Engine cylinder sleeve dismounting device

A technology for engine cylinders and dismantling devices, which is applied in hand-held tools and manufacturing tools, etc. It can solve problems such as increased friction of cylinder liners, scratches on cylinder head mounting surfaces, and large screws, so as to improve centering deviation and avoid screw threads Effects of damage and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

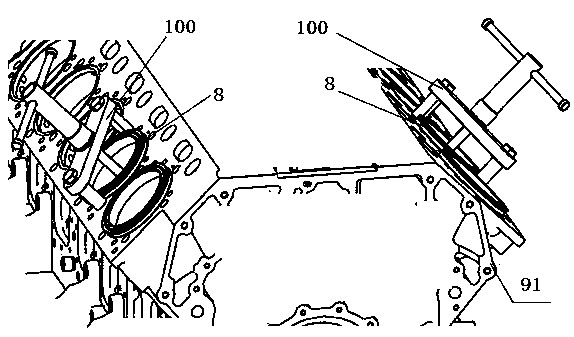

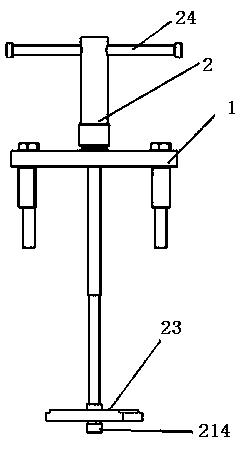

[0031] Figure 1 to Figure 11 Shown is the structure of an engine cylinder liner removal device according to an embodiment of the present invention. see Figure 1 to Figure 11 , according to an embodiment of the present invention, an engine cylinder liner removal device 100 includes a bracket assembly 1 and a pulling assembly 2 .

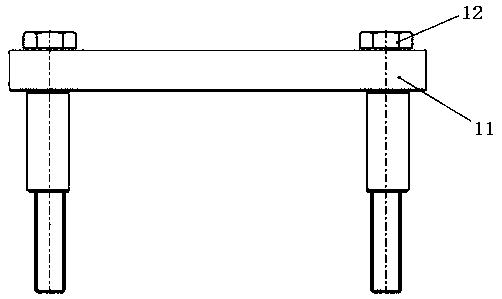

[0032] The bracket assembly 1 plays the role of bearing and positioning, which includes a bracket 11 and a pair of mounting bolts 12 , the bracket 11 can be connected with a pair of cylinder head bolt holes 912 on the body 91 of the engine through a pair of mounting bolts 12 . The bracket 11 includes a top plate 111 and a pair of uprights 112 , the upper ends of the pair of uprights 112 are welded to the bottom of the top plate 111 . Each column 112 has a bolt installation through hole 113 extending along the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com