Motor bearing assembly radial clearance measuring method and device

A technology for radial clearance and motor bearings, applied in measuring devices, mechanical bearing testing, optical devices, etc., can solve the problems of low manual measurement accuracy, low efficiency, easy damage to bearings, etc., to avoid hidden dangers of shaft damage, Open space and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

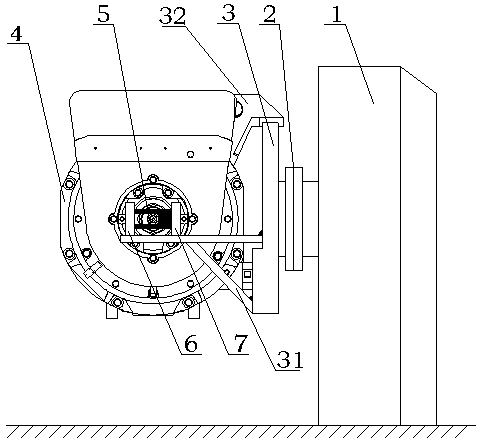

[0035] Such as figure 1 As shown, the motor bearing assembly radial clearance measurement device includes a motor displacement device and a laser measurement device, wherein the motor displacement device includes a main base 1, a flange 2, a displacement plate 3, a bracket 31 and a fastening frame 32. The main base 1 is provided with a servo motor, the servo motor is connected to the flange 2, and the displacement plate 3 is connected to the flange 2, and then the support 31 and the fastening frame 32 are fixedly connected to the displacement plate 3 superior. The fastening frame 32 is also fixedly connected with the motor casing 4 , in order to prevent loosening between the fastening frame 32 and the motor casing 4 during the rotation of the motor, the fastening frame 32 will be fixedly connected with multiple parts of the motor casing 4 .

[0036] The laser measuring device includes a laser emitter 7 and a laser receiver 6, a bracket 31 is fixedly installed on the displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com