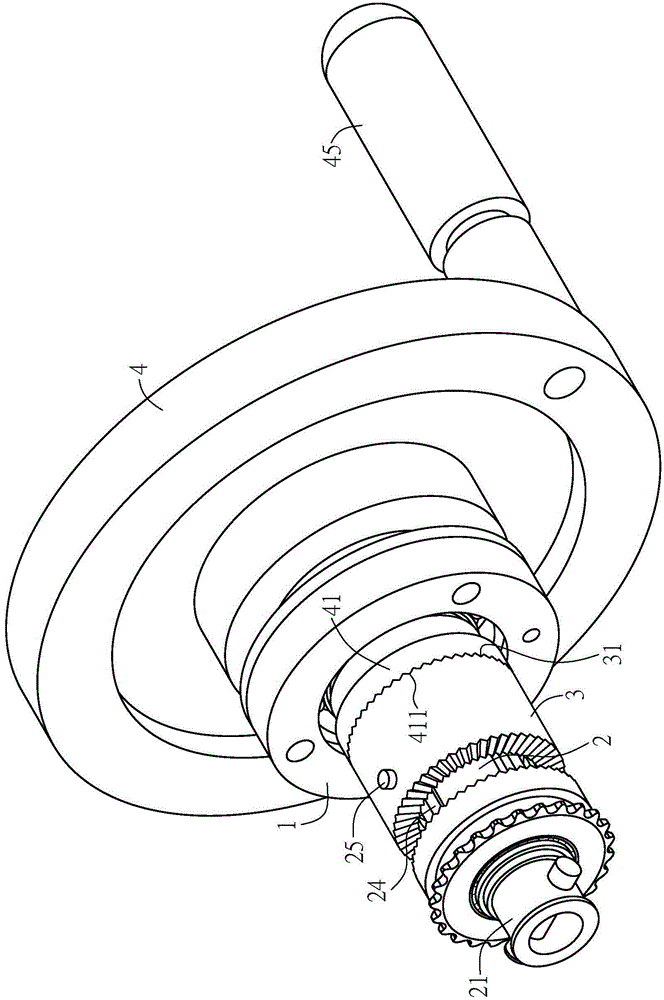

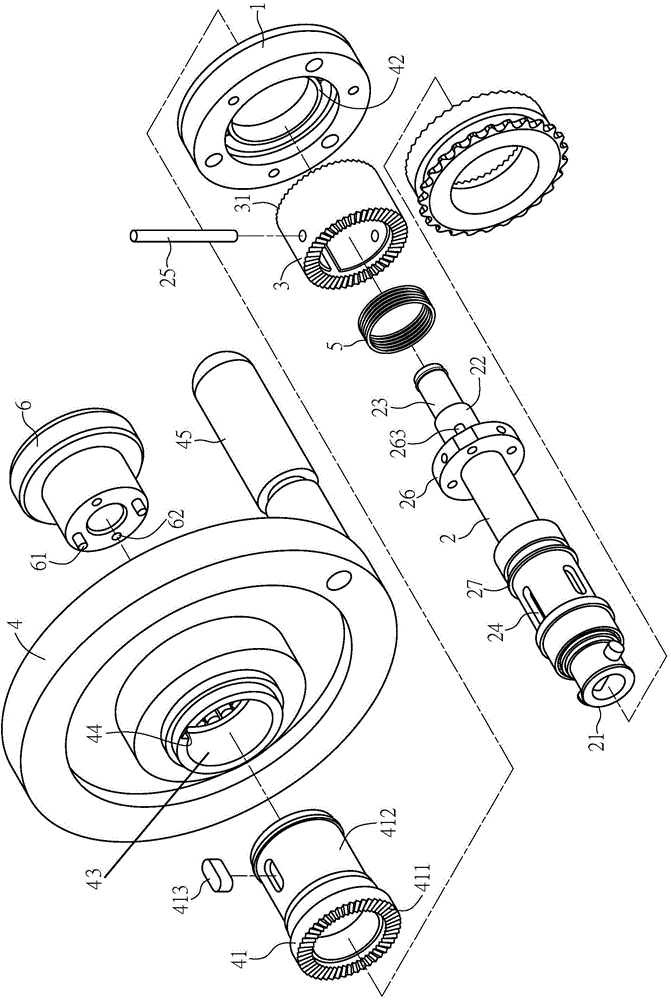

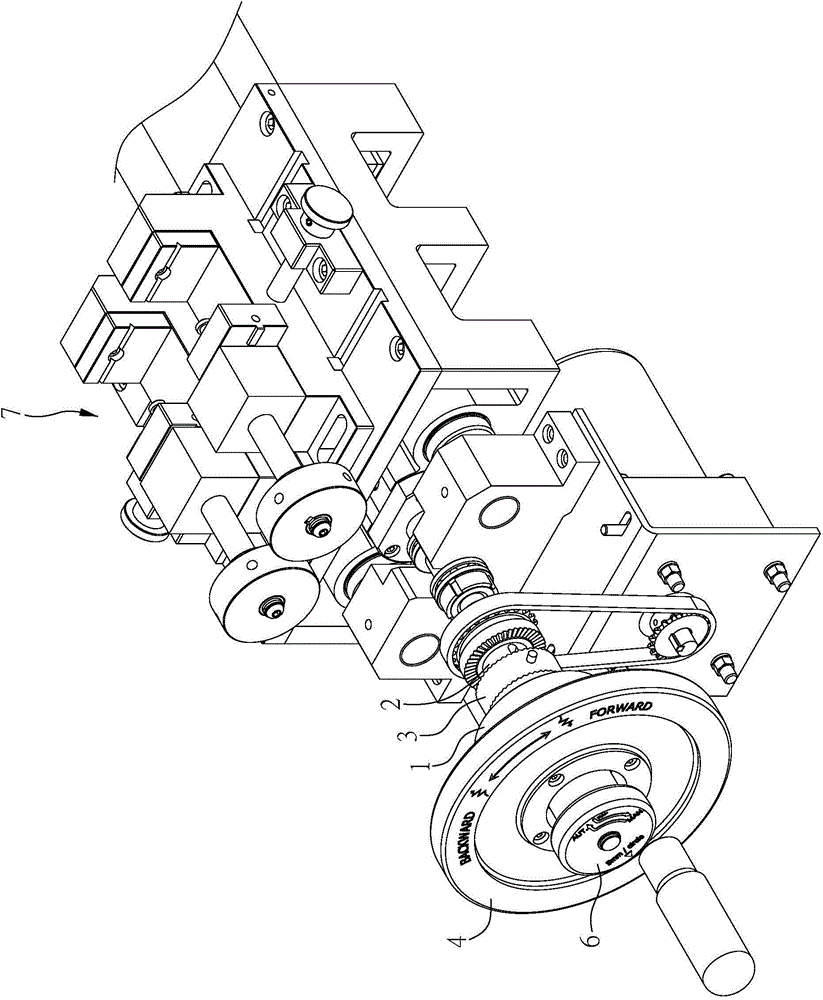

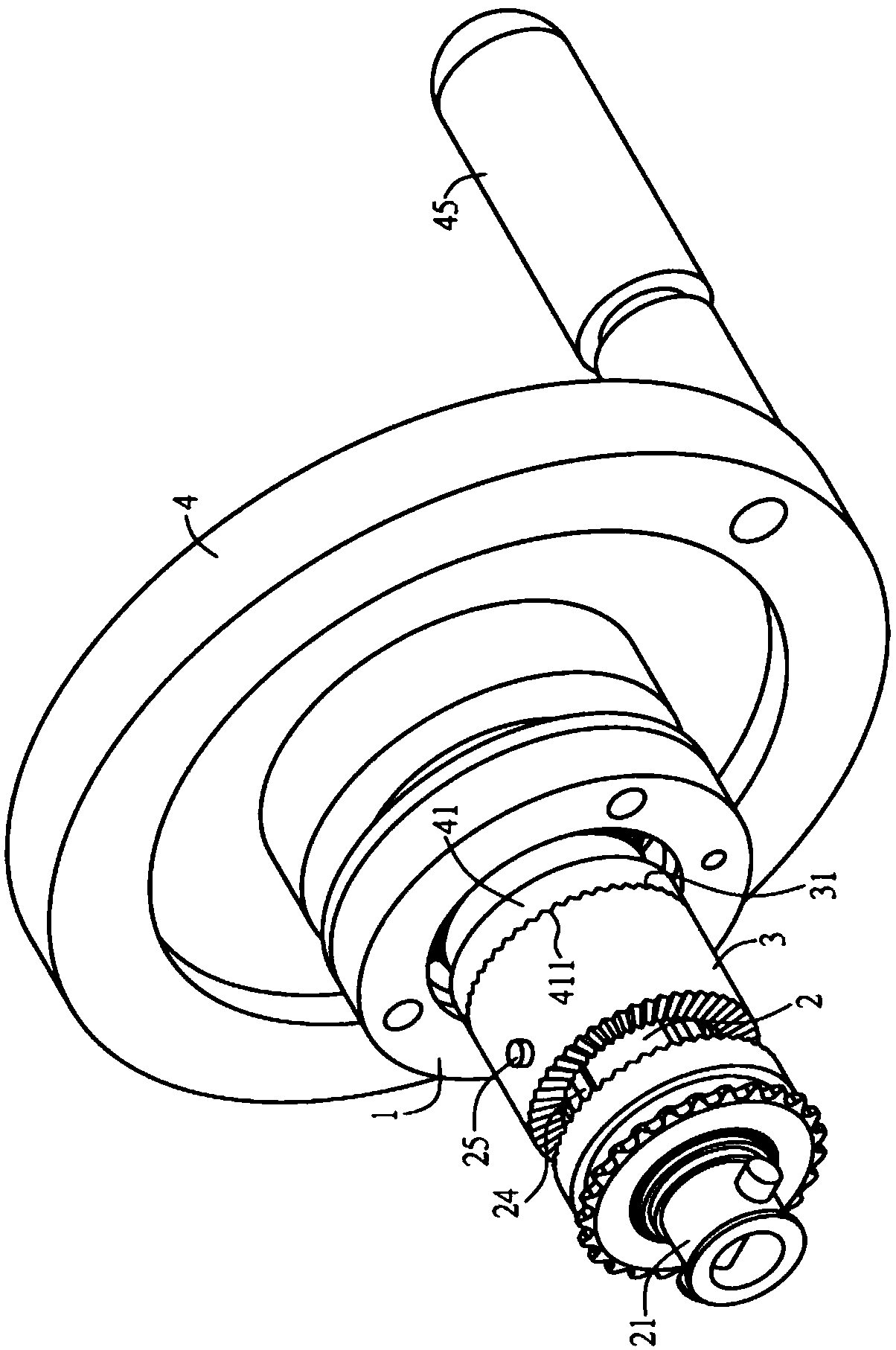

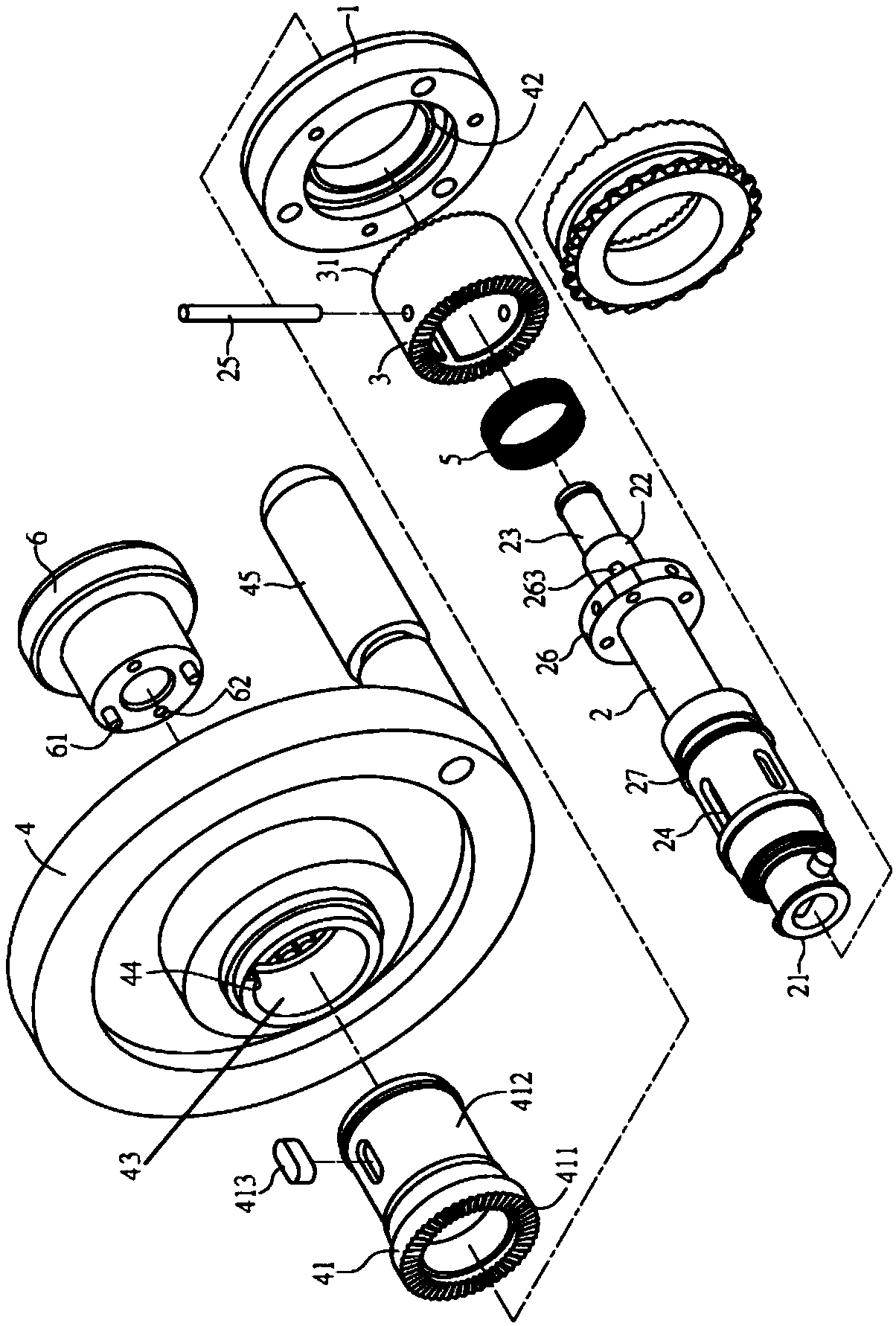

Clutch mechanism of control grip of machine

The invention provides a clutch mechanism of a control grip of a machine. The clutch mechanism is a pivot bonding base bonded to the machine. An axis pipe is arranged in the pivot bonding base in a penetrating mode. An insertion rod is arranged in the axis pipe in a penetrating mode. One end of an insertion rod is exposed out of the axis pipe. A movable block is arranged on the axis pipe in a sleeving mode and connected with the insertion rod on the periphery of the axis pipe. A positioning block is arranged on one side of an operation wheel. The operation wheel is arranged on the axis pipe in a coaxial and pivoted mode through the positioning block. A control piece is bonded with the end of the insertion rod and can be pulled and drive the movable block to move between a first position and a second position through axial displacement of the insertion rod. At the first position, the movable block is disengaged from the positioning block. At the second position, the movable block and the positioning block are clamped so that the operation wheel can rotate and drive the axis pipe to rotate, and the clutch mechanism is obtained in this way.

Owner:KING YU FANG ENTERPRISE

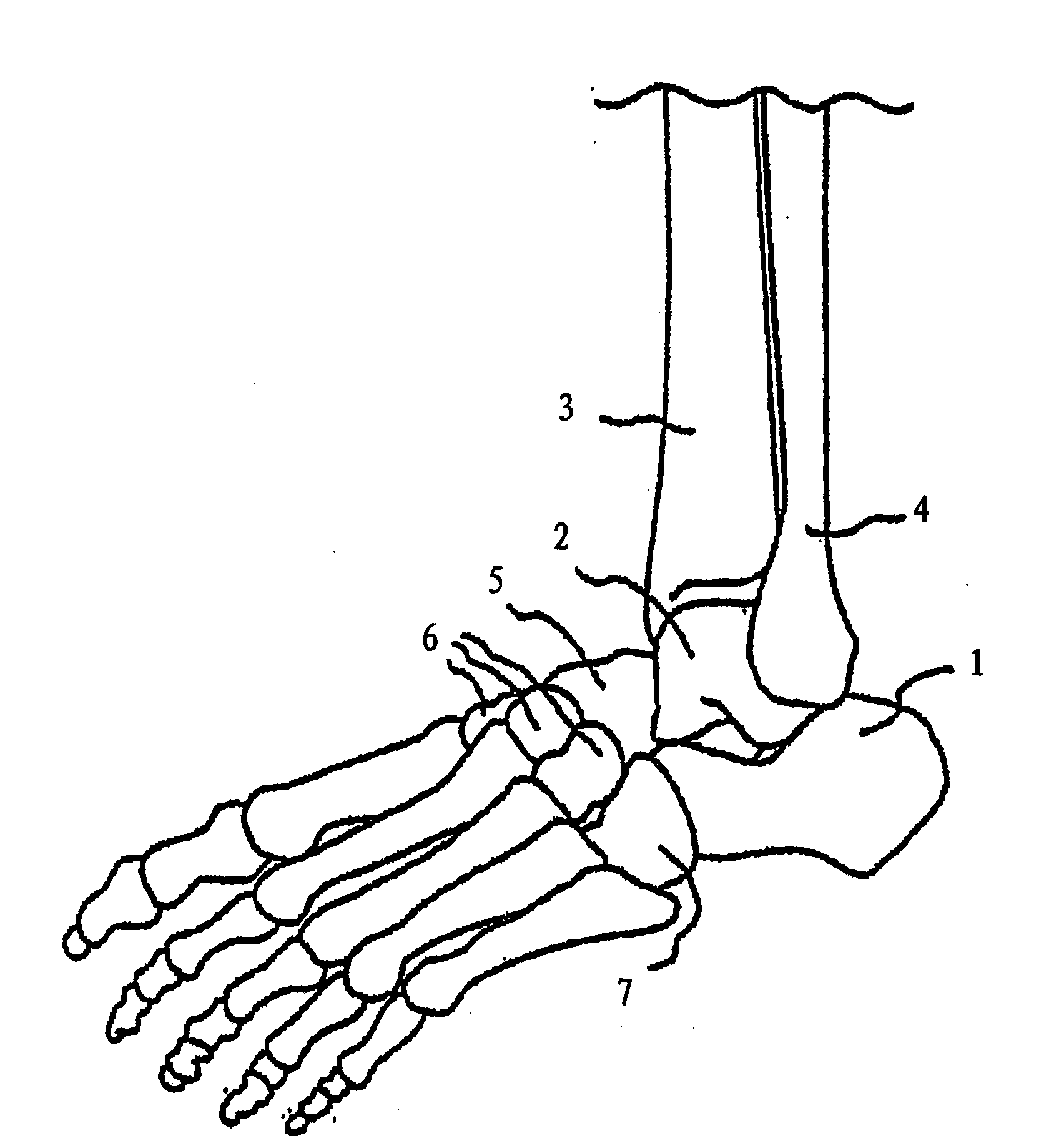

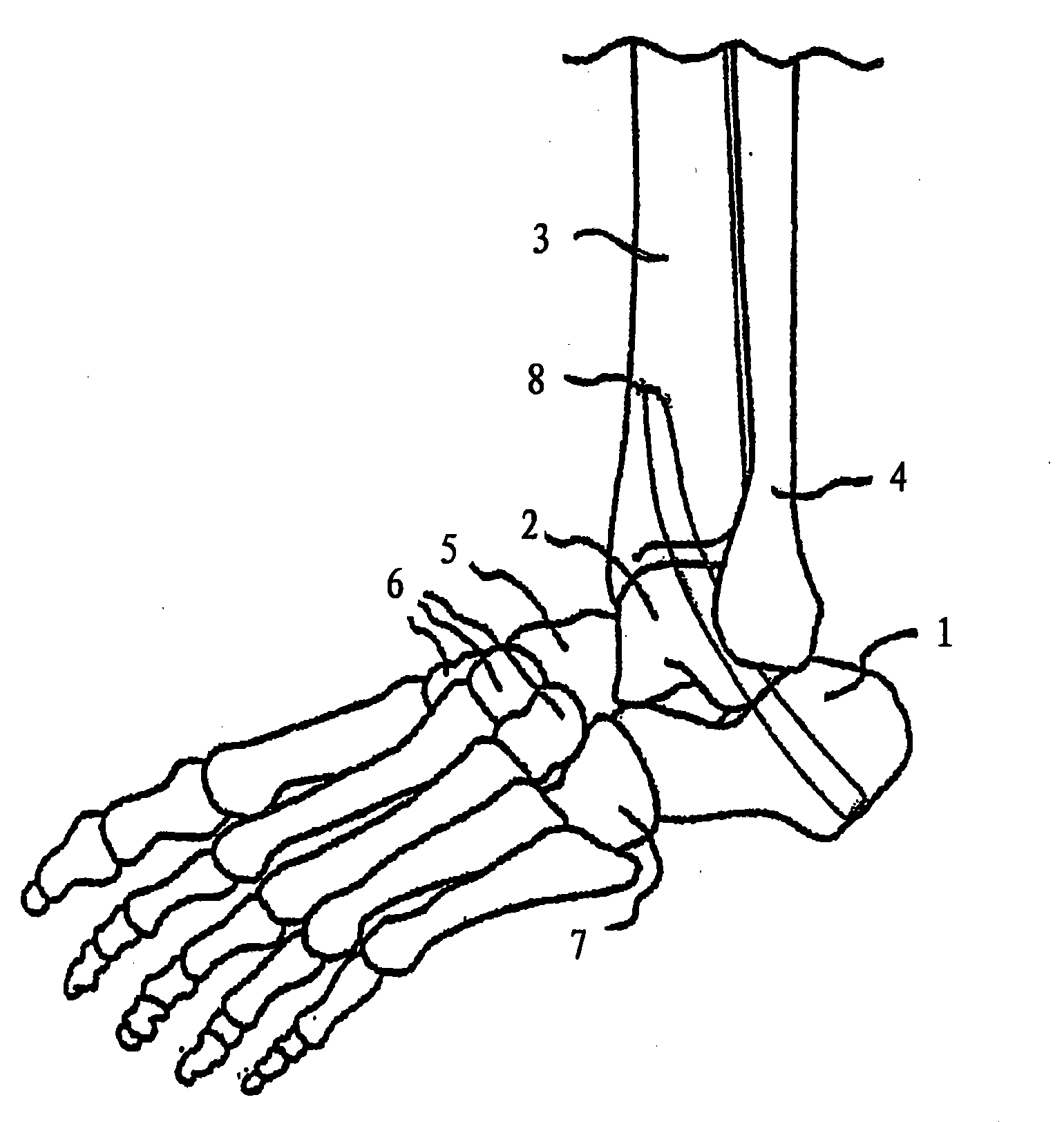

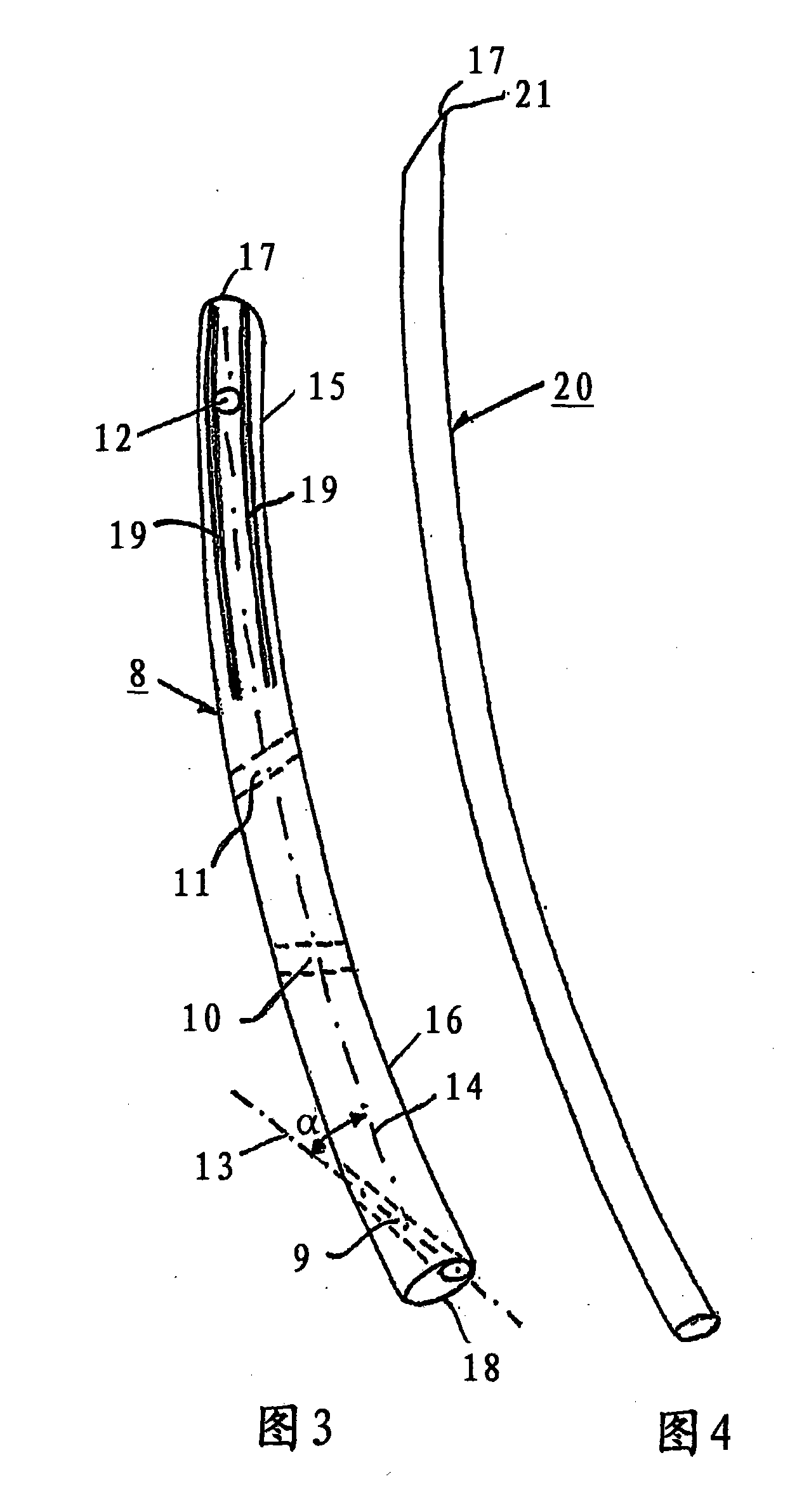

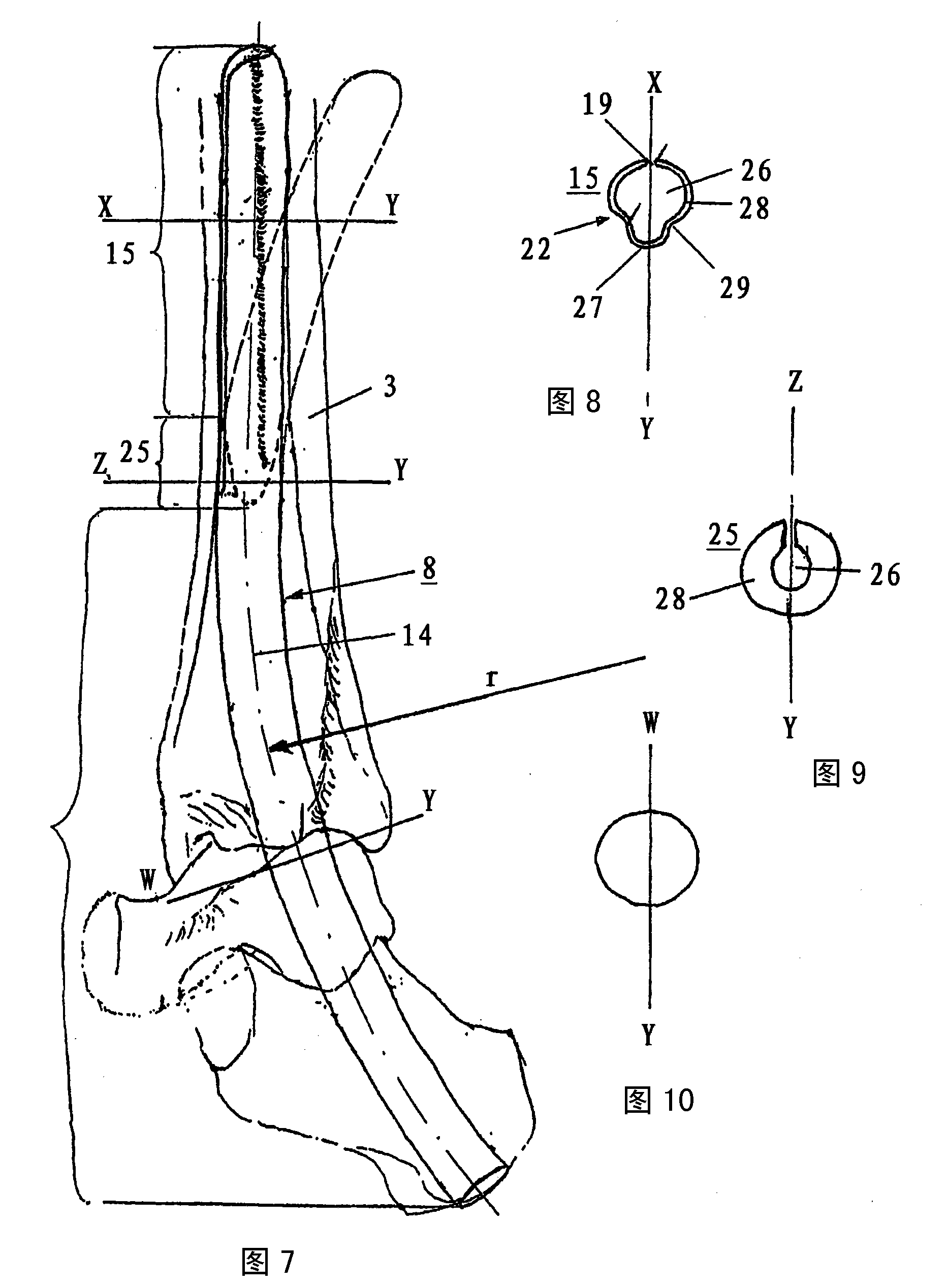

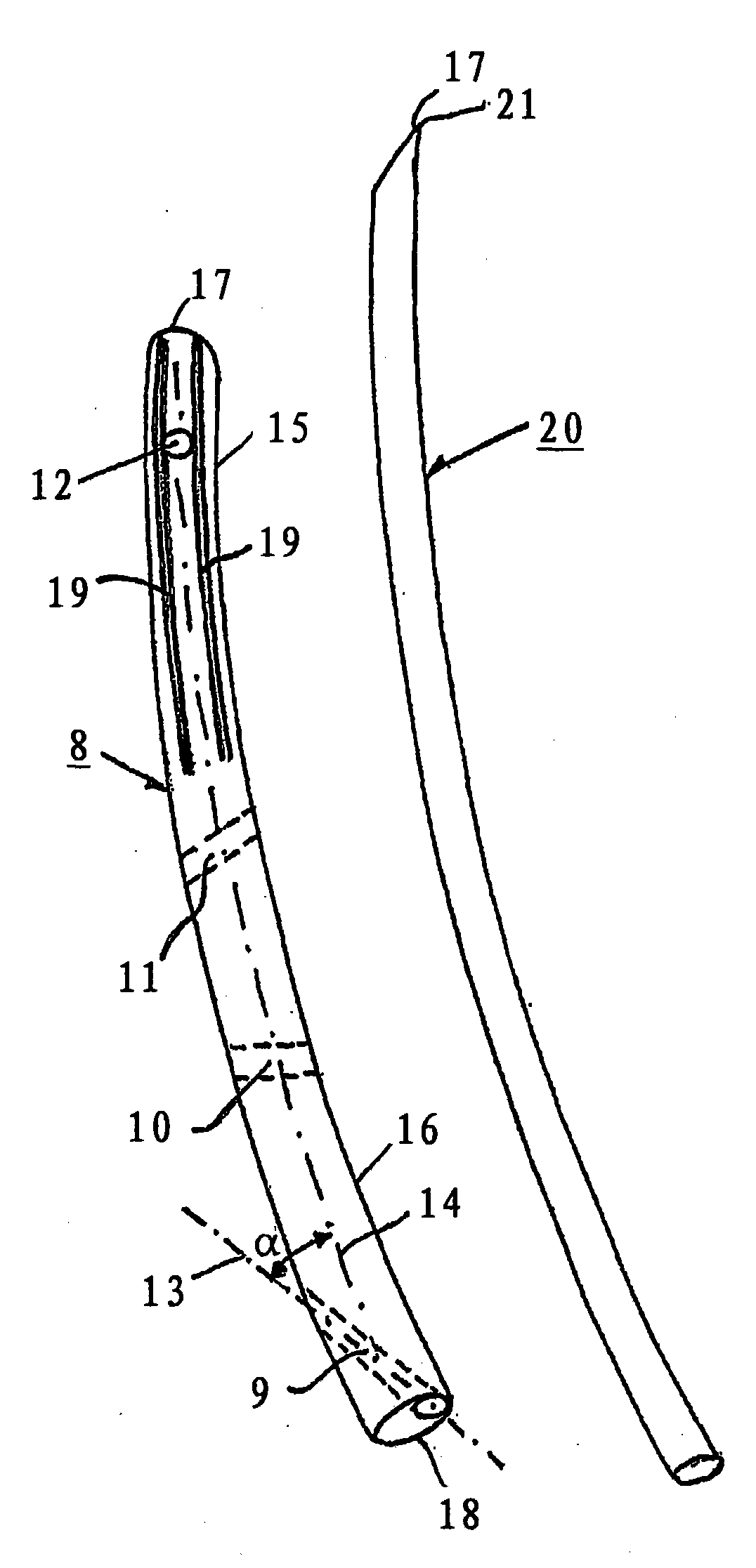

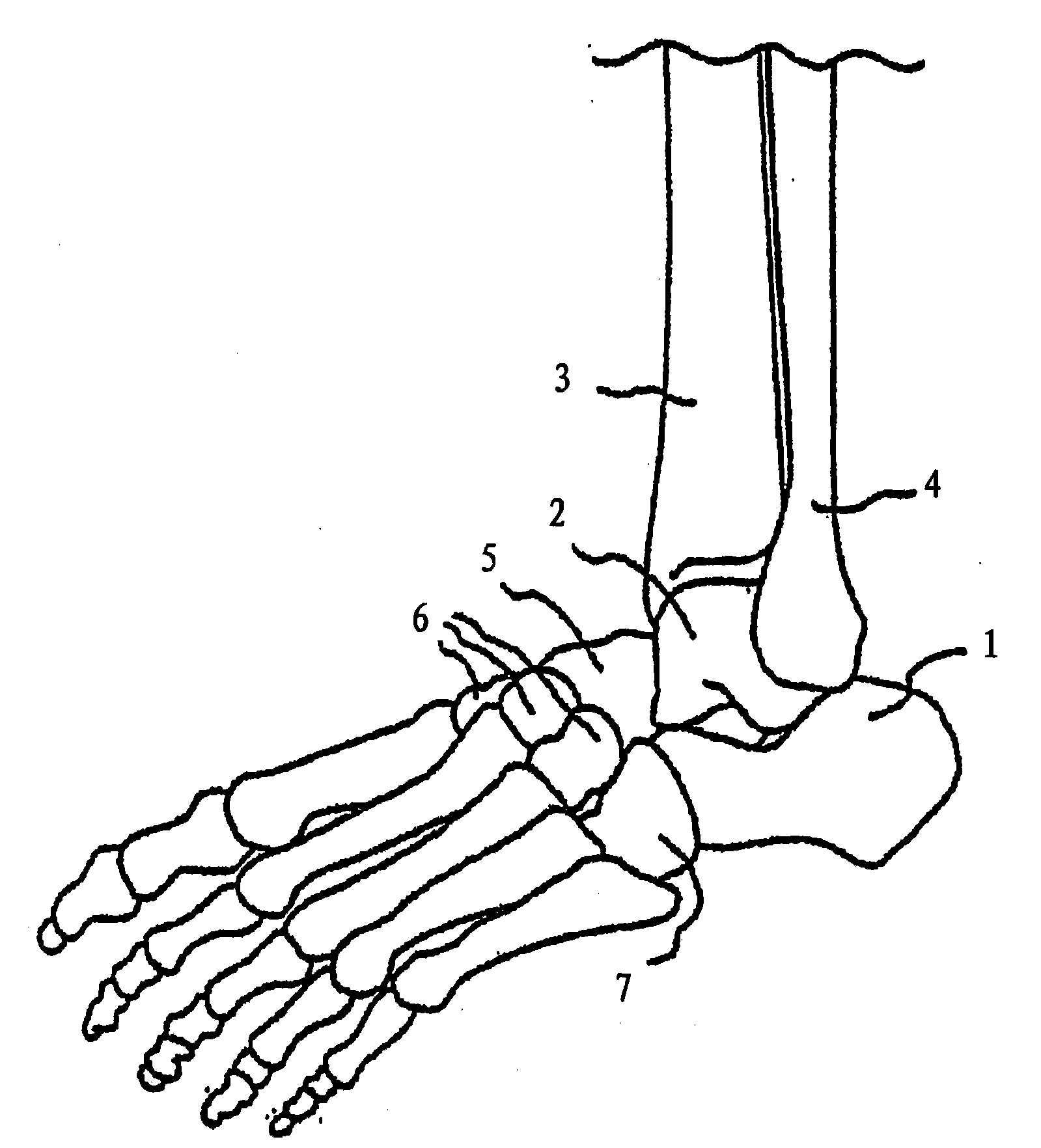

Bone nail for the heel

InactiveCN101917915ALess invasiveHigh precision adjustmentInternal osteosythesisBone drill guidesLess invasiveBone staple

The bone nail is intended for the heel. It comprises a front part (15) that is intended to be inserted in the bone and is provided with a tip (17) and it also comprises a rear part (16) having an end (18). The rear part (16) is rigid at a length of at least 120 mm, starting from the end (18). The bone nail is curved in a plane and the curvature for each infinitesimal section of the bone nail has a curvature radius that is at least 130 mm. The key advantages that can be achieved with the bone nail according to the invention and thanks to the surgical technique that becomes possible with it are the possibility to adjust the heel with high precision relative to the lower leg and knee axis, the avoidance of the risk of an injury to the plantar nerves, and a less invasive implant compared to known surgical techniques using other nails.

Owner:帕拉贡28公司

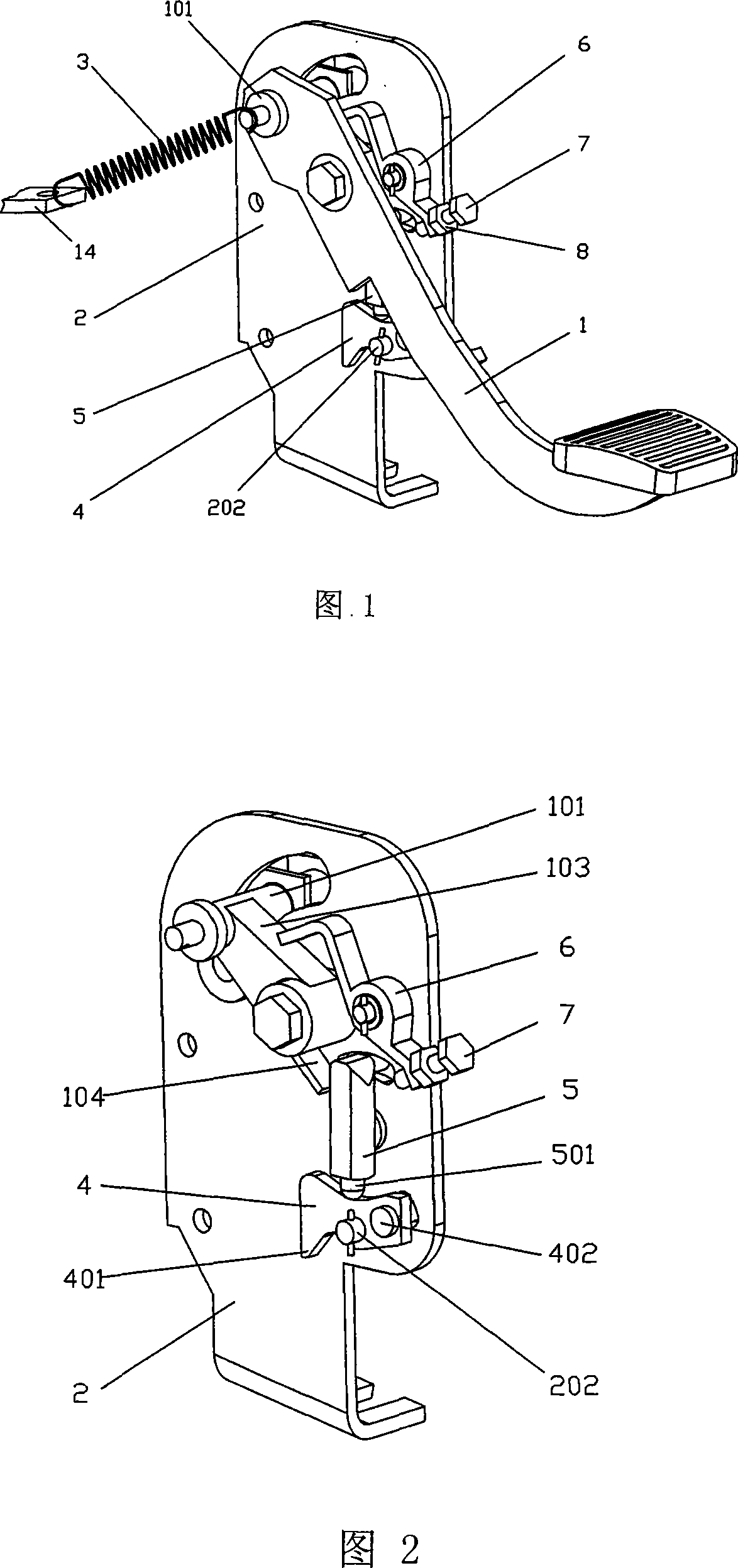

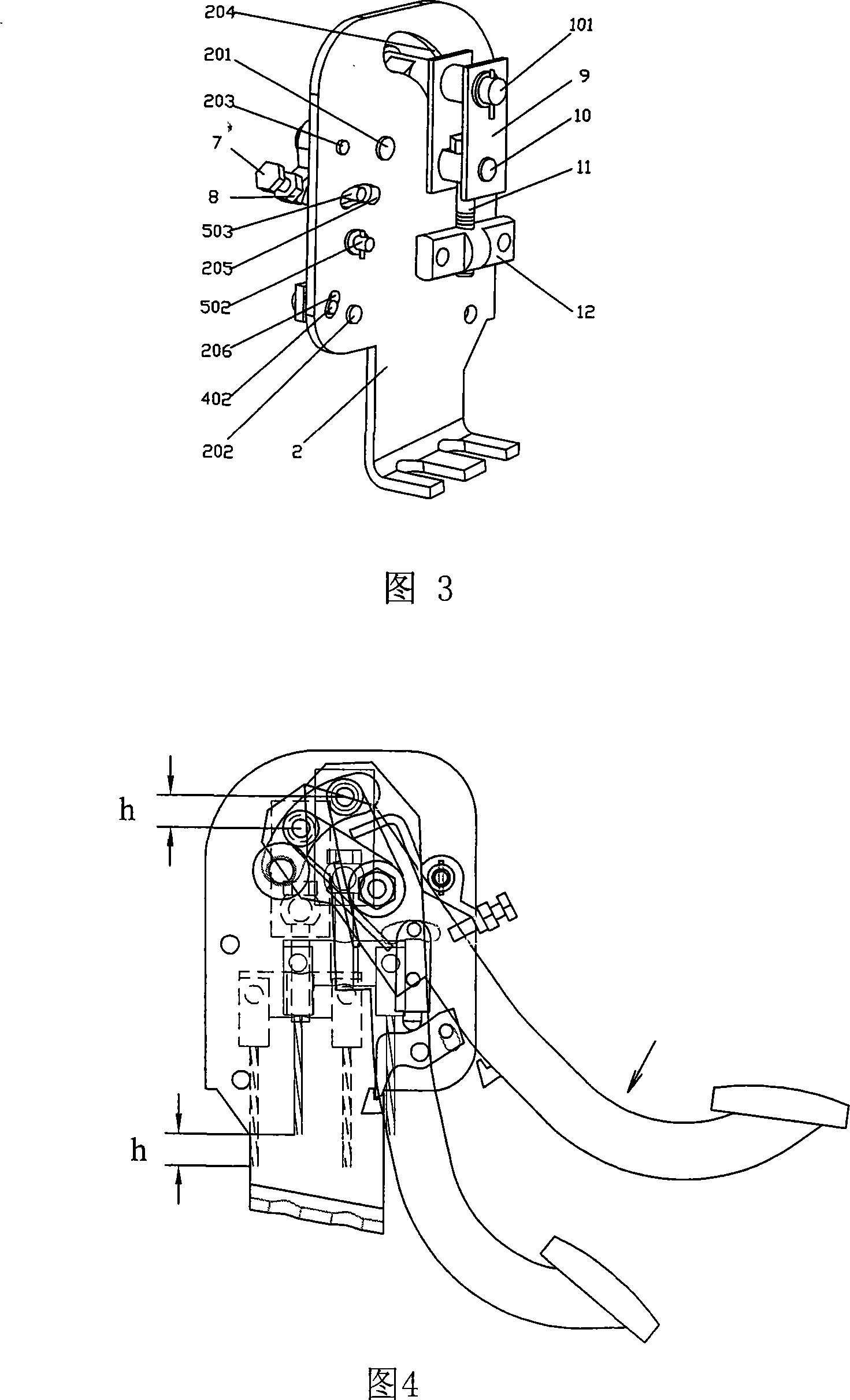

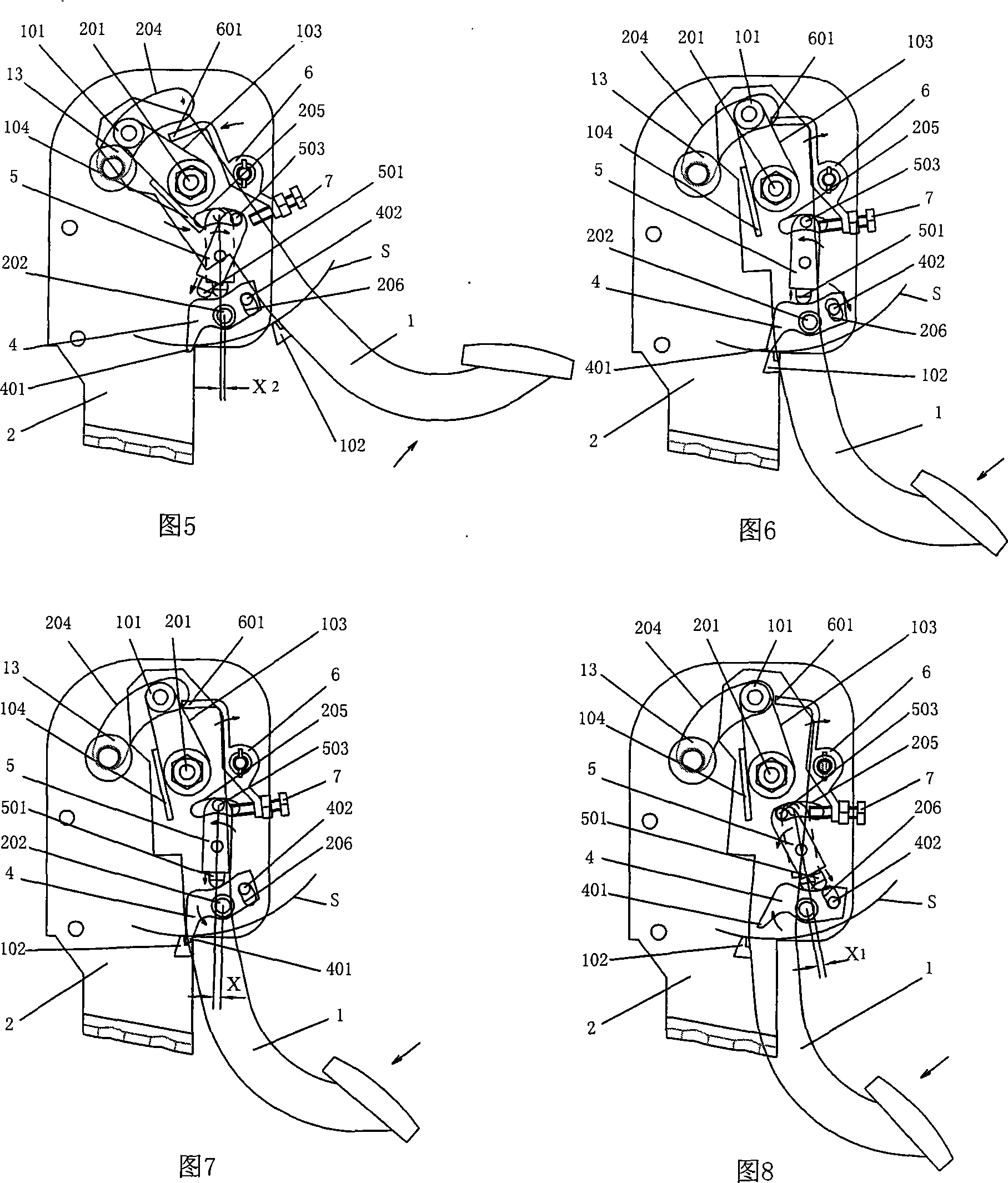

Brake of industrial vehicle

The invention relates to a brake of industry vehicles. The brake mainly comprises a pedal arm, a support, a return spring, a lock pawl, an elastic finger, a control level, a control screw, a lock nut, zip-fastener hanging parts, a hanging scroll, an adjusting bolt, a zip-fastener balancer and an elastic body. One side of the pedal arm facing to the support is fixedly connected with a wiredrawing scroll, the latch hook of the pedal arm, the thrust face of the level, the return piece of the finger. One side of the support facing the pedal arm is fixedly connected with the pivot shaft of the pedal arm, the pivot shaft of the lock bolt pawl, and the pivot of the control level. The side is also equipped with the stop slot of the pedal arm, the stop slot of the finger and the stop slot of the lock bolt pawl. The invention has the advantages of simple structure, easy fabrication, reliable operation, being completely controlled by the pedal, the only locking position and the subsequent stable brake force due to locking at the first operating position and unlocking at the second operating position, moreover having the function of the adjustable unlocking travel and the compensation of the abrasion of the brake block.

Owner:WUXI KIPOR POWER CO LTD

Rotational-speed-controlling variable piston pump

ActiveCN107407263AAvoid injury hazardPump controlPositive-displacement liquid enginesRadial piston pumpHydraulic circuit

Provided is a rotational-speed-controlling variable piston pump with which it is possible to satisfactorily avoid abnormal pressures in the bore chamber of a cylinder block with a simple configuration, without causing loss of pump efficiency or increases in cost. The present invention provides a rotational-speed-controlling variable piston pump in which pistons move back and forth within a bore at a stroke suited to the angle of inclination of a swash plate along with the rotation of a cylinder block, whereby hydraulic oil is drawn into a bore chamber from an intake oil passage formed in a casing, via an intake port of a port plate against which the cylinder block slides, and the hydraulic oil is discharged to a discharge oil passage formed in the casing, via a discharge port of the port plate; wherein an abnormal-pressure-avoiding oil pressure circuit, which releases the hydraulic oil in the bore chamber out of the bore chamber when the pressure in the bore chamber positioned between the intake port and the discharge port of the port plate exceeds a predetermined pressure, is provided as being incorporated in the same unit structure within the same casing.

Owner:YUKEN KOGYO

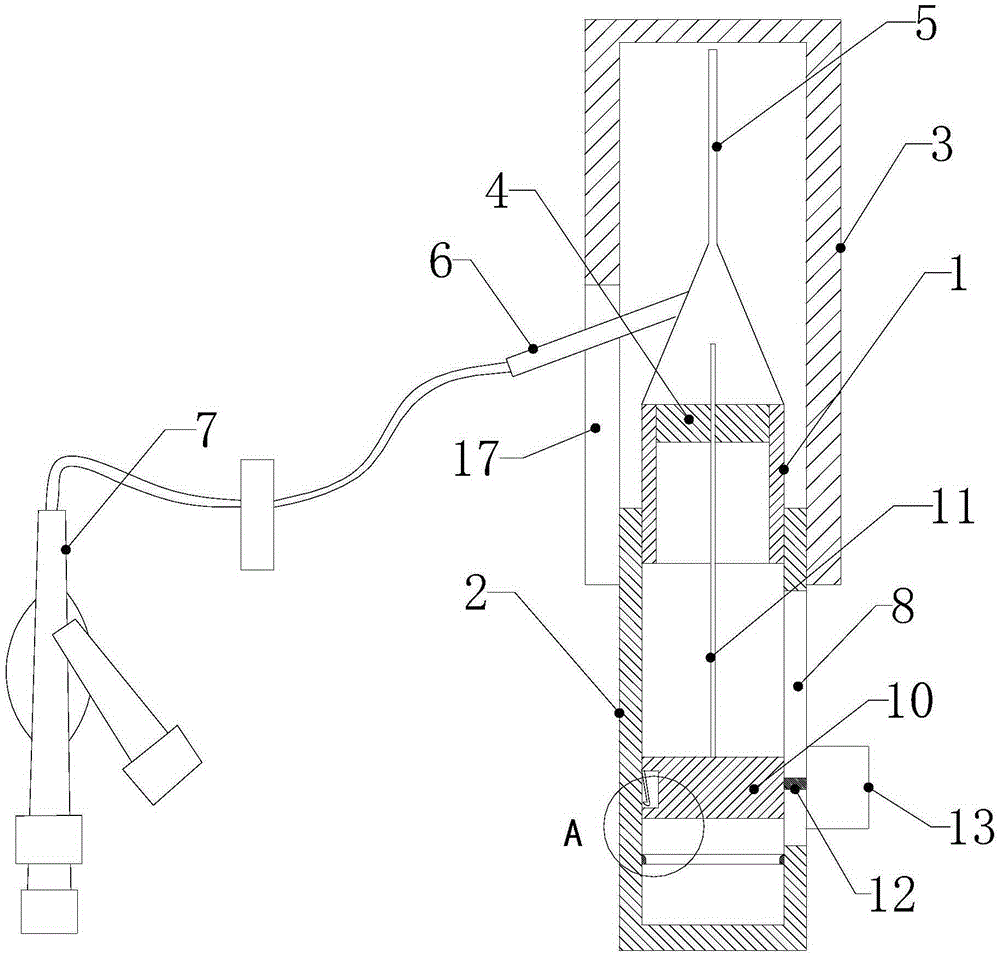

Multifunctional steel wire rope lock pouring platform and pouring method thereof

The invention relates to a multifunctional steel wire rope lock pouring platform and a pouring method thereof, and belongs to the technical field of steel wire rope lock pouring equipment. According to the technical scheme, the multifunctional steel wire rope lock pouring platform is characterized in that a worktable is arranged above a box body (1), wherein a head pulling device (2), a crucible (3), a pouring cooling device (4), a lock guide device (5) and a gas stove (21) are arranged on the worktable; a handwheel (9) is arranged at one end of a locking bolt (10) in the head pulling device (2); the locking bolt (10) is pulled to a head pulling tube (11); a lock hole (7) and a gap (19) which communicates with the lock hole (7) are formed in a lock tray (13) in the pouring cooling device (4); a hand-chain hoist lug (17) and two steel wire rope clamping buckles (18) are arranged on a lock fixing support (16) in the lock guide device (5). The multifunctional steel wire rope lock pouringplatform has the beneficial effects that the worktable integrating the functions of pulling the head of a steel wire rope, guiding the lock and casting cooling is provided, thus the pouring time is decreased, and the production efficiency is improved.

Owner:PORT OF CAOFEIDIAN ORE TERMINAL CO LTD

A cable connection mechanism for a data storage cabinet

ActiveCN113612041BOptimize workflowAvoid injury hazardElectric connection structural associationsCable junctionsCopper wireStructural engineering

The present invention relates to the technical field of cable connection, in particular to a cable connection mechanism for data storage cabinets, including a connection housing, two ends of the connection housing are provided with guide wire through holes, the connection housing Both ends are connected with fixing sleeves, and both ends of the two fixing sleeves are equipped with cable fixing sleeves, and the cable fixing sleeves are fixedly connected with wiring sleeves, and the connecting housing, fixing sleeve , the cable fixing sleeve and the wiring sleeve wrap the thermoplastic pipe on the surface after the cable is connected, the inside of the connecting shell is fixedly connected with a contact element, and the two first limit bolts are arranged in reverse mirror image, The invention enables the copper wire to be firmly fixed on the contact element, replaces the traditional work process of winding the copper wire on the contact element, simplifies the cable connection process, reduces labor input, and avoids the hidden danger of worker injury At the same time, the connection efficiency between the cable and the contact element is improved.

Owner:西安特茂电子科技有限公司

Disengaging and engaging mechanism for control grip of machine tool

InactiveCN107605982AAvoid mixingAvoid falling overInterengaging clutchesMetal working apparatusAxial displacementEngineering

A disengaging and engaging mechanism for a control grip of a machine tool comprises a pivoting seat, a shaft core pipe, a movable block, an operation wheel and a control piece. The pivoting seat is combined with the machine tool; the shaft core pipe penetrates through the pivoting seat, an inserting rod is arranged in the shaft core pipe in a penetrating mode, and one end of the inserting rod is exposed out of the shaft core pipe; the shaft core pipe is sleeved with the movable block, and the position, on the periphery of the shaft core pipe, of the movable block is connected with the inserting rod; a positioning block is arranged on one side of the operation wheel, and the operation wheel coaxial with the positioning block is arranged on the shaft core pipe in a pivoted mode; the controlpiece and the end of the inserting rod are combined; the control piece can be pulled to drive the movable block through axial displacement of the inserting rod to move between the first position and the second position, when in the first position, the movable block is disengaged from the positioning block, and when in the second position, the movable block is clamped with the positioning block sothat rotation of the operation wheel can drive the shaft core pipe to rotate, and accordingly the disengaging and engaging mechanism for the control grip of the machine tool is formed.

Owner:郭继安

Shock-absorbing comfortable sole

A shock-absorbing comfortable sole comprises an outsole in contact with the ground and a midsole fixed on the upper surface of the outsole. The midsole comprises an upper layer and a lower layer. One or a plurality of through holes penetrating through the midsole in the thickness direction are respectively reserved on a heel, a rear sole and / or a front sole of the upper midsole. Projections corresponding to the through holes on the upper midsole are arranged on the upper surface of the lower midsole. The projections on the lower midsole are connected with the through holes on the upper midsole respectively in an embedded manner. Bottom grains protruding the lower surface of the outsole and corresponding to the projections on the lower midsole in position are arranged on the lower surface of the outsole. The upper midsole is hard, the lower midsole is soft, and when the surface of the upper midsole is stepped by a foot in walking, the upper surfaces of the soft projections are recessed highly and the upper surface of the hard upper midsole is recessed lowly, so that the upper surface of the upper midsole is flat or slightly uneven alternately, a foot sole of a wearer can be massaged, walking fatigue can be relieved, and the effect is evident.

Owner:MAOTAI FUJIAN SOLES CO LTD

Automatic polishing device for inner surface of traffic signal lamp reflector

InactiveCN112247733ASave sanding timeImprove production efficiencyOptical surface grinding machinesGrinding drivesTraffic signalEngineering

The invention relates to the related field of indicating lamps, and discloses an automatic polishing device for the inner surface of a traffic signal lamp reflector. The automatic polishing device comprises a main box body, a rotating block cavity with a downward opening is formed in the main box body, the upper side of the rotating block cavity is provided with a telescopic rod cavity in a communicating mode, and the right side of the telescopic rod cavity is provided with an auxiliary magnetic block cavity in a communicating mode. A lead screw belt cavity extending leftwards is formed in theupper side of the telescopic rod cavity. According to the automatic polishing device, a friction wheel is driven by a rotating block to move up and down, so that the friction wheel can perform automatic continuous operation, the polishing time of the traffic signal lamp reflector is greatly shortened, and the manufacturing efficiency of a traffic signal lamp is improved; and then through rotationof the rotating block, the friction wheel polishes the inner wall of the reflector, meanwhile, a friction wheel fixing rod is opened, so that the reflector is polished more thoroughly, force is exerted evenly, and the problem that polishing is too heavy or too light is avoided. On the other hand, the automatic polishing device is operated automatically, the labor cost is reduced, and meanwhile the hidden danger that workers are injured is also avoided.

Owner:福州中天泰电子科技有限公司

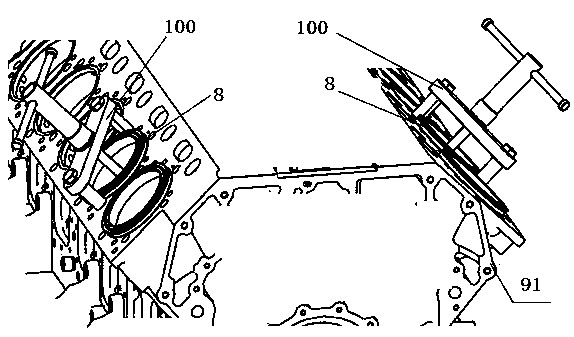

Bone nail for the heel and osteosynthesis suite

InactiveCN101917915BHigh precision adjustmentAvoid injury hazardInternal osteosythesisBone drill guidesBone stapleBiomedical engineering

Set as a bone peg for the heel. It comprises a front part (15) intended for introduction into a bone and having an apex (17) and a rear part (16) having a tip (19). The rear portion (16) is rigid over a length of at least 120mm measured from the end (18). The bone screw bends in a plane, the bend having a radius of curvature of at least 130 mm for each infinitesimal segment of the bone screw. The following advantages are achieved by the bone screw according to the invention and thanks to the surgical technique which can be achieved thereby: the rear foot can be adjusted with high precision relative to the axis of the calf and the axis of the knee, avoiding the risk of damage to the plantar nerve; and Less invasive implantation compared to surgical techniques using other staples.

Owner:帕拉贡28公司

Wooden pallet automatic nailing machine

InactiveCN104908115BAvoid injury hazardReduce labor intensityStapling toolsNailing toolsEngineeringMachining process

The invention discloses an automatic wood pallet nailing machine. The automatic wood pallet nailing machine comprises a rack, a moving trolley, a clamp and a plurality of fastener devices. Guide rails are arranged on the two sides of the rack. Sliding wheels are arranged at the bottom of the moving trolley and are in sliding connection to the guide rails on the two sides of the rack. The clamp is installed on the rack and used for positioning a wood pallet material to be machined. The fastener devices are installed on the moving trolley in the transverse direction and used for nailing the wood pallet material to be machined. According to the automatic wood pallet nailing machine, manual machining is replaced by mechanical automation machining, the production efficiency is greatly improved, the machining quality is good, the using stability of products is good, the service life is long, meanwhile, the hidden danger of worker injuries prone to being caused in the machining process is avoided, the labor intensity of workers is relieved, and the production cost is reduced.

Owner:上海佰亲自动化设备有限公司

Horizontal umbrella stand of bicycle

InactiveCN101941486AConvenient horizontal placementAvoid injury hazardArticle supporting devicesOther supporting devicesArchitectural engineering

The invention relates to a bicycle fitting, in particular to a horizontal umbrella stand of a bicycle. The horizontal umbrella stand comprises an umbrella stand, a sleeve, a rotor axis, a base handle, an upper clamping sleeve, a lower clamping sleeve, fastening bolts, screw caps and an axis sleeve, wherein center of the upper surface of the upper clamping sleeve and the upper clamping sleeve are integrally welded into the base handle; the base handle is columnar and vertically crossed with the upper clamping sleeve; center at the top of the base handle is provided with a groove; the groove is fixed with the rotor axis; the lower end of the umbrella stand is provided with a circular axis sleeve formed as an entirety with the umbrella stand; the axis sleeve is positioned in the groove at the top of the base handle and sleeved on the rotor axis; and the sleeve is synchronously sleeved on the umbrella stand and the base handle and synchronously formed as moveable fitting relations with the umbrella stick and the base handle. The present invention can very conveniently place idle umbrella stands horizontally. Compared with the prior art, the horizontal umbrella stand avoids dangers of the traditional umbrella stand from hurting human body when not used and has higher safety.

Owner:CHENGDU CHUNJIANG SCI & TECH

Machine comprising a lifting device for receiving bulk material of a track bed

A lifting device (7) with a rotatable, endless conveyor-chain (8) for receiving bulk material (9) of a track bed (10) is associated with a machine (1) comprising a machine frame (2) that can be moved on a track (6) during a working advancement (5). A discharging device (12) for discharging the received bulk material (9) and a mounting (13) for connecting the lifting device (7) to the machine frame (2) in an articulated manner are provided in the region of an upper conveyor-chain deflection (11). The mounting (13) is movably supported on the machine frame (2) relative to same in a longitudinal direction of the machine, said mounting moving in a displacing motion (20) that is limited by a front working position (18) with respect to a working direction (4) and by a rear end position (19). The mounting is also connected to a buffering element (21) that is fixed on the machine frame (2), said buffering element enabling a displacement of the mounting (13) together with the lifting device (7) to the end position (19) after a target resistance (22) acting against the displacing motion (20) is exceeded. A switch (25) that detects the displacing motion (20) and the exceeding of the target resistance (22) is designed to interrupt the working advancement (5) of the machine (1).

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

Cable connection mechanism for data storage cabinet

ActiveCN113612041AOptimize workflowAvoid injury hazardElectric connection structural associationsCable junctionsCopper wireStructural engineering

The invention relates to the technical field of cable connection and particularly relates to a cable connection mechanism for a data storage cabinet. The mechanism comprises a connection shell, wherein guide wire through holes are formed in two ends of the connection shell, fixing sleeves are connected to two ends of the connection shell, cable fixing sleeves are mounted at two ends of the two fixing sleeves, the cable fixing sleeves are fixedly connected with wiring sleeve shells, the connecting shell, the fixing sleeves, the cable fixing sleeves and the wiring sleeve shells wrap the thermoplastic pipeline on the surface after cables are connected, a contact element is fixedly connected into the connecting shell, and two first limiting bolts are arranged in a reverse mirror image mode. According to the mechanism, a copper wire can be firmly fixed on the contact element, the traditional working process of winding the copper wire on the contact element is replaced, the cable connection process is simplified, labor input is reduced, hidden danger of injury of workers is avoided, and connection efficiency of the cable and the contact element is improved.

Owner:南通屹洲网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com