Full-automatic digital control roll grinder backup roll belt box grinding device

A roll grinder and back-up roll technology, used in grinding machines, grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, etc. Bearing box and other problems, to achieve the effect of convenient use and ensure grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

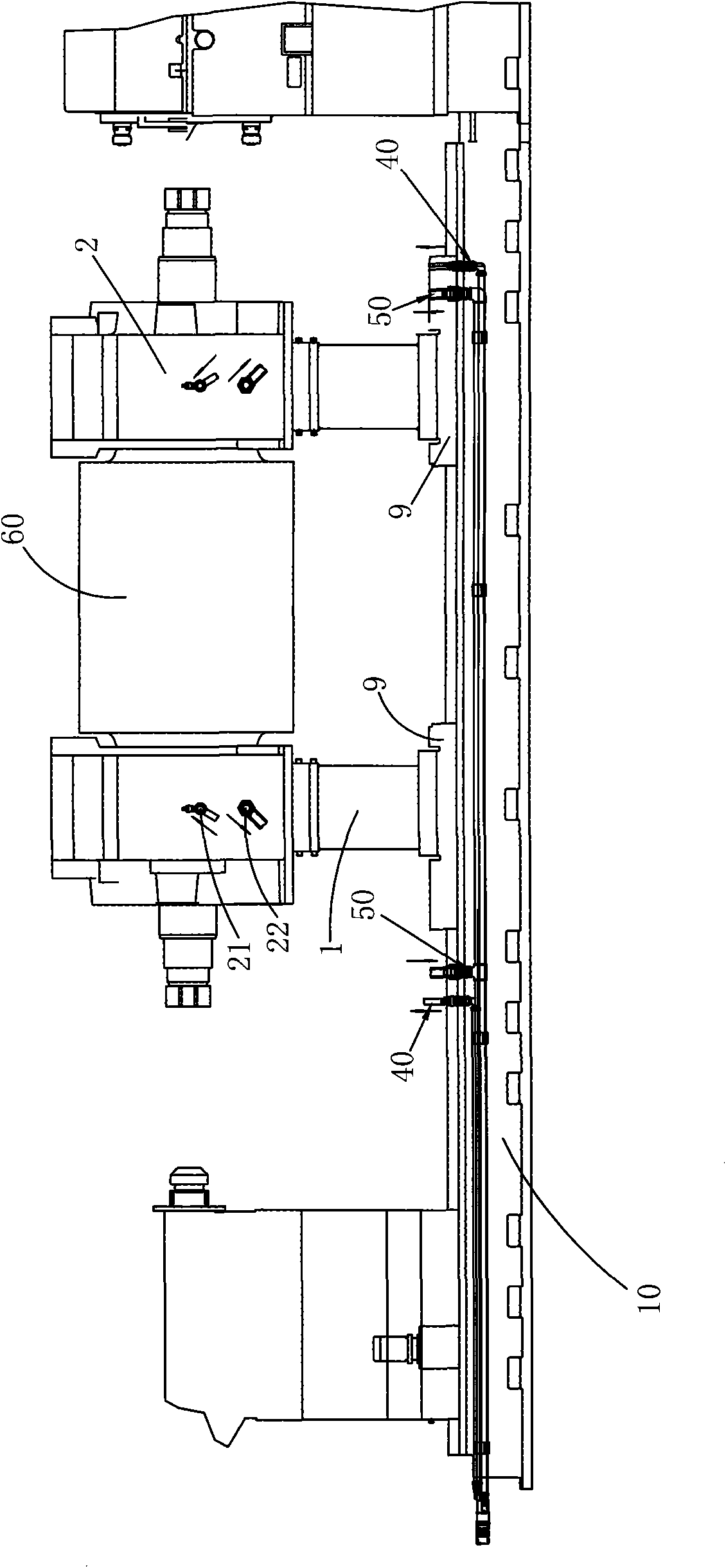

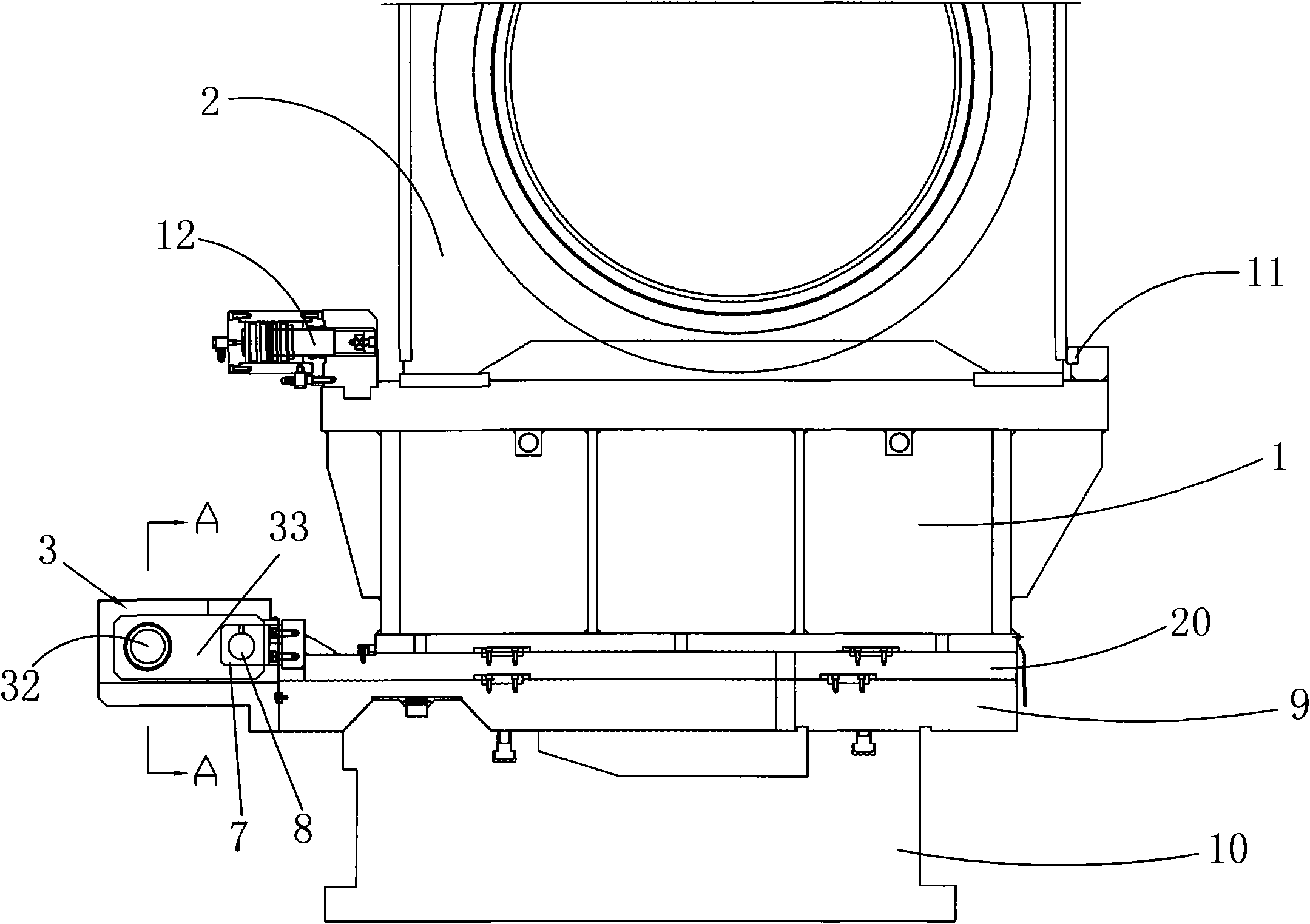

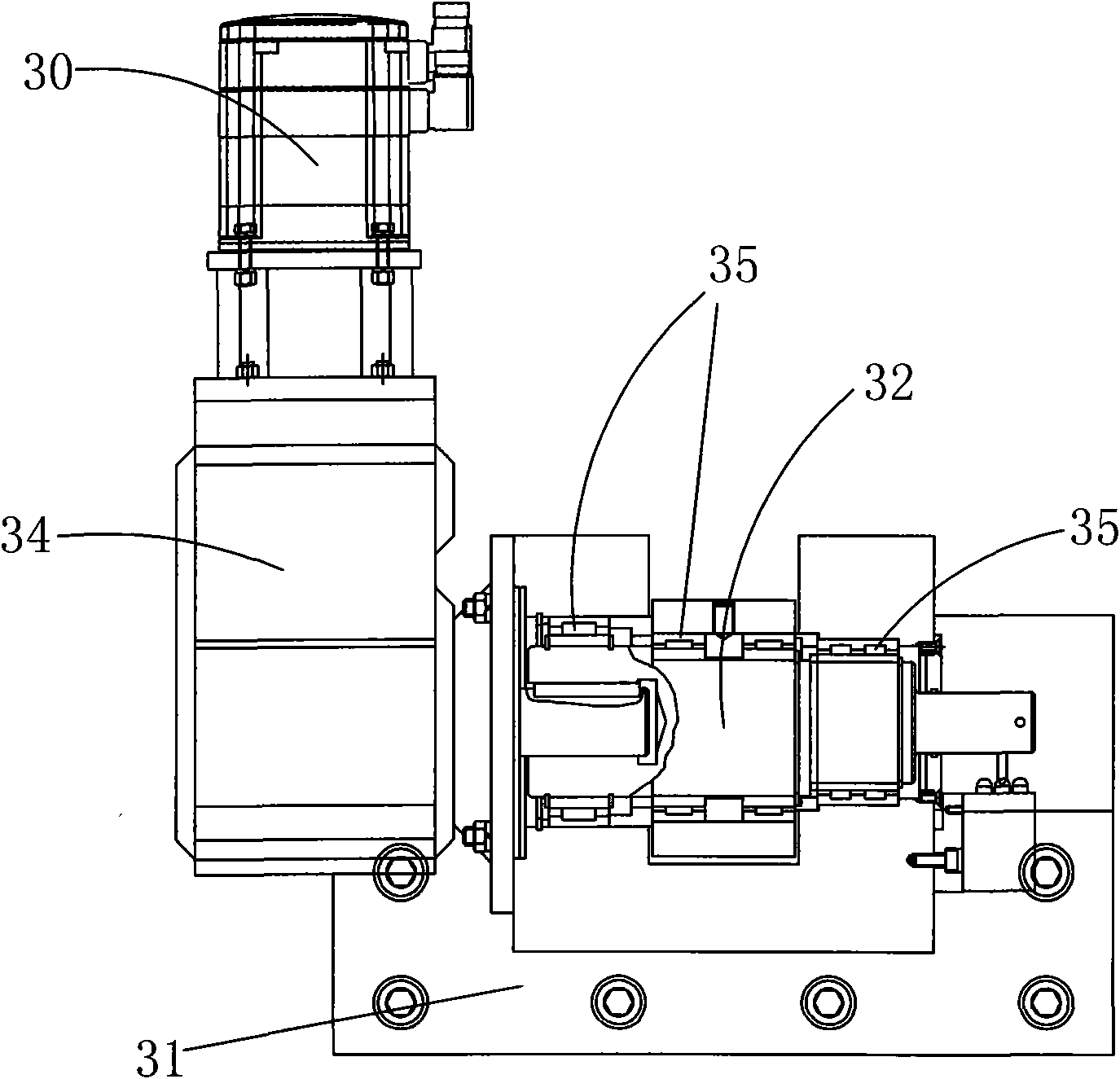

[0018] Embodiment: a fully automatic numerically controlled roll grinder support roll belt box grinding device, the workpiece bed 10 is provided with a headstock, a tailstock, a center frame bottom plate 9 and a supporting device, and the bearing box 2 is provided with an oil inlet 21 and The oil return port 22, the oil inlet 21 communicates with the oil outlet pipeline of the fuel tank 4, and the oil return port 22 communicates with the oil inlet pipeline of the fuel tank, including an installation accuracy adjustment device, an oil supply device and an oil temperature control device ,in:

[0019] The support device includes two box bases 1, the bearing box 2 is placed on the box base 1, the box base 1 is provided with a limit block 11 and a bearing box pushing oil cylinder 12, and the limit block 11 is fixed on the bearing box 2- On the box seat 1 on the side, the bearing box pushes the oil cylinder 12 to be fixed on the box seat 1 on the other side of the bearing box 2. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com